Featured Application

This study proposes a method for quantitatively analyzing the effective bitumen content of RAP and the blending degree of virgin and RAP binders in RAM; furthermore, the findings discussed herein provide a scientific reference for the design of RAM and for improving its pavement performance.

Abstract

Recycled asphalt mixtures (RAM), which are prepared by blending reclaimed asphalt pavement (RAP), virgin bitumen and mineral additives, provide a variety of advantages, including resource recycling, reductions in costs, and reduced negative environmental impacts. However, multiple agencies have expressed concerns about the utilization ratio of RAP; thus, a comprehensive understanding of the blending degree of virgin and RAP binders in RAM would be significantly helpful for promoting the application of RAP. This study aims to quantitatively analyze the blending degree of virgin and RAP binders in RAM with high RAP contents. Carboxyl-terminated butadiene acrylonitrile (CTBN) was utilized as a tracer to mark the virgin bitumen; in addition, Fourier transform infrared (FTIR) spectroscopy was used to develop the structural index of CTBN (ICTBN). By establishing the standard curve between ICTBN and the CTBN content, the blending degree of virgin and RAP binders at different locations within RAM can be determined quantitatively. The study results indicate that the RAP binder was completely blended with the virgin bitumen in the outer RAP layer. However, the blending degree decreased with an increase in the RAP depth, and the blending degree in the inner RAP layer was only approximately half that which was found in the case of complete blending.

1. Introduction

With the aging of asphalt pavement, large quantities of reclaimed asphalt pavement (RAP) are produced. Virgin bitumen and aggregate materials are non-renewable, and their costs have significantly increased over the past few years; as a result, RAP needs to be recycled more effectively to reduce mixture costs and negative environmental impacts. At present, most agencies permit the use of only 10–25% RAP in recycled asphalt mixtures (RAM), which greatly contributes to a low RAP utilization rate and directly diminishes the economic benefits of RAM. Hence, increasing the RAP ratio in RAM would be significantly helpful for promoting the application of RAP; moreover, satisfying the performance requirements of RAM with a high RAP content is a critical issue that needs to be addressed [1,2,3,4,5].

Most highway agencies assume that the blending state of virgin and RAP binders in RAM is complete, but this assumption is not applicable to RAM with high RAP contents. To date, many studies have explored the effects of high RAP contents on RAM [6,7,8,9,10,11]. Huang et al. evaluated the cracking resistance of RAM, the results of which indicated that the inclusion of RAP generally increased the stiffness and indirect tensile strength of the mixture. Moreover, the mixture properties changed significantly at a RAP content of 30% compared with those at RAP contents of 10% and 20% [12]. The studies indicated that RAM were more susceptible to various modes of cracking (i.e., fatigue, thermal, and reflection cracking) with an increase in the RAP content, likely resulting in a lower resistance to cracking and the occurrence of moisture damage. The primary reason is that the RAP binder is stiffer than virgin bitumen [11], and the different viscosities of their compositions leads to poor blending between virgin and RAP binders during the mixing process. Because the virgin and RAP binders do not blend fully, relatively weak regions are present in the final product; as a result, the RAM exhibits a reduced water stability, a low-temperature crack resistance, and a short fatigue life [13,14]. Therefore, to improve the performance of RAM and increase the RAP content of it, it is necessary to evaluate the blending degree of virgin and RAP binders.

Many studies have explored the blending state of virgin and RAP binders in pure bitumen; these investigations were conducive to promoting research on the blending degree of virgin and RAP binders [15,16,17,18]. For example, Bowers et al. quantitatively explored the blending degree of virgin and RAP binders in each recycled binder layer; the blending degree was extracted from RAM using Fourier transform infrared (FTIR) spectroscopy and gel-permeation chromatography (GPC) [19]. However, due to the influences of aggregates, fibers and other materials, the analysis of blending state of virgin and RAP binders in RAM is difficult compared to that of pure bitumen [20,21]; hence, the use of tracer is a viable approach to distinguish virgin bitumen from the RAP binder, and to explore the blending degree of virgin and RAP binders in RAM. Druta et al. used X-ray computed tomography to qualitatively analyze the blending state of virgin bitumen containing metal powder in the simulated asphalt mixture and found that the virgin and RAP binders were only partially mixed [22].

Carboxyl-terminated butadiene acrylonitrile (CTBN) was used as the tracer in a previous study to mark virgin bitumen and track its movements [23], and the blending degree of virgin and RAP binders in RAM was investigated qualitatively using FTIR. The results indicated that the blending states of virgin and RAP binders depends on the location of RAP and is not uniform hierarchically across the three sample layers; however, the blending degree was not clearly understood. Thus, a quantitative analysis is necessary to determine the appropriate virgin bitumen content and mixing parameters for the production of RAM. Since FTIR can be used to quantitatively detect the changes in chemical functional groups [24,25,26,27,28,29], FTIR and CTBN can be combined to directly and quantitatively investigate the blending degree of virgin and RAP binders in RAM with a high percentage of RAP. Accordingly, in this study, the characteristic absorption peaks of CTBN and bitumen were confirmed, and the reliability of using ICTBN to quantitatively analyze the blending degree of virgin and RAP binders was investigated. By establishing the standard curve between ICTBN and the CTBN content, the CTBN contents at different locations in RAM were explored, and by comparing the CTBN contents added into the virgin bitumen, the blending degree of virgin and RAP binders was accurately determined.

