Abstract

Bitumen content is a critical factor influencing the long-term performance and durability of asphalt pavements. This study evaluates how different binder percentages affect the mechanical behaviour of asphalt mixtures. Mixtures containing 4.7%, 5.1% and 5.5% binder were tested through an extensive experimental program that included Marshall stability and flow, semi-circular bending, PAV aging, wheel rutting, dynamic modulus, creep compliance and fatigue resistance, supported by finite element simulations. To model the nonlinear viscoplastic and damage behaviour, a Perzyna-type viscoplastic formulation and Lemaitre’s isotropic damage model were applied. Model parameters were further refined using Bayesian estimation, based on 10,000 samples generated with a Markov Chain Monte Carlo procedure employing the Metropolis–Hastings algorithm. The findings indicate that mixtures with 4.7% binder content develop fatigue damage earlier, while increasing the binder above 5.1% leads to greater rutting susceptibility and higher creep compliance, as seen in the 5.5% mixture. Among the three, the 5.1% binder content delivered the best overall performance, reducing plastic strain-related damage by 40% compared with the 4.7% mixture and by 27% compared with the 5.5% mixture.

1. Introduction

The percentage of bitumen in asphalt mixtures plays a critical role in determining the overall performance and durability of flexible pavements. Bitumen acts as a binder that holds the aggregate particles together and contributes to the mixture’s viscoelastic behaviour. Its proportion within the mix has a direct influence on key engineering properties, including stiffness, durability, fatigue resistance and susceptibility to permanent deformation. In standard mix design methodologies consisting of the Marshall Mix Design and the Superpave Mix Design, a range of bitumen contents is tested to determine the optimum binder content. This optimum value is typically selected based on achieving approximately 4% air voids in the compacted mixture, which has been found to provide a desirable balance between durability and strength [1]. Selecting the right bitumen content is essential because deviations from the optimum can significantly compromise the pavement’s structural integrity and service life.

A bitumen content lower than the optimum often leads to mixtures that are too dry, resulting in poor coating of the aggregates and insufficient binding between particles. This lack of cohesion can cause increased air voids, reduced tensile strength and vulnerability to cracking, ravelling and moisture damage. These issues typically accelerate pavement deterioration, especially under heavy traffic or in harsh climates. Conversely, using a bitumen content higher than the optimum can also lead to performance issues. While it may initially improve workability and reduce cracking due to increased flexibility, an excess of binder often results in overly plastic or unstable mixtures. Such mixtures are prone to bleeding, stripping, reduced skid resistance and severe rutting under repeated traffic loads [2].

Even with the correct selection of optimum binder content in the design phase, the quality of construction, which includes mixing temperature, placement procedures and compaction levels, also plays a crucial role in achieving the intended pavement performance. Poor workmanship during construction can offset the benefits of an ideal mix design, resulting in suboptimal density, segregation or inadequate binder distribution. Additionally, environmental factors including temperature variations, moisture exposure and oxidative aging further influence the behaviour of asphalt mixtures in the field. These conditions can alter the properties of the bitumen over time, thereby affecting its stiffness, adhesion and resistance to fatigue [3].

A lower bitumen content of 4.7% typically results in stiffer asphalt mixtures with higher air voids. While this stiffness may provide enhanced rutting resistance and load-carrying capacity in the short term, it also introduces several constraints. Reduced bitumen content can lead to insufficient coating of aggregate particles, resulting in higher permeability, poor compaction and a greater susceptibility to cracking due to limited flexibility and reduced fatigue resistance. These characteristics can significantly compromise the mixture’s long-term durability, especially in environments subjected to repeated traffic loading and thermal cycling. On the other hand, a higher bitumen content of 5.5% tends to improve mixture flexibility, resistance to cracking and fatigue life, particularly under low-temperature fatigue conditions. However, permanent deformation under high temperatures and heavy traffic loads can occur [4]. Mixtures with excessive binder content can exhibit lower internal friction, leading to instability, binder drain-down and a higher likelihood of rutting. This reduction in structural integrity can pose significant issues for pavement performance in hot climates or on heavily trafficked roadways.

Based on the balance between stiffness and flexibility at both ends of the bitumen content spectrum, an intermediate bitumen content of 5.1% is often selected as the optimum. This value offers a balanced performance in terms of durability, strength and workability of the asphalt mixture [5]. It provides sufficient cohesion and aggregate coating to resist cracking while minimizing the risk of rutting and deformation. The Marshall mix design method provides a foundational framework for determining optimum binder content based on parameters such as stability, flow, air voids and volumetric properties. However, with the growing emphasis on performance-based specifications, modern asphalt design requires a more comprehensive evaluation that includes mechanical and durability-based testing to better predict long-term behaviour under field conditions [6].

Recent advancements in test methodologies have enhanced the understanding of bitumen’s influence on asphalt mixture behaviour. For example, the Semi-Circular Bending (SCB) test has been used for evaluating cracking resistance. It provides critical indicators, including fracture energy and the Flexibility Index (FI), both of which are sensitive to binder content and aging effects [4]. Additionally, simulated long-term aging using a Pressure Aging Vessel (PAV) helps assess oxidative hardening and its impact on mixture stiffness and cracking susceptibility. These performance-based tests enable more accurate assessment of mixture behaviour over the pavement’s service life, helping engineers optimize binder content short-term performance and long-term durability.

Rutting resistance is a critical performance indicator for asphalt mixtures, especially in regions with high temperatures and heavy traffic. It is commonly evaluated using Hamburg Wheel Tracking equipment, which simulates the effects of repeated heavy axle loads in a controlled laboratory environment. This test provides valuable insights into the rutting susceptibility and moisture-induced damage potential of asphalt mixtures under both dry and wet conditions. To assess the stiffness characteristics of asphalt mixtures, stiffness modulus tests are typically conducted to determine the dynamic modulus. This value reflects the mixture’s ability to resist deformation under varying loading rates and temperature conditions. The dynamic modulus is also a key input in mechanistic empirical pavement design and is especially useful for modelling the viscoelastic behaviour of asphalt under real-world service conditions [7].

In addition to rutting and stiffness evaluations, creep compliance tests and fatigue performance tests are used to assess the long-term deformation and cracking potential of asphalt mixtures. Creep compliance measures the time-dependent deformation of the asphalt mixture under a sustained load, offering a clear indication of its resistance to permanent deformation. On the other hand, fatigue tests simulate the damage accumulation resulting from repeated cyclic loading, which is essential for understanding how mixtures will perform under traffic over time [8,9]. These tests complement rutting and stiffness data to provide a more complete analysis of the mixture’s mechanical behaviour.

