Abstract

Ridge tillage is one of the essential tillage methods in China. It affects the soil structure by altering the soil-water environment. With the rapid development of agricultural mechanization, the mechanized ridge tillage technology that combines modern mechanized agriculture with conservation tillage has become a pertinent agricultural production technology in the hilly regions. However, to date, the effects of mechanized ridge tillage on soil structure have garnered little attention. In this study, a field plot experiment involving the following four treatments: conventional tillage with rice and winter fallow (CK1), conventional tillage with rice-rape rotation (CK2), wide ridge tillage with rice-rape rotation (BT), and narrow ridge tillage with rice-rape rotation (RT) was conducted to study the effects of mechanized ridge tillage with rice-rape rotation on soil aggregate stability and soil porosity. The results indicated that mechanized ridge tillage could reduce the porosity of pores > 30 μm in diameter and increase the porosity of pores < 0.5 μm. Furthermore, mechanized ridge tillage could increase soil aggregate stability; the order of average mass diameter and geometric average diameter was RT > BT > CK2 > CK1. The BT and RT treatments could increase the agglomeration degree of the soil particles, which followed the order of RT > BT > CK2 > CK1. Therefore, mechanized ridge tillage with rice-rape rotation is effective in enhancing soil structure.

1. Introduction

In China, rice cultivation areas occupy approximately 25% of the total cultivation area in the country [1]. Rapeseed oil accounts for more than 50% of all edible oils [2]. Rice-rape rotation is one of the major cropping systems in the rice soils of southern China [3]. During rape cultivation, the soil water content is less than the field water-holding capacity. Conversely, during rice cultivation, the soil water content is greater than the field water-holding capacity, implying a near-saturated or saturated state [4]. In the 1980s, the “ridge culture and no tillage technology in paddy fields” was proposed [5]. It involves artificial ridge tillage technology, and results in the constant infiltration of the soil using capillary water. This method can enhance the stress resistance and coordination ability of the soil, rendering it highly fertile [6,7,8]. Such changes addressed a series of issues, such as heavy wet damage, low yield, and deterioration of the soil physicochemical properties in paddy fields in South China; hence, the use of ridge tillage has been increasing [9,10] and its promotion has been successful in several provinces and cities [11]. Wide- and narrow-ridge tillage belong to conservation tillage. In the 1940s, the studies on ridge tillage appeared abroad. At present, most of the wheat growing areas in Mexico have adopted ridge tillage, and more than half of the cultivated land in the United States has adopted ridge forming, no-tillage and other types of conservation tillage [12]. Different tillage methods have different degrees of disturbance to the soil. As such, their impact on the soil structure will also be different [13]. No-tillage technology causes the least disturbance to the soil, resulting in enhanced soil porosity and increased organic matter content; however, in the long term, it causes soil caking [14]. Rotary tillage can effectively loosen the topsoil up to a depth of 0–15 cm, but long-term rotary tillage will cause the plow bottom to be more rigid [13]. Ridge cultivation can improve the water and heat status and the physical structure of the soil, which promotes the formation of stable large aggregates [15,16]. Traditional tillage technology and protective no-tillage also cause fundamental changes in the total porosity and pore distribution of the soil [17,18].

Studies have shown that ridge tillage has various advantages; it can not only promote the formation of water-stable aggregates in soil, but also change the soil porosity. In ridge tillage soil, the soil is infiltrated with water, and the soil water environment has an important impact on the soil-particle aggregation state and soil structure [19,20,21]. The ridge soil is continuously infiltrated by capillary water, and the soil colloid adsorbs polar water molecules to form a large area of water film, which produces capillary adhesion and enhances the agglomeration effect of the soil particles [11]. The technology of mechanized ridge tillage with rice-rape rotation is the product of the combination of modern mechanical agriculture and conservation tillage [8]. Mechanized ridge tillage technology has become one of the important agricultural production promotion technologies in Chongqing, China in 2022 [22]. Using this technology, rice straw was crushed and returned to the field after harvesting, and the rapeseed was directly sown on the ridge surface (the most common ridge widths are 0.8 and 1.2 m) after plowing the paddy by a rotary ridging machine; after the rape matured, it was harvested, the rape straw was returned to the field, and the rice was sown on the original ridge surface until it matured and was harvested. This operational process was conducted annually [23].

Soil porosity is an important component of soil structure. Differences in soil porosities and pore distributions affect the water storage and infiltration of the soil [24,25]. Pores can be divided into small, medium, and large pores. Pore diameters < 0.5 μm represent small pores (i.e., residual and bound pores), which usually inhibit some microbial activities and activation reactions, but also maintain and transport water and nutrients in the soil; pore diameters between 0.5 and 30 μm represent mesopores (i.e., storage pores), which are generally suitable for the development of crop roots and the preservation of the effective water required for root growth; pore diameters > 30 μm represent macropores (i.e., exchange pores), which are conducive to the exchange of air between the atmosphere and the soil, ventilate the soil, and facilitate the infiltration of water and rapid drainage [24,26].