2. Materials and Methods

2.1. Materials

2.1.1. Mineral additives

Limestone was used as the mineral filler, and basalt was used as both the coarse aggregate and fine aggregate in this study. Virgin aggregate with a maximum grain size of 13.2 mm was used; the gradation is described in Table 1.

Table 1.

Virgin aggregate gradation.

2.1.2. Bitumen

A bitumen sample with penetration grades A-70 provided by shell co ltd. (Foshan, Guangdong, China) was used in this study. The physical properties of the bitumen were shown in Table 2.

Table 2.

Physical properties of A-70 bitumen.

2.1.3. RAP

RAP was obtained from the surface layer of the Expressway. The bitumen content of the RAP is 5.0 wt. %, and the gradation of the RAP is described in Table 3.

Table 3.

RAP aggregate gradation.

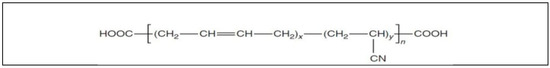

2.1.4. Tracer

The tracer was required to be both compatible with the bitumen and distinguishable from the bitumen without affecting its characteristics. CTBN (Lanzhou Petrochemical Co., Ltd., Lanzhou, Gansu, China) was utilized as the tracer; the chemical formula of CTBN is shown in Figure 1. The density of CTBN is 0.950 g/cm3, which is nearly the same as that of bitumen. In addition, CTBN is highly compatible with bitumen and does not produce a chemical reaction.

Figure 1.

The chemical formula of CTBN.

2.1.5. The Virgin Asphalt Mixture

AC-13 graded asphalt mixture gradation was adopted for the virgin asphalt mixture; the aggregate gradation is described in Table 4. The optimum bitumen content is 5.1 wt. %.

Table 4.

AC-13 aggregate gradation.

2.1.6. RAM

In this study, the percentage of RAP in the RAM is 45 wt. %, and the same AC-13 graded asphalt mixture gradation (Table 4) used for the virgin asphalt mixture was adopted for the RAM. The optimum bitumen content is 5.1 wt. %. In addition, the RAP contained 5.0 wt. % asphalt.

Because the virgin aggregate particles were smaller than 13.2 mm, aggregate particles greater than 13.2 mm in size were selected as RAP aggregate particles, and FTIR samples were obtained at random locations. The RAP aggregate particle samples are collectively referred to as RAM samples hereafter.

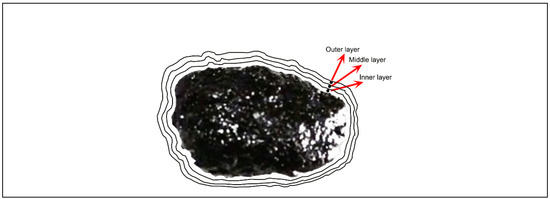

2.2. FTIR Spectroscopy

A Vector 33 FTIR spectrometer and infrared microscope (Bruker, Ettlingen, Baden-Wutenberg State, Germany) were used for the analysis. Bitumen samples for the FTIR test were first heated by a thermal radiative lamp. The softened bitumen was then evenly poured onto KBr disks, and the FTIR tests were performed by the Vector 33 FTIR spectrometer. For the asphalt mixture, samples were scraped from the asphalt mixtures at randomly selected locations. The samples were taken using a microscope to obtain stratified samples accurately. Since the asphalt film thickness levels of asphalt mixtures are different in different locations, samples were scraped from outside to inside continuously until reaching the surface of the aggregate, and the scraped asphalt film samples were then evenly divided into three parts according to the sampling total depth. These parts were separated to the outer layer sample, the middle layer sample, and the inner layer sample. Because the depth of manual sampling is difficult to control accurately, multi-point sampling was used for statistical analysis to improve the representativeness of the stratified sampling. The sampling scheme is illustrated in Figure 2. The samples were placed on the microscope stage, and the infrared spectrum of each sample was obtained.

Figure 2.

Illustration of the sampling of aggregate particles for Fourier transform infrared (FTIR) analysis.

