Abstract

The need to diversify food products on the market, the interest of producer-farmers and food processors in nutritionally healthy raw materials, and especially the demand among consumers for new, high-quality product assortments have led to the introduction of ancient wheat species into cultivation. Ancient plant species are often grown using environmentally friendly agricultural technologies. The aim of the study was to compare the technological parameters, rheological properties of dough, and baking indicators of grains (and the flour milled from them) from ancient wheat species T. sphaerococcum and T. persicum with common wheat. These were cultivated using both traditional ploughing and simplified shallow tillage systems. The wheat grain was obtained from field experiments located in three certified organic farms in Poland. In the plant material samples, physical, technological and rheological parameters were determined. The grain, flour, baked bread, and the colour of grain and flour were characterised. It was found that the tested cultivation systems did not have a significant effect on the analysed traits (except for dough parameters: dough stability time, dough softening, and bread weight after removal from the oven and 24 h after baking where shallow tillage turned out to be more advantageous). In turn, the wheat species significantly influenced the tested traits. This factor was found to determine relatively high (higher than common wheat) values of protein complex and water absorption characteristics in ancient wheat flour (T. persicum: TPC/TPCF—156/150 g·kg−1, WG/WGF—39.4/34.5%, WA—62.9%; T. sphaerococcum: TPC/TPCF—145/142 g·kg−1, WG/WGF—38.5/33.3%, WA—58.2%). The obtained results for the technological and rheological properties of the grain and flour indicate that ancient wheat species, particularly T. persicum, can be a potential raw material for the production of healthy food, including bread baking.

1. Introduction

Cereals are among the oldest crop species cultivated in the world. Wheat, along with corn and rice, is considered the primary grain for human consumption in the world and forms the basis of human nutrition. The grain of these cereal yields flour, which is mainly used for food purposes, especially for the production of bread [,,]. FAO’s preliminary forecast for global wheat production in 2025 indicates a modest increase, with world output projected at 796 million tonnes (a near 1% rise year-on-year) [], with allohexaploid bread wheat (Triticum aestivum L.), as reported by Suchowilska et al. (2020) [], accounting for approximately 94% of total production. This plant also holds a prominent position among cereals in the EU, including Poland [,]. Its tillage area in Poland in the years 2018–2022 ranged from 2.4 to 2.5 million ha, and the harvests in the seasons 2018–2019 and 2020–2021 were 8.6 million tonnes and 12.4 million tonnes, respectively [].

The results of research into the dynamically developing food sciences over the years, combined with the analysis of the relationship between diet and human health, the need to diversify food products on the market, the interest of food producers and processors in nutritionally sound food raw materials, and, in particular, the search by consumers for a new, quality-optimised range have given rise to the reintroduction of ancient wheat. In the subject literature, information can be found on wheat, such as emmer, spelt, and einkorn wheat [,,,,,,], as well as Caucasian wheat Triticum timopheevii and Triticum zhukovskyi [,]. In contrast, Persian (Triticum persicum) and round-grain (Triticum sphaerococcum) wheat are relatively new research materials [,].

Ancient wheat, despite being generally less prolific compared to common wheat, is a rich source of dietary fibre, minerals, antioxidant compounds, and B vitamins, and has fewer habitat requirements and lower inputs in means of production, which is now favoured in sustainable and organic agriculture [,,,]. Raw materials and products obtained from cereals grown on organic farms are characterised by better pro-health properties, which are related to their higher nutritional value and lower level of contamination compared to those from conventional tillage []. Wheat grain and flour milled from it are characterised by more favourable quality parameters compared to wheat grown today. This applies in particular to the protein complex and the amount of minerals [,,,,]. Protein content in ancient wheats can reach high levels of 169–201 g·kg−1 (Caucasian wheats) [] and 150–199 g·kg−1 (einkorn, emmer, spelt) [,,]. In turn, the gluten content and the sedimentation index value in these cereals can reach up to 44.5% [] and 45.4% [], respectively, and 41.2 cm3 [] and 53.3–68.3 cm3 []. As Suchowilska et al. [] report, for example, spelt grain is richer in P, S, Mg, Fe, Zn, Mn, Cu, B, and S than common wheat. In addition, it should be noted that these cereals exhibit high resistance to diseases (fusarium, powdery mildew, and rusts), tolerance to salinity and excessive moisture, and are well adapted to cool climates []. Obtaining specific values of individual quality parameters of wheat is determined by the ability to choose the tillage technology appropriate for the given soil and climatic conditions, as well as the level of management and a specific variety, for which the tillage conditions will allow the objectives set by the manufacturer [,,,,].

An important criterion, largely verifying the suitability of grains of different wheat species for food purposes, are the values of technological characteristics, including those determining the enzyme and protein complex of the raw material and its rheological and baking properties [,,,,,]. They are influenced by both environmental and agrotechnical factors used in cereal tillage [,,,,,]. Among the latter, in addition to fertilisation, the tillage system plays an important role [,,,,]. Intensive ploughing causes accelerated mineralisation of organic matter and determines soil nutrient losses [,]. Increasing costs of production are leading to the increasing use of shallow tillage systems in agriculture (including organic farming) [,,]. They have a beneficial effect on soil properties (reduced evaporation, higher content of C-org., N-og., K, and assimilable Mg) compared to conventional tillage [,]. Such systems also combine environmental aspects with economic and organisational benefits for farms [].

The study aimed to compare the technological parameters, dough rheological properties, and baking indices of the grain (and the flour milled from it) of two ancient spring wheat genotypes, i.e., two ancient genotypes: Indian dwarf wheat (Triticum sphaerococcum Percival), and Persian wheat (Triticum persicum Vavilov), and comparatively common wheat (Triticum aestivum ssp. vulgare), grown under ploughing and shallow tillage farming systems. According to the hypothesis, it was assumed that reduced tillage may affect the technological properties of wheat grown in an organic farming system, and the response of ancient wheat and common wheat may be different.

The results obtained in studies on Persian and round-grain wheat, in cases where a specific tillage method yields a positive response, could pique farmers’ interest in their production under organic farm conditions and provide an alternative to the tillage methods used for other cereals. The analysis of technological indices (especially some rheological and bread characteristics) and colour of wheat grain and flour (poorly described in the literature) will help to broaden the state of knowledge on the quality and suitability of grain and flour of the above-mentioned wheats for agri-food processing, especially for baking bread.

2. Materials and Methods

2.1. Field Experiment

In order to verify the hypothesis, three close field experiments were carried out in 2019 on certified organic farms located in Budziszewo, Kujawsko-Pomorskie voivodeship (53°37′ N; 19°12′ E), Zblewo, Pomorskie voivodeship (53°93′ N; 18°31′ E), and Grabina Wielka, Greater Poland voivodeship (52°11′ N; 18°80′ E). Experiments were set up in a split-plot arrangement in four replications. The size of the plots, depending on the type of agricultural equipment available on individual farms, ranged from 12 m2 to 16 m2. The whole plots consisted of tillage method (ploughing, and shallow tillage), and subplots consisted of wheat species (two primary wheats: Indian dwarf wheat (Triticum sphaerococcum Percival), and Persian wheat (Triticum persicum Vavilov) and common wheat (Triticum aestivum ssp. vulgare).

