Abstract

The aim of this study was to determine the effects of hygiene (H) and nano-color pigment (NCP) modifications on hardness, glossiness, and adhesion strength of some surface coating materials produced specifically for use in wooden toys. For this purpose, H- and NCP-modified polyurethane (PU) and waterborne (WBV) varnishes were applied to specimens prepared from Oriental beech (Fagus orientalis L.) and Oriental plane (Platanus orientalis L.) woods; Oriental beech, birch (Betula pendula), and poplar (Populus deltoides) plywood; and medium-density fiberboard (MDF). Then, hardness, glossiness, and adhesion values were determined. Results indicated that the highest values were obtained for hardness in PU and PU*NCP applied to MDF; for glossiness in WBV*H applied to birch plywood and MDF; and for adhesion strength in WBV and PU*H applied to beech. H and NCP modifications have significant effects on hardness, glossiness, and adhesion strength. As a result, it was determined that hardness and glossiness increased with H modification and decreased with NCP, especially glossiness. Furthermore, it was determined that H and NCP decreased the adhesion strength. Future studies comparing natural antibacterial effects of different wood species with various coating types will contribute to the development of products that are safe for children and sustainable.

1. Introduction

Toys are more than just entertainment for children; they are among the fundamental elements that directly contribute to their physical, cognitive, and psychological development. The educational and developmental functions of toys, especially in the preschool period, significantly impact children’s developmental milestones in later years. In this context, toys and games play a crucial role in early childhood education and support children’s holistic development. Developmental appropriateness and educational goals should be considered when selecting and using toys []. Therefore, criteria such as affordability, age-appropriateness, healthiness and safety of use, the type of materials used, and product quality play a decisive role in families’ toy selection. The COVID-19 pandemic has brought hygiene and microbial safety even more to the forefront of toy design and production. At the same time, the physical durability of the protective layers (paint and varnish) used on the surface of toys is also the subject of increased expectations regarding antimicrobial or hygienic properties. In this context, evaluating the performance of hygiene-added varnishes on toy surfaces stands out as an important area of research for protecting children’s health. However, the success of these varnishes depends on their ability to remain on the surface without deforming.

Children’s intense physical contact with toys, particularly in early childhood, and frequent mouthing or biting of these objects pose serious health risks. Such interactions facilitate the direct contact of pathogenic microorganisms with children’s bodies, increasing the risk of infection. The potential for disease-causing agents to spread on the surfaces of toys and similar items used in crowded environments such as schools, hospitals, and playgrounds is higher [,,].

Today, wood is the most commonly used material in the production of toys that meet toxicological requirements [], although polymer-based composite materials are also widely used. These materials are coated with various protective layers to extend their lifespan and improve their esthetic surface quality []. Considering children’s health, producing toys from natural wood and coating them with waterborne varnish systems is preferred. Furthermore, regardless of the type of coating, compliance with the Toy Safety Directives 2009/48/EC [] and EU 2021/903 [], as well as the relevant standards [,], is a fundamental requirement for the industry to ensure that children’s health is not at risk.

The antibacterial properties of wood can be characterized under two main headings: passive and active. Passive antibacterial activity stems from wood’s inherent porous structure and hygroscopic characteristics, which can physically limit the growth of microorganisms. In contrast, active antibacterial activity is associated with the biochemical inhibitory effects of extractive substances naturally present in wood cells against microorganisms []. However, it has been observed that many commercially available wood species lack suitable extractives, resulting in low or no active antibacterial properties [,]. Accordingly, giving antibacterial properties to varnishes and paints [] has become a necessity.

A company operating in the chemical industry has conducted R&D studies in previous years aimed at developing surface coatings with antimicrobial properties. Within the scope of these studies, it has also been reported that some bacteria (Staphylococcus aureus, Enterococcus faecalis, Bacillus cereus, Escherichia coli, Klebsiella pneumoniae, Shigella Flexneri, Pseudomonas aeruginosa) and yeast species (Candida parapsilosis, Candida krusei) cannot survive on the wet forms of these varnishes []. The antiviral activity of these varnishes was tested at the Virology Research Services Laboratory [], while their antibacterial and antifungal activities were examined at the Kazlıçeşme R&D Center and Laboratory, accredited by TÜRKAK []. The test results revealed that the examined material had no cytotoxic effect and did not affect the susceptibility of cells to infection. Based on these findings, it was determined that the product named Kubilay Antivirus Series ZA2 exhibited virucidal activity against human coronavirus NL63. The antiviral efficacy of this product was evaluated in accordance with the ISO 21702 standard [], and a significant reduction in viral load was observed after a 24 h contact period. The mean number of infectious viruses (TCID50/cm2) was determined as 16.1 for the treated material, while this value was measured as 199 for the control material. According to these results, the antiviral activity value (R) was calculated as 1.09, and since it met the criterion of R ≥ 1, the material was confirmed to exhibit antiviral activity [].

Some studies have reported that bacteria and viruses cannot survive on natural and organic wood materials [] and that this is due to the tree species [,,,,,,] and the extracts it contains [,,]. There is a widespread belief among the public that microbial contamination is lower on the surface of wooden spoons, and this reflects confidence in the natural hygienic properties of wooden materials. This perception contributes to the preference for wood-based toys over synthetic or composite-based alternatives. Accordingly, manufacturers have developed antibacterial and antimicrobial coating systems that can reduce the stabilization of pathogens on high-contact toy and wooden furniture surfaces [,,].

Nowadays, the fungi that are frequently encountered and have been found to cause disease include Candida krusei and Candida parapsilosis, while bacteria include Escherichia coli, Klebsiella pneumonia, Staphylococcus aureus, Enterococcus feacalis, Bacillus cereus, Shigella flexneri, and Pseudomonas aeruginosa. In some studies in the literature, Staphylococcus aureus bacteria have been detected on toys used in children’s hospitals []. With the addition of antimicrobial agents and nano-pigment, the growth of microorganisms is prevented in waterborne and polyurethane varnishes []. Synthetic varnishes modified with some nanomaterials confer higher hardness values compared to waterborne varnishes []. It has been reported that nano-boron-modified synthetic varnishes have lower antimicrobial activity than waterborne varnishes [].

The protective layers used in wooden toys are exposed to various physical and mechanical effects. Therefore, the protective layers must have high surface hardness and adhesion resistance []. Generally, hardness [,], adhesion, and glossiness [] are important indicators of varnish and paint performance. Hardness determines the resistance of toy surfaces, particularly against scratches and impacts, while glossiness determines the coating’s esthetic appeal and light reflectance. Adhesion is one of the critical parameters that expresses the bond strength of the coating to the wood surface. When these three properties are evaluated together, it is possible to carry out a holistic assessment of coating performance. However, the type of wood material, fiber direction, and surface roughness [,,], as well as the type of protective coating system and its chemical composition [], number of layers, and drying conditions [], significantly affect the results of hardness, gloss, and adhesion measurements [,]. The chemical composition of protective coatings being fluid and transparent generally enables the formation of high-gloss surfaces. Glossy surfaces are associated with high hardness, good adhesion, and strong resistance to chemical effects. However, when binders and additives are present in dispersion form, the surface gloss typically remains at a satin level []. In addition, the inclusion of pigments causes the distribution of colored particles within the coating layer, which reduces the mechanical strength of the coating; consequently, the hardness and adhesion properties tend to weaken [].

