1. Introduction

When excavating tunnels, caverns, or underground roadways in high-stress and hard-brittle rock masses, rockburst dynamic disasters are extremely likely to occur. Predicting rockburst proneness has long been one of the major global challenges in rock engineering. After tunnel excavation, the surrounding rock transitions from a triaxial stress state to a biaxial stress state, causing stress concentration. The stress concentration leads to the progressive accumulation of energy within the surrounding rock mass. The energy can be released, inducing rockburst when it has accumulated to a certain level [

1]. Rockbursts are characterized by burstiness, destructiveness, and instantaneity, and are difficult to predict in engineering practice. They frequently inflict catastrophic damage on underground construction and directly endanger construction personnel and equipment [

2]. Identifying the main influencing factors of rockbursts and providing timely and accurate predictions and prevention measures have become critical tasks in the construction of underground projects such as tunnels, mines, and hydropower works. At present, based on strength theory, damage theory, and energy theory, the mechanism of rockburst occurrence has been analyzed by numerous scholars [

3,

4]. Various methods have been proposed for predicting rockburst proneness. However, most of these methods take into account only a few factors affecting rockbursts and therefore are one-sided and limited in scope. Therefore, it is essential to establish a predictive method for rockbursts that considers multiple influencing factors, possesses objectivity and universality, and has a high precision rate.

Over the past few decades, domestic and international scholars have conducted extensive studies on rockburst prediction. Firstly, some scholars use a single evaluation index to predict the rockburst proneness. Rock mechanics parameters and in situ stress parameters were used to establish the rockburst prediction methods. These methods included Russenes evaluation method [

5], Turchaninov evaluation method [

6], Hoek evaluation method [

7], Barton evaluation method [

8], Kidybiński evaluation method [

4], Hou FL evaluation method [

9], Lu JY evaluation method [

10], Tao ZY evaluation method [

11], Xu LS evaluation method [

12], Tan YA evaluation method [

13], etc. As research progresses, some new evaluation indexes have been proposed for predicting rockburst. The fractal dimension of the rock surfaces was proposed to predict rockburst by Li [

14]. A new index of rockburst potential exponent was proposed by Zhang [

15], and the corresponding critical value was obtained. Based on energy storage and release characteristics, Yin [