In this study, we focus on the rice-rape rotation soil and examine it through the comparative analysis of soil aggregates and porosity under different tillage methods; we study the impact of mechanized ridge tillage on soil structure, and provide a theoretical basis for the sustainable development of agricultural modernization in the Chongqing hilly areas. Our major objectives were to explore the effect of (1) mechanized ridge tillage on soil porosity; (2) mechanized ridge tillage on the particle size distribution and stability of soil aggregates; and (3) mechanized ridge tillage on the agglomeration degree of soil particles.

2. Materials and Methods

2.1. Experimental Site Description

This study was conducted in the test field of the national monitoring station of soil fertility and fertilizer efficiency, on purple soils (30°26′ N, 106°26′ E; 230 m altitude), for two years (August 2019–December 2021). The soil was neutral purple paddy soil (anthrosols in the World Reference Base Taxonomy) [27] developed on the parent material of purple sandy mudstone of the Shaximiao Formation of the Middle Jurassic (J2s), which contains a lot of mineral nutrients. This area is characterized by a subtropical monsoon humid climate, with abundant rainfall mostly from May to September. The annual average precipitation is 1105.40 mm, the annual average air temperature is 18.30 °C, the annual average sunshine time is 1276.70 h, and the annual frost-free period is 334 days. The actual plots in the rice and rape seasons are shown in Figure 1.

Figure 1.

Experimental plots in the rice and rape seasons. CK1: conventional tillage with rice and winter fallow; CK2: conventional tillage with rice-rape rotation; RT1: wide ridge tillage with rice-rape rotation; RT2: narrow ridge tillage with rice-rape rotation.

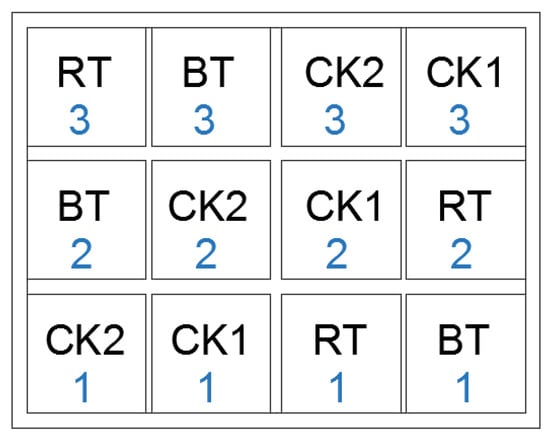

2.2. Experimental Design

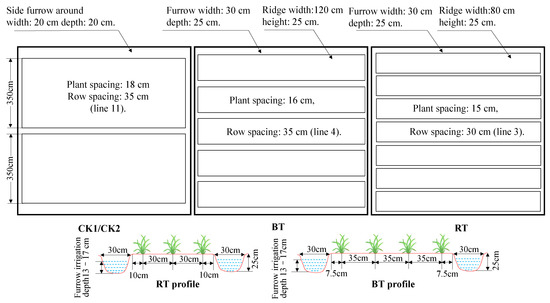

The schematic diagram of different treatments is shown in Figure 2. The field plot experiment that was conducted to study the mechanized ridge tillage with rice-rape rotation involved four tillage treatments: (1) conventional tillage with rice and winter fallow (CK1), one season medium rice, year-round flooding, and direct seeding of rice; (2) conventional tillage with rice-rape rotation (CK2), with a box surface of 350 cm and a height difference of no more than 3 cm; (3) wide-ridge tillage with rice-rape rotation (BT) and mechanical ridging, 120 and 30 cm wide ridges and a 25 cm deep furrow; and (4) narrow-ridge tillage with rice-rape rotation (RT), mechanical ridging, 80 and 30 cm wide ridges and 25 cm deep furrow. The furrows of BT and RT were flooded to a depth of 10–15 cm in the rice planting season. As shown in Figure 2, this study was conducted in experimental plots with an area of 64 m2 (8 m × 8 m). There were 12 experimental plots with four different farming treatments. Each treatment was replicated three times. Information about the experimental plots, experimental design management, and mechanical information are shown in Figure 3 and Figure 4 and Table 1. For direct seeding of rape and rice, Chuanhuayou 320 was selected for rice, while 120 kg of pure nitrogen, 90 kg of phosphorus fertilizer, and 75 kg of potassium fertilizer were applied per hectare. Nitrogen fertilizer was applied according to the ratio of base fertilizer: topdressing (jointing stage) = 6:4. Phosphorus and potassium fertilizer were applied once; the variety of rape was Dezayou No. 5, while 180 kg of nitrogen fertilizer, 105 kg of phosphorus fertilizer, and 90 kg of potassium fertilizer were applied per hectare. The nitrogen fertilizer was applied according to the ratio of base fertilizer: topdressing (the stage with 3–4 leaves) = 6:4. The phosphorus and potassium fertilizers were applied once, and 15 kg of borax were applied per hectare in the early flowering stage. Grass removal was once a month. The field plot experiment was carried out for two years.

