Abstract

The electrification of agricultural equipment is a critical pathway to address the dual challenges of increasing global food production and ensuring sustainable agricultural development. As the core power unit, the permanent magnet synchronous motor (PMSM) drive system faces severe challenges in achieving high performance, robustness, and reliable control in complex farmland environments characterized by sudden load changes, extreme operating conditions, and strong interference. This paper provides a comprehensive review of key technological advancements in PMSM drive systems for agricultural electrification. First, it analyzes solutions to enhance the reliability of power converters, including high-frequency silicon carbide (SiC)/gallium nitride (GaN) power device packaging, thermal management, and electromagnetic compatibility (EMC) design. Second, it systematically elaborates on high-performance motor control algorithms such as Direct Torque Control (DTC) and Model Predictive Control (MPC) for improving dynamic response; robust control strategies like Sliding Mode Control (SMC) and Active Disturbance Rejection Control (ADRC) for enhancing resilience; and the latest progress in fault-tolerant control architectures incorporating sensorless technology. Furthermore, the paper identifies core challenges in large-scale applications, including environmental adaptability, real-time multi-machine coordination, and high reliability requirements. Innovatively, this review proposes a closed-loop intelligent control paradigm encompassing environmental disturbance prediction, control parameter self-tuning, and actuator dynamic response. This paradigm provides theoretical support for enhancing the autonomous adaptability and operational quality of agricultural machinery in unstructured environments. Finally, future trends involving deep AI integration, collaborative hardware innovation, and agricultural ecosystem construction are outlined.

1. Introduction

Global agriculture faces the dual pressures of continuous population growth and increasingly scarce natural resources. The Food and Agriculture Organization of the United Nations (FAO) explicitly states that global food production needs to increase by 70% by 2050 to meet the survival needs of 9.7 billion people [1]. However, the sustainability of current agricultural production is under a severe challenge—traditional internal combustion engine agricultural machinery has an average energy efficiency of less than 40% yet contributes up to 23% of agricultural carbon emissions. Its high-energy-consumption, high-emission operating mode contradicts green and low-carbon development goals. In this context, the electrification and intelligent transformation of agricultural equipment have become crucial solutions. As the core drive unit, the PMSM, with its high power density, excellent efficiency, and wide speed regulation capability, provides an ideal driving force for the green upgrade of agricultural machinery [2,3].

In harsh agricultural environments, motor selection is critical to the performance, cost, and durability of the drive system; therefore, a comparative analysis against other common motor types is necessary. While induction motors (IMs) and switched reluctance motors (SRMs) offer benefits in certain scenarios, PMSMs have emerged as the preferred solution for high-performance agricultural applications due to their superior power density and exceptional efficiency—key factors for battery-powered equipment and tasks requiring precise control, such as variable-rate seeding and spraying. Table 1 summarizes the key characteristics, advantages, and disadvantages of PMSMs relative to IMs and SRMs, providing a foundation for understanding their growing adoption in modern agricultural machinery [4,5].

Table 1.

Comparison of motor technologies for agricultural applications [4,5].

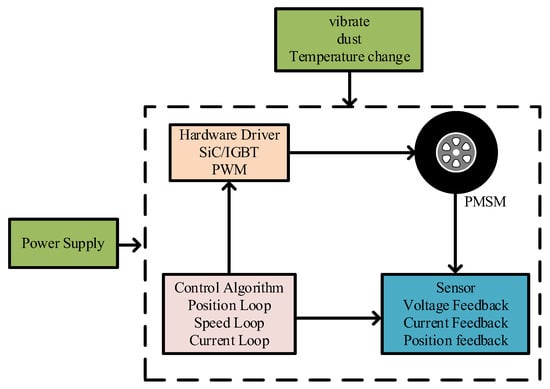

The PMSM drive system, comprising the motor, power converter, and controller (as shown in Figure 1), serves as the core powertrain for an increasing number of agricultural machines, from electric tractors and seeders to combine harvesters. These systems must operate reliably under the exceptionally demanding and unpredictable conditions of the farm environment. Key challenges include sudden ±70% soil resistance mutations during tillage or seeding, extreme ambient temperature variations (−40 to 85 °C) from season to season and region to region, strong electromagnetic interference from various onboard equipment, persistent broadband vibration (3–500 Hz) generated by uneven terrain and implements, and exposure to corrosive agents like acidic mud and fertilizer. These factors collectively push the drive system to its limits, threatening both hardware integrity and control stability. Factors such as high voltage, large current, and temperature cause a decline in the reliability of the power converter, whose reliability determines the continuous and reliable operation capability of agricultural machinery. Furthermore, the sophistication of the control algorithms ultimately determines the system’s ability to translate raw power into precise, efficient, and high-quality agronomic outcomes. The performance of these algorithms is therefore not merely an engineering metric but a direct determinant of agricultural operational quality, influencing factors such as seeding depth uniformity, harvesting efficiency, and overall yield [4].

Figure 1.

Block diagram of the motor drive system.

Currently, silicon-based power devices remain dominant in the global power market (market share > 75%) due to their mature manufacturing processes, excellent cost-effectiveness, and complete supply chain, particularly in medium-to-high voltage applications such as agricultural machinery. Although SiC and GaN materials show significant potential in terms of efficiency and high-temperature performance, their high costs and reliability issues in harsh agricultural environments, such as vibration and dust, limit their widespread adoption in the short term [6,7].

To enhance the adaptability of silicon-based devices in complex environments, technological development is focused on device optimization and system integration. At the device level, super-junction technology has significantly improved the trade-off between on-resistance and breakdown voltage, while trench gate design reduced gate charge. Combined with flexible packaging and potting processes have been developed to withstand the broadband vibration (3–500 Hz) typical of harvesters and tillage equipment operating on uneven terrain, markedly enhancing vibration resistance and fatigue endurance. In terms of heat dissipation, microchannel heat sinks, oleophobic coatings, and split-type heat pipe designs are critical for combating the dust-induced thermal resistance surge (>45%) encountered during prolonged operations in dry fields, such as those common during wheat harvest or in arid regions [7].

At the system level, reliability is enhanced through intelligent and environmentally adaptive design. Integrated temperature and dust sensors enable dynamic power regulation and overheating warnings, while common-mode chokes and distributed capacitor layouts effectively reduce electromagnetic interference in multi-motor systems, ensuring stable operation of the entire machine under field conditions [8].

Regarding motor control algorithms, Field Orientation Control (FOC) and DTC are two commonly adopted strategies for PMSMs. However, the former requires complex coordinate transformations and suffers from slow response speed and large motor speed pulsation in complex agricultural environments. DTC, due to its non-fixed switching frequency of power devices, not only results in ±10% torque ripple, directly causing uneven seeding depth and harvest loss, but also leads to severe motor current harmonic distortion (THD), reducing motor operating efficiency [9].

To overcome the limitations of FOC and DTC in complex farmland environments, MPC is regarded as a promising alternative due to its excellent dynamic response capability, showing broad application prospects in agricultural drive motors. However, its practical application still faces two key bottlenecks. First, the online rolling optimization process of MPC imposes a heavy computational burden, making it difficult to meet the requirements for high-precision, real-time control of motor speed in complex field operation environments. Second, the control performance of MPC highly depends on the accuracy of motor model parameters (e.g., inductance, resistance). Under typical farmland conditions with drastic temperature and humidity changes accompanied by significant mechanical vibration, motor parameters are prone to drift, leading to model mismatch, reduced prediction accuracy, and deteriorated control performance. These issues, particularly the impact of parameter drift in harsh environments, severely constrain the promotion and application of MPC in agricultural machinery drive systems [10,11].

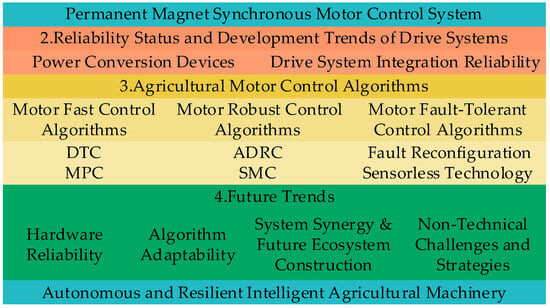

Furthermore, robust control strategies with strong disturbance rejection capabilities also have their limitations: the high-frequency chattering of SMC exacerbates mechanical wear, while the Extended State Observer (ESO) of ADRC is prone to amplifying noise under high gain, weakening system stability. Crucially, when multi-stress coupling effects like vibration, drastic temperature changes (−40~85 °C), and corrosion act on the drive system, the lack of a synergistic mechanism between fast control (dynamic response), robust control (disturbance rejection and stabilization), and fault-tolerant control (fault reconfiguration) in existing control architectures makes it difficult to build a closed-loop protection system of “disturbance suppression—fault isolation—dynamic reconfiguration”. Under such complex conditions, the robust layer may fail to compensate for key performance degradation (e.g., torque loss) in time, the fault-tolerant layer struggles to dynamically reconfigure the system state and accurately acquire necessary information (e.g., rotor position and speed), and the fast layer loses control due to inaccurate commands, potentially leading to system collapse. This systemic failure profoundly reveals the core disconnect in current research: control theory mostly focuses on single-algorithm optimization in laboratory environments, while agricultural engineering emphasizes local hardware improvements, both failing to establish a collaborative model that accurately captures the strong coupling dynamic relationship of “motor-load-environment” [12,13,14]. Figure 2 shows the overall flowchart of the article.

