Abstract

Semi-Flexible Pavement (SFP) combines the flexibility of asphalt concrete and the rigidity of cement concrete to provide excellent high-temperature rutting resistance in the summer. However, its application is often limited by the fluidity and mechanical properties of cement-based grouting materials. This study systematically optimized the mix ratios of three types of grouting materials (cement-based, mineral-modified, and polymer-enhanced) using response surface methodology combined with orthogonal tests. The effects of water–binder ratio (W/B), sand–binder ratio (S/B), mineral admixtures and polymer additives on the key properties of grouting materials were systematically studied. By using Scanning Electron Microscopy (SEM) and X-ray Diffraction (XRD), the evolution of the mixture microstructure and the mechanism of performance change were also analyzed. The test results show that the optimal mix ratio of the cement-based grouting material is W/B = 0.46 and S/B = 0.15; the optimal mix ratio of the mineral grouting material is to replace part of the cement with fly ash (9%), silica fume (6%) and microspheres (3%). Microscopic tests show that fly ash effectively inhibits bleeding; silica fume and fly ash promote the formation of calcium silicate hydrate (C-S-H) gel; microspheres optimize the rheology of the slurry; and the synergistic effect of silica fume and microspheres reduces the internal pores of the grouting material, achieving high fluidity, low bleeding rate and excellent mechanical properties of the grouting material. The polymer-reinforced grouting material is an enhanced slurry formed by adding high-performance water reducer (0.8%), rubber powder (2%) and coupling agent (0.9%) to the optimal mineral grouting material. The combined effect of rubber powder and coupling agent significantly improves the adhesive property between the grouting material and the asphalt interface, making it more suitable for the road performance of SFP in low-temperature environments.

1. Introduction

Semi-Flexible Pavement (SFP), integrating the flexibility of asphalt concretes with the rigidity of cement concrete, has exceptional rutting resistance to widely apply in urban main roads, bus lanes, and road intersections. The strength of Semi-Flexible Pavement is that it is composed of aggregate of asphalt mixture and cement, which improves the ability of the road surface to resist deformation. As the core constituent of SFP [1,2,3,4,5,6], cement-based grouting materials critically determine pavement service lifespan. Traditional cement-based grouting materials still have deficiencies in aspects such as fluidity, strength, and durability, failing to meet the high-performance requirements of SFP [7,8,9].

Consequently, optimizing mix proportions of cement-based grouting materials to enhance comprehensive performance has emerged as a vital research focus.

In recent years, researchers have significantly improved the properties of cement-based grouting materials by adjusting the water-binder ratio, incorporating mineral admixtures (such as silica fume, fly ash, and ground granulated blast-furnace slag), and using admixtures (such as water reducer and coupling agent). Maleki Tagba et al. [10] found that compared with the pure cement grouting material, the flow performance and compressive strength of the cement-based composite grouting material added with silica fume were improved. Jarosław et al. [11] reported that microsphere increased specific surface area of whole composite materials, enhancing moisture adsorption capacity while reducing spacing factor L to decrease capillary rise phenomena. Muhammad Tausif Arshad et al. [12] studied the influence of the structure, mechanical properties and microstructure of the fly ash cement system. The experiment showed that fly ash had a key influence on the strength improvement and hydration development of the composite cement system; adding fly ash to the composite cement system could improve the fluidity of the cement system, and the combination of 18% fly ash and 2% silica fume could achieve the highest compressive and flexural strength. Sun et al. [13] observed that 10%–15% slag content significantly improved fluidity of grout but compromised strength development. However, when the content of ground granulated blast-furnace slag increased to 15% to 20%, the late-stage strength of the grouting material was improved, but the fluidity decreased significantly. Krishnaraj L et al. [14] further studied the effect of fly ash on the flow performance of grouting materials, and the results showed that the addition of fly ash could reduce the water requirement of standard consistency, shorten the setting time, and effectively reduce the porosity of materials. The research of Zhang et al. [15] showed that 10% fly ash and 10% slags co-addition synergistically improved both fluidity and mechanical properties, and the influence of fly ash on fluidity and strength was greater than that of mineral powder. Memon et al. [16] observed that adding 10% silica fume could increase the flexural strength and compressive strength of concrete by 11.5% and 6.9%, respectively. In addition, some researchers further improved the performance of the grout material by optimizing the use of admixtures. By adding rubber powder, Maleki Tagba et al. [10] improved the chloride ion penetration resistance of the grout material, and the strength at 7 days and 28 days increased by 26.30% and 24.63%, respectively, which could reduce the possibility of fatigue damage and cracks. Cheng et al. [17] studied the effect of silane coupling agent on the properties of SFP materials, and found that with the increase in the content of silane coupling agent, the high temperature performance, low temperature performance and water stability performance of the SFP were significantly improved, and all of SFP performance were in the optimal state when the content of silane coupling agent was 0.5%. Huang et al. [18] demonstrated through experiments that although adding rubber powder would reduce the toughness of the cement matrix, and the energy at the crack tip, and the complementary energy, it was helpful to promote the formation of a saturated multi-crack system and enhance the strain hardening performance of the material. Jindarat E et al. [19] found that high-performance water-reducing agents with proper contents could improve the early strength of grout and reduce the amount of cement. At the research of micro/meso scale, Geok Wen Leong [20] and Asad Hanif [21] observed that the microstructure of cement-based grouting material would change in adding fly ash and other materials by using Scanning Electron Microscopy (SEM) and X-ray Diffraction (XRD) tests.

Although existing research has made some progress in optimizing the performance of cement-based grouting materials, there are still some limitations, such as a single mineral admixture failing to concurrently achieve high fluidity and early-age strength, with most studies focusing on isolated factors but neglecting multi-parameter synergies. Yi et al. [22] employed uniform design methodology to optimize the mix ratio of cement slurry for SFP. An optimal water-to-cement mass ratio of 0.41 was proposed through regression analysis of fluidity, compressive strength, and flexural strength, which could reduce cement consumption and SFP construction costs. Sun et al. [23] studied the influence of the water–binder ratio, mineral admixtures, sand–binder ratio, and water-reducing agents on the properties of cement mortar through orthogonal experiments. The study showed that the water–binder ratio, the content of mineral admixtures, the sand–binder ratio, and polycarboxylate water-reducing agents had a significant impact on the properties of grouting materials, and polycarboxylate water-reducing agents and the water–binder ratio had the greatest impact on the properties of grouting materials. However, the interaction among all of factors has not been deeply explored. Khan et al. [24] established response surface models for grout fluidity and compressive strength optimization with validation. Furthermore, although the use of mineral admixtures and admixtures could improve the properties of grout materials, the optimal dosage and compounding scheme would still need to be further optimized.

