Influence of Air Layer Characteristics on the Heat Transfer Performance of Photovoltaic Dairy Barn Roofs

Abstract

1. Introduction

2. Materials and Methods

2.1. Overview of the Test Barn

2.2. Thermal Environment Testing of the Test Barn

2.3. PV Roof Design

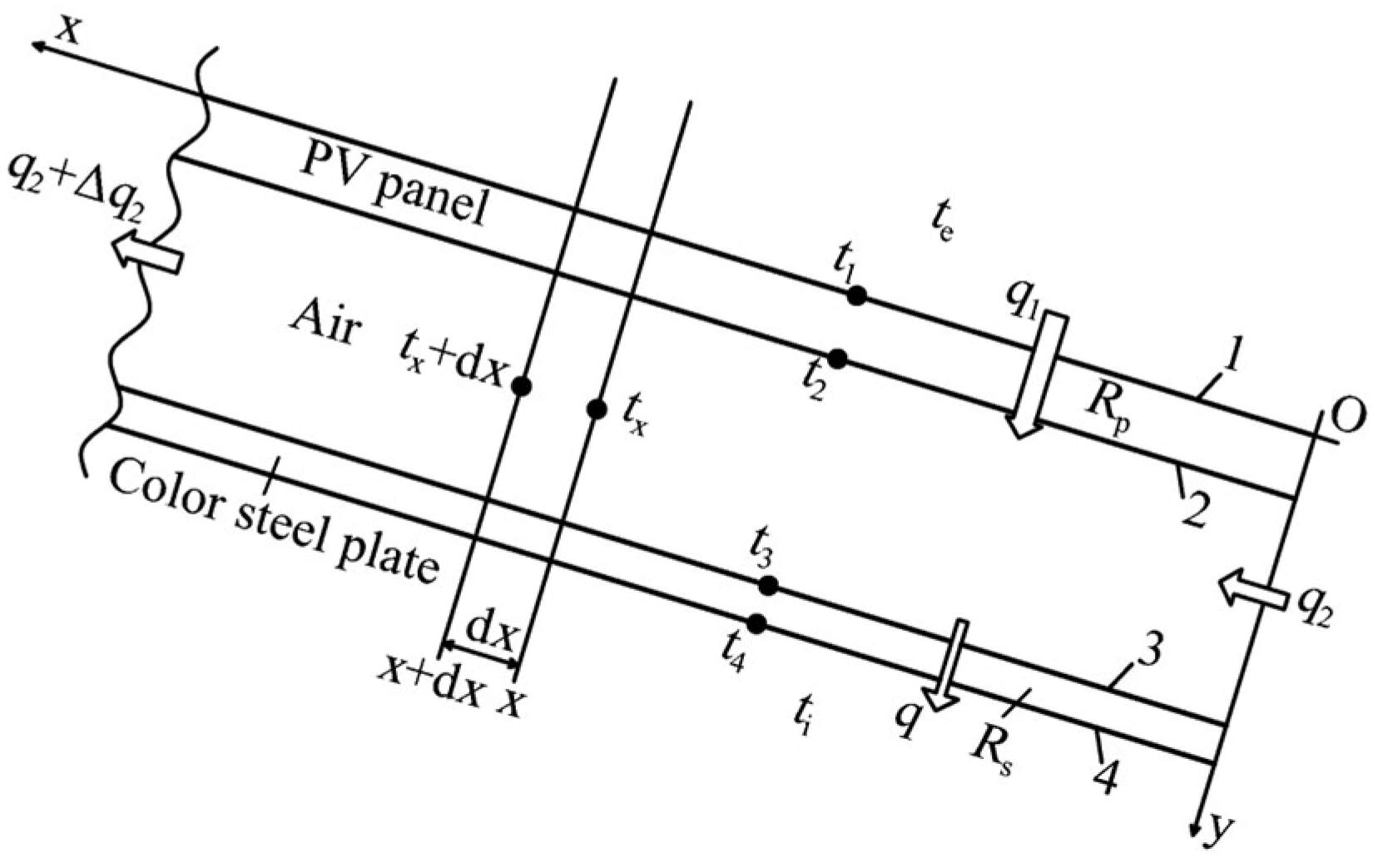

2.4. Heat Transfer Modeling

2.4.1. Thermal Performance Indicators for Roofs

2.4.2. Calculations for Different Conditions

- 1.

