Abstract

Kapok is a hollow fiber with a 90% hollow degree. Compared with cotton fiber, kapok fiber has excellent performances, such as good hygroscopicity, and a good warmth retention property. In this work, desized indigo kapok/cotton denim fabrics were bleached in different ways: Laser, cellulose enzyme, sodium hypochlorite, potassium permanganate and hydrogen peroxide. After bleaching, the K/S values, tensile strength, air permeability, thickness, color fastness to rubbing and the crease recovery angle of denim fabrics were measured through the spectrophotometer, tensile strength tester, air permeability tester, thickness tester, rubbing fastness tester and fabric crease elasticity tester, respectively. The surfaces of fabrics and fibers were observed by scanning electron microscopy (SEM). Results show that the kapok/cotton fabrics were color-faded after five kinds of bleaching, the K/S values of denim with laser bleaching was declined dramatically, while there was a little change in the permeability. The tensile strength and the weight of the fabrics were decreased, and cloth which was bleached with potassium permanganate was most affected. The color fastness to rubbing and the crease recovery angle of denim fabrics with laser treatment is most suitable for industrial production. In general, laser bleaching is the better way to fade the kapok/cotton denim fabrics. Meanwhile, after five kinds of bleaching, the physical properties of kapok/cotton denim fabrics were similar to those of cotton denim fabric, which indicates that kapok/cotton denim fabric is suitable for the existing industrial bleaching technology.

1. Introduction

Denim is a rugged cotton twill fabric with weft yarns passing under two or more warp threads. In the history of the world, the continued popularity of blue jeans among consumers is well documented, which makes indigo one of the most important industrial dyes. In the dyeing process, indigo undergoes complex heterogeneous processes that occur at the solid–liquid interface. The indigo dissolution process involves the conversion of water insoluble dye molecules to water soluble, colorless forms by reduction [1,2]. Indigo denim fabric is characterized by only warp dyeing and the weft remains white.

The result of a warp-faced twill is a blue warp on one side and a white weft on the other [3]. The bleaching process can further improve the value of denim.

However, the bleaching effect can not only depend upon the development of processing technology, but also considers the appropriate fabric properties of jeans [4]. Denim garment manufacturers traditionally use pumice stones to wash clothes in order to achieve a satisfactory wearing effect [5], but the denim garment after stone washing has a rougher hand feeling and emits a large amount of water-containing chemicals to pollute the environment [6]. At present, there are four kinds of commonly-used bleaching technologies for denim fabrics to achieve a smooth and soft hand feeling [7,8,9]:

Enzymatic treatment is an eco-friendly method to improve the color-fading performance of denim fabrics [10,11]. It had been estimated that about 80% of denim bleaching is now done in this way [12]. The worn appearance of denim fabrics can be obtained by the synergistic action of enzymes and mechanical action to unevenly remove the indigo dye in the fibers [13]. Previous studies show that cellulose-catalyzed hydrolysis is not limited to the surface of the fiber, because cellulase is easy to diffuse into the fiber, resulting in a certain loss of strength of the fiber fabric.

Hydrogen peroxide (H2O2) is the most commonly-used oxidative bleaching agent for denim fabrics. Hydrogen peroxide has a high degree of whiteness, and is not easily yellowed during storage. Moreover, this is the cheapest bleaching method. However, it also has a disadvantage, in that high temperature bleaching under alkaline conditions requires an increase in energy efficiency, and more seriously, it may cause considerable fiber damage [14].

Chlorine bleaching by sodium hypochlorite (NaClO) is another conventional denim bleaching method. Bleaching agents that are widely used in conventional bleaching processes can include chemicals such as sodium chlorite (NaClO2) and sodium hypochlorite, formic acid (CH2O2), sodium nitrate (Chile saltpeter, NaNO3), and peroxides. These chemicals clearly have a number of disadvantages, including the production of toxic fumes, high time and energy consumption, reduced fabric strength and environmental pollution [15].

The use of potassium permanganate (KMnO4) to bleach denim fabric can brighten the color of the indigo denim garment, while overcoming the shortcomings of bromine indigo against chlorine bleaching, making the indigo more beautiful. Meanwhile, potassium permanganate bleaching does not need high temperature, has little damage to spandex and there is a fast bleaching effect. However, to avoid yellowing of the fabric, a reasonable ratio of potassium permanganate to phosphoric acid (H3PO4) is required.

Using traditional technologies to produce faded jeans requires a lot of water, most of which is seriously polluted by the chemicals used in the production process [16]. Recently, laser treatment as a new clean process for bleaching the denim fabrics is widely applied in the textile industry. The laser is a source of energy which can be directed on desired objects, and of which its power and intensity can be easily controlled [3]. In designed systems, the laser beams are controlled by computer, and are used to change the color of the denim surface by directing the laser beams at the suitable parameters [17]. Advantages of laser bleaching over other conventional bleaching are: Less pollution of the environment by a reduction of chemical agents and water consumption; process flexibility allows the replication of designs or creation of new finish styles; the finishing process can be applied on parts or assembled garments, or on uncut material as it is; by using automated control of laser-faded technology, the manufacturers can change the finish style to another without retooling; micro graphics can be applied onto the garment; special logos or characters can be applied to denim products [18].

The kapok fiber is a single-cell natural cellulose fiber. Its walls comprise 64% cellulose, 13% lignin, 8.6% water, 1.4–3.5% ash, 4.7–9.7% water-soluble substances, 2.3–2.5% xylan, and 0.8% waxes [19]. This kapok fiber has a very thin cell wall with a huge hollow region full of air, so it has a 90% hollow degree. In addition, kapok fiber has many excellent performances with good hygroscopicity, oil absorption, moisture guide properties and warmth retention property. The high performance and environment friendly character made kapok become a new material of denim fabric. Furthermore, the price of kapok fiber has high market competitiveness, since it is only about half of that of cotton fiber.

Kapok fiber length is short, however, and has low intensity, no significant convolution, poor cohesion and a lack of flexibility, so it is difficult to separately spin. Years of research focuses on the blending spinning of kapok fiber and cotton fiber [20]. Our laboratory used an efficient short process embedded spinning technology (Ruyi spinning) to make the blended yarns of kapok fiber and cotton fiber, and thus produced the kapok/cotton denim fabrics. The volume ratio of kapok fiber arrived at 30%.

In this work, a new type of kapok/cotton blend denim fabrics were woven and tested for basic physical properties. The kapok/cotton denim fabric and cotton denim fabric were bleached by laser, cellulose enzyme, hydrogen peroxide, sodium hypochlorite and potassium permanganate. After bleaching, the K/S values, tensile strength, air permeability, thickness, color fastness to rubbing and crease recovery angle of these denim fabrics were measured through the spectrophotometer, tensile strength tester, air permeability tester, thickness tester, rubbing fastness tester and fabric crease elasticity tester, respectively. The surfaces of the fabric and the fiber were observed by scanning electron microscopy (SEM). The physical properties of the denim fabric treated by different methods were compared.

2. Materials and Methods

2.1. Materials

Two denim samples were used in the test, and their composition and specifications are shown in Table 1. Additionally, the warp yarn of the two denim samples was dyed with indigo dye. The indigo dye was bought from the Sigma-Aldrich Shanghai Trading Co Ltd (Huaihai Road East Section, Lu Wan Qu, Shanghai, People’s Republic of China). The denim fabrics were woven in our lab by the efficient short process embedded spinning technology (Ruyi spinning). The cellulose enzyme was obtained from the Guangdong Jun’an Denim Research Institute (Shunde, People’s Republic of China). The sodium carbonate (Na2CO3, AR (aqua regia; analytically pure)), sodium hypochlorite (NaClO, AR), sodium thiosulfate (Na2S2O3·5H2O, AR), potassium permanganate (KMnO4, AR), phosphoric acid (H3PO4, AR), oxalic acid (H2C2O4·2H2O, AR), hydrogen peroxide (H2O2, AR, 30%) and sodium hydroxide (NaOH, AR) were purchased from China National Medicine Group Chemical Reagent Limited Company. The Laser machine (E-400) was provided by the Wuhan Golden Laser Limited Company (Huangpi District, Wuhan, Hubei, People’s Republic of China), and the picture of this laser machine is found in Figure 1.

