Abstract

Marine engineering equipment operates under extreme conditions such as high salinity, humidity, and flow velocity during marine resource exploration. These harsh environments impose strict requirements on surface performance, especially in terms of wear and corrosion resistance. Wear-resistant coatings are increasingly regarded as a crucial surface engineering approach to mitigate multi-mechanism degradation and improve the long-term reliability of marine equipment. In this review, the typical wear mechanisms in marine environments are systematically analyzed. Corresponding to different service scenarios, the main categories of coating materials, such as metal matrix composite coatings, cermet coatings, functionally graded coatings, and nanolayered coatings are summarized in terms of their structure and performance characteristics. Furthermore, mainstream fabrication techniques, including high-velocity oxy-fuel (HVOF), high-velocity air-fuel (HVAF), laser cladding, cold spray, and physical/chemical vapor deposition (PVD/CVD), are reviewed with respect to their influence on coating micro-structure and properties. Standardized evaluation methods for coating performance are also discussed. Finally, the current research challenges are identified, and future development trends are outlined, with an emphasis on multifunctional, intelligent, and environmentally friendly coating systems. This work aims to provide a systematic reference and theoretical basis for the design and application of wear-resistant coatings in marine environments.

1. Introduction

With the expanding exploration and utilization of global marine resources, marine engineering equipment is increasingly deployed in offshore oil and gas, wind energy, deep-sea exploration, and transoceanic transportation. Compared with terrestrial conditions, marine environments feature high salinity, elevated humidity, strong hydrodynamic forces, and complex corrosion–wear interactions (including erosion, cavitation, and biofouling), imposing stringent demands on surface integrity and durability. The long-term retention of wear resistance, corrosion resistance, and high strength in structural components is therefore critical to operational safety and reliability.

Conventional metals (e.g., carbon steel, stainless steel) are prone to accelerated corrosion and wear in marine environments, leading to frequent maintenance, shortened lifespans, increased costs, and even catastrophic accidents [1]. Consequently, developing advanced wear-resistant coatings has become a key strategy to extend the service life and safety of marine infrastructure.

In recent years, both coating material systems (e.g., WC–Co, Cr3C2–NiCr, thermally sprayed aluminum, TSA) and deposition technologies (e.g., HVOF, HVAF, laser cladding, cold spray, and PVD/CVD) have markedly improved coating density, hardness, corrosion resistance, and long-term stability [2]. Standardized evaluation methods have also been established to assess performance under combined erosion–corrosion, wear, and fatigue conditions. However, challenges remain, including limited service life under extreme conditions, complex failure mechanisms, and trade-offs between performance and cost. The long-term behavior of coatings under deep-sea hydrostatic pressure and synergistic erosion–corrosion is still insufficiently understood [3].

Driven by advances in materials science and surface engineering, novel systems—such as high-entropy alloy coatings, MAX-phase coatings, and nano-multilayer composites—have shown excellent wear, corrosion, and thermal stability, making them promising for future marine protection [4]. Intelligent, self-healing, and environmentally friendly coatings are also attracting growing attention as future trends.

Distinguished from broader overviews, this review adopts a systematic, application-oriented framework: it first analyzes predominant wear mechanisms (erosion, fatigue, cavitation, abrasive wear) and their synergies with corrosion, then details coating systems tailored to key marine components (e.g., subsea pipelines, ship structures, propellers). It critically compares advanced fabrication techniques (HVOF, HVAF, laser cladding, cold spray, PVD/CVD), highlighting process–microstructure–property linkages, and discusses standardized performance evaluation to bridge laboratory research with practice. Through this integrated approach—linking failure mechanisms to tailored coating solutions, optimized fabrication, and rigorous evaluation—the review provides a structured, practical reference for selecting and developing high-performance wear-resistant coatings in marine engineering.

This review is organized as follows. Section 2 outlines marine service conditions and dominant wear/corrosion mechanisms. Section 3 examines representative coating systems and application-specific demands for key components (e.g., subsea pipelines, structural steels, propulsion and hydraulic parts, wind-energy structures, seals/connectors). Section 4 analyzes fabrication routes (HVOF/HVAF, laser cladding, TSA/arc spray, cold spray, PVD/CVD) with a quantitative comparison. Section 5 summarizes standardized performance-evaluation methods (wear, corrosion, cavitation, and corrosion-fatigue). Section 6 synthesizes recent advances, environmental/economic considerations, and future trends, and provides a practical decision tree for coating selection.

2. Wear Mechanisms in Marine Environments

This section defines the marine exposure regimes and clarifies the five dominant degradation modes considered in this review: erosion wear, fatigue wear, cavitation erosion, abrasive wear, and corrosion–wear synergy. For each mechanism, we briefly state the operative micro/meso-scale processes and the key controlling parameters relevant to marine service.

2.1. Erosion Wear

Under fluid flow conditions carrying solid particles, erosion wear commonly occurs on material surfaces, particularly in applications related to oil and gas, shipbuilding, and marine engineering. This wear phenomenon is primarily caused by continuous particle impact from high-velocity flows, triggering damage mechanisms such as plastic deformation, micro-cutting, and fatigue-induced surface degradation [5].

The rate and pattern of erosion wear are governed by multiple factors, including particle size, concentration, fluid velocity, impact angle, and substrate material properties. Notably, flow velocity has a significant influence on erosion rate, which typically increases with the square of velocity [6]. Higher fluid viscosity can effectively reduce particle kinetic energy, thereby lowering erosion rates.

In deep-sea natural gas hydrate extraction research, Tang et al. employed CFD simulations to reveal that the sliding cone angle and particle diameter in pressure-controlled jetting systems are critical factors determining internal erosion wear distribution. Their findings indicate that adjusting the sliding cone inlet angle to 30° while controlling solid particle diameters below 0.3 mm can significantly reduce erosion rates [6].

Concurrently, in studies of localized erosion at pipeline connections during oil/gas fracturing operations, Manlai Zhang et al. combined experimental and CFD approaches to demonstrate that excessively high initial erosion rates may lead to subsequent misjudgment of equipment service life, and emphasized the necessity of adopting dynamic evolution models for service life assessment [7].

With the advancement of artificial intelligence, Yang et al. proposed the FLUID-GPT machine learning framework, which can efficiently predict erosion distribution in industrial equipment based on initial flow conditions. Compared with conventional CFD methods, this approach improved prediction accuracy by 54% while significantly reducing computational resource requirements [5].

2.2. Fatigue Wear

In marine environments, materials are subjected not only to corrosion and erosion damage, but also to fatigue wear induced by cyclic mechanical and hydrodynamic loading. Fatigue wear refers primarily to the cumulative damage that occurs on material surfaces or subsurface layers under cyclic stresses, resulting in the formation of micro-cracks and ultimately leading to material spalling or surface layer failure.

In marine engineering applications, components such as flexible risers, offshore wind turbines, and floating platform mooring chains are frequently exposed to combined low-cycle and high-cycle fatigue due to wave action, currents, and operational loads. Pinto et al. proposed a fatigue life assessment method based on the finite element method combined with wear modification, which demonstrated that surface micro-wear accelerates both fatigue crack initiation and propagation, and that critical distance parameters evolve with fatigue life and should be dynamically adjusted to accurately predict failure [8].

In addition, Zhou et al. investigated the real working conditions of marine diesel engine main bearings and used a convolutional neural network model to identify three typical wear mechanisms: fatigue wear, abrasive wear, and adhesive wear Their work confirmed the prevalence and diagnostic complexity of fatigue wear in complex marine mechanical systems [9].

2.3. Cavitation Erosion

Cavitation erosion refers to the process in which bubbles within a fluid rapidly collapse under pressure fluctuations, generating high-pressure microjets and shock waves that cause localized plastic deformation and surface material loss. In marine environments, components such as ship propellers, pump housings, valves, and other submerged equipment often operate in high-velocity flow regions where cavitation erosion is especially likely to occur. It is considered a major contributor to equipment failure and performance degradation [10].

The cavitation erosion mechanism involves bubble nucleation, growth, movement, and eventual collapse. Each collapse event induces high localized stress on the material surface, which can lead to fatigue damage, micro-crack formation, and eventual material spalling. Studies have shown that incorporating micro-vortex generators in hydrodynamic systems can effectively control cavitation inception and delay bubble collapse, thereby reducing cavitation-induced damage.

To improve cavitation resistance, T. Zhao et al. prepared Inconel 625 and Hastelloy C-276 nickel-based alloy coatings using the cold metal transfer method, and evaluated their cavitation–corrosion synergy behavior in a 3.5% NaCl solution. The results showed that the Hastelloy C-276 coating exhibited a lower cavitation erosion rate and superior corrosion resistance, significantly enhancing service life compared with 304 stainless steel substrates [11].

