Featured Application

The work discussed herein provides a reference method for connecting eight modules at the central column in modular steel buildings.

Abstract

Modular buildings have the highest levels of precasting in the current building system. There are some defects in present modular connections, such as the difficulties of construction, the weakening of the bearing capacity of beams or columns, and damage to decorations. This paper presents an innovative modular connection with installed bolts in the columns. Two symmetrical monotonous static loading tests were conducted to explore the flexural behavior of the innovative connection. Meanwhile, the moment–rotation relations, destruction process, ultimate bearing capacity, stiffness classification and internal stress distribution were analyzed. The results showed that the specimen S1 with smaller diagonal stiffeners lost its bearing capacity due to the failure of the welding seam, and the extreme moment was 169 kN·m. The failure mode of S2 with large diagonal stiffeners was beam buckling, and the extreme moment was 209 kN·m. The stress of diagonal stiffeners and the join between the upper beam and stiffeners increased rapidly. Stiffeners can increase the stiffness and load-bearing capacity. The connection failures occurred on the beam or beam–column joints, while the connection between modules remained undamaged, which showed that the new connection has a good bearing capacity under the action of bending moment and pressure.

1. Introduction

The modular building is the product of the high-speed development of prefabricated buildings. Usually, this kind of building, together with floors, lighting, plumbing and heating, is fabricated in the factory to the level of the complete installation. Then, the modules are transported to the construction site, where they are assembled into a complete piece of architecture [1,2,3]. It is then suitable for users to move in directly after the module assembly is completed. Generally, more than 85% of the architecture is prefabricated. With most parts completed in the factory and fewer at the construction site, modular buildings have many advantages, such as flexible designs, low carbon use, energy savings, high efficiency in manufacturing, fast construction, fine quality, low cost, safety in construction, reduced sensitivity to the environment and no need for secondary decoration [4,5,6]. Their most prominent advantage over other structural forms is their fast construction. It is reported that a 9-storey building in Melbourne, Australia, was successfully installed in just five days [7]. Another 8-storey modular building was assembled with finishes within 8 days [8], while a 25-storey modular building is claimed to have been completed with 27 weeks of on-site work [9]. At present, there are various structural forms of buildings—such as masonry structure, wood structure, concrete structure, steel structure and steel–concrete composite structure [10]—among which the steel structure is more suitable for modular building due to its good prefabrication and convenient assembly.

Modular buildings are reported to have been applied to apartments, hotels, schools, hospitals, offices, student residences and other types of building where repetitive units are preferred [11,12]. It is not a new concept nowadays and has been used in the United States, Japan, Sweden, and the United Kingdom, and is currently gaining popularity in Australia, Germany, the Netherlands and China [13,14]. Although the modular building has aroused the interest of many experts and scholars, who are generally optimistic about it, its current market share is not large and its promotion speed is slow. One of the main concerns is that the modular building needs a reliable connection between the modules for capacity and construction, which should be as convenient as possible. Due to this difficulty, much relevant research has been undertaken.

Lawson, R.M. [15,16] proposed a kind of cover plate connection joint. Locations were reserved for punching on the beam and column at the corner of the module unit. Then, the modules were transported to the construction site, where they were lifted and aligned with each other to be connected together as a whole, with prefabricated steel deck plates and high-strength bolts. However, it seems hard to connect eight modules as a whole in this way. Annan, C.D. [17,18,19] proposed a joint that connects the upper and lower modules by welding one side of the upper and lower column end plates. However, welding may have a huge impact on the construction environment, and the construction quality is difficult to guarantee. Chen, Z.H. [20] proposed a prestress connection by running through the whole column with a long and thin screw to exert prestress, but its bearing capacity is not sufficient and the connection is only applicable to low-rise buildings. Choi, K.S. [21,22] proposed a kind of connection with bolted connection plates, which requires the opening of a hole on the column to provide a working face for construction. Deng, E.F. [23] proposed a connection with a cruciform gusset plate which also needs holes to be opened on the beam and column to provide a working face for construction; however, the load-carrying capability of the joints may be weakened due to the opening of holes. Chen, Z.H. [24,25] proposed a kind of plug-in split bolt connection joint which requires the insertion of the plug-in into the column to connect the beams or columns together with the split bolts. Park, K. [26] proposed a kind of beam-to-beam bolted connection. Deng, E.F. [27] proposed a bolted interior steel connection; however, the indoor and outdoor decoration may be damaged when the beams or columns are joined together by bolts.

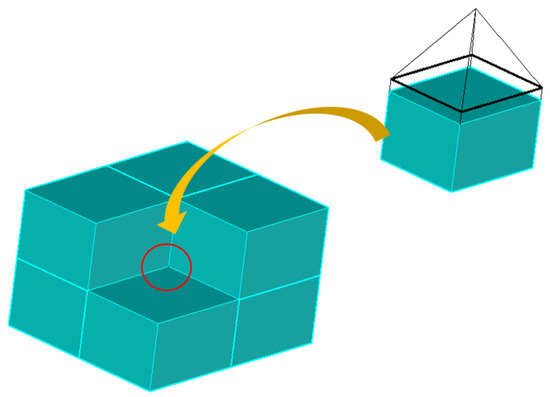

The modular joint is the key to, and the main difficulty of, modular buildings. Nowadays, various connection types rather than a particular one are employed in the construction industry—mainly due to the fact that current connection types have difficulties in meeting all the design and construction requirements of the modular buildings [28]. The difficulties are mainly as follows. Firstly, for the central joint, it is necessary to connect the eight modules as a whole on the construction site. Secondly, welding should be avoided as far as possible in the site operation. Thirdly, as the assembly of the modules comes after their fabrication, it is usually difficult to find the working face of the construction, especially the assembly of the last module, as shown in Figure 1. Fourthly, damage to the modules during field assembly needs to be avoided to spare the need for secondary decoration. Finally, the weakening of the original force performance of the beams and columns should also be avoided. Thus, the design of innovative connections becomes necessary for overcoming the challenges in the design and construction of modular buildings.

