Abstract

In this study, a two-stage fluidized-bed gasification system was used to determine the distribution of heavy metal contaminants in simulative waste and evaluate the effect of the bed operating temperature, Equivalence ratio (ER), and Steam/Biomass ratio (S/B) in stage 1. The heavy metal concentrations in bed materials and fly ash were measured in two stages. The results show that as the operating temperature of stage 1 increased, the quantity of heavy metals entrapped by stage 1 bed material decreased, while that captured by stage 2 bed material increased. The less volatile Cu was mostly entrapped in stage 1 bed material. The ER and S/B results show that increasing the ER and S/B caused a slight increase in the concentrations of heavy metals entrapped in stage 1 and stage 2 bed materials. However, the influences of ER and S/B were less than that of temperature. The major factors affecting the heavy metal distribution were the operating temperature and the heavy metal volatility. Stage 2 bed material was able to entrap gaseous heavy metals or particles containing heavy metals by particle filtration and chemical adsorption. Thus, the heavy metals (Cu and Pb) had a downward trend after passing through stage 2.

1. Introduction

Taiwan produces about 750 million metric tons of municipal solid waste (MSW) every year. The two predominant methods for MSW treatment are recycling and incineration. At present, there are 24 large incineration plants treating over 600 million tons of waste every year in Taiwan. In order to reduce the influence of MSW incineration, the government has been actively seeking treatment methods other than just recycling resources from waste and incineration. Since most of the waste is organic matter, if the incineration treatment could be transferred to a gasification treatment of waste, not only can the pollution from traditional incineration plants be solved, but we can also obtain reusable energy from the process. The mixture of gases obtained after gasification is called synthesis gas (syngas), and it contains mainly CO, CH4, H2, and other gases [1]. Syngas can be further purified and directly burned or used as raw chemical materials; thus, this technology is a promising alternative to incineration [2].

According to the literature, the parameters affecting the composition of the final syngas from the gasification process include the feed species, temperature, catalyst, feed diameter, bed material diameter, Equivalence ratio (ER), and Steam/Biomass ratio (S/B) [3,4,5,6]. The ER is defined as the ratio of the actual amount of oxygen supplied to the gasifier to the amount of oxygen required for complete combustion of a given quantity of biomass. The S/B is the ratio of the amount of steam to the amount of biomass feed in the gasifier, and it is also an important parameter affecting gasification. Of these factors, the gasification temperature, ER, and S/B have the greatest influence on the gasification process. The gasification temperature directly affects the gasification reactions. Luo et al. [7] pointed out that increasing the operating temperature could increase the yield of H2 and CO by promoting some reactions, such as methane–steam reforming, water–gas reactions, and the Boudouard reaction. Kumar et al. [3] increased the gasification temperature from 650 to 850 °C, and the results showed that the carbon conversion efficiency (82%) and energy conversion efficiency (96%) were higher at 850 °C than at 650 °C. Furthermore, H2 concentrations increased from 4% at 650 °C to 15% at 850 °C. Gómez-Barea et al. [8] also pointed out in their studies that increasing the gasification temperature could increase both the gas production rate and carbon conversion efficiency. Gao et al. [9] and Ma et al. [10] also indicated in their studies that an increase in gasification temperature resulted in increased H2 content in the syngas.

An increase in the ER value suggests that more oxygen has entered the gasifier, causing more carbon to be oxidized and the carbon conversion efficiency to increase. This results in more CO2 in the produced syngas while decreasing the concentrations of CO and H2 [11]. The same results were obtained when the ER value was increased in experiments conducted by Chiang et al. [12] and Gregorio and Zaccariello [13]. However, having too high of an ER value means that excess oxygen is provided, so the reaction tends to be complete oxidization, reducing the gross heat value of the syngas [14]. If the results of previous studies are taken as a whole, then controlling the ER value of gasification within the range of 0.2–0.4 is the most appropriate approach [4]. The S/B is the ratio between the steam feed rate and biomass material feed rate in the gasifier and is also an important parameter affecting gasification. Wang et al. [15] pointed out that when S/B was increased to 1.23, the H2 percentage in the syngas and the total syngas production both increased, whereas the tar production decreased. Ruiz et al. [16], Dascomb et al. [17], and Ge et al. [18] also pointed out in their studies that as the S/B increased, H2 production increased. The main reason that an increase in S/B leads to an increase in H2 production is that increasing S/B causes more hydrogen to participate in oxidization; thus, more H2 is produced. However, the S/B needs to be controlled within a certain range; otherwise, excess steam will absorb the heat in the gasifier, causing a drop of temperature, which is unfavorable for gasification to proceed.