Additionally, Linek et al. [12] investigated the cavitation resistance of CrN+WC/C low-friction composite coatings under extreme cavitation conditions. These coatings, deposited via PVD, demonstrated reduced mass loss rates and smaller changes in surface roughness on various steel substrates, highlighting the potential of surface engineering techniques for enhancing cavitation resistance [12].

2.4. Abrasive Wear

In marine environments, seawater often contains a large number of solid particles, such as sand, silt, and fine marine sediment. When these hard particles come into contact with material surfaces under the influence of fluid flow, waves, or mechanical motion, abrasive wear is induced. This wear process occurs through mechanisms such as scratching, cutting, or plowing, which continuously remove surface material and represent a significant physical degradation mode that limits the service life of marine equipment.

Abrasive wear can be classified into two basic types: two-body abrasive wear, where fixed particles directly scratch the surface; and three-body abrasive wear, where free particles roll or slide between two contacting surfaces [13].

In practical applications, severe abrasive wear is often observed in systems such as ship stern shaft mechanical seals, subsea pipeline protective coatings, and offshore wind turbine foundations due to the presence of marine sand particles. Jin et al., through simulations and experiments, found that larger seawater particle sizes significantly increased the residual stress and deformation of the static ring in mechanical seals, thereby accelerating the wear rate. Additionally, soft-ring materials were more prone to surface spalling under particle erosion [14].

Zhang et al. conducted experiments on EH47 high-strength ship steel in a 3.5 wt% NaCl solution containing sand particles, and observed that abrasive effects intensified with increasing external load. Under high-load conditions, abrasive wear was found to be the dominant mechanism, while corrosion played a secondary role [15].

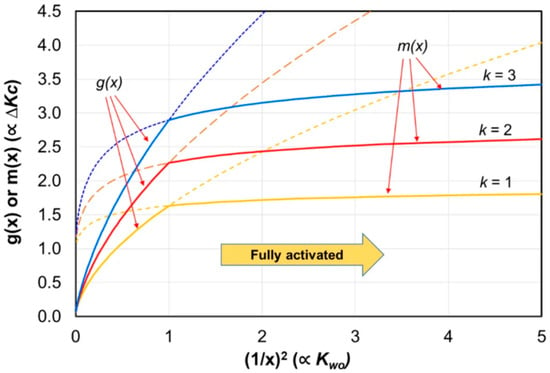

Notably, recent studies have increasingly focused on the synergistic effects between abrasive wear and corrosion. Jiang et al. proposed a coupled damage modeling approach based on the formation of abrasion grooves and corrosion enhancement, revealing that freshly exposed areas on the surface can be rapidly attacked by corrosive media in marine environments, thus further reducing wear resistance [13]. The predicted trend of wear-accelerated corrosion is depicted in Figure 1, where functions g(x) and m(x) represent corrosion behavior under low and high wear intensity, respectively. This model visually underscores the critical synergistic effect where corrosion is enhanced in areas freshly exposed by abrasive wear.

Figure 1.

Predicted general trend of wear-accelerated corrosion as a function of wear intensity. (The horizontal axis represents wear intensity as (1/x)2. Functions g(x) and m(x) denote corrosion behavior under low and high wear intensity conditions, respectively.) Reprinted with permission from Ref. [13]. 2024, Springer Nature.

Therefore, in abrasive marine conditions, the development of composite coatings with high hardness and excellent impact resistance—such as WC-Co coatings and ceramic-based composites—has become an effective strategy to enhance surface durability.

2.5. Corrosion-Wear Synergy

In marine environments, materials are frequently exposed to high salinity, high humidity, and highly dynamic seawater conditions. As a result, mechanical wear and electrochemical degradation frequently occur concurrently, leading to a synergistic corrosion-wear effect. The resulting material loss rate substantially exceeds the sum of the individual effects of wear and corrosion, demonstrating a typical synergistic degradation mechanism.

Corrosion processes tend to degrade passive films or protective layers on material surfaces, thereby exposing fresh metal that becomes more susceptible to mechanical wear. Conversely, mechanical wear continuously removes corrosion products and damaged areas, further accelerating the progression of corrosion. This dynamic interaction is particularly evident in abrasive and erosive wear scenarios, such as those encountered in tidal power generators, subsea pipelines, and propulsion systems.

Pondicherry et al. investigated the corrosion-abrasive wear behavior of martensitic and duplex stainless steels in seawater, and demonstrated that in 3.5% NaCl solution, the effect of mechanical wear in promoting corrosion was much more significant than the effect of corrosion on wear. Mechanical damage was identified as the dominant contributor to overall material degradation [16]. In another study, De Stefano and Ruggiero examined the corrosion-wear synergy of 316L stainless steel in artificial seawater, and found that corrosion products temporarily functioned as solid lubricants under mild load and low sliding velocity conditions, reducing friction and wear. However, under higher loads and sliding velocities, corrosion was shown to accelerate wear, exhibiting a typical positive synergistic effect [17].

In the context of wear-resistant coatings, the synergistic interaction between corrosion and wear necessitates the simultaneous optimization of coating micro-structure and chemical stability. For instance, Dong et al. developed a wavy nanolayered coating that exhibited outstanding corrosion-wear resistance in artificial seawater. The coating’s high hardness and ability to form a reactive surface film effectively prevented the ingress of corrosive media [18].

Therefore, in the development of wear-resistant coatings for marine environments, it is essential to fully consider corrosion-wear synergy and to optimize coating microstructure and chemical stability in order to achieve long-term service performance.

3. Types and Properties of Marine Wear-Resistant Coatings

This section links application demands to coating choices. Section 3.1 summarizes what each key component class needs in service (e.g., resistance to erosion–corrosion, cavitation, splash/cyclic wet–dry, or corrosion–fatigue) and highlights the coating types that have shown quantified benefits in those conditions. Section 3.2 then groups these options by material family and distills the core property levers (density/defect control, hard-phase continuity, multilayer interface design, graded architectures) that underpin the reported improvements (see Table 1).

Table 1.

Comparative performance of representative wear-resistant coating materials for marine environments.

3.1. Demand Analysis of Wear-Resistant Coatings for Key Components in Marine Engineering

3.1.1. Wear-Resistant Coatings for Subsea Pipelines and Oil & Gas Transportation Systems

As a critical infrastructure for offshore oil and gas development and transportation, subsea pipelines operate under extreme environmental conditions characterized by high salinity, humidity, flow velocity, and suspended sand or silt particles. These conditions pose a significant risk of erosion, abrasion, and synergistic corrosion–wear damage. Studies have shown that the combined effects of particle impingement in solid–liquid two-phase flow and corrosive media significantly accelerate surface degradation of pipeline materials, resulting in localized thinning of pipe walls and threatening structural integrity and service life [19].

To address these complex wear conditions, various high-performance wear-resistant coating systems have been developed. Notably, WC–Co coatings applied via high-energy thermal spraying techniques (e.g., HVOF) are widely used for internal wall protection due to their high hardness (>1200 HV), excellent erosion resistance, and strong adhesion.

Beyond laboratory characterizations, quantitative tests under simulated marine conditions further substantiate the effectiveness of such coatings: Muazu, Oke, and Sanni (2021) reported that a particulate composite zinc–aluminum coating on carbon steel pipeline coupons exposed to 3.5 wt% NaCl with cyclic flow for 2000 h yielded a corrosion rate of 0.025 mm·year−1 versus 0.087 mm·year−1 for uncoated steel—i.e., a 71% reduction—alongside markedly improved slurry-wear behavior [20].

Similarly, Liu et al. (2025) deposited a silicon-hydrogenated diamond-like carbon (Si-HDLC) film on N80 pipeline steel via PECVD; in a coupled erosion–corrosion slurry test the coating achieved 88% protection efficiency relative to the uncoated specimen, evidencing strong resistance to particle-induced degradation [21].

These experimental data provide direct evidence that properly engineered composite or nanostructured coatings can significantly mitigate synergistic wear–corrosion in oil and gas transportation systems, offering practical guidance for material selection in subsea pipeline protection. Consistent with this, Singh et al. systematically evaluated the wear performance of HVOF-sprayed WC-12Co coatings on pipeline steels using the Taguchi method and showed a significant reduction in wear rate, with particle impact velocity identified as the most influential factor for erosion wear [22].