Figure 1.

Difficulties in the last module installation.

To overcome the above difficulties, taking advantage of the fast construction of module buildings and achieving the goal of complete decoration in the factory, this paper proposes a new type of modular connection which can connect eight modules as a whole at the central column on the construction site. The structure of this connection will satisfy the requirements for the construction installation of modular architecture. In order to simulate the response of a modular connection when a modular building is under gravity load, symmetrical monotonous static loading tests were performed to study the load bearing mechanism of the new modular connection under the action of static load. The results can provide some useful guidance and serve as a reference to modular building design in the future.

2. The Designing and Assembling of the New Modular Connection

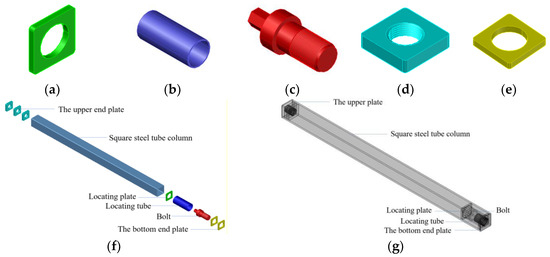

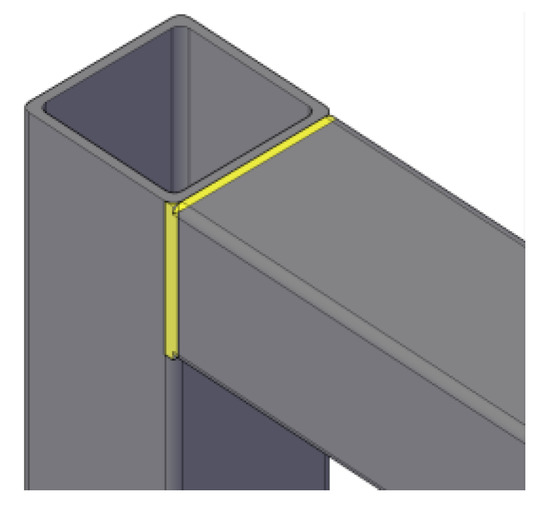

The connection is composed as follows. The locating plate and locating tube are successively welded into the square steel tube. The locating tube is the inscribed circle for the square steel tube. The giant bolt is placed into the locating tube, and the prefabricated end plates are welded to the upper and lower ends of the column. This process is completed in the factory. It is assembled as shown in Figure 2f, and the assembly is completed in the way shown in Figure 2g. To avoid the bolt tilting or even reversing, the upper part of the bolt will be made into a cylinder whose diameter is slightly less than that of the positioning cylinder. For the convenience of centering, a certain space is reserved in front of the screw thread. To ensure firm welding, the upper-end plate with the screw thread on the top of the column will be divided into three parts, which are welded one after another. The bottom-end plate with no screw thread at the bottom of the column is welded twice successively; groove welding is adopted. The other assembly processes of the modules in the factory stay unchanged. The beams and the columns are welded together, and V grooves are made on the four beam edges to strengthen the welding, as shown in Figure 3, and the yellow part of the figure shows the weld seam.

Figure 2.

Diagram of the new connection structure. (a) Locating plate (b) locating tube (c) bolt (d) upper-end plate (e) bottom-end plate (f) assembly (g) assembly completed.

Figure 3.

Beam–column joint.