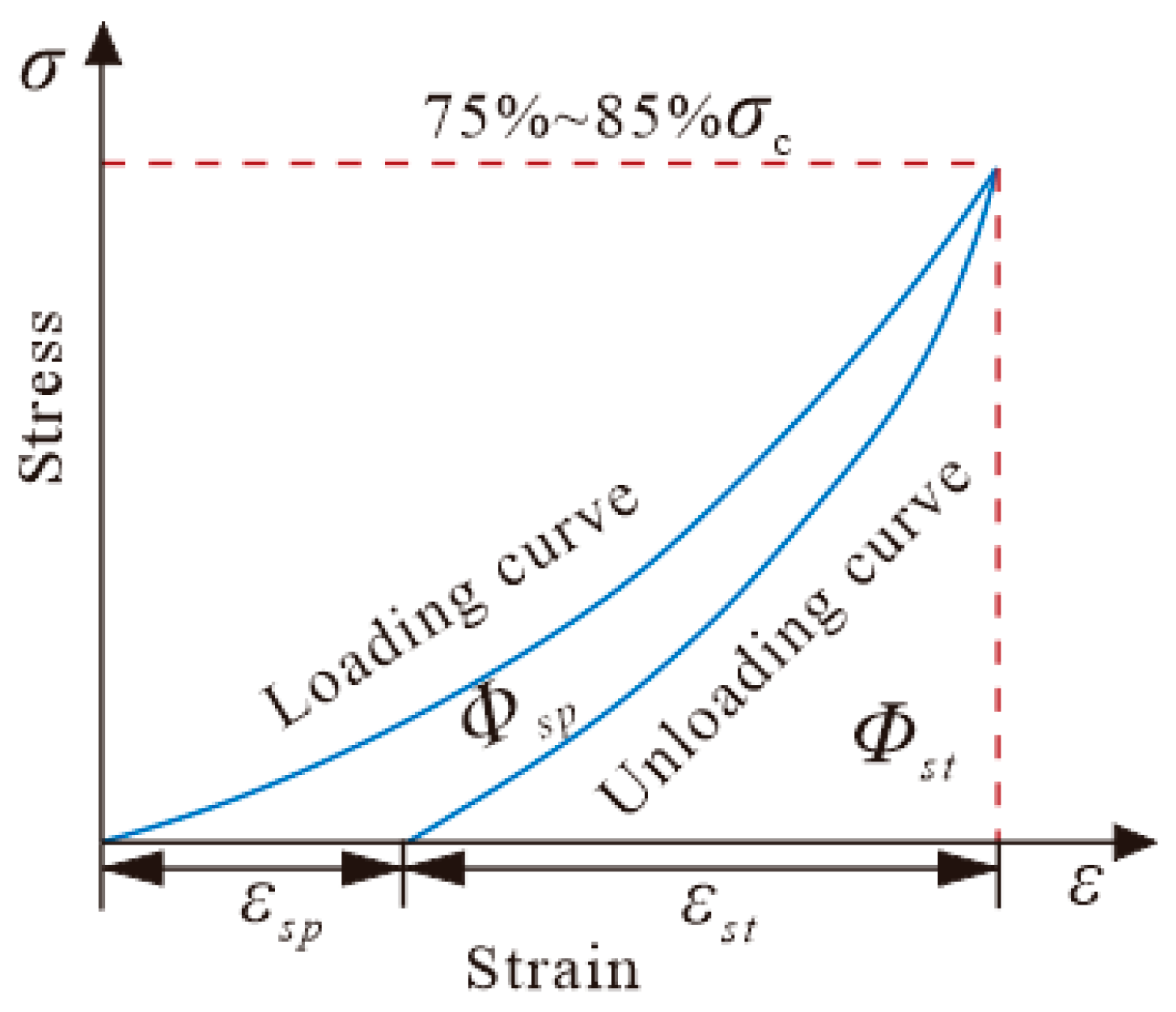

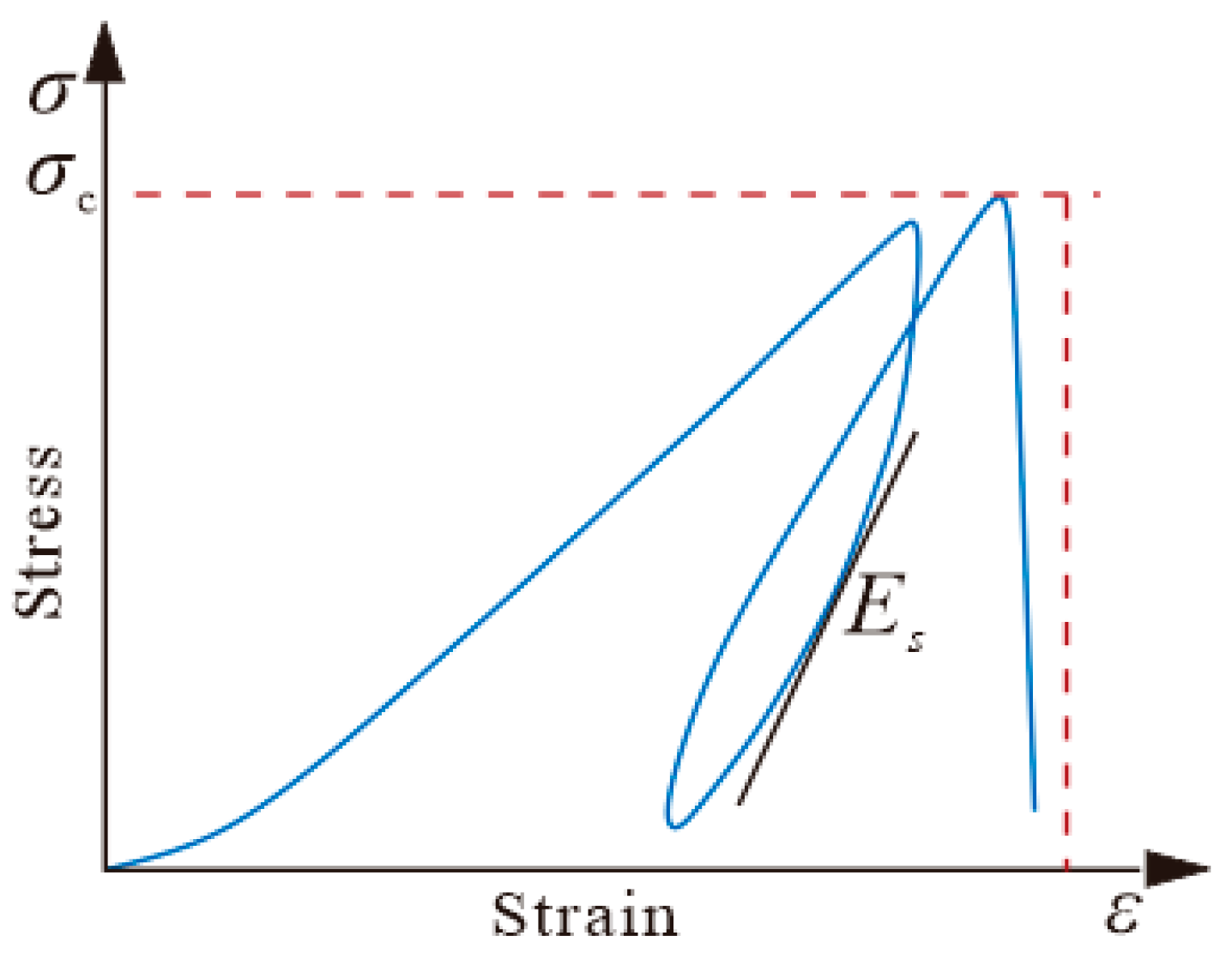

16] proposed a new evaluation index to predict rockburst under combined static and dynamic loading. Five-factor discriminant index was used to predict rockburst by Jia [

