Abstract

Smart supply chains, enabled by Industry 4.0 technologies, are increasingly recognized as key drivers of competitiveness, leveraging data across the value chain to enhance visibility, responsiveness, and resilience, while supporting better planning, optimized resource utilization, and agile customer service. Effective data management has thus become a strategic capability, fostering operational performance, innovation, and long-term value creation. However, existing research and practice remain fragmented, often focusing on isolated functions such as production, logistics, or quality, the most data-intensive and critical domains in smart manufacturing, without comprehensively addressing data acquisition, storage, integration, analysis, and visualization across all supply chain phases. This article addresses these gaps through a systematic literature review of 55 peer-reviewed studies published between 2020 and 2025, conducted following PRISMA guidelines using Scopus and Web of Science. Contributions are categorized into reviews, frameworks/models, and empirical studies, and the analysis examines how data is collected, integrated, and leveraged across the entire supply chain. By adopting a holistic perspective, this study provides a comprehensive understanding of data management in smart manufacturing supply chains, highlights current practices and persistent challenges, and identifies key avenues for future research.

1. Introduction

Over the last decade, manufacturing has experienced a profound transformation through the adoption of Industry 4.0 technologies. Smart factories now rely heavily on interconnected systems, sensors, and digital tools that capture and analyze data in real time, enabling higher agility, resilience, and operational efficiency [1,2]. Unlike traditional linear supply chains, smart supply networks are dynamic, with machines, systems, and human operators continuously exchanging information to support both operational and strategic decisions [3,4,5].

Data is the cornerstone of this transformation—but also its greatest challenge.

Every function of the value chain produces massive, heterogeneous information streams:

- •

- Procurement records purchase orders, supplier certifications, and contract performance metrics.

- •

- Production lines generate high-frequency IoT sensor feeds, equipment health logs, and machine-vision images.

- •

- Warehousing and logistics track real-time inventory positions, vehicle telemetry, route optimizations, and temperature or humidity conditions for sensitive goods [2,4,6].

- •

- Customer interfaces collect after-sales feedback, product-usage telemetry, and warranty claims, while reverse flows record returns and recycling data [7,8].

While Industry 4.0 technologies have rapidly advanced, a significant challenge remains in managing cross-functional data effectively [9,10]. Many studies focus on individual segments such as production or logistics, neglecting upstream and downstream processes including procurement, customer service, and reverse logistics [8,11,12]. Addressing this gap is crucial for developing supply chains capable of dynamic, informed decision-making across all functions [13].

Despite the abundance of available data, many manufacturers still struggle to transform it into actionable knowledge. Common obstacles include data fragmentation, with information trapped in legacy ERP systems or isolated SCADA servers [14,15,16]; inconsistent quality and standards, due to heterogeneous data formats; unclear governance, with poorly defined roles and access rights; and limited analytical integration, where predictive models for maintenance or demand forecasting operate in isolation [8,17,18]. In this context, it is important to note that data management and data governance, though often used interchangeably, are distinct yet complementary: data management addresses the technical handling of data [19,20], while governance provides the organizational policies and accountability frameworks that ensure data quality, consistency, and compliance [21,22,23,24]. These issues result in tangible business impacts—redundant safety stocks, delayed responses to equipment failures, missed opportunities for energy efficiency, and difficulties meeting increasing regulatory demands for traceability and sustainability [25,26].

To address these issues, this article proposes a systematic literature review, based on 55 peer-reviewed publications (2020–2025) on data management in smart manufacturing supply chains, in order to address 3 main research goals:

- Examine how current research links data management practices with smart manufacturing supply chain processes, identifying the depth and nature of these interconnections.

- Assess the extent to which existing studies integrate technical, organizational, and governance dimensions when addressing data management in supply chain contexts.

- Identify research gaps and unaddressed challenges that hinder the development of a coherent and unified approach to data-driven decision-making across the smart manufacturing supply chain.

Accordingly, four research questions guide this review. Each question is designed to address one or more of the study’s objectives: RQ1 informs the first goal, RQ2 and RQ3 support the second goal, and RQ4 addresses the third goal:

- •

- RQ1: How is data collected, integrated, and utilized across different functions within smart manufacturing supply chains between 2020 and 2025?

- •

- RQ2: What technologies, tools, and frameworks support data management and integration in these contexts?

- •

- RQ3: What technical, organizational, and strategic challenges limit effective cross-functional data use?

- •

- RQ4: What future research directions could help improve interoperability, governance, and decision-making across the full value chain?

This study adopts a holistic perspective, examining how data is managed across the entire smart manufacturing supply chain rather than focusing on isolated functions [19]. By systematically reviewing academic literature published between 2020 and 2025 through a Systematic Literature Review following the PRISMA model, this work explores current practices, identifies technological and organizational barriers, and identifies areas for further research to support fully integrated, end-to-end data-driven supply chains.

This paper begins by establishing the conceptual background, defining smart manufacturing as a data-driven paradigm and reviewing the evolution of data management practices. The study then identifies key standards and persistent challenges that motivate the research, before outlining the methodological approach and presenting the descriptive and bibliometric results that reveal current trends and research gaps. Building on these findings, the paper introduces a unified data management framework and discusses its positioning within existing enterprise architecture models. Finally, it concludes by summarizing the key contributions and offering directions for future research.

2. Background and Foundations

This chapter provides the conceptual foundation for the study. It introduces the key principles of smart manufacturing and Industry 4.0, highlights the increasing importance of data across the supply chain, and sets the stage for understanding the role of data management, governance, and analytics in modern industrial operations.

2.1. Smart Manufacturing as a Data-Driven Paradigm?

The concept of Industry 4.0 marks the fourth industrial revolution, characterized by the convergence of cyber-physical systems (CPS), the Internet of Things (IoT), cloud computing, and artificial intelligence (AI) in manufacturing environments. This convergence transforms production systems into interconnected, adaptive, and autonomous networks capable of real-time optimization and decision-making [3,27].

Smart manufacturing extends the core principles of Industry 4.0 by embedding data-driven intelligence across the full value chain—from product design and procurement to production, logistics, and after-sales services [28,29].

Unlike traditional linear factories, smart factories leverage digital twins, advanced analytics, and machine learning algorithms to monitor and predict operations, minimize waste, and dynamically adapt to demand changes [30,31].

This shift represents both a technological and a data-centric transformation, positioning data as a core production resource essential for competitiveness, resilience, and sustainability [32,33].

2.2. The Industrial Shift Toward Data-Centric Operations

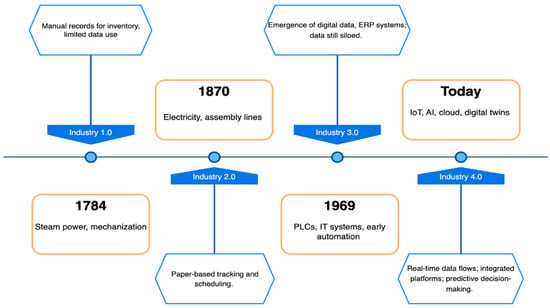

The evolution of modern industry has been shaped by successive technological revolutions, each progressively increasing the role and strategic importance of data. Industry 1.0 introduced mechanization and relied on manual recordkeeping, while Industry 2.0 brought electrification and early process documentation, enabling basic performance monitoring [9,34]. With the advent of Industry 3.0 in the late 20th century, factories began integrating programmable logic controllers (PLCs), basic IT systems, and enterprise resource planning (ERP) tools, digitalizing operations and enabling more structured data collection and analysis [1]. Industry 4.0, however, fundamentally transforms the role of data, turning it from a passive byproduct of operations into an active, strategic asset that drives decision-making, process optimization, and innovation across the value chain [3,35,36]. Modern smart factories leverage IoT, AI, cloud computing, and cyber-physical systems to collect, process, and exploit real-time data, enabling predictive operations, autonomous decision-making, and seamless coordination across supply chains [37,38].

In this new paradigm, data flows seamlessly between systems, machines, and humans, enabling predictive and prescriptive decision-making [37]. Real-time analytics, AI-driven forecasting, and edge–cloud architectures allow for decentralized yet coordinated decision processes, creating a continuous feedback loop between the physical and digital worlds [39,40].

This evolution underlies the rise of Supply Chain 4.0, where information integration across suppliers, manufacturers, distributors, and customers enhances agility, visibility, and efficiency [41,42,43]. Yet the increasing volume and complexity of industrial data also introduce challenges related to organization, governance, and strategic exploitation—challenges that lie at the core of data management.

2.3. What Is Data Management in Supply Chain?

Data management in supply chains involves the structured handling of information across all value-creating activities, from sourcing and production to distribution and after-sales services [19]. In Industry 4.0 contexts, this task becomes particularly complex due to high-volume, real-time, and heterogeneous data streams generated by IoT devices, ERP, MES, WMS, and interactions with external stakeholders. These streams include a wide variety of data types, such as operational metrics (machine status, production rates, inventory levels, shipment tracking), maintenance and quality records (sensor readings, inspection logs, maintenance history), financial and transactional data (procurement orders, invoices, supplier performance), and customer and market information (demand forecasts, sales trends, feedback) [14,19].