- Condition A:

- 2.

- Condition B:

- 3.

- Condition C:

2.5. Correlation Equation Validation Methodology

3. Results and Discussion

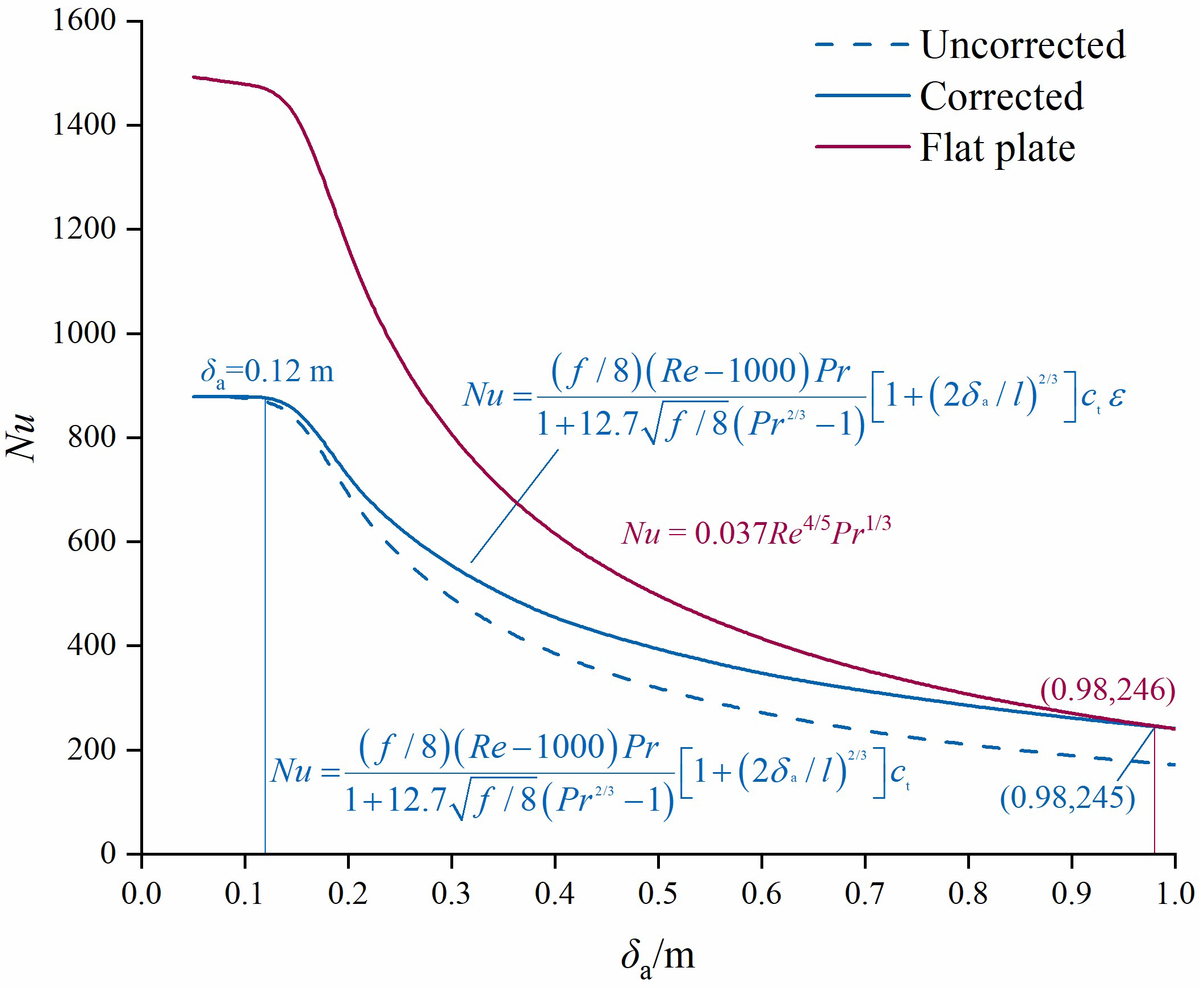

3.1. Corrections to Relevant Calculation Formulas for PV Dairy Barns

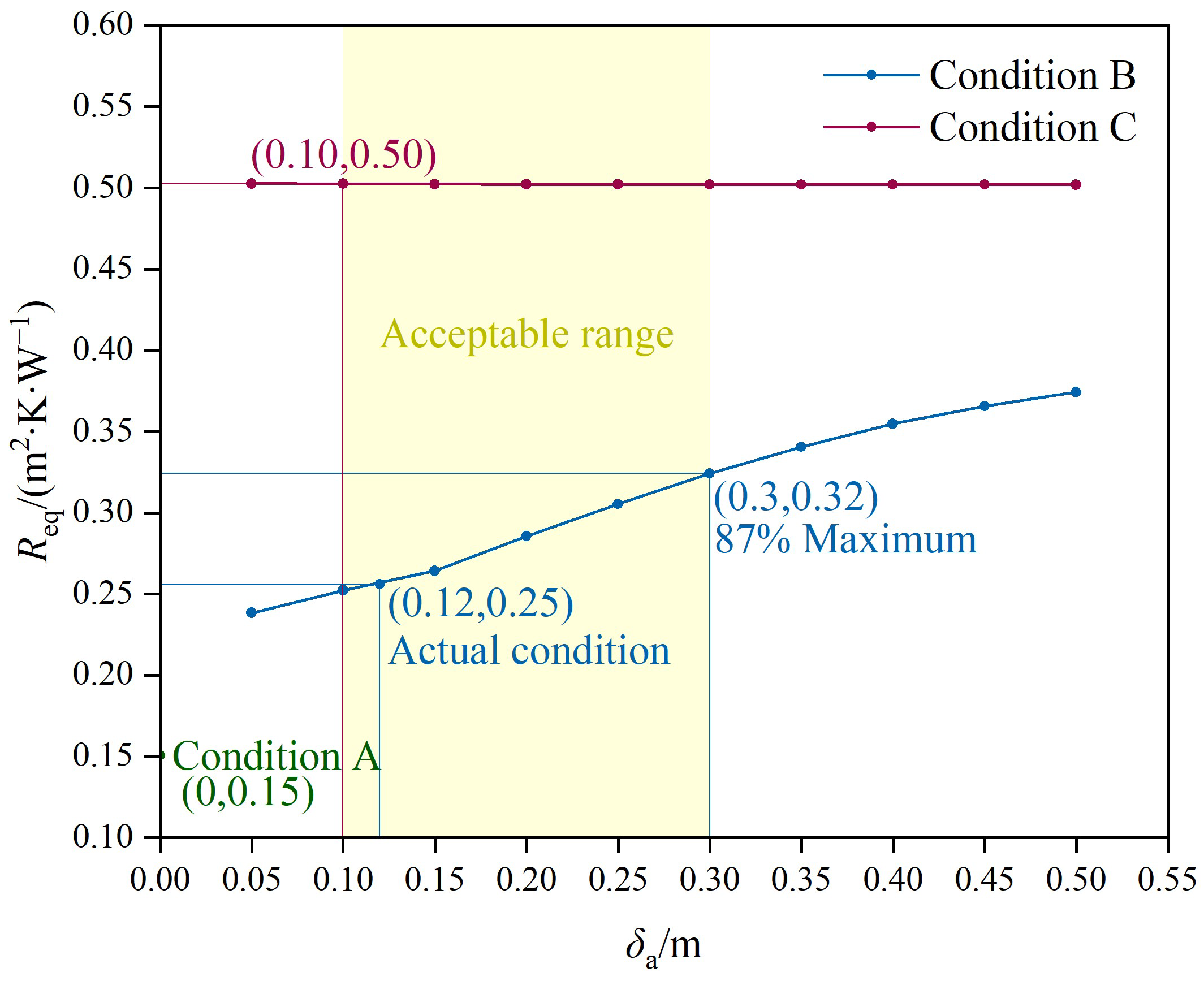