Several studies have investigated the effect of bitumen content variation on these performance characteristics. For instance, Ai et al. [10] observed that asphalt mixtures with a reduced binder content of 4.5% were significantly more prone to fatigue and thermal cracking. This was attributed to higher air voids and insufficient aggregate coating, which increased permeability and vulnerability to moisture damage. Similarly, Lv et al. [11] reported that mixtures with suboptimal binder content showed reduced fatigue life and lower fracture energy under low-temperature loading, indicating a higher risk of early cracking and structural failure. In a related study, Bi et al. [12] found that mixtures with higher air void content and lower binder content exhibited accelerated aging when subjected to simulated long-term aging in a Pressure Aging Vessel. This led to increased brittleness and a reduction in service life.

Huang et al. [13] reported that increasing binder content from 4.7% to 5.5% improved resistance to cracking and fatigue loading, particularly under cold and intermediate temperature conditions. This improvement was attributed to enhanced energy dissipation and more uniform stress distribution throughout the mixture. However, the study also showed that higher binder content led to a significant increase in rutting and permanent deformation when mixtures were exposed to elevated service temperatures.

Similarly, Safaeldeen et al. [14] concluded that while higher binder contents can enhance crack resistance and also result in bleeding, loss of surface texture and reduced skid resistance leading to compromise pavement safety and surface performance. In another comprehensive study, Khorshidi et al. [15] investigated asphalt mixtures with binder contents ranging from 4.6% to 5.6% and found that a mid-range binder content of approximately 5.1% consistently yielded superior performance in terms of mechanical integrity and resistance to aging. Results suggested that this intermediate value provides adequate aggregate coating and long-term durability without increasing the risk of excessive deformation. Furthermore, Underwood et al. [7] emphasized the importance of performance-based approaches to binder content selection. Results demonstrated that minor adjustments in binder content can significantly impact fatigue life and thermal cracking resistance, particularly in climate sensitive regions.

Despite these findings, there remains a lack of detailed experimental comparisons focusing on closely spaced binder contents, specifically 4.7%, 5.1% and 5.5% and using an integrated framework of mechanical and durability performance evaluation. This knowledge gap is particularly critical in the context of modern performance-based specifications, which require a deeper understanding of how incremental binder content changes affect field performance over time. To address this gap, the present study undertakes a comprehensive investigation into the long-term durability, flexibility and load resistance behaviour of asphalt mixtures with varying percentages of bitumen binder. The research combines extensive laboratory testing with advanced modelling techniques to analyse the influence of binder content on key performance metrics.

Specifically, a series of mechanical and durability tests, including Marshall stability and flow, Semi-Circular Bending (SCB), Pressure Aging Vessel (PAV), wheel tracking, dynamic modulus, creep compliance and fatigue performance, are conducted to evaluate the physical response of the mixtures. Furthermore, the study introduces finite element modelling (FEM) integrated with the Perzyna-type viscoplastic model and Lemaitre’s isotropic damage model to simulate the effects of binder variation on accumulated strain, damage evolution, rutting behaviour and fatigue cracking over the service life of pavements. By combining empirical testing and numerical modelling, this research aims to provide a performance-driven framework for selecting optimum binder content that balances strength, durability and flexibility in asphalt mix design.

2. Materials and Methods

In this research, the samples prepared with binder content variations of 4.7%, 5.1% and 5.5% were subjected to a series of experimental tests, including the Marshall test, semi-circular bending tests, dynamic tests, creep compliance tests, fatigue tests and incorporation with finite element modelling. A 70–22 grade bitumen was used, sourced from OMV. Properties of the bitumen are shown in Table 1.

Table 1.

Properties of bitumen.

The aggregates used in this research were sourced from a local quarry and complied with standard specifications for use in hot mix asphalt (HMA). Crushed granite was used as the coarse aggregate, and natural sand was used as the fine aggregate. The mineral filler consisted of limestone dust. Gradation of the aggregates is shown in the table below. The asphalt mixture was prepared with a well-graded aggregate mixture and using a nominal maximum aggregate size of 19 mm. Aggregate gradation is shown in Table 2.

Table 2.

Aggregate gradation.

Three asphalt mixtures were prepared with bitumen contents of 4.7%, 5.1% and 5.5% by total weight of the mixture. The aggregate gradation and other components remained constant across all mixtures to isolate the effect of bitumen content. The Marshall mix design method was used to determine the initial optimum bitumen content, around which the selected values were centred. For each binder content, specimens were prepared at the standard compaction level (75 blows per side) using a Marshall hammer.

3. Experiments

3.1. Outline of Tests

To simulate long-term aging, the loose asphalt mixtures were subjected to aging in a Pressure Aging Vessel (PAV) following short-term oven aging per AASHTO R30. This procedure was applied before mechanical testing. Short-term aging was conducted at 135 °C for 4 h and long-term aging (PAV) at 100 °C and 2.1 MPa for 20 h. Table 3 shows the comprehensive lists of tests conducted on the mixtures with variable bitumen contents.

Table 3.

List of tests.

3.2. Marshall Stability Test

The Marshall stability and flow tests were carried out in accordance with ASTM D6927 to evaluate the strength and plastic deformation capacity of the asphalt mixtures. Cylindrical specimens with a diameter of 101.6 mm and a height of approximately 63.5 mm were prepared using a Marshall compactor and applying 75 blows per face at a compaction temperature of 150 °C. After compaction, specimens were allowed to cool at room temperature for 24 h and then conditioned at 60 °C for 30 min prior to testing. Each specimen was loaded vertically at a rate of 50 mm/min until failure. The peak load and the corresponding deformation were recorded for each sample, as shown in Equation (1).

where S is stability (KN), is peak load at failure (N) and is cross-sectional area (mm2).

As observed from Table 4, the asphalt mixture with a 4.7% bitumen content yields the lowest stability, although it exhibits a relatively limited flow value of 2.5%. This lower stability can be attributed to the insufficient binder amount, which may lead to inadequate coating of the aggregates and weaker inter-particle adhesion. As a result, the mixture may lack cohesion under loading, reducing its ability to resist deformation and load-induced stresses. When the bitumen content increases to 5.1%, the stability reaches its maximum value of 9 kN, indicating an optimal balance between binder and aggregate. At this binder content, there is sufficient bitumen to properly coat the aggregates, enhancing adhesion and allowing the mixture to effectively distribute loads and resist deformation. Additionally, the flow value remains moderate, suggesting that the mixture retains enough flexibility to accommodate stresses without excessive deformation. However, further increasing the bitumen content to 5.5% results in a decrease in stability and an increase in flow to 3.8%, indicating that the mixture becomes less stable and more prone to deformation. Excess binder can lead to a softer mixture with reduced internal friction between aggregates, causing instability under load.

Table 4.

Marshall stability and flow.