3. Results and Discussion

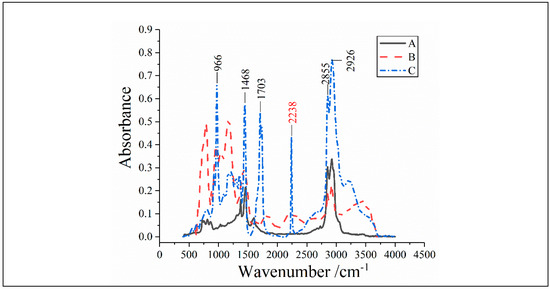

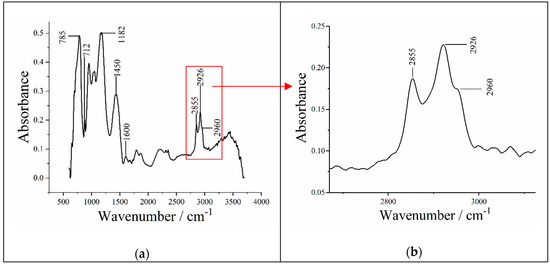

3.1. Characteristic Absorption Peaks

The infrared spectra of the CTBN, RAP and virgin bitumen simples are shown in Figure 3, where A indicates virgin bitumen, B indicates RAP, and C indicates CTBN. The peak at 966 cm−1 is attributed to the bending vibration of C–H in the double bonds of butadiene (–CH=CH–). The peak at approximately 1468 cm−1 corresponds to the bending vibration of the –CH2 group, whereas the peaks at 2855 cm−1 and 2926 cm−1 are ascribed to the symmetric and antisymmetric vibrations, respectively, of –CH2 groups [24,30].

Figure 3.

Infrared spectra of the virgin bitumen, reclaimed asphalt pavement (RAP), and carboxyl-terminated butadiene acrylonitrile (CTBN): (A) is virgin bitumen, (B) is RAP, and (C) is CTBN.

In contrast to the characteristic absorption peaks of the virgin bitumen and RAP, the peaks at 1703 cm−1 and 2238 cm−1 represent the characteristic absorption peaks of CTBN. The peak at 2238 cm−1 is due to nitrile stretching vibrations, whereas the peak at 1703 cm−1 is ascribed to the stretch vibration of the carbonyl group; the infrared spectrum of CTBN coincides with its chemical equation [26]. Since carbonyl could also be produced during the aging process of bitumen, the peak at 2238 cm−1 was chosen as the characteristic peak of CTBN to analyze the blending degree of virgin and RAP binders [24,31].

The chemical formula of CTBN and the absorbance peaks in Figure 3 indicate that CTBN does not possess a –CH3 group, and the bond of the –CH3 vibrations is steady during the aging process [26]; therefore, the characteristic absorption peaks of the –CH3 group (at 2960 cm−1, 1460 cm−1 and 1375 cm−1) can be used to distinguish the bitumen from CTBN. Figure 4a displays the spectrum of RAP; the absorption peaks at 1460 cm−1 and 1375 cm−1 are obscured by the strong absorption peaks of the mineral powder and aggregate, indicating that the absorption peaks at 1460 cm−1 and 1375 cm−1 cannot be used as characteristic absorption peaks. Meanwhile, since the infrared spectrum of RAP (Figure 4b) exhibits a characteristic absorption peak at 2960 cm−1, which is attributed to the antisymmetric vibrations of –CH3 groups, the peak at 2960 cm−1 was chosen as the characteristic absorption peak of the bitumen.

Figure 4.

The infrared spectrum of RAP: (a) Whole; (b) Partial.

3.2. Semi-Quantitative Analysis and Standard Curve

FTIR has mostly been used for semi-qualitative analysis to identify different kinds of chemical functional groups in bitumen [30,32]. In the previous research [23], the study utilized FTIR to qualitatively assess the blending state of virgin and RAP binders in RAM with a high percentage of RAP by counting the number of samples in which blending occurred. It was found that the virgin and RAP binders in the RAM did not fully blend; furthermore, the study indicated that the combined use of FTIR with a tracer constitutes a useful method for investigating the blending states of virgin and RAP binders. However, quantitative analysis used to directly investigate the actual blending degree of virgin and RAP binders in RAM with a high percentage of RAP is still lacking.

Considering that the absorption peak intensity is influenced by the thickness of the sample film covering the KBr table, the structural indices of the chemical functional groups were used to semi-quantitatively analyze the proportions of CTBN in the samples for the sake of avoiding any effects associated with the film thickness. Following Wang et al. [26], the structural indices considering the area of chemical functional groups can be calculated by the following equation:

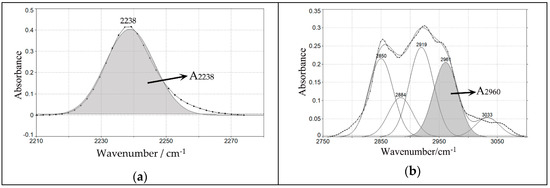

where ICTBN is the structural index of CTBN, is the absorbance area of nitrile stretching vibrations and is the absorbance area of the antisymmetric vibrations of –CH3 groups.

The software package Peakfit (v4.12, Systat Software Inc, San Jose, California, US) was utilized to fit the spectra of the FTIR samples to obtain the absorption peak areas of the chemical functional groups [33,34,35]. After applying a spectral baseline correction, the spectrum was smoothed by a Savitsk–Golay function and a second derivative was carried out. By fitting the spectrum with a Gaussian peak [36], the number and location of sub-peaks can be estimated roughly. After multiplex fitting, the residual reaches a minimum, and the absorption peak area of the sub-peaks can be obtained quantitatively, as shown in Figure 5.