Regardless of whether wastes are incinerated or gasified, the escape of heavy metals contained in the wastes during heat treatment needs to be discussed. The primary issue is that heavy metal contaminants that escape into the environment not only affect the environment and ecology but also are likely to be harmful to humans [19,20]. From analyzing the heavy metal distribution contained in wastes, Zhang et al. [21] found that the major heavy metal elements included Zn, Cr, Cu, Pb, Ni, Hg, and Cd and that these heavy metal elements might escape into the environment during heat treatment. Barton et al. [22] proposed that less volatile heavy metals do not undergo chemical reactions in the combustion environment, so they do not volatilize and become part of the bottom ash; more volatile heavy metals, however, may react with other substances in incineration systems, producing species with higher boiling points (such as metal oxides), which are left in bottom ash. Furthermore, some heavy metals or compounds will volatilize into vapors under high temperatures, and heavy metals with high boiling points may also react with other species, producing highly volatile species (such as metal chlorides) that will leave the combustion zone with the exhaust gas. Lin [23,24] pointed out in his study on heavy metal entrapment by the bed material of a fluidized-bed that the distribution of a heavy metal during incineration is associated with the heavy metal’s own element properties and boiling point. Metals with higher boiling points (such as Cr) mostly stay in the bottom ash, and heavy metals with higher volatilities (such as Cd) mostly form vapors and leave the combustion zone with the exhaust gas. Hence, the escape of either heavy metals or their compounds is mainly associated with the operating temperature. Hiraoka and Takeda [25] and Gerstle and Albrinck [26] pointed out in their studies that the combustion temperature will affect the distribution percentages of heavy metals in the bottom ash; an increase in temperature reduces Zn, Pb, and Cd distributions in the bottom ash but increases As, Cd, Hg, Zn, and Pb contents in the exhaust gas. Hence, the transfer behavior of heavy metals during heat treatment may differ depending on the metal’s physical and chemical properties, the form of the produced compounds, and the operating conditions.

In recent years, gasification-related studies have mostly been focusing on changing the syngas composition or improving gasification efficiency. Two-stage gasification is one of the gasification technologies proposed by researchers. Two-stage gasification consists of two tandem gasification devices. Gasification products generated in the stage 1 gasifier (syngas, tar, or char) enter the stage 2 gasifier, in which they undergo reactions, and the products are gasified or cracked again to increase the syngas yield while reducing the tar or char yield. Soni et al. [27] performed two-stage gasification with two tandem fixed-bed gasifiers, and the results showed that the H2 yield increased from 7.3% to 22.3%, and the gross syngas yield increased from 30.8% to 54.6%, while the tar yield was reduced (from 18.6% to 14.2%). At present, most two-stage gasifiers are made of two tandem fixed-bed reactors [27,28]. However, a fluidized-bed reactor has the advantages of high heat transfer and high mass transfer efficiencies. Thus, running two tandem fluidized-bed gasifiers with a two-stage gasification program will help increase the gasification efficiency. In waste gasification, one-stage and two-stage gasifiers both have the problem of heavy metal escape. Moreover, since the gasification process takes place in an oxygen-deprived environment, the heavy metal distribution might be different from that resulting from incineration. In this study, the distribution of heavy metal contaminants in a two-stage fluidized-bed gasification system was explored by applying a two-stage fluidized-bed gasification system using simulative waste containing heavy metals as biofuel and changing the bed operating temperature, ER value, and S/B ratio of stage 1. The experimental results may serve as a reference for the practical design and operation of such a system.