Figure 2.

Schematic diagram of the experimental community.

Figure 3.

Schematic diagram of different treatments.

Figure 4.

Picture showing ridge ploughing.

Table 1.

Management information for experimental design.

2.3. Measurements

2.3.1. Soil Porosity

Soil samples were collected at the flowering stage (9 March), maturity stage of rape (27 April), and the heading (8 August) and maturity (5 September) stages of rice. Soil samples were collected using a ring knife with a diameter of 6.10 cm and a height of 2 cm. Samples were collected repeatedly in triplets, at two different depths: 0–10 cm and 10–20 cm. Soil porosity was measured by the pressure film instrument method [28]. The pressure film instrument measured soil quality at 0.1, 0.3, 0.5, 1.0, 3.0, and 6.0 bar. Moreover, we measured and calculated the moisture-characteristic curve of the pressure film instrument under multiple pressure points (0.1, 0.3, 0.5, 1.0, 3.0, and 6.0 bar). The number of soil pores was expressed by porosity (i.e., ratio of pore volume to total volume; unit: cm3/cm3). The equivalent aperture was calculated as follows [28,29]:

where, S is suction (Pa) and d is the equivalent pore (mm).

2.3.2. Soil Aggregate

Soil samples were collected at the flowering stage, maturity stage of rape, and heading and maturity stages of rice. Three points were selected in each plot; the flat planting centers were selected for the CK1 and CK2 treatments, and the mid-points of the ridges were selected for the T and RT treatments. Samples were collected from the 0–10 and 10–20 cm soil layers, using a shovel. Three points in the same plot were mixed into a soil sample, which was loaded into a sealed plastic box with a volume of 3000 mL. At the laboratory, the soil was broken into about 1 cm3 soil blocks according to the cracks, while the plant roots, small stones, and other sundries were removed before drying the samples. The composition of dry-sieve aggregate sizes was determined by the dry-sieve method [30], and the composition of wet-sieve aggregate sizes was determined by the wet-sieve method [31,32,33]. The percentage of mean weight diameter (MWD) and geometric mean diameter (GMD) were important indicators reflecting the structural stability of soil aggregates [30], and they were calculated according to the following [34]:

where, wi > 0.25 is the >0.25 mm water stable aggregate mass (unit: g); WT is the total mass of dried agglomerates (unit: g); wr > 0.25 is the >0.25 mm wet-sieve aggregate mass fraction (%); and Dr > 0.25 is the is the sum of the percentage of dry-sieve aggregates (%).

where, di is the average diameter of the aggregate of the i-th aggregate size (unit: mm); and Wi is the mass percentage of wet-sieve aggregate of the i-th aggregate size (%).

2.3.3. Aggregate Degree of Soil Particles

Soil micro-aggregates may be representative of soil structural characteristics depending on their degree of aggregation. The degree of agglomeration was used for measuring the number of micro-aggregates formed by soil particles in the soil. The agglomeration degree of soil particles was expressed by the quantitative relationship between mechanical composition and micro aggregates. The straw method [35,36] was used for determination, in which the chemical treatment method [37,38] was used for mechanical composition, and the physical treatment method [37] was used for micro-aggregates. The soil particles were classified according to the American standard [39], and the calculation method of soil particle agglomeration was as follows [40]:

where, b is the percentage of 0.05 mm water stability aggregates, and a is the percentage of 0.05 mm sand particles.

2.4. Statistical Analysis

All statistical analyses were performed with Excel 2016 and SPSS 26.0. The one-way analysis of variance (ANOVA) and the least significant difference (LSD) method were used to evaluate the differences in MWD, GMD, and soil agglomeration degree among different treatments; the independent samples t-test was performed to compare the differences in the degree of soil agglomeration between soil layers. Microsoft Excel and AutoCAD were used for plotting the data and performing the statistical analyses.

We used SPSS software Version 26.0 for Windows and ANOVA for analyzing the data (means ± SD; n = 3). We used LSD at p < 0.05 to test the differences between different treatments.