In addition to cermets, emerging polymer-based nanocomposite coatings (e.g., epoxy–polyurethane matrices with Al2O3 or TiO2 nanoparticles) have shown promise for combined wear and corrosion protection; nanoparticle incorporation improves wear resistance, corrosion resistance, and interfacial bonding strength, making these systems suitable for sand-laden and corrosive service conditions [23]. For extreme erosion–corrosion environments (e.g., oil-sand transport), Cr3C2–NiCr composite coatings have been investigated; Lu et al. demonstrated that coating density critically governs corrosion resistance, with denser coatings effectively impeding corrosive media ingress and delaying corrosion–wear synergy progression [24]. Moreover, superhydrophobic micro/nano-structured surfaces have been introduced for pipeline internal protection to minimize corrosive species adherence and suppress cavitation/corrosion initiation; Zang et al. designed a robust biomimetic superhydrophobic coating and validated its superior wear and corrosion resistance under coupled erosion–corrosion with sand particles, indicating strong potential in deep-sea service [25]. These results indicate that carbide continuity and coating density control particle-induced micro-cutting and repassivation kinetics, which explains the lower erosion–corrosion rates observed under slurry flow.

3.1.2. Wear and Corrosion-Resistant Coatings for Ship and Offshore Platform Steel Structures

Steel structures used in ships and offshore platforms are subjected to complex and variable marine environments over long service periods, enduring combined effects from wave action, tides, splash-zone corrosion, mechanical wear, and cyclic fatigue loading. These harsh conditions often lead to abrasive wear, erosion wear, and corrosion–wear synergy, resulting in localized deterioration, crack initiation, and ultimately fatigue-induced failure. Therefore, high-performance wear-resistant coatings play a crucial role in protecting marine platforms and hull steel structures and extending their service life.

Field and laboratory investigations have provided quantitative data that confirm the protective performance of several coating systems on marine structural steels. These real-environment and accelerated-test results establish valuable benchmarks for coating design in offshore engineering.

For instance, Gericke et al. (2022) [26] examined arc-sprayed aluminum (TSA) coatings applied to welded S355 structural-steel joints representative of offshore platform components. After 12 months of cyclic immersion in artificial seawater, the TSA-coated specimens exhibited no measurable pitting and a fatigue-limit increase of approximately 32% compared with uncoated joints, demonstrating coupled improvement in corrosion and fatigue resistance.

In a related large-scale exposure study, Syrek-Gerstenkorn et al. (2019) [27] evaluated TSA coatings under full-immersion and splash-zone conditions. After 6 months, the fully immersed coatings formed a compact, adherent Al-oxide layer with a corrosion rate below 0.005 mm·year−1, whereas specimens in cyclic splash conditions showed a rate of 0.012 mm·year−1, still an order of magnitude lower than uncoated steel. Collectively, these findings confirm that TSA coatings significantly enhance the durability of ship and offshore-platform steels by mitigating both electrochemical corrosion and mechanical degradation.

To address the specific environmental challenges of marine service, various advanced coating systems have been developed for structural-steel protection. Among inorganic ceramics, nanostructured TiO2 coatings fabricated by plasma spraying have attracted attention because of their dense microstructure and high hardness. Tests conducted in 3.5 wt% NaCl solution showed that nano-TiO2 coatings exhibited markedly lower corrosion current densities and erosion rates than conventional TiO2 coatings, indicating superior barrier and erosion-resistant performance.

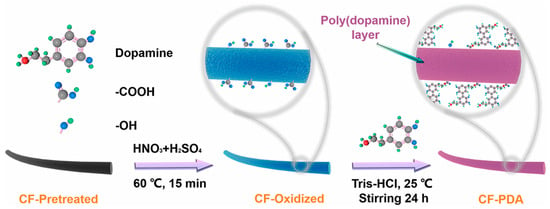

In terms of substrate reinforcement, Zhao et al. [28] proposed a composite coating reinforced with polydopamine-modified carbon fiber (CF-PDA) embedded in an epoxy matrix (Figure 2). This configuration improved interfacial bonding strength and enhanced resistance to wear and corrosion under high hydrostatic pressure and severe erosion–corrosion. Compared with unmodified epoxy coatings, the CF-PDA-reinforced system exhibited an approximately 19.4% improvement in erosion–wear resistance and a substantial increase in electrochemical impedance.

Figure 2.

Schematic illustration of the CF-PDA synthesis process. Reprinted with permission from Ref. [28]. 2022, Elsevier.

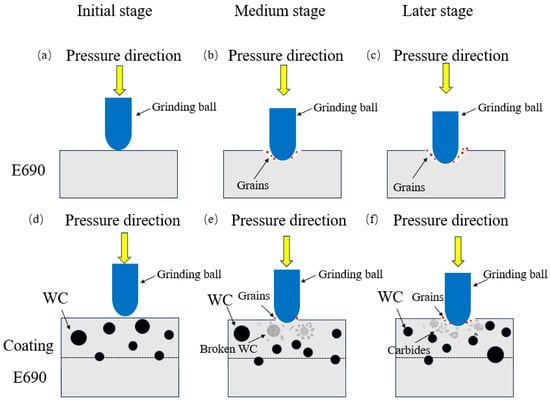

Laser-cladding technology has also gained broad application in the surface protection of offshore structural steels. Cao et al. [29] prepared a Ni60–WC composite coating on E690 high-strength steel (Figure 3), achieving a 103% increase in average hardness, a 62% enhancement in corrosion resistance, and a 79% improvement in wear resistance. Figure 4 compares the wear mechanisms between the substrate and the Ni60–WC coating, illustrating how the uniformly dispersed WC particles suppress crack propagation and surface spalling, accounting for the substantial improvement in wear behavior.

Figure 3.

Wear mechanisms of the substrate and the Ni60-WC composite coating. (a) Initial stage of E690 substrate: the grinding ball contacts the surface and begins material removal. (b) Medium stage of E690 substrate: loose wear grains form at the contact interface. (c) Later stage of E690 substrate: wear grains are compacted and accumulate under continuous load. (d) Initial stage of Ni60–WC coating: the grinding ball presses on the coating surface containing WC particles. (e) Medium stage of Ni60–WC coating: partial WC grains break and mix with the wear debris. (f) Later stage of Ni60–WC coating: carbides and fragmented WC grains form a stable tribolayer reducing wear. Reprinted with permission from Ref. [29]. 2024, MDPI.

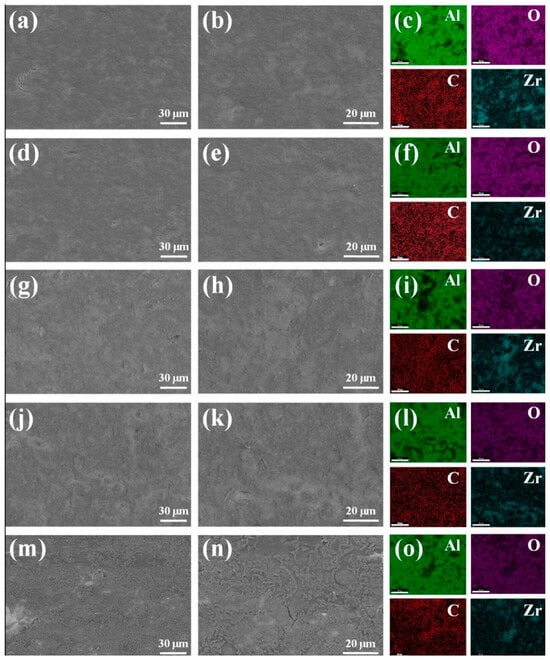

Figure 4.

FE-SEM images of the worn surface of the AT3-CW coating after (a–c) 5, (d–f) 10, (g–i) 21, (j–l) 45, and (m–o) 70 days of corrosion cycling. Reprinted with permission from Ref. [30]. 2025, Elsevier.

To further mitigate accelerated corrosion and fatigue damage in splash-zone regions, multilayer coating systems have been developed. These multilayer structures not only improve coating density and barrier properties but also provide superior resistance to mechanical impact and micro-crack propagation, offering a comprehensive protection strategy for long-service offshore structures. The sacrificial Al layer and compact oxides delay pit nucleation and fatigue crack initiation, accounting for the measured corrosion-rate reduction and the ~32% fatigue-limit increase.

3.1.3. Coatings for Propulsion Systems and Hydraulic Components

Key components of marine equipment such as propellers, pump impellers, and propulsion units operate under long-term exposure to high-speed fluid environments. They are frequently subjected to damage from solid-particle erosion, cavitation wear, and corrosion–cavitation synergy. The collapse of bubbles near metal surfaces produces high-energy microjets and shock waves, resulting in microcrack formation, fatigue-induced spalling, and plastic surface deformation, which can ultimately lead to coating delamination and substrate exposure. Therefore, the application of high-performance coatings resistant to both erosion and cavitation has become a critical strategy to enhance the service life of propulsion systems.

