Abstract

In this study, the metal injection molding (MIM) process is applied to produce Ti-6Al-4V parts using blended and prealloyed powders, respectively. The feedstocks are prepared from a polyformaldehyde-based binder system with a powder loading of 60 vol%, exhibiting a low viscosity. The decomposition behavior of the binders is investigated and the thermal debinding procedure is designed accordingly. The debound parts are subsequently sintered at 1200 and 1300 °C. The results show the mechanical properties of the sintered samples prepared from blended powder are comparable to those prepared from prealloyed powder, with yield strength of 810 MPa, ultimate tensile strength (UTS) of 927 MPa, and elongation of 4.6%. The density of the as-sintered samples can reach 4.26 g/cm3 while oxygen content is ~0.3%. Based on the results, watch cases with complex shapes are successfully produced from Ti-6Al-4V blended powder. The case gives a good example of applying metal injection molding to mass production of precise Ti-6Al-4V parts with complex shapes in a cost-effective way.

1. Introduction

Ti-6Al-4V is one of the most important and widely used titanium alloys, exhibiting specific mechanical properties, good biocompatibility, and outstanding corrosion resistance. It has been applied in the aerospace, biomechanical, and electronic industries [1]. Most Ti-6Al-4V components are fabricated by conventional techniques involving a significant amount of machining, such as turning, end milling, drilling, reaming, tapping, sawing, and grinding, accompanied by a high loss of raw materials [2,3]. However, high chemical reactivity, low thermal conductivity, high strength, and low elastic modulus result in the poor machinability of Ti-6Al-4V alloy [4]. Hence, the poor machinability and high manufacturing cost for complex shaped components limit its further applications. To solve these problems, the metal injection molding (MIM) process of Ti-6Al-4V is becoming more and more attractive in both research and industry [5,6,7]. MIM is a near-net-shape process that combines the merits of powder metallurgy and plastic injection molding and offers freedom in structure design [8]. The technique provides a unique opportunity for the mass production of microstructurally uniform and high-performance Ti-6Al-4V components with complex shapes.

In order to successfully obtain Ti-6Al-4V components with balanced mechanical properties by MIM, sophisticated processing, including powder handling, binder system design, debinding, sintering, and post-processing technologies, is considered carefully [9,10,11,12]. Generally, prealloyed Ti-6Al-4V powder with spherical particle shape and low impurity levels is preferred because of its good moldability and low initial oxygen content. Most research works on MIM of Ti-6Al-4V alloy have been designed starting from prealloyed powder, such as the processing optimization and improvement of mechanical properties [13,14,15,16,17]. In addition, Ti-6Al-4V components have been successfully manufactured for industrial as well as medical applications by the MIM process from prealloyed powder [8,18].

Nevertheless, the high cost of fine prealloyed Ti-6Al-4V powder limits its applications in the high-end market, becoming a barrier to wide utilization. The recycling of machine turnings by the hydrogenation-dehydrogenation (HDH) method to produce low-cost Ti-6Al-4V powders has been tried in previous literature [19,20]. Furthermore, some attempts have been reported using blended plasma-atomized Ti and 60Al40V powder [21], blended TiH2 and 60Al40V powder [22], and blended gas-atomized (GA) Ti-6Al-4V and HDH Ti-6Al-4V powder [12] to fabricate Ti-6Al-4V alloy by MIM to reduce the cost. However, there are almost no successful business cases reported by these reduced-cost fabrication methods. In our previous study, we demonstrated a Ti-6Al-4V part manufactured by MIM for industrial applications at a reduced cost by using blended GA Ti and 60Al40V powder [23]. Although the using of blended powder is a cost-effective way for mass production of MIMed Ti-6Al-4V components, the homogeneity of the microstructure, the stability of impurity composition and mechanical properties, and the tolerance control of MIMed products remain to be further investigated, especially for the parts with complex shapes.

In this study, Ti-6Al-4V alloy is fabricated by MIM using blended and prealloyed powders. The effects of MIM processing details and sintering parameters on the final mechanical properties and microstructures are studied. Finally, a Ti-6Al-4V part manufactured from blended powder is demonstrated, showing the possibility of industrial application of the cost-reducing process.

