Sorghum-Based Power Generation in Southern Ukraine: Energy and Environmental Assessment

Abstract

:1. Introduction

- To find the carbon dioxide emission factor, embodied energy, and production costs of sorghum silage based on a field experiment;

- To compare sorghum to other biomass-based and fossil fuels (coal and natural gas);

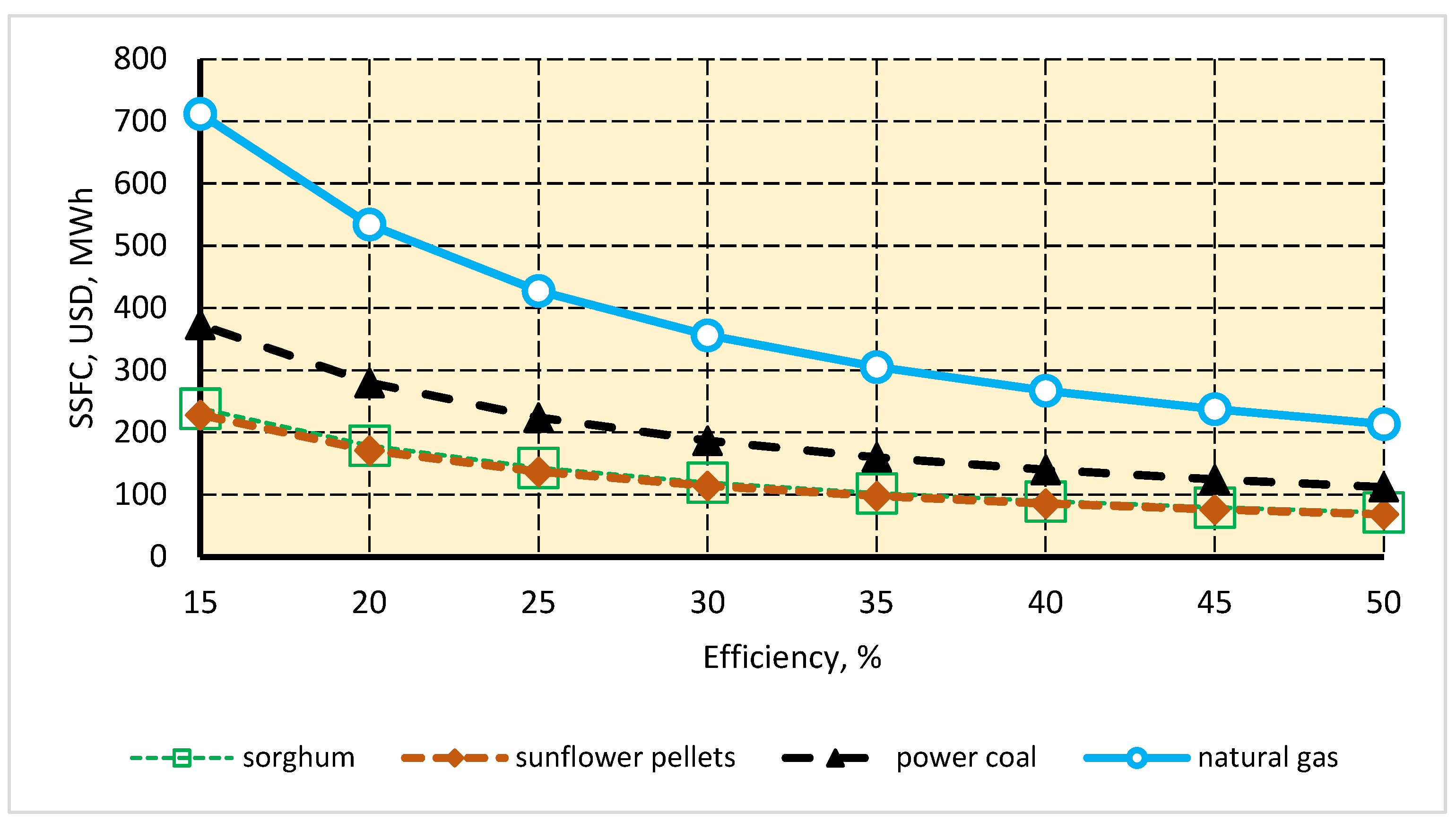

- To determine the energy-specific cost for different power generation technologies;

- To evaluate the carbon dioxide savings.

