Abstract

The study of cotton stalk extraction resistance provides important parameters for the design of cotton stalk harvesting machinery. To investigate the effects of soil moisture content, cotton stalk diameter, and extraction angle on the extraction force of densely planted cotton stalks, this paper designs a real-time measurement system based on virtual instrument technology and conducts field tests. The tests were carried out in cotton fields at the First Farm in Aral City, Xinjiang, using the cotton variety “Xiulu Zhong 70”. Single-factor experiments were conducted with extraction angle and stalk diameter as influencing factors. A combined three-factor experiment was performed under the following conditions: soil moisture contents of 21.87% and 26.32%; extraction angles of 25°, 30°, and 35°; and cotton stalk diameters of 8.50–9.00 mm, 10.00–10.50 mm, and 11.50–12.00 mm. The results show that the minimum extraction force is required when the extraction angle is 30°. Soil moisture content significantly affects the extraction force, which increases with stalk diameter. The combined test results indicate that the order of significance of the three factors is as follows: cotton stalk diameter (A), extraction angle (B), and soil moisture content (C). The optimal combination is A1B1C2, corresponding to a diameter of 8.50–9.00 mm, an extraction angle of 35°, and a soil moisture content of 26.32%. Based on comprehensive analysis, the recommended extraction angle range is 30–35°. The proposed system can efficiently complete cotton stalk extraction force tests, and the collected data provide valuable references for the design of cotton stalk harvesting machinery. By appropriately selecting the extraction angle and conducting harvesting under suitable soil moisture conditions, it is possible to reduce power consumption and improve production efficiency.

1. Introduction

Cotton is one of the most important crops in the world. It has good light absorption, breathability, softness, and non-allergenic properties. It is widely used in papermaking, spinning, clothing, home manufacturing, and various industrial fields [1]. Cotton is not only an important industrial raw material but also a strategic resource for many countries [2]. Cotton stalks (CS), as a byproduct of the cotton industry, are rich in lignin and natural plant fibers and have broad applications in areas such as bioethanol production, composite material manufacturing, and papermaking [3,4,5,6,7,8]. In 2022, the total cotton planting area in China was 3000.3 thousand hectares, with Xinjiang accounting for 2496.9 thousand hectares, representing 83.22% of the total. The annual production of CS in China is approximately 15 million tons [9], which will generate significant economic benefits. Manual harvesting of CS is labor-intensive and energy-consuming. Therefore, research into mechanical harvesting technology for CS has become one of the key focuses of research into full mechanization of cotton production in recent years [10,11,12,13].

Under the CS shredding and returning-to-field model, resource waste is caused, and the stalks decompose slowly. This not only leads to a decrease in plastic mulch recovery rates and sowing difficulties [14] but also exacerbates pest and disease problems and soil pollution [15]. Using a whole-stalk CS harvesting method can effectively eliminate these issues. It not only generates economic benefits but also helps maintain the integrity of the plastic mulch, facilitating its recovery [16]. Currently, researchers have conducted in-depth studies on CS harvesting machinery from aspects such as machine structural parameters and operational targets [17,18,19]. Based on harvesting principles and structural characteristics, mainstream CS harvesting mechanisms can be categorized into three types: the shovel-cut method, the roll-cut method, and the extraction force. Among these, the extraction force involves using a pull-out mechanism to lift the CS out of the soil intact. Due to its low power consumption, high extraction rate, and simple operation, it has been widely recognized by farmers in practical production [20]. In the design of CS pull-out machinery, the extraction force is one of the main technical parameters. Li et al. [21] investigated the effects of Vitex negundo root system properties on soil resistance caused by extraction force at different positions around the stem. Zhang et al. [22] designed a toothed disc CS harvester, analyzing the impact of factors such as disc diameter, disc speed ratio, and pull-out height on operational quality. Li et al. [23] used the discrete element method to simulate and calibrate CS contact parameters. Rui et al. [24] designed a belt-clamping CS pulling device and analyzed the effects of forward speed, driving wheel rotation speed, and pull-out height on extraction force, using CS breaking rate and missed pulling rate as test indicators. Jiachen Zhang et al. [25] developed a novel clamping mechanism with precise control over roller speed, roller gap, and surface morphology, systematically investigating the influence of key parameters on the peak pulling force of cotton stalks and its timing of occurrence. This study provides a new methodology for the development of low-damage, high-efficiency cotton stalk harvesting equipment. Yasenjiang Baikeli et al. [26] addressed practical challenges such as soil structure disruption and plastic film recovery difficulties during cotton stalk harvesting. Their research on the structural design and optimization of core components (e.g., clamping rollers, toothed discs) in both soil-disturbing and soil-preserving cotton stalk harvesters promotes the synergistic development of agricultural waste resource utilization and environmental conservation. Yong Yue et al. [27] highlighted a gap in discrete element method (DEM) research for mechanized cotton stalk harvesting, noting that high-precision modeling and parameter calibration for cotton root systems with complex morphological characteristics remain insufficient, which limits the accuracy of numerical simulations for the design and optimization of stalk-pulling devices.

It is worth noting that densely planted cotton stalks in China are thin and difficult to pull out. Simply using the extraction force can easily lead to cotton stalk (CS) breakage. Current research primarily focuses on the influence of harvesting machinery parameters on pulling efficiency. However, there is a lack of systematic studies on the effects of key factors—such as extraction angle, stalk diameter, and soil moisture content—on the extraction force during harvesting. To identify favorable conditions for the removal of densely planted cotton stalks, this study conducted field experiments and analyzed the main factors affecting extraction resistance. We integrated LabVIEW virtual instrument technology to design a real-time test system for measuring cotton stalk extraction resistance and investigated the mechanism underlying efficient cotton stalk harvesting. Through experimental analysis, this study quantifies the effects of soil conditions, stalk diameter, and extraction angle on stalk-pulling resistance; determines the optimal ranges for key parameters; and aims to provide a theoretical basis and data support for the design of extraction mechanisms and the optimization of operational parameters in cotton stalk harvesting machinery.