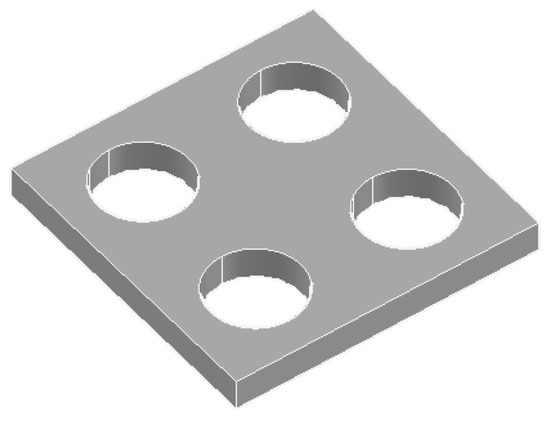

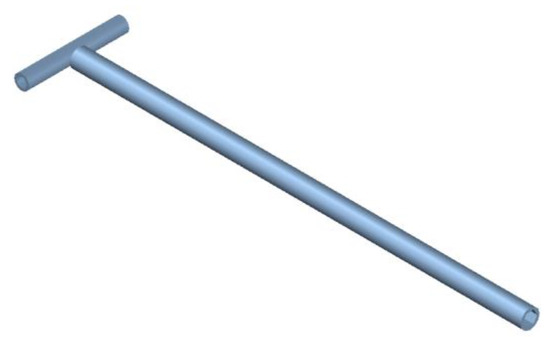

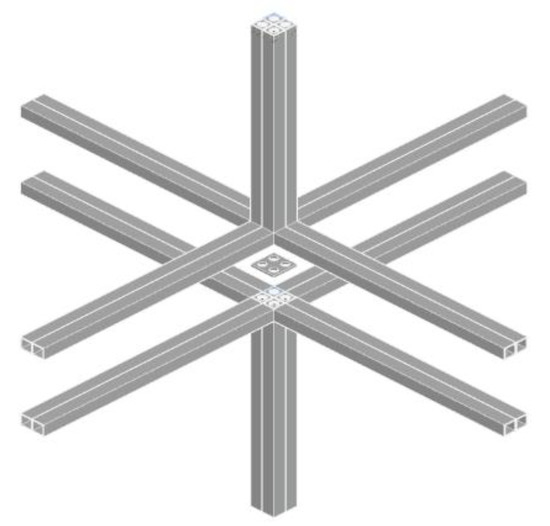

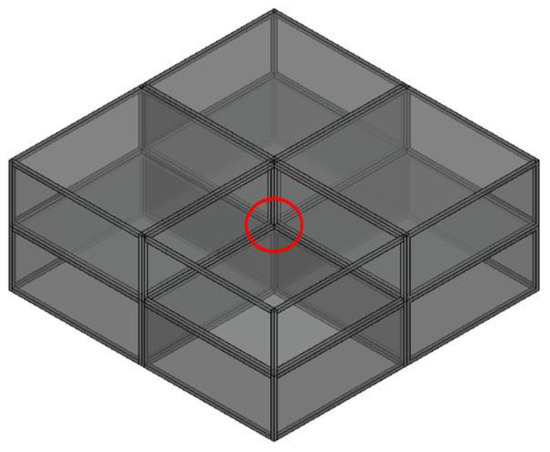

The prepared modules are hoisted and assembled on the construction site. After hoisting and assembling the lower modules, the base plate is installed as shown in Figure 4. Then, the upper modules are hoisted and assembled. A tailored twisting tool as shown in Figure 5 is stretched through into the column from above, to screw down the giant bolt. The bolt will join the vertical modules together, and the base plate transverses the horizontal modules together. Finally, eight modules are connected as a whole. Figure 6 and Figure 7 show the connection location in the eight-module building.

Figure 4.

Base plate.

Figure 5.

Twisting tool.

Figure 6.

Connection.

Figure 7.

Connection in the modular building.

3. Experimental Analysis

3.1. The Design and Preparation of the Elements

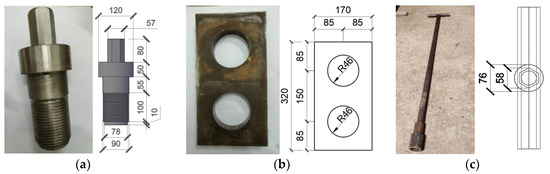

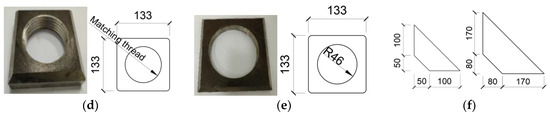

The modular connection with four beams and four columns was tested. Two full-size joints, numbers S1 and S2, were designed. The bolts were made with No.45 steel; other elements were made of Q235B steel. The columns and beams were made by cold-bending 150 mm × 150 mm × 8 mm square steel, while the beams were 1500 mm long and the columns 1000 mm long. Three groups of beam steel and bolt steel were selected for the material test, and the average result is shown in Table 1. The bolt and its size are shown in Figure 8a. The base plate is 30 mm thick, as shown in Figure 8b. The twisting tool is shown in Figure 8c. The upper plate is 30 mm thick, as shown in Figure 8d. The bottom plate is 15 mm thick, as shown in Figure 8e. The diagonal stiffener for specimen S1 is 10 mm thick and the one for S2 is 16 mm thick, as shown in Figure 8f.

Table 1.

Results of the material test.

Figure 8.

Object picture and dimension drawing of components. (a) Special bolt (b) base plate (c) twisting tool (d) upper-end plate (e) bottom-end plate (f) diagonal stiffener of S1 and S2.

To avoid possible damage to the welding line between the end plate and the column, the number of welding lines was increased, with three upper-end plates and two bottom-end plates. No gaps were designed between the end plates; otherwise, the bolt would not be screwed on. After that, the welding was polished. Figure 9 shows the upper-end plate, which was welded three times successively. E43 welding rods were adopted for all of the welding.

Figure 9.

Object picture of column with three upper-end plates.

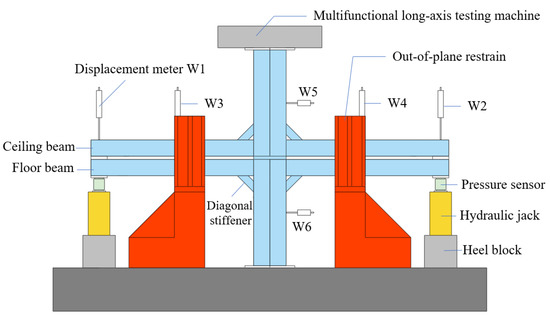

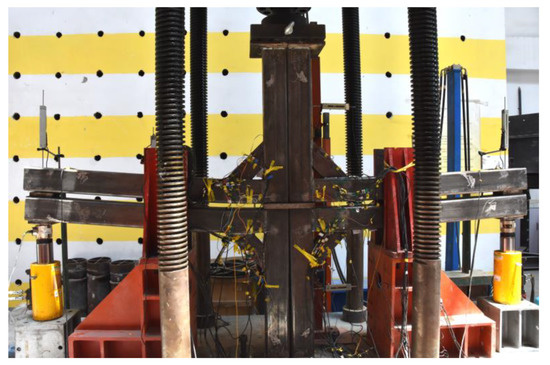

3.2. Symmetric Monotonic Loading Static Test

This test was carried out in the Jiangsu Key Laboratory of Environmental Impact and Structural Safety in Engineering. The specimen and test loading device are shown in Figure 10. To simulate the actual condition of the connection under the action of vertical gravity load, the loading specimen was placed upside-down before loading, and then the constant axial force value was preset for the top of the column by a multifunctional long-axis testing machine. A hydraulic jack was used to add symmetrical force on both ends of the beam in a vertical direction. Before loading, the pressure plate of the long-axis testing machine and the column-top force transferring plate were centered geometrically and held closely together to ensure that both the column ends did not slide in the opposite horizontal direction, and that the loading of both ends proceeded synchronously. There were two security bolts at the bottom end of the column, which were not intended to keep the components in place but to prevent their accidental collapse. Preloading before the formal test was carried out to ensure that all parts of the joints were in full contact with each other. At the same time, the field test system and the loading system were adjusted. Before the formal loading, a constant axial force was applied on the square steel tube column with a nominal ratio of axial compression stress of 0.25. The axial load N at the end of the column is calculated as follows:

where fyc is the nominal yield strength of the square steel, and As is the cross-sectional area of the square steel tube column.

