Experimental Research on Bond Behavior between GFRP Bars and Stirrups-Confined Concrete

Abstract

:Featured Application

Abstract

1. Introduction

2. Testing Program

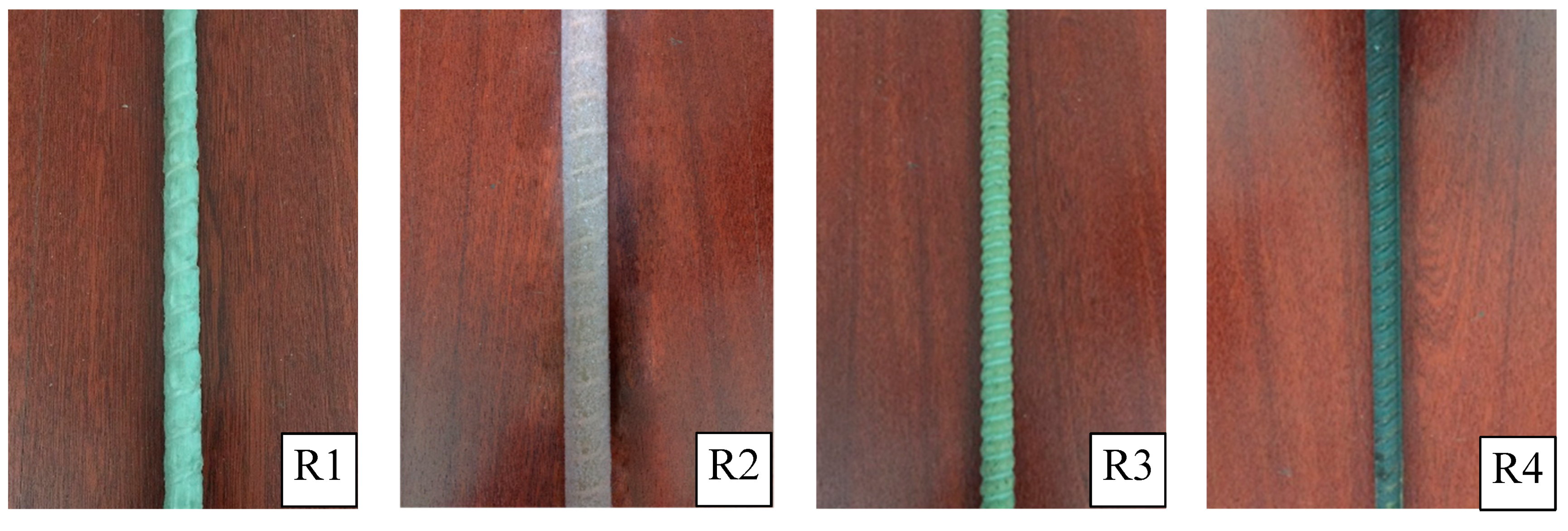

2.1. Material Properties

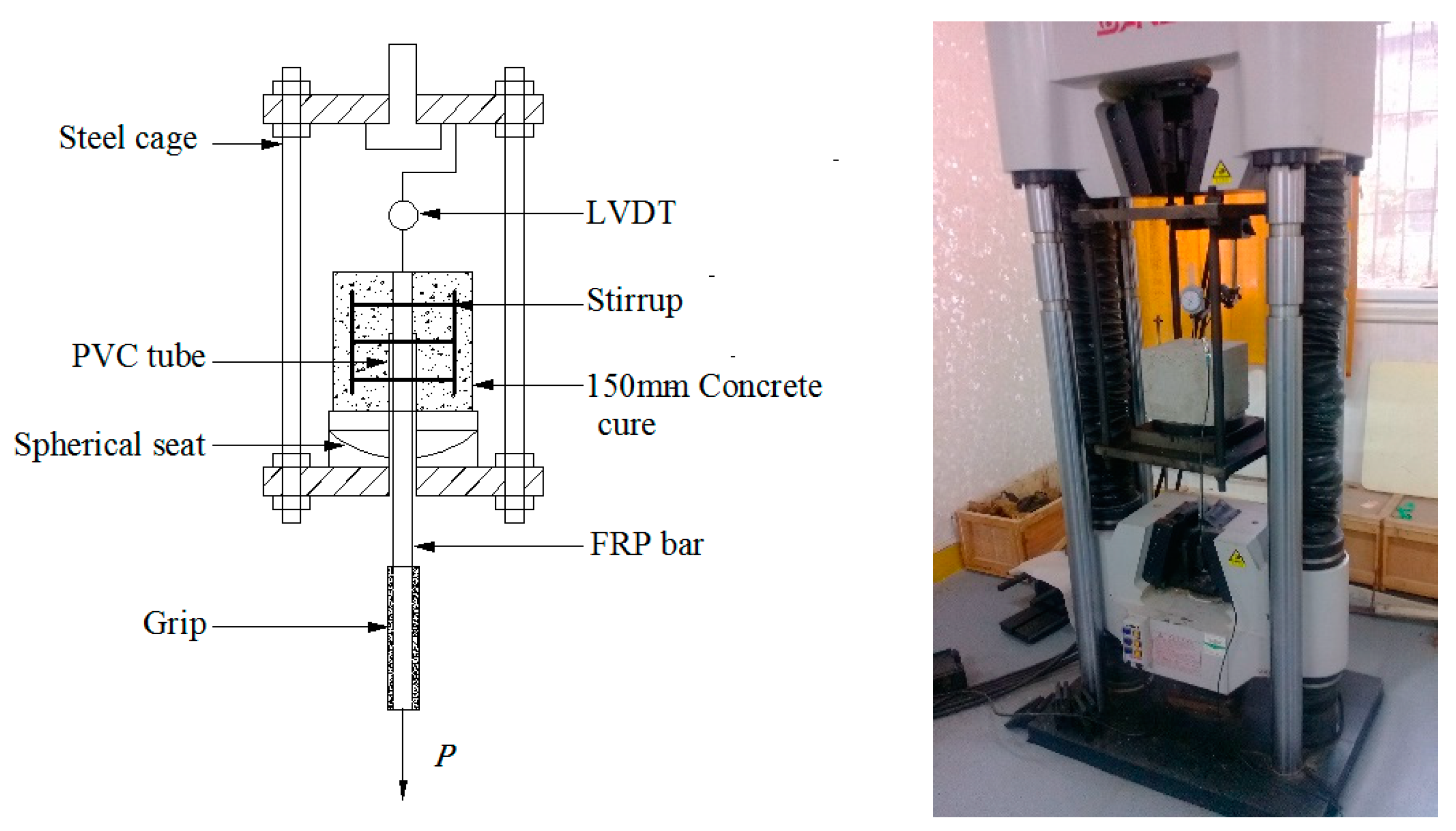

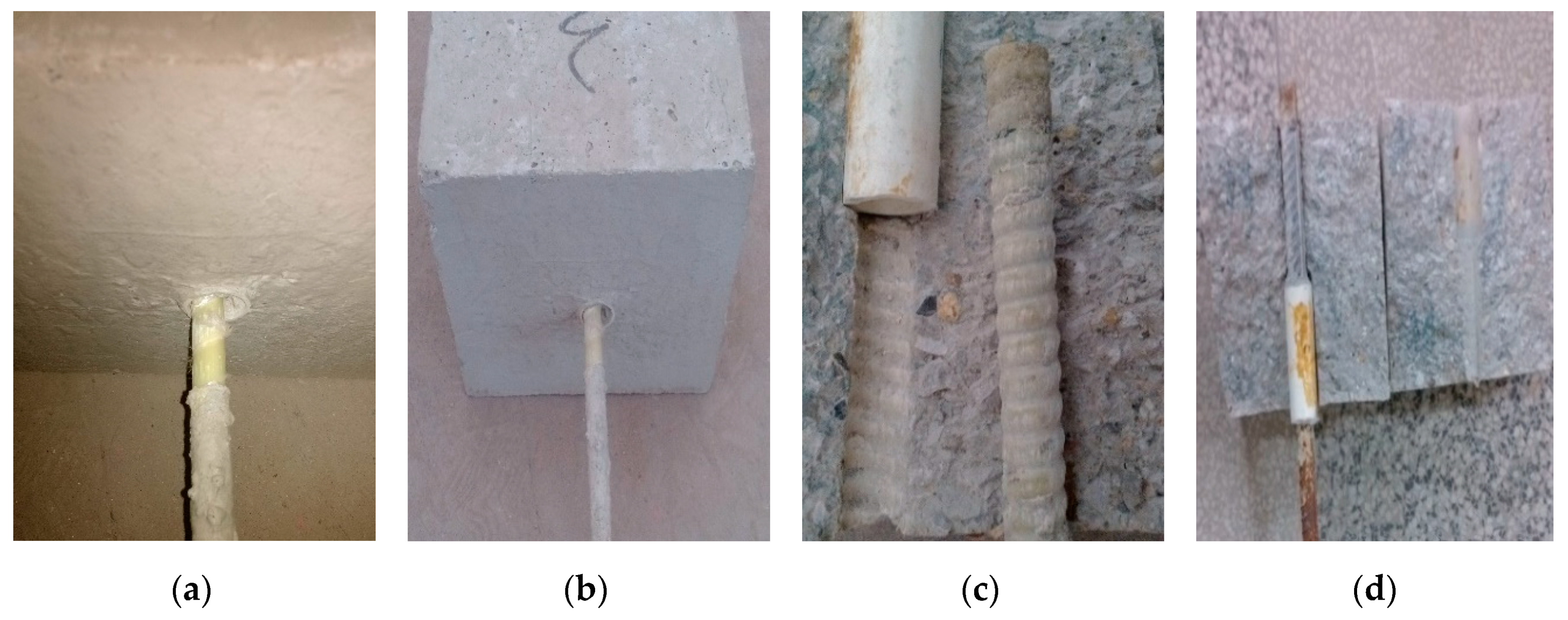

2.2. Specimens, Setup and Testing Equipment

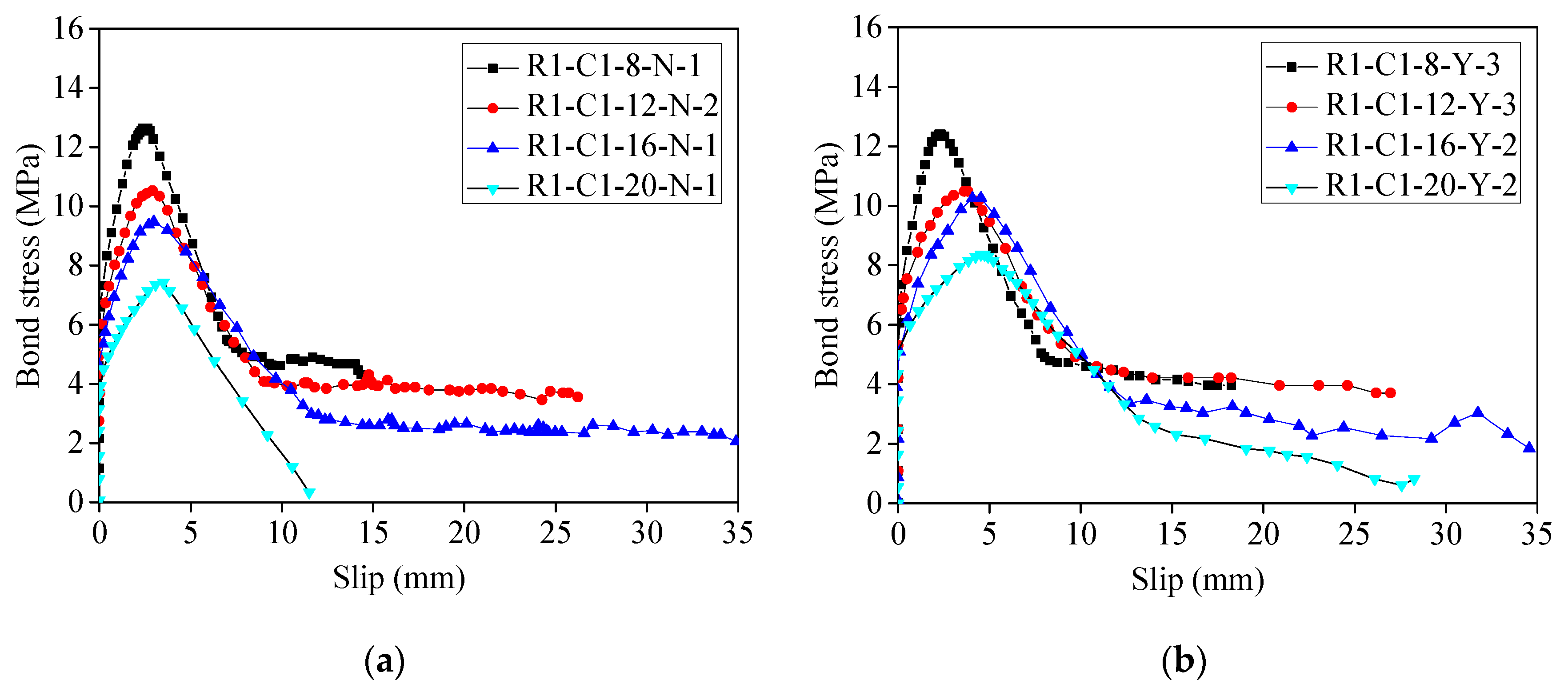

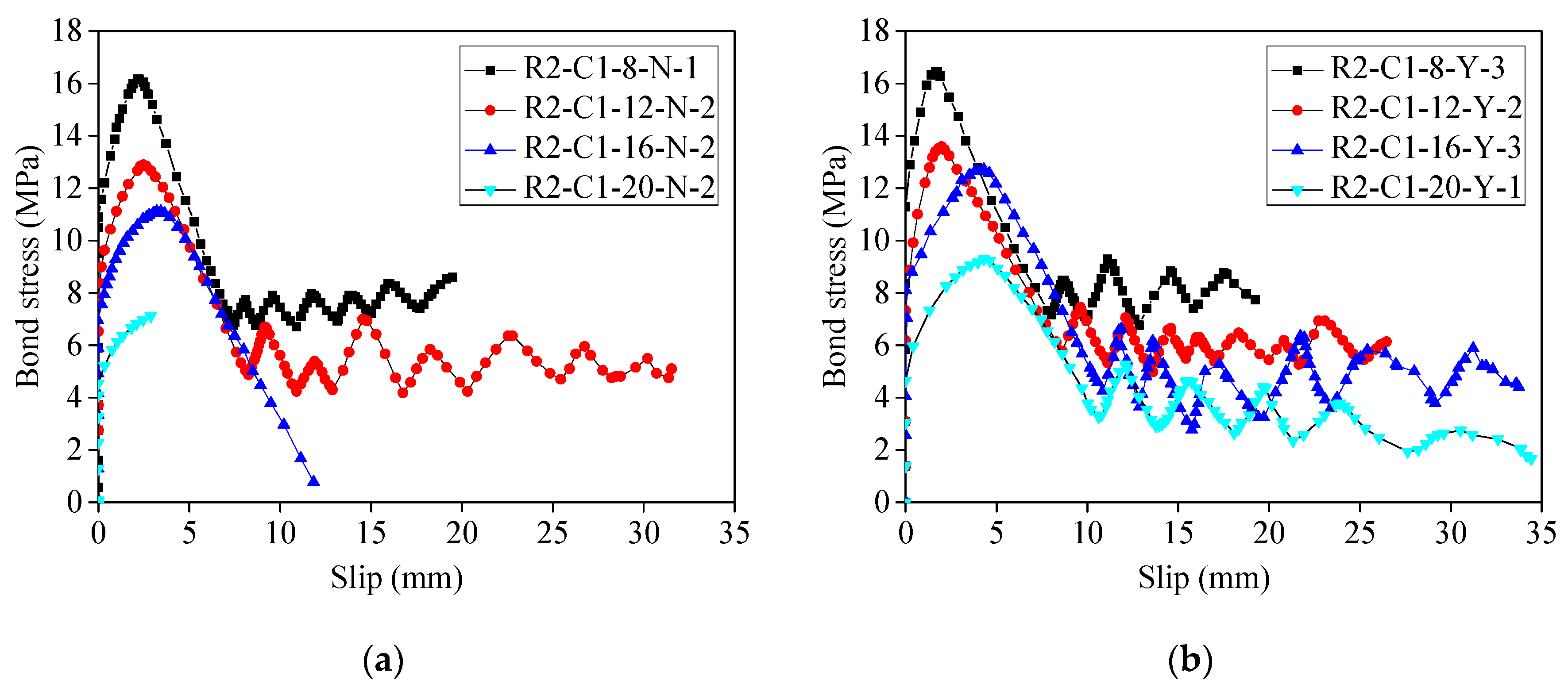

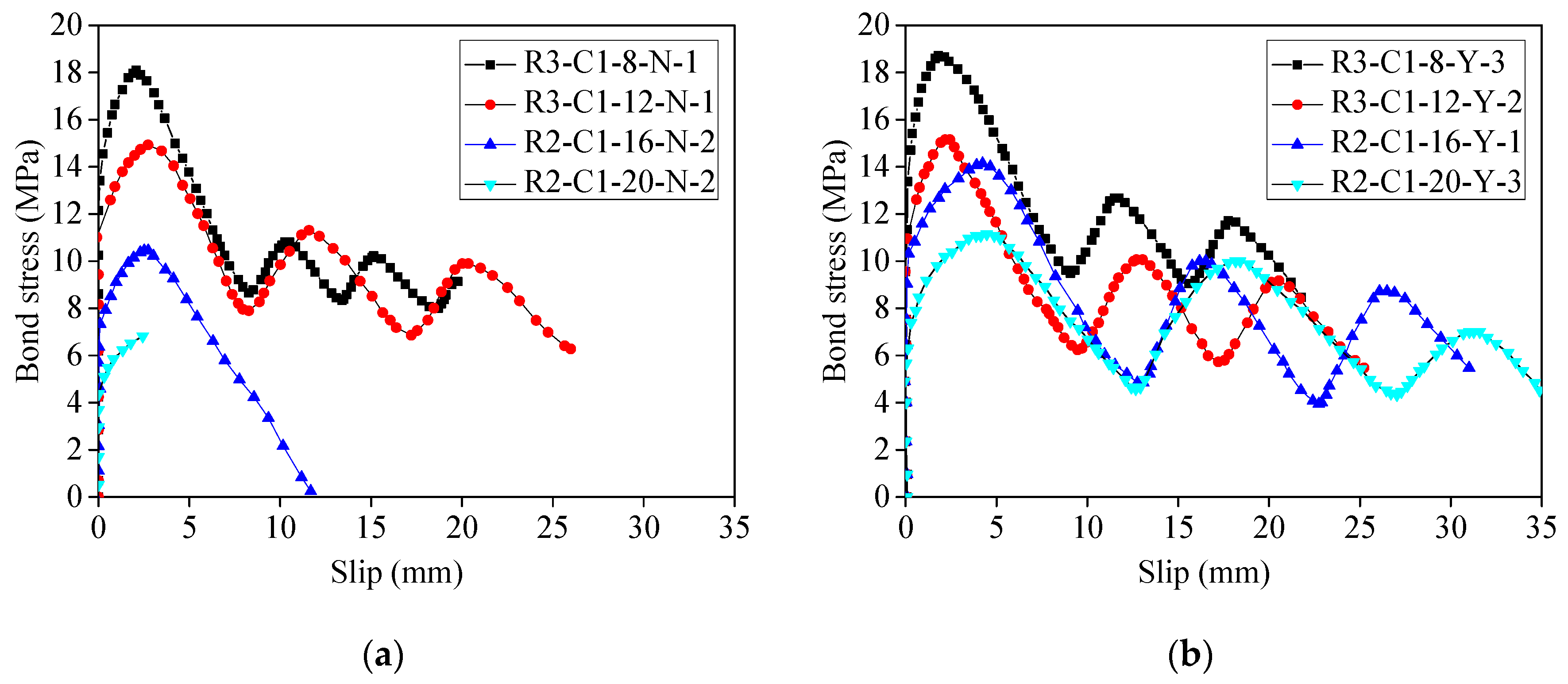

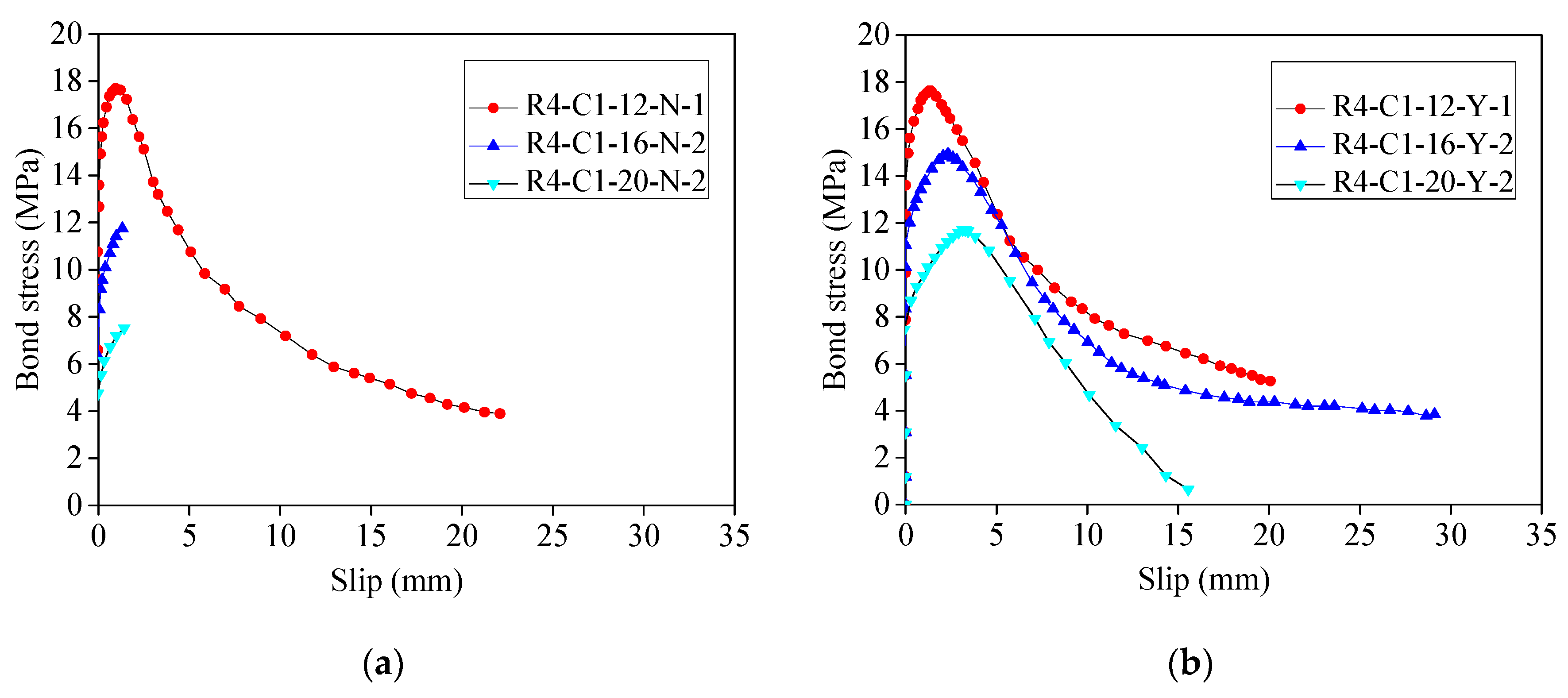

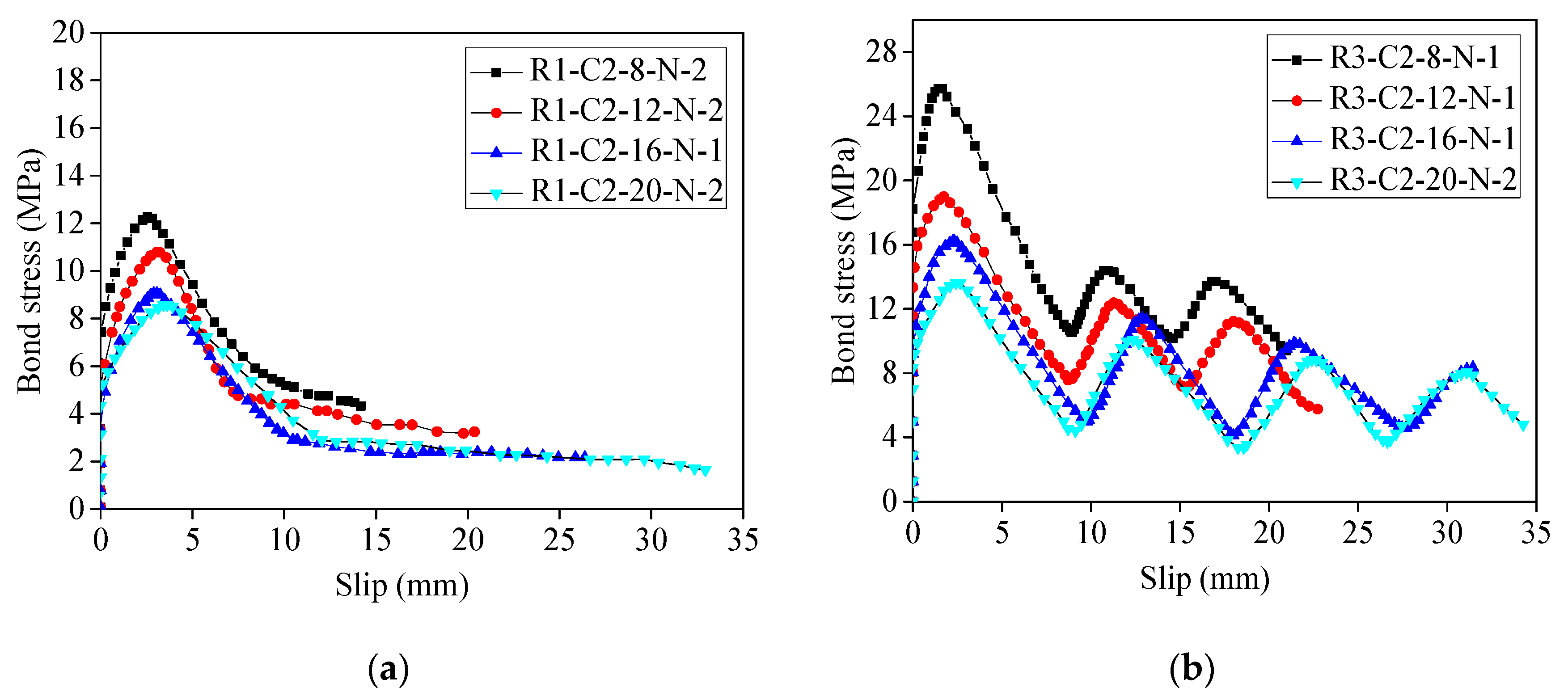

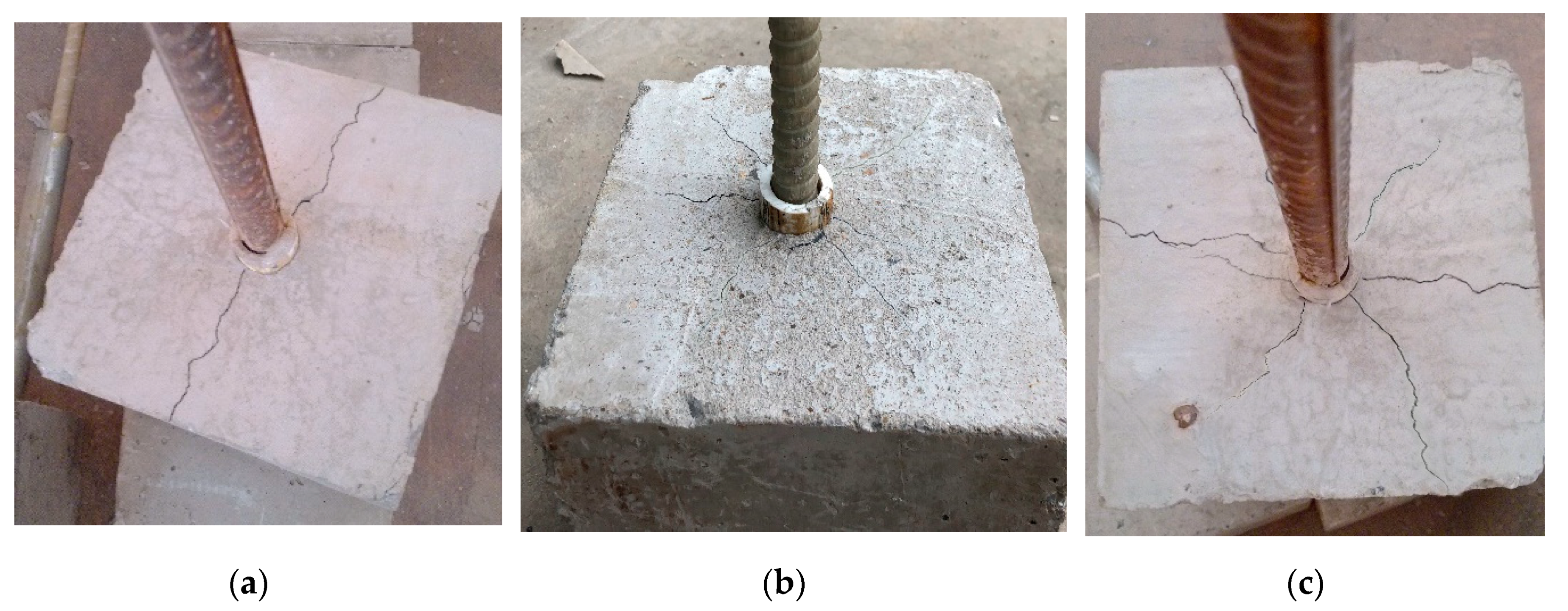

3. Experimental Result

4. Parameterization Analysis

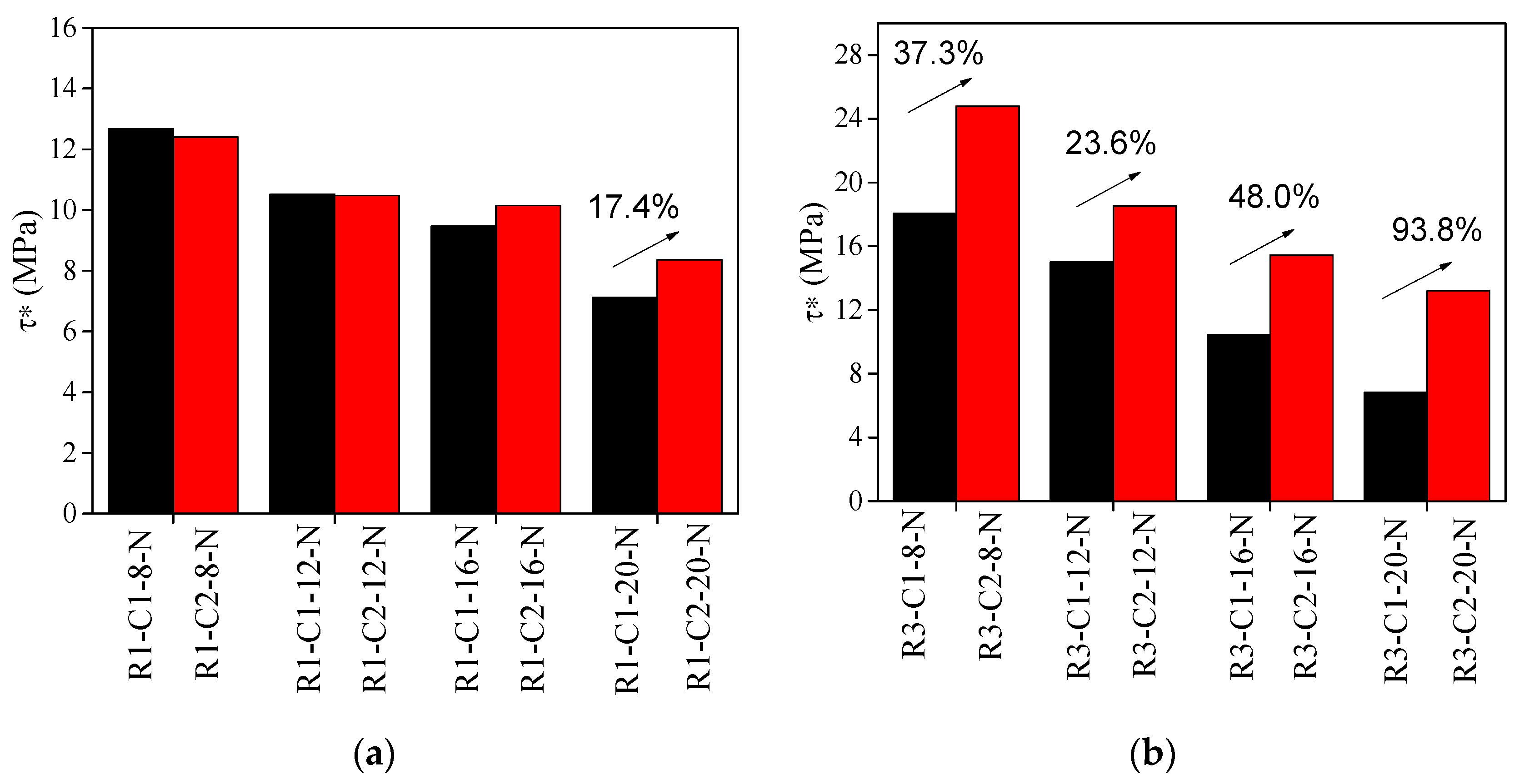

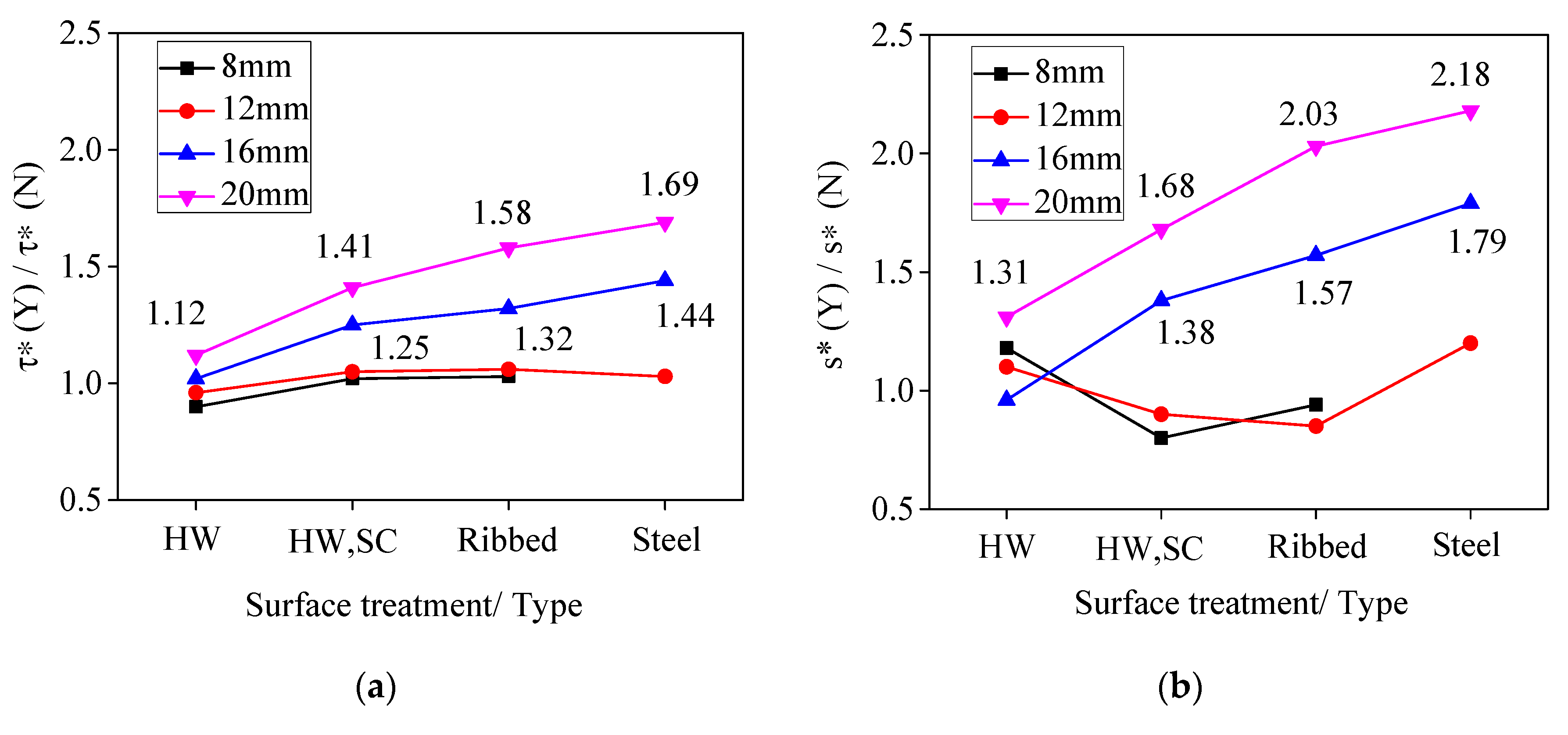

4.1. Influence of Bar Surface Characteristics

4.2. Influence of Bar Diameter

4.3. Influence of Concrete Strength

4.4. Influence of the Confined Effect of Stirrups

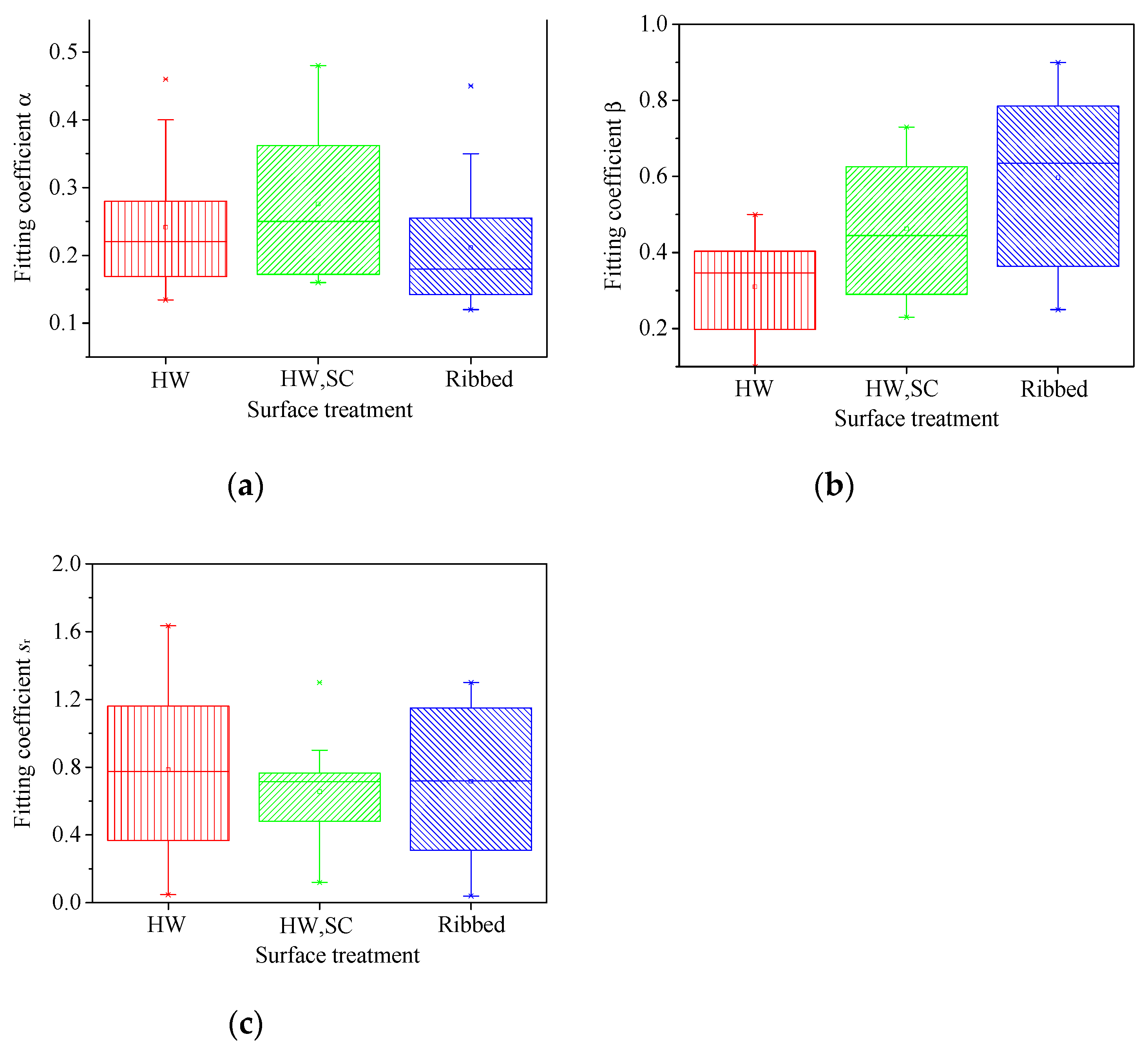

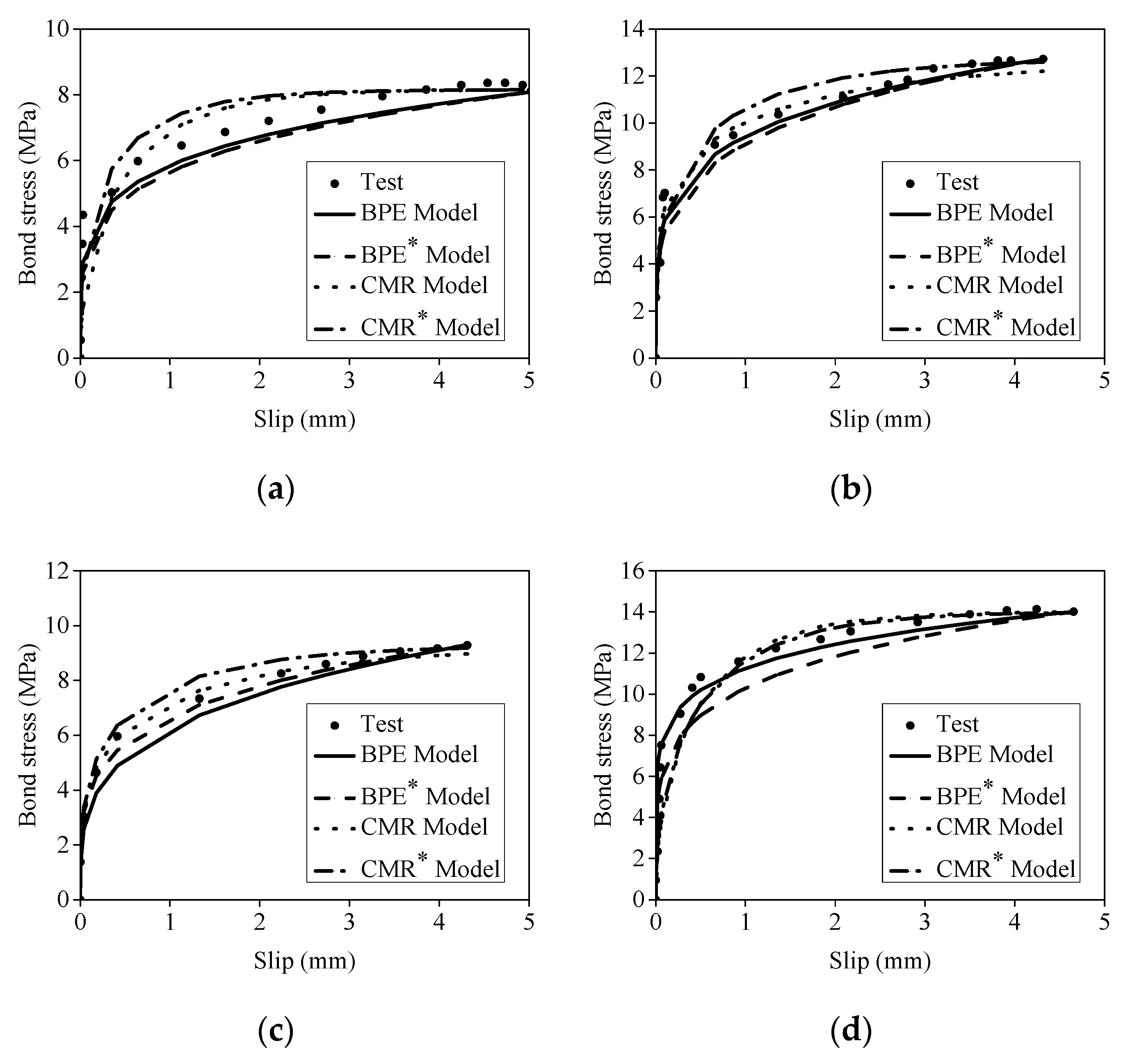

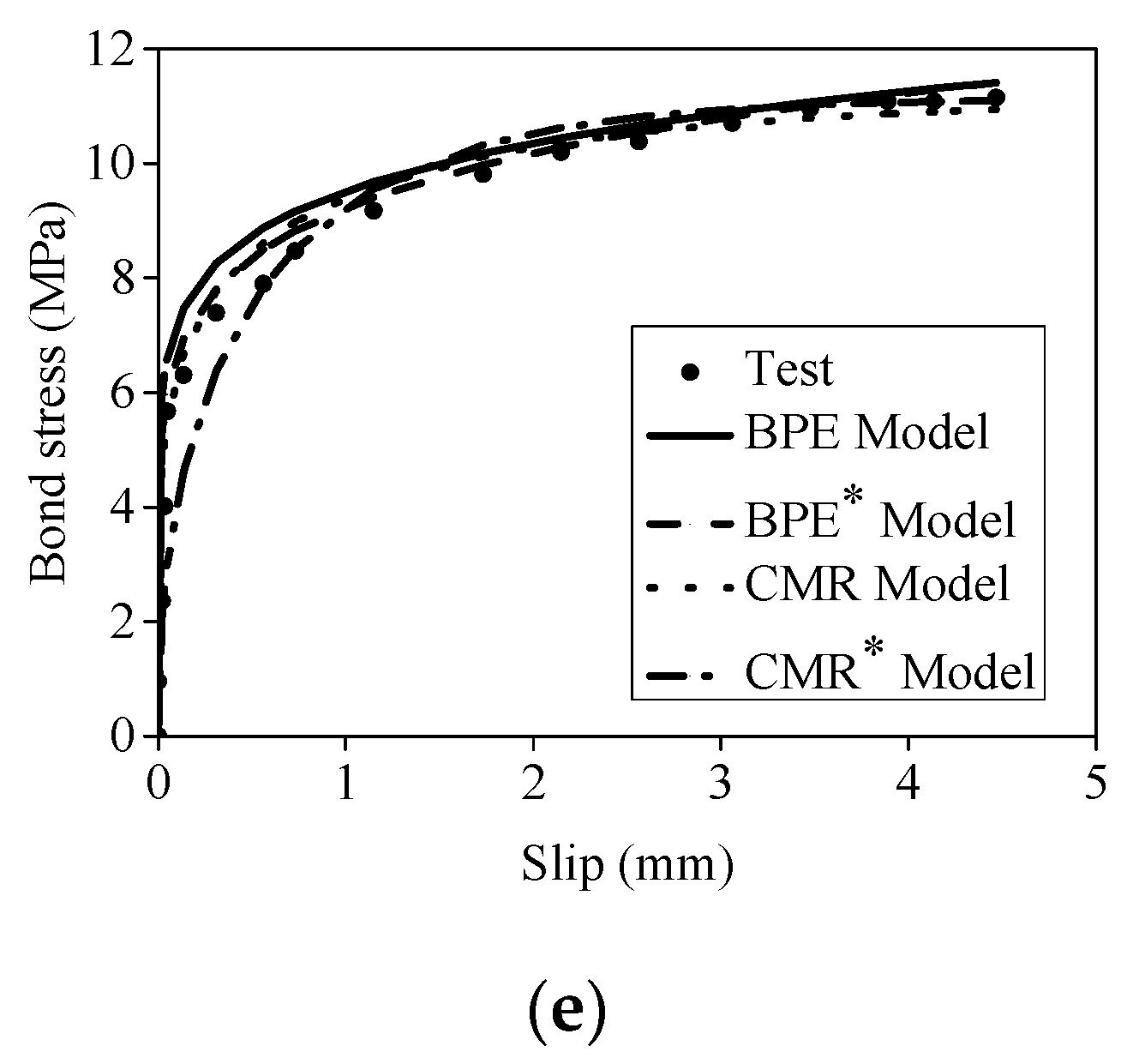

5. Bond Stress-Slip Relationship Model Between GFRP Bar and Stirrup-Confined Concrete

