Abstract

This study investigated the synergistic mechanisms of flame retardancy and smoke suppression exhibited by a novel ternary additive in warm-mix asphalt (WMA). The ternary additive consisted of aluminum hydroxide (ATH), organic montmorillonite (OMMT), and expandable graphite (EG). A comprehensive experimental program was conducted, encompassing limiting oxygen index (LOI) testing, cone calorimeter testing, thermogravimetric analysis (TGA), and scanning electron microscopy coupled with energy-dispersive X-ray spectroscopy (SEM–EDS). The results showed that incorporation of 6 wt% of the ternary additive (by mass of the asphalt binder) markedly improved the fire resistance of the WMA. The LOI increased from 19.8% (neat asphalt) to 25.2%. Cone calorimeter tests revealed a 23.9% increase in time to ignition, a 24.2% reduction in peak heat release rate, and a 47.5% decrease in total smoke production. These improvements are attributed to a synergistic mechanism involving the endothermic decomposition of ATH, the char-promoting effect of OMMT, and the intumescent expansion of expandable graphite (EG) forming a compact insulating barrier, which collectively inhibit combustion and smoke release. The ternary additive exhibits considerable promise as an effective flame-retardant modifier for enhancing the fire safety of warm-mix asphalt pavements, especially in high-risk scenarios such as tunnels.

1. Introduction

In recent decades, global warming has emerged as one of the most pressing environmental challenges. The transportation sector is a major contributor, releasing substantial quantities of greenhouse gases (GHGs), predominantly carbon dioxide (CO2), through fossil fuel combustion. Urban areas represent critical emission hotspots, with transportation accounting for approximately 71% of urban energy consumption [1]. This situation highlights the urgent need for sustainable infrastructure solutions to mitigate adverse environmental impacts. In response, numerous governments have developed and enacted comprehensive climate action plans. For example, China has pledged to reach peak CO2 emissions before 2030 and achieve carbon neutrality by 2060, while the European Union’s “Green Deal” targets a minimum 55% reduction in GHG emissions by 2030 (relative to 1990 levels) and carbon neutrality by 2050. Globally, transportation accounts for approximately 24% of energy-related GHG emissions, with China’s transportation sector contributing nearly 25% of the nation’s total carbon emissions [2,3]. Consequently, mitigating emissions from this sector is imperative, particularly given China’s substantial contribution to global emissions.

Within this context, national economic and technological progress is closely tied to infrastructure development, with road networks serving as a fundamental component. Asphalt pavements are widely used because of their ease of maintenance, smooth surface, and good ride quality. However, conventional hot-mix asphalt (HMA) production requires high mixing and compaction temperatures and generates substantial aerosol emissions [4]. These emissions consist of complex mixtures of fine particulate matter, benzene-soluble compounds, and volatile organic compounds (VOCs), which are associated with high energy consumption, air pollution, and occupational health risks. In addition, asphalt pavements in confined spaces such as tunnels are prone to thermal decomposition and combustion during traffic-related fires.

To mitigate these hazards and promote sustainable pavement construction, flame retardants and smoke suppressants have been incorporated into asphalt binders [5,6,7]. Although various additives—including polymers, warm-mix agents, adsorbents, and nanomaterials—have shown promise, inorganic flame retardants, particularly aluminum hydroxide (ATH), remain the most widely used [8]. However, ATH-based systems suffer from several drawbacks, such as limited flame-retardant efficiency and adverse effects on asphalt binder stability, which in turn necessitate relatively high dosages to achieve the desired performance [9]. To overcome these limitations, recent studies have focused on improving the performance and compatibility of inorganic flame retardants through composite modification. For example, organic montmorillonite (OMMT) can intercalate asphalt macromolecules, thereby imparting flame-retardant and smoke-suppressant properties [10]. Nevertheless, Yang et al. [11] reported that compounding ATH with OMMT significantly improved high-temperature performance but simultaneously reduced resistance to low-temperature thermal cracking.

Beyond conventional inorganic systems, expandable graphite (EG)—an adsorbent with a complex layered porous structure [12]—has been widely used to enhance the flame retardancy of polymeric materials [13]. Sheng et al. [9] developed halogen-free flame retardants based on EG, magnesium hydroxide (MH), calcium hydroxide (CH), and ammonium polyphosphate (APP). While this formulation reduced the flammability of asphalt binders for tunnel applications, it provided insufficient resistance to low-temperature cracking. Wang et al. [14] combined EG with three additional additives to develop halogen-free flame retardants that effectively suppressed VOC emissions; however, the synthesis route was relatively complex. In parallel, warm-mix asphalt technology has been adopted to reduce production temperatures, thereby limiting asphalt aging, emissions, energy consumption, and associated costs. In particular, the incorporation of Sasobit into styrene–butadiene–styrene (SBS)-modified asphalt improves high-temperature stability and helps maintain overall pavement performance [15,16,17,18,19].