The cultivar ‘Trispa’ of Indian dwarf wheat was used in the study. In this field experiment, for the locality and tillage methods, this cultivar developed stems with an average length of 75 cm, 18 spikelets per ear (including 68% fertile spikelets), and 23 grains per ear []. For Persian wheat, the cultivar ‘Persa’ was used. In this experiment, the stem length of this variety was 76 cm, the number of spikelets per ear was 14 (of which 77% were fertile), and the number of grains per spike was 19 [].

Previous studies indicate that both of the primary wheat varieties used in the experiment have a high content of phenolic acids and alkylresorcinols, with proven pro-health effects [].

The ‘Torridon’ variety of common wheat used in the research is classed as a quality wheat. In the analysed field experiment, the shoot length determined in this variety was 72 cm, the number of spikelets per ear was 17 (of which 79% were fertile), and the number of grains per ear was 29 [].

The forecrop in the field experiments was winter wheat or winter triticale, followed by a pea intercrop. During the previous crop harvest, the straw was removed from the field, but 10–15 cm of stubble was left. Before winter, pre-winter ploughing to a depth of 22–24 cm was carried out on the part of the field intended for ploughing on only shallow crops (approx. 10–12 cm), using a cultivator. In the spring, seasoning of the soil was carried out with a cultivation unit consisting of a cultivator and a string roller, to a depth of 7–8 cm (at the early propagation stage of the wheat). Fertiliser intended for organic tillage of Bioils was screened (6% N; 5% P2O5; 13% K2O; 2% MgO, 10% SO3), at a dose of 200 kg·ha−1. Wheat sowing in narrowly spaced rows (10.5–11.5 cm) was carried out at the end of March, at a density of 600 units-m−2. The cereal was harvested in the first 10 days of August (Persian wheat at the earliest, and after 7–10 days other species) with a Wintersteiger field combine at full grain maturity. Plant samples were collected from each experimental plot at three locations for chemical analysis. The results obtained, in accordance with the project’s assumptions, were averaged and, after statistical analysis, presented in this publication.

2.2. Soil and Weather Conditions

The soil at experimental sites was characterised as Alfisol (USDA). The soil at Grabina Wielka had a pH of KCl 5.9 and contained 64.5 mg·kg−1 P, 182.6 mg·kg−1 K, 57.0 mg·kg−1 Mg, and 1.63% Corg. (medium content of P and Mg, high content of K). In contrast, the soils at Budziszewo and Zblewo were neutral (pH KCl 6.8 and 6.7, respectively) and contained 99.0 and 45.5 mg·kg−1 P, 193.4 and 169.3 mg·kg−1 K, 110.0 and 51.0 mg·kg−1 Mg, and 1.92 and 0.97% Corg (Budziszewo—high content of K, very high content of P and K; Zblewo—medium content of P and Mg, high content of K). A detailed characterisation of the soil conditions at the locations of the field experiments is presented in Szczepanek et al. [].

In the region where the research was conducted, the vegetation period for cereals starts at the end of March and lasts until late July or early August. In the three localities of the field experiments, namely, Grabina Wielka, Zblewo, and Budziszewo, the multi-year average (1981–2010) of precipitation from March to July is similar and amounts to 252 mm, 254 mm, and 254 mm, respectively [].

However, in 2019, weather conditions varied quite widely from place to place. The sum of precipitation in March and April was smallest in Budziszewo (32.1 mm), while in Grabina Wielka and Zblewo it was nearly 50% greater. In May to July, rainfall was greatest in Zblewo and slightly less in Budziszewo (187 and 170.1 mm, respectively). During this period, the total precipitation was the smallest in Grabina Wielka (119.1 mm). The Zblewo region was the coldest; average air temperature during the growing season (from March to July) was 10.9 °C on average. For Grabina Wielka and Budziszewo, it was 12.2 and 12.0 °C, respectively. A detailed characterisation of the weather conditions at the locations of the field experiments is presented in Szczepanek et al. [].

2.3. Laboratory Analysis Procedure

- Grain and Flour Analysis. In previously cleaned, representative grain samples, the following parameters were determined in four replicates:

- ➢

- Mass of thousand grains (MTG)—determination consisted of counting 1000 grains and then weighing them; a grain counter (Sadkiewicz Instruments, 2 Startowa Street, 85-744 Bydgoszcz, Poland) and an electronic scale were used for the test [].

- ➢

- Hectolitre mass (HM)—an SH-type densitometer and electronic balance [].

- ➢

- Vitreosity (VIT)—a farinotome [] was used for the analysis, 50 wheat kernels were placed in the farinotome and cut crosswise, the number of vitreous and mealy kernels was counted and converted to %.

- ➢

- Falling number (FN) was determined using the Hagberg–Perten method [], after prior grinding of the grain on a special hammer mill (type RT 120—Sweden), using an automatic SWD device to determine the value of the falling number (to 7 g of grinded grain placed in a tube, 25 mL of distilled water was added, a viscometer stirrer was mixed and inserted, the whole was placed in a viscometer; after the analysis was completed, the result was read—the time of the viscometer stirrer falling in seconds).

- ➢

- Total protein content (TPC, TPCF), Starch Content (SC), Wet Gluten (WG, WGF), Sedimentation Value according to Zeley’ny (SV), and Ash Content (AC) were determined in the grain or flour using the whole grain analyser InfratecTM 1241 (FOSS Analytical AB, Höganäs, Sweden) [,,,,].

- ➢

- The flour yield (FY) and milling efficiency factor (MEF) were also calculated. The flour yield (FY) is the amount of flour obtained from the weight of milled grain expressed as a percentage (a laboratory grain mill type WZ-1 was used).

The milling efficiency factor (MEF) was calculated using the formula MEF = FY: ACInfratecTM 1241 is a near-infrared transmission (NIT) apparatus that allows the simultaneous and accurate determination of several components in whole grain or flour samples. The essence of the measurement is the absorption of radiation in the near-infrared range by the main components of grain and flour.

- Dough Analysis. To determine the rheological properties of the dough, a consistograph connected to a computer was used, on the screen of which a consistographic graph was obtained and the results were read []. This device measures and records the resistance that the dough exerts during mixing, allowing properties such as water absorption of flour (WA), dough development time (DDT), dough stability time (DST), and dough softening (DSF) to be determined.

- Bread Evaluation. The value of the direct baking index, which is the volume of bread from 100 g of flour, was obtained after a single-phase baking process [].

The dough was prepared with 400 g of flour, 6 g of table salt, 12 g of baker’s yeast, and an appropriate amount of water, which depended on the water absorption of the flour sample in question. All ingredients were placed in a laboratory mixer and mixed for 10–15 min. After this time, the dough was inserted twice (each time interrupting the process with manual kneading) into the fermentation chamber (30 min, 30 °C). The dough was then divided into two 300 g pieces, dampened on the surface with water, and placed into laboratory moulds, followed by the fermentation process again (30 min, 30 °C). When the dough reached the top edge of the mould, it was moistened with water and placed in the oven for final fermentation (30 min, 230 °C). After the baked bread was removed from the oven and cooled, its volume was measured using a laboratory volumeter (Sa-wy apparatus). The operating principle of the device is based on measuring the volume of loose material equal to the volume of the bread being tested. Based on the results obtained, the loaf volume (bread volume—BV) from 100 g of flour (V100) was calculated according to the following formula:

where

- a—volume of 1 loaf (cm3),

- b—dough yield (weight of dough obtained from 100 g of flour),

- c—the mass (g) of a piece of dough formed for baking [=300 g].

The weight of the bread (bread weight) was determined twice, immediately after removal from the oven (BW) and 24 h (BW24) after baking.

