Abstract

In order to study the effect of calcium sulfate whiskers and calcium carbonate whiskers on the road performance of asphalt mixtures, the high temperature stability, low temperature performance, and the change of water stability, the effect of two whiskers with different dosage levels on the road performance of asphalt mixture was obtained. The test results show that the calcium carbonate whiskers can improve the high temperature stability and water stability of the asphalt mixture within a certain dosage level range, but the low temperature performance has no obvious improvement effect, and adding excessive calcium carbonate whiskers will reduce the low temperature performance. The addition of calcium sulfate whiskers can significantly improve the road performance of the asphalt mixture. Under the same dosage level, the effect of calcium sulfate whiskers in improving road performance is better than that of calcium carbonate whiskers. When the content of calcium sulfate whisker is 0.4%, the road performance improvement effect of asphalt mixture is the best.

1. Introduction

The asphalt pavement has the advantages of good road flatness, low driving noise, short construction period, simple maintenance, renewable use, and so on. It is widely used on highways in China, and it is the main road type of highway in our country [1]. As a thermosensitive material, the physical properties of asphalt are very sensitive to changes in temperature, and its strength will decrease with the increase of temperature, and when the temperature is too low, asphalt is prone to brittle cracking [2]. With the development of highway vehicles, the appearance of various large buses and trucks makes the traffic load situation become complex and changeable, which makes the early damage to asphalt pavement become an inevitable problem for our road researchers.

The emergence of modifiers has improved the road performance of asphalt mixtures. At this stage, fiber materials are widely used in the field of improving the road performance of asphalt mixtures. Fiber materials are diverse, and their performance is also different. In improving the high temperature performance, low temperature performance, and water stability of asphalt mixtures, different fiber materials have their own advantages and disadvantages [3]. Kamil et al. and Ferrotti et al. tested and studied the influence of fiber materials on the road performance of asphalt mixture and found that fiber materials can improve the road performance of asphalt mixture [4,5]. Therefore, the development of low-cost, high performance, energy saving, and environmentally sustainable fiber material modifiers has become a research hotspot.

Calcium sulfate whisker is a fibrous single crystal, white and fluffy, with high strength, high modulus, good durability, resistance to high temperature, and other excellent properties [6]. The published literature has shown that the incorporation of calcium sulfate whisker into asphalt mixture as a modifier can improve the high temperature performance of asphalt mixture, but the influence on the low temperature performance is different. Liqin Li et al. found that the high temperature performance of asphalt slurry was improved with the increase of calcium sulfate whisker content within a certain dosage level, while the low temperature performance decreased with the increase of whisker content [7]. Daijun Li found that the incorporation of calcium sulfate whisker could improve the high temperature stability of asphalt mixture, but the long-term high temperature environment would attenuate the physical properties of calcium sulfate whisker [8]. Xiushan Wang proposed that adding calcium sulfate whisker into asphalt mixture can improve its high temperature stability, water stability, and road performance [9]. Tengbin Huang found that within a certain dosage range, calcium sulfate whisker can improve the high temperature performance, low temperature performance, and water stability of asphalt mixture [10].

As one of the most abundant and common minerals on earth, calcium carbonate is ubiquitous in rocks and biological eggshells [11]. The mechanical properties of calcium carbonate whisker are similar to those of calcium sulfate whisker, which also has the characteristics of high modulus and high strength. CO2 and CaO account for 43.97% and 56.03% respectively [12,13]. Calcium carbonate whisker is resistant to high temperature, with a melting point of 759 °C and a density of 2.86 g/cm3 [14]. The crystalline form of calcium carbonate whisker is single crystal, which overcomes the defects of traditional calcium carbonate materials, such as holes and incomplete structure [15]. At present, the influence of nano-calcium carbonate on the road performance of asphalt mixture has been thoroughly studied, but the influence of calcium carbonate whisker as a modifier on the road performance of asphalt mixture has not been thoroughly studied. However, as a substitute for nano-sized calcium carbonate, calcium carbonate whisker does not have the disadvantages of nano-sized calcium carbonate, i.e., small particle size and easy agglomeration affecting its indoor performance. Therefore, it can be inferred that calcium carbonate whisker has a more obvious effect on improving the road performance of asphalt mixture than nano-sized calcium carbonate.