2. Materials and Methods

2.1. Crop Properties

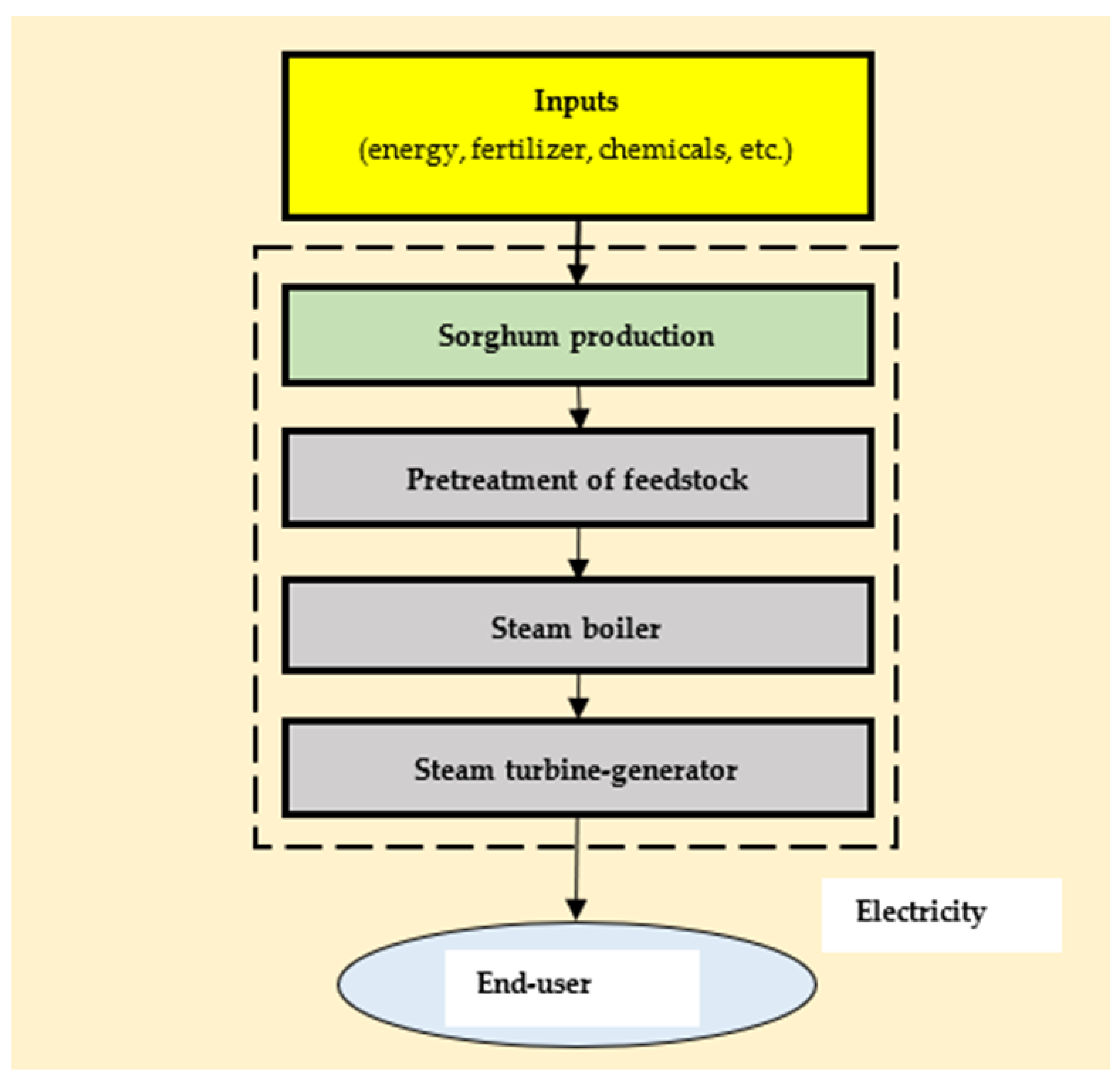

2.2. System Boundary

2.3. Energy Indicators

2.4. Environmental Indicators

2.5. Energy, Environmental and Economic Indicators of Sorghum Silage Production

3. Results and Discussion