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kassem, C.; Farghaly, A.S.; Benmokrane, B. Evaluation of flexural behavior and serviceability performance of concrete beams reinforced with frp bars. J. Compos. Constr. 2011, 15, 682–695. [Google Scholar] [CrossRef]

- Ali, M.A.; El-Salakawy, E. Seismic Performance of GFRP-Reinforced Concrete Rectangular Columns. J. Compos. Constr. 2016, 20, 04015074. [Google Scholar] [CrossRef]

- Mady, M.; El-Ragaby, A.; El-Salakawy, E. Seismic behavior of beam-column joints reinforced with gfrp bars and stirrups. J. Compos. Constr. 2011, 15, 875–886. [Google Scholar] [CrossRef]

- Sebastian, W.M.; Vincent, J.; Starkey, S. Experimental characterization of load responses to failure of a RC frame and an NSM CFRP RC frame. Constr. Build. Mater. 2013, 49, 962–973. [Google Scholar] [CrossRef]

- Achillides, Z.; Pilakoutas, K. Bond behavior of fiber reinforced polymer bars under direct pullout conditions. J. Compos. Constr. 2004, 8, 173–181. [Google Scholar] [CrossRef]

- Okelo, R.; Yuan, R.L. Bond strength of fiber reinforced polymer rebars in normal strength concrete. J. Compos. Constr. 2005, 9, 203–213. [Google Scholar] [CrossRef]

- Lee, J.Y.; Kim, T.Y.; Kim, T.J.; Yi, C.K.; Park, J.S.; You, Y.C.; Park, Y.H. Interfacial bond strength of glass fiber reinforced polymer bars in high-strength concrete. Compos. Part B Eng. 2008, 39, 258–270. [Google Scholar] [CrossRef]

- Aiello, M.A.; Leone, M.; Pecce, M. Bond performances of frp rebars-reinforced concrete. J. Mater. Civ. Eng. 2007, 19, 205–213. [Google Scholar] [CrossRef]

- Baena, M.; Torres, L.; Turon, A.; Barris, C. Experimental study of bond behavior between concrete and FRP bars using a pull-out test. Compos. Part B Eng. 2009, 40, 784–797. [Google Scholar] [CrossRef]

- Hao, Q.; Wang, Y.; He, Z.; Ou, J. Bond strength of glass fiber reinforced polymer ribbed rebars in normal strength concrete. Constr. Build. Mater. 2009, 23, 865–871. [Google Scholar] [CrossRef]

- Davalos, J.F.; Chen, Y.; Ray, I. Effect of frp bar degradation on interface bond with high strength concrete. Cement Concrete Compos. 2008, 30, 722–730. [Google Scholar] [CrossRef]