Figure 2.

Research framework and logical flow of the review.

Therefore, this paper focuses on the latest developments in power converters and motor control strategies, analyzing their critical roles in enhancing the overall performance and operational reliability of agricultural PMSM drive systems [15]. First, the paper systematically analyzes packaging and protection schemes for power devices in multi-stress coupled environments such as vibration, dust, and corrosion, exploring structural optimization and system integration methods from a hardware perspective; second, from the control algorithm perspective, the paper delves into the key technologies of agricultural machinery drive motors: in terms of fast control, it analyzes the technical pathways of virtual vector DTC and Bayesian optimization MPC in addressing sudden changes in soil resistance; in terms of robust control, it discusses the suppression mechanisms of adaptive sliding mode and ESO for parameter drift and mechanical vibration; in terms of fault-tolerant control, it reviews innovative methods for achieving high-precision control under position sensor failure using a hybrid observation architecture; finally, it combines the development needs of agricultural intelligence to explore the technical evolution direction of high-reliability drive systems.

2. Reliability Status and Development Trends of Drive Systems

2.1. Power Conversion Devices

Technological innovation focuses primarily on structural optimization and system integration specifically designed for agricultural applications: At the device level, Super Junction (SJ) technology significantly improves the trade-off relationship between on-resistance and breakdown voltage, achieving a breakthrough from traditional to quasi-linear modes, thereby enhancing the energy efficiency ratio particularly important for battery-powered agricultural equipment. Simultaneously, trench gate and split gate designs reduce gate charge. Combined with flexible terminal packaging and bottom potting processes, they increase solder joint vibration fatigue life by 3 times, effectively mitigating failure risks caused by field mechanical vibration commonly encountered during plowing and harvesting operations [14,16].

At the system level, intelligent monitoring and environmental adaptability design are key for agricultural applications. Integrating real-time temperature and dust sensors enables dynamic output power adjustment (e.g., automatic derating by 20% at 85 °C ambient temperature commonly reached in summer harvesting). Predicting cleaning cycles based on thermal resistance models reduces downtime caused by overheating during prolonged operations in dusty conditions. EMC is improved using common-mode chokes and distributed busbar capacitor designs, suppressing multi-motor interference and reducing EMI peaks by 30%, which is crucial for reliable operation of agricultural equipment with multiple electric drives [17,18].

2.2. Drive System Integration Reliability

Building upon solving single-device reliability, the collaborative management of Electromagnetic Interference (EMI) in multi-motor systems becomes core to ensuring stable operation of the entire agricultural machine. Conducted interference is primarily addressed through a “source suppression + path blocking” strategy: Gate driver voltage slew rate control (10 V/ns) reduces switching noise intensity at the source; multi-stage filtering uses Ni-Zn ferrite cores to block common-mode currents in the 150 kHz to 1 MHz range, while X2Y capacitors absorb higher-frequency harmonics. This solution achieved over 30 dB attenuation of power bus noise in the Lovol Guoshen corn harvester application, complying with GB/T18655-2018 [19] Class 3 standard. Radiation interference shielding employs different tier solutions: The high-performance path adopts chip-level magnetic shielding integrated copper layers, compressing radiation interference from 150 kHz to 30 MHz by over 30 dB and reducing false triggering rates to below 0.1% per thousand hours; the economical solution uses a simple design of double-layer aluminum foil wrapping sensitive control boards, significantly reducing RS485 communication bit error rate from 8.5% to 0.9% at only 1/5 the cost of the professional solution—particularly valuable for cost-sensitive agricultural applications [8,20].

System-level architectural innovation fundamentally decouples interference: Distributed drive architectures disrupt common-mode paths through functional reconstruction. For example, the Weichai hybrid harvester employs a “range extender + independent electric drive module” design, configuring dedicated motors for the threshing drum (30 kW), cutting platform (18 kW), and grain bin auger (7 kW), eliminating interference conduction through mechanical transmission chains. Measured multi-machine collaborative positioning error is less than 5 cm. Intelligent anti-jamming technology also plays a key role: XAG agricultural drones equipped with the spectrum-sensing Mosaic navigation module dynamically scan the 10 to 6000 MHz electromagnetic environment using AIM+ technology, actively avoiding harmonic frequency points of high-voltage lines, maintaining centimeter-level positioning accuracy in strongly interfering cotton fields; lightweight communication protocol design (e.g., a command transmission protocol based on CoAP over UDP) compresses data packet overhead by 40%, achieving measured command latency below 50 ms in Xinjiang cotton picker fleets, with robustness improved by 3 times compared to traditional CAN bus [21,22].

However, as SiC/GaN devices push switching frequencies into the MHz range, ultra-high-frequency interference above 100 MHz presents a new severe challenge, with existing filtering solutions experiencing efficiency attenuation exceeding 50% in this band. Future breakthroughs require the integration of material innovation and system architecture optimization: Ferrite-graphene composite materials show promise for broadening the wave absorption band; domestic chips like Xinmai GC4938, certified for automotive standards from −40 to 150 °C and reducing costs by 15%, provide support for large-scale application; distributed architectures are evolving towards integrated photovoltaic-storage-charging, buffering bus current ripple generated by inverter operation using local energy storage (e.g., supercapacitors or batteries), reducing interference conducted to other subsystems via power lines, while local photovoltaic or storage power supply reduces injection points for long-distance cable conducted interference, suppressing EMI coupling at the source. Ultimately, eradicating the chronic EMI issue in agricultural multi-motor systems relies solely on the deep collaborative advancement of device-level protection, architecture-level decoupling, and system-level intelligent suppression. This tight coupling of hardware and system design is the cornerstone for building highly reliable, high-performance electrified agricultural drive systems adapted to complex farmland environments [23,24].

2.3. Maintenance and Serviceability Considerations

Beyond inherent reliability, the ease of maintenance and serviceability of PMSM drive systems are paramount operational criteria for agricultural applications, where downtime during critical planting or harvesting seasons can lead to significant economic losses. Designs must prioritize diagnosability through intelligent monitoring systems that enable predictive maintenance, allowing farmers to schedule repairs during non-critical periods. Modularity is another key factor, facilitating the rapid replacement of sub-systems like power modules in field workshops rather than requiring complete unit returns. Furthermore, robustness against environmental ingress (e.g., dust, moisture, chemicals) through protective enclosures and coatings extends service intervals and reduces maintenance frequency. These factors—diagnosability, modularity, and environmental protection—collectively determine the total cost of ownership and operational availability of agricultural machinery, making them as critical as performance metrics for adoption success [21,22,23,24,25].

3. Agricultural Motor Control Algorithms

The preceding section established that hardware reliability—encompassing robust packaging, thermal management, and EMC design—forms the critical physical foundation (the “body”) of the PMSM drive system, enabling it to withstand harsh agricultural environments characterized by vibration during field operations, dust during harvesting, and extreme temperatures across seasons. However, to translate this physical resilience into high-precision, high-efficiency, and autonomous field operations, advanced control algorithms are indispensable as the “brain” of the system. This section delves into these control strategies, which leverage the robust hardware platform to achieve ultimate performance in agricultural applications. We will explore how fast control algorithms (e.g., DTC, MPC) ensure dynamic response to sudden load changes such as soil resistance mutations; how robust controllers (e.g., SMC, ADRC) maintain stability under disturbances and parameter drift caused by environmental variations; and how fault-tolerant and sensorless technologies enhance overall system reliability for continuous agricultural operations. The seamless collaboration between the reliable hardware discussed in Section 2 and the intelligent algorithms reviewed herein is paramount for building a high-performance drive system that meets the demanding requirements of modern agricultural equipment.

Agricultural machinery faces harsh challenges during field operations, such as sudden soil resistance changes, extreme temperature and humidity, strong electromagnetic interference, and highly uncertain loads, imposing comprehensive demands for high performance, strong robustness, and high reliability on PMSM drive systems. Fast control (e.g., DTC and MPC), as the core of system dynamic response, strives to achieve precise and fast tracking of torque and flux, forming the foundation for ensuring agricultural operation efficiency and precision. However, strong disturbances and model uncertainties introduced by the complex and variable farmland environment make systems relying solely on fast control prone to instability or performance degradation [8,9,10,11,12,13].

To address this, robust control significantly enhances system stability and disturbance rejection capability under harsh conditions by actively estimating and compensating for internal and external disturbances (e.g., load mutations, parameter drift), providing a solid operational guarantee for fast control. Furthermore, considering the significantly increased risk of motor winding faults and permanent magnet demagnetization under multi-stress coupling environments (vibration, temperature change, corrosion), fault-tolerant control, through deep synergy with fast control and robust control (e.g., utilizing robust observers for fault diagnosis combined with predictive control for dynamic reconfiguration), builds a closed-loop protection system of “detection-diagnosis-reconfiguration”, ensuring the drive system maintains safe and reliable operational capability even when partial faults occur. Therefore, fast control, robust control, and fault-tolerant control are not isolated but tightly coupled and layered, collectively constituting the core algorithmic pillars for tackling the challenges of complex agricultural operating conditions and achieving high-performance, highly reliable drives for smart agricultural machinery. This chapter systematically elaborates on the latest advances in these key control algorithms and their adaptive improvements for agricultural applications [25,26,27].