Against this background, ATH, OMMT, and EG were used as raw materials to prepare an inorganic–organic ternary flame-retardant and smoke-suppressant additive, and Sasobit was incorporated into the asphalt using warm-mix technology. To comprehensively and systematically investigate the development and application of this inorganic–organic ternary flame-retardant and smoke-suppressant additive, and to validate its practicality in engineering applications, the asphalt performance, flame-retardant efficiency, and smoke-suppression behavior of the modified binders were systematically evaluated. A variety of macro- and microscale characterization methods, thermodynamic analyses, and controlled experiments were employed to investigate the warm-mix ternary flame-retardant and smoke-suppressant system for asphalt binders.

2. Materials and Methods

2.1. Raw Materials

Styrene–butadiene–styrene (SBS)-modified asphalt was employed as the base binder in this study. The binder exhibited a penetration of 55 (0.1 mm) at 25 °C, a ductility of 31 cm at 5 °C, and a softening point of 68 °C. Sasobit, a white spherical wax-based additive characterized by low water solubility, was employed as the warm-mix agent. The flame-retardant and smoke-suppressant additive, designated as AOE, was formulated based on the authors’ previous research [20] and relevant literature [21]. The AOE additive was prepared by blending ATH, OMMT, and EG at a mass ratio of 6:2:3.

2.2. Sample Preparation of Asphalt Binder

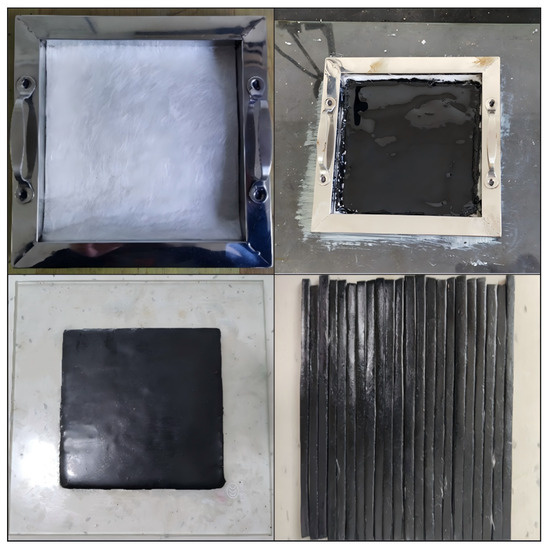

The warm-mix flame-retardant and smoke-suppressant asphalt binder was prepared using a high-shear mixing method. First, SBS-modified asphalt was heated to 165 °C, after which 2 wt% Sasobit (by mass of asphalt binder) was added. The mixture was then subjected to high-shear mixing at 1000 r·min−1 for 15 min. The mixture was subsequently reheated to 150 °C and maintained at this temperature. AOE was added at dosages of 0%, 4%, 6%, and 8% by mass of the asphalt binder. Subsequently, the mixture was stirred at a constant speed for 10 min, sheared at 4500 r·min−1 for 45 min, and finally sheared at 1000 r·min−1 for 10 min. Consequently, four warm-mix flame-retardant and smoke-suppressant asphalt binders, designated AOE-0, AOE-4, AOE-6, and AOE-8, were obtained. The modified materials and the preparation process for the test specimens are illustrated in Figure 1.

Figure 1.

The preparation process of asphalt binder.

2.3. Test Methods

2.3.1. LOI Test

The limiting oxygen index (LOI) of the asphalt binder was determined in accordance with the JTG 3410-2025 standard [22]. A glass fiber surface felt measuring 150 mm × 150 mm was prepared and placed in a metal mold frame with an internal cavity measuring 151 mm × 151 mm × 3 mm. The warm-mix flame-retardant and smoke-suppressant asphalt binder, preheated to the target temperature, was then poured onto the glass fiber felt until it was fully saturated. After cooling to ambient temperature, the specimens were demolded and cut into strips 65 mm in length, as shown in Figure 2.

Figure 2.

LOI test samples.

2.3.2. Burning Test

The combustion test was conducted using a fuel-ignition method. For each test, 50 g of asphalt binder was placed in a thermally insulated container, after which 15 mL of 92-octane gasoline was added and the mixture was ignited. The entire combustion process was recorded using a digital camera . During the test, the temperature at the center of the specimen surface was continuously recorded throughout combustion and after complete burnout, and the final mass of the specimen was measured.

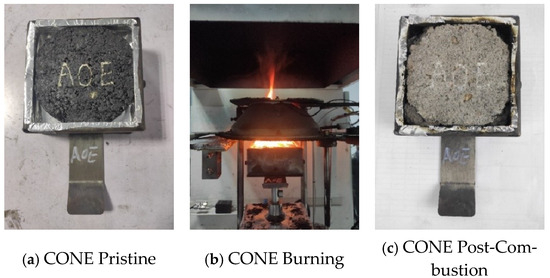

2.3.3. CONE Test

Two representative asphalt binders, AOE-0 and AOE-6, were selected for cone calorimetry testing. Thin Marshall specimens were fabricated by the Marshall compaction method and used as cone calorimeter (CONE) specimens, with the specimen height controlled to 10 ± 1 mm to ensure consistency and comparability of the test data. A VOUCH 6810 cone calorimeter was employed, and the combustion performance of the two asphalt mixture specimens was quantitatively characterized in accordance with ISO 5660-1:2015 [23]. A heat flux of 50 kW/m2 was selected to simulate the thermal environment of medium-scale fires and to approximate the heat-radiation characteristics of actual asphalt pavement fire scenarios. .