3.1. Embodied Energy and Well-to-Tank Carbon Dioxide Emissions of Feedstock

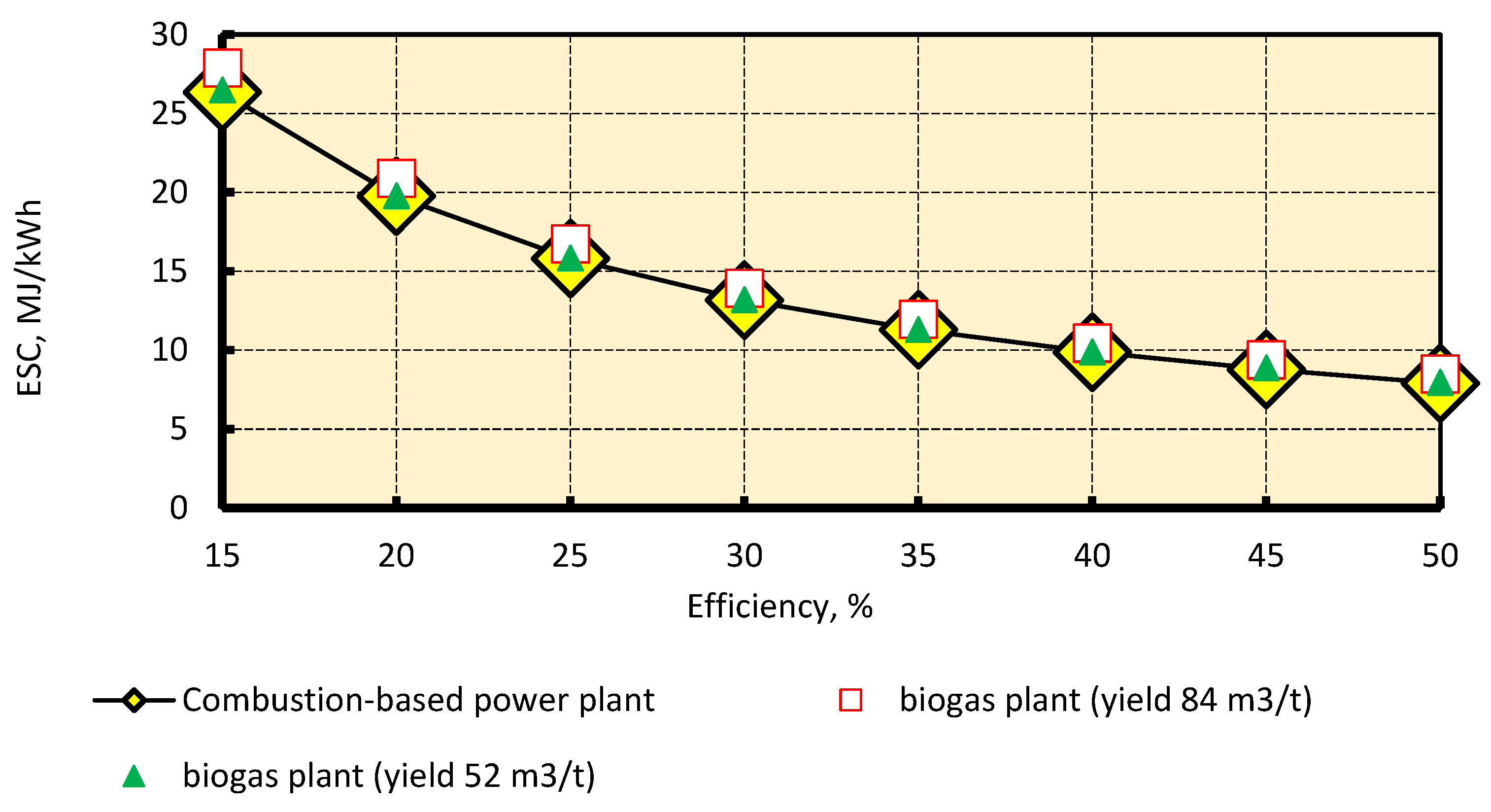

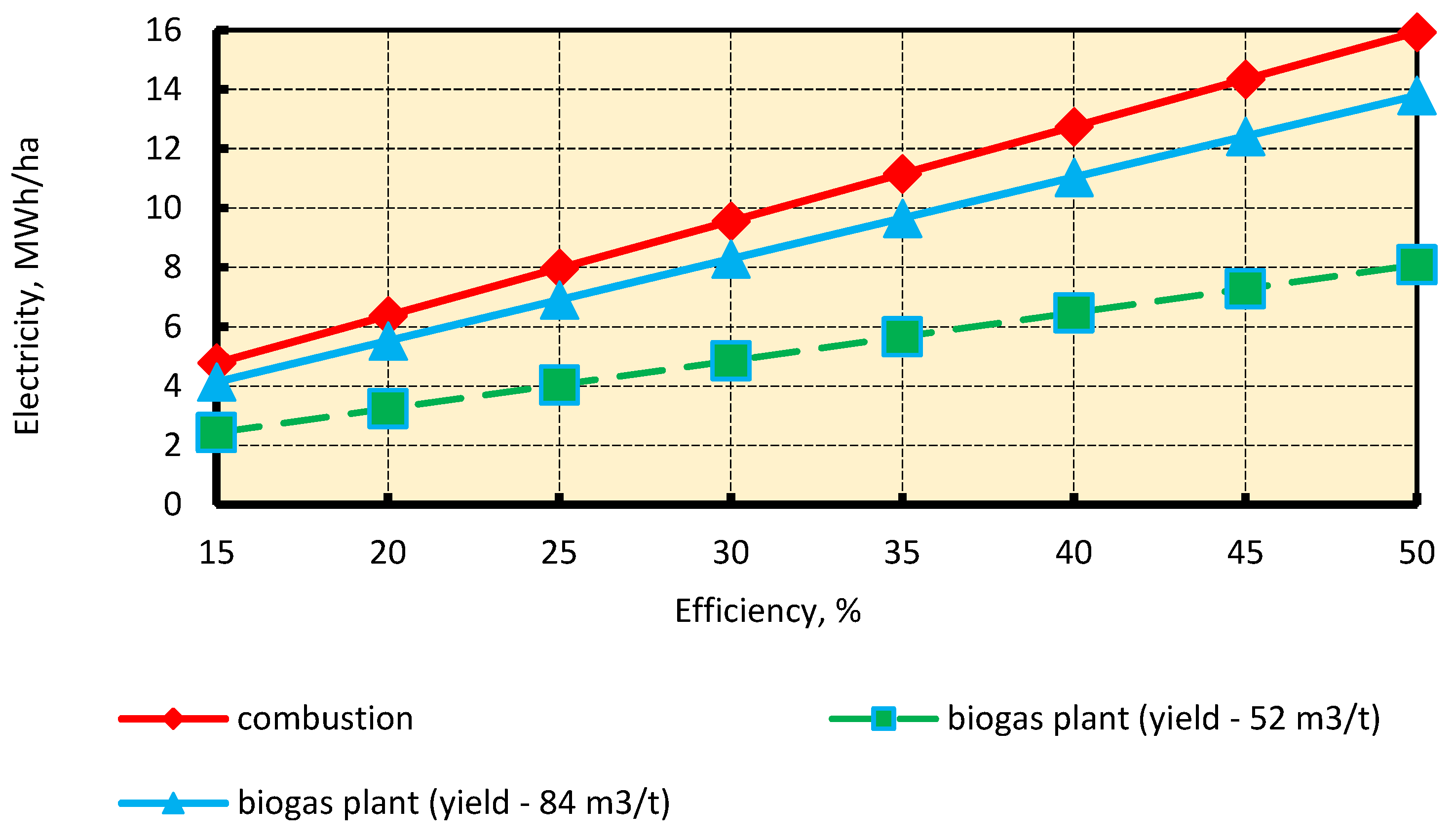

3.2. Energy Indicators

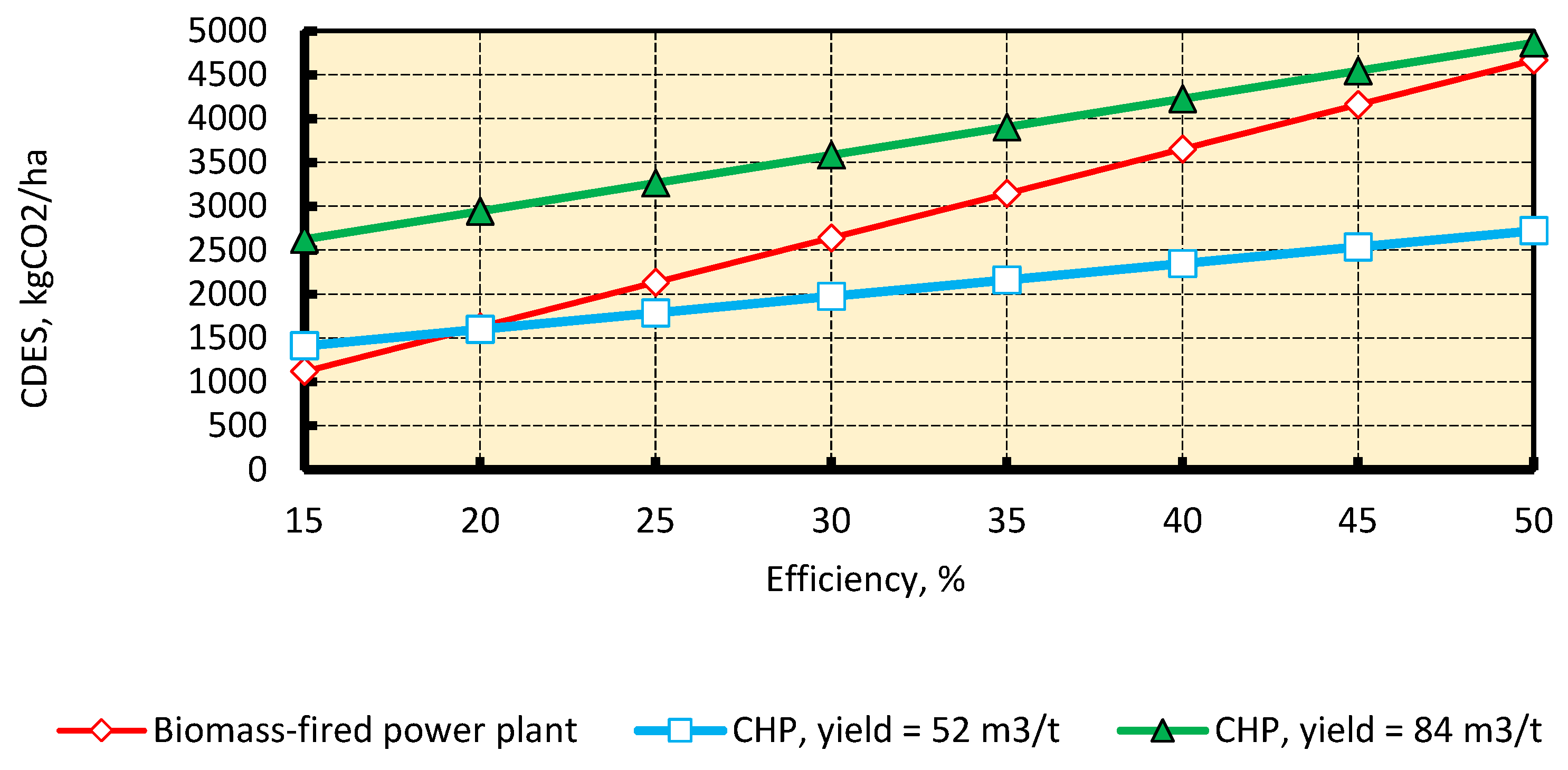

3.3. Carbon Dioxide Emissions Savings

3.4. Economic Efficiency

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Statistical Review of World Energy. 2021. Available online: https://www.bp.com/content/dam/bp/business-sites/en/global/corporate/pdfs/energy-economics/statistical-review/bp-stats-review-2021-full-report.pdf (accessed on 18 October 2022).