Figure 5.

Characteristic absorption peak area at: (a) 2238 cm−1; (b) 2960 cm−1.

To explore the reliability of ICTBN as a semi-quantitative analysis index for investigating the blending degree of virgin and RAP binders, the infrared spectra of virgin bitumen with 1 wt. %, 5 wt. % and 10 wt. % CTBN were tested to obtain the values of ICTBN. Correlation analysis and a one-way analysis of variance (one-way ANOVA) were performed to investigate whether the CTBN content had a significant effect on ICTBN. Each sample with a different CTBN content was measured three times. The data were analyzed to calculate the mean values (MV), standard deviations (SD) and coefficients of variation (CV) for each sample; the results are listed in Table 5.

Table 5.

CTBN indices of the virgin bitumen with different CTBN contents.

Table 5 shows that the MV of ICTBN increased with an increase in the CTBN content, and the SD and CV results indicate that the CTBN was evenly distributed throughout the virgin bitumen. To analyze the relationship between ICTBN and the CTBN content, correlation analysis was performed; the results indicated that the correlation is 0.978 and that the p-value was <0.0001, which is lower than 0.05, indicating that the effect of the CTBN content on ICTBN is statistically significant.

In addition to correlation analysis, one-way ANOVA was performed using Tukey’s method of multiple comparisons to evaluate the effect of the CTBN content on ICTBN with a confidence interval of 95% (α = 0.05) [37,38,39]. The one-way ANOVA results are summarized in Table 6, and the multiple comparisons results are shown in Table 7.

Table 6.

The values of the one-way ANOVA analysis of ICTBN for the virgin bitumen.

Table 7.

Multiple comparison results for the mean value of ICTBN for the virgin bitumen.

The one-way ANOVA results in Table 6 display a p-value < 0.0001, which means that the effect of the CTBN content on ICTBN is statistically significant. According to multiple comparisons, for each pair of CTBN content groups, if the confidence interval of their mean difference excludes zero, the two CTBN content groups are significantly different; otherwise, the two CTBN content groups are not significantly different. As shown in Table 7, all 95% confidence intervals of the ICTBN differences exclude zero, indicating that each pair of ICTBN values is significantly different and that the CTBN content significantly affects the ICTBN of the virgin bitumen.

Considering that the motivation of this study is to explore the blending degree of virgin and RAP binders in RAM and that the mineral powder and aggregate have significant effects on the absorption peak area (as shown in Figure 3), the virgin AC-13 asphalt mixtures, to which virgin bitumen with 1 wt. %, 5 wt. %, 10 wt. %, and 15 wt. % CTBN were added, were tested by FTIR. FTIR samples were scraped from the virgin asphalt mixtures at randomly selected locations, and each kind of virgin asphalt mixture with a different CTBN content was measured three times; the outer, middle, and inner layers of each sample were each measured once at a certain point. The data were analyzed to calculate the MV, SD and CV of each sample, and the results are listed in Table 8. The SD and CV data indicate that CTBN was evenly distributed throughout the virgin asphalt mixtures. Meanwhile, one-way ANOVA was performed using Tukey’s method of multiple comparisons with a confidence interval of 95% (α = 0.05). The one-way ANOVA results of the virgin asphalt mixtures are summarized in Table 9, and the multiple comparisons results of these mixtures are shown in Table 10.

Table 8.

CTBN indices of the virgin asphalt mixtures with different CTBN contents.

Table 9.

One-way ANOVA of ICTBN for the virgin asphalt mixtures.

Table 10.

Multiple comparison results for the MV of ICTBN for the virgin asphalt mixtures.

The one-way ANOVA results in Table 9 display a p-value < 0.0001, which means that the effect of the CTBN content on ICTBN is statistically significant. Table 10 shows that all 95% confidence intervals of the ICTBN differences exclude zero, indicating that each pair of ICTBN values is significantly different and that the CTBN content significantly affects the ICTBN of an asphalt mixture. The correlation analysis and one-way ANOVA results indicate that the use of ICTBN as a quantitative analysis index to investigate the blending degree of virgin and RAP binders is reliable.

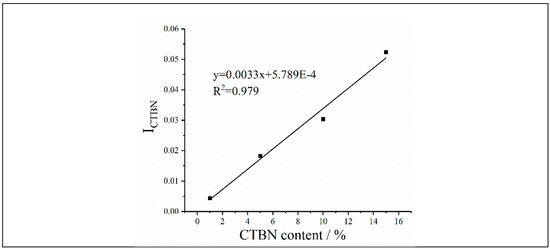

According to Lambert–Beer’s law, ICTBN is directly proportional to the CTBN content; moreover, the abovementioned analysis indicated that the CTBN content has a significant effect on ICTBN. Therefore, the CTBN contents and ICTBN values of the asphalt mixtures were fitted by linear regression to establish a standard curve, as shown in Figure 6. The infrared spectra of the RAM with certain proportions of CTBN were examined to calculate the ICTBN values at different locations of RAP in the RAM, after which the CTBN contents were obtained by fitting the standard curve quantitatively.