The baking loss (BL) and total baking loss (TBL) were also calculated according to the following formulas:

where

BL [%] = ((a − b) × 100)/b

- a—the mass of a piece of dough formed for baking [g].

- b—weight of the baked bread immediately after removing from the oven [g].

TBL [%] = ((a − c) × 100)/c

- a—the mass of a piece of dough formed for baking [g].

- c—weight of baked, cooled bread after 24 h [g].

- Colour of wheat grain and flour. The colour of the grain and flour of the cereals tested was determined using a CR-410 colorimeter (Konica-Minolta, Tokyo, Japan).

2.4. Statistical Analysis of the Results

The one-year research results were statistically verified by analysis of variance. The significance of differences was evaluated using the Tukey multiple confidence intervals for the significance level of α = 0.05. The analysis of data variance was calculated using Statistica® (ver. 13.3) software, and the main effects were tested by ANOVA. The normality of the distribution was tested with the Kolmogorov–Smirnov test, while equality of variance in different samples was tested with a Levene test. Fixed factors were soil tillage and species.

3. Results and Discussion

3.1. Physical Parameters of Grain

The milling value of wheat is mainly determined by grain characteristics such as mass of thousand grains (MTG), hectolitre mass (HM), and vitreosity (VIT). The maturity of the grain significantly affects the yield and quality of the flour obtained, as well as its colour and ash content. The lower the MTG, the poorer the milling performance. HM, on the other hand, is an index that characterises the maturity and degree of kernel formation, as well as the structure and thickness of the kernel cover [,].

The tillage methods used in the experiment (PL, ST), regardless of the tested wheat species, did not have a significant impact on the values of the physical characteristics of the grain (Table 1). This has also been found in other work analysing organic and conventional farming methods [,]. In other studies with ancient wheat, the tillage method had a significant effect on MTG. Andruszczak [] found a 3.7% higher average MTG of spelt in the simplified tillage system compared to the conventional system. Rachoń et al. [] report that in conventional tillage, spelt and emmer were characterised by MTG of 33.1 g and 33.9 g. On the other hand, Mitura et al. [] reported that HM common wheat had the highest value (average 75.6 kg·hL−1) in the integrated cropping system. Lower values were found by these authors in ecological and conventional crops (average: 73.0 and 73.8 kg·hL−1). These relationships are also confirmed by other authors [,].

Table 1.

Physical parameters of grain depending on wheat species and agronomic practices.

The MTG found for T. sphaerococcum, irrespective of cropping system, was significantly lower by 12.5% than for common wheat, while there was no difference in the value of this trait between T. persicum and T. aestivum (Table 1). In turn, HM values for these wheats were higher in relation to those obtained for common wheat, although this was not statistically proven. In the work of Nocente et al. [], ancient Caucasian wheat was characterised by lower MTG and HM values compared to those obtained for durum wheat. It should also be noted that the HM of two ancient wheat varieties were larger than the guidelines of the Polish Standards [] (the minimum value is 72 kg·hL−1) and it was larger in the range of 3.2 to 4.3%. In the paper by Lacko-Bartošová et al. [] The MTG of the tested ancient wheat species and varieties differed significantly and reached higher values (except for einkorn—26.6 g) compared to the results of our own study. These authors obtained, on average, very high values for spelt and emmer, respectively: 51.7 g and 56.3 g, while for T. aestivum, only 37.4 g. Similar values of the trait in question for spelt, emmer, and T. aestivum (38.3; 33.6; 33.9 g) were shown by Kulathunga et al. [], while for einkorn the MTG was slightly higher (28.0 g) compared to our own results. Tran et al. [], on the other hand, obtained a low value of 25.5 g for einkorn, and the wheat with the highest MTG (from 39.71 g to 41.05 g) belonged to spelt and common wheat.

Ancient wheat was also characterised by a higher Vitreosity (VIT) compared to the value of this trait obtained for common wheat. At the same time, the highest value was indeed recorded for Persian wheat, and it was higher by 8.1% compared to T. aestivum (Table 1). The high values of this physical trait translated into favourable values for the traits characterising the protein complex, i.e., high total protein, wet gluten, or sedimentation value, both in the grain and in the flour milled from it (Table 2 and Table 3). These relationships are confirmed by the high correlation coefficients between VIT and TPC, WG, SV, TPCF, and WGF (Table 4).

Table 2.

Technological value of grain depending on wheat species and agronomic practices.

Table 3.

Flour characteristics depending on wheat species and agronomic practices.

Table 4.

Significant correlation coefficients between the studied features.

3.2. Technological Parameters of Grain

Falling number is a technological characteristic of the grain that indicates its enzymatic activity. The level of α-amylase activity present in the flour significantly determines the quality of the bread obtained from it. When the falling number reaches a value of less than 150 s, then wheat grain should not be used for breadmaking, as the bread produced will be characterised by low volume, a flaky crust, a dark crumb, and will be flat. This distinction also indirectly informs the storability of the grain [,].

The falling number (FN) was relatively high, and it was observed that, regardless of the type of cereal grown, in the shallow tillage, there was a tendency to increase grain FN compared to plough tillage (Table 2). Significantly lower results for this feature were recorded in the work of Knapowski et al. [] for spelt in conventional tillage, and Buczek et al. [] for T. aestivum, where conventional ploughing and no-till tillage were analysed. The fall number of all T. spelta samples analysed ranged from 338 to 508 s, while that of T. diccocon samples ranged from 363 to 428 s in conventional tillage [].

In turn, the wheat species significantly determined the value of the discussed qualitative feature. The highest FN was found in T. persicum grain, followed by common wheat and T. sphaerococcum. Lower results for this trait (291–375 s), relative to our own studies, were reported in common wheat [,]. In contrast, the three Caucasian wheat species analysed by Nocente et al. [] were characterised by an FN higher than 400 s, and in the study by Bobryk-Mamczarz et al. [], spelt, emmer, and durum reached values in the range of 388 to 477 s. High values of this trait indicate low α-amylase activity, which may consequently lead to poor baking properties, including crumb texture and low loaf volume.

The interaction of the ploughing system of the tillage system and the wheat tested in on the trait under study was also noted. The highest FN was recorded for Persian wheat, significantly higher by 17.8% compared to T. sphaerococcum.

The results obtained for this parameter are relatively high; however, taking into account the grouping of wheat in Poland and the European Union [], it was shown that these cereals in terms of FN value are suitable for further processing for food purposes (they reached the minimum values for the group of elite wheat—280 s), including bread making. In addition, it should be noted that flours from different groups (with high and low α-amylase activity) can be mixed to achieve an optimal FN.

Total protein content (TPC), the amount of gluten in the grain (WG) and flour (WGC), and its quality, as determined by sedimentation value (SV), are important determinants of the baking value of wheat, which is included in the protein complex. Low values of the above-mentioned features determine the reduction in the technological suitability of the obtained raw material [,,]. It is also worth noting that the above characteristics are positively correlated with each other, as observed in the experiment (Table 4).

There was no significant effect of the tillage system on TPC and TPCF (Table 2 and Table 3). However, it was noted that the wheat species statistically significantly determined the values of the above indicators. The highest TPC and TPCF were recorded for Persian wheat, and these were higher than the values obtained for T. aestivum by, respectively, 17.3% (grain) and 17.2% (flour). In experiments with spelt, emmer, and einkorn, protein amounts ranging from 112 to 174 g·kg−1 were recorded [,]. Wenda-Piesik et al. [] in their research for several varieties of spring wheat give the average value of this feature at the level of 125.6 g·kg−1, which indicates that it was lower by 42% compared to the value for T. aestivum obtained in the discussed work. The higher TPC and TPCF contents found in ancient wheat, relative to modern wheat varieties, have already been reported in earlier work [,,,,,,]. This indicates that the wheat varieties tested have a higher potential nitrogen use than modern varieties of this cereal []. Thus, it may predispose them to tillage in low-input agriculture.