3.1. Motor Fast Control Algorithms

3.1.1. Direct Torque Control

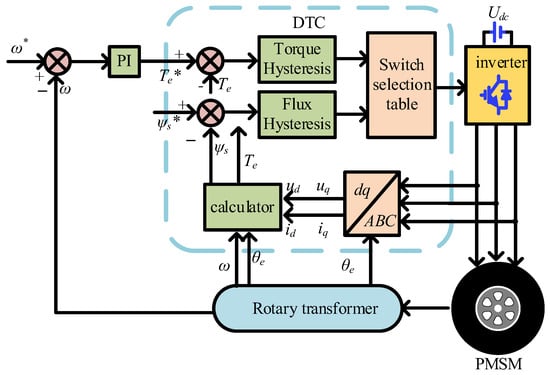

DTC is a relatively new high-performance AC variable frequency speed control technology developed after vector control. The DTC block diagram is shown in Figure 3.

Figure 3.

DTC block diagram.

The basic working principle of DTC is to detect the motor stator voltage and current in real-time, calculate the magnitude of torque and flux, compare them with their respective reference values(* denotes a given value.), and use the resulting errors to control the amplitude of the stator flux linkage and the angle of the voltage vector relative to the flux linkage. Torque and flux regulators directly output the required space voltage vector, achieving the goal of direct flux and torque control [11].

Unlike vector control technology, DTC uses Bang-Bang control to generate PWM signals, optimally controlling the inverter’s switching states to achieve high dynamic performance in torque. DTC abandons the decoupling idea in traditional vector control, replacing rotor flux orientation with stator flux orientation and eliminating rotating coordinate transformations. This not only reduces the computational burden but also weakens the system’s dependence on motor parameters, effectively mitigating the impact of motor parameter variations on operational performance. This characteristic is particularly valuable for electric tractors, where load torque can fluctuate violently due to changing soil conditions, helping to maintain traction and prevent wheel slip [11].

However, the traditional DTC’s two-level hysteresis mechanism leads to non-fixed switching frequency, causing >10% torque ripple and >13% current harmonic distortion (THD). This torque ripple directly translates into uneven torque output at the wheel or implement, leading to agronomically detrimental effects such as uneven seeding depth in planters or uneven cutting height in harvesters, ultimately resulting in yield loss. Simultaneously, in applications using high-frequency SiC/GaN devices, zero vectors can excite 300V-level common-mode voltage oscillations, while torque non-smoothness issues during multi-flux trajectory switching (e.g., circular → hexagonal) further limit its applicability in precision agricultural scenarios [11].

To overcome these limitations, recent research has advanced in both single-motor performance optimization and multi-motor cooperative control. At the single-motor level, multi-voltage vector modulation technology is a key breakthrough: Addressing the insufficient resolution of traditional 8 vectors, adjacent forward/reverse vectors are combined to generate virtual vectors with adjustable amplitude and phase (e.g., sequential synthesis of V1(100) and V4(011)), achieving 40 dB attenuation of common-mode voltage across the full frequency band and reducing current THD to 2.1%. Dual three-phase PMSM systems further achieve 60% suppression of 5th/7th harmonic currents through harmonic plane decoupling and constructing zero-projection vectors. Concurrently, a parameter adaptive compensation mechanism uses an ESO to identify online inductance variations ΔL, dynamically correcting vector application time to ensure THD remains stable at 2.1% under ±20% parameter drift, combined with direct dead-time voltage compensation in the αβ coordinate system to eliminate current clamping. Deadbeat Predictive Fusion (DB-DTFC) innovates algorithmically—a simplified model based on stator flux differential eliminates quadratic term calculation, reducing computational load by 50% and shortening transient recovery time by 40%, significantly enhancing stability under sudden loading conditions in plowing machinery [9,10,11,12,13].

At the multi-motor cooperation level, agricultural machinery systems like the closely spaced electric drive groups (“cutting platform—threshing drum—grain bin auger”) in harvesters face dual challenges: timing conflicts causing DC bus voltage oscillations (amplitude fluctuation > 15%) and disturbance transmission through mechanical coupling. Phase-shifted PWM technology staggers the modulation wave phases of dual inverters (e.g., 30° offset), attenuating bus voltage ripple by 40% and optimizing harmonic spectrum distribution. A dynamic voltage vector reconstruction strategy, based on a global ESO estimating multi-machine disturbance components (e.g., impact of threshing drum shocks on the cutting platform), embeds compensation terms into the switching table, achieving torque synchronization error < 5%, ensuring harvesting height stability. Agronomy-adaptive architecture further integrates operation modes into the control logic: plowing mode adopts a hexagonal flux trajectory to maximize torque output, precision seeding mode switches to a circular trajectory to suppress harmonics. Coordinated with multi-objective optimization of traction and seeding motors, it reduces the variation coefficient of corn seeding plant spacing from 9.8% to 6.3% [16].

Although DTC has significantly improved dynamic performance through vector synthesis innovation and cooperative control architecture, its discrete switching table mechanism and insufficient multi-objective trade-off capability still show limitations in complex agricultural trajectory tracking (e.g., continuous curve motion of apple picking robotic arms). When the system needs to simultaneously optimize torque response speed, harmonic suppression, and energy efficiency, DTC’s fixed hysteresis tolerance struggles to dynamically balance multi-objective conflicts. This is precisely the domain where MPC demonstrates its unique advantages through rolling optimization and flexible configuration of cost functions—providing a new generation solution for agricultural machinery drives transitioning from “single-variable fast tracking” to “multi-constraint global optimization” [9,10,11].

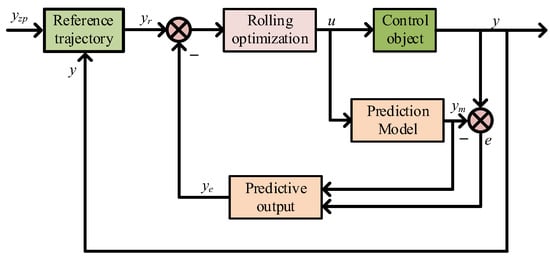

3.1.2. Model Predictive Control

MPC is a feedforward-feedback compound control strategy based on a dynamic model. Its core is to generate an optimal time sequence of voltage vectors through rolling optimization to achieve multi-objective coordinated regulation. While theoretically adaptable to parameter changes via rolling optimization, its practical robustness heavily depends on the accuracy of the prediction model. Under extreme farmland conditions, motor parameter drift (e.g., ±30% inductance change) causes model mismatch, leading to current THD > 5% and response lag. Its control structure block diagram is shown in Figure 4.

Figure 4.

MPC Structure Diagram.

Model Predictive Torque Control (MPTC) achieves decoupled control of torque and flux by directly optimizing the voltage vector sequence. Its cost function is typically:

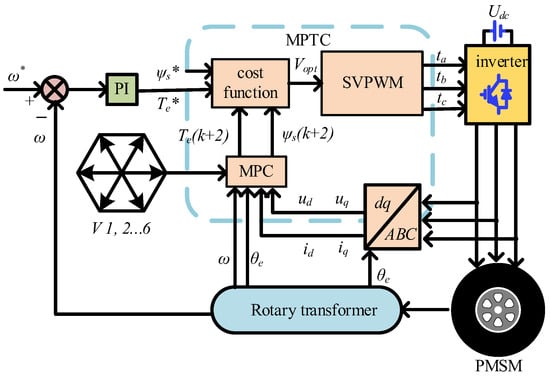

where ψs is the stator flux linkage, Te is the electromagnetic torque, λψ is the weighting coefficient. Its control block diagram is shown in Figure 5. Therefore, compared with traditional control strategies, MPC exhibits significant advantages in multiple aspects: Its core lies in the ability to flexibly configure weighting coefficients in the cost function, enabling collaborative optimization of multiple objectives such as torque and flux tracking accuracy, switching losses, and current harmonic suppression. Simultaneously, it explicitly handles physical constraints (voltage, current, torque) during the rolling optimization process, effectively enhancing system safety. Furthermore, the mechanism of prospectively generating optimal voltage vector sequences based on the prediction model significantly improves system dynamic response speed (response time can be shortened by about 30% compared to FOC), thereby better suppressing speed fluctuations caused by sudden soil resistance changes. Particularly important is that MPC does not rely on a precise decoupled motor model; it predicts future behavior by discretizing the system state, exhibiting stronger adaptability and robustness to parameter drift during operation.

Figure 5.

MPTC block diagram.

The evolution of MPC in the field of motor drives, especially innovations for single/dual motor systems, has been consistently constrained by the dual challenges of high computational complexity and difficulty in weighting coefficient tuning, severely hindering its deployment in real-time farmland control scenarios.

In single-motor control, to break through the real-time computation bottleneck, early research attempted to restructure the cost function: Literature [28] proposed a torque-flux error grouping screening mechanism for weightless optimization, but ignoring dynamic disturbance compensation led to tracking failure during sudden loading in plowing machinery; Literature [29] retained only the voltage vector tracking term to drastically simplify the design, eliminating the need for weight tuning but expanding torque/flux errors by 60% under external disturbance; Literature [30] turned to d-q axis flux decoupling to improve steady-state accuracy, but lacking a torque prediction loop caused response delays exceeding 10 ms; Literature [31] adopted a dual-torque architecture causing speed oscillations in combine harvesters. While these methods avoid the weight tuning problem, they are confined to single-variable optimization paradigms, struggling to coordinate the dynamic coupling of torque and flux, resulting in insufficient adaptability under time-varying field conditions.