In conclusion, in order to further study the influence of fiber modifiers on the road performance of asphalt mixture, calcium sulfate whisker and calcium carbonate whisker with different dosage levels were added to the asphalt mixture, and the high temperature performance, low temperature performance, and water stability of asphalt mixture were measured through experiments. The effects of two whiskers on the road performance of asphalt mixture at different dosage levels were analyzed and compared to provide a more substantial basis for the selection of road modifiers.

2. Materials and Methods

2.1. Test Raw Materials

- (1)

- The asphalt used in the experiment is 90# matrix asphalt. According to the “Test Regulations for Highway Engineering Asphalt and Asphalt Mixture” (JTG E20-2011), its three major indexes and other technical indexes meet the specification requirements. See Table 1 for technical indicators. Through literature review, there are various methods for measuring the wax content of asphalt, such as differential scanning calorimetry (DSC) (ATA Instrument, model 2920 DSC, New Castle, DE, USA) [16], distillation cracking method [17], and the method of detecting wax content in terahertz band [18] explored earlier by Chinese researchers. The method used to test wax content is cracking distillation and the way to test the flash point of asphalt is the Cleveland open cup method.

Table 1. Technical index and experimental data of 90# matrix asphalt.

Table 1. Technical index and experimental data of 90# matrix asphalt.

- (2)

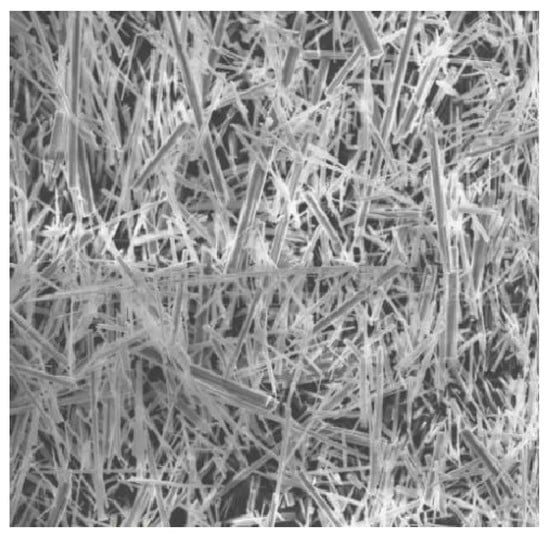

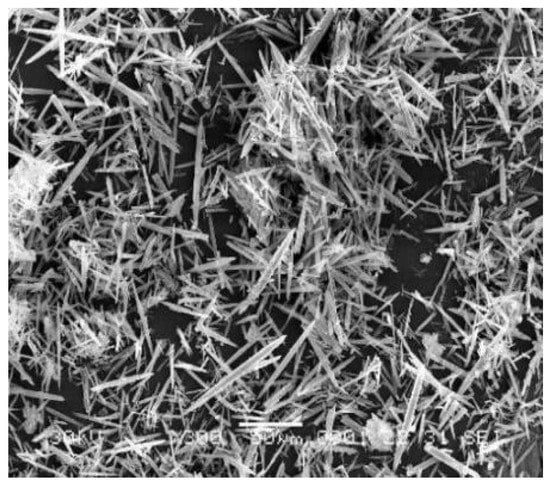

- Figure 1 and Figure 2 are the photos of calcium sulfate whiskers and calcium carbonate whiskers observed under the electron microscope (Shenzhen Aoshi Microoptics Instrument Co., LTD, Shenzhen, China)

Figure 1. Calcium sulfate whisker.

Figure 1. Calcium sulfate whisker. Figure 2. Calcium carbonate whisker.

Figure 2. Calcium carbonate whisker.

Calcium sulfate whisker produced by Xingtaiqin Innovative Material Technology Co., LTD (Xingtai, China) is adopted, and the technical indicators are shown in Table 2.

Table 2.

Technical specifications of calcium sulfate whisker.

The calcium carbonate whisker produced by Shijiazhuang Zhuzhong Technology Co., LTD (Shijiazhuang, China) is used, and the technical indicators are shown in Table 3.

Table 3.

Technical specifications of calcium carbonate whisker.