2. Materials and Methods

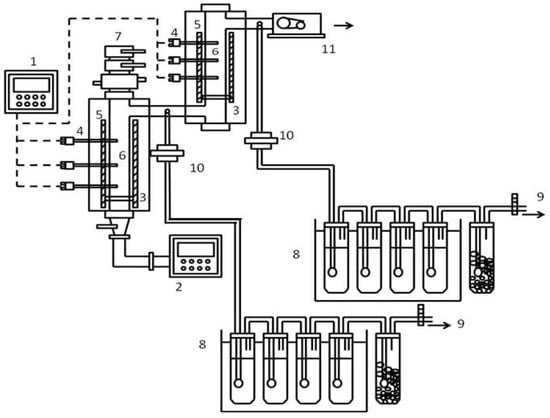

A two-stage fluidized-bed gasification system at the laboratory scale was used in this study, and a structural diagram of the two-stage fluidized-bed gasification system is shown in Figure 1. Each gasifier body was made of stainless steel (AISI-310) with a thickness of 0.49 cm, a height of 50 cm, an outer diameter of 4.27 cm, and an inner diameter of 3.29 cm. Both the stage 1 and stage 2 gasifier bodies had the same specifications. Both stage 1 and stage 2 gasifiers had a stainless-steel distributor installed in the bed bottom. The heating mode of the gasifiers was electrical heating, while a programmed logical controller (PID) was used to control the temperature inside the gasifiers. The gasifier reactors were coated with fibrous insulation on the outside to reduce heat loss, and the temperature of gasifiers was monitored and recorded by using thermocouples. The bed material used in both stages during the experimental process was silica sand, the bulk density of which was 2.6 g/cm3. The bed material diameter of stage 1 was 0.775 mm, and bed material diameter of stage 2 was 0.545 mm. During the experimental process, in order to reduce the influence of the waste’s composition, artificial simulative waste was mainly used. The simulative waste consisted of polypropylene (PP) plastic granules, wood chips, and a polyethylene (PE) bag. The elemental compositions, principal components, and heating values of the materials used in the simulative waste are derived from Lin and Weng [29]. Cu and Pb were selected as the representative heavy metals in the simulative waste because Cu and Pb usually exist in municipal solid waste. These heavy metals were all added in the form of a nitrate aqueous solution. Simulative waste was mainly composed of wood chips and PP plastic granules wrapped with the PE plastic bag material, and 1 mL aqueous solutions of the nitrate salts of the heavy metals were added to the PE plastic bag for coating. The concentration of the heavy metal was 0.3 wt% of the total weight (2.372 g).

Figure 1.

Two-stage fluidized bed gasification system. 1. Programmed logical controller (PID); 2. Mass flow meter; 3. Distributor; 4. Thermocouple; 5. Electric heater; 6. Gasifier; 7. Manual feeder; 8. Impingers and cooling system; 9. Sampling pump; 10. Glass filter; 11. Induced fan.

A water column manometer was used to determine the minimum fluidization velocity before the experiment; the method was described by Lin et al. [30]. The experimental gas flow rate was 1.3 times that of the minimum fluidization velocity, and the minimum fluidization velocity in this study was 0.1 m/s for the 0.775 mm bed material in stage 1. Experimental parameters that were varied included the operating temperature, S/B, and ER of stage 1. Table 1 lists the operating conditions of the different stages. In the experimental process, artificial simulative waste was first placed into the gasifiers for gasification, and sampling was performed at the sampling ports of the stage 1 and stage 2 gasifiers using an active sampling pump at 3 min intervals after the first 5 min. The syngas first passed through a glass fiber filter so that fly ash was entrapped using GF/A filter paper, and then passed through 100 mL of heavy metal absorption solution (containing H2O2 (33 mL), HNO3 (7.67 mL), diluted with deionized water to 100 mL) in an impinger placed in a low-temperature water tank so that gaseous heavy metals were absorbed. After the experiment, the bed material was cooled and then removed. The sampling filter papers and bed materials from stage 1 and stage 2 were treated with microwave digestion to completely break down the contained heavy metal substances.

Table 1.

The operating conditions for each experiment.

The digestion process using a microwave apparatus (CEM MARS Xpress, Kohan Instruments Co., LTD., Taiwan) was divided into two parts. In the first part, the 0.5 g bottom ash or GF/A filter paper (fly ash) was prepared, and then concentrated hydrofluoric acid (3 mL) and concentrated nitric acid (9 mL) were added to the digestion vessels. The temperature program of the oven was set to reach 180 ± 5 °C in 10 min and then held at 180 ± 5 °C for 10 min. In the second part, as the digestion solution in the vessels was cooled, concentrated boric acid (15 mL) was added to the digestion vessel; the temperature profile was the same as that of the first step. At the same time, the standard addition method was employed, and each analysis required a resulting recovery efficiency of 100 ± 15%. The digested solutions were analyzed with an inductively coupled plasma spectrometer (ICP-AES) to determine the heavy metal concentrations.

3. Results and Discussion

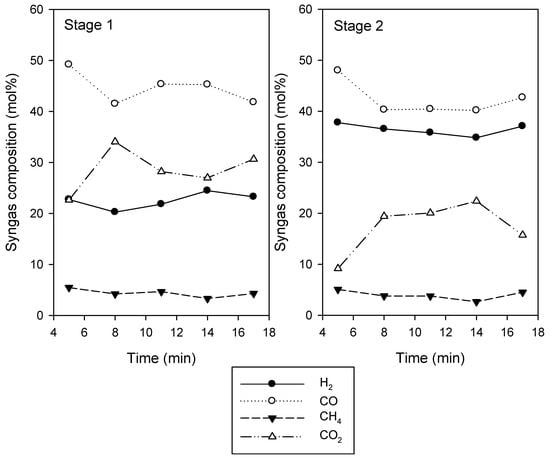

Figure 2 represents the syngas composition after the two-stage fluidized-bed gasification system. The operating temperatures of the stage 1 and stage 2 gasifiers were controlled at 800 °C and 900 °C at an ER of 0.3. The productivity of H2 was increased after passing the stage 2 gasifier because of the reheated environment for the reaction of the syngas. As a result, the stage 2 gasifier increased the H2 concentration in the syngas by 10–16 percentage points. Therefore, using the stage 2 gasifier can slightly improve the generation of H2 in the syngas.