3.2. Setting of Air Layer Thickness

3.3. Thermal Environment Test Data

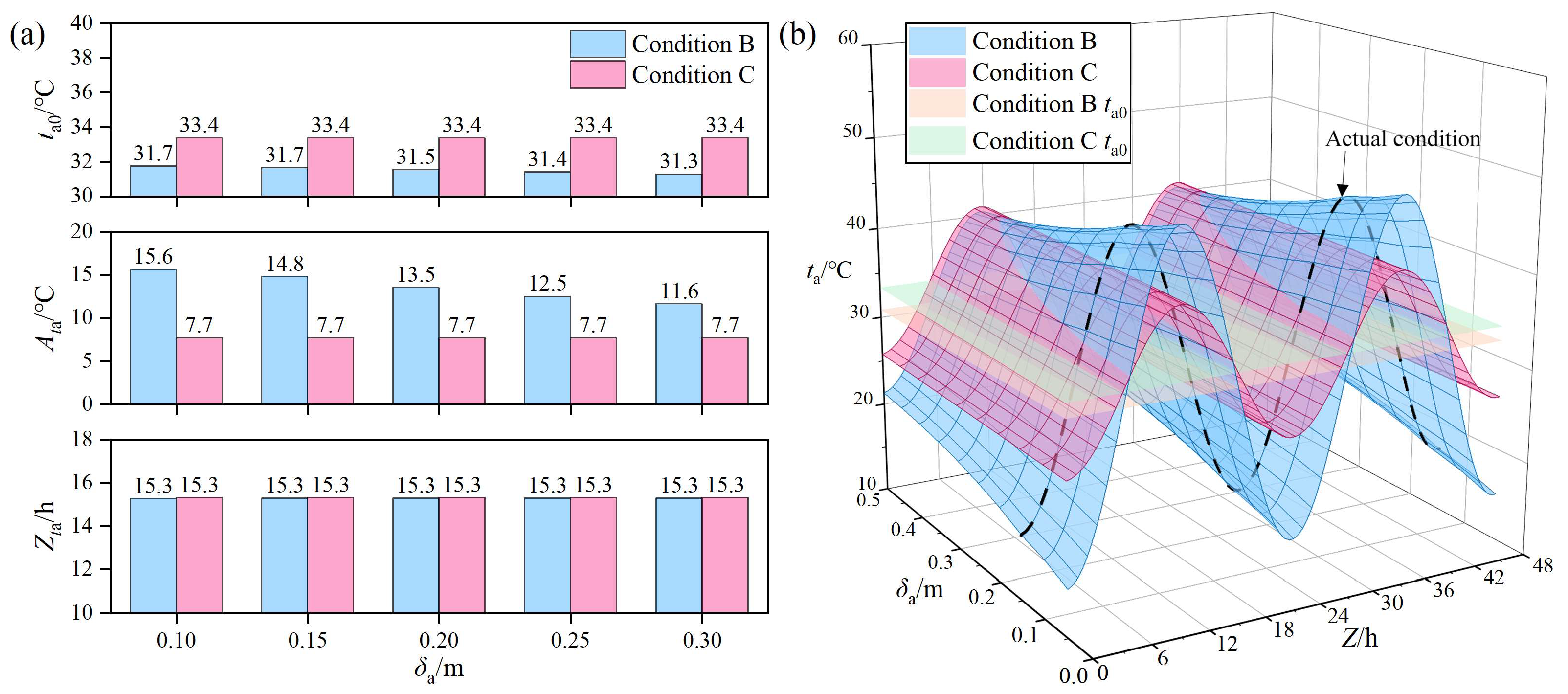

3.4. Variation in Air Layer Temperature with Air Layer Thickness

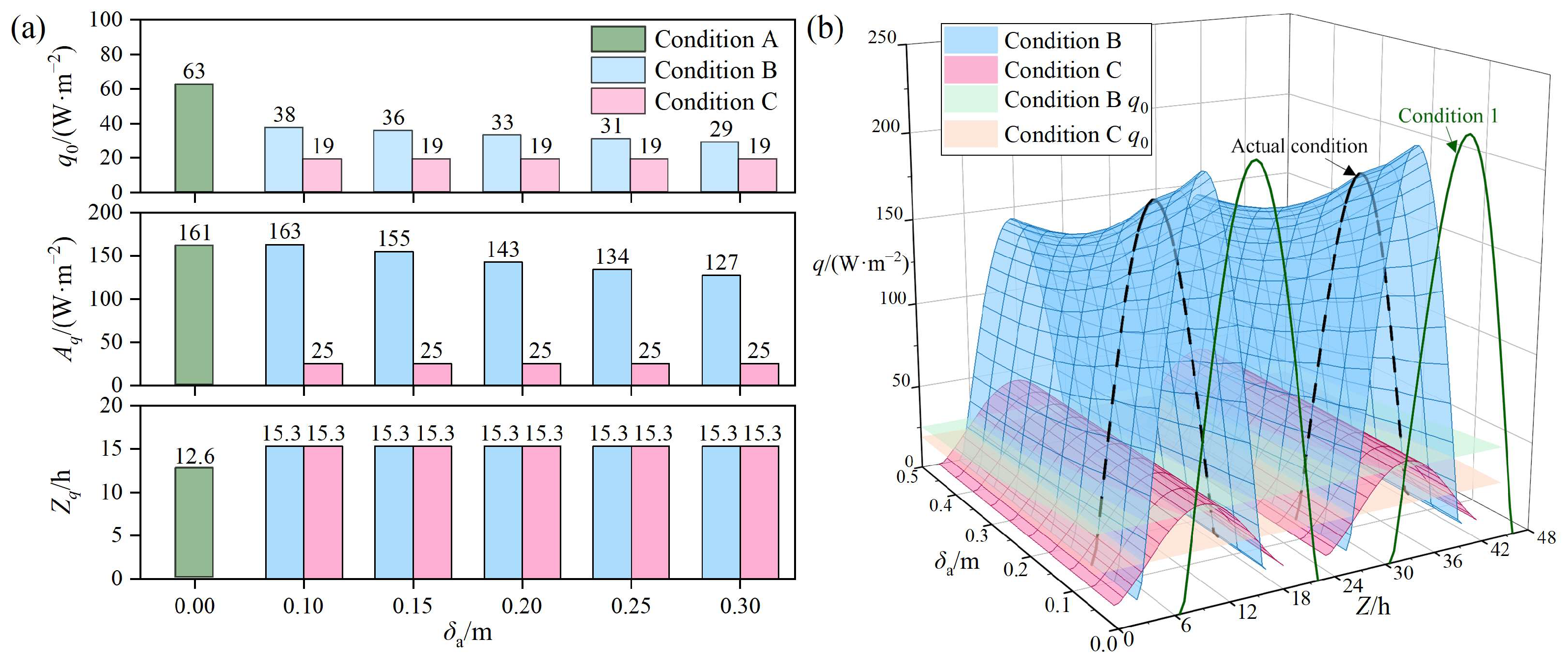

3.5. Variation in Heat Entering the Barn Through the Roof with Air Layer Thickness

3.6. Variation in Roof Equivalent Thermal Resistance with Air Layer Thickness

3.7. Prospects

4. Conclusions

- Convective heat transfer correlation: A characteristic number correlation equation for convective heat transfer in ventilated air layers was developed. The correlation aligns closely with the characteristic number for external flow over a flat plate when the air layer thickness exceeds a critical value. The modified characteristic number equations are more applicable to PV roof structures of agricultural or industrial buildings.