2. Cotton Stalk Extraction Force Measurement System

2.1. Design of the Frame-Type Cotton Stalk Extraction Force Measurement Device

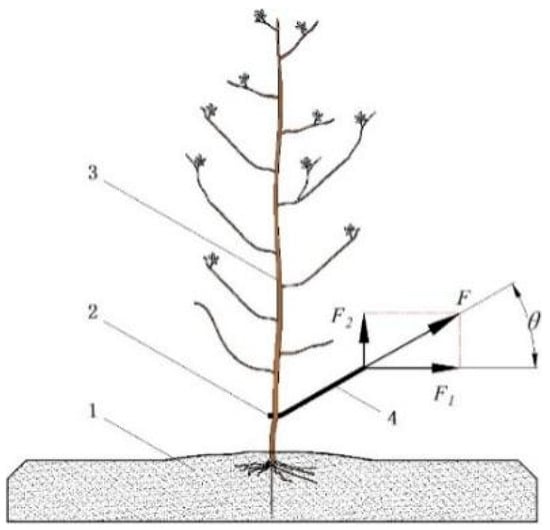

During the CS extraction force test, the force analysis of the CS is illustrated in Figure 1. The CS extraction force forms an angle with the horizontal plane (termed the extraction angle). This force can be decomposed into a horizontal component and a vertical component .

Figure 1.

Testing Principle of Extraction Force for Densely Planted Cotton Stalks. 1. Cotton field 2. Gripping point 3. Cotton stalks 4. Pulling rope.

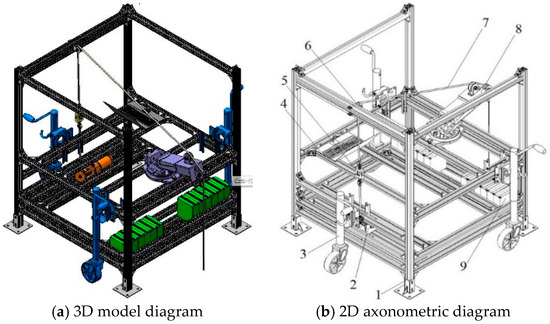

Cotton roots are taproots, consisting of a primary root and lateral roots. Under suitable conditions of soil nutrients, water, and texture, the root system develops extensively. During the extraction process, factors such as root breakage, soil deformation, root–soil adhesive force, and frictional resistance collectively contribute to the extraction resistance [26,27]. The magnitude of varies during the operation, so the maximum value of the CS extraction force was taken as the measured value for this experiment. To reduce errors caused by manual pulling and ensure the accuracy of experimental results, a frame-type CS extraction force measurement device was designed, whose structure is shown in Figure 2.

Figure 2.

Structural Diagram of the Frame-Type Measurement Device. 1. Frame 2. Electric winch 3. Jack-type guide wheel 4. Laptop computer 5. Push-pull force sensor 6. Fixed pulley 7. Pulling rope 8. Tiltable-angle rotating platform 9. Battery.

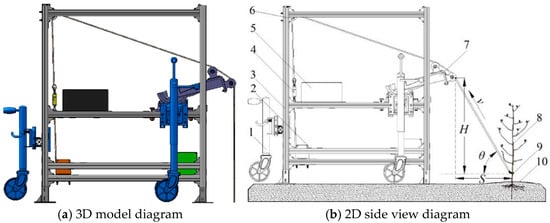

The working principle of the device is illustrated in Figure 3. The device is positioned stably in the cotton field. The section of the cotton stalk 450 mm above the ground is retained, while the remainder and any side stems are removed. A slipknot is tied with a rope at the base of the cotton stalk (CS) main stem, approximately 30–50 mm above the ground. By adjusting the height of the tiltable-angle rotating platform and varying the distance between the test device and the main stalk, the desired extraction angle (θ) is achieved. The electric winch is then activated to reel in the steel wire rope, thereby performing the pulling operation. The push-pull force sensor transmits real-time pulling force data to the laptop software, and the test system simultaneously acquires, displays, and stores these values.

Figure 3.

Working Principle of the Frame-Type Measurement Device. 1. Jack-type guide wheel 2. Electric winch 3. Frame 4. Push-pull force sensor 5. Laptop computer 6. Fixed pulley 7. Tiltable-angle rotating platform 8. Cotton stalk 9. Main stem pulling connection point 10. Cotton field.

This device is equipped with a model Winch 3000 Ib electric winch manufactured by Donghong Crane Machinery Manufacturing Co., Ltd. (Baoding, China), which is powered by a DC battery and controlled manually via a handle switch. The DS2-S type push-pull force sensor produced by Dongguan Zhiqu Precision Instruments Co., Ltd. (Dongguan, China) is used for extraction force testing. Its load capacity is 0~2000 N, with an accuracy of , and an output voltage range of ±10 V.

2.2. Design of the Cotton Stalk Extraction Force Measurement System

The is a time-dependent force with a peak value that exists for an extremely short duration. To measure this force, we developed a measurement program using LabVIEW 2021SP1 graphical programming software. The virtual control panel of this program is divided into five sections: time display area, sampling parameter settings area, real-time numerical display area, graphical display area, and data saving area, all of which are displayed and operated by a laptop computer. This program enables real-time observation of test data and results. During experiments, clicking the “Start Measurement” button allows the program to display and save the sampled data in real time at a sampling rate of 1 ksps, facilitating subsequent data analysis.