Figure 2.

Synthetic gas compositions in the two-stage fluidized bed gasifier. (Stage 1: 800 °C and Stage 2: 900 °C, ER = 0.3, S/B = 0).

3.1. Influence of Different Operating Temperatures on Heavy Metal Concentrations in Bed Material and Fly Ash

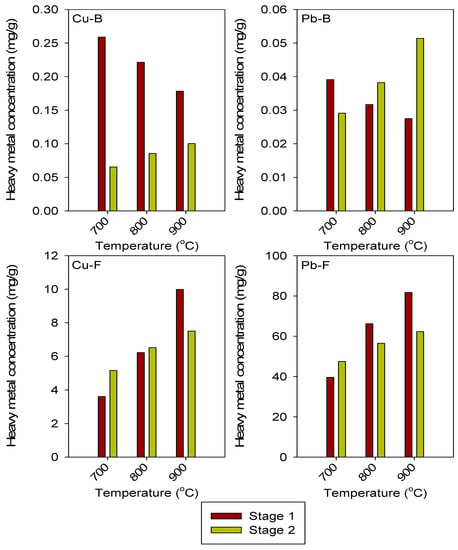

In this study, in order to determine the influence of different operating temperatures on heavy metal entrapment in the bed material and heavy metal escape, the operating temperature of the stage 1 gasifier was changed from 700, 800, to 900 °C, while the temperature of the stage 2 gasifier was fixed at 900 °C. Figure 3 shows the changes in heavy metal concentrations in the bed material and fly ash during gasification with different stage 1 operating temperatures. The heavy metal concentrations in the bed material were obtained by analyzing stage 1 and stage 2 bed materials after completing the experiment. Since the heavy metal concentrations in fly ash changed with different operating conditions and given the variations in different compositions of the gasification syngas, it was found that the sampling data after 14 min were relatively stable. Thus, the sampling result obtained at the 14th minute of the experiment was used to represent the heavy metal concentrations in fly ash.

Figure 3.

Heavy metal distributions at different operating temperatures in stage 1. (B: Bed materials, F: Fly ash; Stage 2: 900 °C, ER = 0.3, S/B = 0).

Figure 3 also shows a comparison of the heavy metal concentrations in the bed materials between stage 1 and stage 2 under different operating temperatures. When the stage 1 operating temperature increased, the concentrations of entrapped heavy metals in stage 1 bed material decreased, causing an increase in heavy metal concentrations in the bed material of stage 2. The same trend was obtained for both heavy metals. As pointed out by Barton et al. [22], when subjected to heat treatment, heavy metals escape as a result of three mechanisms—homogeneous nucleation, heterogeneous deposition, and chemical adsorption—and they are mainly affected by the operating temperature [31,32,33]. Since Cu has the higher boiling point of the two heavy metals (boiling points: Cu 2562 °C and Pb 1749 °C), stage 1 bed material had the highest Cu concentration, indicating that most Cu did not escape with the syngas but was entrapped in stage 1 bed material. However, some Cu still escaped to stage 2 with the fly ash. So, stage 2 bed material not only provided the syngas with the opportunity for steam (which could be produced in stage 1) reforming or cracking to increase the H2 yield but also entrapped the fly ash that escaped from stage 1. Thus, some heavy metals that escaped from stage 1 were entrapped in stage 2 bed material. According to studies conducted by Chiang et al. [34] and Wey et al. [35] on heavy metal contaminant control using a fluidized-bed, the main mechanisms that control heavy metal escape are filtration and chemical adsorption by bed particles. Therefore, gaseous heavy metals or particles containing heavy metals entering the stage 2 fluidized-bed gasifier could be entrapped in stage 2 bed material because by these two mechanisms.

According to Nzihou and Stanmore [36], who pointed out that the escape of a heavy metal is mainly affected by the metal’s boiling point, heavy metals with relatively low boiling points are more volatile, so they escape at relatively high rates. Hence, the Pb concentration in stage 1 bed material was lower than the Cu concentration and significantly decreased with increasing operating temperature. However, the Cu and Pb concentrations in stage 2 bed material were proportional to the operating temperature, suggesting that the greater the amount of heavy metals that escaped from stage 1 gasification, the greater the amount of heavy metals that would be entrapped in the stage 2 bed material.