This study aims to develop high-performance grouting materials for SFP through a multi-stage optimization process of grouting materials. The main research objectives were as follows: the optimal water–cement ratio (W/B) and sand–cement ratio (S/B) for the foundation cement grouting were determined using the response surface method (RSM). Orthogonal experimental design (OED) was used to identify the synergistic effects and optimal substitution levels of industrial solid wastes (fly ash, silica fume, microspheres) in mineral-optimized grouting. The dosages of polymer additives (rubber powder, coupling agent, water reducer) were optimized to enhance low-temperature and interfacial performance of grouting materials. The microscopic mechanisms controlling the macroscopic properties were clarified through scanning electron microscopy (SEM) and X-ray diffraction (XRD) analysis.

This research provides a scientific basis for the design and application of SFP grouting materials under different environmental conditions.

2. Materials and Methods

2.1. Raw Materials

The grouting material used Common Portland cement with strength grade 42.5 MPa (sourced from Qilian Mountain Cement Group Co., Ltd. Lanzhou, China), river sands, fly ash (Class F, sourced from Henan Yixiang New Materials Co., Ltd., Activity Index ≥ 95%, Lanzhou, China), silica fume (sourced from Henan Yixiang New Materials Co., Ltd. Lanzhou, China), microspheres (sourced from Henan Yixiang New Materials Co., Ltd. Lanzhou, China), 40 meshes rubber powder, KH550 silane coupling agents, and high-performance water-reducing agents (sourced from Jiangsu Aolite Co., Ltd. Lanzhou, China). The technical properties of these materials are summarized in Table 1, Table 2, Table 3, Table 4, Table 5 and Table 6, and all materials met the relevant Chinese standards.

2.1.1. Cement

Portland cement was employed in this paper. According to the “Common Portland Cement” [25] in China, cement was tested for standard consistency, initial setting time, and final setting time. The results are summarized in Table 1.

Table 1.

Technical requirements testing of Portland cement.

Table 1.

Technical requirements testing of Portland cement.

| Test Parameters | Apparent Density/(g·cm−3) | Standard Consistency/% | Initial Setting Time/min | Final Setting Time/min | Soundness |

|---|---|---|---|---|---|

| Test results | 3.095 | 28 | 190 | 372 | Up to Standard |

| Technical requirements | × | × | ≥40 | ≤600 | × |

2.1.2. Grouting Sand

Clean river sand was adopted, and grain composition of grouting sand is shown in Table 2. According to “Sand for Construction and Technical Specification for Grouting Semi-flexible Pavement of Urban Road” [26,27] in China, all test values of sieve sizes satisfied with the specification.

Table 2.

Grain composition of grouting sand.

Table 2.

Grain composition of grouting sand.

| Sieve Sizes/mm | Cumulative Passing/% | |

|---|---|---|

| Test Values | Requirements | |

| 1.18 | 100 | 100 |

| 0.6 | 100 | ≥80 |

| 0.075 | ≤2 | ≤2 |

2.1.3. Fly Ash

Fly ash with activity index ≥95% after 28 days was utilized in this paper. According to “ Fly Ash Used for Cement and Concrete” [28] in China, fly ash was tested and is shown in Table 3.

Table 3.

Test results of fly ash. (Data sourced from the manufacturer’s certificate and verified in accordance with GB/T 1596-2017 [28]).

Table 3.

Test results of fly ash. (Data sourced from the manufacturer’s certificate and verified in accordance with GB/T 1596-2017 [28]).

| Test Items | Test Results | Technical Requirements |

|---|---|---|

| Fineness, % | 16 | ≤18 |

| Loss on lgnition, % | 2.62 | ≤5% |

| Al2O3 content, % | 36.8 | ≥30 |

| SiO2 content, % | 45.1 | ≤50 |

| Moisture content, m2/g | 0.40 | ≤1.0% |

| Chloride ion content, % | 0.015 | ≤0.02 |

| SO3 content, % | 1.2 | ≤3 |

| CaO content, % | 4.5 | ≤10 |

| Alkali content, % | 0.75 | ≤1.5 |

| Fe2O3 content, % | 0.85 | 0.8–1.0 |

| Free CaO content, % | 0.85 | ≤1.0 |

| Density, g/cm3 | 2.1 | ≤2.6 |

| Bulk density, g/cm3 | 1.10 | 0.63–1.38 |

2.1.4. Silica Fume

According to “Silica Fume for Cement Mortar and Concrete” [29] in China, silica fume was tested (as shown in Table 4). All test results met the technical requirements.

Table 4.

Test results of silica fume. (Data provided by the manufacturer).

Table 4.

Test results of silica fume. (Data provided by the manufacturer).

| Test Items | Test Results | Technical Requirements |

|---|---|---|

| SiO2 content, % | 96.1 | >85 |

| Loss on lgnition, % | 2.3 | ≤6.0 |

| Specific Surface Area, m2/g | 19 | ≥15 |

| Chloride ion content, % | 0.07 | ≤0.3 |

| Fe2O3 content, % | 0.12 | ≤0.4 |

| Al2O3 content, % | 0.19 | ≤0.5 |

| Na2O content, % | 0.02 | ≤0.05 |

| K2O content, % | 0.01 | ≤0.02 |

| TiO2 content, % | 0.015 | ≤0.05 |

2.1.5. Glass Microsphere

According to “Fly Ash Used for Cement and Concrete” in China, glass microsphere was tested for 200-mesh sieve residue, bulk density, and SiO2 contents, etc. (Table 5).

Table 5.

Test results of glass microsphere. (Data provided by the manufacturer).

Table 5.

Test results of glass microsphere. (Data provided by the manufacturer).

| Test Items | Test Results | Technical Requirements |

|---|---|---|

| 200-mesh sieve residue | 8.3 | <10 |

| Bulk density, g/cm3 | 0.65 | 0.6–0.75 |

| SiO2 content, % | 52.5 | <52 |

| Fe2O3 content, % | 3.5 | <4 |

| Al2O3 content, % | 22.5 | <22 |

| CaO content, % | 11.5 | <12 |

2.1.6. Water-Reducing Agent

According to “Methods for Testing Uniformity of Concrete Admixture” [30] in China, the water-reducing agent was tested for chloride ion content, total alkali content, and solid content, etc. (Table 6). These tests are essential to ensure the admixture’s compliance with standards and to prevent potential detrimental effects on the cementitious matrix, such as steel corrosion (from chlorides) and alkali-silica reaction (from alkalis).

These tests were crucial for ensuring that the admixtures met the standards and preventing potentially harmful effects on the cementitious matrix (such as steel bar corrosion caused by chlorides and alkali-silicic acid reactions caused by alkali).

Table 6.

Test results of water-reducing agent. (Tested according to GB/T 8077-2012 [30]).

Table 6.