Table 1.

The composition and specification of denim fabrics.

Figure 1.

Picture of our laser machine.

2.2. Methods

2.2.1. Desizing

The denim fabrics (30 × 30 cm2) were first treated with 5% o.w.f (on weight of fabric) sodium carbonate at a neutral pH (=7), at 60 °C with a liquor ratio 1:10 for 30 min to remove the sizing agent from the fabrics. The denim fabrics were then immersed into the deionized water for 10 min at 60 °C to wash away abraded fibers and the sodium carbonate from the fabric. The denim fabrics were squeezed to remove water and dried at 60 °C.

2.2.2. Bleaching

- Laser:

The laser treatment process was conducted with a CO2 source laser engraving machine. After the desizing, the fabrics were put onto the laser machine, and would then be bleached by the laser. The power was 240 W, the speed was 10,000 mm/min. The parameters of the experiment were shown in Table 2.

Table 2.

Parameters of the laser bleaching.

- Conventional:

- (a)

- Bleaching with cellulose enzyme.

The desized fabrics were put into the bleaching baths, which were prepared according to the recipe mentioned in Table 3. The bleaching was carried out for 15 min at 25 °C with a liquor ratio of 1:10. The stirring was continuously done by glass rod to ensure uniform bleaching. After the requisite time, cooling was allowed, and the fabrics were taken out of the bleaching baths [14]. The bleached fabrics were moved to a vessel covering the 3 g/L sodium carbonate for 5 min with a liquor ratio of 1:10. At last, the denim fabrics would be washed twice in cold water and dried.

Table 3.

Recipe for conventional bleaching.

- (b)

- Bleaching with available sodium hypochlorite.

The treated denim fabrics were placed in the bleaching bath containing 14 mL/L sodium hypochlorite and 10 g/L sodium carbonate for 10 min and at a temperature of 50 °C with a liquor ratio of 1:14. After desized time, the denim fabrics were moved into a beaker which included 4.2 g/L sodium thiosulfate for 5 min at an indoor temperature with a liquor ratio of 1:14, washed twice in cold water and dried. The recipe for bleaching with the available sodium hypochlorite is described in Table 3.

- (c)

- Bleaching with potassium permanganate.

Firstly, the desized cloths were placed into the bleaching bath of 20 g/L potassium permanganate for 5 min and a temperature of 50 °C with a liquor ratio of 1:14. Secondly, the 10 g/L phosphoric acid would be added into the vessel, and the experiment length was 10 min. At the third, the bleached cloths were put into the cold liquor of 2.5 g/L oxalic acid for 5 min and the liquor ratio was 1:14. Finally, the denim cloths would be washed in cold water and dried. Table 3 illustrates the recipe of potassium permanganate bleaching.

- (d)

- Bleaching with hydrogen peroxide

The liquor of 8% o.w.f hydrogen peroxide and 2 g/L sodium hydroxide was used to bleach the denim cloths after desizing. The temperature of this experiment was 80 °C, and it would continue 15 min with a liquor ratio of 1:14, then the cloths were washed twice in cold water and dried. The recipe is depicted in Table 3.

2.2.3. Testing and Analysis

The K/S values of the denim fabrics were measured using the spectrophotometer (X-rite Color I 7, Grand Rapids, MI, USA; subsidiary of Danaher, Washington, D.C., USA), and each sample was made 10 times, and the average value was taken.

The fabric strength tester produced (YG026H, Wuhan Guoliang Instrument Co., Ltd., Hubei, People’s Republic of China) was used to measure the tensile strength values of denim fabrics in the warp and weft directions according to GB/T3923.1-1997 [21].

The change of denim fabrics weight was ensured by an electronic balance (LD, Shenyang Longteng Electronics Co., Ltd, Liaoning, People’s Republic of China), tested 10 times and averaged data.

The air permeability of denim fabrics would be measured by an air permeability tester (YG461E, Wuhan Guoliang Instrument Co., Ltd., Hubei, People’s Republic of China) according to GB/T 5453-1997 [22].

The thickness tester (YGB141D, Wenzhou Darong textile standard instrument factory, Zhejiang, China) was used to determine the thickness of the fabrics according to the national standard GB/T1380-1997.

The color fastness to rubbing was tested by a rubbing fastness tester (Y571N, Nantong Hongda Experimental Instrument Co., Ltd., Jiangsu, People’s Republic of China), where each sample was examined of dry and wet, and the gray scale according to GB/T 3920-2008 [23].

The crease recovery angle had been measured with a fabric crease elasticity tester (YGB541D, Wenzhou Darong textile standard instrument factory, Zhejiang, People’s Republic of China), and each sample was cut 2.5 × 5 cm2 then tested 10 times, according to GB/T 3819-1997 [24].

The morphology was observed using scanning electron microscopy (SEM) (JSM-6510LV, Japan Electronics Co., Ltd., Japan).

3. Results and Discussion

3.1. K/S Values

The K/S value indicates the degree of dyeing of the fabric. The Kubelka-Munk theory is used to calculate the absorption coefficient K and the scattering coefficient S of the measured object, and establishes a certain functional relationship with the concentration C of the colored substance in the solid sample. The result is the K/S value. The smaller the K/S value obtained by calculation, the lighter the surface color of the fabric; that is, the lower the concentration of the colored substance, the better the bleaching effect [25].

Table 4 shows the K/S values of denim fabrics with different bleaching methods. It is a fact that after laser or potassium permanganate treatment, the K/S values decrease dramatically. This shares a similar trend with the cellulose enzyme treatment, sodium hypochlorite treatment and hydrogen peroxide treatment on K/S values loss. The different mechanism of color-fading causes this huge difference. The changes of kapok/cotton and cotton denim fabrics are similar. The principle of sodium hypochlorite bleaching is that sodium hypochlorite generated ClO- ions which oxidize organic pigment on the fabric in the alkaline condition. During the bleaching, a partial double-bond of the pigment would get saturated, and the original conjugated double-bond would be broken. The chromophore of dyes was damaged, and the color was faded. The theory of hydrogen peroxide bleaching is similar with sodium hypochlorite bleaching. Hydrogen peroxide produces HO2- ions with strong oxidizing in alkaline condition, then the organic pigment oxidizes, and the conjugated structure would be destroyed. Finally, the denim fabrics would be discolored.

Table 4.

K/S Values of samples with different bleaching methods.

With potassium permanganate under the condition of the acid decomposition of active oxygen with special strong oxidizing [O], the fibers could be damaged and the dye disappeared, so as to achieve the purpose of color-fading. Bleaching mechanisms, such as oxygen bleaching, chlorine bleaching and manganese drift lotion, involve the use of the mechanism of water oxidation which acts directly on the pigment. But for potassium permanganate bleaching, both the dye and the fibers of these fabrics are decomposed, so the K/S value of the denim fabric with potassium permanganate bleaching is the smallest. The bleaching mechanism of the enzyme is that the cellulose enzyme decomposes cellulose fiber (cotton fiber), resulting in the pigment on the cellulose fiber bleaching out. Laser bleaching uses the heat produced by the laser machine to etch the fiber directly onto the fabric surface in a short time. The fibers are damaged, and the dye which adheres to the fibers would not be in existence. Both enzyme bleaching and laser bleaching decomposes the fiber, but the fiber degradation by this enzyme is a slow process, whereas the fiber decomposition by laser etching is a fast process. Compared with enzyme bleaching, the laser bleaching is a more efficient method to wash denim fabrics, and the K/S value decreases greatly. For the five kinds of bleaching above, the effect of laser bleaching was the best, and the K/S value loss is greater than others. As to the same reason, the kapok/cotton denim fabrics bleached in different ways share a similar trend with cotton denim fabrics, as shown in Table 4. It means that kapok/cotton fabric is suited for the denim industry.