The comparison of heavy metal concentrations in fly ash between stage 1 and stage 2 under different operating temperatures are displayed in Figure 3. It can be seen that at a higher gasification temperature in stage 1, the content of Cu and Pb in fly ash both trended upward since high temperature facilitates the volatilization of heavy metals, leading to the escape of heavy metals deposited on fly ash through homogeneous nucleation and heterogeneous nucleation [22]. Therefore, a higher temperature will result in an increase in the heavy metal content of fly ash. As expected by their difference in volatility, according to the results, the order of the amount of the two heavy metals in fly ash was Pb > Cu. The amount of heavy metal that can escape is mainly related to the heavy metal’s own volatility. According to the fly ash results shown in Figure 3, the Cu and Pb concentrations in fly ash were higher in stage 1 than in stage 2 when the temperature of stage 1 and 2 was 900 °C. This phenomenon is due to the increased emission of Cu and Pb in stage 1 when the temperature of stage 1 was up to 900 °C. The amount of Cu and Pb condensation on the fly ash in stage 1 was increased; therefore, the concentration of Cu and Pb in fly ash in stage 1 was also increased. On the other hand, the emission of Cu and Pb declined, and the amount of the Cu and Pb condensation on the fly ash in stage 1 decreased when the temperature of stage 1 was lower than that of stage 2. As a result, the concentration of Cu and Pb in fly ash in stage 1 was lower than that in stage 2.

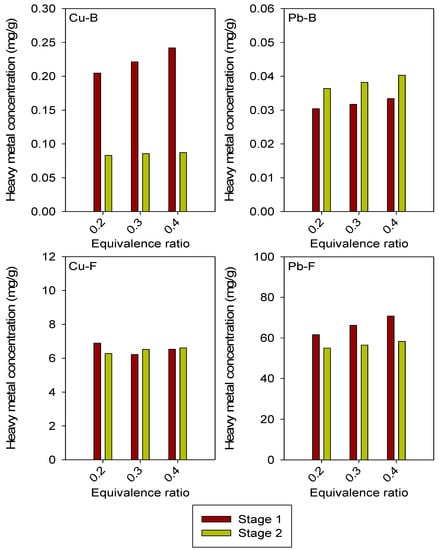

3.2. Influence of Different Equivalence Ratio Values on Heavy Metal Concentrations in Bed Material and Fly Ash

Figure 4 shows a comparison of the heavy metal concentrations in the bed material and fly ash in stage 1 and stage 2 at different ER values. The results show that increasing the ER slightly increased the concentrations of heavy metals entrapped in stage 1 and stage 2 bed materials. The inference is that the increase in ER caused an increase in the amount of oxygen that entered the stage 1 gasifier, improving the decomposing effect on wastes. Thus, heavy metals in the waste had more contact with the bed material, increasing the adsorption of heavy metals by the bed material and causing an increase in heavy metal concentrations in the bed material. The distributions of different heavy metals in the bed material were similar to the results shown in Figure 3. Cu has the lowest volatility, so it was more concentrated in stage 1 bed material than in stage 2 bed material, whereas Pb displayed the opposite pattern. The change in the ER had an insignificant influence on the heavy metal distribution in fly ash, especially for Cu. This phenomenon is due to the enhanced efficiency of gasification when the ER is increased. In this condition, the waste was decomposed more completely and then converted to fine particles mixed with the bed material. Therefore, the emission of heavy metals decreased and resulted in the ER having an insignificant influence on their distribution in fly ash.

Figure 4.

Heavy metal distributions at different ER ratios. (B: Bed materials, F: Fly ash; Stage 1: 800°C and Stage 2: 900°C, S/B = 0).