Effective data management in smart manufacturing involves several interrelated processes that together form a comprehensive analytical framework encompassing Data Management, Data Governance, and Data Analytics. Data acquisition and integration require collection from multiple sources and interoperability among heterogeneous systems, often facilitated by standards and frameworks supporting Industry 4.0 architectures [44]. Data storage and governance include organizing data in secure, scalable repositories while ensuring quality, consistency, regulatory compliance, and proper access control, reflecting the principles of Data Governance [8,10]. Data processing and analytics transform raw data into actionable insights via descriptive, diagnostic, predictive, and prescriptive analytics, leveraging AI, simulation, and digital twin models, representing the Data Analytics dimension of the framework [15]. Finally, data sharing and collaboration enables transparent, timely information flows across internal teams and external partners, supporting coordinated planning, logistics, and strategic decision-making [16,34].

Through these processes, the triad framework supports several value-driving capabilities. Operational visibility is enhanced via real-time dashboards and KPIs, allowing the detection of bottlenecks and disruptions [17]. Predictive maintenance and quality optimization leverage sensor and maintenance data to prevent downtime and improve product quality [44]. Collaborative planning and procurement ensure alignment of production with demand, reduce inventory buffers, and improve supply chain responsiveness. Strategic decision-making is strengthened through AI-based forecasting, scenario simulation, and digital twin models, integrating insights from Data Analytics and governed by Data Governance principles to enable resilient, proactive supply chain strategies [27].

In sum, in smart manufacturing contexts, Data Management, Data Governance, and Data Analytics together constitute an active, dynamic ecosystem of integration, analysis, and sharing—from raw data capture to strategic insight generation, and forms a critical enabler of visibility, agility, and strategic resilience in modern supply chains.

2.4. Historical Evolution of Data Management in Industrial Revolutions

Each industrial revolution has shaped the role of data. From manual records during Industry 1.0 to basic digital files in Industry 3.0, data gradually became more central. Industry 4.0 marks a fundamental shift: data is generated continuously and systematically across machines, systems, and partners [9]. Modern smart supply chains are expected not only to collect data but to transform it into timely, actionable insights through integrated, governed, and interoperable architectures [8]. Figure 1 illustrates the key milestones in industrial revolutions and their corresponding data management characteristics.

Figure 1.

Historical Data Management Characteristics across Industrial Revolutions (Industry 1.0–4.0).

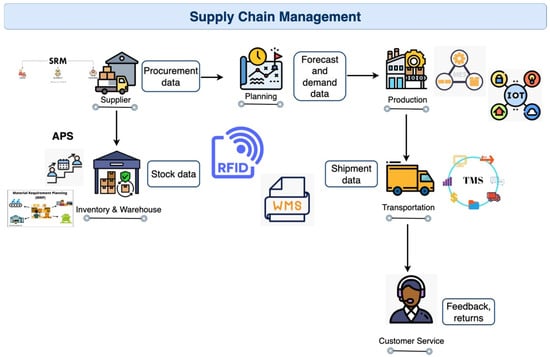

2.5. Data Use in Supply Chain Management Functions

Effective data management is essential throughout the supply chain, enabling better decision-making, increased responsiveness, and continuous improvement. Figure 2 provides an integrated overview of how data is leveraged across six core supply chain functions, supporting coordination, visibility, and decision-making from procurement to customer service.

2.5.1. Procurement

Procurement relies on historical purchasing records, supplier performance metrics, and market intelligence to support sourcing strategies, supplier evaluation, and risk mitigation. Supplier Relationship Management (SRM) platforms and e-sourcing tools consolidate data from multiple suppliers, helping organizations select reliable partners, negotiate better terms, and ensure continuity of supply [38,45,46].

2.5.2. Planning

Planning functions depend on timely and accurate data to align capacity with demand. Forecast data, production capabilities, and lead times are integrated into Advanced Planning Systems (APS) and Material Requirements Planning (MRP) tools. This enables dynamic production scheduling, inventory planning, and capacity optimization across global networks [39,47,48].

2.5.3. Production

On the shop floor, data supports real-time control, product traceability, and predictive maintenance. Manufacturing Execution Systems (MES), IoT sensors, and digital twins capture machine status, quality parameters, and operational events. This allows manufacturers to detect anomalies, reduce downtime, improve Overall Equipment Effectiveness (OEE), and ensure consistent product quality.

2.5.4. Inventory and Warehousing

Warehouse Management Systems (WMS) integrate barcode, RFID, and sensor-based data to track stock levels, shelf life, and location of goods. This data drives automated replenishment, slotting optimization, and efficient internal material flows. Advanced tools such as digital twins and 3D mapping further enhance intralogistics visibility and decision-making [1,49,50].

2.5.5. Transportation and Distribution

Transportation data, including route constraints, fleet availability, traffic conditions, and carrier performance, is captured by Transportation Management Systems (TMS), GPS trackers, and telematics. These systems support route optimization, freight cost reduction, and transparency in delivery processes, improving both efficiency and customer satisfaction [37].

2.5.6. Customer Service and Returns

Customer-facing and reverse logistics activities generate valuable insights for continuous improvement. Customer Relationship Management (CRM) platforms and returns management systems monitor return rates, complaints, feedback, and after-sales service performance. This data informs product redesign, quality improvement, and better customer experience strategies [21,51,52].

Figure 2.

Data Flows Across Supply Chain Functions.

2.6. Reference Models and Standards in Data Management of Smart Manufacturing

To address interoperability and data integration challenges, several reference architectures have been developed:

- •

- RAMI 4.0 (Reference Architecture Model for Industry 4.0): combines factory hierarchy levels, product lifecycles, and IT architecture layers to guide the integration and interoperability of systems [53].

- •

- IBM Industry Data Models: provide sector-specific semantic models and templates to accelerate data integration and analytics deployment [54].

- •

- TOGAF (The Open Group Architecture Framework): offers a high-level enterprise architecture framework to align processes, applications, and data with strategic business objectives [55,56,57].

Together, these frameworks offer the conceptual and technical foundations for unified data management in Industry 4.0 environments [58,59].

2.7. Cross-Cutting Challenges in Supply Chain Data Management

Despite the proliferation of digital tools, many organizations still struggle with fragmented data, poor interoperability between systems, and inconsistent data governance [60]. Data silos—whether departmental or geographic—limit visibility and undermine agility. Ensuring high data quality, standardizing formats, and defining clear ownership are ongoing challenges [61,62].

Moreover, as supply chains become increasingly connected, cybersecurity and data privacy emerge as critical concerns [63,64]. Harmonizing data flows across ERP, MES, WMS, and external platforms requires robust integration frameworks and governance models [44,65].

Frameworks such as RAMI 4.0 and TOGAF offer conceptual guidance for aligning data, systems, and business processes. Their implementation supports a more cohesive, cross-functional approach to managing supply chain data in smart manufacturing contexts [53,55,66].

2.8. Motivation Behind the Work

Supply chains are experiencing a profound digital transformation, largely driven by innovations in smart manufacturing technologies. Although modern factories increasingly deploy intelligent machines, connected sensors, and advanced analytics platforms, many organizations still face challenges in converting value chain data into actionable insights [32,37]. The promise of real-time, data-driven decision-making often conflicts with the practical reality of fragmented information systems and isolated functional silos [1].

This systematic review is motivated by the need to understand how organizations currently utilize data generated across procurement, planning, production, logistics, inventory, and customer service to manage their supply chains—and why many struggle to achieve their data-driven objectives [38,42,67]. By analyzing research from 2020 to 2025, the study seeks to clarify existing data management practices, identify key technical and organizational barriers, and explore avenues for future research and industrial initiatives aimed at closing the gap between theoretical potential and practical implementation [19,68].

Ultimately, the review aims to support the development of smarter, more connected, and more efficient supply chains, where data is not merely collected but strategically leveraged across the entire value chain [28].

3. Problem Statement and Research Methodology

With the emergence of Industry 4.0, supply chains have become increasingly data-intensive, generating large volumes of information spanning sourcing, production, logistics, warehousing, and customer service. These data streams hold substantial potential to enhance visibility, responsiveness, and operational efficiency in smart manufacturing environments [28,42,69]. However, many organizations continue to face challenges in unlocking this value due to fragmented data sources, limited interoperability, inadequate real-time analytics, weak governance structures, and uncertain returns on technology investments [19]. These issues hinder cross-functional collaboration and impede the realization of fully integrated, data-driven supply chains [13].

In this context, the present study examines how value chain data are utilized in supply chain management within smart manufacturing environments between 2020 and 2025 and investigates the barriers that limit effective use [3,38,70,71]. The objectives are threefold: (i) to assess current data management practices across smart supply chains, (ii) to identify key technological and organizational limitations, and (iii) to highlight future research opportunities for more cohesive, end-to-end integration [21,72].

To accomplish these goals, a systematic literature review was conducted, focusing on the implementation of data management across key supply chain functions, including production, logistics, and quality management [1,37,73]. The review followed established best practices in systematic literature analysis to ensure methodological rigor, transparency, and reproducibility [19].