- Renewable Energy Statistics 2022. IRENA. Available online: https://www.irena.org/publications/2022/Jul/Renewable-Energy-Statistics-2022 (accessed on 18 October 2022).

- Renewable Capacity Statistics 2022. IRENA. Available online: https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2022/Apr/IRENA_RE_Capacity_Statistics_2022.pdf (accessed on 18 October 2022).

- Renewable Power Generation Costs in 2021. IRENA. Available online: https://irena.org/publications/2022/Jul/Renewable-Power-Generation-Costs-in-2021 (accessed on 18 October 2022).

- Wholesale Prices of Electricity in Poland from 2018 to 2022 (in Zloty/MWh). Available online: https://www.statista.com/statistics/1066654/poland-wholesale-electricity-prices/ (accessed on 20 October 2022).

- Polish Zloty to Euro Spot Exchange Rates for 2021. Available online: https://www.exchangerates.org.uk/PLN-EUR-spotexchange-rates-history-2021.html (accessed on 20 October 2022).

- Average Monthly Electricity Wholesale Prices in Selected Countries in the European Union (EU) from January 2020 to January 2022. Available online: https://www.statista.com/statistics/1267500/eu-monthly-wholesale-electricity-price-country/ (accessed on 15 October 2022).

- Purchase Prices on the Day-Ahead Market for Group b Consumers in 2021. Available online: https://tek.energy/electricity/prices (accessed on 20 October 2022).

- Electricity Prices for Non-Household Consumers. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Electricity_price_statistics#Electricity_prices_for_non-household_consumers (accessed on 20 October 2022).

- Hosseini, S.E. Transition Away from Fossil Fuels toward Renewables: Lessons from Russia-Ukraine Crisis. Future Energy 2022, 1, 2–5. Available online: https://fupubco.com/fuen/article/view/8 (accessed on 30 October 2022). [CrossRef]

- Scientific American: Science News, Expert Analysis, Health Research—Scientific American. Available online: https://www.scientificamerican.com/ (accessed on 30 October 2022).

- Renewable Energy and Jobs. Annual Review 2022. Available online: https://www.irena.org/publications/2022/Sep/Renewable-Energy-and-Jobs-Annual-Review-2022 (accessed on 30 October 2022).

- Energy Profile of Ukraine. IRENA. 2021. Available online: https://www.irena.org/IRENADocuments/Statistical_Profiles/Europe/Ukraine_Europe_RE_SP.pdf (accessed on 20 October 2022).

- Zachmann, G. Reaching Ukraine’s Energy and Climate Targets. Berlin Economics. Available online: https://www.lowcarbonukraine.com/wp-content/uploads/LCU_Reaching-Ukraines-energy-and-climate-targets.pdf (accessed on 20 October 2022).

- Shlapak, M. Carbon Emission Factor for Ukrainian Electricity Grid. 2017. Available online: https://www.linkedin.com/pulse/carbon-emission-factor-ukrainian-electricity-grid-mykola-shlapak/?articleId=6324279390976962560 (accessed on 20 October 2022).

- Warner, E.S.; Heath, G.A. Life Cycle Greenhouse Gas Emissions of Nuclear Electricity Generation. J. Ind. Ecol. 2012, 16 (Suppl. 1), 73–92. [Google Scholar] [CrossRef]

- Kadiyala, A.; Kommalapati, R.; Huque, Z. Evaluation of the Life Cycle Greenhouse Gas Emissions from Hydroelectricity Generation Systems. Sustainability 2016, 8, 539. [Google Scholar] [CrossRef] [Green Version]

- Comparison of Lifecycle Greenhouse Gas Emissions of Various Electricity Generation Sources. World Nuclear Association Report. July 2011. Available online: http://www.world-nuclear.org/uploadedFiles/org/WNA/Publications/Working_Group_Reports/comparison_of_lifecycle.pdf (accessed on 18 October 2022).

- In 2020, the Installed Capacity of WPPs and SPPs Increased by 41% and Their Share in the Generation Mix Doubled. Ukrenergo. Available online: https://ua.energy/general-news/in-2020-the-installed-capacity-of-wpps-and-spps-increased-by-41-and-their-share-in-the-generation-mix-doubled/ (accessed on 18 October 2022).

- Havrysh, V.; Kalinichenko, A.; Szafranek, E.; Hruban, V. Agricultural Land: Crop Production or Photovoltaic Power Plants. Sustainability 2022, 14, 5099. [Google Scholar] [CrossRef]

- Moro, A.; Lonza, L. Electricity carbon intensity in European Member States: Impacts on GHG emissions of electric vehicles. Transp. Res. Part D 2018, 64, 5–14. [Google Scholar] [CrossRef]

- Bórawski, P.; Bełdycka-Bórawska, A.; Szymańska, E.J.; Jankowski, K.J.; Dubis, B.; Dunn, J.W. Development of renewable energy sources market and biofuels in the European Union. J. Clean. Prod. 2019, 228, 467–484. [Google Scholar] [CrossRef]