2. Materials and Methods

In this study, the Ti-6Al-4V specimens were produced from two kinds of starting materials, blended and prealloyed powders. The blended Ti-6Al-4V was prepared by blending of commercial pure (CP) Ti powder (99.8%, −325 mesh), Al powder (99.5%, −500 mesh), and 35Al65V powder (99.5%, −325 mesh). For comparison, gas atomization (GA) Ti-6Al-4V powder (99.8%, −325 mesh) was used to fabricated Ti-6Al-4V parts as well. The fabricated Ti-6Al-4V starting from blended and prealloyed powders are designated as B and P samples in the following paragraphs, respectively.

Feedstocks were prepared by mixing the starting powders with binders in a Z-blade kneader at 190 °C with a powder loading of 60 vol%. To achieve a homogeneous feedstock, the B powder was kneaded with binders for 60 min while the P powder was kneaded with binders for 30 min. The binder system used in this study consisted of polyformaldehyde (POM), stearic acid (SA), paraffin wax (PW), ethylene vinyl acetate (EVA), and polyethylene (PE). The feedstocks were then granulated, and injection molded using an injection molding machine (Nissei Nex 80IIIT, Nagano-ken, Japan). In order to measure the mechanical properties, “dog-bone” tensile bars with a nominal length of 90 mm and a gauge diameter of 5 mm were fabricated. After injection molding, the green samples were debound in two steps. Firstly, most of the polyformaldehyde was removed in the catalytic debinding process, which was carried out at 120 °C for 240 min in a catalytic debinding furance (SinterZone, Shenzhen, China) with a nitric acid vapor flow of ~2 g/min. After that, thermal debinding for final removal of the remaining binders and subsequent sintering were carried out in a single-step heat treatment run, using a MIM furnace (Hiper vacuum, Ningbo, China). Sintering was conducted under flowing argon at 1200 °C for 180 min and 1300 °C for 120 min, respectively, followed by controlled furnace cooling.

The viscosity of the feedstock was measured using a capillary rheometer (Göttfert RG20, Buchen, Germany). A die with diameter of 1 mm and length of 30 mm was selected. The cavity of the rheometer was heated to 190 °C during measurement. The chemical reaction in B green sample during heating was analyzed by thermogravimetry (TG) and differential scanning calorimeter (DSC) in a simultaneous thermal analyzer (Netzsch STA 449 F3, Selb, Germany), where a green sample was scanned from room temperature to 1250 °C with a heating rate of 10 °C/min in argon atmosphere. The density of the sintered Ti-6Al-4V was measured by the Archimedes water immersion method in a density balance (Sartorius, Goettingen, Germany). The impurity levels of the samples, such as levels of oxygen, nitrogen, and carbon, were determined using the melt extraction method in element composition analyzers (Leco ON736 and CS744, Saint Joseph, MI, USA). The tensile tests were conducted on sintered samples at room temperature at a strain rate of 3.3 × 10−4 s−1 using a universal test machine (Sans CMT5504, Zhuhai, China). For metallographic examination, samples were cut from the center of the sintered tensile test bar. An etching reagent (2 mL HF, 5 mL H2O2 in 100 mL H2O) was used to etch the samples for optical metallography. The pore distribution and grain size of the sintered parts were observed by an optical microscope (Leica, Wetzlar, Germany). The powder morphology and fracture surfaces of green and sintered samples were observed using a scanning electron microscope (SEM, Zeiss EVO-10, Jena, Germany).