Test results of water-reducing agent. (Tested according to GB/T 8077-2012 [30]).

| Technical Parameters | Test Results | Technical Requirements |

|---|---|---|

| Chloride ion content, % | 0.020 | ≤0.6 |

| Total alkali content, % | 0.71 | ≤10.0 |

| Solid content, % | 23.22 | ≥20 |

| Density, g·cm−3 | 1.056 | 1.050 ± 0.020 |

| PH | 4.03 | 3~5 |

| Na2SO3 content, % | 0.48 | ≤5.0 |

2.2. Test Methods

The test contents selected in this study were determined based on the key factors affecting the construction and performance of SFP, mainly including initial fluidity, 30 min fluidity, bleeding rate and early (7 day) mechanical strength. Fluidity can ensure the pumpability of the grouting material and allow it to fully penetrate the asphalt skeleton. Low bleeding rate can prevent the segregation of grouting material and ensure the uniformity of grouting material. Early strength is crucial for achieving rapid traffic opening on SFP.

The initial fluidity, 30 min fluidity, 3 h bleeding rate, 7 day flexural strength, and 7 day compressive strength were tested in accordance with “Testing Methods of Cement and Concrete for Highway Engineering” [31]. Bending tests were conducted under a controlled temperature −10 °C and a loading rate 50 mm/min, following “Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering” [32] in China.

X-ray Diffraction (XRD) and Scanning Electron Microscope (SEM) tests were conducted, and the detailed instrumental parameters for those tests are summarized in Table 7.

Table 7.

Instrumental parameters for microstructural characterization.

2.3. Research Methods

A three-stage experimental strategy was adopted to efficiently optimize the grouting materials:

Stage 1: Base Grout Optimization. Central Composite Design (CCD) within Response Surface Methodology (RSM) was used to optimize the fundamental ratios of Water–Binder (W/B) and Sand–Binder (S/B), establishing a performance baseline without admixture interference.

Stage 2: Mineral Grout Optimization. Based on the optimal base mix from Stage 1, an Orthogonal Experimental Design (OED) was employed to determine the optimal replacement levels of fly ash, silica fume, and microspheres, aiming to enhance performance and sustainability.

Stage 3: Polymer Grout Enhancement. Using the optimal mineral grout from Stage 2, the dosages of polymer additives (rubber powder, coupling agent) and water-reducer were optimized to tailor the material for specific performance needs like low-temperature cracking resistance and early strength.

To systematically explore the synergistic mechanism of key mix proportion parameters of grouting materials on their rheological and mechanical properties, and to efficiently develop three types of grouting materials suitable for different needs (basic cement-based grouting material, mineral-optimized grouting material, and polymer-reinforced grouting material), this study adopted a three-stage experimental design. In the first stage of the experiment design, the ratio of the basic cement-based grouting materials which included water-binder ratio (W/B) and sand-binder ratio(S/B) was optimized by using the Central Composite Design (CCD) in Response Surface Methodology (RSM). This stage of design could avoid the interference of complex factors and determine the optimal ratio of the basic cement-based grouting material. In the second stage of experiment design, based on the optimal ration of the basic cement-based grouting material, the mineral-optimized grouting material with added industrial solid wastes (fly ash, silica fume, microspheres) to replace some cement was analyzed by using the Orthogonal Experimental Design (OED). In the third stage of the design, based on the optimal ratio of the mineral-optimized grouting material, the polymer-reinforced grouting material with added rubber powder and coupling agent separately was optimized to further improve the applicability of grouting materials to the environment.

2.4. Curing, Grouting Process, and Statistical Analysis

Curing Regime: All specimens for mechanical and microstructural testing were cast and demolded after 24 h. They were subsequently cured in a standard curing chamber at a temperature of 20 ± 2 °C and a relative humidity of ≥95% until the designated testing ages (3 h, 1 d, 7 d, 28 d). This water-saturated curing condition was maintained to ensure full hydration and prevent carbonation during the early stages of strength development.

Grouting Process Simulation: To directly evaluate the fullness of grouting under simulated field conditions, this study introduced the grouting rate (or filling efficiency) as a key metric. This indicator is essential for ensuring that the grout sufficiently fills the voids of the asphalt mixture, thereby preventing performance degradation of the semi-flexible pavement due to incomplete grouting. The test was conducted using Marshall asphalt mixture specimens with a designed air void content of 25%. A sufficient amount of grout was poured onto the specimen surface under its own weight until seepage ceased and a continuous mirror surface formed. The grouting rate was calculated based on the change in the connected air voids of the specimen before and after grouting, using the following formula:

where Pr—Impregnation ratio (%);

VVC—Interconnected porosity before impregnation (%);

VVC’—Interconnected porosity after impregnation (%).

A grouting rate approaching 100% indicates excellent penetrability and complete filling capability, which is crucial for ensuring the structural integrity of the SFP. The standard fluidity test serves as a supplementary indicator, as higher fluidity (shorter flow time) generally facilitates the achievement of a higher grouting rate.

Statistical Rigor: All experimental tests in this study, including fluidity, bleeding, and strength measurements, were conducted with a minimum of three replicates (n ≥ 3). The data presented in tables and figures are the mean values, with error bars or standard deviations provided where applicable. For the Response Surface Methodology, the ANOVA assumptions (normality of residuals, homogeneity of variance) were verified using the Shapiro–Wilk test and residual plots within the Design-Expert software, confirming the validity of the statistical models. For orthogonal experimental analysis, the range analysis method was employed, which was robust and did not require strict adherence to normality assumptions.

3. Results and Discussion

3.1. Ratio Optimization of Basic Cement-Based Grouting Material

Central Composite Design is a commonly used experimental design method that combines factor design and star point design to construct Response Surface Models by selecting appropriate experimental points in the factor space and is mainly used for analysis and optimization of Response Surface Models. This study adopted the Central Composite Design method in Response Surface Methodology. Based on previous experimental experience, the water–binder ratio (W/B) and sand–binder ratio(S/B) were set to 0.42–0.5 and 0.1–0.2, respectively. The experimental results are summarized in Table 8.

Table 8.

Test results of cement grouting materials.

By fitting and analyzing the 13 sets of test results in Table 7 through Design Expert, the following relationship equations between W/B, S/B, and response values were obtained, as shown in Equations (2)–(6).

where X1 and X2 represent the W/B and S/B, respectively, while Y1–Y5 correspond to initial fluidity, 30 min fluidity, bleeding rate, 7 d flexural strength, and 7 d compressive strength.