Recent experimental studies have provided quantitative evidence that advanced composite and alloy coatings can effectively suppress cavitation-induced surface failure and extend the service life of propulsive and hydraulic components in marine environments.

Linek et al. (2021) [12] evaluated a duplex CrN + WC/C low-friction coating deposited by PVD on ferritic–pearlitic P265GH and austenitic 304L steels under severe ultrasonic cavitation. After 10 h of testing in 3.5% NaCl solution, the coated samples showed a mass-loss rate of 0.4 mg·cm−2·h−1, compared with 2.1 mg·cm−2·h−1 for the uncoated substrate, corresponding to an 81% reduction in cavitation–erosion damage [12].

Similarly, Zhao et al. (2022) [11] prepared nickel-based alloy coatings (Inconel 625 and Hastelloy C-276) on 304 stainless steel using the cold metal transfer process. In a combined cavitation–corrosion test lasting 8 h in 3.5% NaCl, the Hastelloy C-276 coating exhibited a cumulative volume loss of 0.17 mm3, approximately 64% lower than that of uncoated 304 steel, confirming its superior resistance to synergistic cavitation–corrosion attack.

These controlled studies establish a quantitative foundation for the practical use of multi-phase ceramic–metal and nickel-based coatings in marine propulsion systems, highlighting the effectiveness of dense, well-adhered microstructures in resisting cavitation-driven material removal.

In the field of high-energy thermal spraying, coatings composed of WC–CrC–Ni deposited by HVAF spraying have demonstrated excellent cavitation resistance due to their dense microstructure, uniform dispersion of hard phases, and strong interfacial bonding. Alwan et al. developed a WC–20CrC–7Ni coating using the HVAF process, which exhibited superior cavitation resistance compared to conventional WC–10Co–4Cr coatings, achieving a ~17% reduction in volume loss during cavitation testing in artificial seawater [31].

Under actual seawater service conditions, the cavitation-wear resistance of coatings can be further affected by carbide morphology, residual porosity, and surface density. Addressing these variables, Algoburi et al. studied WC–NiCrBSi coatings prepared by thermal spraying and demonstrated that even without hot isostatic pressing, optimized carbide dispersion and coating compactness significantly enhanced resistance to cavitation-induced failure [32].

In terms of emerging coating materials, Al2O3–40TiO2 ceramic composite coatings have been increasingly applied to the surfaces of marine pump sleeves and impellers. Paleu et al. found through dry-wear testing that these ceramic coatings exhibited superior wear resistance compared to traditional stainless steel, along with measurable cavitation resistance, making them highly suitable for high-flow-rate hydraulic components [33].

Beyond composition optimization, recent work has emphasized microstructural tailoring as a means to improve cavitation performance. To address cavitation sensitivity caused by microstructural defects on propeller surfaces, the formation of strain-induced martensite from metastable austenite within the coating has been proposed. This transformation-induced hardening mechanism enhances surface strength under cavitation impact and suppresses crack propagation, providing a promising microstructural strategy for next-generation propeller coatings. Dense cermet and nickel-based matrices dissipate micro-jet shock and suppress crack coalescence, consistent with the reduced cavitation mass loss in 3.5% NaCl.

3.1.4. Coatings for Key Components of Offshore Wind Turbines and Floating Platforms

With the rapid expansion of offshore wind power, offshore wind turbines and their associated floating platforms are increasingly deployed in harsh marine environments, including strong winds, waves, and salt spray. These structures are frequently subjected to combined cyclic stress and corrosion, resulting in fatigue wear, corrosion fatigue, and abrasive–corrosive degradation—all of which severely compromise service life and operational safety [34].

To address corrosion fatigue failures at bolted joints—such as ring–flange connections—on floating wind turbine towers, various wear- and corrosion-resistant composite coatings have been developed. In recent years, a combination of laboratory and field investigations has quantitatively demonstrated that optimized thermal-sprayed coatings can greatly extend the operational durability of offshore wind-turbine and floating-platform steels.

Syrek-Gerstenkorn, Paul, and Davenport (2019) [27] conducted a comparative exposure study on thermally sprayed aluminium (TSA) coatings under submerged and splash-zone conditions to simulate offshore foundation service. After 180 days of cyclic wet–dry testing in 3.5% NaCl, submerged TSA coatings formed a dense oxide film and maintained a corrosion rate below 0.005 mm·year−1, while splash-zone samples showed 0.012 mm·year−1, still an order of magnitude lower than uncoated steel.

Extending these findings, Gericke et al. (2022) [26] evaluated TSA-coated welded S355 steel joints representative of offshore tower structures. After 12 months of seawater immersion and cyclic fatigue testing, the coated specimens exhibited no visible pitting and a 32% increase in fatigue limit relative to uncoated joints.

These results quantitatively validate that TSA coatings markedly enhance both corrosion and fatigue resistance for offshore wind-turbine foundations and floating-platform components operating in harsh marine environments.

Zhang et al. employed a multiphysics simulation framework coupled with experimental validation to reveal the degradation mechanisms of high-strength bolts under coupled wind–wave loading and salt-spray exposure. The study highlighted the critical importance of maintaining coating integrity and corrosion resistance to extend the service life of structural connectors.

For the structural protection of floating platforms, thermally sprayed aluminium coatings have been widely applied due to their excellent cathodic-protection capability and corrosion resistance. Gericke et al. reported that TSA coatings increased the fatigue limit of steel structures by >30% and provided superior corrosion resistance in simulated splash zone environments, effectively delaying fatigue crack initiation [26].

Coating systems are equally vital for mooring chains and connectors exposed to complex tensile–bending fatigue. Takeuchi et al. systematically evaluated the corrosion and wear-fatigue behaviour of mooring chains in floating wind turbines and found that coating defects such as local delamination significantly accelerated localized fatigue damage. The authors proposed enhancing coating densification and implementing targeted surface restoration strategies for mooring components [35].

In addition, Shojai et al. investigated the influence of pitting corrosion on the fatigue strength of offshore wind-support structures using 3D scanning techniques. Their results indicated that even minor pitting markedly reduced local fatigue life, underscoring the importance of coating systems in maintaining microstructural integrity [36].

Overall, both simulation-based analyses and quantitative field data converge to show that corrosion- and fatigue-resistant coatings—particularly TSA-based multilayer systems—are indispensable for ensuring the long-term reliability and safety of offshore wind-turbine towers and floating platforms.

3.1.5. Special Applications: Wear-Resistant Coatings for Seals and Connectors

In marine equipment, sealing components (such as hydraulic cylinder seals and pump shaft seals) and connectors (e.g., bolts and cable joints) are constantly subjected to high humidity, salinity, and severe mechanical vibration. These components frequently suffer from the combined effects of friction, erosion, and corrosion. Once failure is initiated in these components, the reliability of equipment operation is compromised and significant safety risks may arise. Therefore, the application of high-performance wear-resistant coatings on seals and connectors is considered an effective approach to extend service life and improve operational stability.

Recent experimental studies have provided quantitative verification of the tribological and corrosion-protective performance of advanced coating systems specifically designed for marine sealing and connector components.

Li, H. et al. (2022) [37] examined multilayer carbon-based coatings (Ti/DLC, TiCx/DLC, and Ti–TiCx/DLC) applied to stainless-steel substrates under tribocorrosion conditions. During a long-term test (sliding at 5 N load) the optimal Ti–TiCx/DLC coating exhibited a friction coefficient around 0.06 and remained functional for more than 24 h, indicating excellent coupling resistance to wear and corrosion.

These results quantitatively confirm that nanocomposite and self-lubricating coatings can markedly improve the service reliability of seals and connectors under coupled mechanical and electrochemical stresses in marine environments.

For sealing interfaces, multifunctional self-lubricating composite coatings have been developed in recent years. Lv et al. introduced Brazilian palm wax into an Al2O3–TiO2 ceramic-based coating to form a composite with excellent wear resistance, corrosion resistance, and low friction [30]. The wax phase sealed micro/nano-scale defects in the coating and significantly enhanced corrosion resistance. During frictional wear, the wax also formed a continuous lubricating film that effectively reduced wear rates, rendering the coating especially suitable for protecting sliding sealing interfaces. The evolution of the worn surface of the self-lubricating coating over 70 days of corrosion cycling is shown in the FE-SEM images of Figure 4, providing direct evidence of the coating’s durability and sustained lubricating function of the wax phase, which is key to its long-term performance in sealing interfaces.