- Harmonic analysis of heat flux: Harmonic analysis revealed that for ventilated air layers, increasing the air layer thickness reduces the mean heat flux and its amplitude entering the barn through the roof, with minimal changes to the peak time. In contrast, for sealed air layers, the mean heat flux, amplitude, and peak time remain relatively stable regardless of changes in air layer thickness.

- Thermal resistance evaluation: The thermal resistance of the roof with a PV system was evaluated. Compared to a roof without a PV system, the thermal resistance of the roof with a ventilated air layer structure increases by 1.67–2.15 times, with further increases observed as air layer thickness grows. For a roof with a sealed air layer structure, the thermal resistance is 3.33 times higher, with little variation observed with increasing air layer thickness.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- FAO; Global Dairy Platform. Climate Change and the Global Dairy Cattle Sector—The Role of the Dairy Sector in a Low-Carbon Future; FAO: Rome, Italy, 2019. [Google Scholar]

- National Development and Reform Commission. “14th Five-Year” Renewable Energy Development Plan; National Development and Reform Commission: Beijing, China, 2021.

- Lin, W.; Green, A.; Ledo Gomis, L.; Kokogiannakis, G.; Cooper, P. Thermal Effects of Dew on Cool Roofs and Conventional Roofs in Building Performance Simulations. Energy Build. 2023, 279, 112645. [Google Scholar] [CrossRef]

- Yang, T.; Athienitis, A.K. A Review of Research and Developments of Building-Integrated Photovoltaic/Thermal (BIPV/T) Systems. Renew. Sustain. Energy Rev. 2016, 66, 886–912. [Google Scholar] [CrossRef]

- Dominguez, A.; Kleissl, J.; Luvall, J.C. Effects of Solar Photovoltaic Panels on Roof Heat Transfer. Sol. Energy 2011, 85, 2244–2255. [Google Scholar] [CrossRef]

- Bianco, V.; Diana, A.; Manca, O.; Nardini, S. Numerical Investigation of an Inclined Rectangular Cavity for Ventilated Roofs Applications. Therm. Sci. Eng. Prog. 2018, 6, 426–435. [Google Scholar] [CrossRef]

- Calati, M.; Doretti, L.; Zilio, C.; Mancin, S. 3D Numerical Simulation of a Novel Ventilated Roof: Thermal Performance Analysis and Fluid Flow Behavior. Sci. Technol. Built Environ. 2021, 27, 819–831. [Google Scholar] [CrossRef]

- Zhang, T.; Tan, Y.; Yang, H.; Zhang, X. The Application of Air Layers in Building Envelopes: A Review. Appl. Energy 2016, 165, 707–734. [Google Scholar] [CrossRef]

- Tikul, N.; Prachum, S. Passive Cooling Strategies for Cattle Housing on Small Farms: A Case Study. Maejo Int. J. Sci. Technol. 2022, 16, 25–39. [Google Scholar]

- Pan, Z.; Zhao, W.; Wang, H. Comparative Study on Numerical Simulation of Temperature Field of Farm House with Different Roof Forms. Sci. Rep. 2024, 14, 7772. [Google Scholar] [CrossRef]

- Lee, S.; Park, S.H.; Yeo, M.S.; Kim, K.W. An Experimental Study on Airflow in the Cavity of a Ventilated Roof. Build. Environ. 2009, 44, 1431–1439. [Google Scholar] [CrossRef]

- Luo, Y.; Zhang, L.; Bozlar, M.; Liu, Z.; Guo, H.; Meggers, F. Active Building Envelope Systems toward Renewable and Sustainable Energy. Renew. Sustain. Energy Rev. 2019, 104, 470–491. [Google Scholar] [CrossRef]

- Villi, G.; Pasut, W.; Carli, M.D. CFD Modelling and Thermal Performance Analysis of a Wooden Ventilated Roof Structure. Build. Simul. 2009, 2, 215–228. [Google Scholar] [CrossRef]

- Li, D.; Zheng, Y.; Liu, C.; Qi, H.; Liu, X. Numerical Analysis on Thermal Performance of Naturally Ventilated Roofs with Different Influencing Parameters. Sustain. Cities Soc. 2016, 22, 86–93. [Google Scholar] [CrossRef]

- Phiraphat, S.; Prommas, R.; Puangsombut, W. Experimental Study of Natural Convection in PV Roof Solar Collector. Int. Commun. Heat Mass Transf. 2017, 89, 31–38. [Google Scholar] [CrossRef]

- Incropera, F.P.; DeWitt, D.P.; Bergman, T.L.; Lavine, A.S. Fundamentals of Heat Transfer and Mass Transfer, 6th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- GB50176–2016; Thermal Design Code for Civil Building. Ministry of Housing and Urban-Rural Development: Beijing, China, 2016.