A parallel path is changing the optimization objective—Model Predictive Current Control (MPCC) shifts the cost function to current tracking [32,33], simplifying the design process but reducing dynamic response speed by 30% compared to traditional MPTC and making it extremely sensitive to inductance parameter drift, failing to meet the instantaneous torque demands of seeders; Model Predictive Speed Control, while theoretically enabling an efficient single-loop architecture [34,35,36,37], suffers from computational load explosion and dynamic lag (delay > 10 ms), causing significant real-time degradation in multi-motor cooperative scenarios like harvesters. These technical attempts partially alleviate single contradictions (e.g., weight tuning or computation load) but fail to simultaneously overcome the synergistic challenge of high complexity and parameter sensitivity, leaving MPC facing severe obstacles in achieving real-time precise control in complex farmland environments [37,38].

Cooperative control of dual-motor systems faces even more severe spatio-temporal coupling challenges. In multi-power-source agricultural machinery like electric tractors and combine harvesters, timing conflicts between traction motors and working motors (e.g., harvester threshing drum motor) can cause DC bus voltage oscillations (amplitude fluctuation > 15%), while mechanically coupled transmitted disturbances further degrade operational stability. Addressing this, a distributed MPC architecture achieves breakthroughs through two core innovations: First, phase-shifted PWM technology staggers the modulation wave phases of dual inverters (e.g., 30° offset), suppressing voltage ripple by up to 40%, avoiding seeding timing disorder caused by power fluctuations at the source. Second, embedding agronomic constraints into the cost function, for instance, in corn precision planter control, incorporating seeding phase deviation as a penalty term into the traction motor speed tracking objective, achieving dual-variable (“speed-phase”) cooperative optimization, reducing the plant spacing variation coefficient from 9.8% to 6.3%. For transient impact during mode switching, the Dual Motor Drive System (DMDS) of an electric tractor employs an MPC engagement strategy and Torque Transfer Control (TRC) separation strategy to coordinate traction motor and PTO (Power Take-Off) motor outputs, reducing shift shock intensity by 56.24% and operational speed deviation by 51.42%, significantly improving smoothness [11,37].

The deep integration of intelligent algorithms and predictive control is gradually driving MPC towards “lightweight + strong generalization”. Xinjian Electromechanical Drive [38] proposed a dual-neural-network MPC using a GRU network to approximate the system dynamics model and a NARX network to accelerate optimization solving, addressing the real-time computation bottleneck in high-dimensional nonlinear systems, reducing robotic joint control response delay to milliseconds. Fractional-order neural networks depict current dynamic characteristics through fractional calculus, suppressing switching current oscillation amplitude to 0.5% under 25~175% load mutation conditions, providing a new solution for disturbance-resistant motor operation. Notably, dual-motor synchronous control witnesses innovations in observer technology—the adaptive disturbance observer developed by Zhongke Shanhaiwei [39], combined with sliding mode control, accurately estimates nonlinear disturbances and compensates in real-time, significantly enhancing system anti-interference capability and laying the foundation for multi-machine collaborative robustness.

3.2. Motor Robust Control Algorithms

During the operation of agricultural motor systems, stability issues arise under parameter drift, sudden load changes, and unmodeled disturbances. Consequently, researchers have conducted extensive and in-depth studies on robust control for drive motors. In this paper, robust control specifically refers to stability algorithms targeting disturbances (e.g., SMC/ADRC), while observer technologies (e.g., Sliding Mode Observer SMO) belong to the fault-tolerant control layer. At the single-motor level, SMC exhibits strong disturbance rejection capability due to its variable structure nature [40].

Traditional SMC can force system states to converge in finite time by designing the sliding surface, but the high-frequency chattering (>500 Hz) induced by the sign function sgn(s) exacerbates mechanical wear and requires manual gain adjustment under time-varying disturbances. Addressing this, Fixed-Time Non-singular Terminal Sliding Mode (FNTSM) fused with an Adaptive Disturbance Observer (ADO) can estimate soil resistance torque in real time (error < 5%) during sudden load changes in rice transplanter plant spacing adjustment, compressing speed fluctuation from ±12 rpm with traditional PID to ±2 rpm, while simultaneously reducing chattering amplitude by 60% (Literature [19]). Notably, a derivative application of the SMO—achieving position estimation error < 1° on hard roads through back-EMF tracking—lays the foundation for sensorless control, significantly reducing encoder failure risk caused by salt spray corrosion (MTBF increased to >15,000 h) [40,41,42,43].

Due to mechanical linkage structure issues, the disturbance coupling problem in dual-motor cooperative operations is even more severe. For example, when the threshing drum of a combine harvester suddenly encounters changes in crop density, the impact load is transmitted through the mechanical structure to the cutting platform motor, causing mutual interference between the speeds of the two motors. ADRC treats such coupled disturbances as “total disturbances” and estimates and compensates for them uniformly through an ESO [44], achieving decoupling without the need for precise mathematical models. Its control structure diagram is shown in Figure 6.

Figure 6.

ADRC Structure Diagram.

ADRC observes and compensates for both internal and external system disturbances as “total disturbance” through the ESO. Traditional ESO under high gain tends to amplify noise, causing wheel hub motors to generate ±8 rpm speed ripples on muddy roads. To address this, the Disturbance observation Error-constrained ESO (DE-ESO) designs an observation error constraint term based on Lyapunov stability theory. Under deep plow impact conditions, it compresses response time to <50 ms, suppresses wheel hub motor speed fluctuation to ±0.9 rpm (88% reduction) in 5 cm deep mud, and reduces current THD by 2.3 percentage points simultaneously. This observer architecture can be extended to multi-motor systems: ADRC position observers maintain <3° error even under 20% tire slip rate, ensuring heading stability for dual-motor tractors in slippery fields [44].

In the dual-motor drive of an electric seeder, a sliding mode-predictive composite control combines the robustness of SMC with the multi-objective optimization capability of MPC: The upper-layer MPC rolls out optimal current commands, while the lower-layer SMC performs fast tracking and suppresses unmodeled disturbances, keeping seeding phase deviation < 0.5° under ±30% soil resistance fluctuation. Adaptive fuzzy ADRC dynamically adjusts ESO gains through fuzzy rules, solving the inertia matching problem between the threshing drum motor and grain bin auger motor in a corn harvester—when feed rate suddenly increases from 5 kg/s to 8 kg/s, dual-motor speed synchronization error drops from 12 rpm to 3 rpm, reducing kernel breakage loss rate by 1.2 percentage points (Weichai 2024 field test). These advancements collectively point to the core mission of robust control: building a disturbance-immune underlying defense line for fast control, enabling the system to maintain stable output under parameter mismatch and external disturbances [28,42,45].

Future development trends focus on the deep integration of intelligent algorithms and hardware architecture. For example, quantum observers using Kalman filtering achieve 40% noise variance reduction; federated learning architectures optimize multi-machine collaborative parameter identification efficiency; and LSTM-based fault-parameter mapping models enable online correction of control reference frames. These technologies collectively target the core mission of robust control: building a disturbance-immune underlying defense, enabling the system to maintain stable output under parameter drift (inductance ± 30%) and external shocks (>5 N·m), providing a “control-agnostic” technological foundation for smart agricultural equipment.

To provide a clear overview and facilitate the selection of appropriate control strategies for specific agricultural applications, Table 2 presents a concise comparative analysis of the key algorithms based on critical performance indicators.

Table 2.

Brief comparison of control algorithms for PMSM drives.

The comparative profile of each algorithm leads to distinct advantages and challenges in agricultural settings: DTC’s simplicity and fast dynamics are suitable for high-power traction drives. However, its inherent torque and current ripple can directly lead to uneven seeding depth and harvest loss, while its non-fixed switching frequency complicates EMC design [46]. MPC’s strength lies in its multi-objective optimization capability, making it ideal for precision tasks. Its primary drawback is acute sensitivity to motor parameter drift (e.g., inductance variation due to temperature), which is common in farmland, often requiring complex online identification. Furthermore, its high computational burden presents a significant challenge for real-time multi-motor coordination in complex machinery like harvesters [46]. SMC offers exceptional robustness against parameter variations and disturbances, such as sudden soil resistance mutations. Nevertheless, the chattering phenomenon can exacerbate mechanical wear in transmission systems and generate undesirable acoustic noise [46]. ADRC provides a compelling model-independent approach by actively estimating and compensating for ‘total disturbances,’ beneficial for coupled systems. Its performance, however, depends on the tuning of multiple observer parameters, and its extended state observer may inadvertently amplify sensor noise under high gain on rough terrain, potentially affecting stability [46].”

3.3. Motor Fault-Tolerant Control Algorithms

Traditional mechanical sensors are susceptible to failure under the influence of complex farmland environments such as dust, vibration, and corrosion, posing a high risk of failure and being a key factor in the reduced reliability of motor drive systems. Fault-tolerant control, through deep synergy with fast control (dynamic response) and robust control (disturbance rejection and stability), builds a full-chain “detection-diagnosis-reconfiguration” fault-tolerant control system, enhancing the reliability of motor drive systems.