Figure 10.

Loading devices.

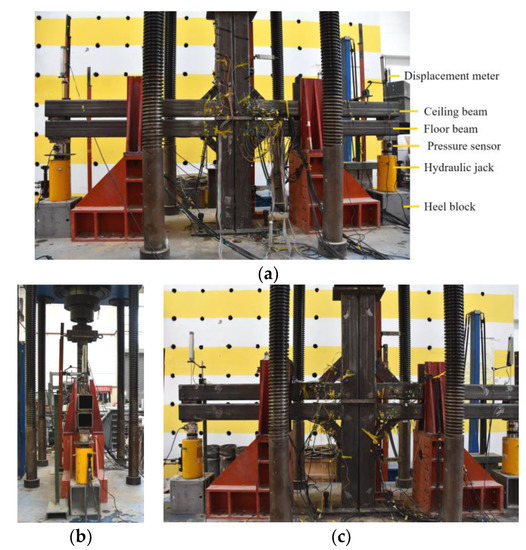

For the sake of safety, the axial force was maintained at the rate of 20 kN/min to achieve 534 kN. After the axial force achieved the predetermined value, synchronous monotonous vertical loads were applied at both ends of the beam. When loading began at the end of the beam, the loading value was increased by 10 kN per level. When the nonlinear evolution of the load–displacement curve occurred, the loading value was reduced to 5 kN per level. The test site is shown in Figure 11.

Figure 11.

Testing site. (a) Front view of S1 (b) side view of S1 (c) front view of S2.

The test mainly measured the force and displacement of the control point by the pressure sensor and the electronic displacement meter. The measuring point layout is shown in Figure 10. The displacement meters W1 and W2 were used to measure the deformation of the beam end. W3 and W4 were used to measure the rotation of the joints. W5 and W6 were used to measure the horizontal displacement of the column.

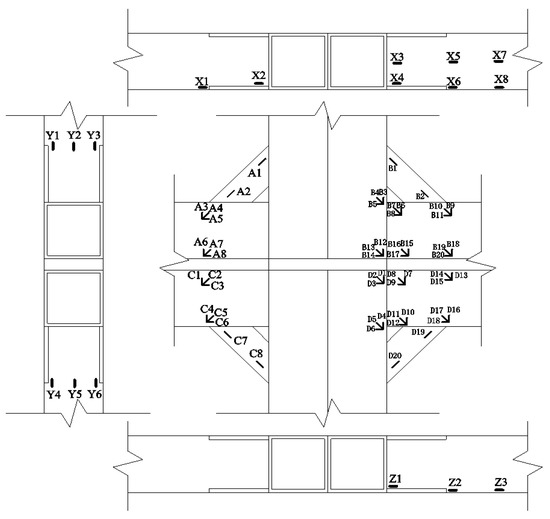

The strain of the control points was collected by a DH3816N static strain tester. The strain gages were laid out as shown in Figure 12. The strain gauges of the front joint were laid out in areas A, B, C and D. Area X shows the strain gauge arrangement from a vertical view; that is, the layout of the strain gauge on the upper part of the upper beam. Area Y shows the arrangement of strain gauges at the left end of the column. Area Z shows the layout of the strain gauges on the lower part of the bottom beam.

Figure 12.

Strain gauge arrangement.

4. The Test Phenomena and the Result Analysis

4.1. The Test Phenomena

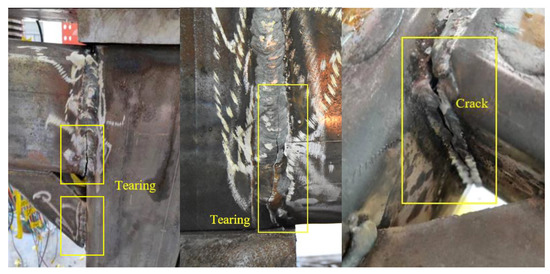

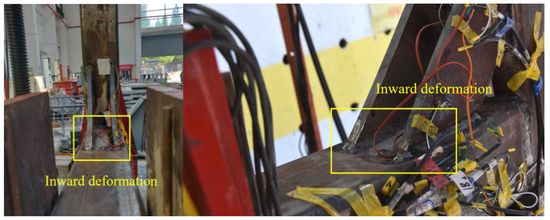

When the vertical load on the beam end was less than 80 kN, no parts of specimen S1 demonstrated significant phenomena, and the measured strain values did not reach the yield strain of the steel material. At the same time, the load–displacement curve showed an approximative linear relationship, which indicated that the specimen was in an elastic state. When the vertical load reached 80 kN and the curve radian increased, the loading was changed by 5 kN per level. When the loading at the end of the beam reached 100 kN, the strain value of measurement points B1, B2 and B9 had also reached the yield strain value of the steel (1.75 × 103), which showed that some parts of specimen S1 had reached the stage of plasticity. Specimen S2 could only reach the yield strain when the load reached approximately 110 kN. As the load on the beam end increased gradually to 105 kN, with a loud bang, a weld failure occurred at the join between the right beam and the column of specimen S1, and the load on the beam end fell back. Then, a weld failure also occurred at the join between the column and the diagonal stiffeners, as shown in Figure 13. As judged, the early breakdown occurred due to the poor quality of the welding line. The undamaged left end beam of S1 continued to be loaded, and a weld failure occurred when the load increased to 120 kN. As for to specimen S2, the diagonal stiffeners had been strengthened and the weld quality had also been inspected. Thus, loading could continue, and the beam warped up obviously, as shown in Figure 14. When the loading reached 150 KN, the left side of the beam end was buckling and its displacement increased suddenly. A large inward deformation occurred at the beam end near the joint domain, as shown in Figure 15, and the loading came to an end.