3.1. Methodological Approach

We adopted a qualitative systematic review methodology. Our objective was not only to capture the breadth of existing research but also to synthesize meaningful insights on how data management is leveraged in real-world supply chain operations. The review focused on both academic contributions and industrial case applications, with attention to tools, frameworks, practices, and reported outcomes.

3.2. Search Process

A structured search was carried out using two major academic databases: Scopus and Web of Science (WoS). The search was limited to peer-reviewed publications in English, published between 2020 and 2025, in order to capture recent developments within the Industry 4.0 era. The starting point of 2020 was selected, as it marks both the consolidation of smart manufacturing technologies and the onset of the COVID-19 pandemic, which accelerated digital transformation.

To construct comprehensive queries, we combined keywords related to:

- •

- Data management and governance (e.g., data storage, sharing, acquisition, analysis, quality),

- •

- Supply chain functions (e.g., supply chain, logistics, production, planning, processes).

The full search strings used were as follows:

Web of Science

TS = (“data management” OR “master data”)

AND TS = (“data governance” OR “data visualization” OR “data analysis” OR “data quality”

OR “data sharing” OR “data acquisition” OR “data storage”)

AND TS = (“supply chain management” OR “supply chain” OR “logistics”

OR “process” OR “production” OR “planning”)

AND PY = (2020–2024)

AND LA = (“English”)

AND (DT = (“Article”) OR DT = (“Proceedings Paper”) OR DT = (“Book Chapter”))

Scopus

TITLE-ABS-KEY (“data management” OR “master data”)

AND TITLE-ABS-KEY (“data governance” OR “data visualization” OR “data analysis”

OR “data quality” OR “data sharing” OR “data acquisition” OR “data storage”)

AND TITLE-ABS-KEY (“supply chain management” OR “supply chain” OR “logistics”

OR “process” OR “production” OR “planning”)

AND PUBYEAR > 2019 AND PUBYEAR < 2025

AND (LIMIT-TO (OA, “all”))

AND (LIMIT-TO (DOCTYPE, “ar”) OR LIMIT-TO (DOCTYPE, “cp”) OR LIMIT-TO (DOCTYPE, “ch”))

AND (LIMIT-TO (LANGUAGE, “English”))

The search yielded 407 articles from Web of Science and 658 from Scopus.

3.3. Inclusion and Exclusion Criteria

Each article was screened based on explicit criteria. Only studies related to data management practices in supply chain domains (production, logistics, or quality) were considered.

3.4. Data Extraction and Synthesis

The 1065 articles were reviewed using a structured coding matrix to extract key information, including:

- •

- Supply chain domain focus (production, logistics, quality),

- •

- Data management technologies mentioned (e.g., platforms, tools, systems),

- •

- Models or frameworks discussed,

- •

- Reported outcomes and limitations.

A thematic analysis was conducted to identify recurring patterns, approaches, and challenges. The analysis was both descriptive (e.g., frequency of specific terms or methods) and interpretive, to understand how and why certain data management practices are adopted in SCM.

Findings were grouped into three main categories—production, logistics, and quality—with a comparative synthesis conducted across these domains to identify:

- •

- Common technologies and frameworks used,

- •

- Integration and interoperability challenges,

- •

- Gaps between academic theory and real-world practice.

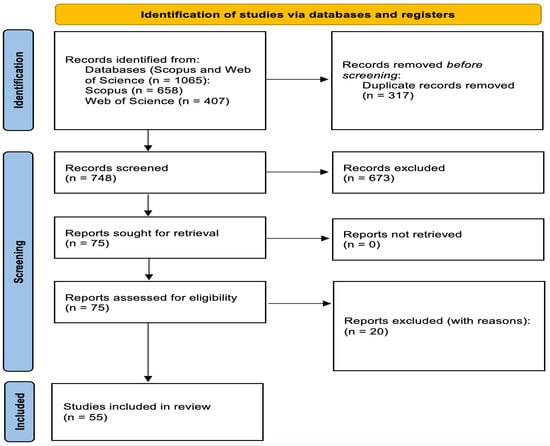

3.5. Article Selection Process

The article selection process followed the PRISMA 2020 guidelines and is illustrated in Figure 3. A total of 1065 articles were initially identified—658 from Scopus and 407 from Web of Science. After removing 317 duplicates, 748 unique articles remained. These were screened based on title and abstract, resulting in the exclusion of 673 studies that did not meet the inclusion criteria. The final sample included 55 peer-reviewed articles for full-text analysis.

Figure 3.

PRISMA 2020 Flow Diagram of the Selection Process.

4. Descriptive and Bibliometric Analysis of the Reviewed Studies

In order to better understand the structure and focus of the 55 articles included in this review, a descriptive analysis was conducted. This overview covers publication years, publication venues, recurring keywords, and citation impact. These bibliometric indicators help contextualize the scientific landscape of data management in smart manufacturing environments.

4.1. Analysis Process Overview

The analysis was structured in a stepwise and systematic manner, progressing from general descriptive insights to specific technological and thematic analyses, and finally to the distribution across supply chain phases. The descriptive analysis provides an overview of publication trends and influential venues. The technologies and keywords analysis highlights dominant tools and concepts. The supply chain phases analysis shows how data management research is applied across different stages, revealing gaps and areas of focus.

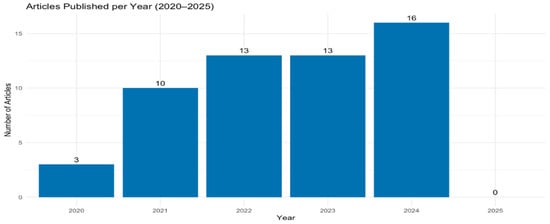

4.2. Publication Frequency

Figure 4 presents the annual distribution of publications from 2020 to 2025. The dataset shows a growing interest over the years, starting with 3 publications in 2020 and increasing to 10 in 2021. The upward trend continues with 13 publications each in 2022 and 2023, peaking at 16 in 2024. No publications were recorded for 2025 within the study period, because the year was still ongoing at the time of data collection. This trend reflects an increasing scholarly focus on the topic, possibly driven by emerging technologies and new challenges in the field. The sustained growth suggests a dynamic research landscape and expanding academic engagement.

Figure 4.

Articles Published per Year (2020–2025).

4.3. Publication Analysis

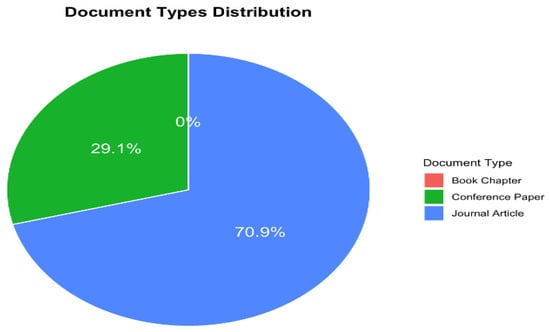

The distribution of publication types is shown in Figure 5, with journal articles accounting for 70.9% and conference papers for 29.1%, while no book chapters were present in the dataset.

Figure 5.

Document Type Frequency.

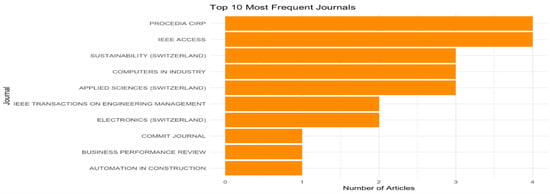

Figure 6 summarizes the distribution of journals publishing the articles in our dataset. Procedia CIRP and IEEE Access lead with four articles each, followed by Sustainability, Computers in Industry, and Applied Sciences Switzerland with three articles each. IEEE Transactions on Engineering Management and Electronics contributed two articles each, while the remaining journals published one article each.

Figure 6.

Most Frequent Journals.

All journals included in the sample are indexed in Scopus. The presence of well-recognized outlets like IEEE Access and Procedia CIRP suggests the research is published in reputable venues with considerable academic influence. The journal scopes suggest an interdisciplinary audience spanning engineering, industrial systems, and computer science. Then, we analyzed the citation impact of publications over the years.

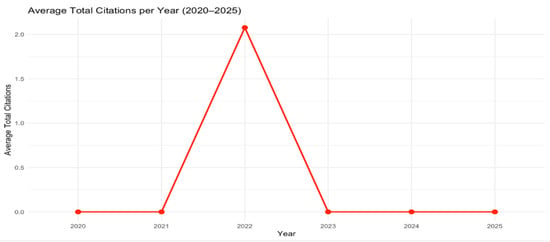

Figure 7 presents the average total citations per year, highlighting 2022 as the most productive year with the highest number of publications and an average of 2 citations per article; other years had zero average citations.

Figure 7.

Average total citations per Year (2020–2025).