- Fava, G.; Carvelli, V.; Pisani, M.A. Remarks on bond of GFRP rebars and concrete. Compos. Part B Eng. 2016, 93, 210–220. [Google Scholar] [CrossRef]

- Kim, B.; Doh, J.H.; Yi, C.K.; Lee, J.Y. Effects of structural fibers on bonding mechanism changes in interface between GFRP bar and concrete. Compos. Part B Eng. 2013, 45, 768–779. [Google Scholar] [CrossRef]

- Li, W.; Ho, S.C.M.; Patil, D.; Song, G. Acoustic emission monitoring and finite element analysis of debonding in fiber-reinforced polymer rebar reinforced concrete. Struct. Health Monit. 2017, 16, 674–681. [Google Scholar] [CrossRef]

- Kai, X.; Changchun, R.; Qingshan, D.; Qingping, J.; Xuemin, C. Real-time monitoring of bond slip between gfrp bar and concrete structure using piezoceramic transducer-enabled active sensing. Sensors 2018, 18, 2653. [Google Scholar]

- Li, W.; Fan, S.; Ho, S.C.M.; Wu, J.; Song, G. Interfacial debonding detection in fiber-reinforced polymer rebar–reinforced concrete using electro-mechanical impedance technique. Struct. Health Monit. 2018, 17, 461–471. [Google Scholar] [CrossRef]