3. Results

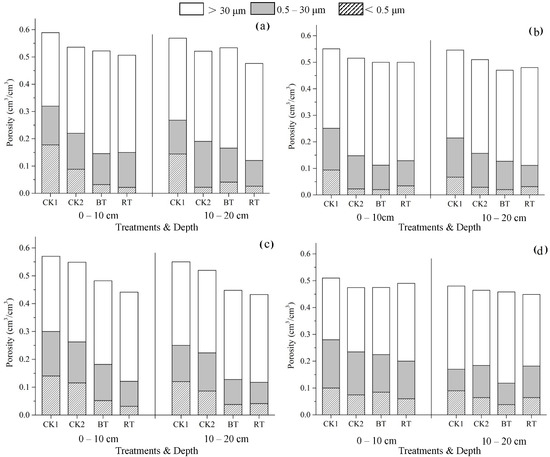

3.1. Soil Porosity

Soil porosity is an important part of soil structure. Differences in soil porosities and pore distributions affect the water storage and infiltration of the soil. The total porosity and pore distribution characteristics of soil under different tillage modes are shown in Figure 5. During the flowering period of rape, the total porosity in the 0–10 cm soil layer was ranked as CK1 > CK2 > BT > RT, and the total porosity in the 10–20 cm soil layer was ranked as CK1 > BT > CK2 > RT. At the maturity stage of rape, the order of total porosity in the 0–10 cm soil layer was CK1 > CK2 > BT = RT, and that in the 10–20 cm soil layer was CK1 > CK2 > RT > BT. At the heading stage of rice, the order of total porosity in the 0–10 cm soil layer was CK1 > CK2 > BT > RT, and that in the 10–20 cm soil layer was CK1 > CK2 > BT > RT. At the maturity stage of rice, the order of total porosity in the 0–10 cm soil layer was CK1 > RT > CK2 = BT, and that in the 10–20 cm soil layer was CK1 > CK2 > BT > RT. Furthermore, we found that the porosity of >30 μm from CK1 to RT showed a decreasing trend, while the porosity of <0.5 μm showed an increasing trend. At the flowering stage of rape, the <0.5 μm pores ranged from 26.92% to 37.66%. At the maturity stage of rape, the <0.5 μm pores ranged from 29.91% to 38.80%. At the heading stage of rice, <0.5 μm pores ranged from 27.00% to 32.00%. At the maturity stage of rice, <0.5 μm pores ranged from 23.00% to 34.00%.

Figure 5.

Soil total porosity and pore distribution at (a) flowering stage, (b) maturity stage of rape, (c) heading stage, and (d) maturity stage of rice under different tillage modes.

3.2. Aggregate Stability

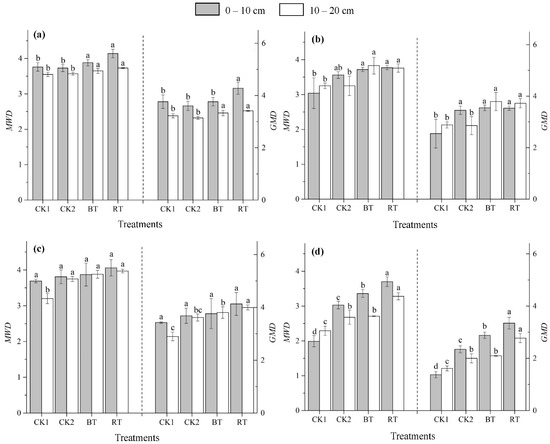

As shown in Figure 6, at the flowering stage of rape, the MWDs of the 0–10 cm and 10–20 cm soil layers in the BT and RT treatments were considerably greater than those in the CK1 and CK2 treatments; the GMD of the RT treatment in the 0–10 cm soil layer was markedly higher than that of the CK1, CK2, and RT treatments, while the GMDs of the BT and RT treatments in the 10–20 cm soil layer were considerably higher than those of the CK1 and CK2 treatments. At the maturity stage of rape, the MWDs of the 0–10 cm soil layer in the BT and RT treatments were considerably higher than those in the CK1 treatment, and the MWDs of the 10–20 cm soil layer of the BT and RT treatments were considerably higher than those of the CK1 and CK2 treatments. The GMDs of the 0–10 cm and 10–20 cm soil layers in the BT and RT treatments were markedly higher than those in the CK1 and CK2 treatments. At the heading stage of rice, the MWDs of the 10–20 cm soil layer in the CK2, BT, and RT treatments were considerably higher than those in the CK1 treatment; the GMD of the 10–20 cm soil layer treated with RT was markedly higher than that treated with CK1, CK2, and BT. At the maturity stage of rice, the MWD and GMD of the 0–10 cm soil layer were considerably different among all treatments; the MWD and GMD of the 10–20 cm soil layer treated with CK2, BT, and RT were considerably higher than those treated with CK1. Therefore, the rice-rape mechanized ridge tillage model can markedly increase the water stability of the topsoil aggregates.

Figure 6.

The MWD and GMD at the (a) flowering stage, (b) maturity stage of rape, (c) heading stage, and (d) maturity stage of rice under different tillage modes. Different lowercase letters in the same line represent significant differences between treatments (p < 0.05).