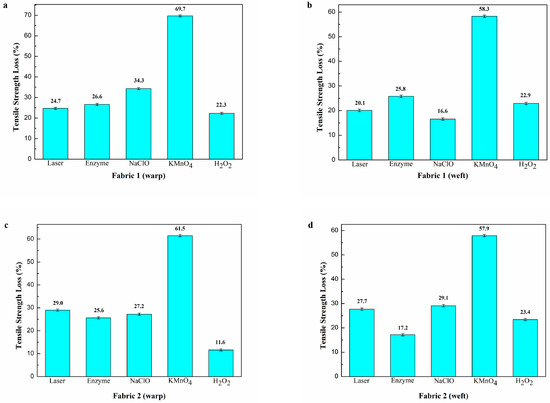

3.2. Tensile Strength and Weight

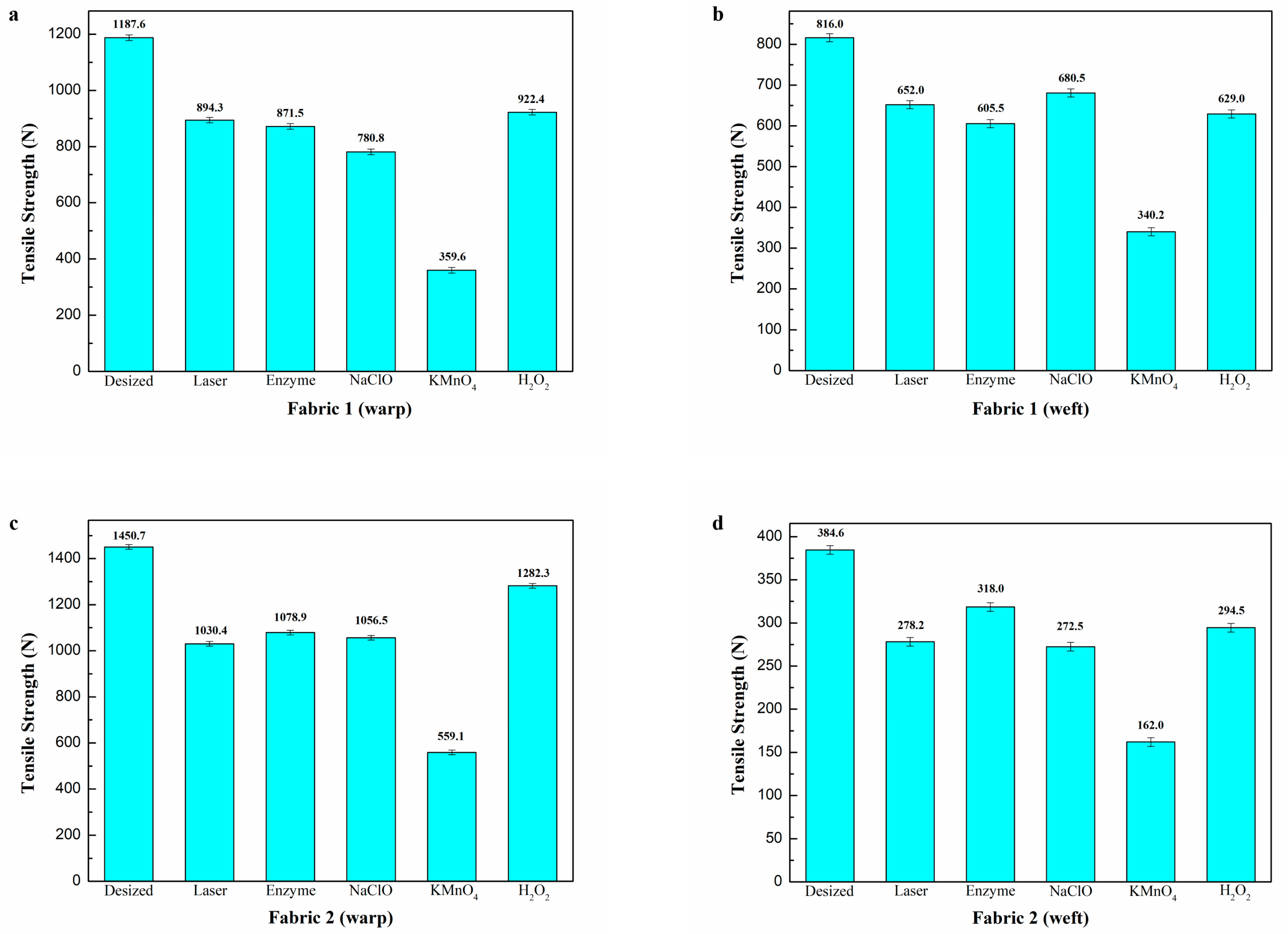

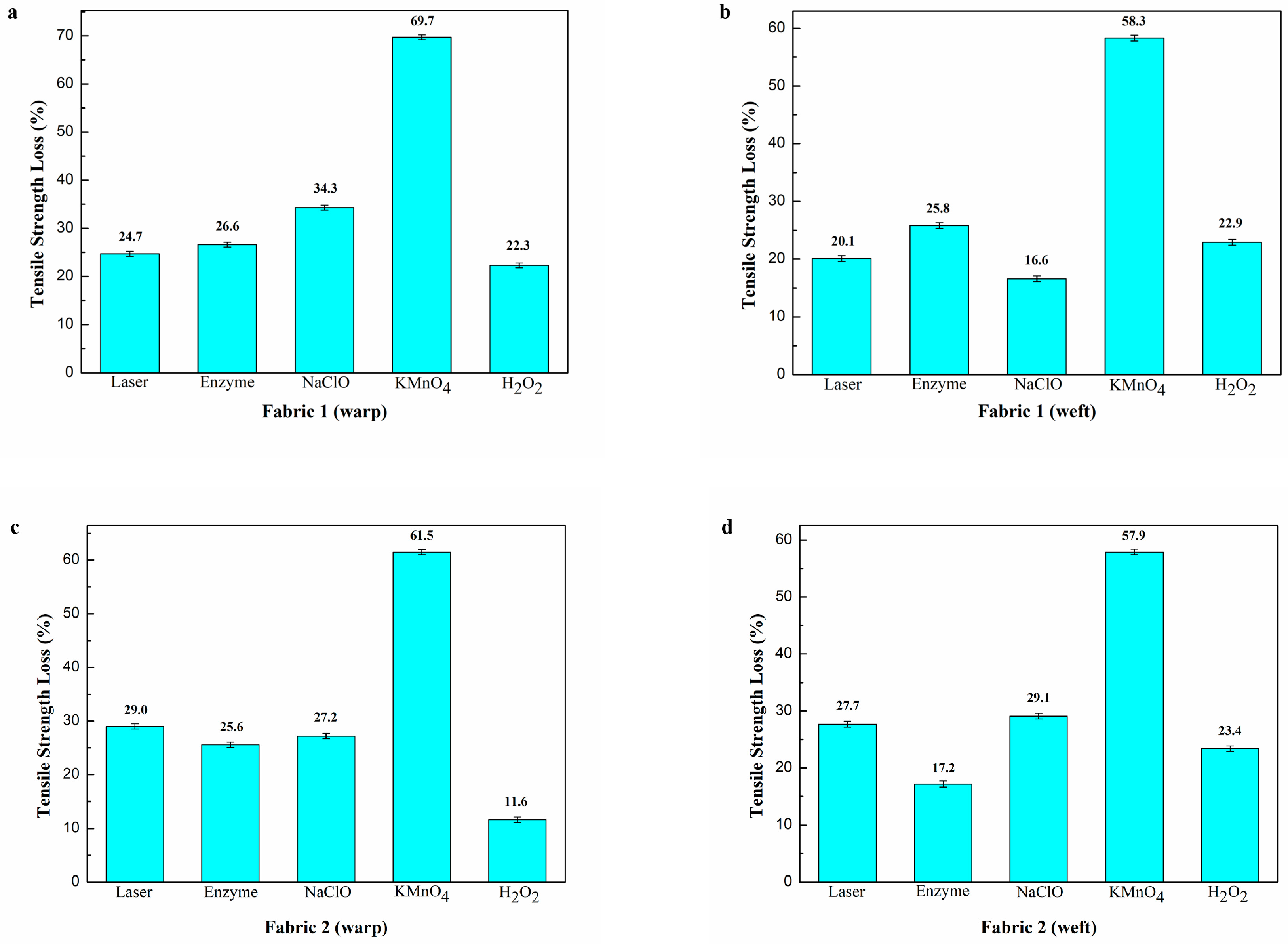

The mean value of tensile strength and tensile strength loss for selected samples are depicted in Figure 2 and Figure 3. The results reveal that a desized denim fabric has a higher tensile strength [23]. For two kinds of denim fabrics, the lowest tensile strength is related to the bleached sample with potassium permanganate, and the tensile strength of treated samples noticeably decreases compared with desized samples. The principle of chemical bleaching (potassium permanganate, sodium hypochlorite and hydrogen peroxide) is that the chemical reagents are used to decompose the dye. The oxidbillity of potassium permanganate is stronger than sodium hypochlorite and hydrogen peroxide, the effect of bleaching is better, the cotton fibers are also damaged, so the tensile strength loss is highest.

Figure 2.

Effects of bleaching types on tensile strength: (a) Fabric 1 (warp), (b) Fabric 1 (weft), (c) Fabric 2 (warp), (d) Fabric 2 (weft).

Figure 3.

Effects of bleaching types on tensile strength loss: (a) Fabric 1 (warp), (b) Fabric 1 (weft), (c) Fabric 2 (warp), (d) Fabric 2 (weft).

The CO2 laser treatment uses the heat to etch the fibers onto the surface of the fabrics in a short time, whereupon the dye disappears, but it does not hurt the fibers inside. The usage of cellulose enzyme is to decompose the cellulose fibers, and after treatment, the tensile strength of denim fabrics declines. Because the enzymatic bleaching needs a long time to set off a chemical reaction, and this experimental length was just 15 min, the chemical reaction was not completed. In general, laser bleaching has been similar to cellulose enzyme, and causes a decrease in tensile strength.

From the Table 1, the warp density of kapok/cotton denim fabrics (338 threads/10 cm) is higher than that of cotton denim fabrics (302 threads/10 cm), which leads to the higher tensile strength of kapok/cotton denim fabrics. In contrast, the tensile strength in the weft direction of kapok/cotton denim fabrics is much lower than that of the cotton denim fabrics, and this may be caused by the fact that the weft of two denim fabrics is made up of different materials [24]. Fabric 1 is made of 100% cotton, but Fabric 2 is a composite of 70% cotton and 30% kapok.

Because of different materials, the fabrics have different properties. The kapok fiber is a hollow fiber of which its hollow degree is more than 90% and the volume ratio is as four times that of cotton. Kapok fiber has a short length, low intensity and poor cohesion, so the fabric made of kapok fiber had a poor mechanical property compared with the other materials. Compared to the warp, the tensile strength loss in the weft of Fabric 2 is smaller, and the kapok’s special structure is the main cause of it. Though the mechanical property of kapok/cotton denim is poorer than cotton denim fabric, it arrives as the standard of the garment. So, the kapok/cotton denim material is suited for industrial production.