3.3.1. Fault Reconfiguration Synergy Mechanism

Current research on fault-tolerant control mainly revolves around strategies based on DTC, sensorless control, and dynamic compensation with controller reconfiguration. Domestic and international scholars’ research on fault-tolerant control has primarily focused on strategies within the DTC framework. Early traditional hysteresis DTC fault-tolerant control solved the basic operation problem under single-phase open-circuit faults but retained inherent drawbacks like non-fixed switching frequency and large torque ripple. Literature [47] proposed a predictive method based on the principles of minimum torque and flux error and minimum zero-sequence current. Under winding open-circuit faults, this method reconstructs the stator flux model and the set of available inverter voltage vectors, selecting the optimal voltage vector for the next cycle through rolling prediction, effectively suppressing torque ripple and fixing the switching frequency. Literature [48] proposed an SVPWM-DTC fault-tolerant strategy for one-phase open-circuit faults in PMSMs. Its core is to compensate the back-EMF of the faulty phase and synthesize the reference voltage vector using the remaining 6 non-zero voltage vectors of equal amplitude. The PWM pattern generated by this reconfiguration is highly similar to the standard SVPWM of a three-phase PMSM under no fault. This strategy overcomes the shortcomings of traditional hysteresis DTC fault tolerance, is computationally fast and easy to implement, providing a new approach for efficient fault-tolerant operation under the DTC framework [49].

The aforementioned DTC-based fault-tolerant strategies effectively solve the execution-layer reliability issue under winding faults, but their control accuracy still heavily relies on the accuracy of rotor position information. Traditional position sensors are precisely the weak link in system reliability; their mechanical structure is vulnerable to vibration, temperature change, and electromagnetic interference. Once they fail, the fault tolerance mechanism collapses directly. Therefore, sensorless control technology, which dynamically reconstructs rotor states algorithmically without relying on hardware, becomes another important research area in fault-tolerant control.

3.3.2. Core Role of Sensorless Technology in Fault Tolerance

Sensorless technology not only avoids the risk of sensor hardware failure but also forms a dual closed-loop “information-execution” protection with the aforementioned fault-tolerant strategies, jointly constituting the core of a highly robust control system. Sensorless control technology can be divided into two main categories: signal injection-based and signal injection-free [50].

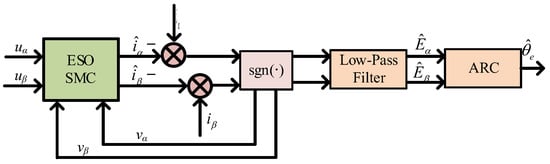

Among them, SMC, with its strong robustness (low requirement on model accuracy, strong resistance to parameter disturbance), holds an important position in signal injection-free methods. Its core lies in designing a SMO based on current tracking error to reconstruct motor back-EMF and estimate rotor position and speed using the arctangent function, as shown in Figure 7.

Figure 7.

Rotor position estimation based on the inverse tangent function.

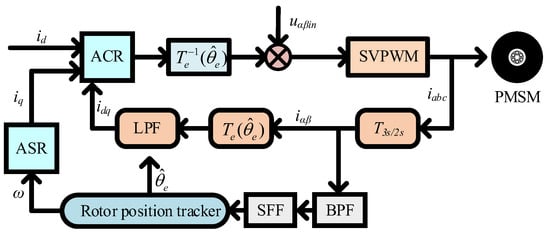

Sensorless control methods based on High-Frequency (HF) signal injection perform well at low and zero speeds. The basic idea is to superimpose a high-frequency voltage (or current) signal onto the fundamental signal and apply it jointly to the motor’s three-phase windings. The corresponding high-frequency current (or voltage) carries rotor position information. By extracting this signal using a bandpass filter and appropriate processing, the rotor position can be estimated. Commonly used injected HF signals mainly include rotating HF voltage signals and pulsating HF voltage signals. The principle of the rotating HF voltage injection method is: superimpose a three-phase balanced high-frequency voltage excitation onto the fundamental excitation, then detect the corresponding current response generated in the motor, and obtain rotor position information through specific signal processing [51]. Its system structure block diagram is shown in Figure 8.

Figure 8.

Block diagram of a sensorless control system for PMSM based on rotating high-frequency voltage signal injection.

In the figure, T3s/2s is the transformation matrix converting three-phase coordinates to stationary coordinates, T(θe) is the matrix converting stationary coordinates to rotating coordinates, LPF is a low-pass filter, and BPF is a band-pass filter.

However, the high-frequency injection component generates audible noise, degrading the operational comfort of agricultural equipment and the production environment for livestock. Furthermore, for FLC-PM motors, significant magnetic field variations occur under various operating conditions [52], leading to particularly prominent electromagnetic noise issues.

Optimizing the form of the injected signal can reduce noise caused by injection [48,49,50]. Adjusting the amplitude and frequency of the injected signal is an effective way to reduce noise. However, a decrease in signal-to-noise ratio poses challenges for demodulating the HF signal and affects the accuracy of rotor position estimation. Reducing acoustic noise by lowering the injection frequency or raising it beyond the range of human hearing. However, for injection signals, frequencies that are too low require precise motor parameters, while frequencies that are too high are limited by power device performance and switching losses. To avoid generating additional noise, a new scheme without extra injected signals was proposed [53,54,55,56,57], enabling rotor position detection through measured current, but detection accuracy is affected by current sensors.

Signal injection-free control technology achieves position identification by exploiting the motor’s inherent electromagnetic characteristics (e.g., back-EMF, magnetic saturation effect), fundamentally avoiding audible noise interference, making it more suitable for acoustically sensitive agricultural scenarios (e.g., livestock farms or orchard night operations). This technology primarily relies on three paths: SMO optimization, Model Reference Adaptive System (MRAS), and Extended Kalman Filter (EKF). The SMO reconstructs back-EMF based on current tracking error, estimating rotor position via the arctangent function. The design key lies in the adaptive tuning of sliding gain and sliding surface function to balance convergence speed and chattering suppression.

For instance, the super-twisting algorithm achieves <1° phase control accuracy in electric seeders. MRAS uses a current model as a reference to adaptively adjust the speed observation value, but it is highly sensitive to motor parameter drift (±30% inductance change can cause >5° error), requiring coupling with online parameter identification (e.g., Recursive Least Squares) to enhance robustness under temperature-varying conditions. EKF integrates noise statistics through a state-space model, offering significant disturbance rejection advantages in broadband vibration environments (−40 dB harmonic attenuation), yet its computational complexity hinders deployment on low-cost agricultural controllers. Current research promotes the deep integration of intelligent algorithms with traditional methods—for example, an LSTM-based SMO gain dynamic regulator can optimize observer bandwidth based on real-time vibration spectrum, compressing position error to ±0.5° under 200 Hz mechanical interference in plowing machinery, providing high-reliability position sensing for complex farmland environments [56,57].

Existing strategies (e.g., SMO) can mitigate interference from single faults like single-phase open circuits through adaptive gain adjustment but face triple challenges under multi-fault coupling conditions: (1) Model parameter decoupling failure—Winding short circuits cause nonlinear inductance saturation, demagnetization weakens back-EMF amplitude, and their mutual coupling makes the motor mathematical model strongly nonlinear, breaking the observer stability boundary; (2) Insufficient state observation dimension—Traditional position observers rely only on fundamental electromagnetic equations, not covering fault harmonic components (e.g., 3rd harmonic induced by demagnetization), leading to loss of information integrity; (3) Dynamic response lag—During fault transients, the rate of parameter time-variation (e.g., inductance drift rate reaching 0.5 mH/ms) far exceeds the observer update frequency (typically ≤10 kHz), causing cumulative phase error [58,59].

Against this background, the function of position information needs redefinition: it is not only a feedback variable for closed-loop control but also the dynamic reference for system reconfiguration in fault tolerance. Post-fault control laws must rebuild the voltage vector synthesis coordinate system (e.g., Clarke transformation matrix modification in SVPWM fault tolerance) based on the position estimate. This reconfiguration process relies on real-time parameter identification techniques (e.g., online inductance identification via HF injection) and multi-model switching strategies (e.g., LSTM-based fault-parameter mapping models), with the technical goal of maintaining electromagnetic torque controllability in the fault state through dynamic calibration of the reference coordinate system [58,59].

4. Future Trends

The development of high-performance PMSM drive systems for complex farmland environments will see future breakthroughs tightly centered around the synergistic evolution of three core directions: hardware reliability, algorithm adaptability, system synergy, and ecosystem construction. These will ultimately deeply integrate into a “Perception-Decision-Control” closed-loop intelligent control paradigm (structural block diagram shown in Figure 7), leading intelligent agricultural machinery from functional realization into a new era of autonomous resilience.

Hardware Reliability: Current wide-bandgap devices (SiC/GaN) offer high-frequency advantages but face bottlenecks like solder joint vibration fatigue, high-temperature permanent magnet demagnetization rate > 25%, and dust-induced thermal resistance surge > 45%. Progress requires material revolution: developing diamond-aluminum nitride composite substrates (>800 W/mK) to enhance thermal conductivity; employing anti-corrosion nano-coatings to combat acidic mud erosion; and reinforcing vibration resistance through rubber-hydraulic composite mounting designs. Although silicon-based devices extend solder joint life by 3 times via bottom potting processes, they still require integration with intelligent thermal management (liquid cooling temperature difference < 2 °C) and EMC co-design (noise attenuation > 30 dB). The goal is to achieve mass production of high-reliability electric drive modules with power density > 5 kW/kg and MTBF > 105 h by 2030 [20,21,22,23,24].