There was also a statistically proven interaction between the ploughing tillage system and the tested wheat on the value of the traits in question. The highest TPC and TPCF for this relationship were found for Persian wheat (Table 2 and Table 3).

The mixture of the proteins gliadin and gluten and water is gluten, which is of paramount importance in bread making. Its quantity and especially its quality determine the baking value of the flour and thus influence the desired elasticity of the dough, as well as the plumpness and the spongy structure of the baked bread [,,]. In the study conducted, similar relationships were found for WG and WGF as for TPC and TPCF, i.e., T. persicum grain had the most gluten (Table 2 and Table 3). Lower values of this trait were recorded in wheat spelt, Caucasian wheats, T. zhukovskyi, and in T. timopheevii, T. durum, and T. aestivum [,,,,]. In contrast, Jaskulska et al. [] and Szafrańska [] noted that the amount of wet gluten in wheat grain ranged from 17.8 to 39.6%.

The sedimentation value is a measure of the quality and, to some extent, also the quantity of proteinaceous substances. The high result of the analysis indicates a high content of gluten proteins, primarily high molecular weight glutenin, which is distinguished by its excellent swelling abilities and provides good baking value. The value of the sedimentation rate ranges from 7 cm3 (feed wheat, characterised by low gluten quality) to 75 cm3 (wheat distinguished by excellent quality and high gluten content) []. In the experiment conducted, there was no effect of the factors studied on the SV value (Table 2). This is confirmed by experiments with wheat carried out by other authors in which wheat species were tested in different cropping systems [,,]. At the same time, the results recorded in them, in relation to their own results, were lower (34.4–42.7 cm3).

It should also be noted that the values of the technological traits discussed above (TPC, WG, SV, TPCF, WGF) were significantly positively correlated with each other (Table 4), as confirmed by the work of other authors [,,].

As a consequence of the higher protein content in the grain of ancient wheat, lower starch contents were obtained than in T. aestivum (Table 3). This is confirmed by the significantly negative simple correlation coefficient between these characteristics (Table 4). Similar relationships were noted in the works of Nocente et al. [], in which two ancient Caucasian wheats and durum wheat and Andruszczak were tested [], and Takač et al. [], in which T. spelt and T. aestivum were compared. With a high protein content and a starch content ranging from 64.9% to 65.9%, T. persicum and T. sphaerococcum grains, as well as the flour milled from them, can be a valuable alternative raw material for bakers to produce a highly nutritious and consumer-appealing range of products from cereals.

3.3. Flour Characteristics

The ash content (AC) allows the amount of mineral substances present in the grain to be determined, which are extremely valuable from a nutritional point of view. Most of them are found in the outer parts of the grain, and the least in the endosperm.

In the studies conducted, there was no significant effect of the factors studied on ash, with values ranging from 0.83 to 0.91% (Table 3). The largest AC among wheat was found in T. aestivum, and shallow tillage proved to be a more favourable tillage system in relation to ploughing. Mitura et al. [] and Bobryk-Mamczarz et al. [] indicate that the average AC for common wheat was, respectively, higher (1.97–2.08%) or lower (0.63%) than in the discussed work. Other wheat species were characterised by higher values, i.e., 0.7% (spelt), 0.80–0.85% (durum), 1.27% (emmer). This is also confirmed by other studies with the species of wheat mentioned [,,,,,], as well as Caucasian wheat [].

In milling, one of the indicators of production efficiency is the flour yield (FY), which allows the determination of the amount of flour obtained from grain milling. In general, flours milled from the endosperm (light flours) are characterised by a lower FY than those containing a higher proportion of the outer layers of the grain (dark flours), i.e., the fruit and seed coat []. In the present study, FY was found to be significantly determined by wheat species and the interaction of the factors studied (Table 3). The highest value of this feature was recorded for common wheat, and it was higher in relation to FY T. sphaerococcum and T. persicum, by 2.9 and 12.9%, respectively. Different results for ancient wheat were obtained by Sobczyk et al. []. When examining spelt, they recorded a higher FY for it (up to 73%) compared to common wheat.

As a result of the cooperation of the tillage system and the wheat species, the common wheat was characterised by the highest flour yield, both in the ploughing and shallow tillage systems.

It is noteworthy that despite the different values of the physical characteristics of ancient wheat grains (lower MTG, higher HM, and VIT) compared to common wheat (Table 1), their FY was at a good level (56.7% and 62.2% of T. persicum-and T. sphaerococcum) and only slightly lower compared to FY common wheat (64.0%).

The milling value factor (MEF) is derived from FY and ash content (AC). Their lowest values, found for Persian wheat, translated into the lowest MEF value (Table 3).

3.4. Rheological Features

It was found that all analysed rheological features were significantly determined by the factors studied (except for the effect of soil management on WA and DDT) and their interaction (Table 5).

Table 5.

Rheological profile of dough depending on wheat species and agronomic practices.

The water absorption of flour indicates the amount of water that can be added to this raw material to achieve a dough with the desired consistency. The value of this indicator is determined by the moisture content and degree of granulation of the flour, the amount and quality of gluten and starch, and should be in the range of 56–60% [].

In the experiment conducted, WA significantly depended on the cereal species and the interaction of the factors tested (Table 5). Among cereal species, the highest value was indeed recorded for T. persicum, which was higher than for T. sphaerococcum and T. aestivum by 4.7% and 8.3%, respectively. T. aestivum flours were characterised by water absorption between 53 and 58% []. In contrast, values ranging from 53.6 to 61.6% have been reported for T. spelta [,] and 59.0 to 61.5% for T. dicoccon [].

In addition, the researchers found that the significant interaction effect of the factors tested indicates that ancient wheats had a higher WA in both cropping systems compared to common wheat, with T. persicum achieving the significantly highest value of this rheological index. Therefore, it can be concluded that from the flour of this wheat we will obtain the largest amount of dough, and consequently a larger amount of bread.

The longest dough development time (from the addition of water to the first signs of dough consistency decreasing), dough stability time, and the lowest dough softening, irrespective of soil management, were recorded for common wheat (Table 5). T. persicum and T. sphaerococcum had these times significantly shorter in relation to T. aestivum by as much as 41.8 and 32.1% (DDT) and 36.6 and 56.4% (DST), respectively. In turn, DSF was lower by 54.4% and 60.3%. Better flour has a longer dough development time. DDT is influenced mainly by the quality of protein, the size of starch granules, and the level of starch degradation. It was noted that lower TPC, TPCF, WG, and WGF, along with higher flour quality as determined by SV (Table 2 and Table 3), resulted in longer DDT and DST and lower DSF. As reported by Lacko-Bartošová et al. [], strong wheat is characterised by longer dough development time (≥3 min), dough stability (≥4 min), and lower dough softening (≤40 FU). Literature data indicate that the most commonly recorded dough development time values for common wheat range from 2.5 to 4 min [,]. However, for ancient flour, lower values of this feature were generally recorded, i.e., T. spelta ranging from 1.61 to 2.98 min, and for T. dicoccon from 0.49 to 1.41 min []. This is also confirmed by the results recorded for hulled wheat (einkorn, emmer, and spelt) in the work of Tran et al. []. Similar relationships were obtained in the case of dough stability time [,]. In turn, DSF for ancient flour was significantly higher in relation to T. aestivum [].