According to some studies in the literature related to this subject, the hardness values of waterborne varnishes are generally low [,]. It has been revealed that boric acid modification increases the hardness value in waterborne varnishes []; it has also been stated that waterborne varnishes provide lower hardness values compared to solvent-based systems []. Waterborne coatings with high contact angles provide better adhesion than solvent-based coatings []; borax pentahydrate modification increases the hardness and adhesion resistance of cellulose varnish []. Urea and antimony trioxide increases the adhesion resistance of a polyurethane-based opaque coating applied to poplar wood modified with acetic acid []. Tensile strength decreases on thermally modified Eastern beech surfaces when sepiolite mineral-modified waterborne paint is applied []. Waterborne coatings applied to MDF surfaces provide higher adhesion and impact resistance than solvent-based coatings []. It has also been reported that nanoparticle additives reduce surface adhesion strength [,]. Additionally, various factors such as resin content, density, and surface roughness may influence adhesion strength [,,,,,].

In some studies on gloss measurements, it has been observed that measurement angles of 20°, 60°, and 85° are used together to determine surface gloss. However, although it has been stated that the information obtained is limited [], it has been reported that the 60° measurement angle is commonly used [] and that it is mostly preferred for determining the surface gloss of wood materials [,]. The literature indicates that structural differences in varnishes and application methods influence gloss levels []; waterborne varnishes exhibit lower gloss values due to the surface roughness they cause on wooden materials [,], whereas UV-cured varnishes have been reported to show higher gloss values compared to waterborne varnishes [].

The pandemic has once again highlighted the importance of microbial spread through toys, particularly exposing children who cannot access new toys to health risks from existing ones. Consequently, determining which wood material can provide more effective protection with which varnish or paint system, and especially the development and performance measurement of new-generation systems with antimicrobial additives, has become a critical task in the industry. Accordingly, the aim of this study is to determine certain physical and mechanical properties of polyurethane (PU) and waterborne (WBV) protective coatings commonly utilized on wooden toy surfaces, as well as their modified versions with hygiene (H) and nano-color pigments (NCPs). In this context, it is hypothesized that the incorporation of hygiene agents and nano-color pigments into polyurethane and waterborne coating systems will preserve or improve key mechanical and surface properties such as hardness, adhesion strength, and glossiness compared to unmodified control samples.

2. Materials and Methods

2.1. Wooden Materials

In the study, wooden materials commonly used in the furniture and toy industries, including oriental beech (Fagus orientalis L.) and oriental plane (Platanus orientalis L.) solid woods, oriental beech, birch (Betula pendula), and poplar (Populus deltoides) plywoods, and medium-density fiberboard (MDF), were chosen as test materials. The selection of materials was influenced by the natural distribution of these wood species in the Sinop region in Türkiye, the continuous production of plywood in this area, and their use in local toy workshops. The materials were randomly obtained from commercial suppliers. Particular attention has been paid to the selection of materials to ensure they are of flawless and first-class quality.

Some physical and mechanical properties of the wood and wood-based materials were tested in accordance with the procedures described in TS ISO 13061-1 (2021) [], TSE EN 322 (1999) [], TS ISO 13061-2 (2021) [], and TSE EN 323 (1999) []. Average moisture content (MC) values were 7.87, 7.91, 7.99, 7.22, 7.87, and 5.63%, and density values were 0.66, 0.57, 0.68, 0.65, 0.49, and 0.82 g/cm3 for solid beech, solid plane, beech plywood, birch plywood, poplar plywood, and MDF, respectively.

2.2. Protective Coating Materials

Within the scope of the study, polyurethane and waterborne varnishes, widely used in the furniture industry and toy production in Türkiye, were chosen as protective surface coating materials. Red nano pigment was added to these varnishes to achieve the color. Polyurethane and waterborne varnishes and nano pigment were supplied by commercial companies. A commercial company produced the polyurethane and waterborne varnishes modified with antibacterial (hygiene) agents in 4 groups (WBV, PU, WBV*H, PU*H) specifically for this study. Then, these 4 groups of varnishes were modified with 5 percent red nano pigment by another commercial company specifically for this study as well. Thus, the number of groups increased to 8 (WBV*NCP, PU*NCP, WBV*H-NCP, PU*H-NCP). Due to the patented nature of the products supplied by the relevant companies, detailed information regarding the exact composition of the additives and the properties of the nano pigments used in the protective coatings has not been disclosed. However, it is known that the protective coatings have an organic structure, that the polyurethane resins used in their production are formulated to form dispersions in water, and that auxiliary substances such as matting and defoaming agents possess inorganic characteristics. The hygienic additives have been reported to consist of a combination of organic and inorganic compounds and to act as a commercial antimicrobial agent in aqueous dispersion form. The nano pigment, used to enhance the color stability of the surface, was specifically developed by the manufacturer for water-based systems and was reported to be homogeneously distributed within the resin matrices. Some technical specifications that were presented by the commercial company for the protective layer materials used are given in Table 1.

Table 1.

The properties of the protective surface coating materials used in this study.

2.3. Preparation of the Test Specimens

In this study, a total of 96 specimens (48 specimens with dimensions of 320 × 80 × 10 mm for hardness and glossiness tests, and 48 specimens also of 320 × 80 × 10 mm for adhesion strength tests) were prepared, consisting of 6 different wooden materials and 8 protective coatings. Hardness and glossiness tests were conducted on the same specimen surfaces, while other specimens were used for adhesion tests. Ten measurements were performed for each specimen. A total of 480 measurements were obtained for each test. After cutting the specimens to exact dimensions, the surfaces were first sanded with 180-grit and 220-grit sandpaper, respectively, to prepare them for varnishing. Varnishing was then carried out in accordance with the producer’s recommendations and TS EN ISO 28199-1 (2021) [] principles. The varnish was applied in two coats at 70 g/m2 using a spray gun with a 1.1 mm nozzle at a pressure of 2 atm under room temperature conditions (20 °C). Between the coats, the surfaces were sanded with 300-grit sandpaper to eliminate surface roughness. The varnished specimens were allowed to dry for three weeks at room temperature, parallel to the ground, away from direct sunlight. Afterwards, all test specimens were kept in the climate cabinet at 20 ± 2 °C and 50 ± 3% relative humidity until they reached constant weight. Since the paints and varnishes are intended for use on toys, the formation of thin coating layers was preferred. The coating thicknesses of the specimens were measured using a micrometer.