For marine connectors such as bolts, nuts, and electrical cable joints, Parylene C/CrN bilayer coatings have recently demonstrated significantly enhanced anti-corrosion and anti-friction properties. Guan et al. reported that the Parylene C/CrN coating exhibited an extremely low corrosion current density (~10−9 A cm−2) and a friction coefficient < 0.05 in seawater. Compared with single-layer CrN coatings, the corrosion resistance was improved by an order of magnitude, and wear performance was also significantly enhanced.

In terms of material selection, recent studies have investigated the tribological behaviour between high-performance marine alloys (e.g., Inconel 625 and super-duplex stainless steel 2507) and PTFE-based sealing materials. Tuominen et al. fabricated Inconel 625 and 2509 coatings via laser cladding and tested them under sliding contact with various PTFE materials. The coatings exhibited favourable wear resistance, particularly when paired with glass-fibre-reinforced PTFE and MoS2-filled PTFE composites [38].

In addition, to address early failure caused by microcracks and porosity on sealing surfaces, Sun et al. developed a triple-functional microcapsule system with self-healing and lubricating capabilities. Upon coating damage, the system actively released healing agents and lubricants, thereby improving the corrosion-fatigue resistance of marine sealing components [39].

Collectively, these studies demonstrate that both hard nanocomposite coatings (e.g., CrN-based and DLC) and adaptive self-lubricating or self-healing coatings offer effective pathways for improving the tribological stability and corrosion resistance of seals and connectors in complex marine environments, thus ensuring safer and longer equipment operation. Solid-lubricant transfer films and hard nitride phases reduce interfacial shear and inhibit third-body abrasion, yielding the observed drops in friction coefficient and wear rate.

3.2. Representative Coating Material Systems

3.2.1. Cermet Coatings

Cermet coatings, particularly WC-Co, WC-CoCr, and Cr3C2-NiCr systems, have been widely applied in marine protection due to their excellent wear resistance, erosion resistance, and moderate to high temperature corrosion resistance.

WC-Co coatings exhibit outstanding durability under severe erosive wear conditions due to their combination of high hardness (typically 1200–1600 HV) and good fracture toughness. However, the Co-based matrix has relatively poor corrosion resistance, making WC-Co coatings susceptible to pitting and accelerated degradation in seawater environments [40]. To overcome this limitation, WC-Co coatings have gained increased attention in recent years, as the addition of Cr improves the matrix’s corrosion resistance.

In contrast, Cr3C2-NiCr coatings provide superior protection in highly corrosive marine environments, primarily attributed to the self-passivating behavior of the NiCr matrix. Studies have shown that Cr3C2-NiCr coatings exhibit excellent corrosion resistance under salt spray exposure, potentiodynamic polarization, and erosion-corrosion coupling tests. Under low erosion loads, Cr3C2-NiCr coatings exhibit a significantly lower mass loss rate compared to conventional WC-based cermet coatings.

Furthermore, multilayer composite structures—comprising alternating layers of WC-Co and Cr3C2-NiCr—have been developed to simultaneously enhance wear and corrosion resistance, thus significantly extending the service life [40]. Moreover, nanostructured Cr3C2-NiCr coatings—with finer, more uniform grain sizes and a continuous ceramic phase network—have shown improvements in hardness, wear resistance, and erosion–corrosion synergy performance.

3.2.2. Metal Matrix Composite Coatings

Metal matrix composite (MMC) coatings are produced by incorporating ceramic particles—such as WC, ZrO2, or SiC—into a metallic matrix, significantly enhancing the coating’s resistance to wear, corrosion, and erosion. In marine environments, Ni-based composite coatings are widely applied due to their excellent corrosion resistance and high hardness. Under combined salt spray corrosion and mechanical wear conditions, Ni-based coatings exhibit favorable long-term stability.

Typical Ni-based MMC coatings, such as Ni-P-ZrC and Ni-SiC, are fabricated using techniques such as electrodeposition, laser cladding, or cold spraying. These coatings provide high mechanical strength along with a self-passivating protective layer (formed by the matrix or additive elements), effectively suppressing localized corrosion and pitting [41]. In Ni-P-ZrC nanocomposite coatings, the uniform dispersion of ZrC particles not only enhances wear resistance but also increases corrosion protection efficiency from 71% to 85.4%.

Although Fe-based composite coatings generally offer lower corrosion resistance than their Ni-based counterparts, they possess significant advantages in terms of cost-effectiveness and mechanical properties, including impact and fatigue resistance [42]. Fe-based coatings reinforced with ZTA (zirconia-toughened alumina) ceramic particles have demonstrated improved abrasive and erosive wear resistance in sand-containing seawater, mainly due to improved bonding strength at the ceramic/metal interface. Additionally, certain studies have explored Fe-based TaC composite coatings doped with antibacterial elements such as Ag or Cu, offering combined mechanical durability, corrosion protection, and antifouling capabilities [43].

3.2.3. Nanolayer Multilayer Coatings

Nanolayer multilayer coatings are constructed by alternately depositing different material layers at the nanoscale—such as TiN/CrN or TiAlN/CrN—to form periodic interfacial structures. These architectures effectively enhance wear resistance, erosion resistance, and corrosion protection. The multiple interfaces act as barriers to crack propagation, improving coating toughness and fatigue life. Additionally, interfacial energy regulation contributes to better corrosion resistance [44].

TiN/CrN nanolayer coatings have been widely applied for protection in marine environments. Studies have shown that multilayer TiN/CrN coatings exhibit superior corrosion and wear resistance in saline solutions compared to their monolayer counterparts. This is primarily attributed to the increased density of interfaces, which promote crack blunting effects. For instance, TiAlN/CrN multilayer coatings demonstrated the highest pore resistance and lowest corrosion current density in 3.5% NaCl solution, significantly outperforming traditional monolithic nitride coatings [45].

Moreover, TiN/TiAlN nanolayer coatings have shown excellent erosion-corrosion synergy resistance. It has been observed that reducing the bilayer period to the nanoscale (e.g., 125 nm) leads to a significant reduction in both mass loss rate and corrosion rate. In fact, the corrosion rate of TiN/TiAlN coatings was more than 70% lower than that of the uncoated steel substrate.

Recent studies have also explored more complex multilayer designs, such as TiAlSiN/Cr nanolayers. The incorporation of Cr-rich layers enhances the toughness, H/E ratio, and corrosion resistance of the coating, enabling significantly lower erosion rates under 90° impact angles. The design flexibility of nanolayered structures allows for precise tuning of wear, corrosion, and fatigue properties based on specific service conditions, making them a highly promising coating system for marine protection applications. High interface density blunts cracks and lengthens diffusion paths, which underlies the lower i_corr and erosion rates compared with monolayers.

3.2.4. Functionally Graded and Composit Structured Coatings

Functionally graded coatings achieve gradient optimization of key properties—such as hardness, corrosion resistance, and thermal expansion coefficient—by continuously or stepwise varying the composition or microstructure through the coating thickness. This design effectively mitigates interfacial stress concentrations between the coating and the substrate, thereby improving overall wear resistance, corrosion resistance, and thermal shock tolerance [46].

In marine applications, TiO2-Al2O3-BTA (benzotriazole)-based functionally graded nanocoatings have demonstrated excellent corrosion protection performance. Studies have shown that corrosion resistance in 3.5% NaCl solution after 96 h of immersion can be more than doubled compared to conventional homogeneous nanocoatings, due to controlled inhibitor release enabled by the graded design.

Ni-based functionally graded composite coatings, such as WC particle-reinforced NiCr matrices, have also shown outstanding wear and erosion resistance at elevated temperatures. In low-velocity erosion environments such as fluidized beds, functionally graded distribution of hard particles can effectively reduce interfacial crack propagation and significantly enhance durability [47].

Composite structured coatings—such as multilayered nanostructures integrated with functionally graded layers—are also increasingly applied in marine protection. By combining the crack-blunting effect of multilayers with the stress-buffering characteristics of gradient designs, these hybrid coatings offer superior performance in erosion-corrosion coupled environments [48]. For example, multilayered functionally graded sol–gel coatings deposited on AA2024-T3 aluminum alloy exhibited significantly enhanced corrosion resistance and cavitation wear resistance, making them suitable for use in marine renewable energy systems.

To provide a concise quantitative comparison across the coating materials reviewed in Section 3, Table 1 summarizes typical ranges of hardness, wear rate, corrosion current density, adhesion strength, and maximum service temperature reported for marine environments.

Building on these material-specific characteristics, Section 4 compares the main fabrication techniques used to deposit these coatings in marine applications.