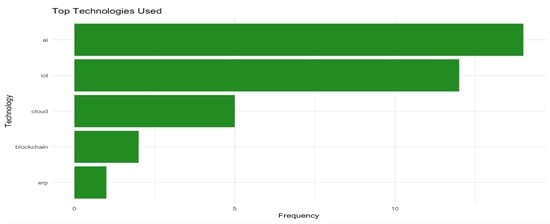

4.4. Technologies Used Analysis

Figure 8 illustrates the main technologies employed in the analyzed publications. Artificial Intelligence (AI) clearly dominates with 14 articles, closely followed by the Internet of Things (IoT) with 12 articles. Cloud computing ranks third with 5 publications, while blockchain and Enterprise Resource Planning (ERP) systems are less represented, with 2 and 1 article, respectively. This distribution reflects the strong interest of researchers in emerging and connected technologies within data management applied to supply chains. The predominance of AI and IoT highlights their central role in the digital transformation of logistics networks.

Figure 8.

Top Technologies Used.

4.5. Keyword Analysis

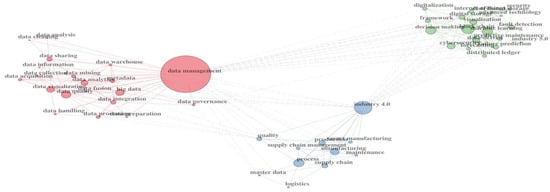

The keyword co-occurrence network (Figure 9) reveals the thematic structure of the research landscape by visually mapping how frequently keywords appear together in the analyzed publications. Each node represents a keyword, with its size reflecting its frequency, while the thickness of the connecting lines indicates the strength of co-occurrence between terms. The network is organized into three clearly defined clusters, each representing a major research domain.

Figure 9.

Keyword Co-occurrence Network.

The red cluster is centered on data management and related data engineering activities. It includes closely connected terms such as data quality, data integration, data mining, data warehouse, metadata, and data visualization. This cluster highlights the central role of data preparation, governance, and processing as foundational components of modern supply chain information systems.

The blue cluster groups concepts related to Industry 4.0 and supply chain operations. Keywords such as supply chain management, manufacturing, logistics, quality, process, and maintenance illustrate how digital transformation intersects with operational performance. The presence of Industry 4.0 as a central node emphasizes its bridging role between technological innovation and production processes.

The green cluster encompasses advanced digital technologies, including machine learning, predictive maintenance, internet of things, cybersecurity, fault detection, and distributed ledger. This group reflects the growing adoption of intelligent and connected systems that support automation, real-time monitoring, and secure data sharing.

Overall, the network reveals how research topics are distributed across the three domains. Strong inter-cluster connections, particularly between Industry 4.0 technologies and data management themes, indicate the integrative nature of modern supply chain digitalization. These links underscore how data handling, advanced analytics, and smart technologies jointly contribute to optimized decision-making and more resilient supply chain ecosystems.

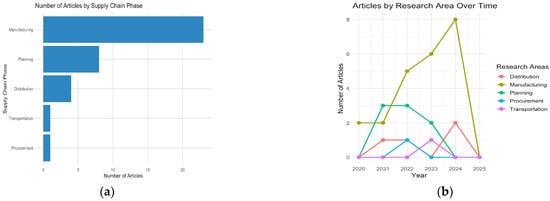

4.6. Supply Chain Phases Analysis

Figure 10a presents the distribution of articles by supply chain phase. The majority of studies focus on the manufacturing phase (23 articles), reflecting its central role in current research. This is followed by the planning phase with 8 articles, and distribution with 4 articles. Procurement and transportation are the least explored phases, with only 1 article each. This imbalance suggests that while manufacturing processes receive significant attention in the literature, other critical phases of the supply chain remain underrepresented, indicating opportunities for further research.

Figure 10.

(a) Numbers of Articles by Supply Chain Phase; (b) Evolution of number of Articles by Phase and Year.

Figure 10b shows the evolution of the number of articles by supply chain phase from 2020 to 2025. The manufacturing phase displays a consistent and notable upward trend, growing from 2 articles in 2020 to 8 articles in 2024, indicating increasing research interest. The planning phase remains stable between 2021 and 2022 (3 articles) before declining to 2 articles in 2023 and reaching 0 in 2025. Distribution exhibits a slow but steady increase, rising from 1 article in 2021–2022 to 2 in 2024, before also falling to 0 in 2025. Procurement and transportation appear only once in the period, with no sign of sustained research activity. Overall, the data suggests a strong and growing focus on manufacturing, while other supply chain phases remain relatively underexplored. The uniform drop to zero across all phases in 2025 reflects that the analysis was conducted during 2025 and does not capture publications that may appear later in the year.

4.7. Summary of Findings

The bibliometric and thematic analysis of the 55 selected articles reveals several clear patterns. Research activity on data management in smart manufacturing supply chains has grown steadily over the last five years, with a marked concentration in reputable, engineering-oriented journals. The dominant technological themes are Artificial Intelligence (14 articles) and the Internet of Things (12 articles), both central to enabling data-driven decision-making. Keyword analysis shows strong clustering around data-related concepts, Industry 4.0 technologies, and cybersecurity topics, while supply chain phase analysis highlights a significant focus on manufacturing (23 articles), with limited attention to procurement, transportation, and other upstream or downstream processes.

While these findings provide valuable insights into the current research landscape, they also expose important gaps. Certain technologies (e.g., blockchain, ERP systems) and phases of the supply chain remain underrepresented, and the literature shows an uneven distribution of attention across thematic areas. This imbalance suggests that existing approaches may not fully capture the interconnected nature of data flows across the entire supply chain.

4.7.1. Classification of the 55 Articles

To better understand the research orientations, the corpus was divided into three main categories (Table 1). Each category is defined by its primary objective, allowing a direct comparison of conceptual versus empirical contributions.

Table 1.

Classification of the articles.

Interpretation of the classification

- •

- Reviews supply a panoramic understanding of the field, mapping core concepts such as data quality, governance, and dataspaces, but they mostly remain descriptive.

- •

- Framework/Model papers dominate (≈53%), reflecting the field’s emphasis on conceptual architecture and methodological proposals—IoT acquisition layers, hybrid edge-cloud pipelines, semantic knowledge graphs, and governance patterns.

- •

- Key Studies provide concrete industrial validations (≈31%), demonstrating the feasibility of predictive maintenance, blockchain traceability, and other advanced solutions, but they remain context-specific and rarely test long-term scalability.

This distribution shows that research is still concept-heavy, with comparatively few mature, multi-site implementations.

Reviews (9 Articles)

The reviewed papers collectively map the evolving landscape of data management in Industry 4.0, addressing topics such as data quality (e.g., ref. [74]), governance and enterprise data strategies [75,76,77], dataspaces and cross-company data sharing [78], IoT and big-data management [79,80], and domain-specific digitalization, such as in mining or blockchain-enabled supply chains [81,82]. Other studies highlight the growing role of analytics in optimizing supply chain processes [83] and the diversity of data management practices across industrial contexts [84].

Despite their contributions, the review papers display several limitations:

- •

- Fragmented scope, often centered on a single technology or sector, with no truly end-to-end view of supply chain data management.

- •

- Heterogeneous methodologies with inconsistently reported search strategies and inclusion criteria, limiting reproducibility.

- •

- Limited quantitative synthesis, as most papers remain descriptive and rarely conduct bibliometric mapping or meta-analysis.

- •

- Recency and coverage biases, with several reviews relying on outdated or narrow datasets.

- •

- Insufficient practical guidance, as conceptual insights seldom translate into actionable or prescriptive frameworks.

Together, these limitations underscore the need for a unified and methodologically rigorous review—precisely the gap addressed by the integrated framework proposed later in the article.

Frameworks/Models (29 Articles)

The analyzed studies propose diverse architectures and conceptual models addressing the technical and organizational challenges of industrial data management. They encompass lifecycle data management frameworks for production systems [85], knowledge-graph-based models for quality control and decision support [86,87], cybersecurity-oriented data governance structures [88,89], and value-oriented data integration approaches [90,91]. Other frameworks focus on sector-specific applications, including predictive maintenance in maritime, power, and oil industries [92,93,94], and data-driven optimization of infrastructure and logistics operations [95,96,97]. Several works also explore data quality and interoperability through middleware, distributed databases, or cloud–edge architectures [98,99,100,101,102], while others address governance and master data maturity models [15,103,104,105].

Collectively, these models emphasize architectural design and integration, often combining IoT-enabled data acquisition, semantic technologies, hybrid edge–cloud computing, and governance-aware dataspaces. However, most remain conceptual, offering limited large-scale or industrial validation. Common limitations include:

- •

- Narrow scope, with a predominant focus on production phases rather than procurement, logistics, or distribution;

- •

- Interoperability assumptions, presuming standardized ontologies or protocols not yet widely adopted;

- •

- Scalability challenges, as few frameworks test performance under real-time, high-volume industrial conditions; and

- •

- Weak governance alignment, since many technical models overlook economic, organizational, or business-process integration.

To overcome these limitations, recent research calls for modular pilot implementations across industries, cross-cutting architecture layers linking IoT, AI, ERP, and blockchain, and semantic mediation approaches such as knowledge graphs and standardized reference models (e.g., RAMI 4.0, IEC 62890 [106]). Additionally, ensuring scalability and governance integration through hybrid cloud–edge deployments, lifecycle data policies, and embedded role-based access control mechanisms remains essential.