2.4. Hardness Measurements

Hardness measurements were carried out using an Onalkon BGD509 pendulum hardness tester (Onalkon, Bursa, Türkiye) in accordance with TS EN ISO 1522 (2022) []. Varnish layer hardness was determined by the König method using two metal balls with a hardness of 63 ± 3.3 HRC and a diameter of 5 ± 0.0005 mm on the test sample surface, based on pendulum oscillations between 3 and 6°. The measurements were made from the surfaces of the varnished specimens in the direction parallel to the grain, and the results were recorded in terms of the number of pendulum damping time seconds. Accordingly, a longer pendulum damping time indicates that the surface has a higher hardness.

2.5. Glossiness Measurements

Glossiness measurements were performed by using a gloss meter measuring at 60° in accordance with the principles of TS EN ISO 2813 (2014) []. As specified in the standard, while 20° or 85° measurement geometries are more suitable for high-gloss or matte coatings, respectively, the 60° geometry can be used for all types of coatings. The measurements were taken from the surfaces of the varnished specimens in the direction parallel to the grain, and the results were recorded in gloss units (GU).

2.6. Adhesion Strength

For the adhesion strength test, Ø20 mm diameter steel test cylinders were bonded to the surfaces of the specimens at room temperature (~20 °C), and the specimens were then left to cure for 24 h. A two-component epoxy-based, non-solvent adhesive was utilized and applied to the surfaces at 150 ± 10 g/m2. The adhesion strength of the specimens was determined using an adhesion tester according to TS EN ISO 4624 (2023) []. Adhesion strength (A) was calculated in (MPa) using the following formula:

where F = force at break (N); d = test cylinder diameter (mm). Adhesion strength values were recorded for each test; the specimens were visually examined and evaluated according to the type of fracture.

2.7. Design of the Experimental Models and Statistical Evaluation

A three-way multi-analysis of variance (MANOVA) general linear model procedure at a 5% significance level was performed for individual hardness, glossiness, and adhesion strength data one by one with the full models (Model 1, Model 2, and Model 3) to analyze main effects (wooden material, coating type, and modification) and interaction factors for the mean of the hardness, glossiness, and adhesion strength. The full linear models are as follows:

where Hijk = hardness (s); Gijk = glossiness (GU); Aijk = adhesion strength (MPa); μ1 = population mean hardness for all wooden material coating type–modification combinations (s); μ2 = population mean glossiness for all wooden material coating type–modification combinations (GU); μ3 = population mean adhesion strength for all wooden material coating type–modification combinations (MPa); Wi = discrete variable representing the effect of the wooden material; Cj = discrete variable representing the effect of the coating type; Mi = discrete variable representing the effect of modification; (W*C)ij, (W*M)ij, (C*M)ij = effect of interactions between the two variables; (W*C*M)ijk = effect of interaction between the three variables; ε = random error term; i = index for wooden material, 1…6; j = index for coating type, 1…2; k = index for modification, 1…4; l = index for the replications, 1…10. The least significant difference (LSD) multiple-comparison procedure at a 5% significance level was performed to determine the mean differences in hardness, glossiness, and adhesion strength values of the specimens considering the significant main effects and the three-factor interactions in the MANOVA results. Minitab (Version 17) statistical software was utilized for the statistical analyses (Minitab, LLC, State College, PA, USA).

3. Results and Discussion

3.1. Solid Content and Coating Thickness of Surface Coating Materials

The solid content of the waterborne and polyurethane varnishes used in the study, as well as varnishes with modified with hygiene agents and red nano pigments, was determined according to the principles of TS EN ISO 3251, 2019 []. The coating thicknesses of the samples were measured using a high-precision micrometer. Measurements were taken from different areas of each sample surface, and the arithmetic mean of the obtained values was calculated to determine the average coating thickness. The obtained results are given in Table 2.

Table 2.

Solid content (%) and coating thickness (µm) of the protective coating materials.

According to Table 2, significant differences are observed between the solid content of protective coating materials. In the WBV group, the solid content was 29.56%, but this value decreased to 29.35% with the addition of H and to 29.41% with the addition of NCP. In the WBV*H-NCP group, where both additives were used together, the solid content increased to 29.81%, the highest among the WBV groups. In the case of the PU varnish group, the solid content was significantly higher. The value for PU without modification was 39.80%, while with the addition of H additives, this value increased to 41.60%. While the NCP modification provided a limited increase of 40.39%, the PU*H-NCP group, where H and NCP were used together, achieved the highest solid content at 41.92%. Generally, PU varnishes contain higher solids than WBV; moreover, modification has an increasing effect on the solid content, especially in PU systems.

As shown in Table 2, significant differences were observed among the coating thicknesses of the protective coating materials. In the WBV group, the coating thickness was determined to be 19.40 µm; however, this value increased with the addition of H, NCP, and H-NCP additives. In the PU varnish group, the coating thickness was measured as 25.20 µm, and the addition of H and H-NCP additives caused an increase in thickness, while the addition of NCP alone did not result in a significant increase in coating thickness.

3.2. Experimental Results for the Hardness Values

The MANOVA results for the hardness values of the specimens are given in Table 3.

Table 3.

Results of the variance analysis for hardness values.

According to the results of MANOVA for hardness, the effects of the main factors of wooden material, coating type, and modification and all two-way interactions on the hardness values of the specimens were found to be statistically significant. The results of the three-way interaction were also statistically significant at a 5% significance level. According to these results, LSD comparison tests were performed for main factors, and a three-way interaction was found to be significant in the MANOVA. When the F-values in the MANOVA are analyzed, the effect of the protective coating type on the hardness of the specimens is much more significant than that of the material type or modification.

A comparison of the means of the effects of the main factors of wooden material, coating type, and modification, which were found to be statistically significant in the MANOVA, on the hardness values of the specimens is given in Table 4.

Table 4.

Comparison results for the main effects for mean hardness values.

Comparing the mean hardness values by wooden material type, the highest hardness value was measured in MDF (64.48 s). This was followed by birch PLY (56.73 s), beech PLY (56.51 s), and solid beech (56.46 s). Plane exhibited a lower hardness (53.60 s), while the lowest value was found in poplar PLY (50.20 s). These results demonstrate that wooden material is an important factor in the hardness values of the specimens. In particular, the high density and relatively homogeneous structure of MDF resulted in higher hardness compared to other wooden materials. Various studies in the literature have revealed that an increase in material density also leads to an increase in hardness values. This finding is consistent with the results obtained in the present study. Indeed, research conducted in previous studies [,,,] reported that as the density increases, the hardness resistance of the material also improves.

According to the results of a comparison of mean values by coating type, the specimens with PU varnish applied to their surfaces reached the highest hardness values, at 71.59 s. In contrast, the specimens with WBV applied to their surfaces had a hardness value of 41.07 s, significantly lower than that of the PU group. These results indicate that the PU varnishes, due to their structural properties, form a harder and more durable surface coating. Various studies in the literature have reported that the hardness values obtained in solvent-based systems are higher compared to those in waterborne systems [,]. This finding is also consistent with the results obtained in the present study.