It was also noted that the interaction of the factors tested, with both ploughing and shallow tillage, influenced the longest DDT and DST and the lowest DSF for flour milled from common wheat.

3.5. Bread Characteristics

Bread volume is a direct indicator of the baking value of the grain and the flour obtained from it, and is influenced by all the quality characteristics analysed above. The study found that it depended on wheat species and the interaction of wheat species and soil management (Table 6). On average, the highest loaf volume was recorded for common wheat and, relative to the value of this trait obtained for T. persicum and T. sphaerococcum, it was 17.2 and 15.0% higher, respectively. The flours of the Triticum species used in this experiment differed in their rheological properties; therefore, the bread baked from them differed in terms of bread volume (BV). This has also been confirmed in other studies of wheat (common wheat, spelt, emmer) [,].

Table 6.

Properties of bread depending on wheat species and agronomic practices.

It was also noted that the highest BV as a result of interaction was obtained for T. aestivum after the application of shallow tillage, and it was higher in relation to T. persicum and T. sphaerococcum by 18.7 and 14.8%, respectively.

The weight of the bread after removal from the oven and after 24 h depended significantly on the factors studied and their interaction (Table 6). The more favourable tillage system for this trait was found to be shallow tillage, where BW and BW24 were higher compared to the values found with ploughing, by 1.3 and 0.93%. On the other hand, among the wheat tested, the highest bread weight was recorded for T. persicum, and this was higher than the BW obtained for T. aestivum and T. sphaerococcum by 0.97 and 2.52% and from 0.74 to 1.44%.

Bake loss (BL) is the difference between the mass of dough formed for baking and the mass of hot bread taken out of the oven. It is caused by the loss of water, carbon dioxide, alcohol, and acids during the bread-baking process. Total baking loss (TBL), on the other hand, is the difference between the mass of dough formed for baking and the mass of bread cooled and is the result of the evaporation of water and volatile substances from the bread. This parameter influences the proper formation of the crust and the correct baking of the bread. The values of these parameters were significantly dependent on wheat species and soil management (Table 6). The lowest BL and TBL were recorded for T. persicum, and the highest for T. sphaerococcum.

3.6. Colour of Wheat Grain and Flour

The colour of the grain and the flour obtained from it are important quality characteristics that are often assessed visually. However, this is subjective, as each evaluator has a different perception of colours, which may be additionally influenced by environmental conditions (e.g., lighting and other colours instead of analysis). The better-quality flour, from the consumer’s point of view, is considered to be the one characterised by a lighter colour. When the grain is milled, it has a yellow hue and later turns chalky white, which is caused by the oxidation of the carotenoid pigments. Colour changes are described as one of the stages of flour maturation [,]. The colour of the flour is referred to as a numerical system for measuring the brightness of the sample (L*) on a scale of 0 to 100 and the “chromaticity” or hue on two scales, each of which ranges from −60 to +60 for green–red (a*) and blue–yellow (b*). A lighter colour is associated with high L* values, while a more yellow colour is indicated by higher b values. The colour of the flour is influenced by the colour of the wheat endosperm, particle size, and ash content of the flour, which can determine the colour of the finished product [].

The study found a significant effect of wheat species and its interaction with the tillage system on the L*ab value, whereas tillage did not have a significant effect on any grain and flour colour parameter (Table 7). The lack of influence of the cultivation system on the colour of grain and cereal flour is also confirmed by other works [].

Table 7.

Colour of wheat grain and flour depending on wheat species and agronomic practices.

Among the flours ground from the grain of the studied cereal species, the lightest flour (the highest L*F value) turned out to be common wheat flour, and the darkest was T. persicum. In contrast, flour redness (a*F) was highest for Persian wheat (indicating a higher proportion of green in its colour) and lowest for common wheat. The lowest yellowness (b*F) was recorded for T. sphaerococcum, and indeed the highest, comparable, for the other wheat species. For common wheat, L* ranged from 87.29 to 92.06; a* ranged from −1.75 to −0.11; b* varied from 5.29 to 14.56 []. In contrast, L* values ranging from 51.36 to 54.35, ‘a*’ from 8.08 to 9.13, ‘b*’ from 26.72 to 28.84 were obtained for hard wheat []. In the conducted research, an inverse relationship was found between the brightness (L*F) and the redness of the flour (a*F), which confirms the negative straight correlation coefficient between these features (Table 4). This is consistent with the results obtained by Zai et al. [].

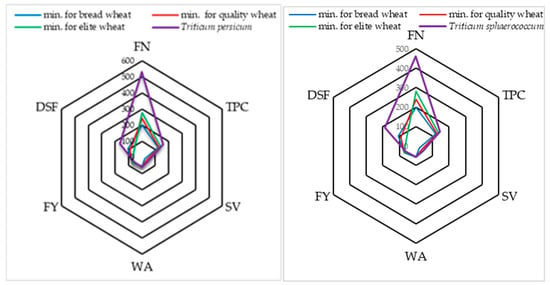

Taking into account the most important baking parameters (FN, TPC, SV, WA) determining the use of wheat grain for food purposes (bread wheat-B, quality wheat-A, elite wheat-E) [], the tested ancient wheat meets the standards allowing it to be used for baking bread (Figure 1). Furthermore, it should be noted that blends of ancient wheat with common wheat flours can also be used to obtain bread with a higher BV.

Figure 1.

Values of the most important baking characteristics of ancient wheats compared to their values given in the wheat classification [].

4. Conclusions

The domestication of wheat and the introduction of increasingly newer, breeder-improved varieties of this cereal into field cultivation have resulted in a significant loss of genetic variability within the cultivated gene pool. This, in turn, has negatively affected the diversity of raw materials obtained and, consequently, the range of food products available on the market. Therefore, the revitalization of ancient wheat species (including Indian dwarf wheat—Triticum sphaerococcum Percival and Persian wheat—Triticum persicum Vavilov), in addition to its beneficial impact on biodiversity, provides the raw material necessary for the production of a new range of health-promoting products. These grains are characterised by properties different from those of T. aestivum, generally offering more favourable nutritional benefits for the human body, and are increasingly sought after by health-conscious consumers.

Agronomic practices, including tillage systems and wheat species, influenced the properties of wheat grain and flour. Regardless of the wheat species tested, the tested tillage systems generally had no significant effect on the values of the analysed traits. It should be noted, however, that in the case of ancient wheats, the most favourable cultivation system in relation to most of the tested parameters was shallow tillage—for T. persicum (MTG, HM, FN, TPC, WG, SV, TPCF, WGF, AC, FY, MEF, WA, BW, BW24, BL, TBL) and ploughing—for T. sphaerococcum (VIT, FN, TPC, TPCF, SC, FY, MEF, BW, BW24, BL, TBL, WA, DDT, DSF).

However, the statistically significant differentiation of the analysed parameters was generally determined by the cereal species. It was found that Persian wheat had the most favourable values for VIT, TPC, WG, TPCF, WGF, WA, BW, BW24, BL, and TBL among the cereals studied.