2.3. Calibration of the System

During the measurement process, the total force acting on the system primarily consists of two components: the internal friction of the system and the cotton stalk extraction resistance. Since the tensile force values measured by the test system include both the frictional force and the extraction resistance , we conducted pre-field-trial determination tests to clarify the relationship between the frictional force and the system measurement values. The known-mass weights were placed on the weight hook, and the hook was then attached to the front end of the pulling rope. The test system and electric winch were activated to begin the test. The test program saved the sensor-measured values in real time, and the trial was halted once the readings stabilized. The test results are presented in Table 1.

Table 1.

Experimental Results of Friction Measurement.

Analysis of the test results indicates that there is no obvious correlation between the frictional force f and the system measurement values. The frictional force does not increase with the weight of the weights; instead, it fluctuates within a certain range (f ∈ [10 N, 16 N]), with an average value of 14 N. The average value of the proportion t of the frictional force f in the system measurement results is 4.22%. To verify the accuracy of this average t, verification tests were conducted, and the results are shown in Table 2. By calculating the predicted value based on the t-value average (4.22%), comparing it with the actual values, and computing the relative error. The relative error ranged from 0.20 to 0.61%, with an average of 0.34%. In summary, during field tests, the extraction force values can be indirectly calculated using the average t of 4.22%.

Table 2.

Verification Results of Experimental Measurements.

3. Materials and Methods

3.1. Test Materials

Field trials for the extraction force test of densely planted cotton stalks were conducted in the cotton fields of the First Farm in Alar City, Xinjiang, China, from October to November 2023. The cotton variety used was Xinluzhong 70 (Xinjiang, China), with the diameter range of the test CS being 6.56~14.21 mm. The selection criteria for CS were as follows: healthy growth, straight and upright stems, uniform thickness, and no damage after cotton picker operations. Due to the narrow row spacing (10 cm) and small plant spacing (average 10.4 cm) of densely planted cotton stalks, pulling out the CS would reduce the soil firmness in the surrounding area (approximately 15 cm in diameter). Therefore, the spacing between selected CS during each test was greater than 30 cm (i.e., at least two stalks apart).

3.2. Test Methods

3.2.1. Determination of Cotton Stalk Diameter

The CS diameters were measured using a digital caliper with an accuracy of 0.01 mm. Taking the point where the main stalk emerges from the ground as the reference, marks were made at the reference level, 5 cm above the reference, and 10 cm above the reference. Each point was measured twice vertically, for a total of six measurements, and the average value was taken as the approximate diameter of the test CS. In the experiments, the extraction speed was set to a fixed value of 100 mm/min. Measurements were taken at these three heights to verify the uniformity of the cotton stalk stems. Since the resistance encountered during the pulling process is primarily related to the diameter of the stalk near the ground level, and this diameter correlates well with the root diameter, using the average of multiple measurements provides a more reasonable representation of the key diameter parameter influencing the pulling force.

3.2.2. Determination of Extraction Angle

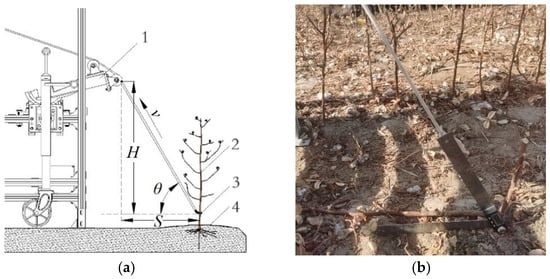

The extraction angle θ serves as the target independent variable, whose theoretical value is determined by parameters H and S in Formula (1). Operationally, the tiltable platform is first fixed to establish H; at this point, θ becomes a single-variable function of S, allowing coarse adjustment of the extraction angle by modifying S. When the system approaches the target angle, final precision measurement and fine-tuning are performed using an angle gauge.

Based on the geometric relationships in Figure 4a, the following equation holds:

where H is the vertical height from the tangent point of the fixed pulley (mounted on the top of the tilt-adjustable rotating platform) to the connection point between the extraction rope and the cotton stalk. This value varies with the positional changes in the tilt-adjustable rotating platform. It varies with the position of the tiltable-angle rotating platform (unit: mm); is the horizontal distance between the tangent point of the fixed pulley (mounted at the top of the tiltable-angle rotating platform) to the extraction rope and the main stalk of the cotton plant (unit: mm).

Figure 4.

Method for Determining Extraction Angle. (a) Schematic Diagram of Extraction Angle 1. Tiltable angle rotary table, 2. Corn stalk, 3. Main stem extraction connection point, 4. Cotton field. (b) Using an Angle Gauge.

3.2.3. Measurement of Soil Moisture Content and Soil Penetration Resistance

A digital soil penetration resistance meter and a soil moisture–temperature tester were used to measure soil penetration resistance (at a depth of 20 cm) and soil moisture content (at a depth of 10 cm), respectively. For each parameter, 12 measurements were taken (6 in narrow rows and 6 in wide rows), and the average values were calculated. The soil conditions during the test are listed in Table 3.

Table 3.

Soil Conditions in Field Trials.

3.3. Experimental Design

Since CS extraction force is influenced by multiple factors, this study identified cotton stalk diameter, extraction angle, and soil moisture content as key influencing factors and conducted single-factor experiments using as the test indicator. Based on the single-factor experiment analysis, orthogonal experiments were further conducted using extraction angle, cotton stalk diameter, and soil moisture content as influencing factors. The test levels and corresponding values are presented in Table 4.

Table 4.

Factor-Level Table for Orthogonal Experiment of Extraction Force.

3.4. Test Data Processing

Each test was promptly recorded, and the test data was organized using scientific data tables. Then, the data was analyzed and processed using EXCEL 2021 and ORIGIN 2021 software.