- Marks-Bielska, R.; Bielski, S.; Novikova, A.; Romaneckas, K. Straw Stocks as a Source of Renewable Energy. A Case Study of a District in Poland. Sustainability 2019, 11, 4714. [Google Scholar] [CrossRef] [Green Version]

- Stolarski, M.J.; Śnieg, M.; Krzyżaniak, M.; Tworkowski, J. Short rotation coppices, grasses and other herbaceous crops: Productivity and yield energy value versus 26 genotypes. Biomass Bioenergy 2018, 119, 109–120. [Google Scholar] [CrossRef]

- Kołodziej, B.; Antonkiewicz, J.; Stachyra, M.; Bielińska, E.J.; Wiśniewski, J.; Luchowska, K.; Kwiatkowski, C. Use of sewage sludge in bioenergy production—A case study on the effects on sorghum biomass production. Eur. J. Agron. 2015, 69, 63–74. [Google Scholar] [CrossRef]

- Dar, R.A.; Dar, E.A.; Kaur, A.; Phutela, U.G. Sweet sorghum-a promising alternative feedstock for biofuel production. Renew. Sustain. Energy Rev. 2018, 82, 4070–4090. [Google Scholar] [CrossRef]

- Cattani, M.; Sartori, A.; Bondesan, V.; Bailoni, L. In vitro degradability, gas production, and energy value of different hybrids of sorghum after storage in mini-silos. Ann. Anim. Sci. 2016, 16, 769–777. [Google Scholar] [CrossRef] [Green Version]

- Ostovareh, S.; Karim, K.; Zamani, A. Efficient conversion of sweet sorghum stalks to biogas and ethanol using organosolv pretreatment. Ind. Crops Prod. 2014, 66, 170–177. [Google Scholar] [CrossRef]

- Maximising the Yield of Biomass from Residue of Agricultural Crops and Biomass from Forestry. Final Report, Project Number: BIENL15082. Ecofys 2016. Available online: https://ec.europa.eu/energy/sites/ener/files/documents/Ecofys%20-%20Final_%20report_%20EC_max%20yield%20biomass%20residue%2020151214.pdf (accessed on 17 November 2022).

- Zhang, Z.; Zhao, W.; Zhao, W. Commercialization Development of Crop Straw Gasification Technologies in China. Sustainability 2014, 6, 9159–9178. [Google Scholar] [CrossRef] [Green Version]

- Perkins, G.; Bhaskar, T.; Konarova, M. Process development status of fast pyrolysis technologies for the manufacture of renewable transport fuels from biomass. Renew. Sustain. Energy Rev. 2018, 90, 292–315. [Google Scholar] [CrossRef]

- Ataei, A.; Azimi, A.; Kalhori, S.B.; Abari, M.F.; Radnezhad, H. Performance analysis of a co-gasifier for organic waste in agriculture. Int. J. Recycl. Org. Waste Agric. 2012, 1, 6. [Google Scholar] [CrossRef] [Green Version]

- Obernberger, I.; Thek, G. Cost assessment of selected decentralized CHP applications based on biomass combustion and biomass gasification. In Proceedings of the 16th European Biomass Conference Exhibition, Valencia, Spain, 2–6 June 2008; Valencia, ETA-Renewable Energies: Florence, Italy, 2008. Available online: https://bios-bioenergy.at/uploads/media/Paper-Obernberger-Cost-assessment-CHP-BM-comustiongasification-2008-05-30.pdf (accessed on 17 November 2022).

- Benato, A.; Macor, A. Biogas Engine Waste Heat Recovery Using Organic Rankine Cycle. Energies 2017, 10, 327. [Google Scholar] [CrossRef]

- Dolz, V.; Novella, R.; García, A.; Sánchez, J. HD Diesel engine equipped with a bottoming Rankine cycle as a waste heat recovery system. Part 1: Study and analysis of the waste heat energy. Appl. Therm. Eng. 2012, 36, 269–278. [Google Scholar] [CrossRef] [Green Version]

- State Statistics Service of Ukraine. Agriculture of Ukraine. Statistical Yearbook 2019; State Statistics Service of Ukraine: Kyiv, Ukraine, 2020. Available online: http://www.ukrstat.gov.ua/druk/publicat/kat_u/2020/zb/09/zb_sg_Ukr_2019.pdf (accessed on 17 November 2022).

- Ukraine Sorghum Production by Year. Available online: https://www.indexmundi.com/agriculture/?country=ua&commodity=sorghum&graph=production (accessed on 17 November 2022).

- Yu, J.; Zhang, T.; Zhong, J.; Zhang, X.; Tan, T. Biorefinery of sweet sorghum stem. Biotechnol. Adv. 2012, 30, 811–816. [Google Scholar] [CrossRef]

- Krzystek, L.; Wajszczuk, K.; Pazera, A.; Matyka, M.; Slezak, R.; Ledakowicz, S. The Influence of Plant Cultivation Conditions on Biogas Production: Energy Efficiency. Waste Biomass Valor 2022, 11, 513–523. [Google Scholar] [CrossRef] [Green Version]

- Matsakas, L.; Rova, U.; Christakopoulos, P. Evaluation of Dried Sweet Sorghum Stalks as Raw Material for Methane Production. BioMed Res. Int. 2014, 2014, 731731. [Google Scholar] [CrossRef]

- Salimbeni, A. Sweet sorghum biogas plant in temperate regions (Belgium)—Demonstration plant for biogas and high value biofertilizer production. In Proceedings of the 21st European Biomass Conference and Exhibition, Copenhagen, Denmark, 3–7 June 2013; Available online: http://www.eubia.org/cms/download/sweet-sorghum-biogas-plant-in-temperate-regions-belgium-demostration-plant-for-biogas-and-high-value-biofertilizer-production/ (accessed on 18 October 2022).