2.2. Test Method

According to the Test Regulations of Asphalt and Asphalt Mixture in Highway Engineering (JTGE20-2011), the high temperature stability, low temperature crack resistance, and water stability of calcium sulfate whisker asphalt mixture and calcium carbonate whisker asphalt mixture were evaluated by rutting test, bending creep test, and freeze-thaw splitting test. Through reading a large amount of relevant literature, the whisker content was determined as 0.2%, 0.3%, 0.4%, 0.5%, and 0.6% (The quality of the whiskers as a percentage of the mass of the asphalt mixture) after analysis.

- (1)

- Asphalt mixture rut test: The asphalt mixture rut test block with a length of 300 mm × 300 mm width and a thickness of 50 mm was prepared. After being made and standing for 24 h, the specimen and the test mold were placed in a 60 °C constant greenhouse to hold heat for 5 h. Then, the test block and the test mold were placed on the rutting test table with the test temperature set at 60 °C and the contact pressure between the test wheel and the test block set at 0.7 mpa.

- (2)

- Flexural creep test of asphalt mixture: the asphalt mixture rut test block was prepared, and the prismatic specimen with a length of 250 mm, width of 30 mm and height of 35 mm was cut after demolding. The specimen was placed in the refrigerator at −10 °C for 1 h, and then placed on the universal testing machine (Chinese Science Test Instrument Center, Dongguan, China) for loading.

- (3)

- Asphalt mixture freeze-thaw splitting test: The cylindrical Marshall specimens were prepared and divided into freeze-thawed and non-freeze-thawed groups with 8 specimens for each dosage. The freeze-thawed group was subjected to vacuum water saturation and -18℃ environment for 16h according to the standard, and then placed in a constant temperature tank at 60℃ for 24h. After freezing and thawing, the two groups of specimens were immersed in a constant temperature tank at 25 °C for 2 h, and the loading speed of 50 mm/min was used for splitting experiment to obtain the maximum load.

3. Results

3.1. Stability at High Temperature

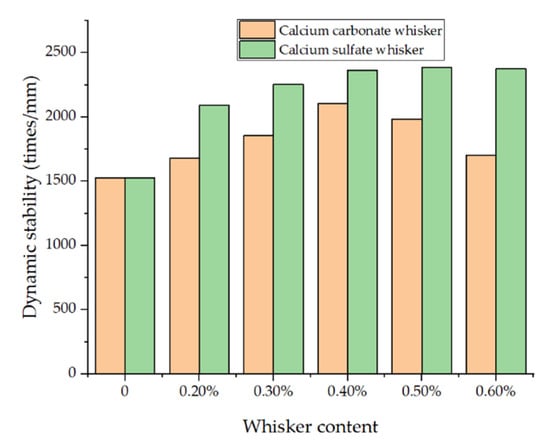

Figure 3 shows the dynamic stability test results of asphalt mixtures with different dosage levels of calcium sulfate whisker and calcium carbonate whisker.

Figure 3.

Rutting test results.

As can be seen from Figure 3, the dynamic stability of asphalt mixture can be improved by adding calcium sulfate whisker or calcium carbonate whisker, indicating that both calcium carbonate whisker and calcium sulfate whisker can improve the high-temperature stability of asphalt mixture. When the yield level of calcium sulfate whisker is in the range of 0%~0.4%, the dynamic stability increases with the increase of the dosage of calcium sulfate whisker. When the dosage level is 0.4%, the peak value is 2364 times/mm, and the dynamic stability increases by 54.9%. When the calcium sulfate whisker content exceeds 0.4%, the dynamic stability will not change with the increase of whisker content. When the calcium carbonate whisker content ranges from 0% to 0.4%, the dynamic stability increases with the increase of the calcium carbonate whisker content. When the content level is 0.4%, the peak value is 2108 times/mm, and the dynamic stability increases by 38.1%. When the content level is more than 0.4%, the dynamic stability decreases with the increase of the content. At the same dosage level, calcium sulfate whisker can improve the dynamic stability of asphalt mixture more than calcium carbonate whisker. This is because the calcium sulfate whisker and calcium carbonate whisker are evenly dispersed in the asphalt mixture, which plays a reinforcing role on the asphalt mixture, and also makes the asphalt and the mixture bond together better. When the calcium sulfate whisker content exceeds 0.4%, the asphalt has been fully coated with whisker, and excessive whisker will not increase the bond between aggregate and asphalt, so the high-temperature stability will not be further improved.