4. Experimental Results and Analysis

4.1. Variation Curve of Extraction Force for Densely Planted Cotton Stalks

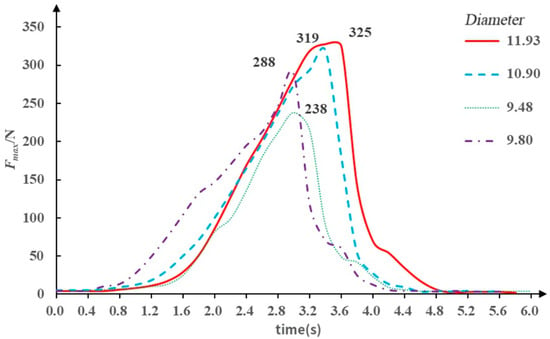

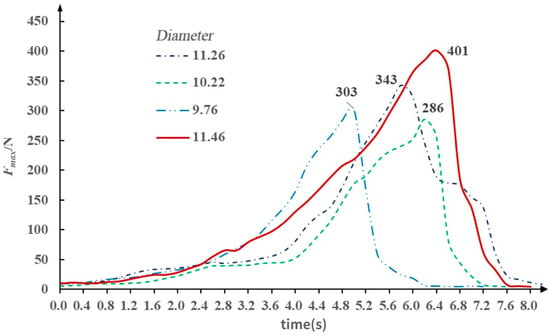

After the field tests on the extraction force of densely planted cotton stalks, single test results under extraction angles of 75° and 60°, along with a soil moisture content of 26.32%, were selected to plot the curves of extraction force–time, as shown in Figure 5 and Figure 6. It can be observed that the process can be divided into two stages, with the extraction force first increasing and then decreasing.

Figure 5.

Variation curve of extraction force with time at soil moisture content of 26.32% and extraction angle of 75°.

Figure 6.

Variation curve of extraction force with time at a soil moisture content of 26.32% and an extraction angle of 60°.

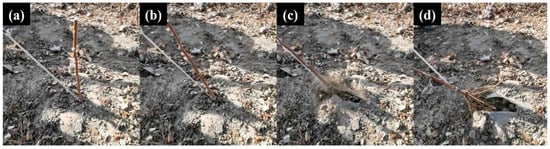

Taking the test at an extraction angle of 45° as an example, a visual analysis of the densely planted cotton stalk extraction process is presented. As shown in Figure 7, during the rising phase of the extraction force, the cotton stalk tilts toward the extraction direction under stress, with its root system moving upward against resistance. Subsequently, significant soil disturbance occurs around the root stubble, and partial soil clods fracture until the extraction force reaches its maximum. In the falling phase, once the cotton roots break free from the extraction resistance, the stalk is pulled out, and the extraction force rapidly decreases to zero. Notably, due to the widespread use of plastic mulch planting in Xinjiang, the CS must overcome residual mulch adhesion resistance during the lifting process. Therefore, there is a segment with a reduced slope in the falling phase.

Figure 7.

Pull-out Process of Densely Planted Cotton Stalks. (a) A initial status; (b) The stalk of the cotton plant is tilted in the direction of the pulling angle. (c) Soil disturbance and uplift. (d) The stalks have been pulled out.

4.2. Variance Analysis of Single-Factor Experiments

4.2.1. Effect of Extraction Angle on Extraction Force

Under the same soil conditions and pulling speed, to minimize the influence of diameter, the diameter difference in CS was controlled within a range of 0.5 mm. The CS with a main stalk diameter of 9.00–9.50 mm were selected, with 15 stalks per diameter group and 3 replicates per group. The average maximum extraction force results are shown in Table 5.

Table 5.

Experimental Results Under Different Extraction Angles (Cotton Stalk Diameter: 9.00~9.50 mm).

The analysis of variance (ANOVA) for the effect of extraction angle on maximum extraction force is shown in Table 6, where the significance level was used to calculate the critical F-value. The results indicated that and p-value < 0.01, suggesting that the extraction angle had a highly significant effect on the maximum extraction force of densely planted cotton stalks.

Table 6.

ANOVA Table for the Effect of Extraction Angle on Extraction Force (Cotton Stalk Diameter: 9.00~9.50 mm).

The degrees of freedom in the table were calculated based on the following principles: the total degrees of freedom were determined by the total number of observations (n − 1), the between-group degrees of freedom were determined by the number of factor levels (k − 1), and the within-group degrees of freedom were the difference between the two. In this experiment, the extraction angle was set at 6 levels, with 5 repeated tests conducted at each level (total sample size N = 30).

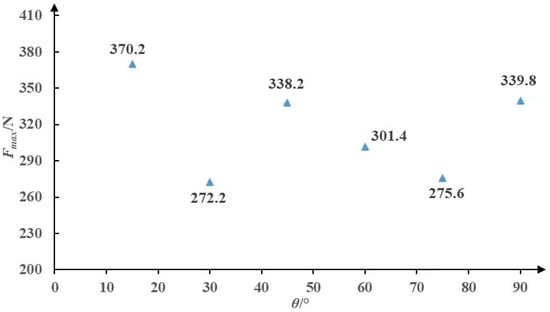

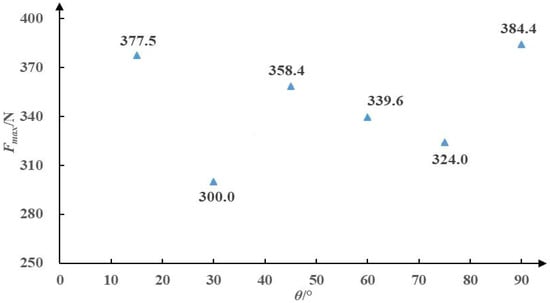

The scatter plot illustrating the relationship between the maximum extraction force and cotton stalk diameter under different extraction angles is shown in Figure 8. Within the tested extraction angle range, the maximum extraction force exhibited a “W”-shaped pattern without obvious regularity. Specifically, the largest extraction force was required at 15° (370.2 N), while the smallest was required at 30° (272.2 N).