2.3.4. Scanning Electron Microscopy Test and Energy-Dispersive X-Ray Spectrometry

After combustion, the asphalt specimens were removed, and a scanning electron microscope (SEM) (TESCAN, Brno, Czech Republic) was used to observe the surface morphology of the carbonaceous residue at 2000× magnification. After carefully selecting appropriate micro-areas, elemental analysis was performed by point analysis using energy-dispersive X-ray spectroscopy (EDS) (TESCAN, Brno, Czech Republic).

2.3.5. TG Test

Thermogravimetric analysis (TGA) was conducted on the asphalt binders and the individual flame-retardant components (ATH, EG, and OMMT) using a thermogravimetric analyzer (METTLER TOLEDO, Switzerland). The experiments were carried out from 20 to 800 °C at a heating rate of 10 K·min−1 under a nitrogen atmosphere with a flow rate of 35 mL·min−1.

3. Results and Discussion

3.1. Analysis of LOI Test Result

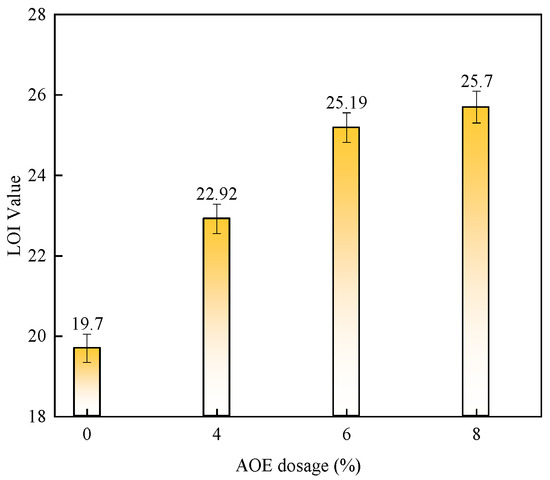

Figure 3 presents the test procedure and the measured limiting oxygen index (LOI) values. The data in Figure 3 indicate that the LOI increases with increasing AOE dosage, confirming that AOE effectively enhances the flame-retardant performance of the warm-mix asphalt binder. Specifically, the LOI values of AOE-0 and AOE-4 are 19.7% and 22.92%, respectively, neither of which satisfies the technical requirement of an LOI greater than 23% for flame-retardant asphalt. When the AOE dosage is 6%, the LOI of AOE-6 increases to 25.19%, which meets the relevant technical requirements. However, when the dosage is further increased to 8%, the LOI of AOE-8 is 25.70%, and the increment is significantly smaller than that observed from AOE-4 to AOE-6. Therefore, 6% was identified as the optimal AOE dosage.

Figure 3.

LOI Value.

Table 1 summarizes previously reported limiting oxygen index (LOI) test results for flame-retardant asphalt. As the data show, the AOE ternary composite additive—composed of ATH, OMMT, and EG in a ratio of 6:2:3—enables the asphalt binder to achieve an LOI of 25.1% at a dosage of only 6%. In comparison, other flame-retardant systems listed in Table 1 require higher loadings to attain similar or lower LOI values. For example, a system with an ATH:EG ratio of 1:1 achieves an LOI of only 24.2% at a dosage of 10%, whereas a ZB:APP:ATH = 6:3:1 system attains an LOI of 24.1% at a dosage of 8%. These results demonstrate that the synergistic interaction among the components in the AOE system provides superior flame-retardant efficiency at a relatively low additive content. This low-dosage, high-performance characteristic not only reduces material consumption but also mitigates potential adverse effects on asphalt properties associated with high loadings of flame-retardant additives.

Table 1.

Comparison of Limiting Oxygen Index (LOI) Performance of Different Flame-Retardant Systems in Asphalt.