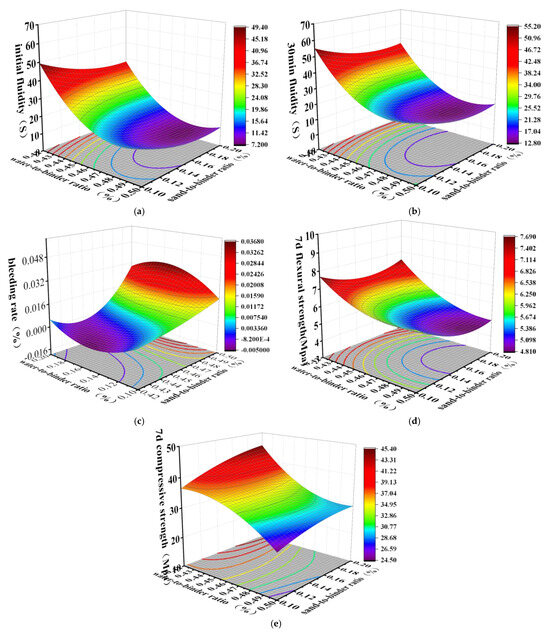

The five models exhibited coefficients of determination (R2) of 97.49%, 95.76%, 98.17%, 93.86%, and 92.22%, respectively. All models were statistically significant, with non-significant lack-of-fit terms. Response surface plots for X1, X2, and Y1–Y5 were shown in Figure 1a–e.

Figure 1.

Response surface plot for X1, X2, and Y: (a) Response surface plot for X1, X2, and Y1; (b) Response surface plot for X1, X2, and Y2; (c) Response surface plot for X1, X2, and Y3; (d) Response surface plot for X1, X2, and Y4; (e) Response surface plot for X1, X2, and Y5.

The five models exhibited coefficients of determination (R2) of 97.49%, 95.76%, 98.17%, 93.86%, and 92.22%, respectively. The optimization goal was defined according to the technical requirements for SFP grouting materials: minimizing initial fluidity (Y1, target: 10–14 s), 30 min fluidity (Y2, target: <18 s), and 3 h bleeding rate (Y3, target: <0.01%), while maximizing 7 d flexural strength (Y4, target: ≥2 MPa) and 7 d compressive strength (Y5, target: ≥15 MPa). A desirability function approach in Design-Expert software was employed to solve this multi-objective optimization problem. Equal importance was assigned to five responses, which would ensure a balanced optimization without bias towards any single property. All models were statistically significant. All models were statistically significant. The high F-values, low p-values (<0.05) for the models, and non-significant lack of fit (>0.05) confirmed the statistical significance and adequacy of five regression models. Response surface plots for X1, X2, and Y1–Y5 were shown in Figure 1a–e.

Response trends explained that the positive correlation between W/B and fluidity (Figure 1a,b) was expected because of more water lubricating the particles. The 3 h bleeding rate increased monotonically with W/B due to a higher proportion of free water, while its complex relationship with S/B (Figure 1c) indicated an optimal packing density that minimized water separation. The negative effect of the higher W/B on mechanical strength (Figure 1d,e) was attributed to increased porosity. Notably, the synergistic effect of lower W/B and higher S/B on compressive strength (Figure 1e) likely stemmed from a denser skeleton formed by the sand particles under a low-water environment. Corresponding ANOVA results were summarized in Table 9 and Table 10 below.

Table 9.

p Values.

Table 10.

F Values.

Based on the ANOVA results in Table 9 and Table 10, all regression models for response variables Y1–Y5 are statistically significant (F-statistic range: 7.17–54.38, all exceeding the F0.01 critical value), with significance levels p < 0.001, far below the conventional threshold (α = 0.05). Specifically, the extreme significance (p < 0.005) of each model confirms the deterministic influence of W/B and S/B on cement paste performance (p < 0.001). Notably, the lack-of-fitting p values for all models (Y1, Y2,… to Y5 are 0.0615, 0.0674, 0.0643, 0.7411, 0.6743, respectively) exceed α = 0.05, demonstrating no systematic bias (p > 0.05) and acceptable experimental error range. It is confirmed that the Response Surface Models are statistically valid and reliable for engineering prediction. Based on the ANOVA results in Table 8 and Table 9, it indicated that all regression models for response variables Y1–Y5 were statistically significant (F-statistic range: 7.17–54.38, all exceeding the F0.01 critical value), with significance levels p < 0.001, far below the conventional threshold (α = 0.05). Specifically, the extreme significance (p < 0.005) of each model confirmed the deterministic influence of W/B and S/B on cement paste performance (p < 0.001). Notably, the lack of fitting p values for all models (Y1, Y2,… to Y5 are 0.0615, 0.0674, 0.0643, 0.7411, 0.6743, respectively) exceeded α = 0.05, demonstrating no systematic bias (p > 0.05) and acceptable experimental error range. It was confirmed that the Response Surface Models were statistically valid and reliable for engineering prediction. The optimal mix proportion predicted by the response surface analysis under these criteria was W/B = 0.46 and S/B = 0.15. The predicted values of technical indexes of cement-based grouting material were in good agreement with those of measured values (as shown in Table 11), and error analysis showed that the predicting deviations were less than ±4.2%. As shown in Table 10, the predicted values from the models showed excellent agreement with the measured values, with all deviations within ±4.2%, and all properties met the technical requirements. The above-mentioned statistical results could validate the reliability of Central Composite Design (CCD) in optimizing ratio of cement-based grouting material.

Table 11.

Predicted and measured values of technical indexes of cement-based grouting material.

3.2. Ratio Optimization of Mineral Grouting Material

In the literature [12,25], the optimal water–binder ratio (W/B) and sand–binder ratio (S/B) of a cementitious system were altered after adding supplementary cementitious materials (SCMs), such as fly ash, silica fume, and microspheres. A re-optimization process was undertaken before conducting the orthogonal design of mineral admixtures. Based on the optimal base mix (W/B = 0.46, S/B = 0.15), the total water–binder ratio and sand–binder ratio of the grouting material were adjusted to prepare the base grouting material. The results showed that when the substitution amount of mineral admixtures was less than or equal to 18%, due to the compensation effect among mineral admixtures (for example, the spherical morphology of fly ash and microspheres improved workability and offset the water requirement of silica fume), the original water–binder ratio = 0.46 and sand-binder ratio = 0.15 remained optimal or nearly optimal workability. Therefore, the subsequent orthogonal experiments employed the water–binder ratio of 0.46 and sand–binder ratio of 0.15. In order to reduce carbon emissions and improve performance of cement-based grouting materials, this study used industrial solid waste materials such as fly ash, silica fume, and glass microspheres to partially replace some of the cement. The main effect and interaction of these mineral additives on key performance parameters of grouting material (initial fluidity, 30 min fluidity, 3 h bleeding rate, 7 d flexural strength, and compressive strength) are systematically analyzed through rigorously designed orthogonal experiments of mineral grouting material (as shown in Table 12 and Table 13).

Table 12.

Orthogonal experimental design of mineral grouting material [33].

Table 13.

Orthogonal experimental results.

Based on the orthogonal experimental results presented in Table 13, the conclusions regarding the influence of mineral admixtures are summarized in Table 14 below.

Table 14.

Analysis of factor influence and optimal levels from the orthogonal experiment.