Figure 6.

The standard curve.

3.3. Blending Degree of the Virgin and RAP Binders in RAM

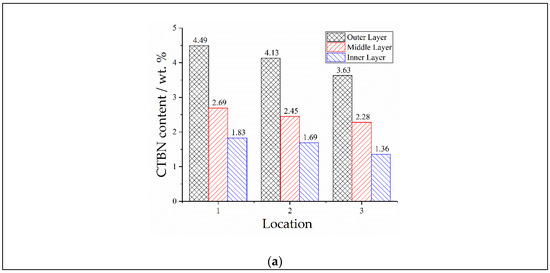

The addition of large proportions of CTBN to virgin bitumen could affect the performance of RAM, while the lack of CTBN could result in a large CV of ICTBN; consequently, the chosen CTBN content of the virgin bitumen used in the RAM was 5 wt. %. Since the virgin aggregate particles were smaller than 13.2 mm, aggregate particles exceeding 13.2 mm in size were selected as RAP, and three RAP specimens were selected randomly. Three locations were selected randomly from each specimen, and three RAP FTIR samples were taken from different depths at each location; subsequently, the spectra of the samples were measured by FTIR microscopy.

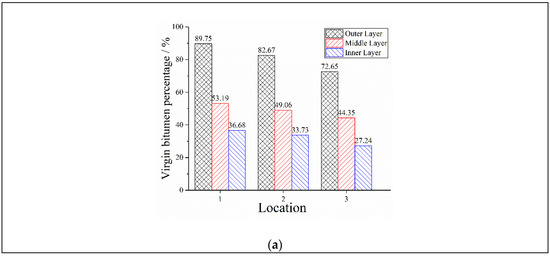

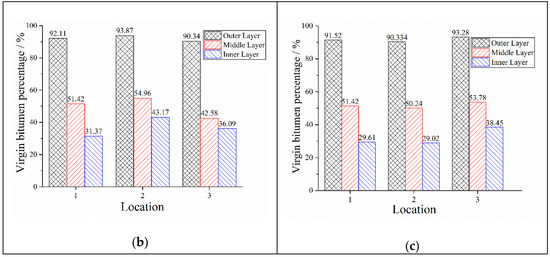

The areas of the absorption peaks associated with nitrile stretching vibrations and the antisymmetric vibrations of -CH3 groups were analyzed with the Peakfit software, and the ICTBN values were calculated by Equation (1). Meanwhile, according to the standard curve (Figure 6), the CTBN contents at different RAP depths were obtained, and the results are shown in Figure 7.

Figure 7.

CTBN contents at different RAP depths: (a) RAP specimen 1; (b) RAP specimen 2; and (c) RAP specimen 3.

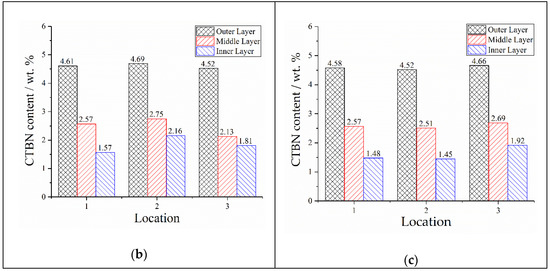

Figure 7 shows that CTBN was present at different depths within the RAP films in the RAM, but the CTBN content decreased with an increase in the depth. This finding indicates that the virgin bitumen blended with the RAP binder in the RAM, but the percentage of virgin bitumen decreased gradually with an increase in the depth. Since the CTBN content in the virgin bitumen was 5 wt. %, the percentages of virgin bitumen at different RAP depths in the RAM were quantitatively acquired by comparing the CTBN contents of RAP specimens with 5 wt. %, as shown in Figure 8. Because the proportion of RAP in the RAM was 45 wt. %, the optimum bitumen content was 5.1 wt. %; in addition, the RAP contained 5.0 wt. % bitumen. Hence, the virgin bitumen ratio at any point in the RAM was 55.88% when the virgin bitumen and RAP binder were completely blended.

Figure 8.

Percentages of virgin bitumen at different depths of RAP in the recycled asphalt mixtures (RAM): (a) RAP specimen 1; (b) RAP specimen 2; and (c) RAP specimen 3.

Figure 8 shows that the virgin bitumen percentage in the outer RAP layer was higher than that found in the case of complete blending (55.88%), indicating that the RAP film was wrapped by the virgin bitumen and that the RAP binder was completely blended with the virgin bitumen. With an increase in the RAP film depth, the percentage of virgin bitumen in the RAP decreased. The virgin bitumen percentage in the middle RAP layer was slightly lower than that in the case of complete blending, which indicates that the virgin and RAP binders were not completely blended, but were still blended relatively well. Meanwhile, although some virgin bitumen contributed to the blending of the virgin and RAP binders within the inner layer of the RAP film, the percentage of virgin bitumen was only approximately half of that in the case of complete blending. This means that the blending degree of virgin and RAP binders was very low, and the inner layer of the RAP film was mainly composed of the RAP binder. These results suggest that the blending of virgin and RAP binders occurs in RAM with high percentages of RAP, but this blending is incomplete. Although the virgin and RAP binders did completely blend together within the outer layer of the RAP film, the blending degree decreased with an increase in the depth of the RAP film. In summary, the virgin and RAP binders did not effectively blend, and the blending degree was relatively low within the inner layer of the RAP film, which may significantly affect the pavement performance of the RAM.