3.2. Analysis of Buring Test Result

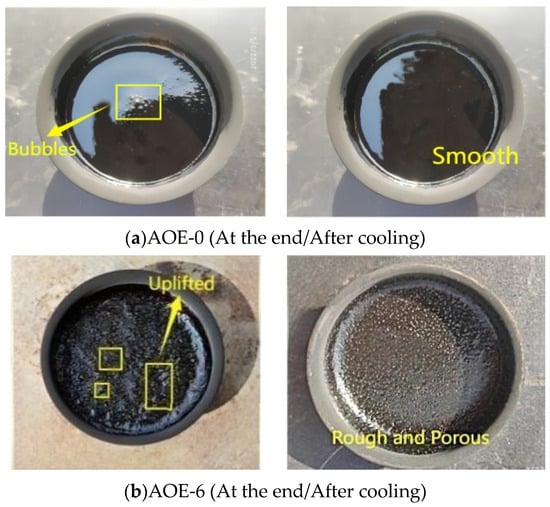

Figure 4 illustrates the surface morphology of the asphalt specimens after combustion and subsequent cooling. In Figure 4a, the surface of the AOE-0 asphalt appears melted and softened as a result of combustion, with bubbles formed in the central region. However, after a period of cooling, the bubbles disappear, the asphalt surface solidifies again, and the specimen gradually returns to a smooth, flat state. In Figure 4b, the surface of the AOE-6 asphalt exhibits uneven uplift, agglomeration, and stacking at the end of combustion, indicating poor fluidity. Upon cooling, the asphalt surface solidifies but appears rough and porous. These observations indicate that the combustion of asphalt triggers the decomposition of AOE. The expansion of EG and the decomposition of ATH lead to the formation of a raised, dough-like layer on the asphalt surface. Subsequently, as the temperature decreases, this surface layer becomes relatively flat and porous. Parallel tests were also conducted on specimens containing 4% and 8% AOE (AOE-4 and AOE-8, respectively). Since their post-combustion surface characteristics were consistent with those of AOE-6, the subsequent comparison focuses solely on AOE-0 and AOE-6 for clarity.

Figure 4.

Surface morphology after combustion and cooling.

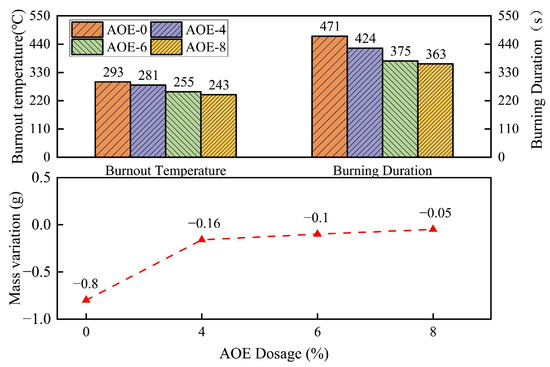

Figure 5 presents the burnout temperature and burning duration of the asphalt specimens after complete fuel burnout. In comparison with AOE-0 (burnout temperature 293 °C and burning duration 471 s), AOE-4 exhibits a 12 °C decrease in burnout temperature (to 281 °C) and a 47 s reduction in burning duration (to 424 s); AOE-6 shows a 38 °C decrease in burnout temperature (to 255 °C) and a 96 s reduction in burning duration (to 375 s); and AOE-8 presents a 50 °C decrease in burnout temperature (to 243 °C) and a 108 s reduction in burning duration (to 363 s). These results indicate that the incorporation of AOE impedes heat transfer during asphalt combustion and reduces the heat-release rate, thereby shortening the duration of combustion and providing a measurable cooling effect.

Figure 5.

Burning Test Result.

3.3. Analysis of CONE Test Result

As shown in Figure 6a–c, the specimens exhibited a grayish-white aggregate morphology after the CONE test, indicating that the asphalt component in the asphalt mixture was completely combusted. In this study, the quantitative CONE test data presented in Table 2 were used to evaluate the fire performance of the specimens. Time to ignition (TTI) is a key parameter used to characterize the flame retardancy and fire resistance of materials. Compared with AOE-0, the TTI of the AOE-6 specimen increased by 23.9%, indicating that AOE enhances the ignition resistance of the material.

Figure 6.

CONE Test Process.

In addition, its peak heat release rate (HRRpeak) decreased by 24.22% and the total heat release (THR) decreased by 32.34%, demonstrating the effective inhibitory effect of AOE on the heat output during combustion. The total smoke release (TSR) decreased by 47.5%, and the peak smoke production rate (SPRpeak) decreased by 47.79%, confirming that the warm-mix flame-retardant and smoke-suppressant agent not only reduces the total smoke production but also mitigates the risk of instantaneous heavy smoke emission. Various gaseous products, including CO and CO2, are generated during combustion.

In general, a higher CO yield coupled with a lower CO2 yield indicates incomplete combustion. However, in this study, the yields of both CO and CO2 for AOE-6 were lower than those for AOE-0. This behavior is attributed to the ability of AOE to inhibit the thermal decomposition and combustion reactions of the asphalt component, thereby reducing the overall amount of combustion products generated.

Table 2.

Comparison of Limiting Oxygen Index (LOI) Performance of Different Flame-Retardant Systems in Asphalt.

Table 2.