The results of tests comparing the means for the modification factor indicated that regarding the effects of the modifications on hardness compared to the control group (56.28 s), the value increased to 58.14 s when the H additive was applied; a 3.3% increase was observed. Similarly, when H and NCP were used together, the hardness value was measured as 58.50 s, a 3.9% increase compared to the control group. In contrast, when only NCP was applied, the hardness values decreased to 52.41 s, a 6.9% decrease. Therefore, the use of H additive alone or in combination with NCP increased the hardness, while the use of NCP alone negatively affected the hardness of the wooden surface. Various studies in the literature have reported that certain modification additives can increase the hardness values in different varnish types [,] and the same is true for nanoparticle modification []. This finding is also partially consistent with the results obtained in the present study.

When the three main factors are assessed together, the parameter that most significantly influences the hardness is the coating type. PU varnishes provide significantly higher hardness compared to WBV. Furthermore, the wooden material is also an important determinant, with MDF and birch PLY notable for their high hardness values. Regarding the modification factor, a positive effect of H additives and a negative effect of NCP were observed. These results demonstrate that coating and modification choices directly affect the mechanical performance of wooden surface coatings.

The three-way interaction results for hardness values obtained as a result of the tests of specimens are given in Table 5, together with the coefficients of variation.

Table 5.

Comparison results for three-way interaction for mean hardness values.

According to Table 5, the highest hardness value was measured at 87.37 s in the MDF*PU*Control group, and the lowest hardness value was recorded at 27.53 s in the Poplar PLY*WBV*NCP group. Compared to the control group, the surface hardness of the polyurethane-coated MDF samples was approximately 217% higher than that of the WBV coated Poplar PLY specimens. This demonstrates the mechanical strength-enhancing effect of PU coatings and the critical role of the density of the MDF in hardness. On the other hand, a significant decrease in hardness (about 19%–20%, compared to the control groups) was observed in the Poplar PLY*WBV*NCP group. These findings demonstrate that the coating type, wooden material, and modification choices are conclusive factors in surface hardness, and they emphasize the importance of choosing high-density wooden materials with PU coatings, especially in applications requiring high hardness.

In general, the highest hardness values were obtained from the specimens coated with PU, whereas those coated with WBV exhibited lower hardness values. However, a direct comparison between these two types of varnishes may not be entirely appropriate. The most accurate approach is to evaluate each varnish within its own group. In this context, it was determined that the addition of H and NCP reduced the hardness in MDF, beech, plane, poplar PLY, and birch PLY specimens coated with PU varnish. For beech PLY specimens coated with PU, the addition of H decreased hardness, whereas NCP increased it. On the other hand, in MDF, beech, beech PLY, poplar PLY, and birch PLY specimens coated with WBV, the addition of H and H-NCP increased the hardness. Similarly, in plane specimens coated with WBV, the addition of H, NCP, and H-NCP enhanced the hardness. Except for plane wood, the use of NCP alone generally resulted in a decrease in hardness. According to the literature, some modification agents have been reported to increase the hardness values in different types of varnishes [,]. The reduction in hardness observed in PU varnishes may be related to the chemical structure of the resin or the varnish preparation methods. The decrease in hardness observed in PU varnishes may be related to the chemical structure of the resin or the varnish preparation methods. Kurtoğlu (2000) stated that modifying agents can reduce the mechanical strength of solvent-based coating layers []. In contrast, the increase in hardness observed in WBV can be attributed to the smaller molecular size of waterborne varnishes, which allows for better compatibility with nano-color pigments [].

3.3. Experimental Results: Glossiness Values

The multi-analysis of variance results regarding the glossiness values of the specimens are given in Table 6.

Table 6.

Results of the variance analysis for glossiness values.

According to the MANOVA results for glossiness values, the effects of the main factors included in the experiments and their two-way and three-way interactions on glossiness were found to be statistically significant with a 5% significance level, and the same was true for the hardness values. When the F-values are examined here, it can be seen that, as with the hardness values, the protective coating type is the most influential factor in glossiness. The modification factor was also determined to have a secondary effect. LSD comparison tests were performed for the main factors and their three-way interaction, and they were found to be significant in the MANOVA.

A comparison of the means of the effects of the main factors of wooden material, coating type, and modification, which were found to be statistically significant in the MANOVA in the glossiness values of the specimens, is given in Table 7.

Table 7.

Comparison results of the main effects for mean glossiness values.

The findings in Table 7 indicate that the glossiness values differ significantly across different wood species, coating types, and modification treatments. According to the results, MDF had the highest gloss (23.15 GU), followed by Birch PLY (20.17 GU) and Plane (20.16 GU). Poplar PLY had the lowest gloss (16.87 GU), indicating that MDF’s natural surface gloss was approximately 37% higher than Poplar PLY. When examining the effect of coating types, significant differences can be observed between WBV and PU varnishes. The glossiness value obtained with WBV varnish is 26.43 GU, while this value is measured as 12.81 GU with PU varnish. These results show that the PU varnish application provides approximately 52% lower glossiness compared to WBV. Therefore, it can be concluded that the coating type used has a significant effect on surface glossiness, with the WBV coating having a gloss-enhancing effect and the PU coating having a gloss-reducing effect. When modification applications were evaluated individually, it was determined that each group yielded different results compared to the control value. After hygiene (H) modification, the glossiness value increased by approximately 57% compared to the control specimens. In contrast, NCP modification reduced the glossiness value by approximately 4%. When H and NCP were applied together, a decrease of approximately 48% in the glossiness value was obtained. These findings prove that modification has different effects on glossiness; H modification has a gloss-enhancing effect, while NCP has a gloss-reducing effect, especially when applied in combination. Sönmez et al. (2011) reported that waterborne varnishes negatively affect surface smoothness, thereby reducing the gloss of the coating layer; however, this finding does not correspond with the results of the present study []. Nevertheless, it is also known that structural differences among varnishes can have a decisive influence on gloss []. The presence of NCP additives in dispersion form may have influenced the gloss. Kurtoğlu (2000) reported that when additives are in dispersion form, the surface gloss generally remains at a silky (satin) level [].

The three-way interaction results of glossiness values obtained as a result of the tests of specimens are given in Table 8 together with the coefficients of variation.

Table 8.

Comparison results for three-way interaction for mean glossiness values.

Based on the data in Table 8, the highest glossiness values were obtained with the combination of WBV coating and H modification. In particular, the Birch PLY*WBV*H, MDF*WBV*H, and Plane*WBV*H groups are the most successful in terms of surface glossiness, with the values of 56.27 GU, 56.01 GU, and 49.35 GU, respectively. This finding shows that the combined use of WBV coating and H modification is highly effective in increasing glossiness. In contrast, the lowest glossiness values were observed in the PU coating with NCP modification or the WBV*H-NCP combination. For example, the Poplar PLY*WBV*H-NCP (7.93 GU), Beech PLY*WBV*H-NCP (8.33 GU), and Poplar PLY*PU*NCP (8.59 GU) groups yielded the most unsatisfactory results in terms of glossiness. This indicates that NCP modification has a strongly reducing effect on glossiness, especially when used in combination. These findings emphasize that coating and modification choices play a critical role in surface quality. The literature has reported that inorganic pigments have a reducing effect on the gloss values of protective coatings []. Although the literature indicates that nano-sized pigments provide high gloss in transparent coatings [], the opposite occurred in this study.