This study proposes a method for quantitatively analyzing the effective bitumen content of RAP and the blending degree of virgin and RAP binders in RAM. By quantitatively evaluating the blending degree of virgin and RAP binders in RAM, the influences of the recycling agent, mixing temperature, mixing time, and other parameters on the performance of RAM can be evaluated more directly and effectively. Furthermore, the findings discussed herein can be used for the development of a more targeted design and production process of RAM to improve the pavement performance of RAM. Considering that different types of bitumen have an effect on the blending degree of virgin and RAP binders, other types of bitumen would be used to develop the same experimental program. Polymer-modified asphalt binders, such as SBS-modified binder, tire-rubber modified binder, aging modified binder, and so on, are more complex in comparison with the neat binder, also the blending degree is more variable than the pure asphalt binder. Since the viscosity of SBS-modified binder is higher than base bitumen, if SBS-modified binder is utilized in this experimental program, the blending degree of virgin and RAP binders will decrease, the viscosity of bitumen has a significant effect on the blending degree [40,41,42,43]. Additional research will be conducted to explore the influences of different bitumen contents and mixing parameters on the blending degree of virgin and RAP binders in RAM, thereby increasing the proportion of RAP in RAM.

4. Conclusions

This study confirmed the characteristic absorption peaks of CTBN and bitumen by using FTIR spectroscopy. The ICTBN was calculated semi-quantitatively and one-way ANOVA was performed to investigate the reliability of ICTBN. By establishing the standard curve between ICTBN and the CTBN content, the blending degree of virgin and RAP binders at different locations of RAM were determined quantitatively. Based on the experimental results and analysis, the following findings were obtained:

The CTBN content has a significant effect on ICTBN. Moreover, a linear relationship exists between the CTBN content and ICTBN which could be used to quantitatively investigate the CTBN contents at different locations of RAP in RAM and to explore the blending degree of virgin and RAP binders in RAM.

It was shown that virgin and RAP binders blend within the different layers of RAP in RAM with high RAP contents, but the blending degree is not uniform; rather, the blending degree decreases with an increase in the RAP film depth. Furthermore, the virgin bitumen percentage in the outer RAP layer mostly reaches 90%, which was higher than that in the case of complete blending (55.88%), and the RAP binder completely blends with the virgin bitumen. Meanwhile, the virgin bitumen percentages in the inner RAP layer are much lower than 55.88%, while the blending degree of virgin and RAP binders in the inner layer is less than half of that in the case of complete blending.

Author Contributions

Conceptualization, Z.Y. and W.X.; Data curation, G.Z. and X.W.; Formal analysis, Z.Y.; Funding acquisition, W.X.; Investigation, Z.Y.; Methodology, Z.Y.; Project administration, Z.Y.; Resources, W.X.; Software, G.Z. and J.W.; Supervision, W.X.; Validation, W.X.; Visualization, X.W. and J.W.; Writing—original draft, Z.Y.; Writing – review & editing, H.Y. and W.X.

Funding

This research received no external funding.

Acknowledgments

The authors express their sincere gratitude to Meijuan Hu and Guosheng Song from South China University of Technology for their technical support and assistance in experimental activities and data analysis.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Li, X.; Marasteanu, M.; Williams, R.; Clyne, T. Effect of reclaimed asphalt pavement (proportion and type) and binder grade on asphalt mixtures. Transp. Res. Rec. 2008, 2051, 90–97. [Google Scholar] [CrossRef]

- Mangiafico, S.; Di Benedetto, H.; Sauzéat, C.; Olard, F.; Pouget, S.; Planque, L. Influence of reclaimed asphalt pavement content on complex modulus of asphalt binder blends and corresponding mixes: Experimental results and modelling. Road Mater. Pavement Des. 2013, 14 (Suppl. 1), 132–148. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.B. Review of very high-content reclaimed asphalt use in plant-produced pavements: State of the art. Int. J. Pavement Eng. 2015, 16, 39–55. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.B.; Frank, R. 100% recycled hot mix asphalt: A review and analysis. Resour. Conserv. Recycl. 2014, 92, 230–245. [Google Scholar] [CrossRef]

- Valdés, G.; Pérez-Jiménez, F.; Miró, R.; Martínez, A.; Botella, R. Experimental study of recycled asphalt mixtures with high percentages of reclaimed asphalt pavement (RAP). Constr. Build. Mater. 2011, 25, 1289–1297. [Google Scholar] [CrossRef]

- Shah, A.; McDaniel, R.; Huber, G.; Gallivan, V. Investigation of properties of plant-produced reclaimed asphalt pavement mixtures. Transp. Res. Rec. 2007, 1998, 103–111. [Google Scholar] [CrossRef]