Figure 8.

Variation in Maximum Extraction Force Under Different Extraction Angles (Cotton Stalk Diameter: 9.00–9.50 mm).

Following the above experiments, with only the cotton stalk diameter range adjusted, 15 stalks with a root diameter range of 11.00~11.50 mm were selected for each group, with 3 replicates per group. The average maximum extraction force results are shown in Table 7. The scatter plot illustrating the relationship between the maximum extraction force and diameter under different extraction angles is presented in Figure 9. The trend is similar to that in Figure 9, with the smallest extraction force still required at 30° (300.0 N). The key distinction is that the largest was needed at 90° (384.4 N).

Table 7.

Experimental Results Under Different Extraction Angles (Cotton Stalk Diameter: 11.00~11.50 mm).

Figure 9.

Variation in Maximum Extraction Force Under Different Extraction Angles (Cotton Stalk Diameter: 11.00–11.50 mm).

Under the condition of the diameter range of 11.00~11.50 mm, ANOVA for the effect of extraction angle on maximum extraction force is shown in Table 8, with a significance level of for calculating the critical F-value. The results indicate that and the p-value < 0.01, further confirming that the extraction angle has a highly significant effect on the maximum extraction force.

Table 8.

ANOVA Table for the Effect of Extraction Angle on Extraction Force (Cotton Stalk Diameter: 11.00~11.50 mm).

4.2.2. Effects of Densely Planted Cotton Stalk Diameter and Soil Moisture Content on Extraction Force

Single-factor experiments on the effect of densely planted cotton stalk root diameter on extraction force were conducted in the field under two extraction angles (60° and 90°) and two soil moisture content conditions (26.32% and 21.87%). The cotton stalks had a diameter range of 6.56–14.21 mm, with 15 stalks of varying root diameters selected per group for the extraction tests. The test results are shown in Table 9.

Table 9.

Experimental Results of Extraction Force Under Different Cotton Stalk Diameters and Soil Conditions.

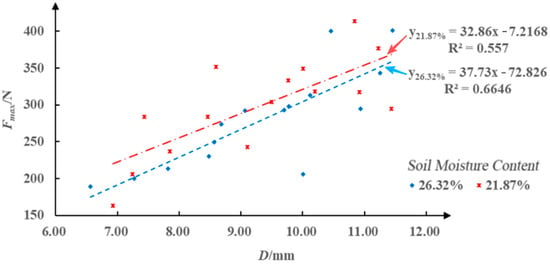

Scatter plots of the test values obtained under the same SMC (Soil Moisture Content) are shown in Figure 10 and Figure 11, indicating a positive correlation between extraction force and cotton stalk diameter. Linear regression fitting was performed on the maximum extraction force scatter values under of 60° and SMC of 21.87% and 26.32%, yielding the following fitting equations:

y21.87% = 32.86x − 7.2168

y26.32% = 37.73x − 72.826

Figure 10.

Variation Curves of Maximum Extraction Force with Cotton Stalk Diameter under Different Soil Conditions at an Extraction Angle of 60°.

Figure 11.

Variation Curves of Maximum Extraction Force with Cotton Stalk Diameter under Different Soil Conditions at an Extraction Angle of 90°.

In the equations, y represents the maximum extraction force value (N), and x represents the cotton stalk diameter (mm).

The coefficients of determination for the equations are R2 = 0.557 and R2 = 0.6647, with corresponding correlation coefficients of r = 0.746 and r = 0.815, indicating a positive linear correlation between the maximum extraction force Fmax and diameter D. As shown in Table 9 and Figure 10, the maximum cotton stalk extraction force under an extraction angle of 60° was 414 N, but this value was not obtained when the CS diameter was the largest.

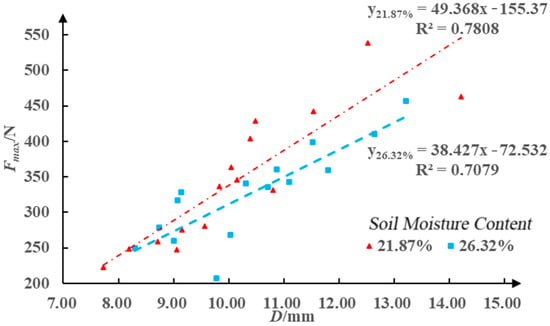

Linear regression fitting was performed on the maximum extraction force scatter values under of 90° and SMC of 21.87% and 26.32%, yielding the following fitting equations:

y21.87% = 49.368x − 155.37

y26.32% = 38.427x − 72.532

The coefficients of determination for the two equations are R2 = 0.7808 and R2 = 0.7079, with corresponding correlation coefficients of r = 0.8836 and r = 0.8414, respectively, indicating relatively significant linear regression and a positively correlated relationship between Diameter and maximum extraction force.

As shown in Table 9 and Figure 11, the maximum extraction force under an extraction angle of 90° was 539 N, but this value was not obtained when the cotton stalk diameter was the largest. This indicates that although cotton stalk diameter has a significant effect on extraction force, the relationship is not strictly linear. This is because other factors influencing extraction force include the distribution and growth pattern of the cotton root system, the frictional force between soil and roots, and the interference between roots under dense planting conditions.

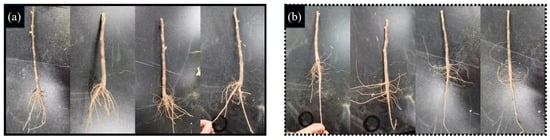

Analysis of the root system distribution of the extracted cotton stalks after the test revealed two main types: complex root type and taproot type, as shown in Figure 12. Different growth conditions result in significant variations in cotton stalk root system distribution. Both the distribution and structure of the root system affect the extraction force, specifically including root diameter and length, root type, number of roots, and the angle between individual roots. Additionally, due to the narrow row spacing in densely planted cotton, overlapping roots of adjacent cotton stalks can influence the extraction force of the selected CS with specific diameters during testing. Based on the above analysis, cotton stalk diameter does not fully reflect the distribution and growth pattern of the cotton root system. Therefore, under the tested conditions, there is no strict linear relationship between extraction force and diameter.