The change of weight of different denim fabrics is reported in Table 5. It is a similar situation with the tensile strength change. The results show that the weights of all the samples were declined, but the weight loss was acceptable (less than 8.74%). The fibers of denim fabrics etched by laser or decomposed by chemicals had all been damaged, and the dye had degraded, so the weights of the samples did decrease. Because of the aforementioned reasons, the denim with potassium permanganate bleaching has the highest weight loss, and the mechanical properties are mostly destroyed. Both the enzymatic bleach and laser bleach act upon the fibers, and this takes a short experimental time, so it shares a similar trend of weight loss. Except for bleaching with cellulose enzyme, the weight loss of Fabric 2 is all less than Fabric 1. The main cause is that the kapok fiber is a kind of hollow fiber, whose hollow degree is more than 90%. After being treated, the internal gas is extruded and the mechanical property changes a little, so the weight loss is smaller than Fabric 1.

Table 5.

Weight of denim fabrics with different bleaching types.

3.3. Air Permeability and Thickness

The air permeability and thickness of denim samples with different bleaching methods are presented in Table 6. The above-mentioned density of Fabric 2 is bigger than Fabric 1, so the air permeability of Fabric 2 is smaller than Fabric 1. However, the air permeability of the bleached fabrics is lower than that of the original fabrics, and the changes are similar with different bleaching methods. After treating the fabrics with the laser, the yarns are worn out and the hairiness of the yarns is generated, which is why it reduces the gap between the yarns, which turns to a decreasing of the air permeability of those treated fabrics. After the laser processing, there are some dye residues on the fabric surface, which are responsible for the reduction in the air permeability [24].

Table 6.

Permeability and thickness of denim fabrics with different bleaching types.

The conventional bleaching methods would all make the dye degrade and the fibers decompose, and they would also produce the hairiness of the yarns, so the air permeability would decrease. There is little change of the thickness in Table 6, and this means that the internal gas that was extruded has no effect upon fabric thickness. In this experiment, we used the denim fabrics directly to cope with different methods of bleaching, and did not weave the cloth by ourselves, so we were not sure of the yarn density and yarn twist of the fabrics. But the thickness is also a kind of fundamental characteristic of denim fabrics, where the thickness of Fabric 1 is about 1.5 times that of Fabric 2, the Fabric weight of Fabric 1 is about 1.27 times of Fabric 2, which means that the yarn density and yarn twist of Fabric 1 are both lower than Fabric 2, the gap of fibers is also smaller, so the air permeability of Fabric 1 is higher than Fabric 2.

3.4. Color Fastness to Rubbing

Color fastness to rubbing refers to the ability of a yarn-dyed fabric to maintain its original color under the influence of an external force. The test method is mainly to take a pure white fabric (dry or wet) and tie it to the friction head, then carry out the reciprocating friction movement on the fabric to be tested, and then finally take off the white fabric, compare the color which is stained on the upper surface with the standard color comparison card, and obtain the color fastness rating. For the color fastness to rubbing, grade 5 is the best and grade 1 is the worst. Compared with grades 4–5, grade 5 indicates that the color of white fabric (after rubbing) is lighter, and the color fastness to rubbing of denim fabric is better.