3.4. Experimental Results: Adhesion Strength

The MANOVA results for the adhesion strength values are given in Table 9.

Table 9.

Results of the variance analysis for adhesion strength values.

According to the MANOVA results for adhesion strength values, the effects of the main factors contained within in the experiments and their two-way and three-way interactions on adhesion strength were found to be statistically significant with a 5% significance level, in the same way as the hardness and glossiness values. When the F-values in the MANOVA are analyzed, this time effect of wooden material on adhesion strength of the specimens is much more significant than the coating type and modification. LSD comparison tests were performed for the main factors and their three-way interaction, which were found to be significant in the MANOVA.

A comparison of the means of the effects of the main factors, which were found statistically significant in the MANOVA on the adhesion strength values of the specimens, is given in Table 10.

Table 10.

Comparison results for the main effects for mean adhesion strength values.

Beech wood (5.42 MPa) exhibited the highest adhesion strength, approximately 241% higher than MDF (1.59 MPa). Among the PLY types, birch PLY (24% lower), beech PLY (39% lower), and poplar PLY (61% lower) achieved weaker results compared to beech wood. This suggests that high-density solid woods offer more favorable surface properties for creating a protective layer, while lower-density materials have disadvantages in terms of adhesion. Comparing the coating types, WBV (3.57 MPa) provided approximately 11% higher adhesion strength than PU varnish (3.21 MPa). This difference may be due to WBV’s better penetration into pores, facilitating chemical bond formation. Therefore, waterborne systems can be said to have advantages over PU-based coatings in terms of adhesion strength. Compared to the control group (3.63 MPa), only the H modification (9% decrease) and the H-and-NCP combination (14% decrease) reduced the adhesion strength value. In contrast, the application of NCP alone maintained the coating adhesion strength, giving results close to the control value (3% lower). The combined application of H and NCP, in particular, had a negative effect, leading to weakened adhesion. A similar situation has been reported, where inorganic pigments added to protective coatings cause a gradual decrease in adhesion strength [].

Overall, the findings suggest that adhesion strength varies significantly depending on the wood species, the protective coating type, and the modification applied. These results demonstrate that both the material and coating selection, as well as the modification type, play a significant role in adhesion strength.

The three-way interaction results for adhesion strength values obtained as a result of the tests of specimens are given in Table 11, together with the coefficients of variation.

Table 11.

Comparison results for three-way interaction for mean adhesion strength values.

Table 11 shows that the Beech*WBV*Control group exhibited the highest adhesion strength value (8.27 MPa), while the Poplar PLY*WBV*Control specimens exhibited the lowest (1.08 MPa). The high performance of the solid beech control group can be explained by its density and uniform fiber structure, while the low values in the poplar plywood control group can be attributed to its low density and heterogeneous surface properties. These differences can be further explained by the influence of the additive type and surface properties on coating performance.

When the effects of H and NCP additives on waterborne varnish and polyurethane varnish (PU) systems applied to different wood-based surfaces were examined, variations in adhesion behavior were observed depending on the type of additive and surface characteristics. It was determined that H and NCP additives decreased the surface adhesion strength of WBV applied to MDF, beech, plane, and birch plywood (PLY) specimens, whereas they increased the adhesion strength in poplar plywood (PLY) specimens. On the other hand, the same additives reduced the adhesion of PUV applied to poplar and plane specimens, while generally increasing the adhesion of PUV applied to MDF, beech, beech plywood, and birch plywood specimens.

Overall, solid beech stands out as the material with the strongest adhesion strength, while the MDF and poplar PLY specimens were the weakest. These findings once again demonstrate that material selection is a critical factor in coating performance. In the literature, it has been reported that nanoparticle additives cause variations in surface adhesion strength values depending on the type of varnish []. Furthermore, it has been stated that nanoparticle additives affect adhesion strength by reducing the initial bonding of the varnish during film formation [] and that inorganic pigments lead to a gradual decrease in adhesion strength []. Nevertheless, several studies have demonstrated that waterborne varnishes generally exhibit good adhesion performance [,,]. These findings are consistent with the results of the present study.

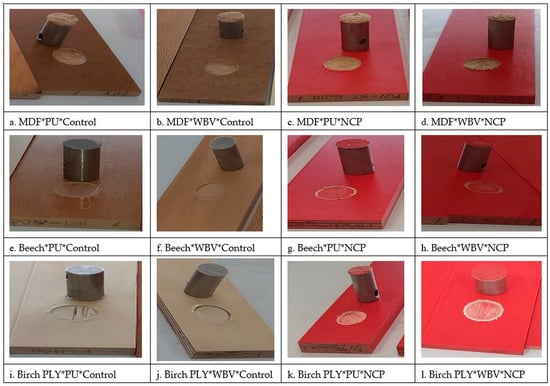

In addition to adhesion strength data, the fracture types of coatings on different substrates were also evaluated. The typical failure appearances obtained during pull-off adhesion testing of coated specimens are summarized in Figure 1.

Figure 1.

Photographs of some specimens tested for adhesion.

The adhesion test results revealed distinct failure characteristics depending on the coating type and substrate. PU coated specimens generally exhibited substrate or cohesive failures, indicating strong adhesion between the coating and the substrate, particularly evident in MDF and birch plywood specimens. In contrast, WBV coatings predominantly showed adhesive failures, suggesting weaker interfacial bonding.

In MDF specimens (Figure 1a–d), fracture typically occurred within the inner part of the substrate in a hollow and complete manner. In beech specimens (Figure 1e–h), detachment occurred from the coating surface in very small fragments, while in plane plywood (PLY) specimens (Figure 1i–l), partial and strip-shaped separations were observed. In general, residues of both adhesive and protective coating layers were detected on the surface of all detached steel pull-off studs. Particularly in MDF specimens, approximately 2 mm thick wood fibers were observed on the stud surface. This indicates that the measured forces in MDF specimens reflect substrate fracture strength rather than true adhesion strength.

4. Conclusions

This study was conducted to examine the effects of hygiene (H) and nano-color pigment (NCP) modifications on the hardness, glossiness, and adhesion strength of polyurethane (PU) and waterborne varnishes (WBVs) produced for use in wooden toys. For this purpose, experiments were conducted on oriental beech and oriental plane wood, as well as oriental beech, birch, and poplar plywood, and on medium-density fiberboard specimens, which are the most commonly used materials in wooden toy production. The findings revealed that surface properties varied depending on both the type of wood and the coating material. It was determined that H and NCP modifications had significant effects on the performance of PU and WBV coatings, indicating that the selection of an appropriate modification type should be carefully considered based on the desired properties in toy applications.

It was determined that the hygiene additive (H) generally increased the hardness resistance of PU and WBV layers, while the H-NCP combination exhibited similar positive effects. In contrast, the use of NCP alone caused a slight decrease in hardness values. These results indicate that the use of H, NCP, and H-NCP additives may provide advantages for manufacturers in wooden toy production.