- Jiang, T.; Kong, Q.; Patil, D.; Luo, Z.; Huo, L.; Song, G. Detection of debonding between fiber reinforced polymer bar and concrete structure using piezoceramic transducers and wavelet packet analysis. IEEE Sens. J. 2017, 17, 1992–1998. [Google Scholar] [CrossRef]

- Malvar, L.J. Bond Stress-Slip Characteristics of FRP Rebars; (No. NFESC-TR-2013-SHR); Naval Facilities Engineering Service Center: Port Hueneme, CA, USA, 1994. [Google Scholar]

- Eligehausen, R.; Popov, E.P.; Bertero, V.V. Local Bond Stress-Slip Relationships of Deformed Bars under Generalized Excitations; Report No. 83/23; Earthquake Engineering Service Center, University of California: Berkeley, CA, USA, 1983. [Google Scholar]

- Cosenza, E.; Manfredi, G.; Realfonzo, R. Analytical modelling of bond between frp reinforcing bars and concrete. In Non-Metallic (FRP) Reinforcement for Concrete Structures: Proceedings of the Second International RILEM Symposium; RC Press: London, England, 1995; Volume 29, p. 164. [Google Scholar]

- Cosenza, E.; Manfredi, G.; Realfonzo, R. Behavior and modeling of bond of FRP rebars to concrete. J. Compos. Constr. 1997, 1, 40–51. [Google Scholar] [CrossRef]