Algorithm Adaptability: Challenges mainly stem from field disturbances (e.g., ±70% sudden soil resistance change) and parameter drift (±30%), severely constraining control performance. Bottlenecks caused by strong field disturbances and severe parameter drift need to be overcome: traditional DTC’s torque ripple issue (>20%); MPC’s parameter sensitivity (current THD > 5% under drift) and high computational complexity (multi-machine coordination delay >50 ms); trade-offs in robust control (SMC, ADRC) between high performance and stability (e.g., ESO high gain amplifying noise). The core breakthrough lies in intelligent enhancement and deep multi-algorithm fusion. Intelligent-enhanced predictive control is a focus, e.g., adaptive MPC fused with Bayesian Inference (BI-AMPCC) dynamically updates model parameters, maintaining high performance (THD < 1.9%) under large parameter drift while reducing latency; using LSTM/GRU networks to replace or assist state equation prediction models significantly improves nonlinear dynamic modeling accuracy (reducing inductance saturation prediction error by 60%) and response speed (e.g., millisecond-level load mutation response); neural network reconstructed DTC switching tables effectively suppress harmonics (THD < 3%). Simultaneously, deepening the development of dedicated robust predictive controllers targeting specific agricultural machinery dynamics (e.g., rotary tiller yaw instability) (e.g., LMI-RMPC) and promoting tight integration of robust algorithms like sliding mode and ADRC with predictive frameworks (e.g., SMC-MPC composite control) are needed to build a solid underlying disturbance-immune defense. Exploring frontier computational paradigms like quantum algorithms (e.g., HHL) offers possibilities for breaking real-time limits. The goal is to construct an intelligent algorithm architecture featuring “Robust-Predictive-Fault-Tolerant” closed-loop synergy, achieving high-precision, strong robustness, and real-time control under extreme disturbances [60,61,62,63,64,65].

System Synergy and Future Ecosystem Construction: Aims to solve systemic challenges like perception limitations (slow traditional visual feedback causing large positioning errors), heterogeneous coordination barriers (protocol differences causing formation delays, disconnection between agronomic decisions and control), and ultra-high-frequency interference (SiC/GaN introducing >100 MHz EMI, low efficiency of existing filtering). Breakthroughs require multi-pronged approaches: Upgrade the intelligent perception network, integrating multi-dimensional sensors like hyperspectral imaging, electronic nose, LiDAR/mmWave radar, and BeiDou 5G centimeter-level RTK to provide real-time comprehensive environmental context. Build real-time cooperative communication and control architectures, applying Time-Sensitive Networking (TSN) to ensure centimeter-level multi-machine coordination (synchronization error < 1 cm) and low-latency (<50 ms) agronomic-control closed loops. Create a cloud-edge-end collaborative intelligent ecosystem, where the cloud leverages the “National Agricultural Machinery Brain Platform” and AI agronomy engines to generate precise operation prescriptions (e.g., variable-rate fertilization reducing pesticides by 30%), and edge/end devices deploy high-performance embedded AI for high-precision target recognition and real-time control (e.g., 1000 fps kinetic vision, 2 mm positioning accuracy), supporting large-scale unmanned farm operations. Comprehensively manage high-frequency EMI, combining new materials (ferrite-graphene composites), domestic chips (cost reduction 15%), and system architecture optimization (distributed PV-storage-charging integration buffering ripple, reducing conducted interference). Strengthen policy and business model drivers, e.g., BeiDou terminal subsidies accelerating unmanned farm adoption (market scale exceeding 100 billion by 2030), blockchain traceability enhancing agricultural product premium. The goal is to construct a full-chain autonomous closed-loop ecosystem spanning “Environmental Perception (real-time multi-dimensional)—Intelligent Decision (cloud agronomy + edge planning)—Highly Reliable Cooperative Control (low latency + disturbance-resistant execution)” [65,66,67,68,69,70,71,72,73,74,75]. Figure 9 depicts the perception–decision–control model referenced in this paper.

Figure 9.

Perception–Decision–Control.

This paradigm achieves precise environmental perception (positioning error < 1 cm) through fused hyperspectral imaging and BeiDou 5G centimeter-level RTK. The cloud “Agricultural Machinery Brain” generates variable-rate fertilization prescriptions (pesticide reduction 30%), achieving command closed-loop in <50 ms via Time-Sensitive Networking (TSN). For >100 MHz ultra-high-frequency EMI induced by SiC devices, ferrite-graphene composites can broaden the wave absorption band, while a distributed PV-storage-charging architecture suppresses conducted interference at the source. At the policy level, reliance on BeiDou terminal subsidies is needed to accelerate unmanned farm penetration. Cross-disciplinary collaboration will establish “Motor Control-Agronomic Demand” joint laboratories, ultimately providing an autonomous and resilient power base for global agricultural green transformation [76,77].

Beyond technological hurdles: The widespread adoption of electrified agricultural machinery faces significant non-technical barriers. The high initial investment cost of advanced PMSM drives, wide-bandgap power converters, and sophisticated sensors remains a major impediment for farmers, particularly those operating small to medium-sized farms. Overcoming this challenge necessitates the development of government subsidy programs and green financing initiatives to lower the financial entry barrier, coupled with clear demonstrations of the compelling return on investment (ROI) through quantified gains in productivity, fuel savings, and reduced maintenance. Furthermore, farmer acceptance and the need for operational training present another critical obstacle, as the transition from traditional machinery to complex high-tech equipment requires a significant shift in operator mindset and skill sets. Therefore, designing intuitive human–machine interfaces (HMIs) and implementing comprehensive training and support programs are paramount for building trust and facilitating smooth operation. Finally, the lack of standardization in communication protocols, interface connectors, and data formats across different manufacturers hinders interoperability and the development of a cohesive agricultural ecosystem. Addressing this requires promoting industry-wide collaboration to establish open standards and protocols. Successfully tackling these non-technical challenges is equally as vital as advancing the core technology to ensure the successful integration and commercialization of intelligent PMSM drive systems in agriculture.

5. Conclusions

Global agriculture faces the dual challenges of increasing food production and sustainability, driving the electrification of smart agricultural machinery as a key solution. This review systematically summarizes advances in Permanent Magnet Synchronous Motor (PMSM) drive systems for complex farmland environments. In hardware reliability, packaging optimization, thermal management, and EMC design enhance durability under agricultural stresses. In control algorithms, techniques like virtual vector DTC and Bayesian-optimized MPC improve precision while adaptive observers enhance robustness. System-level integration enables centimeter-level coordination and AI-driven agronomic control. Future work should prioritize thermal management solutions, algorithms for unpredictable agricultural workloads, and comprehensive autonomous ecosystems. The transition to autonomous agricultural machinery requires collaborative advancement across both technology and industry chains to achieve sustainable agricultural transformation.

Author Contributions

Conceptualization, C.Z. and X.X.; methodology, H.J.; software, H.Z.; validation, C.Z., H.J. and H.Z.; formal analysis, X.X.; investigation, C.Z.; resources, C.Z.; data curation, H.J.; writing—original draft preparation, X.X. and C.Z.; writing—review and editing, C.Z.; visualization, H.J.; supervision, H.Z.; project administration, C.Z.; funding acquisition, C.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

No new data were created or analyzed in this study.

Conflicts of Interest

The authors declare no conflicts of interest. We declare that we have no financial and personal relationships with other people or organizations that can inappropriately influence our work, there is no professional or other personal interest of any nature or kind in any product, service and/or company that could be construed as influencing the position presented in, or the review of, the manuscript entitled. All the authors have been involved with the work agree to submit this paper to Agriculture, and all authors claim that none of the material in the paper has been published or is under consideration for publication elsewhere. This article does not contain any studies with human or animal subjects. All authors have read and agreed to the published version of the manuscript.