3. Results and Discussion

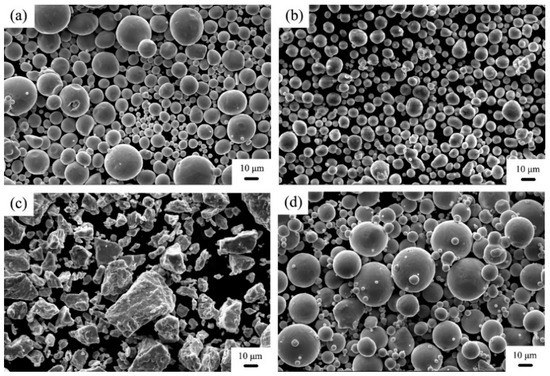

Figure 1 shows the SEM images of the CP Ti, Al, 35Al65V, and GA Ti-6Al-4V powders in the research. Ti, Al, and GA Ti-6Al-4V powders are spherical while 35Al65V powder has an irregular shape. Most fraction of the blended powder is spherical, ensuring good moldability. The smaller Al particles effectively decrease the distance of diffusion, which is beneficial to achieve a uniform structure for B samples. Table 1 summarizes the impurity content (O, C, N) and the prices of the as-received powders. A simple calculation indicates that, in the fabrication of Ti6Al4V alloy, the cost of the raw materials can be reduced by ~60% by replacing the prealloyed powder for the blended powder, which is a big advantage in mass production.

Figure 1.

SEM images of (a) Ti, (b) Al, (c) 35Al65V, and (d) Ti-6Al-4V powders.

Table 1.

Impurity contents and the prices of the raw powders in the present study.

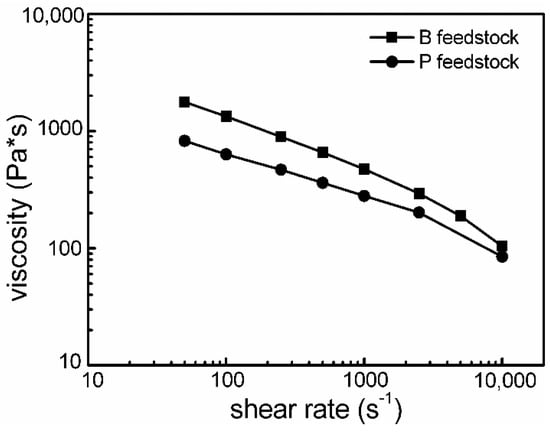

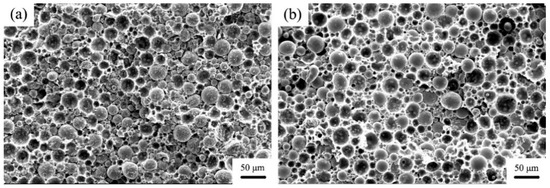

A homogeneous filling of feedstock into the mold depends on viscous flow of mixture into the die cavity, and this requires a understanding of the rheological properties of feedstocks [24]. Figure 2 shows the relationship between shear rate and viscosity of the B and P feedstocks. The P feedstock has a lower viscosity, indicating a better flowability to be injection molded than B feedstock. The discrepancy between them gradually diminishes as the shear rate increases from 50 s−1 to 10,000 s−1. For injection molding, the viscosity of the feedstock is suggested to be lower than 1000 Pa*s at the shear rate range between 100 s−1 and 100,000 s−1 [25]. Although the viscosity of B feedstock is slightly higher than 1000 Pa*s when the shear rate is lower than 250 s−1, it can be injected into the mold cavity to produce samples without black lines. The fracture surfaces of the B and P green parts are shown in Figure 3. The powders are uniformly distributed in both samples and are cladded by a thin layer of binder. No pores and other heterogeneous structures are observed in the green samples.

Figure 2.

The relationship between shear rate and viscosity of the feedstocks prepared from blended and prealloyed powders.

Figure 3.

SEM micrographs of the fracture surfaces of as-molded compacts prepared from (a) blended and (b) prealloyed powders.