The results of color fastness to rubbing of denim fabrics with different bleaching types are described in Table 7. It can be seen from Table 7 that the color fastness to dry and wet friction of four kinds of denim fabrics has declined to different degrees after being bleached in different ways. Generally speaking, the color fastness to wet friction has declined more significantly, because the chemical bonding energy of water-soluble dyes or hydrophilic dyes and fibers will decrease in the presence of water, accelerating the separation and transfer of dye molecules. From the perspective of the washing method, the color fastness to dry and wet rubbing of denim fabric treated by manganese bleaching is the most obvious decline, followed by laser washing. This is because the reaction mechanism of manganese bleaching is that KMnO4 generates reactive oxygen species [O] in acid condition, which has a special strong oxidation property. It can not only decompose the dye on the fiber surface, but also decompose the fiber to a certain extent. However, the acid solution is corrosive to the fiber, which causes the most serious damage to the fiber on the surface of the fabric. The dye directly falls off without the carrier, resulting in most of the reduction of the color fastness to dry and wet friction. Laser bleaching is used to etch the surface fiber of denim fabric at high temperature, which will decompose some fibers. However, due to the controllable parameters and short processing time, the degree of fiber damage is not large. The color fastness to dry and wet rubbing of denim fabric is much lower than that of manganese bleaching, and it is within the allowable range of production. Oxygen bleaching and chlorine bleaching only decompose the dye on the surface of the fabric, and there is no damage to the fiber, so the color fastness to dry and wet rubbing is not greatly reduced. Enzymatic treatment used cellulase to decompose the fiber, but because the actual reaction time required is relatively long, the cellulase reaction is not sufficient in 15 min, so the actual damage to the fiber is not as large as expected. Therefore, the color fastness of denim fabric to dry and wet rubbing was not obviously decreased compared with laser washing and manganese bleaching.

Table 7.

Color fastness to rubbing of denim fabrics with different bleaching types.

3.5. Crease Recovery Angle

The values of the crease recovery angle of selected samples are illustrated in Table 8. As those reasons mentioned above, the denim fabrics with potassium permanganate bleaching has the lowest crease recovery angle, and it means these samples are less wrinkle-resistant [26]. The differences are not huge between the crease recovery angle values of the denim fabrics bleached by sodium hypochlorite and hydrogen peroxide. As is mentioned above, the oxidbillity of potassium permanganate is stronger than sodium hypochlorite bleaching and hydrogen peroxide bleaching, so the crease recovery angle of denim fabrics bleached by potassium permanganate is improved more. The crease recovery angle of Fabric 2 is higher than Fabric 1. The root cause is that kapok fiber is a hollow fiber whose hollow degree is more than 90%, and the bending rigidity of kapok fiber is higher than cotton fibers. It could also be found that the crease recovery angle of warp yarns is higher than the weft, and it had an obvious change of the data after bleaching. The reason is that the warp yarns of denim fabrics are under more stress than the weft during the process of production. After the bleaching, the mechanical property of the warp yarns was declined much more than the weft. Because the laser treatment just etched the surface of the denim fabrics in a short time, the crease recovery angle of both denim fabrics with laser bleaching was significantly higher than before, and the treated samples were more wrinkle-resistant, so the denim fabrics with laser bleaching are suitable for industrial production.

Table 8.

Crease recovery angle of denim fabrics with different bleaching types.