3.2. Crack Resistance at Low Temperature

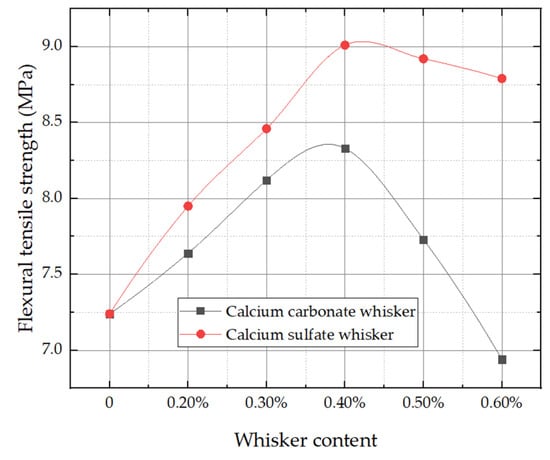

The low temperature creep test of asphalt mixture was carried out on asphalt mixture with different dosage of calcium carbonate whisker and calcium sulfate whisker at 0%, 0.2%, 0.3%, 0.4%, 0.5%, and 0.6%. The test results are shown Figure 4.

Figure 4.

Flexural tensile strength test results.

In Figure 4, it can be seen that: In a certain level range, the flexural tensile strength of asphalt mixture increases with the increase of calcium sulfate whisker and calcium carbonate whisker. When the amount of calcium sulfate whisker reaches 0.4%, the flexural tensile strength reaches a maximum of 9.01 and 8.33 MPa, respectively, which is 24.4% and 15.1% higher than that of asphalt mixture without whisker. When the yield level of whisker exceeds 0.4%, the flexural tensile strength of asphalt mixture slightly decreases with the increase of whisker content level, and the degree to which calcium carbonate whisker increases the flexural tensile strength of asphalt mixture is lower than that of calcium sulfate whisker.

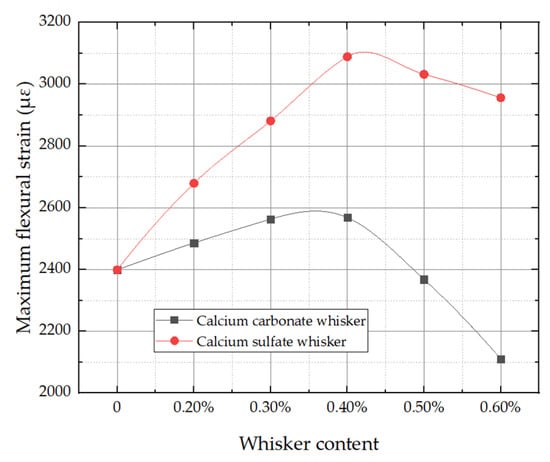

As can be observed from Figure 5, in a certain dosage level interval, with the increase of whisker content, the maximum bending tensile strain of asphalt mixture increases; when the dosage level reached 0.4%, maximum bending tensile strain reached a peak of 3089 and 2568 mu epsilon, respectively, compared with the asphalt mixture without whisker, the maximum flexural strain increased by 28.8% and 7%, respectively. When the content of calcium sulfate exceeds 0.4%, the maximum flexural strain of asphalt mixture decreases with the increase of whisker content. Calcium carbonate whisker has little effect on improving the maximum flexural strain of asphalt mixture.

Figure 5.

Maximum flexural strain test results.

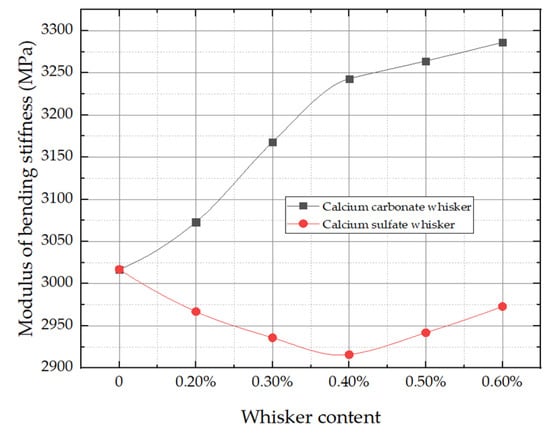

According to Figure 6, within a certain level of mixing, the bending stiffness modulus of asphalt mixture decreases with the increase of calcium sulfate whisker content. When the mixing level reaches 0.4%, the bending stiffness modulus of asphalt mixture reaches a minimum peak value of 2916 MPa, which decreases by 4.4% compared with that of asphalt mixture without calcium sulfate whisker. When the calcium sulfate content level exceeds 0.4%, the bending stiffness modulus of asphalt mixture increases with the increase of whisker content. The bending stiffness modulus of asphalt mixture increases with the increase of calcium carbonate whisker content.