No issues were identified regarding the use of any of the wood types employed in this study for toy production. The wood materials used were found to have sufficient hardness levels; however, it should be noted that poplar plywood specimens were softer compared to the others. If hardness is a priority in selecting a protective coating, PU varnish (PU) should be preferred; if health is the main concern, waterborne varnish (WBV) would be more suitable. Indeed, paints and coatings used in toys must comply with the EN 71-3 (Toy Safety–Chemical Properties) standard []. Therefore, to protect children’s health, it is highly important for parents to support the use of protective surface coatings with antimicrobial properties, especially waterborne systems.

In cases where glossiness is an important factor, all tested wood materials can be used; however, WBV coatings would be the more appropriate choice. When adhesion is a critical property, the intended purpose of the toy should be considered, and the protective coating should be selected accordingly. Although additives do not have a strong effect on adhesion, for toys exposed to higher mechanical stress, all wood types except MDF and poplar plywood can be considered suitable.

In conclusion, this study serves as a guide for the selection of wood types and surface coatings for use in toy production. Future research comparing the natural antibacterial properties of different wood species with various coating types is expected to contribute to the development of safe, child-friendly, and sustainable products.

Author Contributions

Conceptualization, R.A. and H.İ.K.; methodology, R.A. and H.İ.K.; software, R.A. and H.İ.K.; validation, R.A. and H.İ.K.; formal analysis, R.A. and H.İ.K.; investigation, R.A. and H.İ.K.; resources, R.A. and H.İ.K.; data curation, R.A. and H.İ.K.; writing—original draft preparation, R.A.; writing—review and editing, H.İ.K.; visualization R.A.; supervision, H.İ.K.; project administration, H.İ.K.; funding acquisition, R.A. and H.İ.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

This study was derived from the doctoral thesis entitled “Assessing Wooden Toys’ Production in Türkiye through Supply Chain Management Prism” by Recep Aykan conducted under the supervision of Hacı İsmail Kesik at Kastamonu University, The Institute of Science, Forest Industrial Engineering Department. We thank Kubilay Boya Ltd., Company and Kimetsan Chemistry Mining Metallurgy Industry Consulting Engineering Domestic and Foreign Trade Limited Company for their support.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Alotaibi, M.S. Game-based learning in early childhood education: A systematic review and meta-analysis. Front. Psychol. 2024, 15, 1307881. [Google Scholar] [CrossRef]

- Aykan, R.; Avşar, C.; Bilgiç, M.B.; Kesik, H.İ. Determining the Effects of Some Bacteria on Wooden Toys Treated with Antibacterial Protective Coatings. BioResources 2022, 17, 5655–5666. [Google Scholar] [CrossRef]

- Aleksejeva, V.; Dovbenko, A.; Kroiča, J.; Skadiņš, I. Toys in the playrooms of children’s hospitals: A potential source of nosocomial bacterial infections? Children 2021, 8, 914. [Google Scholar] [CrossRef]

- Ibfelt, T.; Engelund, E.H.; Schultz, A.C.; Andersen, L.P. Effect of cleaning and disinfection of toys on infectious diseases and micro-organisms in daycare nurseries. J. Hosp. Infect. 2015, 89, 109–115. [Google Scholar] [CrossRef] [PubMed]

- Onur, Ş.; Öndoğan, E.N. A Study in Modular Wooden Kids Playhouse Design and Development. TJFMD 2020, 3, 97–110. [Google Scholar]

- Budakçi, M.; Sonmez, A. Determining adhesion strength of some wood varnishes on different wood surfaces. J. Fac. Eng. Arch. Gazi Univ. 2010, 25, 111–118. [Google Scholar]

- URL 1, Avrupa Parlamentosu ve Konseyi. Directive 2009/48/EC on the Safety of Toys. Official Journal of the European Union, 2009, L 170. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32009L0048 (accessed on 23 September 2025).

- URL 2, Avrupa Birliği Komisyonu. Commission Directive (EU) 2021/903 of 3 June 2021 Amending Directive 2009/48/EC of the European Parliament and of the Council as Regards Specific Limit Values for Aniline in Certain Toys. Official Journal of the European U. Available online: https://eur-lex.europa.eu/eli/dir/2021/903/oj/eng (accessed on 23 September 2025).

- TS EN 71-3+A2:2025-01; Safety of Toys—Part 3: Migration of Certain Elements [TS EN 71-3:2019+A2:2024]. TSE: Ankara, Türkiye, 2025.

- TS EN 71-9+A1:2013-12; Safety of Toys—Part 9: Organic Chemical Compounds—Requirements (Replaces EN 71-9:2005+A1:2007). TSE: Ankara, Türkiye, 2013.

- Özkan, O.E. Ahşap malzemede aktif anti-bakteriyel özelliklerin defne ve kekik ekstraktları ile artırılması. Orman. Araştırma Derg. 2022, 9, 207–211. [Google Scholar] [CrossRef]

- Tomicic, R.; Tomicic, Z.; Raspor, P. Adhesion of Candida spp. and pichia spp. to wooden surfaces. Food Technol. Biotechnol. 2017, 55, 138–142. [Google Scholar] [CrossRef]

- Munir, M.T.; Pailhories, H.; Eveillard, M.; Irle, M.; Aviat, F.; Dubreil, L.; Federighi, M.; Belloncle, C. Testing the antimicrobial characteristics of wood materials: A review of methods. Antibiotics 2020, 9, 12–16. [Google Scholar] [CrossRef]

- Özder, C.; Atar, M. Bazı Antibakteriyel Nano Malzemelerin Vernik Katman Sertliğine Etkileri. Politek. Derg. 2023, 26, 1705–1714. [Google Scholar] [CrossRef]

- Virology Research Services Ltd. Testing the virucidal activity of Kubilay Antivirus Seri ZA2 (888-2893) against human coronavirus NL63 using ISO21702 [Report]. Kubilay Kimya ve Boya San. Tic. Ltd. Sti. 2022. Available online: https://www.ecotouchpoint.com/wp-content/uploads/2022/03/Eco-TouchPoint_Virology-Research-Services_Page-4-17A.pdf (accessed on 23 September 2025).

- URL 3, Kubilay Kimya ve Boya San. Tic. Ltd. Şti. Kubilay Ultra Hygiene Seri: Ahşap Boyama Sistemlerinde Dünya’da İlk ve Tek Antiviral, Antibakteriyel, Antifungal [Broşür], 2020, İzmir, Türkiye. Available online: https://kubilayboya.com/wp-content/uploads/2020/11/UltraHygieneSeri-yeni.pdf (accessed on 23 September 2025).

- ISO 21702:2019; Measurement of Antiviral Activity on Plastics and Other Non-Porous Surfaces. International Organization for Standardization: Geneva, Switzerland, 2019. Available online: https://cdn.standards.iteh.ai/samples/71365/2308a94aa39744c1b02ad44847bb942f/ISO-21702-2019.pdf (accessed on 23 September 2025).