Figure 13.

Crack in the welding seam.

Figure 14.

Loading procedure

Figure 15.

Inward deformation of the beam.

It was concluded from the experimental phenomena that two kinds of damage occurred—namely weld failure and beam buckling. The former happened when the diagonal stiffeners were small and the welding line was of poor quality. When the diagonal stiffeners were large, the failure mode was beam buckling. The damages happened to the beam or the beam–column joints in the module. The connection between modules remained undamaged, which can be seen from Figure 14 and the experimental phenomenon.

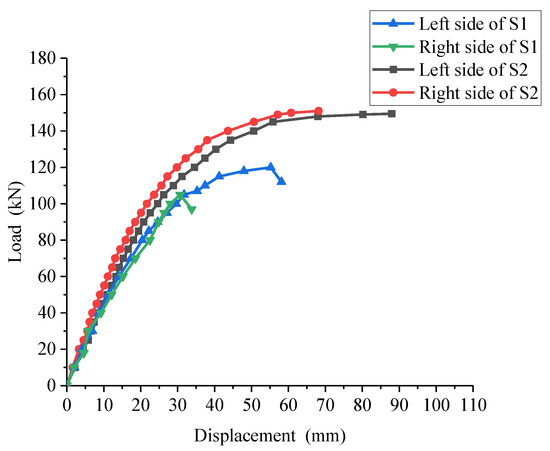

4.2. The Load–Displacement Curve

Figure 16 displays the load–displacement curve of the beam end. Due to the loading on the manual control pump and the fluctuations of the display on the monitor, asymmetry occurred when loading occurred from both ends. It can be seen from the diagram that the load–displacement curve of all specimens basically fits, which means that both ends are fundamentally symmetrical while loading.

Figure 16.

Load–displacement curve.

In the early stage of loading, the load–displacement relation curve of S2 is steeper than that of S1. That is mainly because the diagonal stiffeners of S2 are larger in size. During the loading period, the deformation of S2 developed more slowly compared to S1 under the same load. When the specimen S2 was damaged, the load values on the beam ends of both sides were 149 kN and 151 KN, both of which are greater than the failure load of S1, namely 105 N and 120 kN. Poor weld quality is the main reason for the early damage of the right side of S1. Therefore, the weld quality seems an important factor in ensuring a certain capacity of loading.

Specimen S2 has an obvious plastic phase. The equivalent elastic and plastic yield methods are adopted to judge the yield point. The yield load of S2 is approximately 105 KN, and the yield displacement is approximately 26 mm. Specimen 1 shows less of a plastic phase; however, judging by the curve and the stress at every point, it began to yield. The yield load is approximately 90 kN and the yield displacement is approximately 24.7 mm. Comparing the data of S1 and S2, it can be concluded that the ultimate load increased by approximately 25% and the yield load increased by approximately 17%, after the sizes of the diagonal stiffeners were changed.

4.3. The Moment–Rotation Curve

The vertical displacement of the beam was measured by the electronic displacement meters W3 and W4 as shown in Figure 10. The distance of the displacement meter away from the outer surface of the column was 710 mm. It was a symmetrical and synchronous loading, which was considered to approximately represent the non-rotation of the columns. The measured results of displacement meters W5 and W6 also demonstrated that horizontal displacement basically did not occur to the column. The relative rotation and the joint bending moment M are calculated as follows:

where δ is the displacement of the measurement points W3 and W4, L is the distance between the displacement meter and the flange outer surface of the column, and P is the load at the beam end.

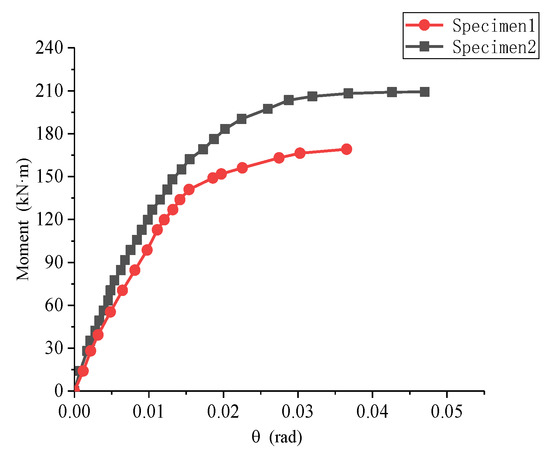

The left sides of specimens S1 and S2 are chosen for analysis, and the bending moment–rotation curve is shown in Figure 17.

Figure 17.

Moment–rotation curve.

Figure 17 shows that the bending moment–rotation curve slope of specimen S1 at the early stage is slightly smaller than that of S2; thus, the initial stiffness of specimen S1 is smaller than that of specimen S2. The yield bending moment of S1 is approximately 110 kN·m, and the corresponding yield rotation is approximately 0.0111 rad. S2 has a greater joint rigidity and its yield bending moment is approximately 140 kN·m, while the corresponding yield rotation is approximately 0.0125 rad. As the loading increases, the curve tends to become gentle and the joint rigidity is reduced until final failure occurs. When S1 is damaged, the ultimate bending moment is around 169 kN·m, while it is 209 kN·m for S2. When the size of diagonal stiffeners increases, the yield bending moment also increases by 27.3% and the ultimate bending moment increases by 23.7%. Thus, it may seem that the size of the diagonal stiffeners has a considerable impact on the performance of the joints. With analysis, it is found that this is mainly because the stiffeners also transmit the force from the beam to the column and take a share of the weld stress. The stress of the joint domain moves outward, and the stiffeners increase the integrity of the beam and the column, thus leading to increases in bearing capacity and stiffness. The ultimate rotation of S1 is 0.037 rad, while it is 0.047 rad for S2. The increase of the rotation of S2 may result from the buckling of the beam of S2, which provides the possibility for rotation, while a large deformation does not happen to the beam of S1. The limit rotation of both components is greater than 0.03 rad, which meets the requirement of the American FEMA that the limit rotation of joints should be no less than 0.03 rad.