3.6. SEM Observations

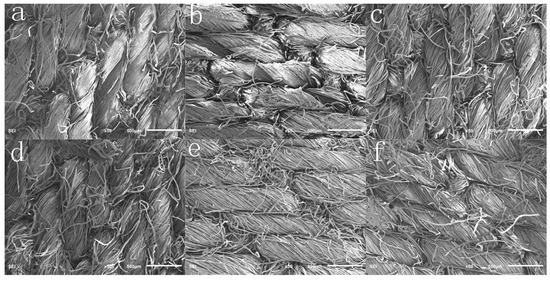

3.6.1. Study of Fabric Surface

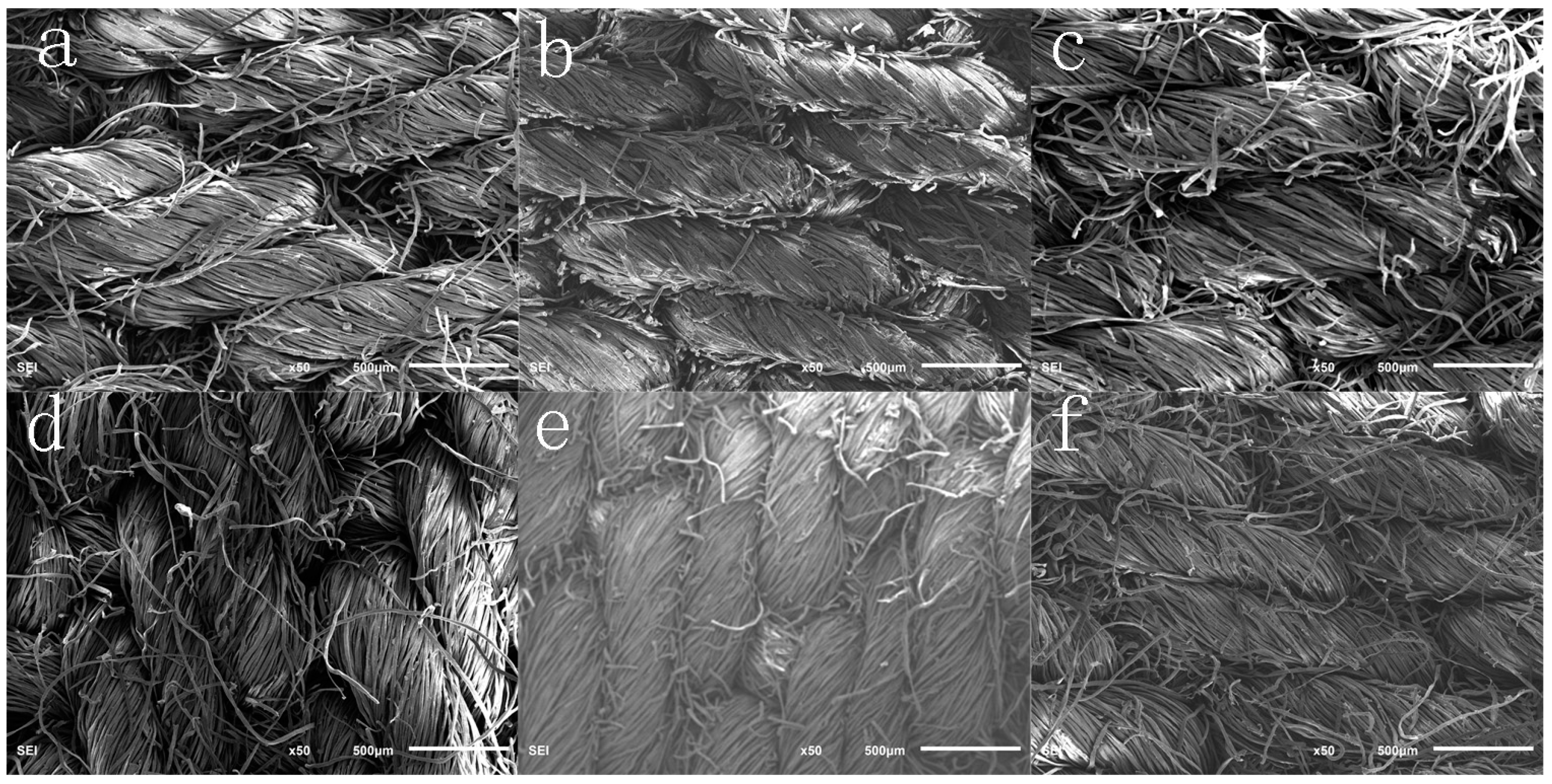

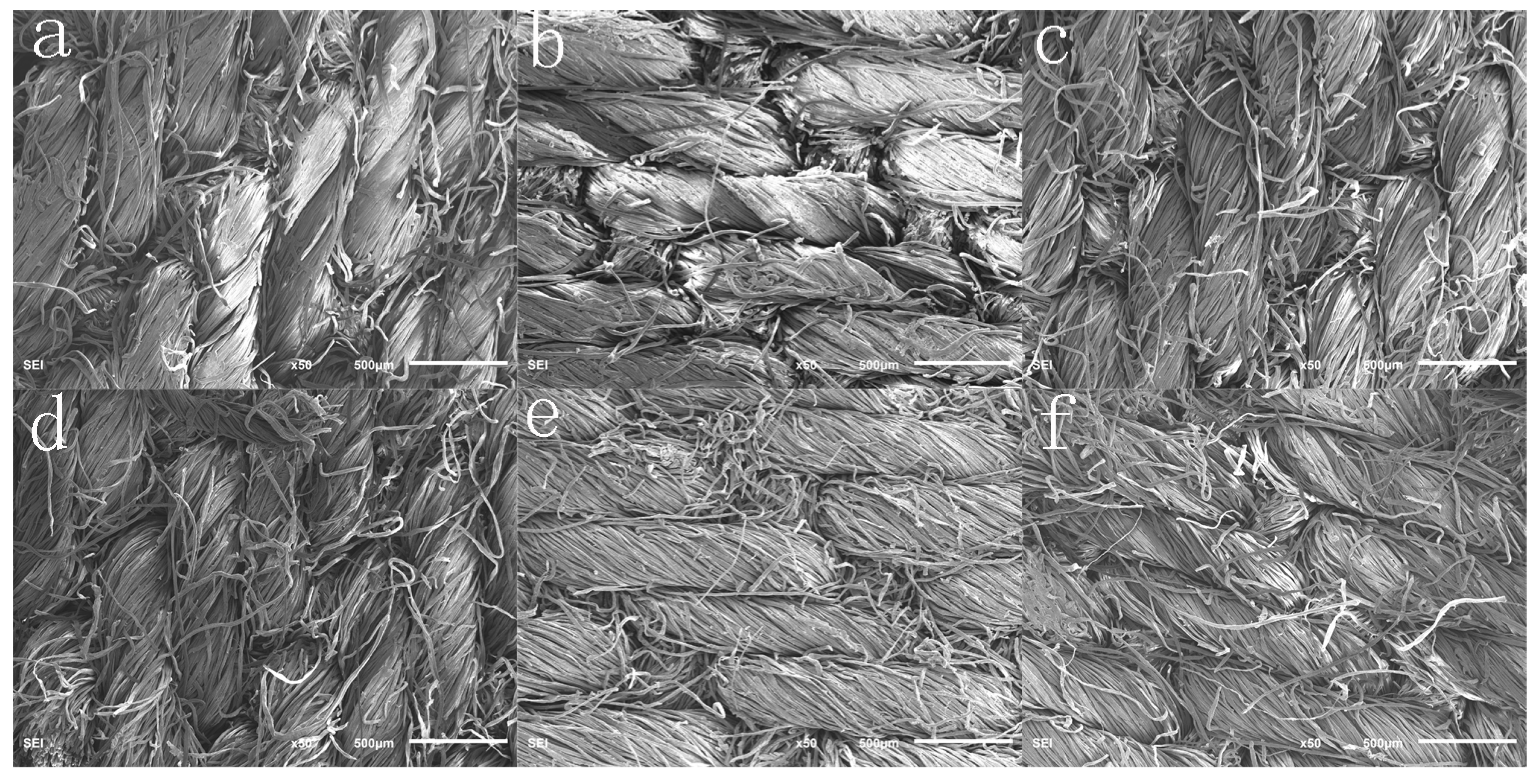

The morphological nature of these denim fabrics was examined by scanning electron microscopy on the desized and bleached samples. Figure 4a and Figure 5a show SEM images of desized cotton fabric and kapok/cotton fabric, respectively, the fibers of which are arranged in parallel in this image. Laser treatment was to use the heat produced by the laser machine to etch the dye onto the fabric surface directly. This would damage some of the fibers, but the arrangement of those fibers is not changed (Figure 4b, Figure 5b). It can be seen from Figure 4 and Figure 5 that the surface arrangement of the fabrics after conventional bleaching treatment are not as neat as that of the desizing denim.

Figure 4.

Scanning electron microscopy (SEM) pictures of different cotton samples (×50): (a) Desized, (b) laser bleaching, (c) enzyme bleaching, (d) sodium hypochlorite (NaClO) bleaching, (e) potassium permanganate (KMnO4) bleaching, (f) hydrogen peroxide (H2O2) bleaching.

Figure 5.

SEM pictures of different kapok/cotton samples (×50): (a) Desized, (b) laser bleaching, (c) enzyme bleaching, (d) NaClO bleaching, (e) KMnO4 bleaching, (f) H2O2 bleaching.

This is because the fabric needs to be continuously stirred with a glass rod in the process of conventional bleaching, and some fibers would be distorted and damaged, resulting in the disorder of the fiber arrangement in the denim fabrics.