17], and satisfactory application results have been obtained in the Houziyan underground powerhouse. Based on multi-physical field parameters, an integrated predicting method for rockburst monitoring was proposed by Zhang [

18], and the results indicated that the sensitivity of the three monitoring techniques to rockburst was ranked as follows: visible-light imaging > far-infrared > acoustic emission. Yang [

19] proposed a new prediction index of the relative energy release rate (per unit time) for predicting rockburst. Based on the energy storage and release characteristics of the Type II evolution curve, a new evaluation index

C was obtained by Cai [

20]. Combining the local energy release rate (LERR) and the limit energy storage rate (LERS), a new index of the rockburst energy release rate (RBERR) was proposed to predict rockburst by Xu [

21]. Based on the consideration of the pre-peak energy dissipation, strain energy accumulation, and post-peak energy dissipation, a novel evaluation index

G for rockburst proneness was introduced by Mo [

22]. The proposed approach addressed the limitations inherent in two widely used rockburst proneness metrics—the elastic energy index and the impact energy index. Based on the numerical simulation techniques, the strain energy analysis method was proposed to predict rockburst by Wang [

23]. Using the disturbance-energy analysis, Cai [

24] studied the basic criteria of rock mass conditions and the geological factors for predicting rockbursts. Tan [

25] found that the more inhomogeneous the coal-rock body was, the shorter the lasting time in the vibration period of AE characteristics was, and this phenomenon can be used to predict the rockburst proneness. Based on the micro-seismic monitoring technology and stress conditions under combined dynamic and static stress, the comprehensive index

ISD was obtained by He [

26]. Based on in situ stress conditions, energy accumulation theory, and numerical simulation method, a new method was introduced to predict the potential location and strength of rockburst by Miao [

27]. He [

28] proposed the classification grade of rockburst, the failure criterion of rockburst, and the control method of rockburst. The above rockburst prediction methods were easy to operate and achieved moderate predictive accuracy. However, the selection of the evaluation index was limited, and the prediction method had significant limitations. Thus, it is necessary to establish the multi-index evaluation method of rockburst to improve prediction accuracy.

Based on the mathematical-statistical method, some researchers have proposed an integrated multi-indexes model for predicting rockburst. By comprehensively analyzing the main evaluation indexes of rockburst, the maximum tangential stress, the rock compressive strength, the rock tensile strength, and the elastic energy index were selected to establish a rockburst prediction model. The models included the fuzzy mathematical model [

29], the matter–element model, the neural network model [

30,

31], etc. The new Bayesian network model was established by Li for predicting rockburst, and its validity and accuracy were verified by using 15 incomplete-case examples [

32]. Based on fuzzy matter–element theory, some major indexes were selected by Wang to establish the rockburst prediction model including the brittleness index, surrounding rock stress, elastic strain energy index, and rock integrality index [

30]. Chen [

33] developed a projection-pursuit model for predicting rockburst, selecting the maximum tangential stress, stress coefficient, and elastic deformation index as predictors. Based on the fuzzy theory and the neural network theory, the fuzzy neural network model was developed by Li to predict rockburst [

34]. Based on an analysis of the primary factors related to rockburst, Chen developed a novel artificial neural network model, and the results demonstrated its accuracy and reliability [

31]. A novel discrete Hopfield neural network (DHNN) model for predicting rockburst was introduced by Xu, and it addressed the random and subjective nature of weight assignment in conventional prediction methods [

35]. Based on the artificial neural networks (ANN) and AdaBoost algorithm approach, the integrated AdaBoost–ANN model was established by Ge [

36], overcoming the instability of single weak classifiers. Wang [

37] established an efficacy-coefficient analysis model for rockburst prediction based on the basic principles of the efficacy coefficient. Based on the fuzzy probability theory, Liu developed a new fuzzy-probability model for rockburst prediction [

38]. Wang [

39] established a Delphi–normal cloud rockburst predicting model that mitigates both fuzziness and randomness in rockburst evaluation, demonstrating superior accuracy compared with the efficacy-coefficient and set-pair analysis approaches. An unascertained measurement classification model was introduced to predict rockburst by Shi [