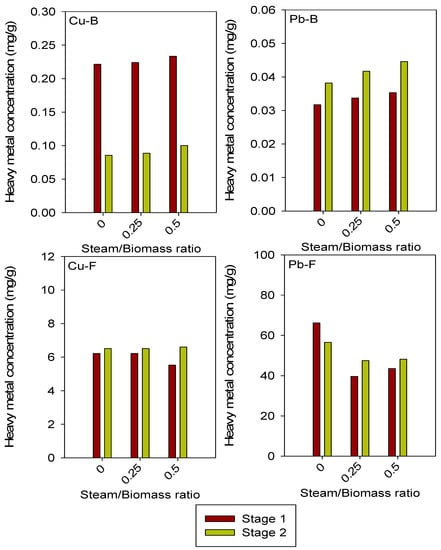

3.3. Influence of Different Steam/Biomass Ratio Values on Heavy Metal Concentrations in Bed Material and Fly Ash

Figure 5 shows the influence of different S/B ratios on the heavy metal concentrations in the bed material and fly ash of stage 1 and stage 2. The results suggest that the increase in the S/B led to an increase in heavy metal concentrations in stage 1 bed material and reduction in heavy metal concentrations in stage 1 fly ash. A possible reason for this is that the increase in the S/B improved the oxidization efficiency so that the waste was more sufficiently decomposed, resulting in more contact between the heavy metals and bed material and further increasing the heavy metal entrapment effect. The distribution patterns of heavy metals with the change in the S/B were similar to those with the change in ER: as the amount of heavy metals entrapped in stage 1 bed material decreased, the heavy metal concentrations in the stage 1 fly ash increased. At the same time, the heavy metal concentrations in stage 2 bed material also decreased. The distribution patterns of different heavy metals were similar to those resulting from the change in the ER.

Figure 5.

Heavy metal distributions at different S/B ratios. (B: Bed materials, F: Fly ash; Stage 1: 800 °C and Stage 2: 900 °C, ER = 0.3).

Figure 3, Figure 4 and Figure 5 compare the three different operating conditions examined in this study (temperature, ER, and S/B). Regardless of whether the focus was the heavy metal distribution in the bed material or fly ash of stage 1 or stage 2, the major influencing factors were the operating temperature and the heavy metal’s own volatility; the ER and S/B had less influence. In addition to stage 2 bed material providing a second opportunity for the syngas to undergo oxidization or cracking to increase the H2 yield, it also could entrap gaseous heavy metals or particles containing heavy metals that entered the stage 2 fluidized-bed gasifier through filtration and chemical adsorption by bed particles, thus reducing the escape of Cu and Pb.

4. Conclusions

In this study, the distribution of heavy metal contaminants in a two-stage fluidized-bed gasification system was explored by applying it with simulative waste containing heavy metals as a biofuel while changing the bed operating temperature, ER value, and S/B ratio in stage 1. The experimental results show that heavy metal escape was mainly affected by operating temperature: as the stage 1 operating temperature increased, the amount of heavy metals entrapped in stage 1 bed material decreased. At the same time, heavy metal concentrations in stage 2 bed material increased. For heavy metals with different volatilities, the less-volatile Cu was mostly entrapped in stage 1 bed material. The order of heavy metal concentrations in fly ash was Pb > Cu. This is mainly because the amount of heavy metal that escapes is related to the heavy metal’s own volatility. Cu and Pb concentrations in fly ash were higher in stage 1 than in stage 2 when the temperature of stage 1 and 2 was 900 °C. This indicates that when the temperature of stage 1 was up to 900 °C, the emission of Cu and Pb was increased in stage 1. The amount of Cu and Pb condensation on the fly ash in stage 1 was also increased.

A comparison of the factors that affect the distribution of heavy metals reveals that the two major influencing factors were the operating temperature and the heavy metal’s own volatility. As the temperature increased, stage 2 bed material could entrap gaseous heavy metals or particles containing heavy metals that entered the stage 2 fluidized-bed gasifier through filtration and chemical adsorption by bed particles. Thus, after passing through stage 2 bed material, the concentrations of heavy metals (Pb and Cu) in the fly ash had decreasing trends.

Author Contributions

Data curation, C.-L.L. and J.-D.C.; Formal analysis, J.-D.C. and W.-C.W.; Funding acquisition, C.-L.L.; Investigation, W.-C.W.; Methodology, C.-L.L.; Project administration, C.-L.L.; Resources, C.-L.L.; Supervision, C.-L.L.; Writing—original draft, J.-D.C. and W.-C.W.; Writing—review & editing, C.-L.L. and J.-D.C.

Funding

This research was funded by Ministry of Science and Technology of the Republic of China contract number MOST 106-2221-E-390-004-MY3.

Acknowledgments

The authors thank the Ministry of Science and Technology of the Republic of China, Taiwan, for financially supporting this research under Contract MOST 106-2221-E-390-004-MY3.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Colpan, C.O.; Hamdullahpur, F.; Dincer, I.; Yoo, Y. Effect of gasification agent on the.performance of solid oxide fuel cell and biomass gasification systems. Int. J. Hydrog. Energy 2010, 356, 5001–5009. [Google Scholar] [CrossRef]

- McKendry, P. Energy production from biomass (part 1): Overview of biomass. Bioresour. Technol. 2002, 83, 37–46. [Google Scholar] [CrossRef]