- Lin, X.; Zhang, Y.X. Evaluation of bond stress-slip models for FRP reinforcing bars in concrete. Comput. Struct. 2014, 107, 131–141. [Google Scholar] [CrossRef]

- Pepe, M.; Mazaheripour, H.; Barros, J.; Sena-Cruz, J.; Martinelli, E. Numerical calibration of bond law for gfrp bars embedded in steel fibre-reinforced self-compacting concrete. Compos. Part B Eng. 2013, 50, 403–412. [Google Scholar] [CrossRef]

- Yoo, D.Y.; Kwon, K.Y.; Park, J.J.; Yoon, Y.S. Local bond-slip response of GFRP rebar in ultra-high-performance fiber-reinforced concrete. Comput. Struct. 2015, 120, 53–64. [Google Scholar] [CrossRef]

- Masmoudi, A.; Masmoudi, R.; Ouezdou, M.B. Thermal effects on gfrp rebars experimental study and analytical analysis. Mater. Struct. 2010, 43, 775–788. [Google Scholar] [CrossRef]

- Long, W.J.; Khayat, K.; Lemieux, G.; Hwang, S.D.; Xing, F. Pull-out strength and bond behavior of prestressing strands in prestressed self-consolidating concrete. Materials 2014, 7, 6930–6946. [Google Scholar] [CrossRef]