3.3. Aggregation of Soil Particles

Soil micro-aggregates can show the potential ability of soil structural characteristics, and the degree of aggregation is used to measure the number of micro-aggregates formed by mechanical soil particles in the soil. The degree of soil particle aggregation under different tillage modes is shown in Table 2. At the flowering stage of rape, the degree of soil aggregation in the 0–10 cm soil layer under the BT and RT treatments was considerably higher than that under CK1 and CK2, while the difference in the soil aggregation degree in the 10–20 cm soil layers among all the treatments was not considerable. At the maturity stage of rape, there was no considerable variation in the degree of soil aggregation in the 0–10 cm soil layers among all the treatments, while the degree of soil aggregation in the 10–20 cm soil layer under the BT and RT treatments was markedly higher than that of the same layer under CK1 and CK2. At the heading stage of rice, the soil aggregation degree of the 0–10 cm soil layer under the RT treatment was markedly higher than that under the CK1, CK2, and BT treatments. However, there was no considerable difference in the soil aggregation degree of the 10–20 cm soil layer among all the treatments. At the maturity stage of rice, the soil aggregation degrees of the 0–10 cm and 10–20 cm soil layers treated with CK2, BT, and RT were considerably higher than those of the same layers treated with CK1. The soil aggregation degree under the RT treatment was not considerably higher than that under the CK treatment in different periods of rape and rice planting. The degree of soil aggregation under the RT treatment was higher than that under the CK treatment. For instance, at the flowering stage of rape, the soil aggregation degree of the 10–20 cm soil layer treated with RT was 25.83% and 22.04% higher than that of the soil layer treated with CK1 and CK2, respectively. In conclusion, compared with conventional flat cropping, mechanized ridge tillage is more likely to promote the aggregation of soil particles, especially in the rice season.

Table 2.

Soil particle aggregation of rape and rice under different tillage modes.

4. Discussion

4.1. Effect of Mechanized Ridge Tillage of Rice-Rape on Soil Porosity

Based on their diameter, pores can be divided into small, medium, and large pores. Pore diameters < 0.5 μm represent small pores (i.e., residual and bound pores), which usually inhibit some microbial activities and activation reactions, but also maintain and transport water and nutrients in soil. Pore diameters between 0.5 and 30 μm represent mesopores (i.e., storage pores), which are generally suitable for the development of crop roots and the preservation of the effective water required for root growth. Pore diameters > 30 μm represent macropores (i.e., exchange pores), which are conducive to the exchange of air between the atmosphere and the soil, ventilate the soil, and facilitate the infiltration of water and rapid drainage [26,28]. Comparative analysis of the soil pore characteristics of different treatments showed that the CK1 treatment had the highest macropores of the four treatments. The percentage of the > 30 μm macropores was the highest among different periods of crop growth and different soil layers, with an average of 11.66%, indicating that long-term flooding and soaking lead to soil loss. Excessive > 30 μm pore content is not conducive to the normal growth of crops, accounting for about 10%–17%, which is optimal for the growth and development of crops [8]. Many studies have shown that different tillage methods have substantial effects on soil pore characteristics. Tillage measures are one of the important factors affecting soil macropores [29]. Different tillage methods mainly affect the distribution of soil pores in terms of the size, mode, frequency, and other aspects of the pressure exerted on the soil [30,31]. Traditional tillage technology and protective no-tillage also cause fundamental changes in the total porosity and pore distribution of soil [32,33]. Some studies have shown that the soil porosity under rotary tillage and subsoiling treatment is more than that under no tillage, and the porosity will decrease with the increasing soil depth [34]. However, other studies have shown that no-tillage can only reduce the porosity of the 0–20 cm soil layer, and has no significant impact on the 20–50 cm soil layer [35]. In this study, 81.25% of the treated soil porosity showed that the 0–10 cm soil layer was higher than the 10–20 cm soil layer, indicating that the total soil porosity under mechanized ridge planting decreased with increasing depth.