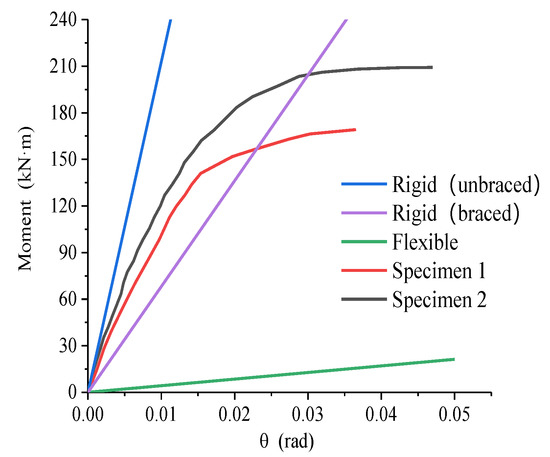

According to the joint stiffness classification method in Eurocode 3, the new connection stiffness classification can be determined. The span of the beam in the frame is set as 6 m. The calculation process is as follows:

Region of rigid joints in braced frame:

Region of rigid joints in unbraced frame:

Region of flexible joints:

where Sj,ini is the slope in the moment–rotation curve, E is the elasticity modulus, Ib is the inertial moment of the beam section, and Lb is the span of the beam. The other region is a semi-rigid joint.

Since the connection has upper and bottom beams, the value of Sj,ini is twice as large. The partition results are shown in Figure 18. It can be seen that S1 and S2 are semi-rigid joints in the unbraced frame and are close to the rigid joints. Both S1 and S2 are rigid joints in the braced frame. Comparing S1 and S2, it can be seen that increasing the size of the diagonal stiffeners will make the joint type more similar to the rigid joint.

Figure 18.

Stiffness classification.

4.4. The Strain Development of Components in the Core Area of the Joint

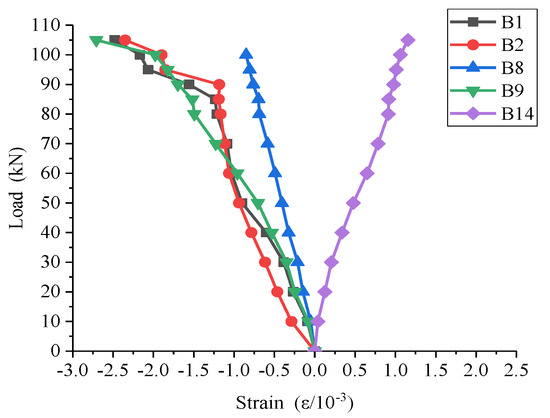

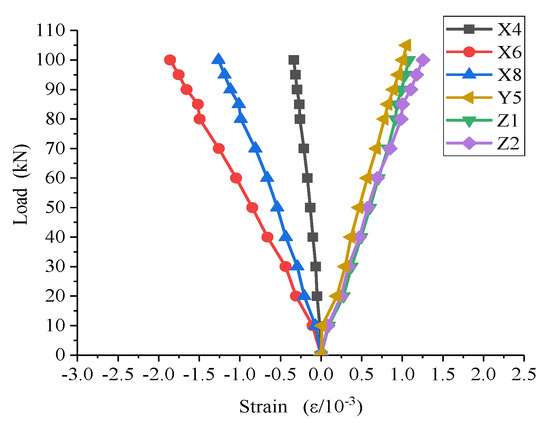

Points exhibiting large strain and points in the key parts for analysis are selected for analysis. The points of specimen S1 are marked with capital letters and those of specimen S2 with lowercase letters. For specimen S1, the load–strain curve of area B is shown in Figure 19, area D is shown in Figure 20, and areas X, Y and Z are shown in Figure 21.

Figure 19.

Load–strain curve of S1, area B.

Figure 20.

Load–strain curve of S1, area D.

Figure 21.

Load–strain curve of S1, areas X, Y, Z.

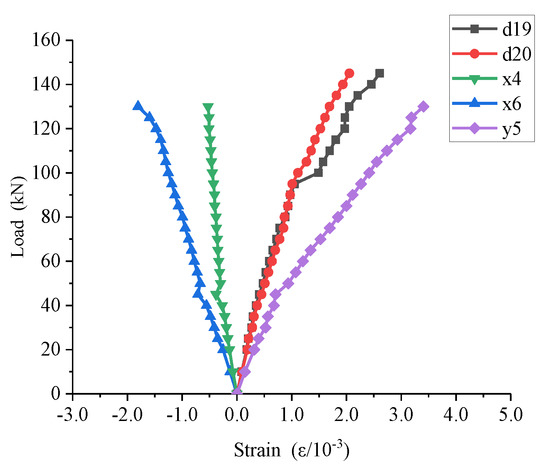

The B1, B2, D19 and D20 points of the diagonal stiffeners experience a greater strain, which indicates that diagonal stiffeners are an important location for force transmission. The strain of B9 expands rapidly, which indicates that the join between the stiffeners and beam experiences greater strain. The lateral strain is 0 > X6 > X8 > X4, which indicates that the upper beam is compressed and the strain at the join between the beam and the column is lesser than the join between the beam and the stiffeners. Therefore, the stiffeners can effectively cause the outward movement of the plastic hinge. Then, moving outward again from X6, the force will decrease rapidly. Z1 and Z2 are roughly equal and more than zero, which indicates that the lower part of the beam is tensed, and the strain distribution at the join between the beam and the column is roughly the same as the one at the join between the beam and the stiffeners. However, the strain is smaller than B1 and B2; i.e., smaller than the point at the stiffeners. The strain at several points of area Y is roughly the same, and Y5 is slightly bigger than the others.