3.3. Semi-Circular Bending Test

The SCB test was conducted in accordance with AASHTO TP 124 to evaluate the fracture resistance and cracking potential of the mixtures. Samples were prepared by coring 150 mm diameter specimens from compacted slabs with a thickness of 50 mm. A 15 mm notch was introduced at the mid span of the flat edge using a precision diamond saw. Specimens were conditioned at 25 °C for a minimum of two hours before testing. The SCB test was performed using a displacement-controlled loading rate of 0.5 mm/min, and the resulting load-displacement data were used to calculate the fracture energy and flexibility index for each binder content. Fracture energy was calculated as shown in Equation (2).

where is the fracture energy, is the work of fracture (area under load-displacement curve, J), is the thickness of the specimen (mm), is the radius of the specimen (mm) and is the notch length (mm).

As observed from Table 5, a lower amount of bitumen content at 4.7% yields the lowest fracture energy, indicating the limited ability of the mixture to resist crack initiation and propagation. As the bitumen content increases, the fracture energy improves significantly, providing the mixture with enough ductility and flexibility to better absorb and dissipate stresses. This trend continues up to a binder content of 5.1%, where the mixture achieves an optimal balance of strength and flexibility. A further increase in bitumen content to 5.5% results in an increase in the flexibility index; however, the fracture energy decreases. This reduction is due to the saturation of bitumen around the aggregates, which can lead to reduced internal friction and cohesion within the mix. Consequently, this saturation potentially makes the mixture unstable, as the excess binder compromises the structural integrity, increasing the risk of deformation and premature damage.

Table 5.

SCB test results.

3.4. Dynamic Modulus Test

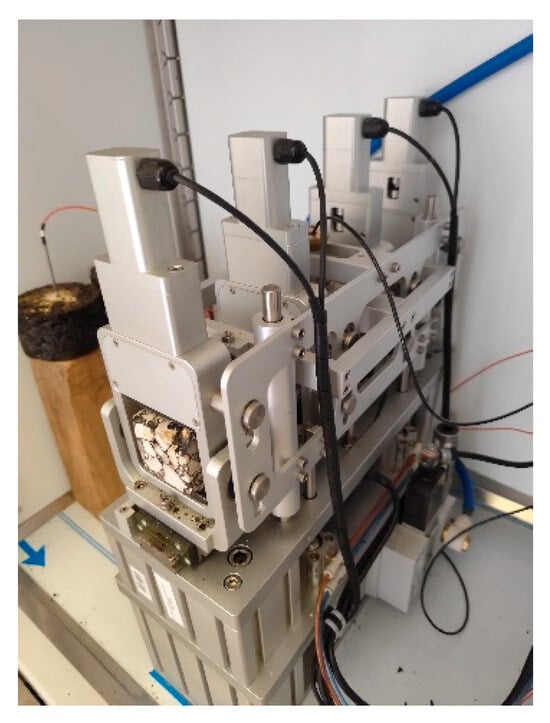

Dynamic modulus testing was performed to determine the stiffness of the mixtures across a range of temperatures and loading frequencies; dynamic modulus testing was performed following ASTM D3497 procedures. Cylindrical specimens measuring 100 mm in diameter and 150 mm in height were prepared using a Superpave gyratory compactor to achieve uniform compaction and desired air voids, as shown in Figure 1.

Figure 1.

Samples for dynamic modulus tests.

The ends of the specimens were trimmed to ensure parallel surfaces and uniform contact during testing. Prior to testing, each specimen was conditioned at the target temperature for at least two hours. Testing was conducted at multiple temperatures of 4 °C, 20 °C and 40 °C and loading frequencies ranging from 0.1 to 25 Hz using a servo hydraulic testing system. The dynamic modulus and phase angle were calculated from the stress–strain response. The dynamic modulus of the asphalt mixture was based on stiffness and was calculated as shown in Equation (3).

where is the dynamic modulus (MPa), is the peak stress (MPa) and is the peak strain. Dynamic modulus is also represented as a function of temperature and frequency using a sigmoidal function, as shown in Equation (4).

where is the reduced frequency and are regression parameters.

As observed from Table 6, a lower bitumen content of 4.7% results in a structurally weaker mixture due to its limited ductility and reduced capacity to effectively distribute compressive and tensile loads. The insufficient binder coating causes poor adhesion between aggregates, leading to stress concentrations that can initiate cracking and reduce overall load bearing performance. This makes the mixture more susceptible to premature distress under traffic loading, especially in tension and flexure. Increasing the bitumen content to 5.1% significantly improves the mixture’s mechanical behaviour. At this binder level, the dynamic modulus reaches approximately 4200 MPa, indicating the highest stiffness and strength among the tested samples. The enhanced bitumen content ensures better aggregate coating and improved inter-particle bonding, which helps distribute applied loads more evenly throughout the mixture. This results in improved resistance to deformation under both compressive and tensile stresses, thereby increasing the pavement’s ability to withstand heavy traffic and varying environmental conditions. Additionally, the improved ductility at this binder content reduces the risk of fatigue cracking by allowing the mixture to flex without damage.

Table 6.

Dynamic modulus test results.

However, further increasing the bitumen content to 5.5% causes a noticeable decrease in both strength and stiffness. Excessive binder saturates the mixture, reducing internal friction between aggregates and weakening the structural skeleton. This softening effect lowers the dynamic modulus and compromises the mixture’s load-carrying capacity, making it more prone to permanent deformation such as rutting under repeated loading.

3.5. Creep Compliance Test

Creep compliance tests were conducted in accordance with AASHTO T 322 to assess the time-dependent viscoelastic deformation behaviour of the mixtures with varying bitumen contents. The same cylindrical specimens used for the dynamic modulus test were employed for this evaluation. These specimens were trimmed and then conditioned at a low test temperature of 10 °C for a minimum of two hours to ensure thermal equilibrium. A constant axial load was applied to each specimen for a duration of 1000 s, and vertical deformation was continuously recorded. From the load and deformation data, the creep compliance curves were generated for each binder content to analyse differences in long-term deformation behaviour. The creep compliance under load is given as shown in Equation (5).

where is time-dependent compliance (1/MPa), ) is strain at time and is the constant applied stress. A power law model is also used for further details on viscoelastic behaviour, as shown in Equation (6).

where, and are regression coefficients and is the material constant.

As observed from Table 7, creep compliance at 4.7% bitumen content remains relatively low at 0.25, indicating that the mixture exhibits higher stiffness and greater resistance to deformation under sustained loading conditions. This lower creep compliance leads to a mixture with better permanent deformation resistance. However, the mixture may lose flexibility, increasing the risk of cracking under repeated traffic loading due to its reduced ability to dissipate stresses. As the bitumen content increases to 5.1%, the creep compliance rises to 0.3, reflecting an increase in the mixture’s ability to undergo time-dependent deformation. This higher compliance indicates improved viscoelastic behaviour, allowing the asphalt to better accommodate and redistribute stresses, which helps delay fatigue cracking and improve overall durability. At this level, the mixture balances stiffness and flexibility, enhancing both load resistance and resistance to cracking.

Table 7.

Creep compliance values.