4. Typical Fabrication Techniques

This section compares the main deposition routes used for marine wear-resistant coatings—HVOF, HVAF, laser cladding, TSA/arc spray, cold spray, and PVD/CVD—from a process–microstructure–property perspective. Across these routes, process variables that set particle temperature/velocity or melt-pool thermal history primarily determine coating porosity, oxide inclusion, and interface stress; in turn, these features govern corrosion current density, cavitation/erosion rate, adhesion strength, and fatigue behavior in seawater. Section 4.1, Section 4.2, Section 4.3, Section 4.4, Section 4.5 and Section 4.6 summarize characteristic operating windows, representative materials, and marine-relevant outcomes with quantitative examples; Table 2 provides a compact side-by-side summary.

Table 2.

Comparative summary of common coating fabrication techniques for marine applications.

4.1. High-Velocity Oxy-Fuel Spraying Technology

HVOF spraying is a widely used thermal spray technique for the fabrication of wear-resistant coatings. It offers several advantages, including high flame temperature, high particle velocity, and the ability to produce coatings with low porosity and strong interfacial bonding. In HVOF, oxygen and fuel (such as propane or kerosene) are combusted under high pressure to generate a high-temperature, high-velocity gas stream, which accelerates and heats powder particles before impacting them onto the substrate to form dense, adherent coatings [49]. Across the routes reviewed in this section, process variables that control particle temperature/velocity or melt-pool thermal history primarily set coating porosity and oxide inclusion level, which in turn govern corrosion current density, cavitation/erosion rate, and adhesion strength in marine service.

In the field of marine wear-resistant coatings, HVOF has been extensively employed to deposit cermet coatings such as WC-Co and Cr3C2-NiCr. These coatings are characterized by high hardness (typically 1000–1400 HV) and outstanding wear and erosion resistance, making them preferred protective materials for critical components such as subsea pipelines, propellers, and pump impellers.

Behera et al. conducted a comparative study on HVOF-sprayed WC-Co/NiCr/Mo and Cr3C2-NiCrAlY coatings under various erosion angles and elevated temperatures. The results indicated that Cr3C2-NiCrAlY coatings exhibited superior toughness and wear performance at high temperatures (600–800 °C), while WC-Co coatings displayed mixed brittle wear behavior across the entire temperature range. These findings underscore the importance of selecting appropriate coating systems based on specific service conditions.

Compared to conventional air plasma spraying (APS), HVOF coatings typically have lower porosity, higher adhesion strength, and fewer heat-affected zone defects. These characteristics confer significant advantages in resisting seawater corrosion and cavitation damage.

HVOF performance depends critically on powder size, gas flow rates, and spray angle. Minor deviations can compromise coating density or induce residual stress, ultimately affecting performance. Behera et al. also noted that variations in particle impact angle and spray temperature play a key role in shifting the wear mechanism from brittle to ductile, highlighting the need for precise process control in practical applications [50].

4.2. High-Velocity Air-Fuel Spraying Technology

HVAF spraying is a rapidly developing thermal spray technique. Compared to the conventional HVOF process, HVAF uses compressed air instead of pure oxygen as the oxidizer, resulting in a lower combustion temperature (approximately 1500–2000 °C), but a significantly higher particle velocity (typically >800 m/s). These characteristics allow HVAF coatings to exhibit lower oxidation levels, higher density, and reduced thermal damage—making the technique particularly suitable for marine applications requiring both high corrosion and wear resistance [50].

For marine wear-resistant coatings, HVAF is widely used to deposit cermet coatings such as WC-CoCr and Cr3C2-NiCr. Matikainen et al. systematically compared Cr3C2-25NiCr coatings prepared by HVAF and traditional HVOF under abrasive wear, dry particle erosion, and cavitation conditions. The HVAF coatings showed higher elastic modulus and fracture toughness, along with superior wear resistance in all test conditions. Notably, in cavitation fatigue environments, HVAF coatings demonstrated a significantly lower damage rate than their HVOF counterparts [50].

In terms of material development, Keslová et al. investigated the microstructure and erosion resistance of FeCrAlY, WC-CoCr, and Cr3C2-NiCr coatings sprayed using HVAF and HVOF. Their results revealed that HVAF coatings had lower porosity and oxide content, along with a more uniform internal structure, which led to better durability under solid particle erosion conditions [51].

Importantly, due to the lower flame temperature of HVAF, the dissolution and reaction of hard phases such as WC and Cr3C2 during spraying are significantly reduced. This allows the original powder morphology and properties to be largely preserved—an advantage that is especially critical for protective coatings exposed to highly corrosive seawater environments. Consistent with this, the lower oxidation and higher density typically achieved by HVAF translate into measurably lower corrosion current densities and slower erosion–corrosion mass loss than comparable HVOF coatings under otherwise similar conditions (see Table 2).

However, HVAF systems are relatively expensive, and the process places strict demands on powder particle size, fuel–air ratio, and spray gun cooling systems. The process window is narrower compared to other thermal spray methods. Furthermore, due to the extremely high particle velocity, challenges remain in controlling coating thickness and depositing onto complex curved surfaces.

4.3. Laser Cladding Technology

Laser cladding is a high-energy beam surface modification technique in which a focused laser beam rapidly melts pre-placed or simultaneously fed alloy powders along with the substrate surface, forming a dense coating with strong metallurgical bonding to the base material. Due to the extremely high cooling rate of the molten pool (103–106 K/s), laser-clad coatings typically exhibit fine grains, low porosity, high hardness, and excellent wear and corrosion resistance.

In marine wear-resistant applications, laser cladding is primarily used to fabricate composite coatings based on Ni-WC systems and reinforced CrNiBSi matrices. Liang et al. investigated the effect of rare earth oxide Y2O3 addition on the microstructure and performance of laser-clad Ni-WC coatings on 316L stainless steel. The results indicated that an appropriate amount of Y2O3 refined the microstructure and inhibited carbide coarsening, thereby improving both microhardness and corrosion resistance. Under optimized conditions, the average hardness exceeded 600 HV, and the coating exhibited excellent corrosion resistance in a 3.5% NaCl solution [52].

In another study, Gowtham et al. examined the deposition characteristics and wear resistance of NiCrBSi + WC composite coatings produced by coaxial powder-fed fiber laser cladding. On SS410 stainless steel, a sound metallurgically bonded coating was obtained, featuring fine γ-Ni dendrites and dispersed WC particles. The presence of WC particles significantly enhanced the coating’s microhardness (up to 1900 HV) and dry sliding wear resistance [53].

For improved microstructural control, Shen et al. introduced a process combining in situ thermal field assistance (ITFA) and post-laser remelting (PLR), which significantly enhanced WC particle distribution uniformity and refined carbide precipitates in NiCrSiBC-WC coatings. This strategy achieved ultra-high hardness (>1100 HV) and excellent wear performance without crack formation, effectively addressing the common issues of particle coarsening and cracking in conventional laser cladding [54].

Nevertheless, laser cladding still faces challenges, including sensitivity to thermal input and the risk of microstructural defects such as segregation, cracking, and porosity if process parameters are not carefully controlled. Additionally, for large and complex surface areas, the process remains limited by constraints in cladding path planning and dynamic melt pool control.

4.4. Thermally Sprayed Aluminum (TSA) and Arc Spraying Technologies

TSA and arc spraying technologies are widely employed for corrosion and wear protection of marine steel structures, particularly in splash zones, intertidal regions, and seawater-immersed facilities. TSA coatings not only act as a physical barrier against corrosive agents but also provide cathodic protection through a sacrificial anode mechanism. When locally damaged, the coating can still protect the steel substrate, significantly extending the service life of marine structures.

In terms of process, arc spraying involves melting two consumable aluminum wires via an electric arc, and propelling the molten droplets onto the substrate surface using a high-pressure air jet. Compared to traditional wire flame spraying, arc spraying offers advantages such as simpler equipment, higher deposition efficiency, and lower cost, making it extensively used for offshore platforms, wind turbine foundations, and ship hull structures.

Syrek-Gerstenkorn et al. investigated the corrosion behavior of TSA coatings under different simulated marine environments, including full immersion and splash zone conditions. Their results showed that TSA coatings form a dense and protective corrosion product layer under full immersion, effectively reducing the corrosion rate. However, under splash zone conditions, cyclic wet-dry exposure led to the formation of loose and discontinuous corrosion products, which aggravated localized corrosion [27].

Grinon-Echaniz et al. further demonstrated that under deep-sea high-pressure conditions (simulated at 5000 m depth), even when TSA coatings had localized defects (e.g., 3% damaged area), the sacrificial anode mechanism could still effectively polarize the exposed steel surface and inhibit corrosion initiation. Results from 90-day electrochemical testing were consistent with field trials, confirming the reliability of TSA systems in long-term deep-sea service [55].