- Zhou, F.; Li, H.; Lee, R.; Scullion, T.; Claros, G. Recycled asphalt shingle binder characterization and blending with virgin binders. Transp. Res. Rec. 2013, 2370, 33–43. [Google Scholar] [CrossRef]

- Shu, X.; Huang, B.; Vukosavljevic, D. Laboratory evaluation of fatigue characteristics of recycled asphalt mixture. Constr. Build. Mater. 2008, 22, 1323–1330. [Google Scholar] [CrossRef]

- Xiao, F.; Amirkhanian, S.N.; Shen, J.; Putman, B. Influences of crumb rubber size and type on reclaimed asphalt pavement (rap) mixtures. Constr. Build. Mater. 2009, 23, 1028–1034. [Google Scholar] [CrossRef]

- Xiao, F.; Amirkhanian, S.N. Laboratory investigation of moisture damage in rubberised asphalt mixtures containing reclaimed asphalt pavement. Int. J. Pavement Eng. 2009, 10, 319–328. [Google Scholar] [CrossRef]

- Sabahfer, N.; Hossain, M. Effect of fractionation of reclaimed asphalt pavement on properties of Superpave mixtures with reclaimed asphalt pavement. Adv. Civ. Eng. Mater. 2015, 4, 47–60. [Google Scholar] [CrossRef]

- Huang, B.; Shu, X.; Vukosavljevic, D. Laboratory investigation of cracking resistance of hot-mix asphalt field mixtures containing screened reclaimed asphalt pavement. J. Mater. Civ. Eng. 2011, 23, 1535–1543. [Google Scholar] [CrossRef]

- Al-Qadi, I.L.; Aurangzeb, Q.; Carpenter, S.H.; Pine, W.J.; Trepanier, J. Impact of High RAP Contents on Structural and Performance Properties of Asphalt Mixtures. FHWA-ICT-12-002. 2007. Available online: https://www.ideals.illinois.edu/bitstream/handle/2142/45810/FHWA-ICT-12-002.pdf?sequence=2&isAllowed=y (accessed on 13 December 2018).

- Copeland, A. Reclaimed Asphalt Pavement in Asphalt Mixtures: State of the Practice (No. FHWA-HRT-11-021). 2011. Available online: https://www.fhwa.dot.gov/publications/research/infrastructure/pavements/11021/11021pdf (accessed on 13 December 2018).

- Doh, Y.S.; Amirkhanian, S.N.; Kim, K.W. Analysis of unbalanced binder oxidation level in recycled asphalt mixture using GPC. Constr. Build. Mater. 2008, 22, 1253–1260. [Google Scholar] [CrossRef]

- Zhao, S.; Huang, B.; Shu, X.; Woods, M.E. Quantitative evaluation of blending and diffusion in high RAP and RAS mixtures. Mater. Des. 2016, 89, 1161–1170. [Google Scholar] [CrossRef]

- Zhao, S.; Bowers, B.; Huang, B.; Shu, X. Characterizing rheological properties of binder and blending efficiency of asphalt paving mixtures containing RAS through GPC. J. Mater. Civ. Eng. 2014, 26, 941–946. [Google Scholar] [CrossRef]

- Zhao, S.; Huang, B.; Shu, X. Investigation on Binder Homogeneity of RAP/RAS Mixtures through Staged Extraction. Constr. Build. Mater. 2015, 82, 184–191. [Google Scholar] [CrossRef]

- Bowers, B.F.; Huang, B.; Shu, X.; Miller, B.C. Investigation of Reclaimed Asphalt Pavement Blending Efficiency through GPC and FTIR. Constr. Build. Mater. 2014, 50, 517–523. [Google Scholar] [CrossRef]

- Kriz, P.; Grant, D.L.; Veloza, B.A.; Gale, M.J.; Blahey, A.G.; Brownie, J.H.; Maccarrone, S. Blending and diffusion of reclaimed asphalt pavement and virgin asphalt binders. Road Mater. Pavement Des. 2014, 15, 78–112. [Google Scholar] [CrossRef]

- Chen, J.S.; Huang, C.C.; Chu, P.Y.; Lin, K.Y. Engineering characterization of recycled asphalt concrete and aged bitumen mixed recycling agent. J. Mater. Sci. 2007, 42, 9867–9876. [Google Scholar] [CrossRef]

- Druta, C.; Wang, L.; Zhu, T. Laboratory investigation of reclaimed asphalt pavement mixed with pure binder using X-ray CT scanner. In Proceedings of the Ninth International Conference of Chinese Transportation Professionals (ICCTP), Harbin, China, 5–9 August 2009; pp. 1–10. [Google Scholar]

- Yang, Z.; Xu, W. Infrared Spectroscopy Analysis of the Blending of Virgin and RAP Binders in Hot Recycled Asphalt Mixture with CTBN as Tracer. J. Test. Eval. in press. [CrossRef]