However, when the bitumen content further increases to 5.5%, the creep compliance reaches 0.35, indicating that the mixture becomes even more susceptible to deformation under long-term loading. Mixtures with higher bitumen and filler contents tend to soften, reducing internal friction between aggregates and weakening the structural framework. This softening effect makes the asphalt more prone to rutting and permanent deformation, especially under heavy traffic or elevated temperatures.

3.6. Four-Point Bending Test

To evaluate the resistance of the asphalt mixtures to fatigue cracking under repeated loading, four-point bending beam fatigue tests were conducted following AASHTO T 321, as shown in Figure 2.

Figure 2.

Fatigue test setup.

Beam specimens measuring 380 mm in length, 63 mm in width and 50 mm in height were cut from large compacted slabs. Prior to testing, beam specimens were conditioned at 20 °C for at least two hours. Testing was performed under constant strain-controlled loading at a frequency of 10 Hz. The number of cycles to failure was recorded for each specimen. The failure was defined as a 50% reduction in initial stiffness. Fatigue evaluation in the four-point bending tests is performed as shown in Equation (7).

where is the number of cycles to failure, is applied tensile strain and and are the material constants obtained from regression.

As observed from Table 8, the lower bitumen content of 4.7% leads to earlier damage and cracking, primarily due to insufficient ductility within the asphalt structure. With less bitumen acting as a binder, the mixture becomes stiffer and less capable of absorbing and redistributing tensile stresses caused by repeated loading. This lack of flexibility means that microcracks can initiate and propagate more rapidly under traffic loads, leading to premature fatigue failure. The reduced binder also results in poorer aggregate coating and bonding, which further compromises the mixture’s ability to resist cracking. However, increasing the bitumen content to 5.1% significantly improves the mixture’s ductility and tensile strength. The additional binder enhances the coating of aggregates, providing better cohesion and a more flexible matrix that can better accommodate strain without cracking. This increased flexibility allows the asphalt to dissipate stresses more effectively, delaying the initiation and growth of fatigue cracks. Consequently, the mixture with 5.1% bitumen content exhibits the highest fatigue life, withstanding approximately 22,000 loading cycles before damage.

Table 8.

Fatigue cycles.

3.7. Wheel Tracking Test

Rutting performance of the asphalt mixtures was evaluated using the wheel tracking test according to EN 12697-22 [28]. Large slab specimens with dimensions of 300 mm by 300 mm and a thickness of 50 mm were prepared. Prior to testing, the slabs were submerged in a water bath at 50 °C for 30 min to simulate high-temperature and moisture damage conditions. A rolling wheel applying a force of 500 N was used for 20,000 passes. Rut depth was measured periodically throughout the test to assess the deformation behaviour of the mixtures with variable bitumen content. Rut depth was calculated using Equation (8).

where is the rut depth in mm, is the number of passes and and are empirical parameters from nonlinear regression.

As observed from Table 9, both higher and lower bitumen contents than the optimum value can accelerate rutting progression under cumulative loading cycles. When the bitumen content is at 4.7%, the asphalt mixture tends to have a higher volume of air voids. These voids reduce the effective contact area between aggregates, creating weak points where stresses concentrate. This leads to uneven load distribution, often referred to as channelled loading, which exacerbates the development of rutting as the pavement surface deforms more rapidly under repeated traffic loads. Moreover, higher air voids increase permeability, making the pavement more susceptible to moisture damage, which further weakens the structure and accelerates deformation.

Table 9.

Wheel tracking test results.

On the other hand, an excessive bitumen content of 5.5% causes the mixture to become saturated with binder, which reduces the internal friction and cohesion between aggregates. Excessive binder softens the mixture, causing a reduction in stiffness. This softer structure is less capable of resisting permanent deformation under heavy and repeated loading, leading to rutting and surface instability. The reduction in aggregate interlock due to excessive binder means that the mixture is more prone to permanent displacement, especially at high temperatures, when the binder becomes even softer.

4. Finite Element Modelling

4.1. Data for Modelling

For the development of material model, a Perzyna-type viscoplastic model was used to simulate the rutting behaviour of asphalt mixtures with variable bitumen content values. A nonlinear viscoplastic material model with damage evolution was utilized. The constitutive formulation was based on Perzyna-type viscoplasticity and was coupled with isotropic damage mechanics. This model used the von Mises yield criterion as implemented in ABAQUS and provided accurate correlation with the cyclic creep experimental testing conducted in the laboratory [29]. In this model, the stress was computed using Hooke’s law, and the accumulated plastic strain was calculated over numerous loading cycles for both rutting and fatigue cracking, as represented in Equation (9).

where, is the yield finction in Von Mises, is flow stress, is the viscosity parameter and is a rate sensitivity exponent. The respective parameters are calculated and shown in Table 10. As observed, the increase in bitumen content leads to an increase in both the flow stress and the rate sensitivity of the asphalt mixtures. Mixtures become more ductile and are better able to resist deformation under increasing loading rates as the binder content rises.

Table 10.

Parameters for the Perzyna-type viscoplastic model.

Moreover, the fatigue limit for each mixture type also increases with the increase in bitumen content due to enhanced flexibility and improved stress distribution capabilities within the mixture. However, when the bitumen content exceeds the optimum value, the fatigue limit begins to decline. Specifically, the fatigue limit decreases to 0.04 for the 5.5% bitumen scenario, indicating a reduced ability to resist damage under repeated loading. In contrast, the maximum fatigue limit is observed in the 5.1% bitumen content scenario, reaching 0.06, which reflects the balance between flexibility and structural integrity. The highest elastic modulus component is associated with the 5.1% bitumen scenario, which ultimately results in the optimal balance of mechanical properties, with a flow stress of 1.14 MPa and a rate sensitivity of 1.27. This indicates that the mixture with 5.1% binder content can effectively resist deformation while maintaining controlled viscoplastic behaviour under varying loading rates. On the other hand, the lower bitumen content of 4.7% results in insufficient binder coating, leading to stiffer behaviour and limited ductility. This scenario yields a high rate sensitivity of 2.11, suggesting that the material is more sensitive to loading rate variations, which negatively impacts its durability. Moreover, it exhibits the lowest fatigue limit of 0.03, making it the most vulnerable to early fatigue cracking.

With the increase in bitumen content to 5.5%, although the mixture becomes more ductile, the rate sensitivity rises to the highest value among all scenarios, at 2.41, indicating excessive susceptibility to deformation under load. This is further compounded by the highest viscosity observed in this mixture, which also contributes to permanent deformation and reduced fatigue performance when oversaturation occurs.