References

- FAO. The Future of Food and Agriculture: Drivers and Triggers for Transformation; FAO: Rome, Italy, 2023. [Google Scholar]

- Wang, R.; Feng, Y. Research on China’s agricultural carbon emission efficiency evaluation and regional differentiation based on DEA and Theil models. Int. J. Environ. Sci. Technol. 2021, 18, 1453–1464. [Google Scholar] [CrossRef]

- Gao, D.; Zhi, Y.; Yang, X. Assessing carbon emission reduction benefits of the electrification transition of agricultural machinery for sustainable development: A case study in China. Sustain. Energy Technol. Assess. 2024, 63, 103634. [Google Scholar] [CrossRef]

- Lu, M.; Domingues-Olavarría, G.; Alaküla, M. Comparison of PMSM versus PMa-SynRM and IM from an Optimized Electric Vehicle Powertrain Perspective. In Proceedings of the 2023 26th International Conference on Electrical Machines and Systems (ICEMS), Zhuhai, China, 5–8 November 2023; pp. 4075–4080. [Google Scholar] [CrossRef]

- Mohanraj, D.; Gopalakrishnan, J.; Chokkalingam, B.; Mihet-Popa, L. Critical Aspects of Electric Motor Drive Controllers and Mitigation of Torque Ripple—Review. IEEE Access 2022, 10, 73635–73674. [Google Scholar] [CrossRef]

- Ding, Z.; Tang, Z.; Zhang, B.; Ding, Z. Vibration Response of Metal Plate and Shell Structure under Multi-Source Excitation with Welding and Bolt Connection. Agriculture 2024, 14, 816. [Google Scholar] [CrossRef]

- Dai, D.; Chen, D.; Wang, S.; Li, S.; Mao, X.; Zhang, B.; Wang, Z.; Ma, Z. Compilation and Extrapolation of Load Spectrum of Tractor Ground Vibration Load Based on CEEMDAN-POT Model. Agriculture 2023, 13, 125. [Google Scholar] [CrossRef]

- Zhang, T.; Yan, W.; Zhou, M.; Zhao, Y. An EMI suppression method based on impedance characteristics modeling and measurement of piezoelectric ceramics. Ain Shams Eng. J. 2025, 16, 103435. [Google Scholar] [CrossRef]

- Wang, W.; Liu, C.; Zhao, H.; Song, Z. Improved deadbeat-direct torque and flux control for PMSM with enhanced robustness. IEEE Trans. Ind. Electron. 2023, 70, 2254–2263. [Google Scholar] [CrossRef]

- Wang, Z.; Zhu, X.; Xu, L.; Chen, W.-H.; Liu, Q.; Quan, L. Multivoltage-Vector-Modulation-Based Integrated Direct Torque Control of Dual In-Wheel PM Motors for Distributed Drive Electric Vehicles. IEEE Trans. Ind. Electron. 2025, 72, 5538–5548. [Google Scholar] [CrossRef]

- Zhang, X.; Yu, X.; Zhang, G. Adaptive MPC for PMSM drives based on Bayesian inference. IEEE Trans. Power Electron. 2025, 40, 8490–8502. [Google Scholar] [CrossRef]

- Sun, J.; Wang, Z.; Ding, S.; Xia, J.; Xing, G. Adaptive disturbance observer-based fixed time nonsingular terminal sliding mode control for path-tracking of unmanned agricultural tractors. Biosyst. Eng. 2024, 246, 96–109. [Google Scholar] [CrossRef]

- Lu, E.; Xue, J.; Chen, T.; Jiang, S. Robust Trajectory Tracking Control of an Autonomous Tractor-Trailer Considering Model Parameter Uncertainties and Disturbances. Agriculture 2023, 13, 869. [Google Scholar] [CrossRef]

- Ma, C.; Chen, W.; Liu, T.; Zhang, W.; Zhang, B. Recent developments in superjunction power devices. J. Semicond. 2024, 45, 111301. [Google Scholar] [CrossRef]

- Yang, Y.; He, Q.; Fu, C.; Liao, S.; Tan, P. Efficiency improvement of permanent magnet synchronous motor for electric vehicles. Energy 2020, 213, 118859. [Google Scholar] [CrossRef]

- Tian, R.; Ma, C.; Wu, J.; Guo, Z.; Yang, X.; Fan, Z. A review of manufacturing technologies for silicon carbide superjunction devices. J. Semicond. 2021, 42, 061801. [Google Scholar] [CrossRef]

- Xiang, Y.; Lin, H.; Chung, H.S.-H. Extended Physics-Informed Neural Networks for Parameter Identification of Switched Mode Power Converters with Undetermined Topological Durations. IEEE Trans. Power Electron. 2025, 40, 2235–2247. [Google Scholar] [CrossRef]

- Yuan, J.; Ji, W.; Feng, Q. Robots and Autonomous Machines for Sustainable Agriculture Production. Agriculture 2023, 13, 1340. [Google Scholar] [CrossRef]

- GB/T 18655-2018; Vehicles, boats and internal combustion engines — Radio disturbance characteristics — Limits and methods of measurement for the protection of on-board receivers. Standardization Administration of China: Beijing, China, 2018.

- Geng, C.; Zhang, D.; Wu, X.; Shen, W.; Dong, R. A Novel Active Gate Driver with Auxiliary Gate Current Control Circuit for Improving Switching Performance of High-Power SiC MOSFET Modules. In Proceedings of the 2020 IEEE 1st China International Youth Conference on Electrical Engineering (CIYCEE), Wuhan, China, 1–7 November 2020; pp. 1–7. [Google Scholar]

- Wang, X.; Yang, Z.; Zhang, G.; Zhang, J.; Liu, P. Simulation, Prediction, and Verification of the Corrosion Behavior of Cu-Ag Composite Sintered Paste for Power Semiconductor Die-attach Applications. In Proceedings of the 2023 IEEE 73rd Electronic Components and Technology Conference (ECTC), Orlando, FL, USA, 30 May–2 June 2023; pp. 1982–1988. [Google Scholar]

- Rong, C.; Wang, Y.; Chen, M.; Lu, Y.; Wu, Z.; Xia, C.; Liao, Z.; Liu, X. A Comprehensive Analysis of Metamaterial-Coupled WPT Systems for Low Electromagnetic Field Leakage. IEEE Trans. Electromagn. Compat. 2023, 65, 166–176. [Google Scholar] [CrossRef]

- Yang, C.; Chen, W.; Fan, Y.; Gui, P. Design and Characterization of a 10-MHz GaN Gate Driver Using On-Chip Feed-Forward Gaussian Switching Regulation for EMI Reduction. IEEE J. Solid-State Circuits 2021, 56, 3521–3532. [Google Scholar] [CrossRef]

- Moaz, T.; Rajagopal, N.; DiMarino, C.; Fish, M. EMI Mitigation for SiC MOSFET Power Modules Using Integrated Common-Mode Screen. IEEE Open J. Power Electron. 2023, 4, 873–886. [Google Scholar] [CrossRef]

- Yu, Y.; Hao, S.; Guo, S.; Tang, Z.; Chen, S. Motor Torque Distribution Strategy for Different Tillage Modes of Agricultural Electric Tractors. Agriculture 2022, 12, 1373. [Google Scholar] [CrossRef]

- Li, J.; Wu, Z.; Li, M.; Shang, Z. Dynamic Measurement Method for Steering Wheel Angle of Autonomous Agricultural Vehicles. Agriculture 2024, 14, 1602. [Google Scholar] [CrossRef]

- Yang, S.; Zhai, C.; Gao, Y.; Dou, H.; Zhao, X.; He, Y.; Wang, X. Planting uniformity performance of motor-driven maize precision seeding systems. Int. J. Agric. Biol. Eng. 2022, 15, 101–108. [Google Scholar] [CrossRef]

- Wu, X.; Li, H.; Yang, M.; Wu, T.; Huang, S.; Cui, H. A robust parallel predictive torque control based on a proportional integral cost function for PMSM. IEEE Trans. Transp. Electrific. 2024, 10, 5463–5472. [Google Scholar] [CrossRef]

- Zhang, X.; Hou, B. Double vectors model predictive torque control without weighting factor based on voltage tracking error. IEEE Trans. Power Electron. 2018, 33, 2368–2380. [Google Scholar] [CrossRef]

- Wang, Y.; Xie, W.; Wang, X.; Yang, W.; Dou, M.; Song, S.; Gerling, D. Fast response model predictive torque and flux control with low calculation effort for PMSMs. IEEE Trans. Ind. Inform. 2019, 15, 5531–5540. [Google Scholar] [CrossRef]

- Zhang, X.; Yan, K.; Cheng, M. Two-stage series model predictive torque control for PMSM drives. IEEE Trans. Power Electron. 2021, 36, 12910–12918. [Google Scholar] [CrossRef]

- Zhang, X.; Fang, S.; Zhang, H. Predictive current error compensation based strong robust model predictive control for PMSM drive systems. IEEE Trans. Ind. Electron. 2024, 71, 15280–15289. [Google Scholar] [CrossRef]

- Liu, H.; Yan, S.C.; Shen, Y.; Li, C.H.; Zhang, Y.F.; Hussain, F. Model predictive control system based on direct yaw moment control for 4WID self-steering agriculture vehicle. Int. J. Agric. Biol. Eng. 2021, 14, 175–181. [Google Scholar] [CrossRef]

- Wu, X.; Zhu, Z.Q.; Wang, P.; Freire, N.M.A. Sensorless based finite control set model predictive current control of PMSMs with PM flux-linkage immunity. IEEE Trans. Ind. Appl. 2024, 60, 6197–6208. [Google Scholar] [CrossRef]

- Xiao, Q.; Tang, Z.; Zhang, W.; Yu, Z.; Cheng, Z. A robust model predictive current control strategy with low complexity for PMSM. Prog. Electromagn. Res. C 2023, 135, 123–135. [Google Scholar] [CrossRef]

- Liu, M.; Hu, J.; Chan, K.W.; Or, S.W.; Ho, S.L.; Xu, W.; Zhang, X. Dual cost function model predictive direct speed control with duty ratio optimization for PMSM drives. IEEE Access 2020, 8, 126637–126647. [Google Scholar] [CrossRef]

- Kawai, H.; Zhang, Z.; Kennel, R.; Doki, S. Direct speed control based on finite control set model predictive control with voltage smoother. IEEE Trans. Ind. Electron. 2023, 70, 2363–2372. [Google Scholar] [CrossRef]