Comparison of Limiting Oxygen Index (LOI) Performance of Different Flame-Retardant Systems in Asphalt.

| Asphalt Type | TTI (s) | HRRpeak (Kw/m2) | THR (m2) | TSR (m2) | SPRpea (m2/s) | CO (g/kg) | CO2 (g/kg) |

|---|---|---|---|---|---|---|---|

| AOE-0 | 113 | 188.080 | 89.281 | 13.239 | 0.058496 | 0.139 | 3.479 |

| AOE-6 | 140 | 142.532 | 60.411 | 6.951 | 0.03054 | 0.132 | 3.358 |

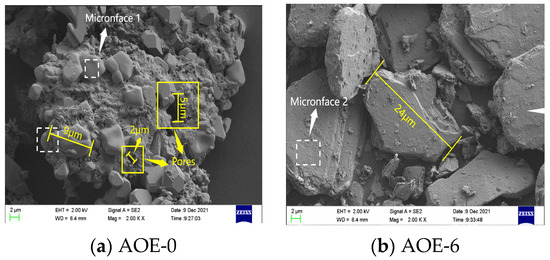

3.4. Analysis of SEM Result

Considering that the SEM images of AOE-4, AOE-6, and AOE-8 are very similar, the present analysis of SEM images primarily focuses on the representative samples AOE-0 and AOE-6. Figure 7 presents the SEM micrographs of the residual carbon derived from AOE-0 and AOE-6 after combustion, acquired at a magnification of 2000×. As observed from the images, the surface of the AOE-0 residual carbon exhibits a loose and porous structure composed of fine particle aggregates, with pore sizes predominantly distributed between 2 and 5 μm and distinct interconnected macropores. This phenomenon can be attributed to the thermal decomposition of asphalt during combustion, during which light flammable components volatilize and escape rapidly, thereby rendering the residual carbon structure loose and forming numerous interconnected pores.

Figure 7.

Char residue morphology diagram.

In contrast, the SEM micrographs of the AOE-6 residual carbon reveal extensive sheet-like stacked structures with pronounced transverse wrapping effects. No obvious macropores are observed at the same magnification; instead, only a small number of discrete small closed pores are present, accompanied by a significant reduction in pore connectivity. It is therefore speculated that this sheet-like structure is a composite barrier layer formed from AOE through thermal decomposition, migration, and aggregation during asphalt combustion. This macroscopic characterization result is consistent with the surface-layer structure formed after asphalt combustion, as illustrated in Figure 7b.

Further comparative analysis reveals that the equivalent size of the sheet-like structures in the AOE-6 residual carbon is approximately 2.7 times that of the particle aggregates on the surface of the AOE-0 residual carbon, and that the sheet-like structures are dense and fully overlapped. In summary, the formation of this composite barrier layer can effectively inhibit the sustained occurrence of asphalt combustion reactions and the release of gaseous products, thereby leading to remarkable flame-retardant and smoke-suppressant efficiency.

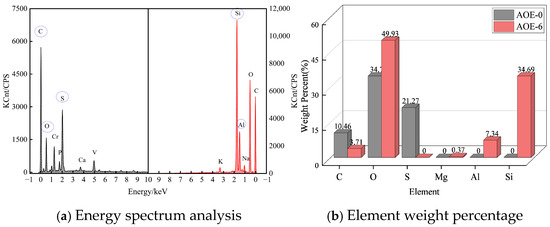

3.5. Analysis of EDS Result

Figure 8a shows the results of the energy-dispersive X-ray spectroscopy (EDS) analysis of two micro-areas (Micro-areas 1 and 2) on the surface of the char residue. As shown in Figure 8a, after the combustion of AOE-0, the surface of the char residue clearly contains C, S, and O, which are among the main elemental constituents of asphalt. This is because, after combustion, part of the asphalt components agglomerates on the surface of the char residue as ash, which can be detected by EDS analysis. In addition, traces of metallic impurity elements such as Cr, Ca, and V can be observed in the spectrum, which likely result from minor interference during sample testing in the laboratory.

Figure 8.

Energy spectrum analysis and element weight percentage.

For AOE-6, a significant amount of Si is observed on the surface after combustion, with a content exceeding those of C and O. Furthermore, higher levels of Al and trace amounts of Na and K are detected. Combining these results with the SEM analysis, it can be inferred that the surface material detected by EDS corresponds to a composite barrier layer formed by the aggregation of the AOE combustion and decomposition products. This composite layer is rich in Si, O, C, and Al, and contains trace amounts of Na and K.

Figure 8b compares the elemental compositions of the AOE-0 and AOE-6 char residues. Upon addition of AOE, the surface O content increases by 15.2 wt%, while the C content decreases by 6.75 wt%. In combination with the SEM observations and the preceding analysis, this behavior can be attributed to the formation of a composite barrier layer on the asphalt surface during combustion. On the one hand, this barrier layer is enriched in oxygen-containing species (e.g., metal oxides and silicates) generated by the decomposition of AOE, thereby increasing the measured O content on the char surface. On the other hand, the barrier layer effectively covers the underlying asphalt, and the increased amounts of inorganic elements at the surface dilute the relative proportion of C, leading to the observed decrease in its measured weight percentage.