Figure 12.

Root System Characteristics of Densely Planted Cotton Stalks. (a) Complex Root Type, (b) Taproot Type.

Figure 10 and Figure 11 show that when diameters are similar, the extraction force at 21.87% SMC is generally higher than that at 26.32%. This indicates that SMC and SPR influence extraction force. Conducting the CS harvesting during periods with more suitable soil conditions is beneficial for further reducing the operational power consumption of harvesting machinery.

4.3. Orthogonal Experiments

4.3.1. Experimental Factors and Levels

Based on the analysis of single-factor experiments, cotton stalk diameter, extraction angle, and soil moisture content were identified as key influencing factors, and an orthogonal experiment on cotton stalk extraction force was conducted. Results from the single-factor analysis indicated that a 30° extraction angle was favorable for cotton stalk uprooting. To further explore the optimal extraction angle, additional tests were conducted around 30°, with two additional levels set at 35° and 25°. For the soil moisture content factor, two initial levels were defined, and the pseudo-level method was applied by repeating the 26.32% SMC level once, making it a 3-level factor. The factor-level table is shown in Table 4.

4.3.2. Experimental Scheme

By applying the pseudo-level method, the mixed-level problem was converted into an equal-level problem. Without considering interactions, the orthogonal array was selected for the experimental design, with one blank column added. The experimental scheme is shown in Table 10, where each group of tests was repeated 3 times, and the average values were recorded in the table.

Table 10.

Orthogonal Experimental Design for Extraction Force Analysis.

4.3.3. Result Analysis

Range analysis of the test data was conducted, and the results are shown in Table 11. It was observed that, under each level of the test factors, the factors influencing the maximum extraction force of densely planted cotton stalks, ranked from most to least significant, were cotton stalk diameter (A), extraction angle (B), and soil moisture content (C). The optimal scheme obtained was , i.e., cotton stalk diameter of 8.50–9.00 mm, extraction angle of 35°, and soil moisture content of 26.32%.

Table 11.

Experimental Results and Intuitive Analysis of Extraction Force.

Further ANOVA was conducted to estimate the error magnitude and precisely evaluate the importance of each factor on the maximum extraction force of densely planted cotton stalks. The results of the ANOVA are shown in Table 12. The p-value represents the probability that a factor has no significant effect on the test results. For factors A and B, p-value ≤ 0.01, indicating that cotton stalk diameter and extraction angle had a highly significant effect on the test index (**). For factor C, 0.01 < p-value ≤ 0.05, indicating that soil moisture content had a significant effect on the test index (*).

Table 12.

ANOVA Table for Experimental Results.

The degrees of freedom were calculated as follows: total df = n − 1 = 8 (based on 9 experimental runs); factor df = number of levels—1; error df = total df—sum of factors df. This orthogonal experiment used an L9 array with 3 factors at 3, 3, and 2 levels, respectively.

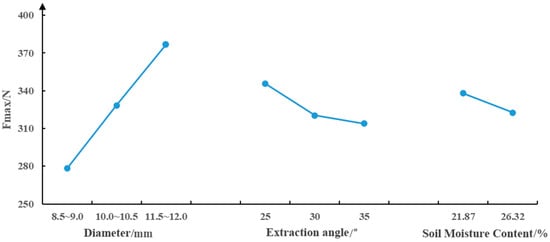

A trend chart illustrating the relationship between cotton stalk diameter, extraction angle, soil moisture content, and maximum extraction force is shown in Figure 13. It can be observed that under the set levels of each factor, cotton stalk diameter has the most significant impact on the maximum extraction force, with the maximum extraction force increasing as the cotton stalk diameter increases. Compared to the optimal extraction angle of 30° identified in the single-factor analysis, the orthogonal experiment determined the optimal extraction angle to be 35°. Based on the comprehensive analysis, the optimal extraction angle range for cotton stalks under the tested conditions is 30°~35°. When designing the pushing plate of the stalk pressing device, setting the pushing angle within 30°~35° range will subject the cotton stalks to greater extraction force within this angle range. And soil moisture content significantly affects the maximum extraction force of cotton stalks; selecting an appropriate cotton stalk harvesting time will help reduce the operational power consumption of cotton stalk harvesting, thereby improving overall operational efficiency.

Figure 13.

Relationship and Trend Analysis of Key Factors Affecting Maximum Extraction Force of Cotton Stalks.

5. Conclusions

(1) A measurement system for the extraction force of densely planted cotton stalks was designed, enabling real-time field measurement of extraction force over the full angle range (0–90°). Additionally, frictional force tests were conducted, revealing that the average friction caused by the fixed pulley and pulling rope was 14 N, accounting for an average proportion t of 4.22% in the system measurement results. Using this pattern, a resistance prediction value was calculated, with an average relative error of 0.34% between the predicted and actual values. Therefore, during field extraction force tests, the extraction force can be indirectly calculated using the average value of 4.22% from the system measurement results.

(2) Single-factor experiments on the effect of extraction angle on extraction force demonstrated that extraction angle had a highly significant impact on the maximum extraction force. For both diameter ranges (9.00–9.50 mm and 11.00–11.50 mm), the minimum extraction force was required at an extraction angle of 30°. Under conditions of soil moisture contents of 26.32% and 21.78% and extraction angles of 60° and 90°, single-factor experiments with cotton stalk diameter as the influencing factor showed that: (i) the maximum extraction force was positively linearly correlated with diameter D, and (ii) soil moisture content also influenced extraction force, and conducting cotton stalk harvesting during periods with more suitable soil conditions helps reduce operational energy consumption.