4.2. Two-Dimensional Model Details

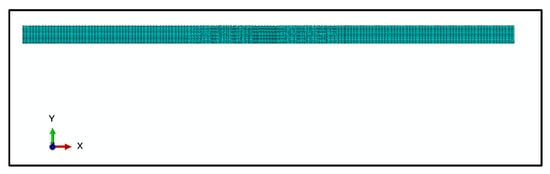

Finite element modelling was used to simulate the mechanical behaviour of various asphalt mixtures with bitumen contents of 4.7%, 5.1% and 5.5%. The performance of the constitutive model was compared with the rutting depth, stress–strain response and fatigue life obtained from laboratory tests. A visco-step loading function was used for accurate determination of permanent deformation under loading cycles. A 2D plane strain model was used in ABAQUS with an asphalt layer thickness of 15 cm. Mesh details are shown in Figure 3.

Figure 3.

Mesh details.

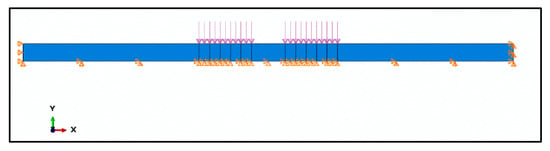

The model type is CPE4R, with reduced integration and hourglass control. The total number of elements is 6215, with element size kept at 2.5 mm, based on the convergence study for accuracy and time efficiency in simulations. Boundary conditions are shown in Figure 4. Movements along the bottom of the model were restricted along horizontal and parallel directions. Only movements along the perpendicular vertical directions were allowed, thereby reducing bias when measuring permanent deformation along the wheel paths. Loading was applied in a sinusoidal form, with a peak load of 0.7 MPa at a frequency of 1 Hz and a total of 10,000 loading cycles.

Figure 4.

Loading and boundary conditions.

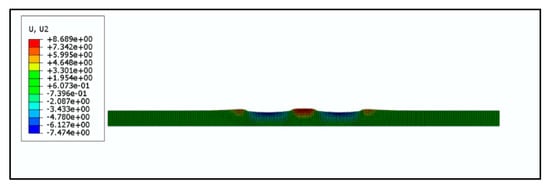

4.3. Simulation Results

Simulations were performed for all three different variations of bitumen percentage with 10,000 cycles of loading. A screenshot taken for the 4.7% scenario is shown in Figure 5. As observed, visible deformation along with upheaval zones appears after the loading cycles are completed. A cut section is later used at various depths to analyse the progress of microstrains under the wheel paths and along the pavement edges for each scenario. For the 4.7% bitumen scenario, higher microstrain values are observed near the wheel path and surface layer. This is due to insufficient binder content leading to poor aggregate coating and higher air voids, which reduce the mixture’s ability to distribute stress effectively. As a result, localized strains accumulate faster, thereby increasing the risk of early rutting and cracking. In contrast, the 5.1% bitumen scenario demonstrates the lowest microstrain accumulation at all measured depths. This optimal binder content provides a balanced structure, with adequate flexibility and stiffness, ensuring efficient load distribution and delaying damage initiation. The reduced strain levels indicate superior fatigue resistance and rutting resistance under repeated loading. For the 5.5% bitumen case, while initial strain levels are moderate, analysis at lower depths show gradually increasing microstrain accumulation. This is due to bitumen saturation, which decreases the internal friction between aggregates and leads to reduced stiffness. Over time, this condition promotes plastic flow and permanent deformation, especially under sustained traffic loading conditions.

Figure 5.

Simulation results.

Von Mises stress values observed at depths of 50 mm, 450 mm and 800 mm. A cut section was used in the finite element simulation to record the corresponding stress values along these depths, as shown in Table 11. Stress distribution shows a clear trend of decreasing stress magnitude with increasing depth. This is consistent with the behaviour of layered pavement structures, where surface layers bear the applied load and underlying layers experience attenuated stress levels due to material damping and dispersion.

Table 11.

Von Mises stress values.

The highest concentration of stress is observed in the 4.7% bitumen scenario. This occurs due to the reduced elastic response and lower cohesion in the mixture caused by inadequate binder content. The mixture lacks sufficient ductility and fails to effectively dissipate stress, leading to localized stress accumulation near the loading zone. As a result, the material becomes more prone to cracking and rutting under repetitive loading. In comparison, the 5.1% bitumen scenario shows the lowest Von Mises stress magnitudes across all depths. This mixture, with its optimum binder content, offers a balanced combination of flexibility and stiffness, allowing it to evenly distribute and absorb stress more effectively. This also contributes to improved fatigue performance and a lower risk of failure over time. The 5.5% bitumen case exhibits stress values that are lower than the 4.7% case but slightly higher than the 5.1% mixture.

5. Damage Evolution, Plastic Strain and Rutting Evaluation

Further enhancements are added using Lemaitre’s Isotropic Damage Model, which uses a scalar damage variable [30]. A typical evolution law for damage evolution is shown in Equation (10).

where is the accumulated plastic strain, is the crirtical strain for fatigue threshold and , are material constants. The parameters used are shown in Table 11.

As observed from Table 12, the damage rate for both the 4.7% and 5.5% bitumen content scenarios is higher compared to the 5.1% scenario. This indicates that mixtures with bitumen contents either lower or higher than the optimum value experience a faster progression of damage under loading. The 5.1% bitumen mixture, on the other hand, exhibits a lower damage rate, which suggests a more durable structure, capable of better withstanding repeated traffic loads over time.

Table 12.

Damage evolution parameters.

Furthermore, the 5.1% bitumen content yields higher critical strain values. Critical strain represents the threshold strain level beyond which significant damage starts to accumulate rapidly. A higher critical strain means the mixture can endure larger deformations before fatigue damage initiates. This allows for a greater number of loading cycles, thereby increasing the overall fatigue life of the pavement. The elastic modulus of the 5.1% mixture is higher compared to the 4.7% and 5.5% mixtures. The 4.7% bitumen content mixture is stiffer but it lacks ductility, making it prone to brittle cracking under tensile stresses. Conversely, the 5.5% bitumen mixture suffers from reduced stiffness and increased susceptibility to permanent deformation, including rutting. Therefore, the 5.1% bitumen content represents an optimal balance between stiffness and ductility, enabling the asphalt mixture to resist both fatigue cracking and permanent deformation.