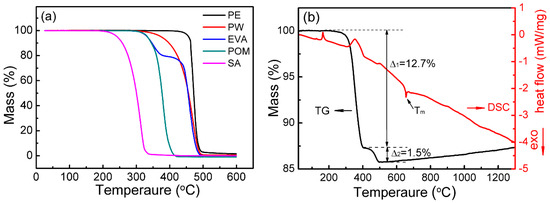

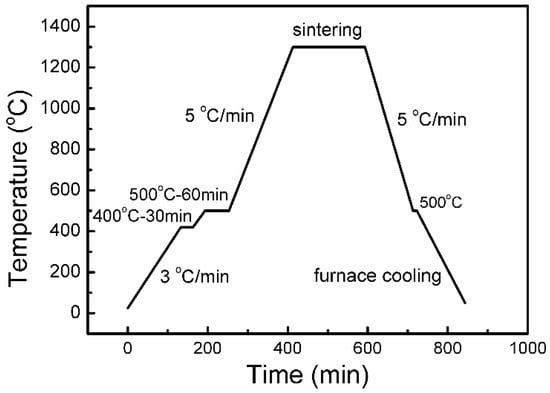

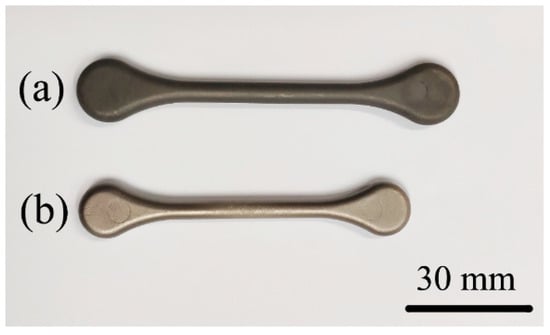

Figure 4a shows the TG curves of polyethylene (PE), paraffin wax (PW), ethylene vinyl acetate (EVA), polyformaldehyde (POM) and stearic acid (SA) with a heating rate of 10 °C/min, revealing the decomposition behavior of the binders. It is observed that SA and POM are easily decomposed when the temperature approaches 400 °C. The decomposition of EVA is composed of two stages ending at 400 °C and 500 °C, respectively. When the temperature increases to 500 °C, PW and PE are finally decomposed. Figure 4b shows the TG and DSC curves of a B green sample heated from room temperature to 1250 °C at a heating rate of 10 °C/min. As shown in the TG curve, two stages of weight loss are observed. The first stage (Δ1) represents the decomposition of SA, POM, and part of EVA, which stops at 400 °C with a weight loss of 12.7%, while the second stage (Δ2) represents the decomposition of PW, PE, and the residual EVA, which finishes at around 500 °C with a weight loss of 1.5%. Though the sample is tested in a protective atmosphere of flowing argon, oxidation still happens at temperatures beyond 500 °C. As a result, a slight weight gain can be seen in the TG curve. The melting and decomposition of the binders can also be observed from the corresponding endothermic peaks in the DSC curve. When the temperature approaches the melting point (Tm) of Al, the reaction between Ti and Al becomes intense and results in an exothermic peak in the DSC curve. The TG and DSC results are subsequently used to design a thermal debinding and sintering schedule, which is shown in Figure 5. During thermal debinding, the binders become soft and the viscosity is reduced. To avoid the distortion from the viscous creep, a relatively low heating rate of 3 °C/min is used during thermal debinding. According to the two-stage weight loss process shown in the TG curve (Figure 4), the samples are isothermally held at two different temperatures (400 °C for 30 min and 500 °C for 60 min) to ensure adequate decomposition of the binders. The thermally debound samples are subsequently heated to the sintering temperature with a rate of 5 °C/min. After sintering, the as-sintered parts are cooled to 500 °C with a controlled rate of 5 °C/min and then cooled to room temperature in the furnace. Figure 6 shows the green and as-sintered tensile bars.

Figure 4.

(a) TG curves of polyethylene (PE), paraffin wax (PW), ethylene vinyl acetate (EVA), polyformaldehyde (POM) and stearic acid (SA) with a heating rate of 10 °C/min; (b) TG and DSC curves of a green sample prepared from blended powder with a heating rate of 10 °C/min.

Figure 5.

The schedule of thermal debinding and sintering.

Figure 6.

The (a) green and (b) as-sintered “dog-bone” tensile bars.