To further enhance performance, recent studies have explored the combination of TSA coatings with post-treatment technologies such as sealing and plasma electrolytic oxidation (PEO). López-Ortega et al. reported that PEO treatment significantly improved the sliding wear resistance and overall corrosion protection of TSA coatings in seawater environments, indicating the potential of composite TSA coating systems for high-end marine applications [56].

However, TSA coatings produced by arc spraying inherently contain a certain degree of porosity and oxide inclusions. If process quality control is inadequate—particularly with respect to ambient temperature and humidity—accelerated local corrosion or coating failure may occur. Therefore, standardized application procedures and regular inspection and maintenance are critical to ensuring long-term coating performance.

4.5. Cold Spray Technology

Cold spray (CS) is a low-temperature, solid-state deposition technique that utilizes a high-velocity gas stream—typically nitrogen or helium—to accelerate metal or composite particles to subsonic or supersonic speeds. Upon impacting the substrate, the particles undergo severe plastic deformation and adhere to the surface without melting. As the material remains in the solid state throughout the process, cold-sprayed coatings exhibit extremely low oxidation, minimal thermal effects, and low residual stress, along with high density, strong interfacial bonding, and excellent corrosion and wear resistance.

In marine environments, cold spray technology has been widely applied to fabricate aluminum-based, copper-based, and metal matrix composite coatings. It is particularly suitable for localized repair of offshore structures and surface modification requiring enhanced corrosion and wear resistance. Zhang et al. deposited dense Al and Al5083 coatings on AA2024-T3 aluminum alloy using a low-pressure cold spray system. The Al5083 coating showed superior mechanical properties (tensile strength > 45 MPa) and corrosion resistance, maintaining high corrosion protection even after 480 h of immersion in 3.5% NaCl solution, demonstrating the significant potential of cold spray for corrosion-resistant applications [57].

In terms of material innovation, Norrell et al. developed a dual-nanoparticle reinforced aluminum matrix composite coating (nB4C/BNNP-Al) using cold spray. The coating exhibited excellent corrosion and wear resistance after 500 h and 2000 h of salt spray testing (Figure 5a–d), and the inclusion of dual nanoreinforcements led to an ~11.7% increase in hardness [58]. The SEM morphology of the nB4C/BNNP-Al composite coating after an extended 2000 h salt spray test is shown in Figure 5a–d. The minimal corrosion damage observed visually validates the exceptional long-term corrosion resistance achieved by the dual-nanoparticle reinforcement strategy in the cold-sprayed coating. This indicates that the performance of cold-sprayed coatings in marine environments can be further enhanced through rational nanocomposite design.

Figure 5.

SEM images of the coating after 2000 h of salt spray exposure. Reprinted with permission from Ref. [59]. 2022, Elsevier.

Cold spray has also been used to deposit coatings based on high-strength aluminum alloys, copper alloys, and composites such as Al-quasicrystal (Al-QC) systems. Jafari et al. reported that an Al-QC composite coating deposited via cold spray exhibited a sevenfold increase in wear resistance during room-temperature tribological testing, showcasing the broad potential of cold spray technology in high-wear applications [59].

Nevertheless, cold spray still faces technical challenges. Coating density is highly sensitive to powder particle size and deposition velocity, and the method is less effective for spraying high-melting-point ceramic materials. Furthermore, uniform deposition on complex curved surfaces, fine structures, and long-term stability in extreme seawater environments require further optimization.

4.6. Fabrication of Nanolayer Multilayer Coatings via PVD/CVD Technologies

Physical vapor deposition (PVD) and chemical vapor deposition (CVD) techniques play a vital role in the fabrication of high-performance nanolayer multilayer coatings. By alternately depositing different materials (e.g., TiN, CrN, TiAlN) to form multilayered structures at the nanoscale, these coatings effectively suppress crack propagation, enhance interfacial adhesion, and optimize residual stress distribution. This significantly improves their wear and corrosion resistance, making them particularly suitable for critical marine components such as seals and connectors.

Lotfi-Khojasteh et al. employed cathodic arc PVD to deposit TiN/CrN nanolayer coatings on carburized H13 steel substrates. The coatings exhibited excellent tribological and corrosion performance, with a corrosion current density reduced to 0.487 µA/cm2 in electrochemical testing—substantially lower than the untreated substrate. The nanolayered architecture effectively blocked the diffusion of corrosive species and enhanced coating density and protective capability [60].

In terms of material innovation, Grips et al. fabricated TiAlN/CrN multilayer coatings via reactive magnetron sputtering. Compared with monolayer TiN or CrN coatings, the TiAlN/CrN multilayers exhibited higher polarization resistance and lower corrosion current density in 3.5% NaCl solution, indicating superior corrosion resistance. This improvement is primarily attributed to the increased diffusion path from multilayer interfaces and the formation of a highly dense microstructure [45].

Additionally, Adesina systematically evaluated the high-temperature wear behavior of TiN/TiAlN, CrN/TiAlN, and CrAlN/TiAlN bilayer coatings. At 500 °C, these multilayer coatings exhibited a higher hardness and elastic modulus compared to monolayer TiAlN coatings, with wear resistance improved by 70–90%. These findings highlight the potential of multilayer structures for applications in high-temperature, highly corrosive marine environments [61].

However, it is important to note that the performance of PVD-deposited nanolayer coatings is highly sensitive to processing parameters such as substrate bias, arc current, and gas composition. Improper control may lead to micropores or stress concentrations, reducing protective performance. Moreover, prolonged salt spray exposure in marine environments can induce interfacial degradation, necessitating further optimization of interface design and post-treatment processes.

To provide a compact, side-by-side view of the deposition routes discussed in Section 4, Table 2 summarizes typical thickness and rate ranges, representative materials, and concise process notes for marine applications. In practice, small shifts in bias, gas composition or arc current map to density, interface stress and defect population, hence to the corrosion, oxidation and wear metrics quantified by the standardized tests in Section 5.

5. Performance Evaluation and Testing Methods for Coatings

This section consolidates standardized methods for quantifying coating performance in marine service. We group the discussion by failure mode—wear (sliding/abrasive/erosive), corrosion (salt spray and electrochemical), cavitation and corrosion–wear coupling, and fatigue—and then summarize cross-cutting metrics and standards that enable reproducible comparison. Emphasis is placed on how test parameters map to service-relevant responses (e.g., porosity/defects to I₍corr₎, hydrodynamics to erosion rate, loading spectra to fatigue life) and on the limits of accelerated protocols.

5.1. Wear Performance Testing Methods

Wear resistance is a critical indicator for evaluating the reliability of wear-resistant coatings under marine service conditions. Common test methods include sliding wear tests, abrasive wear tests, and erosion wear tests.

Sliding wear testing is one of the most widely used methods. According to ASTM G99, the test is performed by controlling normal load, rotational speed, and sliding distance to measure the coefficient of friction and wear rate under defined conditions [62]. Zhang et al. applied this method in the study of Al-based cold-sprayed coatings, using combined measurements of wear depth and friction force to effectively assess the wear resistance of various coating systems in seawater environments [57].

Abrasive wear testing is typically performed following the ASTM G65 standard, also known as the dry sand rubber wheel abrasion test [63]. In this method, fixed abrasive particles are used to simulate low-stress abrasive conditions and assess the material’s resistance to wear. Fu et al. compared wear data from ASTM G65 and pin-on-disk methods for cast iron and steel materials, revealing a predictable linear correlation between the two, suggesting that G65 is well-suited for evaluating coating performance under practical marine conditions [64].

Erosion wear testing is mainly conducted in accordance with ASTM G76, which simulates high-velocity solid particle impacts on material surfaces [65]. It is particularly suitable for assessing the erosion resistance of coatings in environments such as seawater scouring and sand-laden flows. Kumar et al. combined erosion and sliding wear testing to evaluate the wear behavior of Al-Si composites. The results showed that the erosion rate varied significantly with impact angle and particle velocity, and different material systems exhibited distinct failure modes under varying erosion conditions [66].

It is important to note that each test method reflects different wear mechanisms: sliding wear focuses on shear and adhesive damage; abrasive wear emphasizes cutting by hard particles, while erosion wear primarily involves impact-induced material removal. Therefore, a comprehensive evaluation of marine wear-resistant coatings often requires a combination of these methods to capture coating performance across diverse service conditions.

5.2. Corrosion Resistance Testing Methods

In marine environments, corrosion resistance is a critical factor determining the long-term service stability of wear-resistant coatings. Common evaluation methods include neutral salt spray testing and electrochemical techniques such as potentiodynamic polarization and electrochemical impedance spectroscopy (EIS).