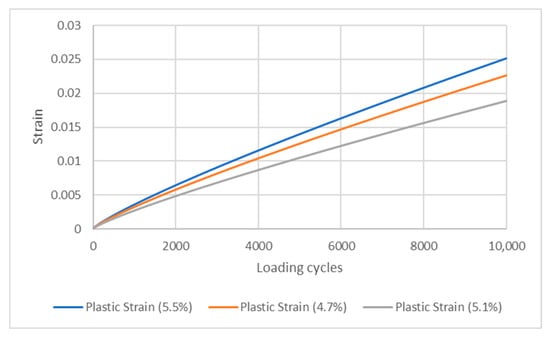

The 4.7% bitumen content scenario tends to exhibit higher plastic strain accumulation due to the insufficient amount of binder, as shown Figure 6. With less bitumen, there is increased direct contact between aggregates, which reduces the flexibility of the mixture. This lack of flexibility leads to greater stress concentration at aggregate contacts, causing more microdamage and higher plastic strain accumulation under repeated loading. In contrast, higher bitumen content improves the coating around aggregates, enhancing particle lubrication and reducing direct interlock. However, as the bitumen content increases, the mixture becomes more ductile, which helps in reducing plastic strain accumulation by accommodating deformation more evenly. The mixture with 5.5% bitumen benefits from improved binder coverage, which reduces inter-particle movement and limits the development of plastic strain. However, excessive binder can also reduce the internal friction between aggregates, potentially leading to a decrease in resistance against permanent deformation. The 4.7% bitumen mixture shows faster strain accumulation because the lower binder volume leads to poor aggregate bonding and reduced ability to distribute stresses, resulting in higher susceptibility to permanent deformation. Conversely, the 5.5% bitumen mixture, with improved binder coverage, demonstrates better resistance to plastic strain accumulation due to increased flexibility and reduced aggregate interlocking.

Figure 6.

Plastic strain comparison.

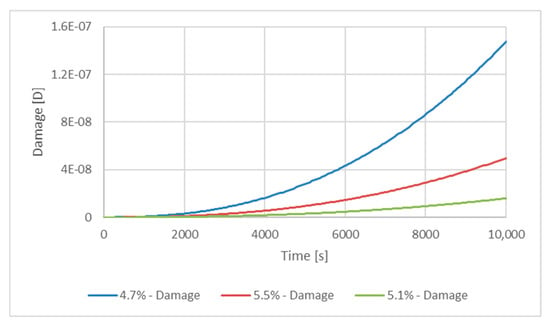

The bitumen content of 5.1% exhibits delayed damage initiation, higher ductility and increased strain tolerance, as shown in Figure 7. This optimal binder level allows the asphalt mixture to better absorb and redistribute stresses caused by repeated loading, thereby slowing the progression of damage and enhancing the pavement’s fatigue life. In contrast, the 4.7% bitumen content leads to faster and more widespread damage propagation. At this lower binder level, the asphalt matrix is less able to dissipate stress effectively, which results in concentrated stress zones that accelerate microcrack initiation and growth across a broader area.

Figure 7.

Accumulated plastic strains against time.

Furthermore, the 5.5% bitumen scenario also exhibits increased damage spread. Excessive binder content reduces the overall stiffness of the mixture, making it more susceptible to permanent deformation under repetitive loading cycles. This decreased stiffness compromises the mixture’s resistance to rutting and fatigue damage, thereby causing higher magnitudes of plastic strain and earlier damage accumulation.

Damage in asphalt mixtures is fundamentally linked to the growth of microcracks as driven by cyclic loading. When bitumen content is low, at 4.7%, the insufficient binder volume prevents effective stress redistribution throughout the matrix. This results in localized stress concentrations that accelerate microcrack propagation. On the other hand, the mixture with 5.1% bitumen demonstrates a delayed and dampened damage evolution due to better stress dissipation and enhanced ductility, which help delay the onset and slow the growth of fatigue damage.

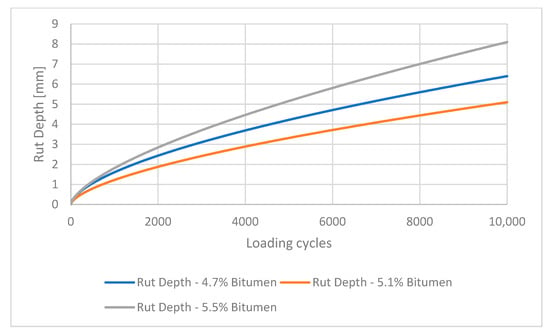

The asphalt mixture with 5.1% bitumen content exhibits minimal rutting during the early stages of loading, indicating strong resistance to permanent deformation, as shown in Table 13. This optimal binder content provides sufficient flexibility and stiffness balance, enabling the mixture to better withstand repetitive traffic loads without significant deformation. In contrast, the 4.7% bitumen mixture shows moderate rutting initially; however, once the plastic strain limit is exceeded, the rutting magnitude increases rapidly. This is primarily due to the mixture’s lower ductility and insufficient binder volume, which limits its ability to redistribute stresses and resist permanent deformation. For the 5.5% bitumen scenario, the rutting magnitude is the highest among the three mixtures. This can be attributed to the higher accumulation of plastic strain combined with lower flow resistance, similar to the behaviour seen in the 4.7% case. Excessive binder content leads to a softer, less stiff mixture, which compromises the internal resistance between aggregates under loading. Consequently, the mixture is more prone to permanent deformation and rutting, especially under repeated cyclic loading conditions.

Table 13.

Rutting progression for each scenario.

Rut depth is directly correlated with viscoplastic strain and damage accumulation within the asphalt mixture. As illustrated in Figure 8, increasing bitumen content initially improves the mixture’s cohesion and flow resistance, thereby reducing rutting. The 5.5% bitumen mixture shows the highest rut depth due to excessive binder, which softens the mixture and reduces its stiffness, making it more prone to permanent deformation under heavy loads. Similarly, the 4.7% mixture, with insufficient binder, lacks adequate cohesion and flexibility, resulting in significant rutting from concentrated stresses and reduced resistance to deformation. The mixture with 5.1% bitumen content demonstrates the best performance, exhibiting the smallest rut depth. This optimum level provides sufficient binder to provide cohesion and flexibility while maintaining adequate stiffness to resist viscoplastic strain accumulation and damage progression.

Figure 8.

Simulated rut depth comparison.

6. Bayesian Parameter Optimization

Bayesian parameter optimization was performed to ensure the correct estimation of model parameters, including yield stress, damage constant and viscoplastic coefficients. Material variability and experimental noise can further alter the accurate prediction performance of asphalt mixtures; therefore, the Bayesian inference framework estimates important parameters that affect viscoplastic deformation and damage evolution in asphalt mixtures. The viscoplastic damage constitutive model was embedded in a Bayesian framework to quantify uncertainty in mechanical parameters. The model structure assumes that experimental strain, rut depth and fatigue response deviates from the model prediction due to measurement noise and material heterogeneity. Bayesian inference identifies the optimal parameters and quantifies their uncertainty through posterior distributions, since there is inherent variability in material properties, temperature sensitivity and loading conditions. Bayesian parameter estimation is provided by the Bayesian theorem, as shown in Equation (11).

where is the posterior distribution of model parameters based on data , is the likelihood function, is prior distribution and is a normalization constant. For the three different asphalt mixture scenarios, the model parameters considered are shown in Table 14.

Table 14.

Viscoplastic and damage parameters.

The likelihood function is based on the assumption of normally distributed experimental noise in observed plastic strain or rut depth data, as shown in Equation (12).

where is the exponential strain and is the model output for given parameters. The posterior distributions are sampled using Markov Chain Monte Carlo and Metropolis Hastings algorithms. For each level of bitumen content, 10,000 samples were generated; the first 2000 samples were discarded, and the convergence was checked via Gelman–Rubin diagnostics. The estimated parameters are shown in Table 15.