- Usta, P.İ. Okul Öncesi Çocukluk Algısında Genç Yetişkinlerin Ahşap Oyuncak Seçimi Young Adults ’ Choices of Wooden Toys Within the Perception of Preschool Childhood. 1980. Available online: https://dergipark.org.tr/tr/pub/mbd/issue/40281/441728 (accessed on 23 September 2025).

- Ak, N.O.; Cliver, D.O.; Kaspar, C.W. Cutting Boards of Plastic and Wood Contaminated Experimentally with Bacteria. J. Food Prot. 1994, 57, 16–22. [Google Scholar] [CrossRef]

- Schönwälder, A.; Kehr, R.; Wulf, A.; Smalla, K. Wooden boards affecting the survival of bacteria? Holz Als Roh-Und Werkst. 2002, 60, 249–257. [Google Scholar] [CrossRef]

- Milling, A.; Kehr, R.; Wulf, A.; Smalla, K. Survival of bacteria on wood and plastic particles: Dependence on wood species and environmental conditions. Holzforschung 2005, 59, 72–81. [Google Scholar] [CrossRef]

- Milling, A.; Smalla, K.; Kehr, R.; Wulf, A. The use of wood in practice—A hygienic risk? Holz Roh Werkst 2005, 63, 463–472. [Google Scholar] [CrossRef]

- Vainio-Kaila, T.; Rautkari, L.; Nordström, K.; Närhi, M.; Natri, O.; Kairi, M. Effect of extractives and thermal modification on antibacterial properties of Scots pine and Norway spruce. Int. Wood Prod. J. 2013, 4, 248–252. [Google Scholar] [CrossRef]

- Kavian-Jahromi, N.; Schagerl, L.; Dürschmied, B.; Enzinger, S.; Schnabl, C.; Schnabel, T.; Petutschnigg, A. Comparison of the antibacterial effects of sapwood and heartwood of the larch tree focusing on the use in hygiene sensitive areas. Eur. J. Wood Wood Prod. 2015, 73, 841–844. [Google Scholar] [CrossRef]

- Chen, J.-C.; Munir, M.T.; Aviat, F.; Lepelletier, D.; Le Pape, P.; Dubreil, L.; Irle, M.; Federighi, M.; Belloncle, C.; Eveillard, M.; et al. Survival of Bacterial Strains on Wood (Quercus petraea) Compared to Polycarbonate, Aluminum and Stainless Steel. Antibiotics 2020, 9, 804. [Google Scholar] [CrossRef]

- Johnston, W.H.; Karchesy, J.J.; Constantine, G.H.; Craig, A.M. Antimicrobial activity of some Pacific Northwest woods against anaerobic bacteria and yeast. Phyther. Res. 2001, 15, 586–588. [Google Scholar] [CrossRef]

- Välimaa, A.L.; Honkalampi-Hämäläinen, U.; Pietarinen, S.; Willför, S.; Holmbom, B.; von Wright, A. Antimicrobial and cytotoxic knotwood extracts and related pure compounds and their effects on food-associated microorganisms. Int. J. Food Microbiol. 2007, 115, 235–243. [Google Scholar] [CrossRef] [PubMed]

- Ateş, S.; Gür, M.; Özkan, O.E.; Akça, M.; Olgun, Ç.; Güder, A. Wood extractives vs. decay. BioResources 2015, 10, 2433–2443. [Google Scholar]

- Galinari, É.; da Nóbrega, J.E.; de Andrade, N.J.; Ferreira, C.L. de L.F. Microbiological aspects of the biofilm on wooden utensils used to make a Brazilian artisanal cheese. Braz. J. Microbiol. 2014, 45, 713–720. [Google Scholar] [CrossRef]

- Knetsch, M.L.W.; Koole, L.H. New strategies in the development of antimicrobial coatings: The example of increasing usage of silver and silver nanoparticles. Polymers 2011, 3, 340–366. [Google Scholar] [CrossRef]

- Nasri, N.; Rusli, A.; Teramoto, N.; Jaafar, M.; Ku Ishak, K.M.; Shafiq, M.D.; Abdul Hamid, Z.A. Past and Current Progress in the Development of Antiviral/Antimicrobial Polymer Coating towards COVID-19 Prevention: A Review. Polymers 2021, 13, 4234. [Google Scholar] [CrossRef] [PubMed]

- Özder, C.; Atar, M.; Atılgan, A. Determination of the Antimicrobial Effect of Varnishes Modified with Nano Particles on the Surface of Wood Materials. Bioresour. 2024, 19, 8935–8946. [Google Scholar] [CrossRef]

- Kesik, H.I.; Akyildiz, M.H. Effect of the heat treatment on the adhesion strength of water based wood varnishes. Wood Res. 2015, 60, 987–994. [Google Scholar]

- Kaygin, B.; Akgun, E. Comparison of conventional varnishes with nanolacke UV varnish with respect to hardness and adhesion durability. Int. J. Mol. Sci. 2008, 9, 476–485. [Google Scholar] [CrossRef]

- Wang, F.; Morsali, M.; Rižikovs, J.; Pylypchuk, I.; Mathew, A.P.; Sipponen, M.H. Fully bio-based water-resistant wood coatings derived from tree bark. Mater. Horiz. 2024, 11, 6504–6515. [Google Scholar] [CrossRef]

- Kurtoğlu, A. Ağaç Malzeme Yüzey İşlemleri 1. Cilt Genel Bilgiler; İ.Ü. Orman Fakültesi: İstanbul, Türkiye, 2000. [Google Scholar]

- Altun, S.; Esmer, M. Isıl İşlemin Bazı Ağaç Malzemelerde Yüzey Pürüzlülüğü ve Vernik Yapışma Direncine Etkisi The Effect of Heat Treatment on The Surface Roughness and Varnish Adhesion of Wood. Politek. Derg. 2017, 20, 231–239. [Google Scholar]

- Salca, E.A.; Krystofiak, T.; Lis, B.; Hiziroglu, S. Glossiness evaluation of coated wood surfaces as function of varnish type and exposure to different conditions. Coatings 2021, 11, 558. [Google Scholar] [CrossRef]

- Sönmez, A.; Budakçi, M.; Yakin, M. Ağaç Malzemede Su Çözücülü Vernik Uygulamalarının Sertlik, Parlaklık ve Yüzeye Yapışma Direncine Etkileri. Politek. Derg. 2004, 7, 229–235. [Google Scholar]

- Çakicier, N.; Korkut, S.; Korkut, D.S.; Kurtoǧlu, A.; Seda Erdinler, E.; Ulay, G. The effects of protective dye layer applied on varnish layer hardness, scratch resistance and glossiness of various blockboard types. Afr. J. Agric. Res. 2011, 6, 2303–2308. [Google Scholar] [CrossRef]

- Salca, E.A.; Krystofiak, T.; Lis, B.; Mazela, B.; Proszyk, S. Some coating properties of black alder wood as a function of varnish type and application method. BioResources 2016, 11, 7580–7594. [Google Scholar] [CrossRef]

- Sönmez, A.; Budakçı, M. Ağaçişlerinde Üstyüzey Işlemleri Koruyucu Katman ve Vernik Sistemleri; Gazi Üniversitesi Teknik Eğitim Fakültesi: Ankara, Türkiye, 2004. [Google Scholar]