Comprehensive analysis indicated that silica fume (Factor B) demonstrated the most significant impact on all properties among the mineral additives. While microspheres optimized slurry rheology via spherical particles, the silica fume promoted C-S-H gel formation through high reactivity. The silica fume and microspheres exhibited complementary effects and synergistically balanced high fluidity-high strength performance of the mixtures. Although fly ash had a relatively small individual impact, as a low-cost filler, it could reduce pore connectivity and effectively suppress bleeding of the mixtures. Despite high dosages of silica fume (Level 3) maximizing mechanical performance, it came at the cost of significantly reduced fluidity (see Table 14). Similarly, the optimal level for minimizing bleeding was a low silica fume content (B1). Therefore, a compromise was necessary to achieve the balanced performance. The combination of A3 (9% fly ash), B2 (6% silica fume), and C1 (3% microspheres) was selected as the optimal ratio. This combination ensured high compressive strength (close to the maximum achievable, as Level 3 only offered a marginal further increase), maintains acceptable fluidity, controlled the bleeding rate effectively, and aligned with the goal of reducing cement and high-cost silica fume consumption. About discussion on mineral admixture synergy, the dominance of silica fume (Factor B) aligned with its well-known high pozzolanic reactivity and micro-filling effect [16,22]. The complementary roles of fly ash (filler and bleeding control) and microspheres (rheology modifier) observed here were consistent with the concept of particle packing optimization in multi-component cementitious systems [12]. The orthogonal results provide quantitative evidence of their synergistic effects, which is an advancement over studies focusing on single admixtures.

3.3. Ratio Optimization of Polymer Additives

3.3.1. Determination of Polymer Additive Dosage

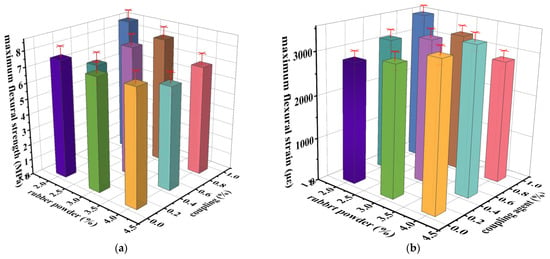

Rubber powder and a coupling agent were added to the mineral-optimized grouting material for enhancing the low-temperature crack resistance of semi-flexible pavement. The experimental results are shown in Figure 2.

Figure 2.

Flexural strength and maximum flexural strain varying dosages of rubber powder and coupling agent: (a) Flexural strength; (b) Maximum flexural strain.

The effects of rubber powder and coupling agent on the low-temperature flexural performance are summarized in Figure 2. The optimal dosages were identified as 2% for rubber powder and 0.9% for coupling agent, which yielded the peak values in both flexural strength and maximum flexural strain. The enhancement was attributed to the following mechanisms: the elastic rubber particles absorbed and dissipated energy at low temperatures, improving toughness and crack resistance [17,19], while the coupling agent promoted interfacial adhesion between the organic polymers and the inorganic cement matrix, leading to a more integrated and durable composite structure [18].

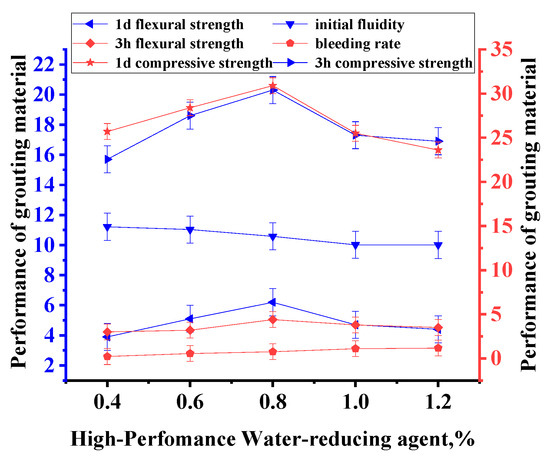

To increase the early strength of the grouting material, a water-reducing agent was incorporated at dosages of 0.4%, 0.6%, 0.8%, 1.0%, and 1.2%. Tests were conducted on initial fluidity, bleeding rate, 3 h flexural strength, 3 h compressive strength, 1 d flexural strength, and 1 d compressive strength. The results are shown in Figure 3.

Figure 3.

Performance of grouting material Varying Dosages of Water-Reducing agent.

The influence of the water-reducing agent dosage on early-age properties was presented in Figure 3. The content of 0.8% was selected as optimal, as it produced the highest 3 h and 1 d compressive strength without inducing segregation or stratification in the mineral grouting material. It was that the water-reducer effectively dispersed cement particles, reducing water demand and increasing packing density, which accelerated early hydration and strength development [20]. At higher dosages (>0.8%), the risk of bleeding and segregation increased, and potentially weakened the microstructure.

The performance of the polymer grouting material formulated with these optimal dosages (0.8% water-reducer, 2% rubber powder, 0.9% coupling agent) was verified, with all technical indexes meeting the specifications, as detailed in Table 15.

Table 15.

Technical indexes of polymer grouting material.

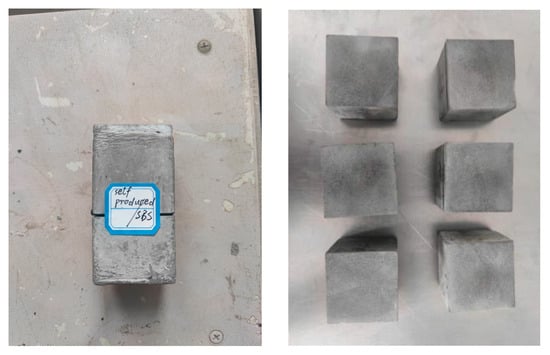

3.3.2. Interface Bonding Strength Test Between Grouting and Asphalt Materials

Considering the need to strengthen the interfacial adhesion between grouting and asphalt materials during the service process of SFP, cubic specimens with dimensions of 40 mm × 40 mm × 40 mm using the above-mentioned three grouting materials were prepared. 0.48 g of Styrene-Butadiene-Styrene modified asphalt (SBS) was evenly applied on the bonding surface of one specimen, with an application amount of 0.48 g, and another specimen was immediately aligned and attached to it (as shown in Figure 4). Subsequently, a static 50 kg load was applied to the top of the adhesive specimen and maintained for 24 h to ensure sufficient interface contact. The adhesive strength test was carried out using a Universal Testing Machine (UTM-100) with a displacement-controlled loading method at a rate of 1 mm/min. When the bonding interface fails, the peak load is recorded. The interface bonding strength is the peak load divided by the bonding area, as shown in Table 16. The results show that polymer-reinforced grouting material significantly improved the interfacial bonding strength between it and SBS modified asphalt, which is significantly higher than that of basic grouting material and mineral-optimized grouting material. It indicates that polymer-reinforced grouting material has advantages in enhancing the interfacial bonding performance between asphalt and grouting material.

Figure 4.

Specimens of interface bonding strength test.

Table 16.

Results of Interface bonding strength.