Figure 6.

Bending stiffness modulus test results.

In conclusion, the incorporation of calcium sulfate whisker can improve the low temperature performance of asphalt mixture, and the improvement effect is the best when the dosage level is 0.4%. However, the incorporation of calcium carbonate whisker has a poor effect on the improvement of the low temperature performance of the asphalt mixture. According to the experimental results of bending stiffness modulus, the incorporation of calcium carbonate whisker reduces the low temperature performance of asphalt mixture. The reason for this is that after calcium sulfate whisker is added to the asphalt mixture, the whisker distribution in the mixture increases the stiffness of asphalt and makes it bond more closely with the aggregate. The fiber mesh formed by calcium sulfate whisker in asphalt mixture can adsorb asphalt and enhance the stability of the asphalt mixture. However, when excessive calcium sulfate whisker is added, the whisker cannot be uniformly dispersed in the asphalt mixture, and the excess calcium sulfate whisker will agglomerate, which reduces the elongation of asphalt and the stability of asphalt mixture, thus affecting its low temperature performance.

3.3. Water Stability

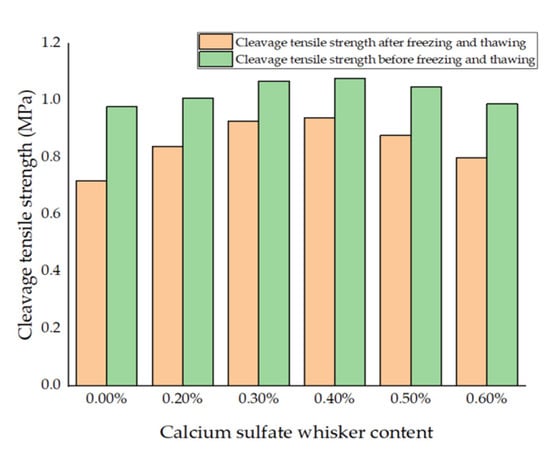

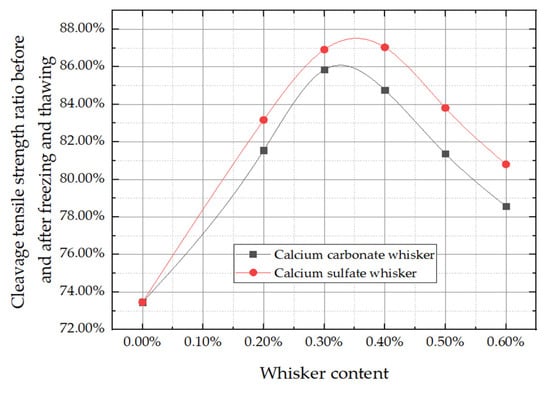

During the service of the road, various damages will occur, and water damage is an inevitable example in the case of asphalt pavement. Therefore, water stability is a necessary property to evaluate the pavement performance of asphalt pavement. The freeze-thaw splitting experiment of asphalt mixture was used to test the water stability of asphalt mixture with different dosages of calcium sulfate whisker, and the test results are shown in Figure 7, Figure 8 and Figure 9 below.

Figure 7.

Freeze-thaw splitting test results of calcium sulfate whisker asphalt mixture.

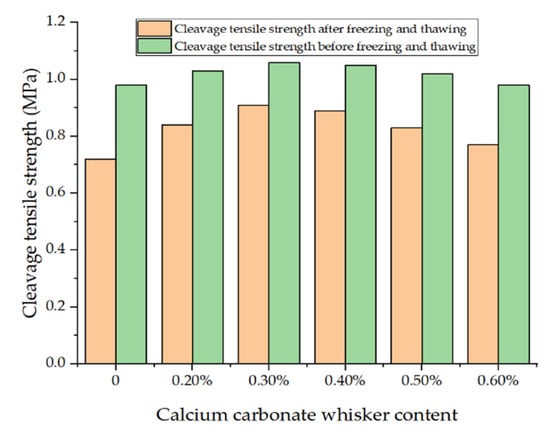

Figure 8.