Key Studies (17 Articles)

This group comprises empirical and experimental papers that validate data management concepts through real-world implementations. The studies span diverse contexts, including manufacturing, logistics, energy, materials research, infrastructure management, and smart-factory operations. Several works demonstrate the deployment of data management platforms and digital tools to improve process visibility and decision-making [107,108,109,110,111,112,113,114,115,116], while logistics-focused case studies validate throughput and transport optimization using flow and traffic data [117]. Other studies address data quality and governance through master-data accuracy assessment, FAIR principles, or TDQM-based interventions and cross-national governance comparisons [118,119,120,121,122]. Advanced technologies such as AI and predictive analytics are leveraged for fault detection and maintenance optimization [123,124,125], and emerging concepts like digital product passports, blockchain traceability, and decentralized sharing systems extend the scope toward transparency and collaboration [126,127]. Finally, smart-factory resource-tracking implementations (e.g., indoor positioning systems) illustrate operational control improvements and mobile-resource management [128].

Collectively, these empirical studies confirm the technical feasibility and tangible benefits of advanced data management practices, including hybrid cloud–edge architectures, real-time monitoring, and analytics-driven optimization. They report measurable improvements in operational performance, cost efficiency, and data visibility across various industrial environments.

Nevertheless, several gaps persist. Most case studies remain context-specific, limited to single factories, product lines, or national systems, which constrains cross-industry generalizability. Long-term lifecycle governance evidence—showing how data policies evolve or sustain quality over time—remains scarce. Furthermore, few works assess integration with legacy systems, such as ERP or MES platforms, which is critical for scalability and adoption in mature industrial settings.

Overall, these findings underline the need for transferable, interoperable, and governance-aware data management frameworks, capable of sustaining performance across multiple supply chain phases and industries—an objective pursued by the integrated model proposed in the next section.

4.7.2. Overall Synthesis and Research Directions

Bringing together the three categories—Reviews, Frameworks/Models, and Key Studies—reveals a maturing but still fragmented research field:

- •

- From Concept to Practice: A large proportion (≈53%) of publications remain conceptual. The smaller set of empirical validations underscores the need for more longitudinal and multi-site evaluations.

- •

- Technology Imbalance: AI and IoT dominate, while blockchain, ERP, and standardized knowledge-graph approaches are emerging but under-explored.

- •

- Supply Chain Coverage: Manufacturing operations are well represented; upstream procurement and downstream distribution remain marginal.

Future work should prioritize:

- •

- Cross-Phase Integration—Developing architectures that span procurement, production, and distribution.

- •

- Governance and Standards—Embedding robust data-governance models and aligning with international standards (RAMI 4.0, IEC 62890 [106]).

- •

- Benchmarking and Replication—Publishing open datasets and reproducible benchmarks to enable comparative evaluation of frameworks.

- Key Findings, Research Gaps and Proposed Directions:

These insights lay the groundwork for the subsequent section of the article, which proposes a unified, integrated framework designed to bridge the identified technological and organizational gaps.

To clearly connect these results to the need for a new approach, Table 2 summarizes the main findings, the identified gaps, and the relevance of a new integrated framework.

Table 2.

Summary of Key Findings, Research Gaps and Future Directions.

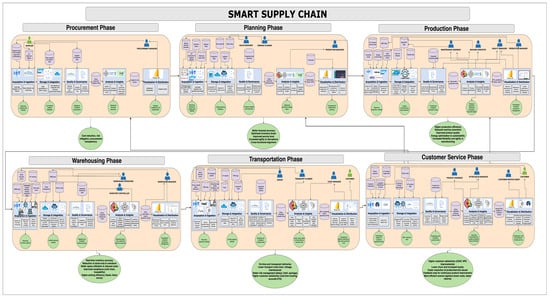

5. Proposed Framework for Unified Data Management in the SCM

Building on the findings and gaps identified in the literature review, this study proposes a comprehensive framework for data management that spans the entire supply chain. Unlike existing approaches that focus predominantly on manufacturing, the proposed framework covers all phases, from procurement to after-sales service. It integrates the concept of the data value chain with the relevant technologies, activities, and actors specific to each phase. The framework also emphasizes cross-functional collaboration, transparency, and the creation of measurable value.

5.1. Integrated Framework Overview

The framework synthesizes all phases of the supply chain into a single, cohesive ecosystem (Figure 11). Its key contributions include:

Figure 11.

Integrated Supply Chain Data Management Framework.

- •

- Holistic coverage–extending beyond manufacturing to encompass procurement, planning, warehousing, transportation, and after-sales.

- •

- Balanced technology adoption–integrating not only AI and IoT, but also blockchain, ERP, WMS, and TMS.

- •

- Empirical grounding–addressing the gap between conceptual models and practice by embedding value-driven outcomes, such as cost savings, service levels, and sustainability.

- •

- Cross-phase integration–ensuring data flows consistently across the supply chain instead of remaining fragmented.

While each phase delivers specific value, the framework’s overall strength lies in its integration across the entire supply chain. By embedding the data value chain into every stage and aligning it with the appropriate technologies, actors, and activities, it provides a holistic approach to supply chain data management. This integrated approach directly addresses the gaps identified in the literature: it expands the scope beyond manufacturing; strengthens alignment between governance, security, and analytics; and establishes a clear link to operational and business outcome.

5.2. Procurement Phase

This architecture (cf. Figure 11, Procurement Phase) illustrates how a procurement manager leverages the data value chain to enhance supplier management and decision-making. At the acquisition and ingestion stage, IoT-based shipment signals and e-sourcing platforms automatically collect supplier-related data, such as prices, lead times, quality scores, and certifications in real time. This ensures continuous visibility into supplier performance.

During the integration stage, these datasets are centralized within ERP or cloud environments (e.g., SAP, Oracle), where they are normalized and enriched with contractual and historical performance data. The quality and governance layer applies validation and traceability rules, using blockchain and master data management tools to ensure supplier compliance and data reliability.

Once the data are clean and governed, the analysis and insights stage employ AI and predictive analytics to evaluate supplier risk, simulate sourcing scenarios, and optimize costs using Total Cost of Ownership (TCO) or machine learning–based models.

Finally, the visualization and distribution layer, through Power BI dashboards and supplier portals, delivers actionable insights to procurement managers, enabling transparent collaboration with suppliers and data-driven sourcing decisions.

Through this end-to-end data architecture, the procurement manager transitions from reactive to proactive decision-making. The process ensures cost reduction, risk mitigation, and enhanced transparency, demonstrating how smart data management directly contributes to supply chain resilience and strategic procurement excellence.

5.3. Planning Phase

This architecture (cf. Figure 11, Planning Phase) represents a scenario in which the demand planner, sales manager, and production manager collaboratively use the data value chain to achieve accurate and agile planning. The process begins with the acquisition and ingestion of heterogeneous data sources, such as market forecasts, customer orders, and IoT production signals, automatically collected from ERP, CRM, and external feeds. This ensures continuous synchronization between real-time demand and supply signals.

During the storage and integration stage, these datasets are centralized within a unified data warehouse or data lake that links planning data with supplier and production capacity information. The quality and governance layer enforces data accuracy, consistency, and compliance with service-level and contractual rules, producing a trusted and reliable planning dataset.

The analysis and insights layer applies AI- and ML-based forecasting models, inventory optimization algorithms, and scenario simulations to balance supply and demand dynamically. This analytical intelligence enables planners to anticipate disruptions, test capacity constraints, and optimize replenishment strategies.

Finally, the visualization and distribution layer, through Power BI dashboards and collaborative planning platforms, provides transparent access to forecasts, KPIs, and deviation alerts. These tools allow managers across sales, production, and logistics to share a single version of truth and coordinate decisions in real time.

By integrating end-to-end data flows and intelligent analytics, this architecture empowers planners to achieve better forecast accuracy, optimized inventory levels, improved service performance, and stronger cross-functional alignment, demonstrating how data management transforms traditional planning into a predictive and collaborative process.

5.4. Production/Manufacturing Phase

This architecture (cf. Figure 11, Production Phase) illustrates how production stakeholders, including the maintenance engineer, machine operator, quality manager, and production manager, leverage the data value chain to enable intelligent, connected, and sustainable manufacturing operations.

In the acquisition and ingestion stage, real-time data from IoT sensors, MES logs, and ERP production orders are automatically collected from machines and shop-floor systems. This continuous data stream provides full visibility into production performance, process parameters, and equipment conditions.

The storage and integration layer centralizes these heterogeneous data sources within a unified repository or digital twin environment, linking IoT, MES, and ERP data. This integration allows production teams to monitor performance both in real time and historically, supporting traceability and contextual analysis.

Through the quality and governance stage, the system applies rules for data cleansing, standardization, and compliance with ISO and safety standards. These governance mechanisms ensure that only trusted, validated data feed the analytical and operational layers—critical for industries where precision and safety are essential.

The analysis and insights layer enables AI-driven predictive maintenance, process optimization, and root-cause analysis of defects. Maintenance engineers and quality managers can simulate production behavior via digital twins to test corrective actions before implementation. These insights translate into proactive, data-driven interventions that minimize downtime and improve yield.