The results showed that the polymer-enhanced grouting material exhibited significantly higher interfacial bonding strength than the other two materials, which was primarily attributed to the synergistic effect among rubber powder, the silane coupling agent. The mechanism is explained as follows:

Physical Toughening by Rubber Powder: Acting as elastic units, the rubber particles effectively absorbed energy and alleviated stress concentration. By reducing the overall modulus of the grout they promoted better deformation compatibility with the SBS, thereby reducing internal stress at the interface.

Chemical Bridging by Coupling Agent: The KH550 coupling agented functions as a “molecular bridge”. One end of its molecule bonded with the inorganic grouting matrix, while the other end interacted with the organic asphalt, fundamentally improving the adhesion between these two incompatible materials.

Synergistic Enhancement: Working together, they established a multi-scale reinforcement system ranging from macroscopic physical toughening to microscopic chemical bonding. This shifted the failure mode from brittle interfacial debonding to a more ductile cohesive failure, significantly enhancing the integrity and durability of the interfacial zone.

In conclusion, this synergistic mechanism markedly improves the interfacial performance between the grout and asphalt, making it particularly suitable for pavement applications demanding high crack resistance, especially in low-temperature environments.

3.3.3. Evaluation of Grouting Fullness

To quantitatively assess the field-like grouting effectiveness of the optimized materials, the grouting fullness (grouting rate) of the three optimized mixtures (cement-based, mineral-optimized, and polymer-enhanced) was tested. The results are summarized in Table 17.

Table 17.

Grouting fullness test results of optimized grouting materials.

As shown in Table 17, all three optimized grouting materials achieved exceptionally high grouting fullness, exceeding 98.5%. It indicated that all formulations possessed excellent penetrability and void-filling capacity, capable of almost completely occupying the interconnected air voids in the asphalt mixture, thereby forming a dense and integrated pavement structure at the macroscopic level.

A further analysis revealed that the grouting fullness was closely related to the rheological properties of the grouts. The polymer-enhanced grout achieved the highest fullness (99.5%), which was a direct consequence of its superior comprehensive fluidity (i.e., the shortest initial and 30 min fluidity times) and low bleeding rate as shown in Table 13; its excellent rheology ensured smoother and more thorough penetration. The grouting fullness of the mineral-optimized grout (98.8%) lay between the other two, reflecting the synergistic effects of mineral admixtures in improving workability and stability. Even the cement-based grout without complex additives achieved a high fullness of 98.4% under its optimal W/B and S/B ratios, validating the effectiveness of the fundamental mix proportion optimization.

In conclusion, the high grouting fullness (exceeding 98%) measured for all optimized mixes, coupled with their excellent fluidity, demonstrated their superior capability to fully penetrate the porous asphalt skeleton. The high fullness ensured a strong mechanical interlock between the grout and the asphalt skeleton, which was a prerequisite for guaranteeing the integrity and long-term durability of the SFP structure.

3.4. Microstructure Test of Grouting Materials

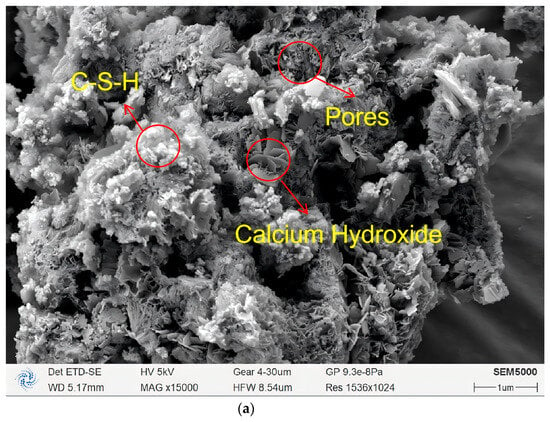

Three types of grouting materials prepared in the previous sections were subjected to Scanning Electron Microscopy (SEM) test, as shown in Figure 5.

Figure 5.

SEM images of three grouting materials: (a) Basic Grouting Material; (b) Mineral-optimized grouting material; (c) Polymer-enhanced grouting material.

The results in Figure 5a show that the structure has a high porosity, with large but unevenly distributed hydration product crystals. The results in Figure 5b indicate an increase in the amount of calcium silicate hydrate and a decrease in the amount of calcium hydroxide. Silica fume reacts rapidly to generate a large number of ultra-fine C-S-H particles with high specific surface area, which fill the pores. The surface of fly ash particles begins to form volcanic ash reaction products. The “ball bearing effect” of microspheres and the micro-filling effect of silica fume greatly fill the capillary pores and some gel pores, making the pore structure finer and more tortuous. The results in Figure 5c show that various long rod-like structures are randomly distributed at all interfaces, which are the result of redispersible polymer powder bridging in the cement pores; the addition of silane coupling agents promotes the formation of fibrous structures in the polymer. The addition of both redispersible polymer powder and coupling agents improves the performance of the interface.

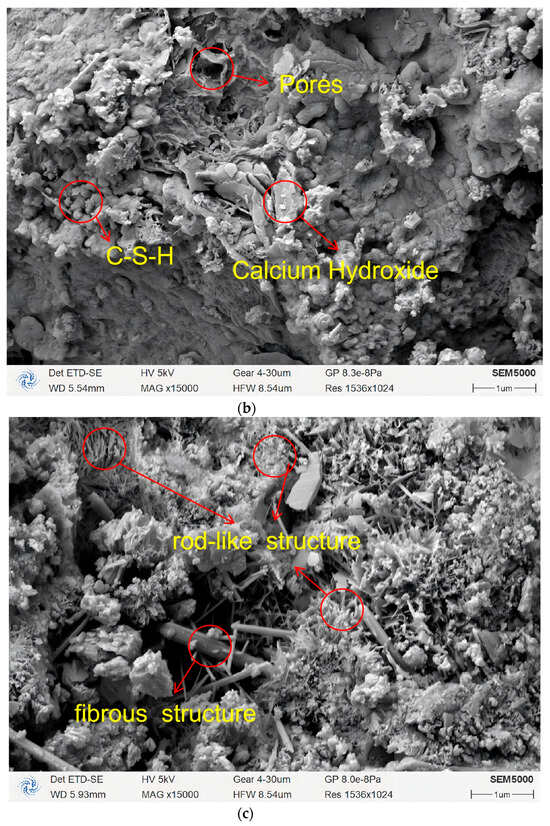

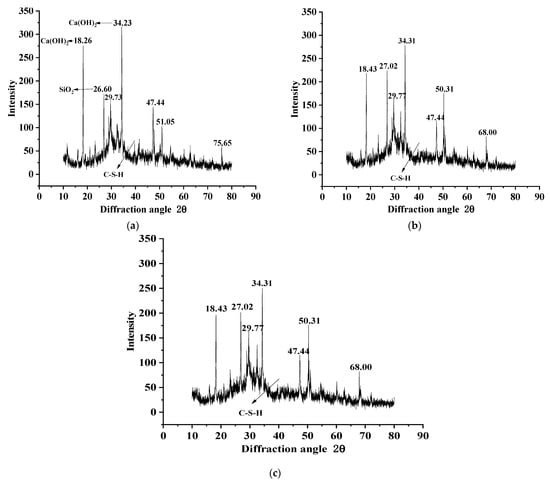

The three types of grouting materials prepared in the previous sections were subjected to X-Ray diffraction (XRD) test. The results are shown in Figure 6.