Freeze-thaw splitting test results of calcium carbonate whisker asphalt mixture.

Figure 9.

Splitting tensile strength ratio before and after freezing and thawing.

According to the analysis of Figure 7, Figure 8 and Figure 9, the freeze-thaw splitting tensile strength of asphalt mixture will be improved after adding calcium sulfate whisker and calcium carbonate whisker, and the ratio of splitting tensile strength before and after freeze-thaw will also be increased with the increase of whisker incorporation level. When the calcium sulfate whisker content reaches 0.4% and the calcium carbonate whisker content reaches 0.3%, the tensile strength ratio of asphalt mixture before and after freezing and thawing reaches a maximum peak, which is 86.7% and 85.85%, respectively. When the content of calcium sulfate whisker exceeds 0.4% and the content of calcium carbonate whisker exceeds 0.3%, the splitting tensile strength and the ratio of tensile strength before and after freezing and thawing will decrease with the increase and decrease of the content of whisker. This indicates that the incorporation of calcium sulfate whisker and calcium carbonate whisker can improve the water stability of asphalt mixture, and there is an optimal dosage level. Moreover, the effect of calcium sulfate whisker on improving the water stability of asphalt mixture is better than that of calcium carbonate whisker. The reasons are analyzed. On the one hand, the whisker is evenly dispersed in the asphalt mixture to adsorb asphalt, which enhances the bond between aggregate and asphalt. When the asphalt mixture is damaged by water, asphalt cannot easily be peeled off from the aggregate surface by water. On the other hand, the whisker plays a void filling role in the asphalt mixture, which makes it difficult for water to penetrate the asphalt mixture, which also enhances the water stability of the asphalt mixture.

4. Conclusions

At present, research on the effect of whiskers on the road performance of asphalt mixtures in China is mostly focused on single whiskers. In this study, calcium carbonate whiskers and calcium sulfate whiskers were mixed into asphalt mixtures with the same proportion. Through the experiment conducted to observe the effect of a change of asphalt mixture on road performance, the influence rule of different dosages of two whiskers on asphalt mixture road performance was obtained. At the same time, the feasibility of applying calcium carbonate whiskers as a substitute for nano-calcium carbonate to improve the road performance of asphalt mixtures was also explored. The following is a summary of the findings of this study:

After adding calcium sulfate whiskers, the high temperature stability, low temperature crack resistance, and water stability of the asphalt mixture will be improved to varying degrees. After adding calcium carbonate whiskers, the high temperature stability and water stability of the asphalt mixture will also be improved, but the low temperature performance is not significantly improved, and even the addition of excessive calcium carbonate whiskers is not conducive to the low temperature performance of the asphalt mixture. At the same dosage level, calcium sulfate whiskers can improve the mixing performance of asphalt mixture better than calcium carbonate whiskers, and there is an optimal calcium sulfate whisker dosage to make the improvement effect of each property reach a maximum value.

When the calcium sulfate whisker content level is 0.4%, the asphalt mixture has the best high temperature stability, low temperature crack resistance, and water stability improvement effect. The dynamic stability increased by 54.9%, the flexural tensile strength increased by 24.4%, the maximum flexural strain increased by 28.8%, the flexural stiffness modulus decreased by 4.4% (the smaller the flexural strength indicates the better toughness of the asphalt mixture), the split tensile strength increased by 10.2% and 30.6% before and after freezing and thawing, and the ratio of tensile strength before and after freezing and thawing increased by 17.5%, respectively. The results show that the incorporation of calcium sulfate whisker can significantly improve the road performance of asphalt mixture.

When the dosage of calcium sulfate whisker exceeds 0.4%, increasing the dosage of whisker cannot further improve the road performance of the asphalt mixture. The reason for this is that the calcium sulfate whisker cannot be evenly dispersed in the asphalt mixture due to the excessive incorporation of calcium sulfate whisker, and the whisker can easily produce an agglomeration phenomenon. The overall stability of the asphalt mixture is reduced.