Finally, the visualization and distribution layer provide role-specific dashboards: maintenance alerts for technicians, quality KPIs for managers, and real-time production views for operators. By sharing the same data-driven environment, teams collaborate seamlessly to anticipate failures, improve throughput, and align production goals with sustainability objectives.

This architecture demonstrates how integrating the full data value chain, from IoT ingestion to predictive analytics, enables higher production efficiency, reduced downtime, improved product quality, and more sustainable, flexible manufacturing.

5.5. Warehousing and Inventory Management Phase

This architecture (cf. Figure 11, Warehousing Phase) illustrates how warehouse stakeholders, including the warehouse manager, inventory controller, and operators, leverage the data value chain to enable intelligent, synchronized, and compliant inventory management.

During the acquisition and ingestion stage, real-time data from RFID scans, IoT sensors, WMS logs, and robotic systems are continuously captured to monitor stock movements and storage conditions. This ensures accurate, up-to-date visibility of inbound and outbound flows.

At the storage and integration level, data from multiple sources are centralized and synchronized across warehouse sites and ERP systems, ensuring unified inventory visibility. Through the quality and governance stage, automated validation and compliance mechanisms enforce standards such as GS1 barcoding and cold-chain traceability, guaranteeing reliable and regulatory-compliant data.

The analysis and insights layer applies advanced analytics and AI for ABC inventory optimization, slotting efficiency, predictive replenishment, and workforce scheduling. Digital twin simulations help optimize warehouse layout and resource allocation.

Finally, visualization and distribution tools, including interactive dashboards and AR-assisted picking, provide real-time decision support and alerts to operators and managers.

By integrating the full data value chain from IoT-enabled acquisition to predictive analytics, this architecture enables reduced stock-outs and overstocking, better space utilization, higher picking accuracy, and improved compliance across the warehouse network.

5.6. Distribution and Transportation Phase

This architecture (cf. Figure 11, Transportation Phase) illustrates how logistics stakeholders, including the fleet manager, transport planner, drivers, and customers, leverage the data value chain to enable intelligent, transparent, and efficient distribution operations.

In the acquisition and ingestion stage, real-time IoT shipment signals, GPS data, RFID scans, and TMS logs continuously capture vehicle location, shipment status, and external factors such as traffic or weather. This live data stream provides full visibility into fleet performance and transport conditions.

Through the storage and integration layer, transport data from TMS, ERP, and telematics systems are merged with customer orders, creating a unified logistics dataset that supports end-to-end shipment traceability. The quality and governance stage ensures compliance with service-level and legal transport standards, with blockchain enhancing traceability and proof of delivery.

The analysis and insights layer applies AI-driven models for route optimization, predictive ETA estimation, risk prediction (delays, theft, spoilage), and fuel consumption analysis. These insights empower planners to minimize costs and improve reliability across delivery operations.

Finally, the visualization and distribution layer delivers real-time dashboards for fleet monitoring, predictive alerts for incidents, and customer-facing applications that provide live shipment tracking and notifications.

By integrating the full logistics data value chain, from IoT-enabled tracking to predictive analytics, this architecture enables on-time and transparent deliveries, reduced transport costs, better risk management, and higher customer satisfaction.

5.7. Customer Service and After-Sales Phase

This architecture (cf. Figure 11, Customer Service Phase) illustrates how after-sales stakeholders, including customer service agents, product engineers, and after-sales managers, leverage the data value chain to deliver responsive, transparent, and customer-centric service operations.

In the acquisition and ingestion stage, customer complaints, return requests, chatbot interactions, and IoT product usage data are continuously captured to monitor customer experience and product performance. This enables centralized visibility of support and return processes.

The storage and integration layer consolidate CRM, ERP, and ticketing systems, linking customer profiles with product serial numbers, warranty records, and service histories to create a 360° customer view. Through the quality and governance stage, data privacy (GDPR compliance) and authenticity of warranty claims are ensured, supported by anti-fraud validation mechanisms.

The analysis and insights layer apply advanced analytics, including sentiment analysis, churn prediction, and root-cause analysis using IoT data, to anticipate customer needs and enhance service quality. Insights also feed back into R&D and product improvement loops.

Finally, visualization and distribution tools, such as dashboards and customer portals, provide service KPIs, real-time feedback to development teams, and transparent communication with customers on issue status and resolution progress.

By integrating customer interaction data across the entire value chain, this architecture enables higher customer satisfaction, faster issue resolution, stronger loyalty, and more efficient reverse logistics operations.

5.8. Discussion: Positioning the Framework Within Existing Enterprise Architectures

The proposed unified framework for data management in the supply chain was developed in response to key gaps observed in the literature. To evaluate its originality and potential, it is important to contrast it with widely recognized enterprise architecture models such as TOGAF, RAMI 4.0, and IBM Industry 4.0 reference architecture. Table 3 highlights how the proposed framework extends existing enterprise architectures to achieve end-to-end supply chain data governance and analytics integration.

Table 3.

Comparison of Existing Architectures and the Proposed Framework.

5.9. Implications for Research and Practice

The Unified Data Management Framework has important implications for both researchers and practitioners, highlighting opportunities to bridge conceptual understanding and practical implementation in smart supply chains.

For researchers, this framework provides a structured lens to study end-to-end supply chain data management, integrating technical, organizational, and governance aspects. Previous studies have often focused narrowly on individual phases (e.g., manufacturing or procurement) or specific technologies (AI, IoT), leaving a gap in large-scale, cross-phase empirical validation [1,2,3,4,5,6,7,8,9,10]. The framework allows researchers to investigate the interplay between governance mechanisms, predictive analytics, digital twins, and performance outcomes across multiple supply chain phases. This enables longitudinal studies on how integrated data management influences operational resilience, agility, sustainability, and business value. Furthermore, the framework encourages interdisciplinary research, combining operations management, information systems, industrial engineering, and organizational studies, thus addressing the fragmentation observed in the current literature [8,11,12,13,14,15,16,17,18,25].

For practitioners, the framework acts as a practical guide for designing and implementing data-driven initiatives across the entire supply chain. By embedding governance, security, and analytics at every stage—from procurement to after-sales service—the framework ensures that technology investments (AI, IoT, blockchain, ERP, WMS, TMS) deliver measurable value rather than operating in silos [19,26,27,28,29,30,31,32,129,130]. It highlights the importance of cross-functional collaboration, data quality, and transparency, allowing managers to make proactive, informed decisions. Additionally, it provides a clear mapping of roles, responsibilities, and workflows, reducing inefficiencies and ensuring compliance with internal policies and external regulations. Organizations can use the UDMF as a benchmarking tool, assessing current practices, identifying gaps, and prioritizing investments to enhance both operational performance and strategic alignment.

In essence, the framework transforms the traditional perception of data management from a support function into a strategic capability, offering actionable insights for research and practice while fostering more resilient, intelligent, and sustainable supply chains.

6. Conclusions

This review highlights the growing importance of AI- and IoT-driven data management in smart supply chains over the 2020–2025 period, particularly in manufacturing contexts. Despite progress, several gaps remain. Key phases such as procurement, logistics, and after-sales are often underexplored, governance and security are treated in isolation, and empirical validation is limited [33,34,35,36,37,38,39,40,41,42].

The proposed Unified Data Management Framework addresses these gaps by providing a holistic, end-to-end model that integrates technical, organizational, and governance dimensions. It ensures that data flows are consistent, analytics are actionable, and governance mechanisms are embedded throughout the supply chain. By combining the data value chain with phase-specific activities, actors, and technologies, the framework provides both a conceptual consolidation of current knowledge and a practical guide for implementation.

In practice, the framework offers a structured blueprint for companies to enhance decision-making, improve operational efficiency, and ensure compliance with governance and security standards. It is particularly relevant for large manufacturing enterprises, high-tech and electronics firms leveraging AI and IoT, logistics and distribution companies seeking end-to-end visibility, and SMEs aiming to scale their digital capabilities. By adopting the framework, organizations can increase resilience to disruptions, enhance agility, optimize resource use, and prepare for the integration of emerging technologies such as generative AI, edge computing, and advanced digital twins.

Future research should focus on large-scale empirical validation across multiple industries and supply chain phases, assessing the framework’s impact on resilience, agility, and sustainability metrics. Additionally, studies could explore its adaptability to emerging technologies such as generative AI, edge computing, and advanced digital twins. For practitioners, the framework offers a blueprint for improving visibility, decision-making, and operational efficiency while ensuring compliance, security, and value creation.

Ultimately, the framework represents a step toward intelligent, integrated, and sustainable supply chain management, bridging the gap between academic research and real-world application and providing a foundation for both scholarly inquiry and managerial practice.