- Xinjian Electromechanical Drive (Shanghai) Co., Ltd. Dual Neural Network Model Predictive Control Method for Robot Flexible Joints. CN Patent CN119396008A, 7 February 2025. [Google Scholar]

- Zhongke Shanhaiwei (Hangzhou) Semiconductor Technology Co., Ltd. Synchronous Control Method for Dual-Motor Drive System Based on Adaptive Disturbance Observer. CN Patent CN119787878B, 10 June 2025. [Google Scholar]

- Wang, Z.; Xu, L.; Zhu, X.; Quan, L.; Chen, W.-H.; Xu, L.; Ding, S. Euler-Lagrange-Model-Based Torque Assignment Control for Dual In-Wheel PM Motors with Voltage Vectors Integrated Modulation. IEEE Trans. Ind. Electron. 2025. early access. [Google Scholar] [CrossRef]

- Lu, E.; Ma, Z.; Li, Y.; Xu, L.; Tang, Z. Adaptive backstepping control of tracked robot running trajectory based on real-time slip parameter estimation. Int. J. Agric. Biol. Eng. 2020, 13, 178–187. [Google Scholar] [CrossRef]

- Li, J.; Shang, Z.; Li, R.; Cui, B. Adaptive Sliding Mode Path Tracking Control of Unmanned Rice Transplanter. Agriculture 2022, 12, 1225. [Google Scholar] [CrossRef]

- Zuo, Y.; Lai, C.; Iyer, K.L.V. A Review of Sliding Mode Observer Based Sensorless Control Methods for PMSM Drive. IEEE Trans. Power Electron. 2023, 38, 11352–11367. [Google Scholar] [CrossRef]

- Zhu, X.; Shi, H.; Zhang, C.; Du, Y.; Xu, L.; Zhang, L. Speed Ripple Suppression of Permanent Magnet Hub Motor Based on ADRC With Observer Error Constraints. IEEE Trans. Ind. Electron. 2025, 72, 1205–1216. [Google Scholar] [CrossRef]

- Ahmed, S.; Qiu, B.; Ahmad, F.; Kong, C.-W.; Xin, H. A State-of-the-Art Analysis of Obstacle Avoidance Methods from the Perspective of an Agricultural Sprayer UAV’s Operation Scenario. Agronomy 2021, 11, 1069. [Google Scholar] [CrossRef]

- Rafaq, M.S.; Midgley, W.; Steffen, T. A Review of the State of the Art of Torque Ripple Minimization Techniques for Permanent Magnet Synchronous Motors. IEEE Trans. Ind. Inform. 2024, 20, 1019–1031. [Google Scholar] [CrossRef]

- Zhou, Y.Z.; Chen, G.T. Predictive DTC with fault-tolerant function for multi-phase PMSM drives. IEEE Trans. Ind. Electron. 2018, 65, 9101–9112. [Google Scholar] [CrossRef]

- Zhang, L.; Fan, Y.; Cui, R.; Lorenz, R.D.; Cheng, M. Fault-tolerant DTC of five-phase PM motor for electric vehicles. IEEE Trans. Veh. Technol. 2018, 67, 910–919. [Google Scholar] [CrossRef]

- Chen, Q.; Liu, G.; Zhao, W.; Qu, L.; Xu, G. Asymmetrical SVPWM fault-tolerant control of five-phase PM brushless motors. IEEE Trans. Energy Convers. 2017, 32, 12–22. [Google Scholar] [CrossRef]

- Wu, S.; Shan, Z. Sensorless FOC of PMSM based on fluctuating HF square wave injection. Electr. Mach. Control Appl. 2020, 47, 41–47. [Google Scholar] [CrossRef]

- Du, B.; Zhao, T.; Han, S.; Song, L.; Cui, S. Sensorless Control Strategy for IPMSM to Reduce Audible Noise by Variable Frequency Current Injection. IEEE Trans. Ind. Electron. 2020, 67, 1149–1159. [Google Scholar] [CrossRef]

- Zhao, H. Research on Sensorless Control of PM Linear Motor Based on HF Injection. Ph.D. Thesis, Beijing Jiaotong University, Beijing, China, 2021. [Google Scholar]

- Naderian, M.; Markadeh, G.A.; Karimi-Ghartemani, M.; Mojiri, M. Improved sensorless control for IPMSM using ePLL with HF injection. IEEE Trans. Ind. Electron. 2024, 71, 2231–2241. [Google Scholar] [CrossRef]

- Chen, P.; Ma, R.; Bai, H.; Chen, Z.; Song, S. Rotating HF voltage injection with dual heterodyne method. IEEE Trans. Energy Convers. 2025, 40, 901–910. [Google Scholar] [CrossRef]

- Bi, G.; Zhang, G.; Wang, Q.; Ding, D.; Li, B.; Wang, G.; Xu, D. HF injection angle self-adjustment for position error suppression. IEEE Trans. Power Electron. 2023, 38, 1412–1417. [Google Scholar] [CrossRef]

- Zhu, Y.; Cui, B.; Yu, Z.; Gao, Y.; Wei, X. Tillage Depth Detection and Control Based on Attitude Estimation and Online Calibration of Model Parameters. Agriculture 2024, 14, 2130. [Google Scholar] [CrossRef]

- Ji, W.; Pan, Y.; Xu, B.; Wang, J.C. A Real-Time Apple Targets Detection Method for Picking Robot Based on ShufflenetV2-YOLOX. Agriculture 2022, 12, 856. [Google Scholar] [CrossRef]

- Liao, J.; Luo, X.W.; Wang, P.; Zhou, Z.Y.; O’Donnell, C.C.; Zang, Y.; Hewitt, A.J. Analysis of the influence of different parameters on droplet characteristics and droplet size classification categories for air induction nozzle. Agronomy 2020, 10, 256. [Google Scholar] [CrossRef]

- Zhu, L.; Chen, S.R.; Zhao, Z.; Ding, H.T.; Zhu, Y.L. Influence of sieve surface attitude on sieving performance of granular materials with non-uniform feeding conditions. Agriculture 2022, 12, 2023. [Google Scholar] [CrossRef]

- Li, Y.; Xu, L.; Lv, L.; Shi, Y.; Yu, X. Study on Modeling Method of a Multi-Parameter Control System for Threshing and Cleaning Devices in the Grain Combine Harvester. Agriculture 2022, 12, 1483. [Google Scholar] [CrossRef]

- Wen, C.K.; Zhang, S.L.; Xie, B.; Song, Z.H.; Li, T.H.; Jia, F.; Han, J.G. Design and verification innovative approach of dual-motor power coupling drive systems for electric tractors. Energy 2022, 247, 123538. [Google Scholar] [CrossRef]

- Zhang, H.; Ji, W.; Xu, B.; Yu, X. Optimizing Contact Force on an Apple Picking Robot End-Effector. Agriculture 2024, 14, 996. [Google Scholar] [CrossRef]

- Ji, W.; He, G.Z.; Xu, B.; Zhang, H.W.; Yu, X.W. A new picking pattern of a flexible three-fingered end-effector for apple harvesting robot. Agriculture 2024, 14, 102. [Google Scholar] [CrossRef]

- Ji, W.; Zhang, T.; Xu, B.; He, G.Z. Apple recognition and picking sequence planning for harvesting robot in a complex environment. J. Agric. Eng. 2024, 55, 1549. [Google Scholar] [CrossRef]

- Hu, J.P.; Zhao, X.S.; Liu, W.; Yao, M.J.; Zhao, J. Development of a seeding control method based on seed height in the hopper of a precision wheat drill. Appl. Eng. Agric. 2021, 37, 1131–1138. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhao, Z.H.; Gao, G.Q. Fuzzy comprehensive evaluation for grasping prioritization of stacked fruit clusters based on relative hierarchy factor set. Agronomy 2022, 12, 663. [Google Scholar] [CrossRef]

- Ji, W.; Gao, X.X.; Xu, B.; Pan, Y.; Zhang, Z.; Zhao, D. Apple target recognition with improved YOLOv4. J. Food Process Eng. 2021, 44, e13866. [Google Scholar] [CrossRef]

- Xu, J.; Liu, H.; Shen, Y.; Zeng, X.; Zheng, X.P. Individual nursery trees classification and segmentation using a point cloud-based neural network with dense connection pattern. Sci. Hortic. 2024, 328, 112945. [Google Scholar] [CrossRef]

- Sun, J.; Nirere, A.; Dusabe, K.D.; Zhong, Y.H.; Adrien, G. Rapid and nondestructive watermelon (Citrullus lanatus) seed viability detection based on visible near-infrared hyperspectral imaging technology and machine learning algorithms. J. Food Sci. 2024, 89, 4403–4418. [Google Scholar] [CrossRef]

- Wang, Y.; Li, T.; Chen, T.; Zhang, X.; Taha, M.F.; Yang, N.; Mao, H.; Shi, Q. Cucumber Downy Mildew Disease Prediction Using a CNN-LSTM Approach. Agriculture 2024, 14, 1155. [Google Scholar] [CrossRef]

- Zhong, Y.H.; Sun, J.; Yao, K.S.; Cheng, J.H.; Du, X.J. Detection of rice (with husk) moisture content based on hyperspectral imaging technology combined with MSLPP-ESMA-SVR model. J. Food Saf. 2024, 44, e13112. [Google Scholar] [CrossRef]