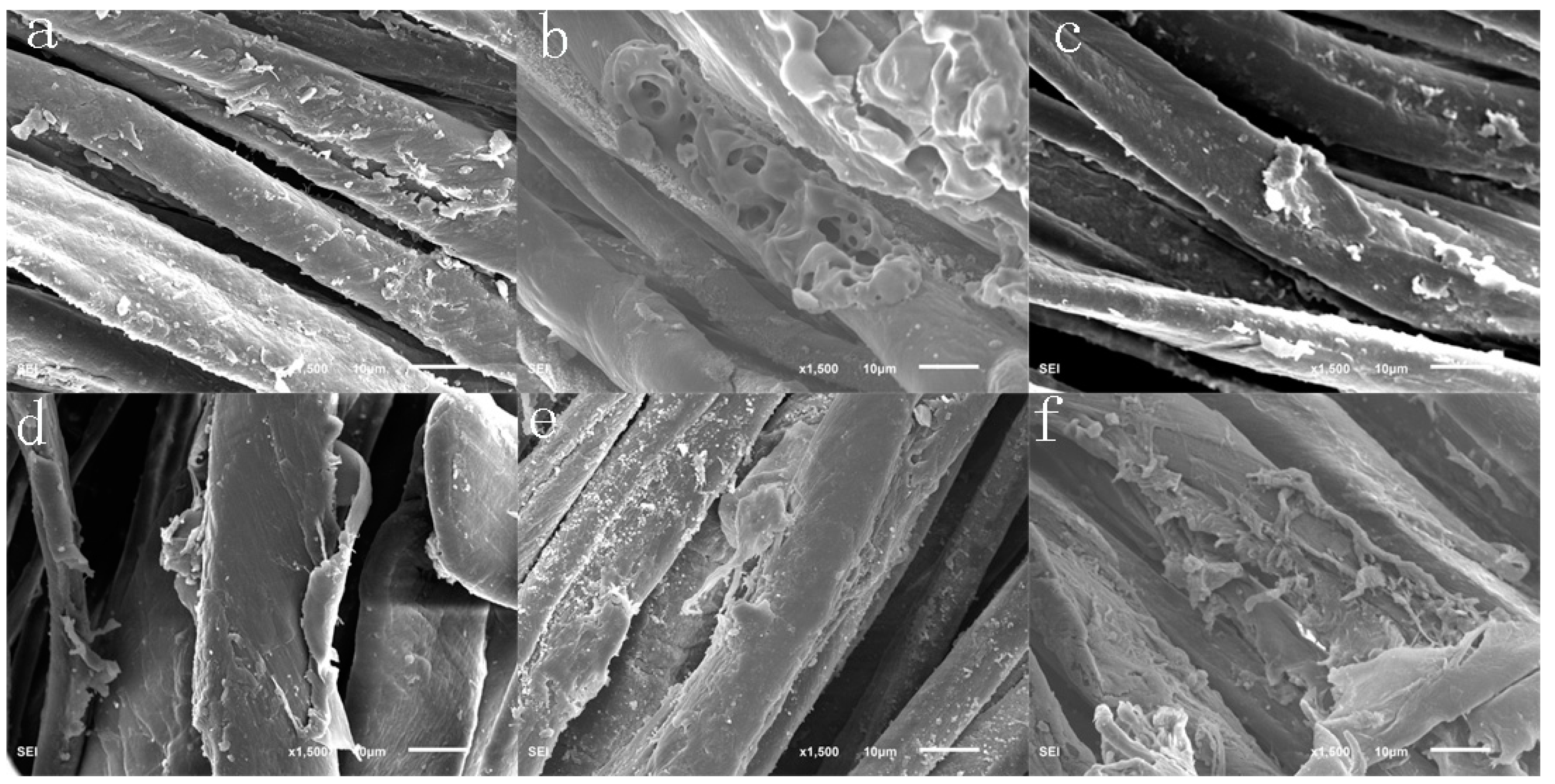

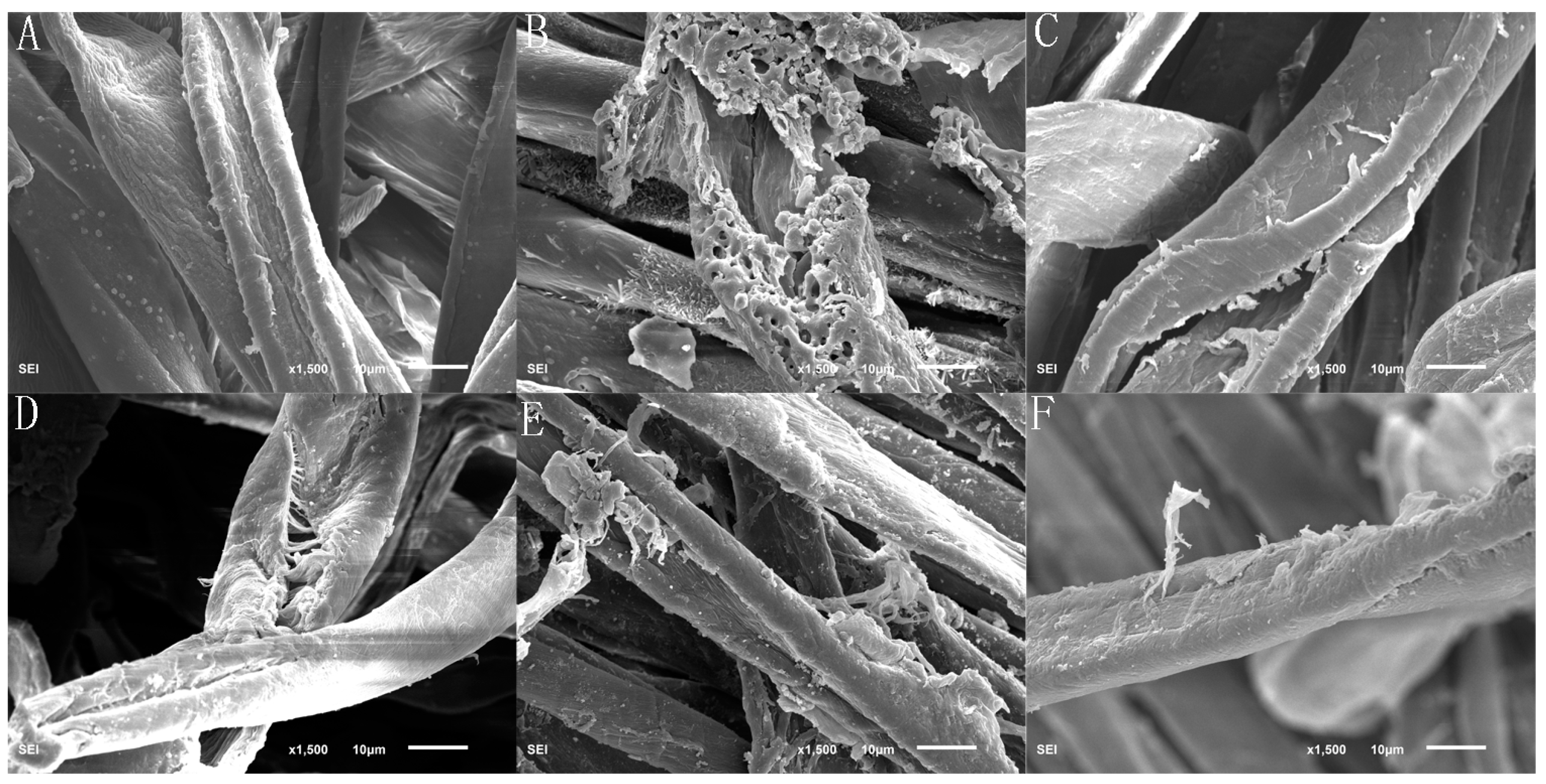

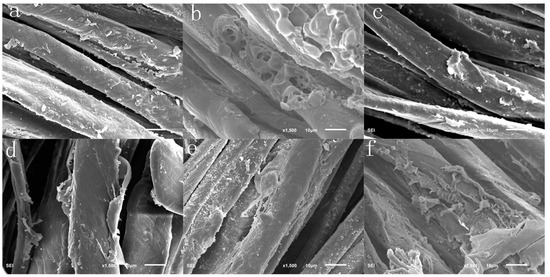

3.6.2. Study of Fiber Surface

In order to investigate the changes of fibers, the SEM images with higher magnification are observed, as shown in Figure 6 and Figure 7. Apparently, the surfaces of the fibers are attached to dyes (Figure 6a, Figure 7a). It can be seen from Figure 6b and Figure 7b that the surface of the outer fibers of denim fabrics after laser bleaching were damaged, and some fibers were broken. Compared with Figure 6b and Figure 7b, it can be found that after etching, the fibers of fabric 1 only have holes on the surface, and the structure has not been damaged. However, for fabric 2, it can be seen that the interior of the fibers is hollow, and the structure has been damaged.

Figure 6.

SEM pictures of different treatment of cotton denim fabrics (×1500): (a) Desized, (b) laser bleaching, (c) enzyme bleaching, (d) NaClO bleaching, (e) KMnO4 bleaching, (f) H2O2 bleaching.

Figure 7.

SEM pictures of different kapok/cotton denim fabrics (×1500): (a) Desized, (b) laser bleaching, (c) enzyme bleaching, (d) NaClO bleaching, (e) KMnO4 bleaching, (f) H2O2 bleaching.

This is because kapok is a kind of hollow fiber where the internal hollow degree can reach 90%, so after laser etching, the structure of the fiber is seriously damaged, which will eventually affect the decline of the mechanical properties of the fabric. Nevertheless, the internal fibers appear to remain intact and undamaged. In other words, during laser bleaching, only the surface fibers of the outer fibers are damaged, while the inner fibers are not affected [27]. It can also be seen from Figure 6 and Figure 7 that after the other four bleaching treatments, there will be a little peeling or damage on the fiber surface, but this is not as obvious as with the laser treatment. The decomposition and destruction of the surface fiber is helpful to improve the fading effect of the fabrics, so the laser washing water is the best bleaching process.

4. Conclusions

In this experiment, the desized indigo kapok/cotton denim fabrics and cotton fabrics were bleached with laser, cellulose enzyme, sodium hypochlorite, potassium permanganate and hydrogen peroxide. After bleaching, the K/S values, tensile strength, air permeability, thickness, color fastness to rubbing and crease recovery angle of denim fabrics were measured. The surfaces of fabrics and fibers were observed.