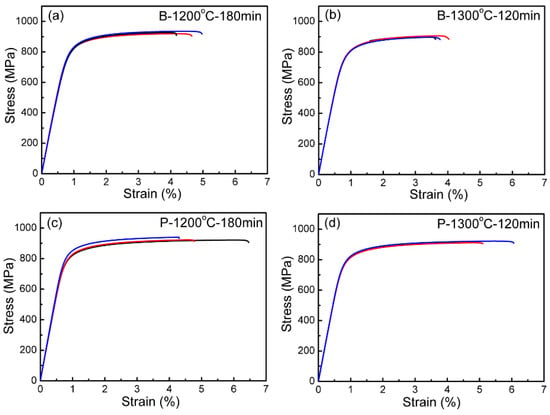

Figure 7 shows the stress-strain curves of B and P samples sintered at 1200 °C for 180 min and 1300 °C for 120 min. Table 2 summarizes the impurity contents, densities, and mechanical properties of the specimens sintered in different conditions. The B samples sintered at 1200 °C for 180 min have a density of 4.26 g/cm3, yield strength of 810 MPa, ultimate tensile strength (UTS) of 927 MPa, and elongation of 4.6%. For comparison, the P samples sintered at 1200 °C for 180 min have a density of 4.26 g/cm3, yield strength of 818 MPa, UTS of 928 MPa, and elongation of 5.2%. The density and mechanical properties of the B samples are similar to those of the P samples although the elongation of B samples is a little bit lower. However, when B and P samples are sintered at 1300 °C for 120 min, the mechanical properties deteriorate. The oxygen content increases when samples are sintered at 1300 °C while the carbon content and nitrogen content are consistently controlled to 0.07~0.08 wt% and ~0.03 wt%, respectively.

Figure 7.

Stress-strain curves of (a) B samples sintered at 1200 °C for 180 min, (b) B samples sintered at 1300 °C for 120 min, (c) P samples sintered at 1200 °C for 180 min, and (d) P samples sintered at 1300 °C for 120 min.

Table 2.

Impurity content, density, and mechanical properties of the sintered specimens.

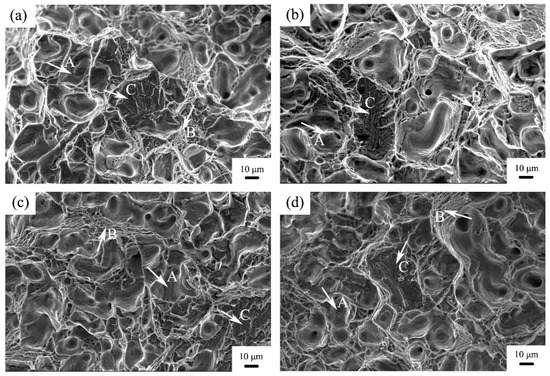

Figure 8 shows the fracture surfaces of B and P samples sintered at 1200 °C for 180 min and 1300 °C for 120 min. The fracture of all the samples exhibits big cavities (white arrow A), fine dimples (white arrow B), and a few cleavages (white arrow C). The cavities derive from the separation of grains, indicating that the metallic bonding between the grains is not well-established. When the sintering temperature increases from 1200 °C to 1300 °C, the number of the cavities in the fracture surface decreases. The fine dimples imply ductile fracture of the specimens upon the tensile test, while the presence of cleavage feature indicates some grains fracture in brittle mode. Hence, the fracture mechanism of sintered B and P samples has a mixed (intergranular and transgranular) mode.

Figure 8.

SEM images of the fracture surfaces of (a) B sample sintered at 1200 °C for 180 min, (b) B sample sintered at 1300 °C for 120 min, (c) P sample sintered at 1200 °C for 180 min, and (d) P sample sintered at 1300 °C for 120 min.