- Yang, Z.; Zhang, X.; Yu, J.; Xu, W. Effects of aging on the multiscale properties of SBS-modified asphalt. Arab. J. Sci. Eng. in press. [CrossRef]

- Wu, S.P.; Pang, L.; Mo, L.T.; Chen, Y.C.; Zhu, G.J. Influence of aging on the evolution of structure, morphology and rheology of base and SBS modified bitumen. Constr. Build. Mater. 2009, 23, 1005–1010. [Google Scholar] [CrossRef]

- Wang, J.; Yuan, J.; Kim, K.W.; Xiao, F. Chemical, thermal and rheological characteristics of composite polymerized asphalts. Fuel 2018, 227, 289–299. [Google Scholar] [CrossRef]

- Hou, X.; Xiao, F.; Wang, J.; Amirkhanian, S. Identification of asphalt aging characterization by spectrophotometry technique. Fuel 2018, 226, 230–239. [Google Scholar] [CrossRef]

- Zhu, C. Evaluation of Thermal Oxidative Aging Effect on the Rheological Performance of Modified Asphalt Binders. Ph.D. Thesis, University of Nevada, Reno, NV, USA, 2015. [Google Scholar]

- Yang, Z.; Zhang, X.; Zhang, Z.; Zou, B.; Zhu, Z.; Lu, G.; Yu, H. Effect of Aging on Chemical and Rheological Properties of Bitumen. Polymers 2018, 10, 1345. [Google Scholar] [CrossRef]

- Yu, H.; Leng, Z.; Zhou, Z.; Shih, K.; Xiao, F.; Gao, Z. Optimization of preparation procedure of liquid warm mix additive modified asphalt rubber. J. Clean. Prod. 2017, 141, 336–345. [Google Scholar] [CrossRef]

- Zhang, F.; Yu, J.; Han, J. Effects of thermal oxidative ageing on dynamic viscosity, TG/DTG, DTA and FTIR of SBS-and SBS/sulfur-modified asphalts. Constr. Build. Mater. 2011, 25, 129–137. [Google Scholar] [CrossRef]

- Mothé, M.G.; Leite, L.F.; Mothé, C. Thermal characterization of asphalt mixtures by TG/DTG, DTA and FTIR. J. Therm. Anal. Calorim. 2008, 93, 105–109. [Google Scholar] [CrossRef]

- Muyonga, J.H.; Cole, C.G.B.; Duodu, K.G. Fourier transform infrared (FTIR) spectroscopic study of acid soluble collagen and gelatin from skins and bones of young and adult Nile perch (Lates niloticus). Food Chem. 2004, 86, 325–332. [Google Scholar] [CrossRef]

- Selvasekarapandian, S.; Baskaran, R.; Kamishima, O.; Kawamura, J.; Hattori, T. Laser Raman and FTIR studies on Li+ interaction in PVAc–LiClO4 polymer electrolytes. Spectrochim. Acta Part A 2006, 65, 1234–1240. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Tang, Y.; Schobert, H.H.; Guo, Y.N.; Gao, W.; Lu, X. FTIR and simultaneous TG/MS/FTIR study of Late Permian coals from Southern China. J. Anal. Appl. Pyrolysis 2013, 100, 75–80. [Google Scholar] [CrossRef]

- Seco, A.M.; Gonçalves, M.C.; Almeida, R.M. Densification of hybrid silica–titania sol–gel films studied by ellipsometry and FTIR. Mater. Sci. Eng. B 2000, 76, 193–199. [Google Scholar] [CrossRef]

- He, G.P.; Wong, W.G. Laboratory study on permanent deformation of foamed asphalt mix incorporating reclaimed asphalt pavement materials. Constr. Build. Mater. 2007, 21, 1809–1819. [Google Scholar] [CrossRef]

- Gunzburger, M.S. Evaluation of seven aquatic sampling methods for amphibians and other aquatic fauna. Appl. Herpetol. 2007, 4, 47–63. [Google Scholar] [CrossRef]

- Hassan, H.F.; Al-Jabri, K.S. Effect of organic fibers on open-graded friction course mixture properties. Int. J. Pavement Eng. 2005, 6, 67–75. [Google Scholar] [CrossRef]

- Yu, J.; Yu, X.; Gao, Z.; Guo, F.; Wang, D.; Yu, H. Fatigue resistance characterization of warm asphalt rubber by multiple approaches. Appl. Sci. 2018, 8, 1495. [Google Scholar] [CrossRef]

- Behnood, A.; Modiri Gharehveran, M. Morphology, rheology, and physical properties of polymer-modified asphalt binders. Eur. Polym. J. 2018, in press. [Google Scholar] [CrossRef]

- Yildirim, Y. Polymer modified asphalt binders. Constr. Build. Mater. 2007, 21, 66–72. [Google Scholar] [CrossRef]

- Yu, J.; Ren, Z.; Yu, H.; Wang, D.; Svetlana, S.; Korolev, E.; Guo, F. Modification of Asphalt Rubber with Nanoclay towards Enhanced Storage Stability. Materials 2018, 11, 2093. [Google Scholar] [CrossRef] [PubMed]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).