The results show that the K/S values of denim fabrics with laser bleaching were lower than the denim treated by conventional methods, which indicates that laser bleaching has the best color-fading effect of denim fabric. The K/S values of denim kapok/cotton fabrics after laser bleaching is 4.219, and the K/S values loss is 70.397%. After five kinds of bleaching methods, the physical properties of kapok/cotton denim and cotton denim were measured. The effect of laser bleaching on the mechanical properties of denim fabric was similar to that of the other four conventional methods. After laser bleaching, the tensile strength loss of denim kapok/cotton fabric was 29.0% (warp) and 27.7% (weft), the weight loss was 6.37%, the air permeability was 32.21 mm/s, and the thickness was 0.41 mm. The results show that the color fastness and recovery angle of denim fabrics with laser bleaching are higher, which indicates that laser is an ideal processing method, which is suitable for the industrial production of denim. SEM photos show that the surface fibers of the denim kapok/cotton fabrics after laser bleaching were damaged, which helps to improve the color-fading effect of the fabrics. The physical properties and SEM images share a similar trend with the kapok/cotton denim fabric and the cotton denim fabric by five kinds of bleaching, and it turns out that kapok is as good a material as cotton for denim fabric; its characteristics are suited for denim industrial production.

Author Contributions

C.Y. and W.D. conceived and designed the experiments; W.D. and D.Z. performed the experiments; W.D. and H.G. analyzed the data and wrote the paper.

Funding

This research received no external funding.

Acknowledgments

The authors would like to thank Mingli Wu for critically reading the manuscript.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Bozic, M.; Gonzalez, M.D.; Tzanov, T.; Guebitz, G.M.; Kokol, V. Voltametric monitoring of enzyme-mediated indigo reduction in the presence of various fibre materials. Enzym. Microb. Technol. 2009, 45, 317–323. [Google Scholar] [CrossRef]

- Bozic, M.; Kokol, V. Ecological alternatives to the reduction and oxidation processes in dyeing with vat and sulphur dyes. Dyes Pigments 2008, 76, 299–309. [Google Scholar] [CrossRef]

- Yu, Y.Y.; Yuan, J.G.; Wang, Q.; Fan, X.R.; Ni, X.Y.; Wang, P.; Cui, L. Cellulase immobilization onto the reversibly soluble methacrylate copolymer for denim washing. Carbohydr. Polym. 2013, 95, 675–680. [Google Scholar] [CrossRef]

- Yang, R.H.; Kan, C.W.; Wong, W.Y.; Law, M.C. Comparative study of cellulase treatment on low stress mechanical properties of cotton denim fabric made by torque-free ring spun yarn. Fibers Polym. 2013, 14, 669–675. [Google Scholar] [CrossRef]

- Tarhan, M.; Sariisik, M. A comparison among performance characteristics of various denim fading processes. Text. Res. J. 2009, 79, 301–309. [Google Scholar] [CrossRef]

- Kan, C.W.; Song, L.J. An artificial neural network model for prediction of colour properties of knitted fabrics induced by laser engraving. Neural Process. Lett. 2016, 44, 639–650. [Google Scholar] [CrossRef]

- Sariisik, M. Use of cellulases and their effects on denim fabric properties. AATCC Rev. 2004, 4, 24–29. [Google Scholar]

- Paulo, A.C. Mechanism of cellulase action in textile processes. Carbohydr. Polym. 1998, 37, 273–277. [Google Scholar] [CrossRef]

- Kan, C.W.; Yuen, C.W.M.; Wong, W.Y. Optimizing color fading effect of cotton denim fabric by enzyme treatment. J. Appl. Polym. Sci. 2011, 120, 3596–3603. [Google Scholar] [CrossRef]

- Belghiht, H.; Chaabouni, S.E.; Gargouri, A. Biostoning of denims by penicillium occitanis (pol6) cellulases. J. Biotechnol. 2001, 89, 257–262. [Google Scholar] [CrossRef]

- Paul, A.C.; Almeida, L.; Bishop, D. Cellulase activities and finishing effects. Text. Chem. Colorist 1996, 28, 28–32. [Google Scholar]

- Heikinheimo, L.; Buchert, J.; Oinonen, A.M.; Suominen, P. Treating denim fabrics with trichoderma reesei cellulases. Text. Res. J. 2000, 70, 969–973. [Google Scholar] [CrossRef]

- Mamma, D.; Kalantzi, S.; Christakopoulos, P. Effect of adsorption characteristics of a modified cellulase on indigo backstaining. J. Chem. Technol. Biotechnol. 2004, 79, 639–644. [Google Scholar] [CrossRef]

- Gursoy, N.C.; Lim, S.H.; Hinks, D.; Hauser, P. Evaluating hydrogen peroxide bleaching with cationic bleach activators in a cold pad-batch process. Text. Res. J. 2004, 74, 970–976. [Google Scholar] [CrossRef]

- Farooq, A.; Ali, S.; Abbas, N.; Fatima, G.A.; Ashraf, M.A. Comparative performance evaluation of conventional bleaching and enzymatic bleaching with glucose oxidase on knitted cotton fabric. J. Clean. Prod. 2013, 42, 167–171. [Google Scholar] [CrossRef]

- Moralesa, M.O.; Poterasua, M.; Ortiza, S.E.A.; Compeana, I.; Alvarado, M.R.H. A comparison between characteristics of various laser-based denim fading processes. Opt. Lasers Eng. 2003, 39, 15–24. [Google Scholar] [CrossRef]

- Du, W.; Gosh, R.C.; Zuo, D.Y.; Zou, H.T.; Tian, L.; Yi, C.H. Discoloration of kapok/cotton indigo denim fabric by using a carbon dioxide laser. Fibres Text. East. Eur. 2016, 118, 63–67. [Google Scholar] [CrossRef]

- Dascalu, T.; Acosta-Ortiz, S.E.; Ortiz-Morales, M.; Compean, I. Removal of the indigo color by laser beam-denim interaction. Opt. Lasers Eng. 2000, 34, 179–189. [Google Scholar] [CrossRef]

- Shi, M.W.; Hong, X.; Yu, W.D. The fine structure of the kapok fiber. Text. Res. J. 2013, 80, 159–165. [Google Scholar]

- Li, S.Y.; Zhang, H.; Zang, C.F. The study on properties of kapok nonwoven material. Adv. Mater. Res. 2012, 535–537, 1487–1490. [Google Scholar] [CrossRef]

- Textiles—Tensile Properties of Fabrics—Part. 1: Determination of Breaking Force and Elongation at Breaking FORCE—STRIP METHOD; GB/T 3923.1-1997; General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China (AQSIQ), and Standardization Administration of the People’s Republic of China (SAC): Beijing, China, 1997.

- Textiles. Determination of the Permeability of Fabrics to Air; GB/T 5453-1997; General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China (AQSIQ), and Standardization Administration of the People’s Republic of China (SAC): Beijing, China, 1997.

- Textiles-Tests for Color Fastness-Color. Fastness to Rubbing; GB/T 3920-2008; General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China (AQSIQ), and Standardization Administration of the People’s Republic of China (SAC): Beijing, China, 2008.

- Textile Fabrics-Determination of the Recovery from Creasing of a Folded Specimen by Measuring the Angle of Recovery; GB/T 3819-1997; General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China (AQSIQ), and Standardization Administration of the People’s Republic of China (SAC): Beijing, China, 1997.

- Kan, C.W. Colour fading effect of indigo-dyed cotton denim fabric by CO2 laser. Fibers Polym. 2014, 15, 426–429. [Google Scholar] [CrossRef]

- Montazer, M.; Maryan, A.S. Influences of different enzymatic treatment on denim garment. Appl. Biochem. Biotechnol. 2010, 160, 2114–2128. [Google Scholar] [CrossRef] [PubMed]

- Du, W.; Yi, C.H.; Wang, X.G.; Zuo, D.Y.; Liu, L.; Gan, H.L. Discussion on cotton indigo denim fabric with a laser washing. In Proceedings of the 89th TIWC Conference, Wuhan, China, 2–6 November 2014; pp. 1068–1071. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).