The evaluation of technological parameters, rheological properties of the dough, and baking performance indicators of grain and flour obtained from ancient wheats showed that these cereals can play an important role in the “from grain to loaf” production chain. The minimum requirements for assessing technological suitability (threshold values) for the most important analysed indicators for bread production were met (features of the enzyme and protein complex, rheological profile of dough). However, the most favourable values of the analysed parameters were generally exhibited by Persian wheat—Triticum persicum Vavilov. Special attention should be paid to the relatively high protein content, both in the grain and in the flour, as well as the water absorption capacity of the flour from this wheat species. The final product—bread baked from Persian wheat flour—despite having a relatively low volume, had the highest weight (BW, BW24) and the lowest baking losses (BL, TBL).

The cultivation of the aforementioned wheat species also aligns with current trends in sustainable and low-input agriculture, especially in the face of ongoing changes in weather conditions and the need for low-input agricultural systems.

The quality traits of grain and flour of ancient wheat species noted in this manuscript are very interesting in the context of the potential use of the obtained raw material for food purposes. However, it should be noted that the research was conducted on three organic farms, but during a single growing season. Therefore, there is a need for further multi-year field experiments on this topic to determine the directional changes in the shaping of quality trait values under the influence of weather conditions.

Author Contributions

Conceptualization, M.S. and T.K.; methodology, M.S. and T.K.; software, M.S. and T.K.; validation, T.K., M.S. and W.K.; formal analysis, M.S.; investigation, T.K. and M.S.; resources, M.S.; data curation, T.K. and W.K.; writing—original draft preparation, T.K., M.S., W.K. and L.D.; writing—review and editing, T.K., M.S., W.K. and L.D.; visualisation, T.K. and M.S.; supervision, T.K. and M.S.; project administration, M.S.; funding acquisition, M.S. All authors have read and agreed to the published version of the manuscript.

Funding

“European Agricultural Fund for Rural Development: Europe investing in rural areas”. The publication co-financed from the European Union funds under the COOPERATION of the Rural Development Programme for 2014–2020, Project No: 00001.DDD.6509.00003.2017.02. Founded by: Agency for Restructuring and Modernization of Agriculture. The Managing Authority of the Rural Development Programme for 2014–2020—the Minister of Agriculture and Rural Development.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Jaskulska, I.; Jaskulski, D.; Gałęzewski, L.; Knapowski, T.; Kozera, W.; Wacławowicz, R. Mineral composition and baking value of the winter wheat grain under varied environmental and agronomic conditions. J. Chem. 2018, 2018, 5013825. [Google Scholar] [CrossRef]

- Lacko-Bartošová, M.; Lacko-Bartošová, L.; Konvalina, P.; Matejková, E.; Bieliková, D. Rheological dough properties of organic spelt and emmer wheat for assessment of bread making quality. Zemdirbyste-Agriculture 2021, 108, 279–286. [Google Scholar] [CrossRef]

- Mitura, K.; Cacak-Pietrzak, G.; Feledyn-Szewczyk, B.; Szablewski, T.; Studnicki, M. Yield and grain quality of common wheat (Triticum aestivum L.) depending on the different farming systems (organic vs. integrated vs. conventional). Plants 2023, 12, 1022. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations. World Food Situation. 2025. Available online: https://www.fao.org/worldfoodsituation/csdb/en (accessed on 28 November 2024).

- Suchowilska, E.; Wiwart, M.; Krska, R.; Kandler, W. Do Triticum aestivum L. and Triticum spelta L. hybrids constitute a promising source material for quality breeding of new wheat varieties? Agronomy 2020, 10, 43. [Google Scholar] [CrossRef]

- EUROSTAT. Available online: https://ec.europa.eu/eurostat (accessed on 15 November 2022).

- Łaba, S.; Cacak-Pietrzak, G.; Łaba, R.; Sułek, A.; Szczepański, K. Food losses in consumer cereal production in Poland in the context of food security and environmental impact. Agriculture 2022, 12, 665. [Google Scholar] [CrossRef]

- Knapowski, T.; Spychaj-Fabisiak, E.; Kozera, W.; Barczak, B.; Murawska, B. Mineral fertilization and baking value of grain and flour of Triticum aestivum ssp. spelta L. Am. J. Exp. Agric. 2016, 11, 1–11. [Google Scholar] [CrossRef]

- Arzani, A.; Ashraf, M. Cultivated Ancient Wheats (Triticum spp.): A potential source of health-beneficial food products. Compr. Rev. Food Sci. Food Saf. 2017, 16, 477–488. [Google Scholar] [CrossRef]

- Shewry, P.R. Do ancient types of wheat have health benefits compared with modern bread wheat? J. Cereal Sci. 2018, 79, 469–476. [Google Scholar] [CrossRef]

- Geisslitz, S.; Longin, C.F.H.; Scherf, K.A.; Koehler, P. Comparative study on gluten protein composition of ancient (einkorn, emmer and spelt) and modern wheat species (durum and common wheat). Foods 2019, 8, 409. [Google Scholar] [CrossRef]

- Belcar, J.; Sobczyk, A.; Sobolewska, M.; Stankowski, S.; Gorzelany, J. Characteristics of technological properties of grain and flour from ancient varieties of wheat (einkorn, emmer and spelt). Acta Univ. Cibiniensis Ser. E Food Technol. 2020, 24, 269–278. [Google Scholar] [CrossRef]

- Tran, K.; Konvalina, P.; Capouchova, I.; Janovska, D.; Lacko-Bartosova, M.; Kopecky, M.; Tran, P. Comparative study on protein quality and rheological behavior of different wheat species. Agronomy 2020, 10, 1763. [Google Scholar] [CrossRef]

- Kulathunga, J.; Reuhs, B.L.; Zwinger, S.; Simsek, S. Comparative study on kernel quality and chemical composition of ancient and modern wheat species: Einkorn, emmer, spelt and hard red spring wheat. Foods 2021, 10, 761. [Google Scholar] [CrossRef]

- Jorjadze, M.; Berishvili, T.; Shatberashvili, E. The ancient wheats of Georgiaand their traditional use in the southern part of the country. Emir. J. Food Agric. 2014, 26, 192–202. [Google Scholar] [CrossRef]

- Nocente, F.; Galassi, E.; Taddei, F.; Natale, C.; Gazza, L. Ancient caucasian wheats: A contribution for sustainable diets and food diversity. Foods 2022, 11, 1209. [Google Scholar] [CrossRef] [PubMed]

- Szczepanek, M.; Lemańczyk, G.; Nowak, R.; Graczyk, R. Response of Indian dwarf wheat and Persian wheat to sowing density and hydrothermal conditions of the growing seasons. Agriculture 2022, 12, 205. [Google Scholar] [CrossRef]

- Szczepanek, M.; Siwik-Ziomek, A.; Lemańczyk, G.; Lamparski, R.; Graczyk, R. Effect of reduced tillage on soil enzyme activity, pests pressure and productivity of organically grown spring wheat species. Agronomy 2023, 13, 287. [Google Scholar] [CrossRef]

- Andruszczak, S. Reaction of winter spelt cultivars to reduced tillage system and chemical plant protection. Zemdirbyste-Agriculture 2017, 104, 15–22. [Google Scholar] [CrossRef]

- Geisslitz, S.; Wieser, H.; Scherf, K.A.; Koehler, P. Gluten protein composition and aggregation properties as predictors for bread volume of common wheat, spelt, durum wheat, emmer and einkorn. J. Cereal Sci. 2018, 83, 204–212. [Google Scholar] [CrossRef]