- Zhang, H.; Yu, R. Inclined fiber pullout from a cementitious matrix: A numerical study. Materials 2016, 9, 800. [Google Scholar] [CrossRef] [PubMed]

- ACI 440.1R-06. Guide for the Design and Construction of Concrete Reinforced with FRP Bars; ACI Committee 440, American Concrete Institute: Farmington Hills, MI, USA, 2006. [Google Scholar]

- CAN/CSA S806-02. Design and Construction of Building Components with Fibre-Reinforced Polymers; Canadian Standards Association: Rexdale, ON, Canada, 2002. [Google Scholar]

- CSA S6-06. Canadian Highway Bridge Design Code; Canadian Standards Association: Rexdale, ON, Canada, 2006. [Google Scholar]

- Machida, A.; Uomoto, T. Recommendation for design and construction of concrete structures using continuous fiber reinforcing materials. In Research Committee on Continuous Fiber Reinforcing Materials; Japan Society of Civil Engineers: JSCE, Japan, 1997; Volume 23. [Google Scholar]

- Darwin, D.; Graham, E.K. Effect of Deformation Height and Spacing on Bond Strength of Reinforcing Bars; University of Kansas Center for Research, Inc.: Lawrence, KS, USA, 1993. [Google Scholar]

- Darwin, D.; Graham, E.K. Effect of deformation height and spacing on bond strength of reinforcing bars. ACI Struct. J. 1993, 90, 646–657. [Google Scholar]

- Darwin, D.; Zuo, J.; Tholen, M.L.; Idun, E.K. Development length criteria for conventional and high relative rib area reinforcing bars. ACI Struct. J. 1996, 93, 347–359. [Google Scholar]

- ACI 408R-03. Bond and Development of Straight Reinforcing Bars in Tension; ACI 408R-03, ACI Committee 408, American Concrete Institute: Farmington Hills, MI, USA, 2003. [Google Scholar]

- Shield, C.K.; Wambeke, B.W. Development Length of Glass Fiber-Reinforced Polymer Bars in Concrete. ACI Struct. J. 2006, 103, 11–17. [Google Scholar]

- Mohamed, H.M.; Afifi, M.Z.; Benmokrane, B. Performance evaluation of concrete columns reinforced longitudinally with frp bars and confined with frp hoops and spirals under axial load. J. Bridge Eng. 2014, 19, 04014020. [Google Scholar] [CrossRef]

- Maranan, G.B.; Manalo, A.C.; Benmokrane, B.; Karunasena, W.; Mendis, P. Behavior of concentrically loaded geopolymer-concrete circular columns reinforced longitudinally and transversely with gfrp bars. Eng. Struct. 2016, 117, 422–436. [Google Scholar] [CrossRef]

- Woraphot, P.; Sitthichai, P.; Athawit, S.; Suchart, L. Behavior and performance of gfrp reinforced concrete columns with various types of stirrups. Int. J. Polym. Sci. 2015, 2015, 1–9. [Google Scholar]

- Sonobe, Y.; Fukuyama, H.; Okamoto, T.; Kani, N.; Kimura, K.; Kobayashi, K.; Masuda, Y.; Matsuzaki, Y.; Mochizuki, S.; Nagasaka, T.; et al. Design guidelines of frp reinforced concrete building structures. J. Compos. Constr. 1997, 1, 90–115. [Google Scholar] [CrossRef]

- ACI 440.3R-04. Guide Test Methods for Fiber-Reinforced Polymers (FRPs) for Reinforcing or Strengthening Concrete Structures; ACI Committee 440, American Concrete Institute: Farmington Hills, MI, USA, 2004. [Google Scholar]

- Zhang, B.; Benmokrane, B. Pullout bond properties of fiber-reinforced polymer tendons to grout. J. Mater. Civ. Eng. 2002, 14, 399–408. [Google Scholar] [CrossRef]

- Tepfers, R. Bond clause proposal for FRP-bars/rods in concrete based on CEB/FIP Model Code 90. Part 1: Design bond stress for FRP reinforcing bars. Struct. Concrete 2006, 7, 47–55. [Google Scholar] [CrossRef]

- Yan, F.; Lin, Z.; Yang, M. Bond mechanism and bond strength of GFRP bars to concrete: A review. Compos. Part B Eng. 2016, 98, 56–69. [Google Scholar] [CrossRef]

| 1Group | Bar Type | Nominal Bar Diameter (mm) | Experimental Bar Diameter (mm) a | Surface Treatment b | Tensile Strength (MPa) | Elastic Modulus (GPa) |

|---|---|---|---|---|---|---|

| R1 | GFRP | 8 | 8.22 | HW | 828 | 48.90 |

| GFRP | 12 | 13.12 | HW | 660 | 44.25 | |

| GFRP | 16 | 15.68 | HW | 578 | 40.69 | |

| GFRP | 20 | 19.21 | HW | 520 | 39.00 | |

| R2 | GFRP | 8 | 8.58 | HW,SC | 876 | 49.5 |

| GFRP | 12 | 12.62 | HW,SC | 634 | 43.80 | |

| GFRP | 16 | 15.53 | HW,SC | 569 | 41.5 | |

| GFRP | 20 | 21.21 | HW,SC | 544 | 40.82 | |

| R3 | GFRP | 8 | 9.14 | Ribbed | 890 | 50.21 |

| GFRP | 12 | 11.45 | Ribbed | 732 | 46.12 | |

| GFRP | 16 | 16.84 | Ribbed | 620 | 42.32 | |

| GFRP | 20 | 21.13 | Ribbed | 570 | 41.57 | |

| R4 | steel | 8 | 7.86 | -- | >500 | 210 |

| steel | 12 | 12.22 | -- | >500 | 210 | |

| steel | 16 | 15.85 | -- | >500 | 210 | |

| steel | 20 | 20.07 | -- | >500 | 210 |

| Concrete Mix | C1 | C2 |

|---|---|---|

| Water (kg/m3) | 185 | 195 |

| Cement (kg/m3) | 429 | 542 |

| Coarse aggregate (kg/m3) a | 1250 | 1164 |

| Fine aggregate (kg/m3) b | 536 | 499 |

| Air content (%) | 2.5 | 2.5 |

| Specimen | τmax (MPa) | τ* (MPa) | sm (mm) | s* (mm) | Failure Mode a | Specimen | τmax (MPa) | τ* (MPa) | sm (mm) | s* (mm) | Failure Mode a |