- Ulay, G.B.M. Studies Carried Out in Turkey Regarding Water-based Varnishes Used on Wood Surfaces. Düzce Üniversitesi Bilim Ve Teknol. Derg. 2015, 3, 470–480. [Google Scholar]

- Miklečić, J.; Turkulin, H.; Jirouš-Rajković, V. Weathering performance of surface of thermally modified wood finished with nanoparticles-modified waterborne polyacrylate coatings. Appl. Surf. Sci. 2017, 408, 103–109. [Google Scholar] [CrossRef]

- Ozalp, M. The investigation of borax pentahydrate influences with double components in varnish applications of wood materials. Wood Res. 2008, 53, 121–128. [Google Scholar]

- Liu, Q.; Gao, D.; Xu, W. Effect of Polyurethane Non-Transparent Coating Process on Paint Film Performance Applied on Modified Poplar. Coatings 2022, 12, 39. [Google Scholar] [CrossRef]

- Taghiyari, H.R.; Antov, P.; Soltani, A.; Ilies, D.C.; Nadali, E.; Lee, S.H.; Grama, V.; Simona, T. Effects of sepiolite addition to acrylic-latex paint on pull-off adhesion strength in nanosilver-impregnated and thermally-modified beech (Fagus orientalis L.) wood. Sci. Rep. 2024, 14, 4168. [Google Scholar] [CrossRef] [PubMed]

- Hazir, E.; Koc, K.H. Evaluation of wood surface coating performance using water based, solvent based and powder coating. Maderas Cienc. Y Tecnol. 2019, 21, 467–480. [Google Scholar] [CrossRef]

- Karamanoğlu, M.; Kesik, H.İ. Factors affecting some properties on surface of thermowood material applied with water-based varnishes modifed with nanoparticles. Cerne 2021, 27, 12886. [Google Scholar] [CrossRef]

- Budakçı, M.; Korkmaz, M.; Karal, İ. Antifungal Effects of Staining Process on Wood: Hardness, Gloss, and Color Change. BioResources 2023, 18, 302–316. [Google Scholar] [CrossRef]

- Söğütlü, C.; Nzokou, P.; Koc, I.; Tutgun, R.; Döngel, N. The effects of surface roughness on varnish adhesion strength of wood materials. J. Coat. Technol. Res. 2016, 13, 863–870. [Google Scholar] [CrossRef]

- Atar, M.; Cinar, H.; Dongel, N.; Yalinkilic, A.C. The Effect of Heat Treatment on the Pull-off Strength of Optionally Varnished Surfaces of Five Wood Materials. BioResources 2015, 10, 7151–7164. [Google Scholar] [CrossRef]

- Demirci, Z.; Sönmez, A.; Budakçi, M. Effect of thermal ageing on the gloss and the adhesion strength of the wood varnish layers. BioResources 2013, 8, 1852–1867. [Google Scholar] [CrossRef]

- Budakçi, M.; Saygin, E.; Şenol, S. Effect of resin cleaning process on adhesion strength of water-based varnishes. BioResources 2019, 14, 1317–1332. [Google Scholar] [CrossRef]

- Farrier, L.M. Influence of Surface Roughness on the Specular Reflectance of Low Gloss Coatings Using Bidirectional Reflectance Measurements. Master’s Thesis, Air Force Research Laboratory, University of Dayton, Dayton, OH, USA, 2006. [Google Scholar]

- Lu, T.; Zhou, Y.; Liu, Y.; Xin, B.; Qin, Y.; Kuang, G. Preparation and performance study of GLC/TMP double crosslinking modified waterborne polyurethane for wood coatings. J. Coat. Technol. Res. 2025, 22, 385–396. [Google Scholar] [CrossRef]

- Pelit, H.; Budakçı, M.; Sönmez, A.; Burdurlu, E. Surface roughness and brightness of scots pine (Pinus sylvestris) applied with water-based varnish after densification and heat treatment. J. Wood Sci. 2015, 61, 586–594. [Google Scholar] [CrossRef]

- Sönmez, A.; Budakçi, M.; Pelit, H. The effect of the moisture content of wood on the layer performance of water-borne varnishes. BioResources 2011, 6, 3166–3177. [Google Scholar] [CrossRef]

- TS ISO 13061-1; Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens—Part 1: De-termination of Moisture Content for Physical and Mechanical Tests. TSE: Ankara, Türkiye, 2021.

- TS EN 322; Wood-Based Panels—Determination of Moisture Content. TSE: Ankara, Türkiye, 1999.

- TS ISO 13061-2; Physical and Mechanical Properties of Wood—Test Methods for Small Clear Wood Specimens—Part 2: Determination of Density for Physical and Mechanical Tests. TSE: Ankara, Türkiye, 2021.

- TSE EN 323; Wood-Based Panels—Determination of Density. TSE: Ankara, Türkiye, 1999.

- TS EN ISO 28199-1; Paints and Varnishes—Evaluation of Properties of Coating Systems Related to the Spray Application Process—Part 1: Vocabulary and Preparation of Test Panels. TSE: Ankara, Türkiye, 2021.

- TS EN ISO 1522; Paints and Varnishes—Pendulum Damping Test. TSE: Ankara, Türkiye, 2022.

- TS EN ISO 2813; Paints and Varnishes—Determination of Gloss Value at 20 Degrees, 60 Degrees and 85 Degrees. TSE: Ankara, Türkiye, 2014.

- TS EN ISO 4624; Paints and Varnishes—Pull-Off Test for Adhesion. TSE: Ankara, Türkiye, 2023.

- TS EN ISO 3251; Paints, Varnishes and Plastics—Determination of Non-Volatile-Matter Content. TSE: Ankara, Türkiye, 2019.

- Xu, C.; Xing, C.; Pan, H.; Matuana, L.M.; Zhou, H. Hygrothermal aging properties of wood plastic composites made of recycled high density polypropylene as affected by inorganic pigments. Polym. Eng. Sci. 2015, 55, 2127–2132. [Google Scholar] [CrossRef]

- Stark, W.J.; Stoessel, P.R.; Wohlleben, W.; Hafner, A. Industrial applications of nanoparticles. Chem. Soc. Rev. 2015, 44, 5793–5805. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, K.; Yang, J.; Zhang, X.; Chen, D.; Yang, Z. Effects of inorganic pigments on color and accelerated weathering of wheat straw fiber /polyvinyl chloride composites. J. Mater. Sci. 2024, 59, 19524–19539. [Google Scholar] [CrossRef]

- Budakçi, M.; Sönmez, A.; Pelit, H. The color changing effect of the moisture content of wood materials on water borne varnishes. BioResources 2012, 7, 5448–5459. [Google Scholar] [CrossRef]

- Vitosyto, J.; Ukvalbergieno, K.; Keturakis, G. The effects of surface roughness on adhesion strength of coated ash (Fraxinus excelsior L.) and Birch (Betula L.) wood. Medziagotyra 2012, 18, 347–351. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).