Table 15.

Calculated parameters.

As observed, the 5.1% bitumen mixture exhibits a higher yield threshold at 0.014, with more gradual damage growth and the smallest viscoplastic coefficient, at 0.0018. The 5.5% scenario yields the lowest initial yield stress at 1175 kPa and the lowest initial damage threshold, with a magnitude of 0.010.

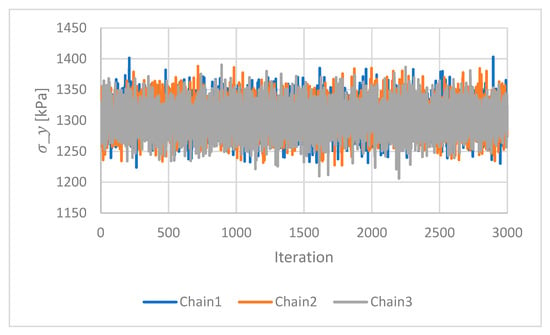

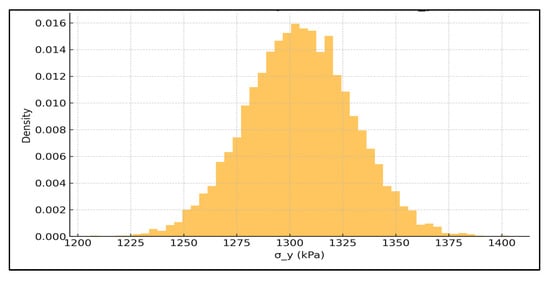

The trace plot illustrating the evolution of sampled values of the yield stress parameter across three independent Markov chains over 3000 iterations is shown in Figure 9. All chains exhibit rapid stabilization after a short initialization period, oscillating around a consistent mean level without visible drift or systematic trends. This behaviour indicates that the chains are exploring the target posterior distribution. The overlap between the chains further confirms convergence, showing that all three chains have settled into the same region of parameter space. The trace plot ensures that posterior estimates for are reliable and that the sampling process achieved statistical equilibrium.

Figure 9.

Trace plot for yield stress.

The posterior density plot shows the estimated probability distribution of the yield stress parameter , aggregated from the combined samples of the three chains, as shown in Figure 10. The distribution exhibits a unimodal shape, centred around approximately 1300 kPa, consistent with the expected mechanical behaviour of asphalt mixtures within this binder content range. The relatively narrow spread of the distribution reflects low posterior uncertainty. This therefore confirms both the stability and the precision of the Bayesian estimation, showing that the inferred value of is statistically accurate.

Figure 10.

Posterior density for yield stress.

7. Conclusions and Findings

In this research, different bitumen percentages of 4.7%, 5.1% and 5.5% are used to conduct an in-depth analysis of stress–strain response, plastic strain accumulation, damage evolution and the resulting rutting and fatigue damage for each variation. Laboratory tests, including Marshall stability, semi-circular bending, wheel tracking, dynamic modulus and fatigue tests, were conducted to evaluate the mechanical and durability performance of the asphalt mixtures. These experimental results are further complemented by finite element modelling (FEM), which incorporated nonlinear viscoplastic behaviour and damage evolution models, providing a comprehensive understanding of the mixtures’ performance under repeated loading conditions.

The results demonstrate that asphalt mixtures with 4.7% bitumen content are prone to early damage accumulation, higher plastic strain rates and more significant rutting. This lower binder content results in insufficient adhesion and reduces the mixture’s ability to withstand cyclic loading, thereby compromising durability. On the other hand, the mixture with 5.5% bitumen shows reduced strain accumulation and damage development. The excessive bitumen leads to lower stiffness, temperature-related softening and reduced Marshall stability, due to excessive flexibility and binder-rich zones.

The mixture containing 5.1% bitumen performs better experimentally than the other two scenarios. It provides a balanced response under mechanical loading by maintaining adequate stiffness, fatigue resistance and rutting performance. FEM simulations also confirmed these trends, showing that the 5.1% mix sustained lower damage fields and accumulated plastic strains as compared to the 4.7% mix, while avoiding the over-softening observed in the 5.5% mixture. The numerical models accurately replicate the stress–strain behaviour and rutting depth observed in laboratory results. The 5.1% bitumen content demonstrates the best balance between deformation resistance and flexibility, thereby outperforming both the lower and higher binder contents in mechanical strength, damage tolerance and longevity. In terms of the limitations of this research, the effect of temperature variations during experimentation and modelling on the properties of the asphalt mixtures was not considered. Furthermore, only one material model, the Perzyna-type viscoplastic model, was used. Future work will include the application of the viscoelastic continuum, viscoelastic plastic coupling, Schapery-type models and the Generalized Maxwell model for a more detailed and comprehensive analysis. The findings are as follows.

- Rutting magnitude increases by approximately 14% when the bitumen content exceeds the optimum value and reaches 5.5%.

- A lower bitumen content of 4.7%, which is 0.4% below the optimum, leads to earlier occurrence of fatigue damage.

- The optimum bitumen content of 5.1% provides the best resistance against permanent deformation.

- Increasing the bitumen content beyond 5.1% can slightly reduce the accumulated plastic strain over time due to increased viscosity.

- The mixture with 5.5% bitumen shows higher viscosity, resulting in a slightly improved fatigue limit compared to the 4.7% scenario.

- The maximum damage limit is observed at 5.1% bitumen content, indicating a greater ability to withstand repeated loading cycles.

- Proper provision of air voids in the mixture is strongly influenced by the percentage of bitumen added, which affects damage evolution.

- Finite element modelling tends to slightly overestimate the rut depth values compared to experimental results due the inherent limitation of material modelling in ABAQUS.

- Insufficient bitumen results in lower critical strain values based on Lemaitre’s Isotropic Damage Model, indicating reduced fatigue resistance.

- Creep compliance increases with bitumen content beyond the optimum, as observed in the 5.5% mixture, implying greater susceptibility to permanent deformation under sustained loads.

- The lowest fracture energy is exhibited by the 4.7% scenario due to limited bitumen availability, resulting in poor aggregate coating and reduced cohesion compared to the 5.1% mixture.

Funding

This research received no external funding.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

The author declares no conflicts of interest.