- Kumar, A.; Eskridge, K.; Jones, D.D.; Hanna, M.A. Steam-air fluidized bed gasification of distillers grains: Effects of steam to biomass ratio, equivalence ratio and gasification temperature. Bioresour. Technol. 2009, 100, 2062–2068. [Google Scholar] [CrossRef] [PubMed]

- Alauddin, Z.A.B.Z.; Lahijani, P.; Mohammadi, M.; Mohamed, A.R. Gasification of lignocellulosic biomass in fluidized beds for renewable energy development: A review. Renew. Sustain. Energy Rev. 2010, 14, 2852–2862. [Google Scholar] [CrossRef]

- Kaneko, K.; Li, L.; Matsushima, A.; Sato, H.; Shimizu, T.; Kim, H.; Takarada, T. Biomass Volatile Decomposition with a Novel Ni Loaded Brown Coal Char at Extremely Low Temperature. J. Chem. Eng. Jpn. 2016, 49, 294–299. [Google Scholar] [CrossRef]

- Kobayashi, N.; Suami, A.; Itaya, Y. Co-gasification Behavior of Woody Biomass and Coal in an Entrained Down-Flow Gasifier. J. Chem. Eng. Jpn. 2017, 50, 862–870. [Google Scholar] [CrossRef]

- Luo, S.; Xiao, B.; Hu, Z.; Liu, S.; Guo, X.; He, M. Hydrogen-rich gas from catalytic steam gasification of biomass in a fixed bed reactor: Influence of temperature and steam on gasification performance. Int. J. Hydrog. Energy 2009, 34, 2191–2194. [Google Scholar] [CrossRef]

- Gómez-Barea, A.; Ollero, P.; Leckner, B. Optimization of char and tar conversion in fluidized bed biomass gasifiers. Fuel 2013, 103, 42–52. [Google Scholar] [CrossRef]

- Gao, N.; Li, A.; Quan, C. A novel reforming method for hydrogen production from biomass steam gasification. Bioresour. Technol. 2009, 100, 4271–4277. [Google Scholar] [CrossRef] [PubMed]

- Ma, Z.; Zhang, S.P.; Xie, D.Y.; Yan, Y.J. A novel integrated process for hydrogen production from biomass. Int. J. Hydrog. Energy. 2014, 39, 1274–1279. [Google Scholar] [CrossRef]

- Lv, P.M.; Xiong, Z.H.; Chang, J.; Wu, C.Z.; Chen, Y.; Zhu, J.X. An experimental study on biomass air–steam gasification in a fluidized bed. Bioresour. Technol. 2004, 95, 95–101. [Google Scholar] [CrossRef]

- Chiang, K.Y.; Chien, K.L.; Lu, C.H. Hydrogen energy production from disposable chopsticks by a low temperature catalytic gasification. Int. J. Hydrog. Energy 2012, 37, 15672–15680. [Google Scholar] [CrossRef]

- Gregorio, F.D.; Zaccariello, L. Fluidized bed gasification of a packaging derived fuel: Energetic, environmental and economic performances comparison for waste-to-energy plants. Energy 2012, 42, 331–341. [Google Scholar] [CrossRef]

- Zainal, Z.A.; Rifau, A.; Quadir, G.A.; Seetharamu, K.N. Experimental investigation of a downdraft biomass gasifier. Biomass Bioenerg. 2002, 23, 283–289. [Google Scholar] [CrossRef]

- Wang, J.; Cheng, G.; You, Y.; Xiao, B.; Liu, S.; He, P.; Guo, D.; Guo, X.; Zhang, G. Hydrogen-rich gas production by steam gasification of municipal solid waste (MSW) using NiO supported on modified dolomite. Int. J. Hydrog. Energy 2012, 37, 6503–6510. [Google Scholar] [CrossRef]

- Ruiz, J.A.; Juárez, M.C.; Morales, M.P.; Muñoz, P.; Mendívil, M.A. Biomass gasification for electricity generation: Review of current technology barriers. Renew. Sustain. Energy Rev. 2013, 18, 174–183. [Google Scholar] [CrossRef]

- Dascomb, J.; Krothapalli, A.; Fakhrai, R. Thermal conversion efficiency of producing hydrogen enriched syngas from biomass steam Gasification. Int. J. Hydrog. Energy 2013, 38, 11790–11798. [Google Scholar] [CrossRef]

- Ge, H.; Guo, W.; Shen, L.; Song, T.; Xiao, J. Biomass gasification using chemical looping in a 25 kWth reactor with natural hematite as oxygen carrier. Chem. Eng. J. 2016, 286, 174–183. [Google Scholar] [CrossRef]