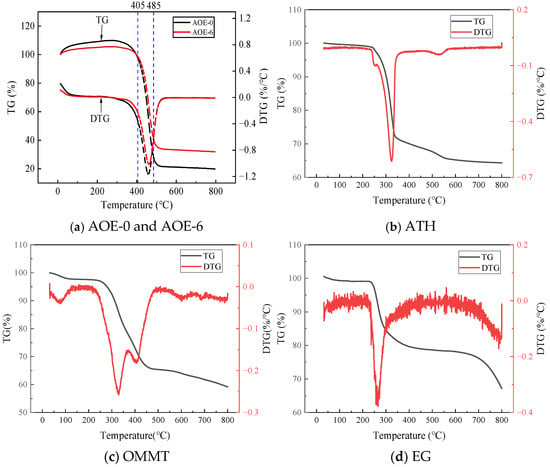

3.6. Thermal Stability Analysis

As demonstrated by the TG-DTG curves in Figure 9, the thermal decomposition process of asphalt can be distinctly divided into three consecutive stages: In the range of 0–405 °C, asphalt undergoes oxidative weight gain attributed to the unstable gas environment in the furnace, wherein the C=C double bonds in its molecular structure undergo oxidative aging to form carbonyl-containing moieties, manifested as an increase in mass fraction. Subsequently, within 405–485 °C (as shown by the dotted line), the side chains of asphalt components undergo scission, generating substantial quantities of gas, while light components volatilize simultaneously, resulting in a precipitous decline in mass [26]. Finally, within the interval of 485–800 °C, the reaction is essentially completed and the mass stabilizes, at which stage the residual mass serves to characterize the char residue content following combustion.

Figure 9.

TG-DTG curve.

The mass loss of AOE-0 (neat asphalt) reaches 80.15%, whereas the AOE-6-modified asphalt exhibits superior thermal stability at 800 °C, demonstrating a mass loss of only 67.15% and a char residue content of 32.85%. Compared with the BMPA-Si composite flame-retardant asphalt reported in a recent study [24]—which requires a dosage of 8% but only achieves a char residue content of 24.67% at 750 °C—the AOE system demonstrates significant performance advantages, underscoring its dual merits of low dosage and enhanced thermal stability at elevated temperatures. The exceptional performance originates from the synergistic flame-retardant mechanism among ATH, OMMT, and EG within the AOE system. This synergistic pathway is directly evidenced by the characteristics of the TG–DTG curves presented in Figure 9a–d.

As shown in Figure 9b, ATH exhibits a stepwise mass loss in the range of 200–350 °C, corresponding to its two-stage endothermic decomposition. In the first stage, the TG curve decreases gradually due to the decomposition of ATH into Al2O3 and liquid water. In the second stage, the mass loss rate slightly increases, which corresponds to the vaporization of water [27]. This decomposition behavior directly slows the descent rate of the asphalt TG curve and delays its initial degradation temperature. The resulting Al2O3 forms a dense barrier layer, effectively suppressing mass loss at high temperatures and thereby achieving a synergistic effect of oxygen insulation and smoke suppression.

Figure 9c reveals that the TG–DTG curves of OMMT display a three-stage characteristic behavior. From room temperature to 200 °C, the TG curve declines slightly, accompanied by a weak DTG peak. In the temperature range of 200–500 °C, the TG curve drops sharply, accompanied by two strong DTG peaks, corresponding to the stepwise decomposition of the two intercalation agents. Previous studies indicate that this process involves a Hofmann elimination reaction, generating acidic sites [25]. Between 500 and 800 °C, the TG curve declines slowly, primarily due to dehydroxylation. The generated acidic sites catalyze the formation of a carbonaceous silicate protective layer from the asphalt, effectively blocking heat and volatile transfer. The free-radical trapping effect further optimizes the thermal decomposition behavior of the composite.

EG functions through an expansion–barrier–temperature-regulation mechanism. Its TG–DTG curves exhibit a stepwise pattern. Before 230 °C, the TG curve remains stable with no DTG peak, indicating excellent thermal stability in this range. Between 230 and 320 °C, the TG curve declines rapidly with a sharp DTG peak. Research attributes this stage to gas production from the decomposition of the intercalated compounds [SO4·7H2O·NO3]x [28], where the TG mass loss rate reflects the gas generation efficiency. The released gas promotes the expansion of the graphite layers, forming a porous barrier structure. Beyond 680 °C, the TG curve shows only a slight decrease, indicating that the expanded porous layer continues to function in blocking oxygen and regulating temperature at high temperatures, thereby retarding the later-stage pyrolysis of the asphalt.

4. Conclusions

(1) AOE exhibits excellent flame retardancy at low dosage. The AOE ternary composite (ATH/OMMT/EG, 6:2:3) at a 6% dosage delivers an optimal LOI of 25.1%, demonstrating superior flame-retardant efficiency through synergistic action that outperforms higher-loading conventional systems.