- Pandino, G.; Mattiolo, E.; Lombardo, S.; Lombardo, G.M.; Mauromicale, G. Organic cropping system affects grain chemical composition, rheological and agronomic. performance of durum wheat. Agronomy 2020, 10, 46. [Google Scholar] [CrossRef]

- Worthington, V. Nutritional quality of organic versus conventional fruits, vegetables and grains. J. Altern. Complement. Med. 2001, 7, 161–173. [Google Scholar] [CrossRef]

- Bobryk-Mamczarz, A.; Kiełtyka-Dadasiewicz, A.; Rachoń, L. Usefulness of hulled wheats grown in Polish environment for wholegrain pasta-making. Foods 2021, 10, 458. [Google Scholar] [CrossRef]

- Rachoń, L.; Krochmal-Marczak, B.; Cebulak, T. Suitability of common, durum and spelt spring wheat grain for bread production depending on the intensity of production technology. Agron. Sci. 2020, 75, 25–36. (In Polish) [Google Scholar] [CrossRef]

- Devi, U.; Grewal, S.; Yang, C.Y.; Hubbart-Edwards, S.; Scholefield, D.; Ashling, S.; Burridge, A.; King, I.P.; King, J. Development and characterisation of interspecific hybrid lines with genome-wide introgressions from Triticum timopheevii in a hexaploid wheat background. BMC Plant Biol. 2019, 19, 183. [Google Scholar] [CrossRef]

- Zargar, M.; Polityko, P.; Pakina, E.; Bayat, M.; Vandyshev, V.; Kavhiza, N.; Kiselev, E. Productivity, quality and economics of four spring wheat (Triticum aestivum L.) cultivars as affected by three cultivation technologies. Agron. Res. 2018, 16, 2254–2264. [Google Scholar] [CrossRef]

- Sułek, A.; Wyzińska, M.; Cacak-Pietrzak, G. Impact of tillage on yield and quality traits of grains of spring wheat cultivars. In Proceedings of the 2019 18th International Scientific Conference on Engineering for Rural Development, LLU, Jelgava, Latvia, 22–24 May 2019; pp. 600–606. [Google Scholar] [CrossRef]

- Wanic, M.; Denert, M.; Treder, K. Effect of forecrops on the yield and quality of common wheat and spelt wheat grain. J. Elem. 2019, 24, 369–383. [Google Scholar] [CrossRef]

- Bouacha, O.D.; Nouaigui, S.; Rezgui, S. Effects of N and K fertilizers on durum wheat quality in different environments. J. Cereal Sci. 2014, 59, 9–14. [Google Scholar] [CrossRef]

- Dziki, D.; Cacak-Pietrzak, G.; Gawlik-Dziki, U.; Świeca, M.; Miś, A.; Różyło, R.; Jończyk, K. Physicochemical properties and milling characteristics of spring wheat from different farming systems. J. Agric. Sci. Technol. 2017, 19, 1253–1266. Available online: https://jast.modares.ac.ir/article-23-7491-en.html (accessed on 20 August 2025).

- Jańczak-Pieniążek, M.; Buczek, J.; Kaszuba, J.; Szpunar-Krok, E.; Bobrecka-Jamro, D.; Jaworska, G. A Comparative assessment of the baking quality of hybrid and population wheat cultivars. Appl. Sci. 2020, 10, 7104. [Google Scholar] [CrossRef]

- Sułek, A.; Cacak-Pietrzak, G. The influence of production technology on yield selected quality parameters of spring wheat cultivars. Agric. Sci. Crop Sci. Anim. Sci. Res. Rural Dev. 2018, 2, 42–48. [Google Scholar] [CrossRef]

- Gawęda, D.; Haliniarz, M. Grain yield and quality of winter wheat depending on previous crop and tillage system. Agriculture 2021, 11, 133. [Google Scholar] [CrossRef]

- Yousefian, M.; Shahbazi, F.; Hamidian, K. Crop yield and physicochemical properties of wheat grains as affected by tillage systems. Sustainability 2021, 13, 4781. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, L.C.; Shi, C.; Chen, J.; Zhou, Q.; Xiong, Y. Soil respiration in a triple intercropping system under conservation tillage. Plant Soil Environ. 2015, 61, 378–384. [Google Scholar] [CrossRef]

- Woźniak, A.; Stępniowska, A. Yield and quality of durum wheat grain in different tillage systems. J. Elem. 2017, 22, 817–829. [Google Scholar] [CrossRef]

- Beach, H.M.; Laing, K.W.; Van De Walle, M.; Martin, R.C. The current state and future directions of organic no-till farming with cover crops in Canada, with case study support. Sustainability 2018, 10, 373. [Google Scholar] [CrossRef]

- Fernandez, M.R.; Zentner, R.P.; Schellenberg, M.P.; Leeson, O.A.; Alandenola, O.; McConkey, B.G.; Luce, M. Grain yield and quality of organic crops grown under reduced tillage and diversified sequences. Agron. J. 2019, 111, 793–804. [Google Scholar] [CrossRef]

- Peigné, J.; Casagrande, M.; Payet, V.; David, C.; Sans, F.X.; Blanco-Moreno, J.M.; Cooper, J.; Gascoyne, K.; Antichi, D.; Bàrberi, P.; et al. How organic farmers practice conservation agriculture in Europe. Renew. Agric. Food Syst. 2015, 31, 72–85. [Google Scholar] [CrossRef]

- Woźniak, A. Chemical properties and enzyme activity of soil as affected by tillage system and previous crop. Agriculture 2019, 9, 262. [Google Scholar] [CrossRef]

- Woźniak, A.; Rachoń, L. Effect of tillage systems on the yield and quality of winter wheat grain and soil properties. Agriculture 2020, 10, 405. [Google Scholar] [CrossRef]

- Chiriţă, S.; Rusu, T.; Urdă, C.; Cheţan, F.; Racz, I. Winter wheat yield and quality depending on chemical fertilization, different treatments and tillage systems. AgroLife Sci. J. 2023, 12, 34–39. [Google Scholar] [CrossRef]

- Skrajda-Brdak, M.; Konopka, I.; Tańska, M.; Szczepanek, M.; Sadowski, T.; Rychcik, B. Low molecular phytochemicals of Indian dwarf (Triticum sphaerococcum Percival) and Persian wheat (T. carthlicum Nevski) grain. J. Cereal Sci. 2020, 91, 102887. [Google Scholar] [CrossRef]

- Sadkiewicz, K.; Sadkiewicz, J.; Sadkiewicz, J. Bydgoszcz Apparatus for Testing Grain, Flour and Bread, 2nd ed.; Wydawnictwa Uczelniane Akademii Techniczno-Rolniczej w Bydgoszczy: Bydgoszcz, Poland, 2004; p. 156. (In Polish) [Google Scholar]

- PN-EN ISO 3093:2010; Wheat, Rye and Flour Obtained from Them, Durum Wheat and Semolina—Determination of Falling Number by the Hagberg-Perten Method. Polish Committee for Standardization: Warsaw, Poland, 2010. (In Polish)

- PN-EN-ISO 20483:2014-02; Cereal Grains and Legume Seeds. Determination of Protein Content Using NIR Devices. Polish Committee for Standardization: Warsaw, Poland, 2014. (In Polish)

- PN-EN ISO 5529:2010; Determination of Sedimentation Index—Zeleny’s Test; Determination of Sedimentation Index Values Using NIR Devices. Polish Committee for Standardization: Warsaw, Poland, 2010. (In Polish)