Author Contributions

Conceptualization, N.S., J.G. and Y.G.; methodology, N.S., J.G. and Y.G.; software, N.S.; validation, N.S. and Y.G.; formal analysis, N.S. and Y.G.; investigation, N.S. and Y.G.; resources, N.S. and Y.G.; data curation, N.S.; writing—original draft preparation, N.S.; writing—review and editing, N.S. and Y.G.; visualization, N.S.; supervision, J.G. and Y.G.; project administration, N.S., J.G. and Y.G.; funding acquisition, J.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

All data analyzed in this systematic literature review are from previously published studies, which are cited in the References section.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Lee, I.; Mangalaraj, G. Big Data Analytics in Supply Chain Management: A Systematic Literature Review and Research Directions. Big Data Cogn. Comput. 2022, 6, 17. [Google Scholar] [CrossRef]

- Cuñat Negueroles, S.; Reinosa Simón, R.; Julián, M.; Belsa, A.; Lacalle, I.; San Julián, R.; Palau, C.E. A Blockchain-Based Digital Twin for IoT Deployments in Logistics and Transportation. Future Gener. Comput. Syst. 2024, 158, 73–88. [Google Scholar] [CrossRef]

- Riahi, Y.; Saikouk, T.; Gunasekaran, A.; Badraoui, I. Artificial Intelligence Applications in Supply Chain: A Descriptive Bibliometric Analysis and Future Research Directions. Expert Syst. Appl. 2021, 173, 114702. [Google Scholar] [CrossRef]

- Atzeni, G.; Vignali, G.; Tebaldi, L.; Bottani, E. A Bibliometric Analysis on Collaborative Robots in Logistics 4.0 Environments. Procedia Comput. Sci. 2021, 180, 686–695. [Google Scholar] [CrossRef]

- Waduge, S.; Sugathadasa, R.; Piyatilake, A.; Nanayakkara, S. A Process Analysis Framework to Adopt Intelligent Robotic Process Automation (IRPA) in Supply Chains. Sustainability 2024, 16, 9753. [Google Scholar] [CrossRef]

- Zaidi, S.A.H.; Khan, S.A.; Chaabane, A. Unlocking the Potential of Digital Twins in Supply Chains: A Systematic Review. Supply Chain. Anal. 2024, 7, 100075. [Google Scholar] [CrossRef]

- Culot, G.; Podrecca, M.; Nassimbeni, G. Artificial Intelligence in Supply Chain Management: A Systematic Literature Review of Empirical Studies and Research Directions. Comput. Ind. 2024, 162, 104132. [Google Scholar] [CrossRef]

- Jahin, M.A.; Shovon, M.S.H.; Shin, J.; Ridoy, I.A.; Mridha, M.F. Big Data—Supply Chain Management Framework for Forecasting: Data Preprocessing and Machine Learning Techniques. arXiv 2025, arXiv:2307.12971. [Google Scholar]

- Willoughby, C.; Frey, J.G. Data Management Matters. Digit. Discov. 2022, 1, 183–194. [Google Scholar] [CrossRef]

- Li, X.; Cheng, Y.; Møller, C. Data Governance: A Critical Foundation for Data Driven Decision-Making in Operations and Supply Chains. arXiv 2024, arXiv:2409.15137. [Google Scholar] [CrossRef]

- Oger, R.; Lauras, M.; Montreuil, B.; Benaben, F. A Decision Support System for Strategic Supply Chain Capacity Planning under Uncertainty: Conceptual Framework and Experiment. Enterp. Inf. Syst. 2022, 16, 1793390. [Google Scholar] [CrossRef]

- Novoszel, L.; Claus, I. A Methodological Framework Addressing Challenges and Opportunities in Supply Chain AI. IFAC-PapersOnLine 2024, 58, 349–354. [Google Scholar] [CrossRef]

- Bližnák, K.; Munk, M.; Pilková, A. A Systematic Review of Recent Literature on Data Governance (2017–2023). IEEE Access 2024, 12, 149875–149888. [Google Scholar] [CrossRef]

- Henderson, D.; Earley, S.; Data Administration Management Association (Eds.) DAMA-DMBOK: Data Management Body of Knowledge, 2nd ed.; Technics Publications: Basking Ridge, NJ, USA, 2017; ISBN 978-1-63462-247-9. [Google Scholar]

- Schmuck, M. Master Data Management as Part of Data Governance: A Maturity Model to Improve Efficiency and Trust in Master Data and Thus Business Performance. Bus. Perform. Rev. 2024, 2, 20–34. [Google Scholar] [CrossRef]

- Lujic, I.; De Maio, V.; Brandic, I. Resilient Edge Data Management Framework. IEEE Trans. Serv. Comput. 2020, 13, 663–674. [Google Scholar] [CrossRef]

- Jackson, I.; Ivanov, D.; Dolgui, A.; Namdar, J. Generative Artificial Intelligence in Supply Chain and Operations Management: A Capability-Based Framework for Analysis and Implementation. Int. J. Prod. Res. 2024, 62, 6120–6145. [Google Scholar] [CrossRef]

- Pan, Y.; Kang, S.; Kong, L.; Wu, J.; Yang, Y.; Zuo, H. Remaining Useful Life Prediction Methods of Equipment Components Based on Deep Learning for Sustainable Manufacturing: A Literature Review. Artif. Intell. Eng. Des. Anal. Manuf. 2025, 39, e4. [Google Scholar] [CrossRef]

- Bahi, A.; Gharib, J.; Gahi, Y. Integrating Generative AI for Advancing Agile Software Development and Mitigating Project Management Challenges. Int. J. Adv. Comput. Sci. Appl. 2024, 15, 54–61. [Google Scholar] [CrossRef]

- Zorrilla, M.; Yebenes, J. A Reference Framework for the Implementation of Data Governance Systems for Industry 4.0. Comput. Stand. Interfaces 2022, 81, 103595. [Google Scholar] [CrossRef]

- Vial, G. Data Governance and Digital Innovation: A Translational Account of Practitioner Issues for IS Research. Inf. Organ. 2023, 33, 100450. [Google Scholar] [CrossRef]

- Al Nuaimi, D.; Awofeso, N. The value of applying big data analytics in health supply chain management. F1000Research 2025, 13, 1237. [Google Scholar] [CrossRef]

- Bena, Y.A.; Ibrahim, R.; Mahmood, J.; Al-Dhaqm, A.; Alshammari, A.; Nasser, M.; Nura Yusuf, M.; Ayemowa, M.O. Big Data Governance Challenges Arising from Data Generated by Intelligent Systems Technologies: A Systematic Literature Review. IEEE Access 2025, 13, 12859–12888. [Google Scholar] [CrossRef]

- Alhassan, I.; Sammon, D.; Daly, M. Data governance activities: An analysis of the literature. J. Decis. Syst. 2016, 25, 64–75. [Google Scholar] [CrossRef]

- Hussain, S.M.; Balakrishna, A.; Naidu, K.T.N.; Pareek, P.; Malviya, N.; Reis, M.J.C.S. Enhancing Supply Chain Efficiency in India: A Sustainable Framework to Minimize Wastage Through Authentication and Contracts. Sustainability 2025, 17, 808. [Google Scholar] [CrossRef]

- Turi, A. Mitigating Data Inaccuracy and Supply Chain Challenges in Western Romania’s Automotive Industry. Acta Logist. 2024, 11, 473–483. [Google Scholar] [CrossRef]

- Reinpold, L.M.; Wagner, L.P.; Gehlhoff, F.; Ramonat, M.; Kilthau, M.; Gill, M.S.; Reif, J.T.; Henkel, V.; Scholz, L.; Fay, A. Systematic Comparison of Software Agents and Digital Twins: Differences, Similarities, and Synergies in Industrial Production. J. Intell. Manuf. 2025, 36, 765–800. [Google Scholar] [CrossRef]

- Jamarani, A.; Haddadi, S.; Sarvizadeh, R.; Haghi Kashani, M.; Akbari, M.; Moradi, S. Big Data and Predictive Analytics: A Systematic Review of Applications. Artif. Intell. Rev. 2024, 57, 176. [Google Scholar] [CrossRef]

- Melo, P.F.S.; Godoy, E.P.; Ferrari, P.; Sisinni, E. Open Source Control Device for Industry 4.0 Based on RAMI 4.0. Electronics 2021, 10, 869. [Google Scholar] [CrossRef]

- Rolf, B.; Jackson, I.; Müller, M.; Lang, S.; Reggelin, T.; Ivanov, D. A Review on Reinforcement Learning Algorithms and Applications in Supply Chain Management. Int. J. Prod. Res. 2023, 61, 7151–7179. [Google Scholar] [CrossRef]

- Werbińska-Wojciechowska, S.; Giel, R.; Winiarska, K. Digital Twin Approach for Operation and Maintenance of Transportation System—Systematic Review. Sensors 2024, 24, 6069. [Google Scholar] [CrossRef]

- Abaku, E.A.; Edunjobi, T.E.; Odimarha, A.C. Theoretical Approaches to AI in Supply Chain Optimization: Pathways to Efficiency and Resilience. Int. J. Sci. Technol. Res. Arch. 2024, 6, 092–107. [Google Scholar] [CrossRef]

- Huda, M.; Rahayu, A.; Furqon, C.; Sultan, M.A.; Hartati, N.; Sugiana, N.S.S. Improving Performance with Big Data: Smart Supply Chain and Market Orientation in SMEs. Int. J. Adv. Comput. Sci. Appl. 2025, 16, 80. [Google Scholar] [CrossRef]