(3) Range and variance analyses of the orthogonal experiments indicated: (i) the significance order of the three factors on maximum extraction force was cotton stalk diameter (A), extraction angle (B), and soil moisture content (C), and (ii) the optimal scheme was , i.e., cotton stalk diameter of 8.50–9.00 mm, extraction angle of 35°, and soil moisture content of 26.32%. Compared to the optimal extraction angle of 30° identified in single-factor tests, the orthogonal experiment determined 35° as the optimal angle. Based on this, the optimal extraction angle range under the tested conditions was inferred to be 30°~35°.

(4) Although this study systematically investigated the cotton stalk extraction forces in the Xinluzhong 70 cotton fields of the Alar region and obtained instructive parameter optimization results, several limitations must be acknowledged. Firstly, the experimental samples were confined to a single ecological region, a single cultivar, and a limited diameter range, which may affect the generalizability of the conclusions. Secondly, due to constraints in field experimental conditions and real-time measurement techniques, a complete quantitative analysis of the key mechanical mechanisms during the cotton stalk extraction process was not achieved. This includes specifically the dynamic failure process of the root–soil composite and the precise characterization of stress distribution under different extraction angles. Furthermore, the lack of in situ root CT scanning technology and dedicated soil bin simulation platforms made it impossible to directly observe the influence of root architecture (taproot vs. fibrous root systems) on soil failure patterns. Although optimized parameter intervals were obtained experimentally, their translation into specific structural design parameters for harvesting machinery still requires consideration of the coupling effects of complex engineering factors such as material strength and transmission efficiency. Additionally, while the current number of experimental replications is sufficient to support the robustness of the conclusions under present conditions, their reliability in more complex field environments needs further verification.

Based on these limitations, future research should focus on: (1) expanding validation experiments across different ecological regions and genotypes; (2) employing X-ray in situ imaging combined with discrete element numerical simulation to construct a three-dimensional mechanical model that accurately reflects the dynamic failure process of the root–soil composite; (3) integrating root CT scanning with mechanical simulation to deeply analyze the interaction mechanisms; and (4) deeply integrating the optimized parameters with agricultural machinery design. These efforts will ultimately contribute to the development of a comprehensive decision-support system for cotton stalk harvesting.

Author Contributions

Conceptualization, X.W. (Xingwang Wang); methodology, X.W. (Xingwang Wang) and X.W. (Xiangyu Wang); investigation, X.W. (Xingwang Wang), J.F. and J.C.; resources, X.W. (Xingwang Wang) and W.C.; data curation, X.W. (Xingwang Wang); formal analysis, X.W. (Xingwang Wang); writing—original draft, X.W. (Xingwang Wang); writing—review and editing, X.W. (Xingwang Wang), X.W. (Xiangyu Wang) and X.C.; project administration, X.W. (Xingwang Wang); funding acquisition, J.F., J.C. and W.C.; supervision, X.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research received “The Anhui Provincial University Innovation Team Project, Digital Agriculture Innovation Team (2023AH010039)” external funding.

Institutional Review Board Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Acknowledgments

The authors would like to thank the College of Mechanical and Electrical Engineering, Fujian Agriculture and Forestry University, as well as the other technicians who were formerly part of the team, for their support during the early stages of the research.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Tokel, D.; Dogan, I.; Hocaoglu-Ozyigit, A.; Ozyigit, I.I. Cotton Agriculture in Turkey and Worldwide Economic Impacts of Turkish Cotton. J. Nat. Fibers 2022, 19, 10648–10667. [Google Scholar] [CrossRef]

- Munir, H.; Rasul, F.; Ahmad, A.; Sajid, M.; Ayub, S.; Arif, M.; Iqbal, P.; Khan, A.; Fatima, Z.; Ahmad, S.; et al. Diverse Uses of Cotton: From Products to Byproducts. In Cotton Production and Uses: Agronomy, Crop Protection, and Postharvest Technologies; Ahmad, S., Hasanuzzaman, M., Eds.; Springer: Singapore, 2020; pp. 629–641. ISBN 978-981-15-1472-2. [Google Scholar]

- Dong, Z.; Hou, X.; Haigler, I.; Yang, Y. Preparation and Properties of Cotton Stalk Bark Fibers and Their Cotton Blended Yarns and Fabrics. J. Clean. Prod. 2016, 139, 267–276. [Google Scholar] [CrossRef]

- Lang, D.; Liu, G.; Wu, R.; Wang, W.; Wu, J.; Wang, L.; Yang, J.; Yang, C.; Wang, L.; Fu, J. Efficient Preparation of Anisotropic Cellulose Sponge from Cotton Stalks: An Excellent Material for Separation Applications. J. Hazard. Mater. 2024, 476, 134941. [Google Scholar] [CrossRef]

- Shamskar, K.R.; Heidari, H.; Rashidi, A. Preparation and Evaluation of Nanocrystalline Cellulose Aerogels from Raw Cotton and Cotton Stalk. Ind. Crops Prod. 2016, 93, 203–211. [Google Scholar] [CrossRef]

- Sachan, A.; Choudhary, V.; Vimal, K.; Kapur, G. Chemical Treatment of Cotton Stalk and Its Effects on Mechanical, Rheological and Morphological Properties of Polypropylene/Cotton Stalk Bio-Composites. Polym. Compos. 2017, 39, E286–E296. [Google Scholar] [CrossRef]

- Wang, M.; Zhou, D.; Wang, Y.; Wei, S.; Yang, W.; Kuang, M.; Ma, L.; Fang, D.; Xu, S.; Du, S.-K. Bioethanol Production from Cotton Stalk: A Comparative Study of Various Pretreatments. Fuel 2016, 184, 527–532. [Google Scholar] [CrossRef]

- Zhou, B.; Wang, L.; Ma, G.; Zhao, X.; Zhao, X. Preparation and Properties of Bio-Geopolymer Composites with Waste Cotton Stalk Materials. J. Clean. Prod. 2020, 245, 118842. [Google Scholar] [CrossRef]

- China Statistical Yearbook. 2024. Available online: https://www.stats.gov.cn/sj/ndsj/2024/indexeh.htm (accessed on 16 July 2025).