(2) ATH undergoes stepwise endothermic decomposition at 200–350 °C, dehydrating and generating Al2O3 to delay asphalt thermal degradation and form a dense protective layer in the condensed phase; OMMT decomposes to produce acidic sites, which catalyze the formation of a robust silicate-rich char layer in asphalt and exert free-radical scavenging effects; EG expands at 230–320 °C, releasing gases to dilute combustible vapors, and its porous expanded char layer effectively blocks oxygen and heat transfer. The three components act synergistically to in situ form a continuous and dense physicochemical composite barrier on the asphalt surface during combustion.

(3) CONE tests show that, compared with AOE-0, AOE-6 exhibits a 23.9% increase in TTI, a 24.22% decrease in HRRpeak, and a 32.34% decrease in THR. Notably, the TSR and the SPRpeak both decrease by approximately 47.5%, achieving synergistic flame retardancy and smoke suppression. Lower surface temperatures and shorter combustion durations in burning tests further confirm its ability to inhibit the combustion process.

(4) SEM observations reveal that the combustion char residue of AOE-6 presents a large lamellar, densely stacked structure, which is in sharp contrast to the loose and porous char residue of AOE-0. EDS analysis confirms that this dense layer is rich in elements such as Si, Al, and O derived from the flame-retardant decomposition products, verifying the formation and chemical composition of the composite barrier layer.

In summary, the ternary composite additive AOE developed in this study, through effective synergy among its components, endows warm-mix asphalt with excellent flame-retardant and smoke-suppressant properties at low dosage. The core mechanism lies in the in situ construction of a composite barrier layer integrating heat insulation, oxygen-barrier, and smoke-suppression functions during combustion. This system provides a promising solution for the development of high-performance fire-resistant asphalt pavements in special scenarios such as tunnels.

Author Contributions

Q.G.: Investigation, Writing, Visualization and Editing. Y.L.: Methodology, Validation, Investigation, Data curation, Reviewing. S.L.: Supervision, Funding acquisition. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Science and Technology Project of Jiangxi Provincial Department of Transportation (2023H0001).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article, and further inquiries can be directed to the corresponding author.

Conflicts of Interest

Author Qiaoming Guo and Yuanbao Liu were employed by the company Ganzhou Management Center of Jiangxi Communications Investment Group Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Zhu, X.-H.; Lu, K.-F.; Peng, Z.-R.; He, H.-D.; Xu, S.-Q. Spatiotemporal variations of carbon dioxide (CO2) at Urban neighborhood scale: Characterization of distribution patterns and contributions of emission sources. Sustain. Cities Soc. 2022, 78, 103646. [Google Scholar] [CrossRef]

- Li, X.; Yuan, F.; Shen, J.; Jia, J.; Gao, J. Application of wood powder for asphalt CO2 emission reduction. J. Clean. Prod. 2022, 375, 134127. [Google Scholar] [CrossRef]

- Wang, F.; Li, X.; Wu, S.; Zheng, L.; Luo, Q.; Zhang, J.; Barbieri, D.M. Comparative study for global warming potentials of Chinese and Norwegian roads with life cycle assessment. Process Saf. Environ. Prot. 2023, 177, 1168–1180. [Google Scholar] [CrossRef]

- Li, N.; Jiang, Q.; Wang, F.; Xie, J.; Li, Y.; Li, J.; Wu, S. Emission behavior, environmental impact, and priority-controlled pollutants assessment of volatile organic compounds (VOCs) during asphalt pavement construction based on laboratory experiment. J. Hazard. Mater. 2020, 398, 122904. [Google Scholar] [CrossRef] [PubMed]

- Yang, X.; Shen, A.; Jiang, Y.; Meng, Y.; Wu, H. Properties and mechanism of flame retardance and smoke suppression in asphalt binder containing organic montmorillonite. Construct. Build. Mater. 2021, 302, 124148. [Google Scholar] [CrossRef]

- Xia, W.; Fan, S.; Xu, T. Inhibitory action of halogen-free fire retardants on combustion and volatile emission of bituminous components. Sci. Prog. 2021, 104, 00368504211035215. [Google Scholar] [CrossRef]

- Xiao, F.P.; Guo, R.; Wang, J.G. Flame retardant and its influence on the performance of asphalt—A review. Construct. Build. Mater. 2019, 212, 841–861. [Google Scholar] [CrossRef]

- Xu, F.; Zhang, H.; Wu, J. Synergistic catalytic flame retardant effect of zirconium phosphate on the poplar plywood. Constr. Build. Mater. 2021, 290, 123208. [Google Scholar] [CrossRef]

- Sheng, Y.; Wu, Y.; Yan, Y.; Jia, H.; Qiao, Y.; Underwood, B.S.; Niu, D.; Kim, Y.R. Development of environmentally friendly flame retardant to achieve low flammability for asphalt binder used in tunnel pavements. J. Clean. Prod. 2020, 257, 120487. [Google Scholar] [CrossRef]