The neutral salt spray test (as per ASTM B117) is a classical and widely applied accelerated corrosion testing method. In this test, samples are exposed to a 5% NaCl fog environment, and the formation and propagation of corrosion products on the coating surface are periodically observed [67]. Zhao et al. evaluated the corrosion resistance of polyarylether-based composite coatings under high-temperature marine conditions using a salt spray system. Their results showed that the optimized coatings maintained excellent protection even after 2400 h of salt spray exposure at 250 °C, demonstrating the test’s significance in assessing coating stability under high salinity stress [68].

Electrochemical testing provides a more quantitative assessment of corrosion performance. Potentiodynamic polarization (e.g., Tafel curves) enables the evaluation of coating protection capability by measuring the corrosion current density (i_corr) and corrosion potential (E_corr). Electrochemical impedance spectroscopy (EIS) further analyzes the coating’s electrochemical behavior using Nyquist and Bode plots, which reveal coating density, barrier properties, and defect severity. Wu et al. combined potentiodynamic scans and EIS to systematically assess the corrosion resistance of laser-clad high-entropy alloy coatings in 3.5% NaCl solution, finding that variations in Cu content significantly influenced the polarization resistance and corrosion rate [69].

It should be noted that while the salt spray test is straightforward and visual, it cannot fully replicate the complex redox cycles and wet-dry alternations experienced under actual marine service conditions. Conversely, electrochemical testing offers higher precision and richer data, but often requires complementary long-term immersion testing and surface characterization (e.g., SEM, EDS) for validation. Therefore, comprehensive corrosion performance evaluations typically combine multiple methods to ensure accuracy and reliability.

5.3. Cavitation Erosion and Synergistic Corrosion-Wear Testing Methods

In marine environments, cavitation erosion and corrosion-wear synergy are common failure mechanisms for protective coatings, particularly in localized high-velocity regions such as propellers, pump impellers, and subsea valves. To accurately evaluate coating performance under such conditions, dedicated cavitation and combined corrosion-wear testing methods are commonly employed.

Cavitation erosion testing is widely conducted following ASTM G32, using either ultrasonic vibration or liquid jet impingement methods. In these tests, cavitation bubbles are generated on the sample surface by ultrasonic waves or high-velocity fluid; the collapse of these bubbles produces localized impact pressures that lead to material removal [70]. Szala et al. applied the ASTM G32 method to test cold-sprayed Al/Al2O3 and Cu/Al2O3 composite coatings. The results showed that these composite coatings exhibited higher durability in cavitation environments than conventional metallic materials. Notably, the dense structure of Cu/Al2O3 coatings effectively resisted microcrack propagation induced by cavitation [71].

To account for the additional influence of corrosion, an increasing number of studies employ electrochemical coupling systems that monitor real-time changes in corrosion current and potential during cavitation testing. Tôn-Thât integrated the ASTM G32 cavitation setup with an electrochemical monitoring system to investigate the cavitation-corrosion behavior of ASTM A27 steel in natural river water [72]. The results revealed a significant increase in corrosion current under cavitation, indicating that the mechanical collapse of bubbles damaged the passive film and accelerated electrochemical corrosion of the metal substrate [73].

For seawater service conditions, Algoburi et al. studied the cavitation-corrosion behavior of HVOF-sprayed WC-NiCrBSi coatings in natural seawater using a modified ASTM G32 method. Their approach combined mass loss measurements with microscopic surface analysis. The study found that coatings subjected to hot isostatic pressing (HIP) exhibited lower cavitation rates and finer surface damage features, confirming that densification treatment plays a crucial role in enhancing cavitation–corrosion protection performance [32].

It should be noted that cavitation-corrosion coupling tests still face technical challenges, including the highly localized nature of bubble collapse, electrochemical signal noise, and the accumulation of corrosion products. To address these issues, recent studies have proposed in situ characterization techniques (e.g., in situ SEM, real-time EIS) and multiscale modeling approaches to provide deeper insight into the degradation mechanisms of coatings under coupled cavitation-corrosion conditions.

5.4. Fatigue Performance Testing Methods

During long-term service in marine environments, coatings must not only resist wear and corrosion but also exhibit adequate fatigue resistance, especially under cyclic loading induced by waves, tides, and wind forces. Fatigue performance is typically evaluated using a combination of testing methods, including rotating bending fatigue, tensile fatigue, and corrosion fatigue testing.

Rotating bending fatigue is a classical high-cycle fatigue (HCF) testing method, in which alternating bending stress of constant amplitude is applied to the specimen. Fatigue life under different stress levels is measured, often represented by an S-N curve. Madhavi et al. conducted corrosion fatigue testing on micro-arc oxidized (MAO) 2024-T3 and 7075-T6 aluminum alloys in 3.5% NaCl solution. The results showed that MAO coatings significantly extended fatigue life, with improvements exceeding 30% compared to the uncoated substrate, highlighting the positive impact of surface modification on fatigue resistance [74].

Tensile fatigue testing applies cyclic axial loads under a specified stress ratio (R-value) and is commonly used to assess the overall fatigue behavior of the coating-substrate system. Yadav et al. investigated the corrosion fatigue behavior of welded AA2024-T3 aluminum alloys after immersion in 3.5% NaCl solution. The results indicated that localized pitting corrosion significantly reduced fatigue life, and the weld zone was more susceptible to crack initiation and propagation due to its microstructural heterogeneity [75].

Corrosion fatigue testing under combined mechanical and corrosive conditions better simulates real-world marine service environments. Chen et al. carried out fatigue tests on aluminum alloys under multiaxial cyclic loading in combination with corrosion exposure. The results revealed that corrosion time, fluid velocity, and temperature all significantly affected fatigue life, with corrosion duration having the most prominent effect [76].

It should be noted that corrosion fatigue results are influenced by multiple parameters, including the type of corrosive medium, loading waveform (e.g., sinusoidal, trapezoidal), frequency, and stress ratio. Moreover, corrosion introduces various defects (e.g., pitting, intergranular corrosion) that alter crack initiation and propagation mechanisms. Therefore, fatigue performance evaluations of wear-resistant coatings should be complemented with microscopic fracture surface analysis (e.g., SEM) and fatigue crack growth rate testing to comprehensively understand failure behavior.

5.5. Comprehensive Evaluation Metrics and Standardized Testing Frameworks

For wear-resistant coatings in marine environments, performance evaluation should not rely on a single test result but instead be based on a comprehensive analysis of multiple indicators. Key evaluation metrics include hardness, adhesion strength, wear rate, corrosion rate, and electrochemical parameters such as corrosion current density. Together, these metrics determine the overall performance of a coating under complex service conditions.

Hardness reflects a coating’s resistance to localized plastic deformation and is typically measured using methods such as Vickers hardness testing or nanoindentation. Xu et al. studied CrCN nanocomposite coatings with varying carbon content and found that coating hardness initially increased and then decreased with increasing carbon content. The sample with 20.3% carbon exhibited a hardness of 14.7 GPa, indicating excellent wear resistance potential [77].

Adhesion strength characterizes the bonding quality between the coating and the substrate. It is commonly evaluated using techniques such as scratch testing or pull-off testing. Pană et al. demonstrated that a high adhesion strength (up to 90 N) in TiNbC coatings significantly improved both corrosion and wear resistance [78].

The wear rate, often measured using the pin-on-disk or dry sand rubber wheel method (e.g., ASTM G65), quantifies the material removal rate under specific load and frictional conditions. Lee et al. reported that incorporating h-BN nanoparticles into micro-arc oxidation (MAO) coatings significantly reduced the wear rate while maintaining excellent corrosion resistance, confirming the importance of integrated coating design strategies [79].

Corrosion rate and corrosion current density (i_corr) are key electrochemical indicators of a coating’s corrosion resistance and are usually assessed through potentiodynamic polarization and electrochemical impedance spectroscopy (EIS). Fayed et al. evaluated Si/DLC coatings in 3.5% NaCl solution using EIS. Their findings showed that increasing the deposition thickness reduced the corrosion rate to 0.001 mm/y, effectively slowing seawater-induced degradation [80].

In terms of standardization, the most widely adopted international protocols include ASTM, ISO, and DIN standards. Examples include ASTM G65 (abrasive wear testing), ASTM B117 (salt spray corrosion testing), ASTM G76 (erosion wear testing), and ISO 2812 (corrosion resistance of coatings) [81]. These standards provide unified procedures and criteria that ensure the reproducibility and comparability of test data.

Overall, no single indicator can fully capture a coating’s service performance. A combined evaluation using hardness, adhesion strength, wear and corrosion resistance—along with microstructural analysis techniques such as SEM, EDS, and fracture surface observation—provides a systematic performance evaluation framework to guide coating design, processing, and application optimization.

5.6. Standardization and Future Perspectives for Coating Performance Evaluation