4.2. Effect of Mechanized Ridge Tillage of Rice-Rape on Soil Aggregates

Compared with the soil treated using flat cropping, the soil treated using mechanized ridge tillage of rice and rape had more reasonable aggregate distribution and higher stability. The MWD and GMD [34] are generally used to evaluate the stability of the soil aggregates; greater MWD and GMD values indicate better aggregate stability [39]. According to the MWD and GMD of different tillage treatments in the rape and rice seasons, it was found that the stability of the water stable aggregates in the RT treatment was higher than that in the CK1, CK2, and BT treatments, and this trend was more obvious during the transition from rape season to rice season. Therefore, we concluded that the stable state of the soil aggregates was in the following order: narrow ridge > wide ridge > flat cultivation. This may be related to the different soil and water environments under different tillage methods. In long-term flooded soil, soil particles usually exist in a dispersed state, thus reducing the stability of the soil aggregates. However, ridge planting can reduce the intensity of water dispersion on soil particles, especially in narrow ridges. Micro-aggregates increase particle size through mutual aggregation, which is pertinent for the formation of larger aggregates. The quantitative relationship between the mechanical composition and the micro-aggregates in the soil is called the aggregation degree, which is an indicator of the aggregation ability of the micro-aggregates in the soil. A large value indicates a strong aggregation ability, the formation of large aggregates, and a stable soil structure. Wei Chaofu et al. [24] found that soil treated by ridge planting has a higher degree of agglomeration than that treated by flat planting, with a considerable surge in the agglomeration degree of mechanical soil particles < 0.001 mm. Our results suggest that under different tillage methods—with the development of rape and rice growing periods from dry land to paddy field—the differences between the soil particle agglomeration degrees of the two ridge planting treatments and the other treatments are becoming increasingly more obvious, indicating that the soil mechanical particles are continuously agglomerated into micro-aggregates under the action of the meniscus force of the saturated capillary water, and the degree of agglomeration of the ridge planting soil is better than that of the year-round flooded soil. The degree of aggregation between different soil layers under the same tillage method is not regulated by a certain rule, so the aggregation of micro-aggregates is less affected by the soil depth. What’s more, soil microorganisms play an important role in the formation and stabilization of soil aggregates. Microbial biomass carbon, as active organic carbon, participates in the transformation of aggregates. Metabolites and enzymes released by microbial metabolic activities can affect the soil’s organic matter and the soil aggregation process. At the same time, the dynamic changes of soil aggregates in turn affect the growth and activities of soil microorganisms [40,41]. Therefore, the distribution of microbial communities of soil aggregates under ridge tillage should be studied further.

5. Conclusions

The comparison of soil structures (i.e., aggregate and pore characteristics) under different tillage methods revealed that, compared with flat cropping, ridge tillage has the following advantages: it significantly improves the water stability of aggregates in the 0–20 cm soil layer, increases the stability of the soil structure, reduces the total porosity of the soil, and makes the pore distribution more suitable for crop root growth. Generally, mechanized ridge tillage can improve soil structure and stability in various ways. Therefore, ridge tillage is prioritized in the mechanized agricultural production practice.

Author Contributions

Conceptualization, C.W. and S.Z.; methodology, L.L., C.W. and S.Z.; investigation, L.L., J.L., C.Y. and S.Z.; data curation, L.L. and S.Z.; writing—original draft preparation, L.L.; writing—review and editing, C.Y., C.W. and S.Z.; project administration, C.W. and S.Z.; funding acquisition, C.W., C.Y. and S.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by [Chaofu Wei] the National Nature Science Foundation of China [grant number 42077007] and [Chaoxian Yang] [grant number 42171257], [Shouqin Zhong] the Fundamental Research Funds for the Central Universities [grant number SWU120065] and the General Project of Chongqing Natural Science Foundation [grant number CSTB2022NSCQ-MSX0446].

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors thank the National Monitoring Station of Soil Fertility and Fertilizer Efficiency on Purple Soils, Southwest Key Laboratory of Cultivated Land Conservation of the Ministry of Agriculture and Rural Areas for providing the analysis and testing platform.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Woodhead, T.; Zhang, J.B. Problemsand Countermeasures of soil physical management in rice farming system. Adv. Pedol. 1992, 20, 19–21. [Google Scholar]

- Qin, C. Study on the Mechanism of Improving Soil Nitrogen Fertility by Combination Ridge with No-Tillage in Paddy Field; Southwest University: Chongqing, China, 2021. [Google Scholar]

- Zhang, J.; Li, F.Q.; Liao, P.Z.; Khan, A.; Hussain, I.; Iqbal, A.; Ali, I.; Wei, B.H.; Jiang, L.G. Smash ridge tillage strongly influence soil functionality, Physiology and Rice Yield. Saudi. J. Biol. Sci. 2021, 28, 1297–1307. [Google Scholar] [CrossRef] [PubMed]

- Guo, H.J.; Fu, Z.Q.; Li, C.; He, B.L.; Yan, L.L.; Xu, Y.; Long, P. Research progress on the application of ridge rice field in ecological cultivation. Chin. J. Ecol. 2020, 39, 2416–2425. [Google Scholar] [CrossRef]

- Xie, D.T.; Wei, C.F.; Huang, Z.X.; Lang, J.W. Study on natural no tillage technology in paddy field. Tillage Cultiv. 1986, 6, 1–5. [Google Scholar]