Figure 6.

XRD images of three grouting materials: (a) Basic Grouting Material; (b) Mineral-optimized grouting material; (c) Polymer-enhanced grouting material.

The quartz peak (26.6°) reaches its highest intensity in Figure 6a. Subsequently, in Figure 6b, the filling of microspheres weakens the diffraction, leading to a decrease in intensity. In Figure 6c, the addition of organic substances such as silane coupling agents causes further intensity reduction due to organic interference. The calcium hydroxide peaks (18°, 34°) appear as sharp and tall peaks in Figure 6a. In Figure 6b, partial consumption of calcium hydroxide by the volcanic ash reaction reduces the peak height. In Figure 6c, the addition of water reducers further lowers the calcium hydroxide peaks, and the redispersible polymer powder and coupling agents coat the calcium hydroxide crystals, inhibiting crystal growth and causing broader peaks. A broad peak in the 20–35° range exists in Figure 6a, which is essentially C-S-H gel generated by cement hydration. In Figure 6b, this broad peak in the 20–35° range widens, primarily due to the formation of calcium silicate hydrate from the volcanic ash reaction. In Figure 6c, the broad peak in the 20–35° range becomes even wider because the water reducers promote the generation of calcium silicate hydrate, and the added redispersible polymer powder increases amorphous scattering.

Discussion on Microstructure–Property Relationships: The SEM and XRD results provided a mechanistic underpinning for the macroscopic observations. The refined pore structure in the mineral-optimized grout (Figure 5b) directly explains its enhanced mechanical strength. The formation of polymer bridges (Figure 5c) offers a clear visual explanation for the improved interfacial bonding and toughness. The consumption of Portlandite (CH) in XRD (Figure 6b,c) confirmed the pozzolanic reactions, linking microstructural changes to performance gains, as reported in [21,22].

4. Conclusions and Perspectives

This study presents a comprehensive investigation into the collaborative optimization of fluidity and mechanical properties for SFP grouting materials, from mix design to micro-mechanism. The key findings are:

- (I)

- The RSM model effectively captured the interactions between W/B and S/B, identifying an optimal base mix of W/B = 0.46 and S/B = 0.15. This ratio achieves a critical balance between flowability for construction and early-age strength for performance, addressing a common dilemma in grout design.

- (II)

- The incorporation of 9% fly ash, 6% silica fume, and 3% microspheres created a superior mineral-optimized grout. Silica fume was the most influential factor, primarily enhancing strength through pozzolanic activity. The synergistic combination of these solid wastes demonstrates a viable path towards more sustainable and high-performance infrastructure materials.

- (III)

- Polymer additives effectively tailored the properties: 0.8% water-reducer secured early strength, while the combination of 2% rubber powder and 0.9% coupling agent synergistically improved both low-temperature crack resistance and interfacial bonding with asphalt.

- (IV)

- Microstructural analysis (SEM/XRD) conclusively linked the macro-properties to underlying mechanisms, including pore structure refinement, promoted C-S-H gel formation, consumption of CH, and the formation of flexible polymeric bridges at the interface.

4.1. Broader Impact and Practical Applications

This research was necessitated by the persistent challenges in balancing the conflicting properties of fluidity and strength in SFP grouts, and the lack of studies on the multi-parameter synergistic effects of admixtures. The findings provided a scientifically grounded and practical mix design protocol. Construction engineers and SFP designers could directly adopt the proposed optimized mixes: the cement-based grout for general (non-frozen) applications; the mineral-optimized grout for high-temperature and rainy regions requiring enhanced durability and sustainability; and the polymer-reinforced grout for frigid zones demanding superior crack resistance. The reduction in cement content and utilization of industrial by-products also offered economic and environmental benefits.

4.2. Limitations and Future Research

This study primarily focused on early-age properties. Future work should investigate long-term durability (e.g., freeze-thaw resistance, fatigue performance) and the scalability of these optimized grouts in full-scale field trials. Exploring the cost–benefit analysis of these mixes would also be valuable for promoting their widespread adoption.

In summary, this work moves beyond isolated factor studies by providing a holistic optimization strategy that integrates macroscopic performance with microscopic understanding, offering significant guidance for the next generation of SFP materials.

Author Contributions

Administration, P.W.; writing—original draft, J.L.; editing, P.L.; Formal analysis, Z.J.; Investigation, F.G.; Supervision, C.W.; Validation, Y.Z.; All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Scientific Research Project of Gansu Provincial Department of Housing and Urban-Rural Development, “Research on Application Technology of Semi-Northwest China” (Grant No. 2025-2-98). The APC was funFlexible Anti-Rutting Pavement” (Grant No. JK2023-17); the Scientific Research Project of Gansu Provincial Department of Housing and Urban-Rural Development, “Research on Composition Design and Anti-Rutting Application Performance of Green Low-Carbon Polyurethane Mixture” (Grant No. JK2025-8); and the Lanzhou City Science and Technology Plan Project, “Research on Permanent Deformation Evolution Law and Service Performance of Low-Carbon Polyether Polyurethane Pavement under Complex Climatic Conditions”. The APC was funded by Cscec Aecom Consultants Co., Ltd.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Conflicts of Interest

Authors Ping Wu and Junjie Lin were employed by the company Cscec Aecom Consultants Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Cai, X.; Huang, W.; Wu, K. Study of the Self-Healing Performance of Semi-Flexible Pavement Materials Grouted with Engineered Cementitious Composites Mortar based on a Non-Standard Test. Materials 2019, 12, 3488. [Google Scholar] [CrossRef] [PubMed]

- Chinh, M.T.D.; Tuan, M.N. Investigating the qualities of grouting material used modifiers in the semi-flexible pavement. IOP Conf. Ser. Mater. Sci. Eng. 2023, 1289, 012059. [Google Scholar]

- Raza, S.M.; Sharma, K.S. Optimizing porous asphalt mix design for permeability and air voids using response surface methodology and artificial neural networks. Constr. Build. Mater. 2024, 442, 137513. [Google Scholar] [CrossRef]

- Albusaisi, K.M.; Al-Busaltan, S.F.; Kadhim, M.A. Characterizing the Mechanical Properties of Sustainable Modified Cementitious Grout for Semi-Flexible Mixture. IOP Conf. Ser. Earth Environ. Sci. 2021, 856, 012047. [Google Scholar] [CrossRef]

- Xu, Y.; Jiang, Y.; Xue, J.; Tong, X.; Cheng, Y. High-Performance Semi-Flexible Pavement Coating Material with the Microscopic Interface Optimization. Coatings 2020, 10, 268. [Google Scholar] [CrossRef]