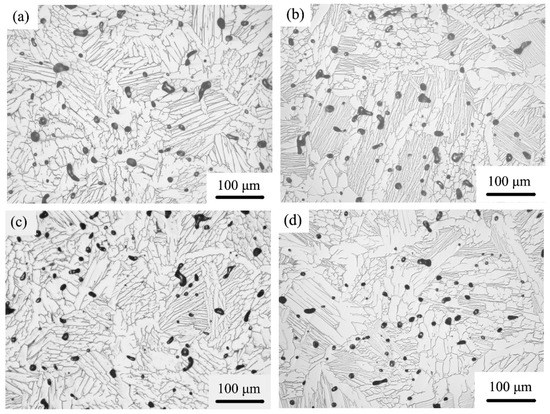

Figure 9 shows the optical micrographs of B and P samples sintered at 1200 °C for 180 min and 1300 °C for 120 min. Typical lamellar microstructures, containing alpha and beta phases, are revealed. The colony sizes of the B and P samples sintered at 1200 °C are ~100 μm, while the microstructures coarsen when the temperature increases to 1300 °C. Circular pores are also observed in the samples. The pores in the B samples are slightly larger than those in the P samples, which can be attributed to the Kirkendall effect generated by imbalanced diffusion between Ti and Al taking place during the sintering of blended powder [26,27].

Figure 9.

Optical micrographs of (a) B sample sintered at 1200 °C for 180 min, (b) B sample sintered at 1300 °C for 120 min, (c) P sample sintered at 1200 °C for 180 min, and (d) P sample sintered at 1300 °C for 120 min.

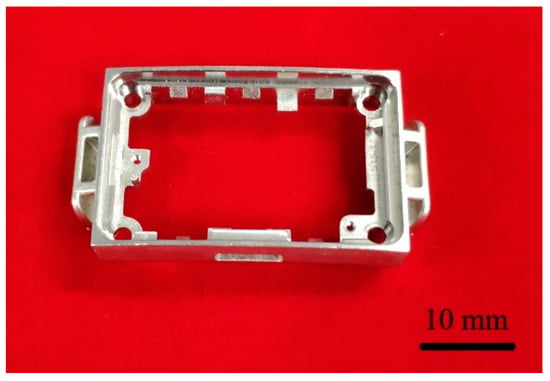

The oxygen level of the B samples sintered at 1200 °C is slightly higher than 0.3 wt%, and its elongation is 4.6%. Both the chemical compositions and mechanical properties cannot meet the aerospace industry standard, which requires the oxygen level for Ti-6Al-4V not exceeding 0.2 wt%. However, the requirements for non-aerospace applications are less stringent [28]. Therefore, we expect that the high strength and acceptable ductility of the MIMed Ti-6Al-4V are still sufficient for many engineering applications. After the processing parameters are optimized, a batch of real industrial Ti-6Al-4V parts can be fabricated by MIM successfully. Figure 10 shows a watch case fabricated by the MIM process from the presented blended powder. Sintered to a density of 4.26 g/cm3, the watch case weighs ~6 g and has a curved surface and internal complex structures. All the complex structures are net shape formed without machining. It is both difficult and expensive for other processing methods, such as forging or casting, to mass produce watch cases. To avoid defects during injection molding, mold flow software was used to determine the suitable injection molding parameters and optimize the gate positions. The debinding and sintering processes are carefully designed to prevent the dimensional distortion. Tolerances controlled within ±0.5% of the nominal dimensions can be consistently achieved.

Figure 10.

The Ti-6Al-4V watch case fabricated by metal injection molding (MIM) from blended powder.

4. Conclusions

Ti-6Al-4V samples were successfully fabricated by metal injection molding from both blended and prealloyed powders. Although the rheological experiment indicates that the viscosity of the feedstock prepared by the blended powder is lower than that prepared by the prealloyed powder, both feedstocks can be molded successfully. Subsequently, the green samples were debound according to the thermal analysis result, and sintered at 1200 or 1300 °C. The density and mechanical properties of samples fabricated from blended powder are very close to those prepared from prealloyed powder. The samples fabricated from blended powder have a sintering density of 4.26 g/cm3, yield strength of 810 MPa, UTS of 927 MPa, and elongation of 4.6%. In order to demonstrate industrial application potentials of the technology, watch cases with complex shapes were fabricated by injection molding of blended Ti-6Al-4V powder without any post processing. The sintered parts exhibit little distortion and good dimensional consistence.

Author Contributions

Conceptualization, P.Y.; Methodology, S.Y., W.M., Y.L., and Z.W.; Investigation, S.Y. and W.M.; Data Curation, S.Y.; Writing—Original Draft Preparation, S.Y.; Writing—Review & Editing, P.Y. and C.T.K.