- Wiloso, E.; Setiawan, A.; Prasetia, H.; Wiloso, A.; Sudiana, I.; Lestari, R.; Nugroho, S.; Hermawan, D.; Fang, K.; Heijungs, R. Production of sorghum pellets for electricity generation in Indonesia: A life cycle assessment. Biofuel Res. J. 2020, 7, 1178–1194. [Google Scholar] [CrossRef]

- Ren, L.T.; Liu, Z.X.; Wei, T.W.; Xie, G.H. Evaluation of energy input and output of sweet sorghum grown as a bioenergy crop on coastal saline-alkali land. Energy 2012, 47, 166–173. [Google Scholar] [CrossRef]

- Jankowski, K.J.; Dubis, B.; Sokólski, M.M.; Załuski, D.; Bórawski, P.; Szempliński, W. Productivity and energy balance of maize and sorghum grown for biogas in a large-area farm in Poland: An 11-year field experiment. Ind. Crops Prod. 2020, 148, 112326. [Google Scholar] [CrossRef]

- Biboum, A.; Yılancı, A. Feasibility study of Biomass power plant fired with maize and sorghum stalk in the Sub-Saharan region: The case of the northern part of Cameroon. Eur. Mech. Sci. 2019, 3, 102–111. [Google Scholar] [CrossRef] [Green Version]

- Adapa, P.; Tabil, L.; Schoenau, G. Grinding performance and physical properties of non-treated and steam-exploded barley, canola, oat, and wheat straw. Biomass Bioenergy 2011, 35, 549–561. [Google Scholar] [CrossRef]

- Physico-Mechanical Properties of Corn. Available online: http://razvitie-pu.ru/?page_id=6629 (accessed on 12 September 2022).

- Mishra, A.; Kumar, A.; Ghosh, S. Energy assessment of second generation (2G) ethanol production from wheat straw in Indian scenario. 3 Biotech 2018, 8, 142. [Google Scholar] [CrossRef]

- Fix, J.; Tynan, S.; Kissinger, M. Carbon Footprint Analysis for Wood & Agricultural Residue Sources of Pulp. Final Report. 2011. Available online: https://www1.agric.gov.ab.ca/$Department/deptdocs.nsf/all/sag13757/$FILE/Final_Report_CFA.pdf (accessed on 14 October 2022).

- Havrysh, V.; Kalinichenko, A.; Mentel, G.; Olejarz, T. Commercial Biogas Plants: Lessons for Ukraine. Energies 2020, 13, 2668. [Google Scholar] [CrossRef]

- Biomass for Heat and Power Technology Brief. IEA-ETSAP and IRENA Technology Brief E05. 2015. Available online: https://biomasspower.gov.in/document/Reports/IRENA_Biomass%20for%20Heat%20and%20Power.pdf (accessed on 20 October 2022).

- Geletukha, G.; Drahniev, S.; Zheliezna, T.; Bashtovyi, A. Prospects of Sunflower Residues Use for Energy. Available online: https://uabio.org/wp-content/uploads/2020/10/uabio-position-paper-25-en-1.pdf (accessed on 20 October 2022).

- Havrysh, V.; Kalinichenko, A.; Brzozowska, A.; Stebila, J. Life Cycle Energy Consumption and Carbon Dioxide Emissions of Agricultural Residue Feedstock for Bioenergy. Appl. Sci. 2021, 11, 2009. [Google Scholar] [CrossRef]

- Goncharuk, A.G.; Havrysh, V.I.; Nitsenko, V.S. National features for alternative motor fuels market. Int. J. Energy Technol. Policy 2018, 14, 226–249. [Google Scholar] [CrossRef]

- Bazaluk, O.; Havrysh, V.; Fedorchuk, M.; Nitsenko, V. Energy Assessment of Sorghum Cultivation in Southern Ukraine. Agriculture 2021, 11, 695. [Google Scholar] [CrossRef]

- Herrmann, C.; Idler, C.; Heiermann, M. Biogas crops grown in energy crop rotations: Linking chemical composition and methane production characteristics. Bioresour. Technol 2016, 206, 23–35. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Battista, F.; Frison, N.; Bolzonella, D. Energy and Nutrients’ Recovery in Anaerobic Digestion of Agricultural Biomass: An Italian Perspective for Future Applications. Energies 2019, 12, 3287. [Google Scholar] [CrossRef] [Green Version]

- Sample Costs to Produce Sorghum Silage. University of California Cooperative Extension. 2016. Available online: https://coststudyfiles.ucdavis.edu/uploads/cs_public/c2/a9/c2a9d0ea-f089-48a9-a9b2-64ec58355b46/2016sorghumsilagesjvfinaldraftmar23.pdf (accessed on 14 October 2022).