- Gupta, C.P. Engineering Heat Transfer, 4th ed.; Nem Chand and Brothers: Roorkee, India, 1976. [Google Scholar]

- Bagusrovsky, В.Н. Building Thermophysics: The Thermophysical Basis of Heating, Ventilation and Air Conditioning; China Building Industry Press: Beijing, China, 1988. [Google Scholar]

- Gnielinski, V. New Equations for Heat and Mass Transfer in the Turbulent Flow in Pipes and Channels. NASA STI/Recon Tech. Rep. A 1975, 41, 8–16. [Google Scholar]

- Hollands, K.G.T.; Unny, T.E.; Raithby, G.D.; Konicek, L. Free Convective Heat Transfer Across Inclined Air Layers. J. Heat Transf. 1976, 98, 189–193. [Google Scholar] [CrossRef]

- Schlichting, H.; Gersten, K. Boundary-Layer Theory, 9th ed.; Springer: Berlin/Heidelberg, Germany, 2016; ISBN 978-3-662-52917-1. [Google Scholar]

- Aung, W.; Fletcher, L.S.; Sernas, V. Developing Laminar Free Convection between Vertical Flat Plates with Asymmetric Heating. Int. J. Heat Mass Transf. 1972, 15, 2293–2308. [Google Scholar] [CrossRef]

- Wilson, M.J.; Paul, M.C. Effect of Mounting Geometry on Convection Occurring under a Photovoltaic Panel and the Corresponding Efficiency Using CFD. Sol. Energy 2011, 85, 2540–2550. [Google Scholar] [CrossRef]

- GB51368-2019; Technical Standard for Photovoltaic System on Building. Ministry of Housing and Urban-Rural Development: Beijing, China, 2019.

- Naghavi, M.S.; Esmaeilzadeh, A.; Singh, B.; Ang, B.C.; Yoon, T.M.; Ong, K.S. Experimental and Numerical Assessments of Underlying Natural Air Movement on PV Modules Temperature. Sol. Energy 2021, 216, 610–622. [Google Scholar] [CrossRef]

- Brian. How to Calculate the Minimum Distance between PV Panels? 2024. Available online: https://www.maysunsolar.com/blog-how-to-calculate-the-minimum-distance-between-pv-panels/ (accessed on 12 August 2025).

- Zhang, T.; Yang, H. Heat Transfer Pattern Judgment and Thermal Performance Enhancement of Insulation Air Layers in Building Envelopes. Appl. Energy 2019, 250, 834–845. [Google Scholar] [CrossRef]

- Bruno, R.; Bevilacqua, P.; Ferraro, V.; Arcuri, N. Reflective Thermal Insulation in Non-Ventilated Air-Gaps: Experimental and Theoretical Evaluations on the Global Heat Transfer Coefficient. Energy Build. 2021, 236, 110769. [Google Scholar] [CrossRef]

- Maleki, A.; Haghighi, A.; El Haj Assad, M.; Mahariq, I.; Alhuyi Nazari, M. A Review on the Approaches Employed for Cooling PV Cells. Sol. Energy 2020, 209, 170–185. [Google Scholar] [CrossRef]

- Wang, H.; Wei, J.; Guo, C.; Yang, L.; Wang, Z. Numerical Investigation of the Effects of Different Influencing Factors on Thermal Performance of Naturally Ventilated Roof. Energy 2024, 289, 130039. [Google Scholar] [CrossRef]

- Ma, Z.; Hu, L.; Mao, H.; Shao, Q.; Tian, Z.; Luo, Y.; Deng, J.; Sun, D.; Fan, J. Shading Effect and Energy-Saving Potential of Rooftop Photovoltaic on the Top-Floor Room. Sol. Energy 2023, 265, 112099. [Google Scholar] [CrossRef]

- ISO6946:2007; Building Components and Building Elements—Thermal Resistance and Thermal Transmittance—Calculation Method. International Organization for Standardization: Geneva, Switzerland, 2007.