Author Contributions

Data curation, Y.X. (Yi Xu); Formal analysis, Y.X. (Yi Xu); Funding acquisition, Y.X. (Yongli Xu); Methodology, Y.X. (Yi Xu); Project administration, Y.X. (Yi Xu); Software, Y.X. (Yi Xu); Writing—original draft, Y.X. (Yi Xu); Writing—review & editing, Y.X. (Yi Xu) and Y.X. (Yongli Xu). All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Qu, X.; Long, W. Experimental study on road performance of high modulus modified asphalt mixture. Constr. Technol. 2019, 48, 133–136. [Google Scholar]

- Liang, J. Study on the performance of polyester fiber on asphalt mixture road. Pet. Asph. 2017, 31, 22–25+35. [Google Scholar]

- Motamedi, H.; Fazaeli, H.; Aliha, M.R.M.; Amiri, H.R. Evaluation of temperature and loading rateeffect onfracture toughness of fiber reinforced asphalt mixtureusing edge notched disc bend (ENDB) specimen. Constr. Build. Mater. 2020, 234, 117365. [Google Scholar] [CrossRef]

- Kaloush, K.E.; Biligiri, K.P.; Zeiada, W.A.; Rodezno, M.C.; Reed, J.X. Evaluation of Fiber-Reinforced Asphalt Mixtures Using Advanced Material Characterization Tests. J. Test. Eval. A Multidiscip. Forum Appl. Sci. Eng. 2010, 38, 1. [Google Scholar]

- Ferrotti, G.; Pasquini, E.; Canestrari, F. Experimental characterization of high-performance fiber-reinforced cold mix asphalt mixtures. Constr. Build. Mater. 2014, 57, 117–125. [Google Scholar] [CrossRef]

- Wang, L.; Xiong, D.; Li, Y.; Zong, Y.; Cao, X.; Ouyang, S. Research progress on preparation and application of calcium sulfate whisker. Nonferrous Met. Sci. Eng. 2018, 9, 34–41. [Google Scholar]

- Li, L.; Li, X.; Zhao, L.; Zibo, X. Experimental study on properties of calcium sulfate whisker modified asphalt. J. Henan Univ. Urban Constr. 2017, 26, 16–20. [Google Scholar]

- Li, M.; Kai, Y.; Luo, K.; Huping, L.; Yi, S.; Guobin, L.; Yi, M. Modification of calcium sulfate whisker and its application in material domain. J. Silates 2017, 36, 1590–1593. [Google Scholar]

- Wang, X. Road performance of calcium sulfate whisker high modulus asphalt concrete. J. Chongqing Jiaotong Univ. 2011, 30, 1331–1334. [Google Scholar]

- Huang, T. Research on Road Performance and Durability of Calcium Sulfate Whisker Asphalt Mixture. Ph.D. Thesis, Chang’an University, Xi’an, China, 2019. [Google Scholar]

- Yuan, J.; Liu, Y. Study on the Development of inorganic salt whisker Materials. Sea Lake Salts Chem. Ind. 2000, 29, 5–7. [Google Scholar]

- Shi, Z. Physical Basis of crystal growth. Appl. Acoust. 1983, 1, 43. [Google Scholar]

- Chen, C. Experimental Study on the Growth of Calcium Carbonate Crystal in Gel System; Chongqing University: Chongqing, China, 2006. [Google Scholar]

- Yang, Y.; Deng, Y. Mechanical properties of hybrid short fibers reinforced oil well cement by polyester fiber and calcium carbonate whisker. Constr. Build. Mater. 2018, 182, 258–272. [Google Scholar] [CrossRef]

- Li, M.; Yang, Y.; Liu, M.; Guo, X.; Zhou, S. Hybrid effect of calcium carbonate whisker and carbon fiber on the mechanical properties and microstructure of oil well cement. Constr. Build. Mater. 2015, 93, 995–1002. [Google Scholar] [CrossRef]

- Pipintakos, G.; Soenen, H.; Goderis, B.; Blom, J.; Lu, X. Crystallinity of Bitumen via WAXD and DSC and Its Effect on the Surface Microstructure. Crystals 2022, 12, 755. [Google Scholar] [CrossRef]

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. Chinese Standard: Beijing, China, 2011.

- Fan, C.; Liu, J.; Yue, Z. Preliminary study on terahertz transmission spectrum of asphalt containing wax. West. Transp. Sci. Technol. 2011, 5, 125–126. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).