- Pricing for 2022 Summer Texas Crops—Some at Record Highshs. Available online: https://agrilife.org/texasrowcrops/2022/05/06/pricing-for-2022-summer-texas-crops-some-at-record-highshs/#:~:text=Some%20preliminary%202022%20silage%20prices,%2465%2Fton%20for%20forage%20sorghum (accessed on 18 October 2022).

- Stanytsina, V.; Artemchuk, V.; Bogoslavska, O.; Zaporozhets, A.; Kalinichenko, A.; Stebila, J.; Havrysh, V.; Suszanowicz, D. Fossil Fuel and Biofuel Boilers in Ukraine: Trends of Changes in Levelized Cost of Heat. Energies 2022, 15, 7215. [Google Scholar] [CrossRef]

- Van Nguyen, H.; Nguyen, C.D.; Van Tran, T.; Hau, H.D.; Nguyen, N.T.; Gummert, M. Energy efficiency, greenhouse gas emissions, and cost of rice straw collection in the mekong river delta of vietnam. Field Crop. Res. 2016, 198, 16–22. [Google Scholar] [CrossRef] [Green Version]

- Ou, X.; Xiaoyu, Y.; Zhang, X. Life-cycle energy consumption and greenhouse gas emissions for electricity generation and supply in China. Appl. Energy 2011, 88, 289–297. [Google Scholar] [CrossRef]

- Kim, S.; Dale, B.E.; Jenkins, R. Life cycle assessment of corn grain and corn stover in the United States. Int. J. Life Cycle Assess. 2009, 14, 160–174. [Google Scholar] [CrossRef]

- Technical Annex to the SEAP: The Emission Factors. Available online: https://www.ces-med.eu/publications/technical-annexseap (accessed on 2 October 2022).

- Hansen, M.T. Biomass based Combined Heat and Power Generation. 2014. Available online: http://www.videncenter.dk/exportcat/combined_heat_and_power.pdf (accessed on 17 November 2022).

- Aguilera, E.; Guzmán, G.I.; Infante-amate, J.; García-ruiz, R.; Herrera, A.; Villa, I. Embodied Energy in Agricultural Inputs. Incorporating a Historical Perspective. DT-SEHA 15. 2015. Available online: http://hdl.handle.net/10234/141278 (accessed on 5 October 2022).

- Skowrońska, M.; Filipek, T. Life cycle assessment of fertilizers: A review. Int. Agrophysics 2014, 28, 101–110. [Google Scholar] [CrossRef]

- Wood, S.; Cowie, A. A Review of Greenhouse Gas Emission Factors for Fertiliser Production. June 2004. For IEA Bioenergy Task 38. Available online: https://www.sciencetheearth.com/uploads/2/4/6/5/24658156/2004_wood_a_review_of_greenhouse_gas_emission_factors.pdf (accessed on 17 November 2022).

- Factsheet Boiler Efficiency. Available online: https://www.energy.gov.au/sites/default/files/hvac-factsheet-boiler-efficiency.pdf (accessed on 18 October 2022).

- Vakkilainen, E.K. 3—Boiler Processes. In Steam Generation from Biomass: Construction and Design of Large Boilers; Vakkilainen, E.K., Ed.; Butterworth-Heinemann: Oxford, UK, 2017; pp. 57–86. [Google Scholar] [CrossRef]

| Indicator | Unit | Value |

|---|---|---|

| Input flows | ||

| Diesel fuel | kg/ha | 63.5 |

| Gasoline | kg/ha | 8.0 |

| Electricity | kWh/ha | 11.38 |

| Sweet sorghum seeds | kg/ha | 6.0 |

| Mineral fertilizer (10:40 N:P2O5) | kg/ha | 187.0 |

| Herbicides | kg/ha | 8.0 |

| Total energy inputs | GJ/ha | 12.27 |

| Total costs | USD/ha | 1279.5 |

| Output flows | ||

| Sorghum silage | t/ha | 40.6 |

| Carbon dioxide emissions | kgCO2/ha | 438.32 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Havrysh, V.; Nitsenko, V.; Hruban, V. Sorghum-Based Power Generation in Southern Ukraine: Energy and Environmental Assessment. Agriculture 2022, 12, 2148. https://doi.org/10.3390/agriculture12122148

Havrysh V, Nitsenko V, Hruban V. Sorghum-Based Power Generation in Southern Ukraine: Energy and Environmental Assessment. Agriculture. 2022; 12(12):2148. https://doi.org/10.3390/agriculture12122148

Chicago/Turabian StyleHavrysh, Valerii, Vitalii Nitsenko, and Vasyl Hruban. 2022. "Sorghum-Based Power Generation in Southern Ukraine: Energy and Environmental Assessment" Agriculture 12, no. 12: 2148. https://doi.org/10.3390/agriculture12122148

APA StyleHavrysh, V., Nitsenko, V., & Hruban, V. (2022). Sorghum-Based Power Generation in Southern Ukraine: Energy and Environmental Assessment. Agriculture, 12(12), 2148. https://doi.org/10.3390/agriculture12122148