|---|---|---|---|---|---|---|---|---|---|---|---|

| R1-C1- 8-N-1 | 12.62 | 13.51 | 2.37 | 2.245 | P | R1-C1- 8-Y-1 | 12.40 | 12.03 | 2.12 | 2.51 | P |

| R1-C1- 8-N-2 | 13.40 | 2.12 | P | R1-C1- 8-Y-2 | 11.8 | 2.25 | P | ||||

| R1-C1- 8-Y-3 | 11.9 | 3.17 | P | ||||||||

| R1-C1- 12-N-1 | 10.52 | 10.32 | 2.91 | 2.82 | P | R1-C1- 12-Y-1 | 9.54 | 10.01 | 2.90 | 3.11 | P |

| R1-C1- 12-N-2 | 10.11 | 2.73 | P | R1-C1- 12- Y-2 | 10.48 | 3.12 | P | ||||

| R1-C1- 12- Y-3 | 10.02 | 3.32 | P | ||||||||

| R1-C1- 16-N-1 | 9.47 | 9.79 | 3.0 | 3.10 | P | R1-C1- 16-Y-1 | 10.25 | 10.02 | 3.18 | 3.50 | P |

| R1-C1- 16-N-2 | 10.1 | 3.2 | P | R1-C1- 16-Y-2 | 9.48 | 3.20 | P | ||||

| R1-C1- 16-Y-3 | 10.34 | 4.11 | P | ||||||||

| R1-C1- 20-N-1 | 7.22 | 7.42 | 3.23 | 3.30 | S | R1-C1- 20-Y-1 | 9.0 | 8.83 | 4.72 | 4.50 | P |

| R1-C1- 20-N-2 | 7.62 | 3.37 | S | R1-C1- 20-Y-2 | 9.3 | 4.67 | P | ||||

| R1-C1- 20-Y-3 | 8.2 | 4.11 | P | ||||||||

| R2-C1- 8-N-1 | 15.89 | 16.19 | 1.89 | 2.10 | P | R2-C1- 8-Y-1 | 16.20 | 16.49 | 1.63 | 1.66 | P |

| R2-C1- 8-N-2 | 16.49 | 2.31 | P | R2-C1- 8-Y-2 | 17.01 | 1.57 | P | ||||

| R2-C1- 8-Y-3 | 16.27 | 1.78 | P | ||||||||

| R2-C1- 12-N-1 | 12.83 | 12.94 | 2.36 | 2.50 | P | R2-C1- 12-Y-1 | 13.11 | 13.58 | 1.98 | 2.24 | P |

| R2-C1- 12-N-2 | 13.05 | 2.64 | P | R2-C1- 12- Y-2 | 14.02 | 2.3 | P | ||||

| R2-C1- 12- Y-3 | 13.61 | 2.43 | P | ||||||||

| R2-C1- 16-N-1 | 10.24 | 10.32 | 2.96 | 3.20 | S | R2-C1- 16-Y-1 | 11.8 | 12.90 | 4.62 | 4.48 | P |

| R2-C1- 16-N-2 | 10.40 | 3.44 | S | R2-C1- 16-Y-2 | 13.7 | 4.24 | P | ||||

| R2-C1- 16-Y-3 | 13.2 | 4.58 | P | ||||||||

| R2-C1- 20-N-1 | 6.72 | 7.11 | 2.85 | 3.00 | S | R2-C1- 20-Y-1 | 9.27 | 9.95 | 4.88 | 5.00 | P |

| R2-C1- 20-N-2 | 7.50 | 3.15 | S | R2-C1- 20-Y-2 | 10.46 | 5.14 | P | ||||

| R2-C1- 20-Y-3 | 10.12 | 4.98 | P | ||||||||

| R3-C1- 8-N-1 | 17.84 | 18.06 | 1.96 | 2.10 | P | R3-C1- 8-Y-1 | 18.8 | 18.64 | 1.98 | 1.97 | P |

| R3-C1- 8-N-2 | 18.28 | 2.24 | P | R3-C1- 8-Y-2 | 19.1 | 2.13 | P | ||||

| P | R3-C1- 8-Y-3 | 18.02 | 1.80 | P | |||||||

| R3-C1- 12-N-1 | 14.22 | 14.67 | 2.57 | 2.81 | P | R3-C1- 12-Y-1 | 14.83 | 15.62 | 2.62 | 2.38 | P |

| R3-C1- 12-N-2 | 15.12 | 3.14 | P | R3-C1- 12- Y -2 | 15.21 | 2.14 | P | ||||

| R3-C1- 12- Y -3 | 16.82 | 2.38 | P | ||||||||

| R3-C1- 16-N-1 | 10.66 | 10.44 | 2.31 | 2.50 | S | R3-C1- 16-Y-1 | 13.22 | 13.78 | 4.32 | 4.00 | P |

| R3-C1- 16-N-2 | 10.22 | 2.69 | S | R3-C1- 16-Y-2 | 14.16 | 3.86 | P | ||||

| R3-C1- 16-Y-3 | 13.96 | 3.82 | P | ||||||||

| R3-C1- 20-N-1 | 6.80 | 7.01 | 2.19 | 2.30 | S | R3-C1- 20-Y-1 | 11.07 | 11.23 | 4.45 | 4.60 | P |

| R3-C1- 20-N-2 | 7.22 | 2.41 | S | R3-C1- 20-Y-2 | 11.27 | 4.78 | P | ||||

| R3-C1- 20-Y-3 | 11.35 | 4.57 | P | ||||||||

| R4-C1- 8-N-1 | / | / | / | R4-C1- 8-Y-1 | / | / | / | ||||

| R4-C1- 8-N-2 | / | / | / | R4-C1- 8-Y-2 | / | / | / | ||||

| R4-C1- 8-Y-3 | / | / | / | ||||||||

| R4-C1- 12-N-1 | 18.20 | 17.5 | 0.98 | 0.90 | P | R4-C1- 12-Y-1 | 18.5 | 18 | 1.12 | 1.1 | P |

| R4-C1- 12-N-2 | 16.80 | 1.32 | P | R4-C1- 12- Y -2 | 17.8 | 1.48 | P | ||||

| R4-C1- 12- Y -3 | 17.7 | 1.53 | P | ||||||||

| R4-C1- 16-N-1 | 10.98 | 11.3 | 1.98 | 1.21 | S | R4-C1- 16-Y-1 | 15.91 | 15.82 | 4.0 | 2.16 | P |

| R4-C1- 16-N-2 | 11.62 | 2.42 | S | R4-C1- 16-Y-2 | 15.17 | 3.69 | P | ||||

| R4-C1- 16-Y-3 | 16.38 | 4.19 | P | ||||||||

| R4-C1- 20-N-1 | 6.96 | 7.14 | 1.98 | 1.43 | S | R4-C1- 20-Y-1 | 11.98 | 10.78 | 4.62 | 3.08 | S |

| R4-C1- 20-N-2 | 7.32 | 2.22 | S | R4-C1- 20-Y-2 | 10.36 | 3.96 | S | ||||

| R4-C1- 20-Y-3 | 10.0 | 4.65 | S | ||||||||

| R1-C2- 8-N-1 | 12.38 | 12.16 | 2.53 | 2.73 | P | R1-C2- 8-Y-1 | 12.54 | 12.28 | 2.78 | 2.54 | P |

| R1-C2- 8-N-2 | 11.94 | 2.93 | P | R1-C2- 8-Y-2 | 11.94 | 2.39 | P | ||||

| P | R1-C2- 8-Y-3 | 12.36 | 2.45 | P | |||||||

| R1-C2- 12-N-1 | 11.02 | 10.73 | 3.34 | 3.27 | P | R1-C2- 12-Y-1 | 10.57 | 10.78 | 3.0 | 3.10 | P |

| R1-C2- 12-N-2 | 10.44 | 3.20 | P | R1-C2- 12- Y -2 | 10.11 | 3.12 | P | ||||

| P | R1-C2- 12- Y -3 | 11.65 | 3.18 | P | |||||||

| R1-C2- 16-N-1 | 9.78 | 9.63 | 2.07 | 2.11 | P | R1-C2- 16-Y-1 | 9.34 | 9.06 | 2.68 | 3.06 | P |

| R1-C2- 16-N-2 | 9.48 | 2.15 | P | R1-C2- 16-Y-2 | 8.78 | 2.4 | P | ||||

| R1-C2- 16-Y-3 | 9.06 | 4.11 | P | ||||||||

| R1-C2- 20-N-1 | 8.07 | 8.21 | 2.49 | 2.70 | P | R1-C2- 20-Y-1 | 8.82 | 8.57 | 3.12 | 3.23 | P |

| R1-C2- 20-N-2 | 8.35 | 2.91 | P | R1-C2- 20-Y-2 | 8.13 | 2.94 | P | ||||

| R1-C2- 20-Y-3 | 8.76 | 3.63 | P | ||||||||

| R3-C2- 8-N-1 | 25.2 | 24.8 | 1.74 | 1.87 | P | R3-C1- 8-Y-1 | 26.21 | 25.74 | 1.56 | 1.44 | P |

| R3-C2- 8-N-2 | 24.4 | 2.0 | P | R3-C1- 8-Y-2 | 24.84 | 1.42 | P | ||||

| R3-C1- 8-Y-3 | 26.17 | 1.34 | P | ||||||||

| R3-C2- 12-N-1 | 17.86 | 18.54 | 2.02 | 2.19 | P | R3-C1- 12-Y-1 | 19.34 | 18.90 | 1.59 | 1.72 | P |

| R3-C2- 12-N-2 | 19.22 | 2.36 | P | R3-C1- 12- Y -2 | 18.74 | 1.82 | P | ||||

| R3-C1- 12- Y -3 | 18.62 | 1.75 | P | ||||||||

| R3-C2- 16-N-1 | 14.48 | 15.54 | 3.11 | 2.80 | P | R3-C1- 16-Y-1 | 15.02 | 16.10 | 2.23 | 2.40 | P |

| R3-C2- 16-N-2 | 16.60 | 2.49 | P | R3-C1- 16-Y-2 | 17.24 | 2.57 | P | ||||

| R3-C1- 16-Y-3 | 16.04 | 2.40 | P | ||||||||

| R3-C2- 20-N-1 | 12.87 | 13.2 | 3.14 | 3.30 | P | R3-C1- 20-Y-1 | 14.28 | 13.75 | 2.96 | 3.16 | P |

| R3-C2- 20-N-2 | 13.53 | 3.46 | P | R3-C1- 20-Y-2 | 14.21 | 3.31 | P | ||||

| R3-C1- 20-Y-3 | 12.75 | 3.21 | P |

| Reference | Surface Characteristic | Number of Tests | BMP | CMR | ||||

|---|---|---|---|---|---|---|---|---|

| α | β | sr | ||||||

| Mean Value | Median Value | Mean Value | Median Value | Mean Value | Median Value | |||

| Cosenza et al. [21] | HW,SC | 10 | 0.251 | 0.559 | 0.41 | |||

| ribbed | 27 | 0.283 | 0.575 | 0.45 | ||||

| Yan et al. [44] | HW,SC | 21 | 0.31 | 0.51 | 0.73 | |||

| ribbed | 34 | 0.38 | 0.62 | 0.65 | ||||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, K.; Li, Z.; Zhang, J.; Tu, J.; Li, X. Experimental Research on Bond Behavior between GFRP Bars and Stirrups-Confined Concrete. Appl. Sci. 2019, 9, 1340. https://doi.org/10.3390/app9071340

Gao K, Li Z, Zhang J, Tu J, Li X. Experimental Research on Bond Behavior between GFRP Bars and Stirrups-Confined Concrete. Applied Sciences. 2019; 9(7):1340. https://doi.org/10.3390/app9071340

Chicago/Turabian StyleGao, Kui, Zhao Li, Jiarui Zhang, Jianwei Tu, and Xinping Li. 2019. "Experimental Research on Bond Behavior between GFRP Bars and Stirrups-Confined Concrete" Applied Sciences 9, no. 7: 1340. https://doi.org/10.3390/app9071340

APA StyleGao, K., Li, Z., Zhang, J., Tu, J., & Li, X. (2019). Experimental Research on Bond Behavior between GFRP Bars and Stirrups-Confined Concrete. Applied Sciences, 9(7), 1340. https://doi.org/10.3390/app9071340