- Sony, M. Pros and Cons of Implementing Industry 4.0 for the Organizations: A Review and Synthesis of Evidence. Prod. Manuf. Res. 2020, 8, 244–272. [Google Scholar] [CrossRef]

- Alsolbi, I.; Shavaki, F.H.; Agarwal, R.; Bharathy, G.K.; Prakash, S.; Prasad, M. Big Data Optimisation and Management in Supply Chain Management: A Systematic Literature Review. Artif. Intell. Rev. 2023, 56, 253–284. [Google Scholar] [CrossRef]

- Fu, X.; Song, H.; Li, S.; Lu, Y. Digital Twin Technology in Modern Machining: A Comprehensive Review of Research on Machining Errors. J. Manuf. Syst. 2025, 79, 134–161. [Google Scholar] [CrossRef]

- Zimmermann, R.; Brandtner, P. From Data to Decisions: Optimizing Supply Chain Management with Machine Learning-Infused Dashboards. Procedia Comput. Sci. 2024, 237, 955–964. [Google Scholar] [CrossRef]

- Huang, J.; Li, S.M. Data-Driven Analysis of Supply Chain Integration’s Impact on Procurement Performance in International EPC Projects. Sustainability 2024, 16, 10729. [Google Scholar] [CrossRef]

- Cañas, H.; Mula, J.; Campuzano-Bolarín, F.; Poler, R. A Conceptual Framework for Smart Production Planning and Control in Industry 4.0. Comput. Ind. Eng. 2022, 173, 108659. [Google Scholar] [CrossRef]

- Oñate, W.; Sanz, R. Integration of Fog Computing in a Distributed Manufacturing Execution System Under the RAMI 4.0 Framework. Appl. Sci. 2024, 14, 10539. [Google Scholar] [CrossRef]

- Perano, M.; Cammarano, A.; Varriale, V.; Del Regno, C.; Michelino, F.; Caputo, M. Embracing Supply Chain Digitalization and Unphysicalization to Enhance Supply Chain Performance: A Conceptual Framework. Int. J. Phys. Distrib. Logist. Manag. 2023, 53, 628–659. [Google Scholar] [CrossRef]

- Iftikhar, A.; Ali, I.; Arslan, A.; Tarba, S. Digital Innovation, Data Analytics, and Supply Chain Resiliency: A Bibliometric-Based Systematic Literature Review. Ann. Oper. Res. 2024, 333, 825–848. [Google Scholar] [CrossRef]

- Douimia, S.; Bekrar, A.; Ait El Cadi, A.; El Hillali, Y.; Fillon, D. Machine Learning and Deep Learning Applications in the Automotive Manufacturing Industry: A Systematic Literature Review and Industry Insights. Robot. Comput. Integr. Manuf. 2025, 96, 103034. [Google Scholar] [CrossRef]

- Grace Tetteh, M.; Gupta, S.; Kumar, M.; Trollman, H.; Salonitis, K.; Jagtap, S. Pharma 4.0: A Deep Dive Top Management Commitment to Successful Lean 4.0 Implementation in Ghanaian Pharma Manufacturing Sector. Heliyon 2024, 10, e36677. [Google Scholar] [CrossRef]

- Kachiche, S.; Gahi, Y.; Gharib, J. An Efficient Framework for the Implementation of Sustainable Industry 4.0. In Innovations in Smart Cities Applications Volume 6; Ben Ahmed, M., Boudhir, A.A., Santos, D., Dionisio, R., Benaya, N., Eds.; Lecture Notes in Networks and Systems; Springer International Publishing: Cham, Switzerland, 2023; Volume 629, pp. 804–815. ISBN 978-3-031-26851-9. [Google Scholar]

- Herrmann, J.-P.; Tackenberg, S.; Padoano, E.; Gamber, T. A Literature Review and Cluster Analysis of the Aachen Production Planning and Control Model under Industry 4.0. Procedia Comput. Sci. 2021, 180, 208–218. [Google Scholar] [CrossRef]

- Rahmani, M.; Romsdal, A.; Sgarbossa, F.; Strandhagen, J.O.; Holm, M. Towards Smart Production Planning and Control; a Conceptual Framework Linking Planning Environment Characteristics with the Need for Smart Production Planning and Control. Annu. Rev. Control. 2022, 53, 370–381. [Google Scholar] [CrossRef]

- Shin, M. Development of Collaboration Model for Data Space-Based Open Collaboration Platform in Continuous Process Industries. Sustainability 2024, 17, 126. [Google Scholar] [CrossRef]

- Unterberger, P.; Müller, J.M. Clustering and Classification of Manufacturing Enterprises Regarding Their Industry 4.0 Reshoring Incentives. Procedia Comput. Sci. 2021, 180, 696–705. [Google Scholar] [CrossRef]

- Merwe, E.; Pisa, N.; Gideon, E.; Chakamera, C. Effects of Material Master Data Management on Supply Chain Performance at FLSmidth: The Moderating Role of PiLog External Service Provider. Acta Logist. 2024, 11, 569–578. [Google Scholar] [CrossRef]

- Spanaki, K.; Dennehy, D.; Papadopoulos, T.; Dubey, R. Data-Driven Digital Transformation in Operations and Supply Chain Management. Int. J. Prod. Econ. 2025, 284, 109599. [Google Scholar] [CrossRef]

- Pellen, C.; Munung, N.S.; Armond, A.C.; Kulp, D.; Mansmann, U.; Siebert, M.; Naudet, F. Data Management and Sharing. J. Clin. Epidemiol. 2025, 180, 111680. [Google Scholar] [CrossRef]

- Helmann, A.; Deschamps, F.; Loures, E.D.F.R. Reference Architectures for Industry 4.0: Literature Review. In Advances in Transdisciplinary Engineering; Pokojski, J., Gil, M., Newnes, L., Stjepandić, J., Wognum, N., Eds.; IOS Press: Amsterdam, The Netherlands, 2020; ISBN 978-1-64368-110-8. [Google Scholar]

- Atakok, G.; Cun, M. Management of the Engineering Data for Manufacturing. J. Eng. Res. 2022, 10, 258–269. [Google Scholar] [CrossRef]

- Binder, C.; Leiter, W.; Joebstl, O.; Mair, L.; Neureiter, C.; Luder, A. Utilizing an Enterprise Architecture Framework for Model-Based Industrial Systems Engineering. In Proceedings of the 2021 IEEE 19th International Conference on Industrial Informatics (INDIN), Palma de Mallorca, Spain, 21 July 2021; pp. 1–6. [Google Scholar]

- Techanamurthy, U.; Iqbal, M.S.; Abdul Rahim, Z. Industry 4.0 readiness and strategic plan failures in SMEs: A comprehensive analysis. PLoS ONE 2025, 20, e0324052. [Google Scholar] [CrossRef]

- Horstkemper, D.; Mülhausen, A.; Hellingrath, B. Structured Approach for Automated Enterprise Architecture Model Generation. IFAC-PapersOnLine 2023, 56, 3648–3653. [Google Scholar] [CrossRef]

- Baptista, L.F.; Barata, J. Piloting Industry 4.0 in SMEs with RAMI 4.0: An Enterprise Architecture Approach. Procedia Comput. Sci. 2021, 192, 2826–2835. [Google Scholar] [CrossRef]

- Jayadi, E.L. The Digitalization of the Humanitarian Supply Chain Performance Management Literature and Practice. J. Humanit. Logist. Supply Chain. Manag. 2025, 15, 175–193. [Google Scholar] [CrossRef]

- Aldossari, S.; Mokhtar, U.A.; Abdul Ghani, A.T. Factor Influencing the Adoption of Big Data Analytics: A Systematic Literature and Experts Review. Sage Open 2023, 13, 21582440231217902. [Google Scholar] [CrossRef]

- Leite, D.; Andrade, E.; Rativa, D.; Maciel, A.M.A. Fault Detection and Diagnosis in Industry 4.0: A Review on Challenges and Opportunities. Sensors 2024, 25, 60. [Google Scholar] [CrossRef] [PubMed]

- Tang, H.; Zhu, J.; Li, N.; Wu, W. Impact of Enterprise Supply Chain Digitalization on Cost of Debt: A Four-Flows Perspective Analysis Using Explainable Machine Learning Methodology. Sustainability 2024, 16, 8702. [Google Scholar] [CrossRef]

- Ma, S.; Ding, W.; Liu, Y.; Zhang, Y.; Ren, S.; Kong, X.; Leng, J. Industry 4.0 and Cleaner Production: A Comprehensive Review of Sustainable and Intelligent Manufacturing for Energy-Intensive Manufacturing Industries. J. Clean. Prod. 2024, 467, 142879. [Google Scholar] [CrossRef]

- Farshadfar, Z.; Mucha, T.; Tanskanen, K. Leveraging Machine Learning for Advancing Circular Supply Chains: A Systematic Literature Review. Logistics 2024, 8, 108. [Google Scholar] [CrossRef]