- Fang, B.; Xu, T.; Shi, S. Laboratory Study on Cement Slurry Formulation and Its Strength Mechanism for Semi-Flexible Pavement. J. Test. Eval. 2016, 44, 907–913. [Google Scholar] [CrossRef]

- Liu, W.; Jiang, Y.; Zhao, Z.; Lei, F.; Li, H.; Jiao, X.; Wang, H. Optimal development of the new type of ultra-fine fly ash semi flexible pavement grouting material: Rheological, mechanical, pore distribution, and hydration characteristics. Constr. Build. Mater. 2024, 438, 137103. [Google Scholar] [CrossRef]

- Khan, M.N.; Khan, M.I.; Khan, J.H.; Ahmad, S.; Azfar, R.W. Exploring waste marble dust as an additive in cementitious grouts for semi-flexible pavement applications: Analysis and optimization using RSM. Constr. Build. Mater. 2024, 411, 134554. [Google Scholar] [CrossRef]

- Zhang, S.; He, Y.; Li, J.; Liu, L.; Cui, X. Preparation of potassium methylsilicate modified one-part alkali-activated slag grouting material and its effect on adhesion properties of semi-flexible pavement. Constr. Build. Mater. 2023, 366, 130139. [Google Scholar] [CrossRef]

- Tagba, M.; Li, S.; Jiang, M.; Gao, X.; Benmalek, M.L.; Boukour, S.; Liu, C. Performance Evaluation of Cementitious Composites Containing Granulated Rubber Wastes, Silica Fume, and Blast Furnace Slag. Crystals 2021, 11, 632. [Google Scholar] [CrossRef]

- Strzałkowski, J.; Stolarska, A.; Kożuch, D.; Dmitruk, J. Hygrothermal and strength properties of cement mortars containing cenospheres. Cem. Concr. Res. 2023, 174, 107325. [Google Scholar] [CrossRef]

- Arshad, M.T.; Ahmad, S.; Khitab, A.; Hanif, A. Synergistic Use of Fly Ash and Silica Fume to Produce High-Strength Self-Compacting Cementitious Composites. Crystals 2021, 11, 915. [Google Scholar] [CrossRef]

- Sun, Y.-Z.; Cheng, Y.-Y.; Ding, M.; Sun, C.-Z. Mix Proportion Design and Performance Study of Semi-Flexible Pavement Materials. Concrete 2019, 09, 124–131. [Google Scholar]

- Krishnaraj, L.; Ravichandran, P. Investigation on grinding impact of fly ash particles and its characterization analysis in cement mortar composites. Ain. Shams. Eng. J. 2019, 10, 267–274. [Google Scholar] [CrossRef]

- Zhang, J.; Cai, J.; Pei, J.; Li, R.; Chen, X. Formulation and performance comparison of grouting materials for semi-flexible pavement. Constr. Build. Mater. 2016, 115, 582–592. [Google Scholar] [CrossRef]

- Memon, F.A.; Nuruddin, M.F.; Shafiq, N. Effect of silica fume on the fresh and hardened properties of fly ash-based self-compacting eopolymer concrete. Int. J. Miner. Metall. Mater. 2013, 20, 205–213. [Google Scholar] [CrossRef]

- Cheng, P.; Ma, G.; Li, Y. Preparation and Performance Improvement Mechanism Investigation of High-Performance Cementitious Grout Material for Semi-Flexible Pavement. Polymers 2023, 15, 2631. [Google Scholar] [CrossRef]

- Huang, Z.; Liang, T.; Huang, B.; Zhou, Y.; Ye, J. Ultra-lightweight high ductility cement composite incorporated with low PE fiber and rubber powder. Constr. Build. Mater. 2021, 312, 125430. [Google Scholar] [CrossRef]

- Ekprasert, J.; Nakhonthong, N.; Sata, V.; Chainakun, P. Investigating the effects of superplasticizer and recycled plastics on the compressive strength of cementitious composites using neural networks. Heliyon 2023, 9, e21798. [Google Scholar] [CrossRef] [PubMed]

- Leong, G.W.; Mo, K.H.; Ibrahim, Z.; Radwan, M.K.; Ling, T.C.; Sinoh, S.S. Lightweight cementitious composites incorporating fly ash cenospheres and perlite microspheres. Constr. Build. Mater. 2023, 404, 133226. [Google Scholar] [CrossRef]

- Hanif, A.; Lu, Z.; Cheng, Y.; Diao, S.; Li, Z. Effects of Different Lightweight Functional Fillers for Use in Cementitious Composites. Int. J. Concr. Struct. Mater. 2017, 11, 99–113. [Google Scholar] [CrossRef]

- Yi, J.-Y.; Mao, Q.-Y.; Wang, D.-S.; Yu, J.; Nan, X.-F. Development and Performance Evaluation of Cement Paste for Semi-Flexible Concrete Pavement. J. Shenyang Jianzhu Univ. 2019, 35, 892–898. [Google Scholar]

- Sun, Y.; Cheng, Y.; Ding, M.; Yuan, X.; Wang, J. Research on Properties of High-Performance Cement Mortar for Semiflexible Pavement. Adv. Mater. Sci. Eng. 2018, 2018, 4613074. [Google Scholar] [CrossRef]

- Khan, M.I.; Sutanto, M.H.; Napiah, M.B.; Zahid, M.; Usman, A. Optimization of Cementitious Grouts for Semi-Flexible Pavement Surfaces Using Response Surface Methodology. IOP Conf. Ser. Earth Environ. Sci. 2020, 498, 012004. [Google Scholar] [CrossRef]

- GB 175-2007; Common Portland Cement. Standardization Administration of China: Beijing, China, 2007.

- GB/T 14684-2011; Sand for Construction. Standardization Administration of China: Beijing, China, 2011.

- CJJ/T 218-2014; Technical Specification for Grouting Semi-flexible Pavement of Urban Road. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2014.

- GB/T 1596-2017; Fly Ash Used for Cement and Concrete. Standardization Administration of China: Beijing, China, 2017.

- GB/T 27690-2011; Silica Fume for Cement Mortar and Concrete. Standardization Administration of China: Beijing, China, 2011.

- GB/T 8077-2012; Methods for Testing Uniformity of Concrete Admixture. Standardization Administration of China: Beijing, China, 2012.

- JTG 3420-2020; Testing Methods of Cement and Concrete for Highway Engineering. Ministry of Transport of the People’s Republic of China: Beijing, China, 2020.

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. Ministry of Transport of the People’s Republic of China: Beijing, China, 2011.

- Chang, X.-F.; Wang, Q.-D.; Hu, J.-L.; Sun, Y.; Chen, S.-J.; Gu, X.-F.; Chen, G. Preparation and Application of New Polyhydroxy Ammonium Shale Hydration Inhibitor. Processes 2023, 11, 3102. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).