- Zhang, T.; Yang, H. Optimal Thickness Determination of Insulating Air Layers in Building Envelopes. Energy Procedia 2018, 152, 444–449. [Google Scholar] [CrossRef]

- Boukendil, M.; Abdelbaki, A.; Zrikem, Z. Numerical Simulation of Coupled Heat Transfer through Double Hollow Brick Walls: Effects of Mortar Joint Thickness and Emissivity. Appl. Therm. Eng. 2017, 125, 1228–1238. [Google Scholar] [CrossRef]

- Nath, B.; Roy, S.; Das, B.; Ehyaei, M.A. Experimental and Numerical Study of a Novel Composite Building Wall U-Value. Therm. Sci. Eng. Prog. 2024, 53, 102751. [Google Scholar] [CrossRef]

- Zhang, Y.; Du, K.; He, J.; Yang, L.; Li, Y.; Li, S. Impact Factors Analysis on the Thermal Performance of Hollow Block Wall. Energy Build. 2014, 75, 330–341. [Google Scholar] [CrossRef]

| Index | Value | |||||

|---|---|---|---|---|---|---|

| l/δa | 20 | 30 | 40 | 60 | 80 | ≥100 |

| ε | 1.28 | 1.18 | 1.13 | 1.05 | 1.02 | 1.00 |

| Environmental Parameter | Value | Unit |

|---|---|---|

| Mean value of outdoor air velocity | 0.9 | m·s−1 |

| Mean value of outdoor temperature | 29.4 | °C |

| Amplitude of outdoor temperature | 5.8 | °C |

| Peak time of outdoor temperature | 14.0 | h |

| Mean value of solar radiation intensity outdoors | 184 | W·m−2 |

| Amplitude of solar radiation intensity outdoors | 232 | W·m−2 |

| Peak time of solar radiation intensity outdoors | 12.0 | h |

| Mean value of indoor temperature | 28.0 | °C |

| Amplitude of indoor temperature | 3.0 | °C |

| Peak time of indoor temperature | 14.0 | h |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Q.; Liu, Y.; Qi, F.; Du, X.; Yan, G.; Wang, Z.; Liu, H.; Wang, C.; Shi, Z. Influence of Air Layer Characteristics on the Heat Transfer Performance of Photovoltaic Dairy Barn Roofs. Agriculture 2025, 15, 1938. https://doi.org/10.3390/agriculture15181938

Wang Q, Liu Y, Qi F, Du X, Yan G, Wang Z, Liu H, Wang C, Shi Z. Influence of Air Layer Characteristics on the Heat Transfer Performance of Photovoltaic Dairy Barn Roofs. Agriculture. 2025; 15(18):1938. https://doi.org/10.3390/agriculture15181938

Chicago/Turabian StyleWang, Qi, Yunying Liu, Fei Qi, Xinyi Du, Geqi Yan, Zhen Wang, Hui Liu, Chaoyuan Wang, and Zhengxiang Shi. 2025. "Influence of Air Layer Characteristics on the Heat Transfer Performance of Photovoltaic Dairy Barn Roofs" Agriculture 15, no. 18: 1938. https://doi.org/10.3390/agriculture15181938

APA StyleWang, Q., Liu, Y., Qi, F., Du, X., Yan, G., Wang, Z., Liu, H., Wang, C., & Shi, Z. (2025). Influence of Air Layer Characteristics on the Heat Transfer Performance of Photovoltaic Dairy Barn Roofs. Agriculture, 15(18), 1938. https://doi.org/10.3390/agriculture15181938