- Li, C.F.; Cao, C.G.; Wang, J.P.; Zhan, M.; Yuan, W.L.; Ahmad, S. Nitrous Oxide Emissions from Wetland Rice-Duck Cultivation Systems in Southern China. Arch. Environ. Contam. Toxicol. 2008, 56, 21–29. [Google Scholar] [CrossRef]

- Yu, J.W.; Huang, W.; Li, Y.C.; Wang, N.; Zhang, X.S. Effects of ecological comprehensive planting and breeding patterns on soil physical and chemical properties and humus in paddy fields. J. Biol. 2020, 37, 81–85. [Google Scholar] [CrossRef]

- Xie, D.T.; Chen, Z.L. Theory and Technology of Paddy Field under Soil Virginization; Chongqing Publishing House: Chongqing, China, 2002. [Google Scholar]

- Peng, X.; Horn, R.; Hallett, P. Soil structure and its functions in ecosystems: Phase matter &scale matter. Soil Till. Res. 2015, 146, 1–3. [Google Scholar] [CrossRef]

- Weil, R.R.; Brady, N.C. The Nature and Properties of Soils, 15th ed.; Pearson: London, UK, 2016. [Google Scholar]

- Rabot, E.; Wiesmeier, M.; Schlueter, S.; Vogel, H.J. Soil structure as an indicator of soil functions: A review. Geoderma 2018, 314, 122–137. [Google Scholar] [CrossRef]

- Wang, T.C.; Wang, Y.; Wei, L.; Wang, J.Z.; Nie, S.W.; Liu, S.W. Research Progress on Crop Raised-bed Planting in China. J. Henan Agric. Univ. 2005, 39, 377–382. [Google Scholar] [CrossRef]

- Li, J.W.; Han, Z.; Zhong, S.Q.; Gao, P.F.; Wei, C.F. Pore size distribution and pore functional characteristics of soils as affected by rock fragments in the hilly regions of the Sichuan Basin, China. Can. J. Soil Sci. 2020, 101, 74–83. [Google Scholar] [CrossRef]

- Shao, M.A.; Wang, Q.J.; Huang, M.B. Soil Physics; Higher Education Press: Beijing, China, 2006. [Google Scholar]

- Zhang, Y.; Jiang, D.H.; Huang, J.L.; Wang, M.S.; Deng, H.W. Effect of deep vertically rotary tillage on particle size distribution and stability of latosolic red soil aggregates. Chin. J. Ecol. 2021, 40, 3922–3932. [Google Scholar] [CrossRef]

- Tang, Z.W.; Zhou, W.T.; Wang, B.R.; Zhong, Y.Y.; Xiong, R.; Long, P.; Xu, Y.; Fu, Z.Q. Effects of ridge-bed cultivation on rice root characteristics and soil physical properties. Chin. J. Ecol. 2021, 40, 3961–3969. [Google Scholar] [CrossRef]

- Xie, Z.Q.; Xu, J.L.; Zhu, Z.L.; An, S. Application of ultrasonic energy for assessing aggregate stability. Res. Soil Water Conserv. 2016, 23, 19–22. [Google Scholar] [CrossRef]

- Ran, Z.L.; Zhong, S.Q.; Liu, B.; Wei, C.F. Particle Characteristics of purple shale soil and their mechanism of shear strength. Soils 2019, 51, 127–134. [Google Scholar] [CrossRef]

- Liu, W.J.; Xu, W.N.; Xia, L.; Chen, J.G.; Cheng, H.; Yu, F.; Xia, D.; Liu, D.X.; Yu, S.P. Effects of Land Use Patterns on Soil Aggregate Stability in Small Watershed of Yangtze River, Located in Western Hubei. Resour. Environ. Yangtze Basin 2020, 30, 925–935. [Google Scholar] [CrossRef]

- Luo, N. Difference of Physical Properties of Soil Profiles under Different Vegetations in Karst Mountainous Area; Guizhou University: Guiyang, China, 2020. [Google Scholar]

- Dane, J.H.; Topp, C.G. Methods of Soil Analysis Part 4: Physical Methods; Soil Science Society of America Book Series No.5 Soil; Science Society of America: Madison, WI, USA, 2002. [Google Scholar]

- Zhong, S.Q.; Liu, B.; Wei, C.F.; Hu, F.N. The Rock Fragments (<2 mm) and Their Action Mechanism on the Shear Strength of Purple Mudstone-Developed Soils. Sci. Agric. Sin. 2015, 48, 4846–4858. [Google Scholar] [CrossRef]

- Han, Z. Rill Erosion Process and Mechanics Mechanism of Partially Saturated Soil; Southwest University: Chongqing, China, 2020. [Google Scholar]

- Zhang, G.L.; Gong, Z.T. Soil Investigation Laboratory Analysis Method; Science Press: Beijing, China, 2012. [Google Scholar]