Funding

This research was funded by the Shenzhen Science and Technology Innovation Committee (grant number SGLH20161212155758670, KQJSCX2018032215242453 and JCYJ20170818161702462) and the National Natural Science Foundation of China (grant number 5180010371).

Acknowledgments

The Ti-6Al-4V parts provided by ElementPlus Co., Ltd. (Shenzhen, China) are appreciated.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Leyens, C.; Peters, M. Titanium and Titanium Alloys Fundamentals and Applications, 1st ed.; Wiley-VCH: Weinheim, Germany, 2003; pp. 1–36. [Google Scholar] [CrossRef]

- Froes, F.H. Titanium alloys. In Handbook of Advanced Materials: Enabling New Designs, 1st ed.; Wessel, J.K., Ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2004; pp. 271–319. [Google Scholar] [CrossRef]

- Froes, F.H.; Qian, M. Titanium background, alloying behavior and advanced fabrication techniques—An overview. In Titanium in Medical and Dental Applications, 1st ed.; Froes, F.H., Qian, M., Eds.; Woodhead Publishing: Duxford, UK, 2018; pp. 23–37. [Google Scholar] [CrossRef]

- Ezugwu, E.O.; Wang, Z.M. Titanium alloys and their machinability—A review. J. Mater. Process. Technol. 1997, 68, 262–274. [Google Scholar] [CrossRef]

- German, R.M. Progress in Titanium Metal Powder Injection Molding. Materials 2013, 6, 3641–3662. [Google Scholar] [CrossRef] [PubMed]

- Ebel, T. Metal injection molding (MIM) of titanium and titanium alloys. In Handbook of Metal Injection Molding, 1st ed.; Heaney, D.F., Ed.; Woodhead Publishing Limited: Cambridge, UK, 2012; pp. 415–445. [Google Scholar] [CrossRef]

- Ebel, T.; Friederici, V.; Imgrund, P.; Hartwig, T. Metal Injection Molding of Titanium. In Titanium Powder Metallurgy Science, Technology and Applications, 1st ed.; Qian, M., Froes, F.H., Eds.; Butterworth-Heinemann: Oxford, UK, 2015; pp. 337–360. [Google Scholar] [CrossRef]

- Dehghan-Manshadi, A.; Bermingham, M.J.; Dargusch, M.S.; StJohn, D.H.; Qian, M. Metal injection moulding of titanium and titanium alloys: Challenges and recent development. Powder Technol. 2017, 319, 289–301. [Google Scholar] [CrossRef]

- Sun, P.; Fang, Z.Z.; Zhang, Y.; Xia, Y. Review of the Methods for Production of Spherical Ti and Ti Alloy Powder. JOM 2017, 69, 1853–1860. [Google Scholar] [CrossRef]

- Wen, G.; Cao, P.; Gabbitas, B.; Zhang, D.; Edmonds, N. Development and Design of Binder Systems for Titanium Metal Injection Molding: An Overview. Metall. Mater. Trans. A 2012, 44, 1530–1547. [Google Scholar] [CrossRef]

- Nyberg, E.; Miller, M.; Simmons, K.; Weil, K.S. Microstructure and mechanical properties of titanium components fabricated by a new powder injection molding technique. Mater. Sci. Eng. C 2005, 25, 336–342. [Google Scholar] [CrossRef]

- Shibo, G.; Xuanhui, Q.; Xinbo, H.; Ting, Z.; Bohua, D. Powder injection molding of Ti–6Al–4V alloy. J. Mater. Process. Technol. 2006, 173, 310–314. [Google Scholar] [CrossRef]

- Obasi, G.C.; Ferri, O.M.; Ebel, T.; Bormann, R. Influence of processing parameters on mechanical properties of Ti-6Al-4V alloy fabricated by MIM. Mater. Sci. Eng. A 2010, 527, 3929–3935. [Google Scholar] [CrossRef]

- Ergül, E.; Özkan Gülsoy, H.; Günay, V. Effect of sintering parameters on mechanical properties of injection moulded Ti–6Al–4V alloys. Powder Metall. 2013, 52, 65–71. [Google Scholar] [CrossRef]