References

- Yan, Y.; Zhang, H.; Bekoe, M.; Allen, C.; Zhou, J.; Roque, R. Effects of Asphalt Binder Type, Aggregate Type, and Gradation Characteristics on Fracture Properties and Performance of Asphalt Mixtures at Intermediate Temperatures. Constr. Build. Mater. 2023, 409, 133801. [Google Scholar] [CrossRef]

- Lin, P.; Liu, X.; Ren, S.; Xu, J.; Li, Y.; Li, M. Effects of Bitumen Thickness on the Aging Behavior of High-Content Polymer-Modified Asphalt Mixture. Polymers 2023, 15, 2325. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.J.; Lee, J.H.; Park, H.M. Performance Evaluation of High Modulus Asphalt Mixtures for Long Life Asphalt Pavements. Constr. Build. Mater. 2007, 21, 1079–1087. [Google Scholar] [CrossRef]

- Batioja-Alvarez, D.; Lee, J.; Haddock, J.E. Understanding the Illinois Flexibility Index Test (I-FIT) Using Indiana Asphalt Mixtures. Transp. Res. Rec. 2019, 2673, 337–346. [Google Scholar] [CrossRef]

- Li, P.; Zheng, M.; Wang, F.; Che, F.; Li, H.; Ma, Q.; Wang, Y. Laboratory Performance Evaluation of High Modulus Asphalt Concrete Modified with Different Additives. Adv. Mater. Sci. Eng. 2017, 361. [Google Scholar] [CrossRef]

- Sirin, O.; Paul, D.K.; Kassem, E.; Ohiduzzaman, M. Evaluation of Short-Term Aging Protocol for Asphalt Mixtures. Appl. Sci. 2019, 9, 2783. [Google Scholar] [CrossRef]

- Underwood, B.; Baek, C.; Kim, Y. Simplified Viscoelastic Continuum Damage Model as Platform for Asphalt Concrete Fatigue Analysis. Transp. Res. Rec. 2012, 2296, 36–45. [Google Scholar] [CrossRef]

- Cheng, H.; Sun, L.; Wang, Y.; Liu, L.; Chen, X. Fatigue Test Setups and Analysis Methods for Asphalt Mixture: A State-of-the-Art Review. J. Road Eng. 2022, 2, 279–308. [Google Scholar] [CrossRef]

- Liu, J.; Liu, J. Prediction Models for Low-Temperature Creep Compliance of Asphalt Mixtures Containing Reclaimed Asphalt Pavement (RAP). Constr. Build. Mater. 2021, 306, 124915. [Google Scholar] [CrossRef]

- Ali, A.; Kabir, S.F.; Al-Badr, B.; Alfalah, A.; Xie, Z.; Decarlo, C.; Elshaer, M.; Mehta, Y. Laboratory Performance of Dense Graded Asphalt Mixtures Prepared Using Highly Polymer Modified Binders Containing Corn Oil as Softening Agent. Constr. Build. Mater. 2022, 345, 128336. [Google Scholar] [CrossRef]

- Lv, Q.; Huang, W.; Zheng, M.; Sadek, H.; Zhang, Y.; Yan, C. Influence of Gradation on Asphalt Mix Rutting Resistance Measured by Hamburg Wheel Tracking Test. Constr. Build. Mater. 2020, 238, 117674. [Google Scholar] [CrossRef]

- Bi, Y.; Mu, M.; Zeng, L.; Ding, T.; Qian, C.; Yu, D.; Jiang, Y. Development and Road Performance Verification of Aggregate Gradation for Large Stone Asphalt Mixture. Materials 2024, 17, 5712. [Google Scholar] [CrossRef] [PubMed]

- Huang, G.; Zhang, J.; Hui, B.; Zhang, H.; Guan, Y.; Guo, F.; Li, Y.; He, Y.; Wang, D. Analysis of Modulus Properties of High-Modulus Asphalt Mixture and Its New Evaluation Index of Rutting Resistance. Sustain. 2023, 15, 7574. [Google Scholar] [CrossRef]

- Safaeldeen, G.I.; Al-Mansob, R.A.; Al-Sabaeei, A.M.; Yusoff, N.I.M.; Ismail, A.; Tey, W.Y.; Azahar, W.N.A.W.; Ibrahim, A.N.H.; Jassam, T.M. Investigating the Mechanical Properties and Durability of Asphalt Mixture Modified with Epoxidized Natural Rubber (ENR) under Short and Long-Term Aging Conditions. Polymers 2022, 14, 4726. [Google Scholar] [CrossRef] [PubMed]

- Khorshidi, M.; Goli, A.; Orešković, M.; Khayambashi, K.; Ameri, M. Performance Evaluation of Asphalt Mixtures Containing Different Proportions of Alternative Materials. Sustainability 2023, 15, 3314. [Google Scholar] [CrossRef]

- ASTM D5/D5M; Standard Test Method for Penetration of Bituminous Materials. ASTM International: West Conshohocken, PA, USA, 2020.

- D36; Standard Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus). ASTM International: West Conshohocken, PA, USA, 2014.

- D113–17; Standard Test Method for Ductility of Asphalt Materials. ASTM International: West Conshohocken, PA, USA, 2017.

- D2872-22; Standard Test Method for Effect of Heat and Air on a Moving Film of Asphalt Binder (Rolling Thin-Film Oven Test). ASTM International: West Conshohocken, PA, USA, 2022.

- D6084; Standard Test Method for Elastic Recovery of Asphalt Materials by Ductilometer. ASTM International: West Conshohocken, PA, USA, 2021.

- D4402; Standard Test Method for Viscosity Determination of Asphalt at Elevated Temperatures Using a Rotational Viscometer. ASTM International: West Conshohocken, PA, USA, 2023.

- D6927-22; Standard Test Method for Marshall Stability and Flow of Asphalt Mixtures. ASTM International: West Conshohocken, PA, USA, 2022.

- TP 124; Standard Method of Test for Determining the Fracture Potential of Asphalt Mixtures Using the Flexibility Index Test. AASHTO: Washington, DC, USA, 2022.

- D3497-79; Standard Test Method for Dynamic Modulus of Asphalt Mixtures. ASTM International: West Conshohocken, PA, USA, 2003.

- T 322-07; Standard Method of Test for Determining the Creep Compliance and Strength of Hot Mix Asphalt (HMA) Using the Indirect Tensile Test Device. AASHTO: Washington, DC, USA, 2020.

- T 321-22; Standard Method of Test for Determining the Fatigue Life of Compacted Asphalt Mixtures Subjected to Repeated Flexural Bending. AASHTO: Washington, DC, USA, 2022.

- T 324; Standard Method of Test for Hamburg Wheel-Track Testing of Compacted Asphalt Mixtures. AASHTO: Washington, DC, USA, 2023.

- EN 12697-22; Bituminous Mixtures—Test Methods—Part 22: Wheel Tracking. CEN: London, UK, 2023.

- Chen, Y.; Smith, L.V. A Nonlinear Viscoelastic–Viscoplastic Model for Adhesives. Mech. Time-Dependent Mater. 2021, 25, 565–579. [Google Scholar] [CrossRef]

- Andriollo, T.; Thorborg, J.; Hattel, J. Analytical Solution to the 1D Lemaitre’s Isotropic Damage Model and Plane Stress Projected Implicit Integration Procedure. Appl. Math. Model. 2016, 40, 5759–5774. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.