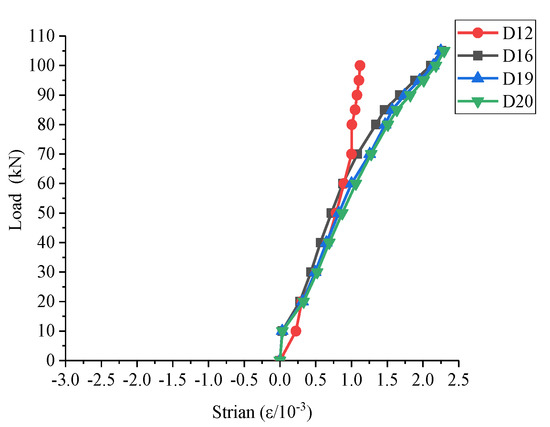

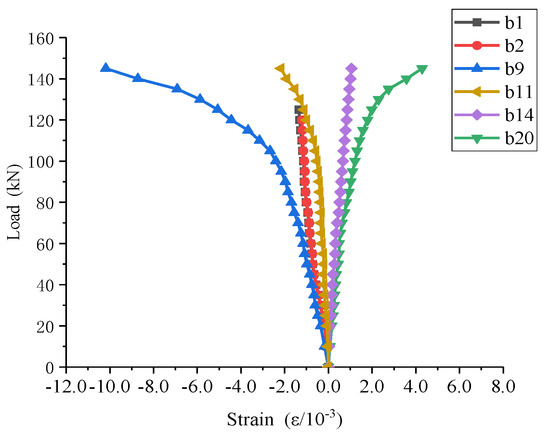

For specimen S2, the loading in area b is shown in Figure 22. The strain at b9 is the most obvious and has completely reached the plastic state. This indicates that the join between the stiffeners and beam experiences the greatest strain in the vertical direction, and buckling finally occurs near the join between the diagonal stiffeners and the beam, which corresponds with the failure mode. Point b20 has also reached the plastic state, indicating that the lower part of the beam bore a large pulling force in the horizontal direction. The laws of other points are similar to that of S1, and Figure 23 shows the load–strain curves of several typical points.

Figure 22.

Load–strain curve of S2, area b.

Figure 23.

Load–strain curve of S2, areas d, x, y.

5. Conclusions

In view of the difficulties in the construction of joints between modules, this paper presents an innovative modular connection. The new connection is suitable for the connection of eight modules at the central column. A detailed introduction to the structure and installation method of the new connection is also given. The performance of the new connection is studied through symmetric monotonous static tests. The conclusions are as follows:

- (1)

- The proposed new connection satisfies the requirement of non-welding construction. It is convenient for connecting and is not restricted to the narrow working face between modules. The beam and the column are neither drilled nor weakened. The indoor and outdoor decoration remains undamaged during installation. This provides a design inspiration to achieve the goal of complete decoration in the factory.

- (2)

- The load transfer capacity of the connection was studied through a static test. When the diagonal stiffeners were small, a stress concentration would occur in the weld. The quality of the welding line was a key factor in determining the connection capacity. Larger stiffeners can increase the bearing capacity and stiffness of the connection. The diagonal stiffeners can effectively share the force on the welding line. When the welding line was of fine quality, the final failure mode was the buckling of the upper beam. Most failures occurred on the beam or at the joint inside of the module, while the connection between modules remained undamaged, which showed that the new connection has a good bearing capacity under the action of gravity load.

- (3)

- In the unbraced frame system, the new connection is similar to the semi-rigid joint. In the braced frame system, the new connection is similar to the rigid joint. Increasing the diagonal stiffeners’ size can bring the connection closer to the rigid joint.

- (4)

- The stress expanded most obviously where the beam and the diagonal stiffeners joined and within stiffeners. Additionally, stress expands fastest where the upper beam and the stiffeners joined, which corresponded to the failure mode.

In further study, it is expected that the bolt form can be changed to optimize the design, such as by using self-locking bolts and anti-loosening bolts; additionally, the shear strength and tensile strength of the new connection will be studied, since the building will be subjected to larger lateral forces when the building is tall.

Author Contributions

Conceptualization, Y.W. and J.X.; software, Y.W., R.M. and T.W.; validation, Y.W., R.M. and B.X.; formal analysis, Y.W.; investigation, Y.W., B.X. and T.W.; funding acquisition, J.X.; writing—original draft preparation, Y.W.; writing—review and editing, Y.W. and J.X.

Funding

This research was funded by Fundamental Research Funds for the Central Universities (2018ZDPY04).