- Wei, C.F. The influence of capillary infiltration on soil aggregate. J. Southwest Agric. Univ. 1987, S2, 136–140. [Google Scholar]

- Kay, B.D.; Vandenbygaart, A.J. Conservation tillage and depth stratification of porosity and soil organic matter. Soil Till. Res. 2002, 66, 107–118. [Google Scholar] [CrossRef]

- Zaffar, M.; Lu, S.G. Pore Size Distribution of Clayey Soils and Its Correlation with Soil Organic Matter. Pedosphere 2015, 25, 240–249. [Google Scholar] [CrossRef]

- Chen, X.W.; Zhang, X.P.; Liang, Z.A.; Jia, S.X.; Shi, X.H.; Fan, R.Q.; Wei, S.C. Tillage effects on soil pore size distribution and soil moisture in Northeast China. J. Arid Land Resour. Environ. 2012, 26, 114–120. [Google Scholar] [CrossRef]

- Luo, L.F.; Henry, L.; Li, S.C. Quantification of 3-D soil macropore networks in different soil types and land uses using computed tomography. J. Hydrol. 2010, 393, 53–64. [Google Scholar] [CrossRef]

- Thomasson, A.J. Towards an objective classification of soil structure. J. Soil. Sci. 1978, 29, 38–46. [Google Scholar] [CrossRef]

- Wang, Q.J.; Liu, F.; Jiao, F.; Chang, B.C.; Jiang, H.; Gong, X.J. Effects of strip-collected chopping and mechanical deep-buried return of straw on physical properties of soil. Trans. Chin. Soc. Agric. Eng. 2019, 35, 43–49. [Google Scholar] [CrossRef]

- Imhoff, S.; Ghiberto, P.J.; Grioni, A.; Gay, J.P. Porosity characterization of Argiudolls under different management systems in the Argentine Flat Pampa. Geoderma 2010, 158, 268–274. [Google Scholar] [CrossRef]

- Edwards, W.M.; Shipitalo, M.J.; Traina, S.J.; Edwards, C.A.; Owens, L.B. Role of lumbricus terrestris (L.) burrows on quality of infiltrating water. Soil Boil. Biochem. 2006, 24, 1555–1561. [Google Scholar] [CrossRef]

- Zhang, L.N.; Evans, A.; Zhang, L.Y.; Tian, K.; Yang, D.T.; Li, J.H. Effects of Tillage Methods on the physical characteristics of red soil of upland. Res. Soil Water Conserv. 2018, 25, 46–50. [Google Scholar] [CrossRef]

- Zou, W.X.; Han, X.Z.; Yan, J.; Chen, X.; Lu, X.C.; Qiu, C.; Hao, X.X. Effects of incorporation depth of tillage and straw returning on soil physical properties of black soil in Northeast China. Trans. Chin. Soc. Agric. Eng. 2020, 36, 9–18. [Google Scholar] [CrossRef]

- Zhou, H.; Lv, Y.Z.; Yang, Z.C.; Li, B.G. Effects of Conservation Tillage on Soil Aggregates in Huabei Plain, China. Sci. Agric. Sin. 2007, 40, 1973–1979. [Google Scholar]

- Ma, R.; Yang, S.; Qin, X.; Zheng, Z.C.; Li, T.X. Effects of Different Tillage Measures and Maize Growing Seasons on Soil Aggregates’ Stability in Sloping Yellow Soil Cropland. J. Yangtze River Sci. Res. Inst. 2020, 37, 46–58. [Google Scholar] [CrossRef]

- Yan, T.Y. Variation Characteristics of Soil Aggregates and Aggregate Carbon in Orchards Covered with Living Mulching; Northwest A&F University: Xianyang, China, 2019. [Google Scholar]

- Chen, E.F.; Guan, L.Z.; Wang, J.K.; Yan, L.; Wang, T.Y.; Zhang, J.H.; Zhou, J.K.; Li, R.H. Composition proportion and fertility evaluation of soil characteristic micro aggregates. Acta Pedol. Sin. 2001, 38, 49–53. [Google Scholar] [CrossRef]

- Shen, X.L.; Wang, L.L.; Zhao, J.N.; Li, G.; Xiu, W.M.; Yang, Q.C.; Zhang, G.L. Effects of tillage managements on soil microbial community structure in soil aggregates of fluvo-aquic soil. Chin. J. Appl. Ecol. 2021, 32, 2713–2721. [Google Scholar] [CrossRef]

- Wang, S.L.; Liu, Y.H.; Song, X.L.; Wei, S.B.; Li, J.P.; Nie, J.J.; Qin, D.L.; Sun, X.Z. Effects of cotton straw returning on soil organic carbon, nitrogen, phosphorus and potassium contents in soil aggregates. Chin. J. Appl. Ecol. 2016, 27, 3944–3952. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).