- PN-EN ISO 21415-2:2015-12; Determination of Wet Gluten. Determination of Wet Gluten Using NIR Devices. Polish Committee for Standardization: Warsaw, Poland, 2015. (In Polish)

- PN-EN ISO 2171:2010; Cereal Grains, Legume Seeds and Their Products—Determination of Ash Content; Determination of Ash Content Using NIR Devices. Polish Committee for Standardization: Warsaw, Poland, 2010. (In Polish)

- Lacko-Bartošová, M.; Lacko-Bartošová, L.; Kaur, A.; Moudrý, J. Comparative assessment of agro-morphological and quality traits of ancient wheat cultivars grown under organic farming. Agriculture 2022, 12, 1476. [Google Scholar] [CrossRef]

- Mazzoncini, M.; Antichi, D.; Silvestri, N.; Ciantelli, G.; Sgherri, C. Organically vs conventionally grown winter wheat: Effects on grain yield, technological quality, and on phenolic composition and antioxidant properties of bran and refined flour. Food Chem. 2015, 175, 445–451. [Google Scholar] [CrossRef]

- Sobolewska, M.; Stankowski, S. The influence of farming systems on the technological quality of grain and flour cultivars of winter wheat. Folia Pomer. Univ. Technol. Stetin. Agric. Aliment. Pisc. Zootech. 2017, 3321, 73–82. [Google Scholar] [CrossRef]

- Rachoń, L.; Bobryk-Mamczarz, A.; Kiełtyka-Dadasiewicz, A. Hulled wheat productivity and quality in modern agriculture, against conventional wheat species. Agriculture 2020, 10, 275. [Google Scholar] [CrossRef]

- Borkowska, B.; Banach, D. Assessment of selected physicochemical properties of wheat and rye from the northern and southern region of Poland. Rocz. Nauk. Stow. Ekon. Rol. Agrob. 2018, 20, 18–22. [Google Scholar] [CrossRef]

- PN-R-74107; Cereal Grain—Wheat. Polish Committee for Standardization: Warsaw, Poland, 1997; pp. 1–5. (In Polish)

- Kulathunga, J.; Simsek, S. Dietary fiber variation in ancient and modern wheat species: Einkorn, emmer, spelt and hard red spring wheat. J. Cereal Sci. 2022, 104, 103420. [Google Scholar] [CrossRef]

- Szafrańska, A. Technological value of wheat grain from the 2018 harvest in Poland. Przegl. Zboż. Młyn. 2018, 62, 26–31. (In Polish) [Google Scholar]

- Buczek, J. Quality and productivity of hybrid wheat depending on the tillage practices. Plant Soil Env. 2020, 66, 415–420. [Google Scholar] [CrossRef]

- Podolska, G.; Sułek, A. Wheat grain quality in Poland and the EU. Pam. Puł. 2003, 132, 363–369. (In Polish) [Google Scholar]

- Takač, V.; Tóth, V.; Rakszegi, M.; Mikó, P.; Mikić, S.; Mirosavljević, M. The influence of farming systems, genotype and their interaction on bioactive compound, protein and starch content of bread and spelt wheat. Foods 2022, 11, 4028. [Google Scholar] [CrossRef]

- Longin, C.F.H.; Ziegler, J.; Schweiggert, R.; Koehler, P.; Carle, R.; Würschum, T. Comparative study of hulled (einkorn, emmer, and spelt) and naked wheats (durum and bread wheat): Agronomic performance and quality traits. Crop Sci. 2016, 56, 302–311. [Google Scholar] [CrossRef]

- Wenda-Piesik, A.; Knapowski, T.; Ropińska, P.; Kazek, M. Grain quality of spring wheat cultivars (Triticum aestivum L. Emend. Fiori et Paol.) planted in late autumn and spring. Acta Agrophysica 2017, 24, 601–612. Available online: http://www.acta-agrophysica.org/Issue-4-2017,7234 (accessed on 25 August 2025). (In Polish).

- De Santis, M.A.; Giuliani, M.M.; Giuzio, L.; De Vita, P.; Lovegrove, A.; Shewry, P.R.; Flagella, Z. Differences in gluten protein composition between old and modern durum wheat genotypes in relation to 20th century breeding in Italy. Eur. J. Agric. 2017, 87, 19–29. [Google Scholar] [CrossRef]

- Augspole, I.; Linina, A.; Rutenberga-Ava, A.; Svarta, A.; Strazdina, V. Effect of organic and conventional production systems on the winter wheat grain quality. In Proceedings of the 2019 13th Baltic Conference on Food Science and Technology “Food. Nutrition. Well-Being”, LLU, Jelgava, Latvia, 2–3 May 2019; pp. 93–97. [Google Scholar] [CrossRef]

- Jurga, R. Technological properties of wheat flour and possibilities of their modification. Przeg. Zboż. Młyn. 2014, 58, 7–9. (In Polish) [Google Scholar]

- Rachoń, L.; Bobryk-Mamczarz, A.; Kiełtyka-Dadasiewicz, A. Study on mineral composition of selected wheat species. Przem. Chem. 2019, 98, 1888–1890. [Google Scholar] [CrossRef]

- Rachoń, L.; Bobryk-Mamczarz, A.; Kiełtyka-Dadasiewicz, A. Assessment of the domestic variety Triticum durum ‘SMH87’ as a raw material for pasta production. Agron. Sci. 2021, 76, 5–16. (In Polish) [Google Scholar] [CrossRef]

- Serban, L.R.; Păucean, A.; Man, S.M.; Chis, M.S.; Muresan, V. Ancient wheat species: Biochemical profile and impact on sourdough bread characteristics—A review. Processes 2021, 9, 2008. [Google Scholar] [CrossRef]

- Shewry, P.R. Wheat. J. Exp. Bot. 2009, 60, 1537–1553. [Google Scholar] [CrossRef]

- Sobczyk, A.; Pycia, K.; Jaworska, G. Comparative characteristics of the technological value of grain of old varieties and new types of spelled (Triticum spelta L.) and common wheat grain (Triticum vulgare). Zesz. Probl. Postęp. Nauk. Rol. 2017, 589, 81–91. [Google Scholar] [CrossRef]

- Szwedziak, K.; Polańczyk, E.; Nowaczyk, M. Analysis of quality of selected wheat flour type. Post. Tech. Przetw. Spoż. 2018, 2, 5–8. (In Polish) [Google Scholar]

- Serna-Saldivar, S.O. Cereal Grains: Properties, Processing, and Nutritional Attributes; CRC Press: London, UK, 2016. [Google Scholar] [CrossRef]

- Żuk-Gołaszewska, K.; Majewska, K.; Tyburski, J.; Gołaszewski, J. Physical and technological properties of kernels and flour made from spelt grown in an organic farming system in north-eastern Poland. J. Cereal Sci. 2018, 79, 501–507. [Google Scholar] [CrossRef]

- Zhai, S.; Liu, J.; Xu, D.; Wen, W.; Yan, J.; Zhang, P.; Wan, Y.; Cao, S.; Hao, Y.; Xia, X.; et al. A genome-wide association study reveals a rich genetic architecture of flour color-related traits in bread wheat. Front. Plant Sci. 2018, 9, 1136. [Google Scholar] [CrossRef] [PubMed]

- Banach, J.K.; Majewska, K.; Żuk-Gołaszewska, K. Effect of cultivation system on quality changes in durum wheat grain and flour produced in North-Eastern Europe. PLoS ONE 2021, 16, e0236617. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).