Acknowledgments

The authors want to thank the reviewers for constructive comments and suggestions that have helped to improve our manuscript.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Lawson, P.M.; Byfield, M.P.; Popo-Ola, S.O.; Grubb, P.J. Robustness of light steel frames and modular construction. Proc. Inst. Civ. Eng.-Struct. Build. 2008, 161, 3–16. [Google Scholar] [CrossRef]

- Annan, C.D.; Youssef, M.A.; El-Naggar, M.H. Effect of directly welded stringer-to-beam connections on the analysis and design of modular steel building floors. Adv. Struct. Eng. 2009, 12, 373–383. [Google Scholar] [CrossRef]

- Lawson, R.M.; Ogden, R.G.; Bergin, R. Application of modular construction in high-rise buildings. J. Arch. Eng. 2012, 18, 148–154. [Google Scholar] [CrossRef]

- Lopez, D.; Froese, T.M. Analysis of costs and benefits of panelized and modular prefabricated homes. Procedia Eng. 2016, 145, 1291–1297. [Google Scholar] [CrossRef]

- Kamali, M.; Hewage, K. Life cycle performance of modular buildings: A critical review. Energy Rev. 2016, 62, 1171–1183. [Google Scholar] [CrossRef]

- Lacey, A.W.; Chen, W.; Hao, H.; Bi, K. Structural response of modular buildings-an overview. Build Eng. 2018, 16, 45–56. [Google Scholar] [CrossRef]

- Boafo, F.E.; Kim, J.-H.; Kim, J.-T. Performance of modular prefabricated architecture: Case study-based review and future pathways. Sustainability 2016, 8, 558. [Google Scholar] [CrossRef]

- Gunawardena, T. Behaviour of Prefabricated Modular Buildings Subjected to Lateral Loads. Ph.D. Thesis, The University of Melbourne, Melbourne, Australia, 2016. [Google Scholar]

- Gunawardena, T.; Tuan, N.; Mendis, P.; Aye, L.; Crawford, R. Time Efficient Post-Disaster Housing Reconstruction with Prefabricated Modular Structures; Open House International: Gateshead, UK, 2014; Volume 39, pp. 59–69. [Google Scholar]

- Amadio, C.; Bedon, C.; Fasan, M.; Pecce, M.R. Refined numerical modelling for the structural assessment of steel-concrete composite beam-to-column joints under seismic loads. Eng. Struct. 2017, 138, 394–409. [Google Scholar] [CrossRef]

- Fathieh, A.; Mercan, O. Seismic evaluation of modular steel buildings. Eng. Struct. 2016, 122, 83–92. [Google Scholar] [CrossRef]

- Fifield, L.J.; Lomas, K.J.; Giridharan, R.; Allinson, D. Hospital wards and modular construction: Summertime overheating and energy efficiency. Build Environ. 2018, 141, 28–44. [Google Scholar] [CrossRef]

- Steinhardt, D.A.; Manley, K. Adoption of prefabricated housing–The role of country context. Sustain. Cities Soc. 2016, 22, 126–135. [Google Scholar] [CrossRef]

- Li, H.X.; Al-Hussein, M.; Lei, Z.; Ajweh, Z. Risk identification and assessment of modular construction utilizing fuzzy analytic hierarchy process (AHP) and simulation. Can. J. Civ. Eng. 2013, 40, 1184–1195. [Google Scholar] [CrossRef]

- Lawson, R.M.; Ogden, R.G. ‘Hybrid’ light steel panel and modular systems. Thin-Walled Struct. 2008, 46, 720–730. [Google Scholar] [CrossRef]

- Lawson, R.M.; Richards, J. Modular design for high-rise buildings. Proc. Inst. Civ. Eng.-Struct. Build. 2010, 163, 151–164. [Google Scholar] [CrossRef]

- Annan, C.D.; Youssef, M.A.; El-Naggar, M.H. Seismic overstrength in braced frames of modular steel buildings. J. Earthq. Eng. 2008, 13, 1–21. [Google Scholar] [CrossRef]

- Annan, C.D.; Youssef, M.A.; El-Naggar, M.H. Experimental evaluation of the seismic performance of modular steel-braced frames. Eng. Struct. 2009, 31, 1435–1446. [Google Scholar] [CrossRef]

- Annan, C.D.; Youssef, M.A.; El-Naggar, M.H. Seismic vulnerability assessment of modular steel buildings. J. Earthq. Eng. 2009, 13, 1065–1088. [Google Scholar] [CrossRef]

- Chen, Z.H.; Li, H.J. Research on pretensioned modular frame test and simulations. Eng. Struct. 2017, 151, 774–787. [Google Scholar] [CrossRef]

- Choi, K.S.; Lee, H.C.; Kim, H.J. Influence of analytical models on the seismic response of modular structures. J. Korea Inst. Struct. 2016, 20, 74–85. [Google Scholar]

- Choi, K.S.; Kim, H.J. An analytical study on rotational capacity of beam-column joints in unit modular frames. Int. J. Civ. Environ. Struct. Constr. Archit. Eng. 2015, 9, 100–103. [Google Scholar]

- Deng, E.F.; Zong, L. Monotonic and cyclic response of bolted connections with welded cover plate for modular steel construction. Eng. Struct. 2018, 167, 407–419. [Google Scholar] [CrossRef]

- Chen, Z.H.; Liu, J.D.; Yu, Y.J. Experimental study on interior connections in modular steel buildings. Eng. Struct. 2017, 147, 625–638. [Google Scholar] [CrossRef]

- Chen, Z.H.; Liu, J.D.; Yu, Y.J.; Zhou, C.; Yan, R.J. Experimental study of an innovative modular steel building connection. J. Constr. Steel Res. 2017, 139, 69–82. [Google Scholar] [CrossRef]

- Park, K.; Moon, J.; Lee, S.; Bae, K.; Roeder, C.W. Embedded steel column-to-foundation connection for a modular structural system. Eng. Struct. 2016, 110, 244–257. [Google Scholar] [CrossRef]

- Deng, E.F.; Yan, J.B.; Ding, Y.; Zong, L. Analytical and numerical studies on steel columns with novel connections in modular construction. Int. J. Steel Struct. 2017, 17, 1613–1626. [Google Scholar] [CrossRef]

- Ferdous, W.; Bai, Y.; Ngo, T.D.; Manalo, A.; Mendis, P. New advancements, challenges and opportunities of multi-storey modular buildings–A state-of-the-art review. Eng. Struct. 2019, 183, 883–893. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).