- Baba, A.; Gurdal, G.; Sengunalp, F. Leaching characteristics of fly ash from fluidized bed combustion thermal power plant: Case study: Çan (Çanakkale-Turkey). Fuel Process. Technol. 2010, 91, 1073–1080. [Google Scholar] [CrossRef]

- Yao, J.; Li, W.B.; Kong, Q.N.; Wu, Y.Y.; He, R.; Shen, D.S. Content, mobility and transfer behavior of heavy metals in MSWI bottom ash in Zhejiang province, China. Fuel 2010, 89, 616–622. [Google Scholar] [CrossRef]

- Zhang, H.; He, P.J.; Shao, L.M. Implication of heavy metals distribution for a municipal solid waste management system—A case study in Shanghai. Sci. Total Environ. 2008, 402, 257–267. [Google Scholar] [CrossRef]

- Barton, R.G.; Clark, W.D.; Seeker, W.R. Fate of metals in waste combustion system. Combust. Sci. Technol. 1990, 74, 327–342. [Google Scholar] [CrossRef]

- Lin, C.L. Effects of fluidized parameters on capture of heavy metal in various bed-material size distributions. Fuel Process. Technol. 2013, 106, 149–159. [Google Scholar] [CrossRef]

- Lin, C.L.; Wu, M.H.; Weng, W.C. Effect of the type of bed material in two-stage fluidized bed gasification reactors on hydrogen gas synthesis and heavy metals distribution. Int. J. Hydrog. Energy 2019, 44, 5633–5639. [Google Scholar] [CrossRef]

- Hiraoka, M.; Takeda, N. Behavior of hazardous substances in stabilization and solidification processes of industrial wastes. In Toxic and Hazardous Waste Disposal; Pojasek, R.B., Ed.; Ann Arbor Science: Ann Arbor, MI, USA, 1980; Volume 3, pp. 107–124. [Google Scholar]

- Gerstle, R.W.; Albrinck, D.N. Atmospheric emissions of metals from sewage sludge incineration. J. Air Pollut. Control assoc. 1982, 32, 1113–1123. [Google Scholar] [CrossRef]

- Soni, C.G.; Wang, Z.; Dalai, A.K.; Pugsley, T.; Fonstad, T. Hydrogen production via gasification of meat and bone meal in two-stage fixed bed reactor system. Fuel 2009, 88, 920–925. [Google Scholar] [CrossRef]

- Zeng, X.; Wang, F.; Li, H.; Wang, Y.; Dong, L.; Yu, J.; Xu, G. Pilot verification of a low-tar two-stage coal gasification process with a fluidized bed pyrolyzer and fixed bed gasifier. Appl. Energy. 2014, 115, 9–16. [Google Scholar] [CrossRef]

- Lin, C.L.; Weng, W.C. Effects of different operating parameters on the syngas composition in a two-stage gasification process. Renew. Energy 2017, 109, 135–143. [Google Scholar] [CrossRef]

- Lin, C.L.; Wey, M.Y.; You, S.D. The effect of particle size distribution on minimum fluidization velocity at high temperature. Powder Technol. 2002, 126, 297–301. [Google Scholar] [CrossRef]

- Jakob, A.; Stucki, S.; Kuhn, P. Evaporation of heavy metals during the heat treatment of municipal solid waste incinerator fly ash. Environ. Sci. Technol. 1995, 29, 2429–2436. [Google Scholar] [CrossRef]

- Sun, C.J.; Li, M.G.; Gau, S.H.; Wang, Y.H.; Jan, Y.L. Improving the mechanical characteristics and restraining heavy metal evaporation from sintered municipal solid waste incinerator fly ash by wet milling. J. Hazard. Mater. 2011, 195, 281–290. [Google Scholar] [CrossRef] [PubMed]

- Wey, M.Y.; Ou, W.Y.; Liu, Z.S.; Tseng, H.H.; Yang, W.Y.; Chiang, B.C. Pollutants in incineration flue gas. J. Hazard. Mater. 2001, 82, 247–262. [Google Scholar] [CrossRef]

- Chiang, B.C.; Wey, M.Y.; Yeh, C.L. Control of acid gases using a fluidized bed adsorber. J. Hazard. Mater. 2003, 101, 259–272. [Google Scholar] [CrossRef]

- Wey, M.Y.; Chen, K.H.; Liu, K.Y. The effect of ash and filter media characteristics on particle filtration efficiency in fluidized bed. J. Hazard. Mater. 2005, 121, 175–181. [Google Scholar] [CrossRef]

- Nzihou, A.; Stanmore, B. The fate of heavy metals during combustion and gasification of contaminated biomass-a brief review. J. Hazard. Mater. 2013, 256–257, 56–66. [Google Scholar] [CrossRef] [PubMed]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).