- Xiu, M.; Wang, X.; Morawska, L.; Pass, D.; Beecroft, A.; Mueller, J.F.; Thai, P. Emissions of particulate matters, volatile organic compounds, and polycyclic aromatic hydrocarbons from warm and hot asphalt mixes. J. Clean. Prod. 2020, 275, 123094. [Google Scholar] [CrossRef]

- Yang, X.; Shen, A.; Su, Y. Effects of alumina trihydrate (ATH) and organic montmorillonite (OMMT) on asphalt fume emission and flame retardancy properties of SBS-modified asphalt. Constr. Build. Mater. 2020, 236, 117576. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, J. Enhanced flame retardant performance of rigid polyurethane foam by using the modified OMMT layers with large surface area and ammonium polyphosphate. Mater. Today Commun. 2022, 32, 104121. [Google Scholar] [CrossRef]

- Bao, J. Study on the Inhibition Effect of Photocatalytic Materials on Road Asphalt Fume. Master’s Thesis, Shihua University, Fushun, China, 2020. (In Chinese). [Google Scholar]

- Wang, S.; Tan, L.; Xu, T. Synergistic effects of developed composite flame retardant on VOCs constituents of heated asphalt and carbonized layer compositions. J. Clean. Prod. 2022, 367, 133107. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, T.; Wang, X.; Shi, R. The influence of different types of warm mix agents on the road performance of asphalt mixture and its efficiency evaluation. J. Jiangsu Univ. Nat. Sci. Ed. 2022, 43, 711–718. [Google Scholar]

- Jiang, W.; Sha, A.; Zhao, H.; Ye, W. Design and performance evaluation of warm mix flame retardant asphalt mixture. J. Hefei Univ. Technol. Nat. Sci. Ed. 2018, 41, 671–676. [Google Scholar]

- Xia, W.; Zhou, X.; Yang, X. Suppressive effects of composite flame retardant on smoke release, combustion soot and residue constituents of asphalt mixture. J. Energy Inst. 2022, 103, 60–71. [Google Scholar] [CrossRef]

- Lai, H.; Cai, X.; Gao, W.; Zhang, Y.; Wang, H.; Zhai, J.; Shi, C.; Xion, R. Research progress of flame retardant and smoke suppression asphalt mixture. Appl. Chem. Eng. 2023, 52, 1237–1242. [Google Scholar]

- Qiu, J.; Yang, T.; Wang, X.; Wang, L.; Zhang, G. Review of the flame retardancy on highway tunnel asphalt pavement. Constr. Build. Mater. 2019, 195, 468–482. [Google Scholar] [CrossRef]

- Lin, Y.; Liu, S.; Huang, H.; Shi, W.; Li, M. High and low-temperature properties of warm mix flame retardant asphalt based on rheological properties. J. Jiangsu Univ. Nat. Sci. Ed. 2023, 44, 483–489. (In Chinese) [Google Scholar]

- Xu, T.; Wang, Y.; Xia, W.; Hu, Z. Effects of flame retardants on thermal decomposition of SARA fractions separated from asphalt binder. Constr. Build. Mater. 2018, 173, 209–219. [Google Scholar] [CrossRef]

- JTG 3410-2025; Highway Engineering Asphalt and Asphalt Mixture Test Procedures. China Communications Press: Beijing, China, 2025.

- ISO 5660-1:2015; Reaction-to-Fire Tests—Heat Release, Smoke Production and Mass Loss Rate—Part 1: Heat Release Rate (Cone Calorimeter Method) and Smoke Production Rate (Dynamic Measurement). International Organization for Standardization: Geneva, Switzerland, 2015.

- Li, C.; Wang, X.; Ma, J.; Liao, W. Combustion Characteristics and Mechanism of Warm-mixed Flame Retardant Compound Modified Asphalt in Changda Highway Tunnel. Contemp. Chem. Ind. 2023, 52, 2074–2079. [Google Scholar]

- Feng, L.; Wang, W.; Song, B.; Zhu, X.; Wang, L.; Shao, R.; Li, T.; Pei, X.; Wang, L.; Qian, X.; et al. Synthesis of P, N and Si-Containing Waterborne Polyurethane with Excellent Flame Retardant, Alkali Resistance and Flexibility via One-Step Synthetic Approach. Prog. Org. Coat. 2023, 174, 107286. [Google Scholar] [CrossRef]

- Xia, W. Combustion Behavior of Asphalt Pavement Under Tunnel Fire and Synergistic Inhibition Mechanism of Composite Flame Retardants. Ph.D. Thesis, Nanjing Forestry University, Nanjing, China, 2020. (In Chinese). [Google Scholar]

- Wu, B. Study on Composite Hydroxide Flame-Retardant Asphalt Systems and Their Pavement Performance. Master's Thesis, Zhejiang University, Hangzhou, China, 2015. (In Chinese). [Google Scholar]

- Barsukov, M.G.; Ritt, C.L.; Barsukov, I.V.; Syth, E.M.; Elimelech, M. Influence of Graphite Geography on the Yield of Mechanically Exfoliated Few-Layer Graphene. Carbon 2023, 208, 355–364. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.