- Ferri, O.M.; Ebel, T.; Bormann, R. Influence of surface quality and porosity on fatigue behaviour of Ti-6Al-4V components processed by MIM. Mater. Sci. Eng. A 2010, 527, 1800–1805. [Google Scholar] [CrossRef]

- Ferri, O.M.; Ebel, T.; Bormann, R. High cycle fatigue behaviour of Ti–6Al–4V fabricated by metal injection moulding technology. Mater. Sci. Eng. A 2009, 504, 107–113. [Google Scholar] [CrossRef]

- Ebel, T.; Blawert, C.; Willumeit, R.; Luthringer, B.J.C.; Ferri, O.M.; Feyerabend, F. Ti–6Al–4V–0.5B—A Modified Alloy for Implants Produced by Metal Injection Molding. Adv. Eng. Mater. 2011, 13, B440–B453. [Google Scholar] [CrossRef]

- Oger, B.; Ebel, T.; Limberg, W. The manufacture of highly-ductile and geometrically complex MIM-parts based on TiAl6V4. In Proceedings of the Euro PM2006, Ghent, Belgium, 23–25 October 2006; Volume 2, pp. 191–196. [Google Scholar]

- Gökelma, M.; Celik, D.; Tazegul, O.; Cimenoglu, H.; Friedrich, B. Characteristics of Ti6Al4V Powders Recycled from Turnings via the HDH Technique. Metals 2018, 8, 336. [Google Scholar] [CrossRef]

- Dunstan, M.K.; Gordon, A.; Paramore, J.D.; Butler, B.G. Feasibility of Using Titanium Machine Turnings in Powder Metallurgy Processes. JOM 2019. [Google Scholar] [CrossRef]

- Lin, D.; Sanetrnik, D.; Cho, H.; Chung, S.T.; Kwon, Y.S.; Kate, K.H.; Hausnerova, B.; Atre, S.V.; Park, S.J. Rheological and thermal debinding properties of blended elemental Ti-6Al-4V powder injection molding feedstock. Powder Technol. 2017, 311, 357–363. [Google Scholar] [CrossRef]

- Li, Y.; Chou, X.M.; Yu, L. Dehydrogenation debinding process of MIM titanium alloys by TiH2powder. Powder Metall. 2013, 49, 236–239. [Google Scholar] [CrossRef]

- Ye, S.; Mo, W.; Lv, Y.; Li, X.; Kwok, C.T.; Yu, P. Metal Injection Molding of Thin-Walled Titanium Glasses Arms: A Case Study. JOM 2018, 70, 616–620. [Google Scholar] [CrossRef]

- Park, S.-J.; Wu, Y.; Heaney, D.F.; Zou, X.; Gai, G.; German, R.M. Rheological and Thermal Debinding Behaviors in Titanium Powder Injection Molding. Metall. Mater. Trans. A 2008, 40, 215–222. [Google Scholar] [CrossRef]

- Lin, D.; Kang, T.G.; Han, J.S.; Park, S.J.; Chung, S.T.; Kwon, Y.-S. Experimental and Numerical Analysis of Injection Molding of Ti-6Al-4V Powders for High-Performance Titanium Parts. JOM 2018, 70, 621–625. [Google Scholar] [CrossRef]

- He, Y.H.; Jiang, Y.; Xu, N.P.; Zou, J.; Huang, B.Y.; Liu, C.T.; Liaw, P.K. Fabrication of Ti–Al Micro/ Nanometer-Sized Porous Alloys through the Kirkendall Effect. Adv. Mater. 2007, 19, 2102–2106. [Google Scholar] [CrossRef]

- Ye, S.; Hao, H.; Mo, W.; Yu, K.; Liu, L.; Deng, C.; Yu, P. Effects of cold compacting pressure on the expansion behavior of Ti-48Al during sintering. J. Alloys Compd. 2016, 673, 399–404. [Google Scholar] [CrossRef]

- Frees, F.H. Powder Injection Molding (Pim) Of Titanium Alloys—Ripe For Expansion. Mater. Technol. 2016, 15, 295–299. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).