- Dai, J.; Dong, H. Intensive Cotton Farming Technologies in China: Achievements, Challenges and Countermeasures. Field Crops Res. 2014, 155, 99–110. [Google Scholar] [CrossRef]

- Lei, H. Development Status and Prospect of Legacy Cotton Picking and Harvesting Machinery. J. Chin. Agric. Mech. 2025, 46, 40. [Google Scholar] [CrossRef]

- Liao, P.W.; Wang, R.B.; Gong, J.X.; Liu, K.K.; Zhang, A.M. Cotton Stalk Baled Harvest Technology and Equipment Status in China. HUBEI Agric. Sci. 2022, 61, 119. [Google Scholar] [CrossRef]

- Yue, H.; Sun, C. Analysis on the Key Problems of Chinese Cotton Full Mechanization Based on System Engineering Theory. IOP Conf. Ser. Mater. Sci. Eng. 2019, 688, 055077. [Google Scholar] [CrossRef]

- Zhang, J.X.; Yang, R.; Wang, Z.W.; Hou, C.F.; Wang, Y.C.; Cai, J.L.; Yasenjiang, B.K.L.; Guo, G. Design and test of the cotton stalk pulling equipment with toothed plate. Trans. Chin. Soc. Agric. Eng. 2024, 40, 41–50. [Google Scholar] [CrossRef]

- Zhao, W.; Chen, M.; Xie, J.; Cao, S.; Wu, A.; Wang, Z. Discrete Element Modeling and Physical Experiment Research on the Biomechanical Properties of Cotton Stalk. Comput. Electron. Agric. 2023, 204, 107502. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, J.; Shen, S.; Li, J.; Huo, Y.; Wang, Z. The Mechanical Analysis and Comparative Performance Test of the Roller-Type Pulling Mechanism for the Whole Cotton Stalk Pulling Machine. Agriculture 2024, 14, 506. [Google Scholar] [CrossRef]

- Khan, A.A.; Sultan, U.; Rudra, R.P.; Ehsan, F.; Kashif, M.; Khan, M.M.; Hashim, S.; Zohaib, M.; Ahmad, S.I. Structural Analysis of Cotton Stalk Puller and Shredder Machine. Alex. Eng. J. 2023, 64, 335–347. [Google Scholar] [CrossRef]

- Wang, P.; Chen, X.; Wen, H. Simulation Research on Cotton Stalk Cutting and Crushing Based on ANSYS/LS-DYNA and Field Experiments. Agriculture 2023, 13, 1268. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, W.; Fu, J.; Xie, H.; Zhang, Y.; Chen, M. V-Shaped Toothed Roller Cotton Stalk Puller: Numerical Modeling and Field-Test Validation. Agriculture 2023, 13, 1157. [Google Scholar] [CrossRef]

- Zhao, W.; Xie, J.; Chen, M.; Gao, Q.; Cao, S.; Wang, Z.; Chen, Y. Design and experiments of the clamping and uprooting device with adjustable stiffness for a cotton stalk. Trans. Chin. Soc. Agric. Eng. 2024, 40, 80–90. [Google Scholar] [CrossRef]

- Li, Y.; Wang, Y.; Wang, Y.; Ma, C. Effects of Vitex Negundo Root Properties on Soil Resistance Caused by Pull-out Forces at Different Positions around the Stem. CATENA 2017, 158, 148–160. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, T.; Chen, M.; Zhao, W.; Wang, Z.; Liu, K.; Yeerbolati, T.M.; Wang, Y.; Liu, X.; Liu, A. Design of toothed disc cotton stalk harvester. Trans. Chin. Soc. Agric. Eng. 2019, 35, 1–8. [Google Scholar] [CrossRef]

- Li, J.; Lu, Y.; Peng, X.; Jiang, P.; Zhang, B.; Zhang, L.; Meng, H.; Kan, Z.; Wang, X. Discrete Element Method for Simulation and Calibration of Cotton Stalk Contact Parameters. BioResources 2022, 18, 400–416. [Google Scholar] [CrossRef]

- Rui, Z.; Zhang, J.; Tsai, C.-l.; Wang, Y.; Yerbolat, T.; Gao, Z. Study and Experiment on the Key Factors of Pull-up Force of Cotton Stalk. Agric. Mech. Res. 2023, 45, 190–196. [Google Scholar] [CrossRef]

- Zhang, J.; Li, J.; Wang, H.; Ge, J.; Zhang, Z.; Sun, H. Design and Experiment of the Clamping Mechanism for a Horizontal Shaft Counter-Rolling Cotton Stalk Pulling Machine. Agriculture 2025, 15, 2137. [Google Scholar] [CrossRef]

- Baikeli, Y.; Xu, H.; Zhang, J.; Yue, Y.; Guo, G. Innovations and Challenges In Mechanized Cotton Stalk Harvesting For Environmental Sustainability In The Field: A Review. J. ASABE 2025, 68, 365–377. [Google Scholar] [CrossRef]

- Yue, Y.; Xing, R.; Baikeli, Y.; Xu, H.; Ma, W.; Guo, L. Systematic Calibration and Validation of Discrete Element Model Parameters for Cotton Root Systems. Agriculture 2025, 15, 1827. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).