40], which showed good agreement with the fuzzy comprehensive evaluation method, the clustering evaluation method, and matter–element extension analysis method. The random forest (RF) model of rockburst prediction was proposed by Dong [

41], and its predictive accuracy was higher than that of support vector machines (SVM) and artificial neural networks (ANN). Sun introduced a fuzzy neural network rockburst predicting model optimized with an improved genetic algorithm combined with backpropagation [

42]. Gao proposed a modified ant-colony-clustering method for rockburst prediction, which improves the computational efficiency and accuracy of the traditional algorithm [

43]. Qin used rough set theory to determine the weights of rockburst evaluation indicators and established an Extenics-based evaluation model for rockburst prediction [

44]. According to the fuzzy inference system (FIS), adaptive neural-fuzzy inference system (ANFIS), and field measurements, Adoko established the knowledge-based and data-driven fuzzy model to predict rockburst, and the model successfully provided a prediction in a case study [

45]. According to set pair analysis (SPA) theory and variable fuzzy set function (VFS), Wang proposed the SPA–VFS model to predict rockburst [

46]. Based on the fuzzy logic body theory, the acoustic emission characteristic parameters and rock mechanics parameters were selected to establish a rule-based fuzzy evaluation model by Liu [

47]. Based on the multi-factor fuzzy evaluation index system, Guo proposed the comprehensive fuzzy evaluation model to predict coal bursts [

48]. Guo Y established a rockburst predicting model based on the theory of variable fuzzy sets [

49]. Based on the inverse weight analysis method, Chen developed a standardized fuzzy comprehensive evaluation model, which overcomes the excessive subjectivity of weight assignments in traditional models [

50]. Based on the index-distance and uncertainty quantification method, Zhang established a finite-interval cloud model for predicting rockburst, and the model addresses the ambiguity of measured indicator values and the fuzzy randomness of intensity classification [

51]. Using the combined-weighting (GEM–GW) method to determine the composite indicator weights, Pei constructed a grey evaluation model for predicting rockburst [

52]. Based on the principal component analysis (PCA) theory and fuzzy comprehensive evaluation (FCE) theory, the PCA–FCE comprehensive evaluation model was established to predicting rockburst by Cai [

53]. Zhou proposed an entropy–cloud rockburst prediction model, which outperformed the Bayesian model, the k-nearest neighbors (KNN) algorithm, and the random forest (RF) model in accuracy [

54]. Based on rock engineering systems (RES) theory, the engineering geologic factor, complex environmental factor, and human excavation factor were used to establish the intelligent predicting model of rockburst by Guo [

55]. Wen investigated the calculation methods of single-index attribute measurements and composite attribute measurements, and developed an attribute-recognition model for rockburst prediction [

56]. Using statistical theory, a distance-based discriminant analysis model was established to predict rockburst proneness by Gong [

57]. Using matter–element theory and correlation functions, Xiong introduced a matter–element model for predicting rockbursts [

58]. Zhao used the support vector machine (SVM) classification method to establish an SVM-based rockburst predicting model [

59].These studies selected two to four rockburst evaluation indexes to establish models for rockburst prediction, thereby improving the reliability and accuracy of predicting results. However, the evaluation indexes of surrounding rock structure conditions were not taken into account. Therefore, further studies are required to enhance the accuracy of rockburst prediction.

Determining the weights of evaluation indexes is a critical step in establishing a rockburst predicting model. At present, the determination of indexes weights predominantly relies on the fuzzy comprehensive evaluation method [

38], Expert scoring method [

60], Analytic Hierarchy Process method [

61], Artificial Neural Network method [

31,

34], and Grey Relational analysis method [

62], etc. Feng was the first to use an expert system to conduct a systematic study of rockburst occurrences in South African deep gold mines [

60]. Accounting for the fuzziness of weight assignments, Liu introduced the concept of fuzzy weights and developed a fuzzy probability model to predict rockburst [

38]. Using Grey Relational analysis and fuzzy recognition theory, Jiang proposed a new approach to calculating weight and established a dynamic-weight grey classification rockburst predicting model [

62]. Although these methods can satisfy the evaluation requirements to some extent, each of these methods exhibits certain shortcomings. For instance, the expert scoring method is characterized by a high degree of subjectivity and is relatively difficult to implement. The fuzzy comprehensive evaluation method assigns disproportionately high weights to extreme values, and it can cause other information to be overlooked, resulting in a loss of information. The evaluation accuracy of Artificial Neural Network methods and Grey Relational analysis method is low. However, the Analytic Hierarchy Process (AHP) has the advantage of taking into account a large number of evaluation indexes and providing a comprehensive assessment, and it helps to reduce the subjectivity and randomness involved in determining index weight.

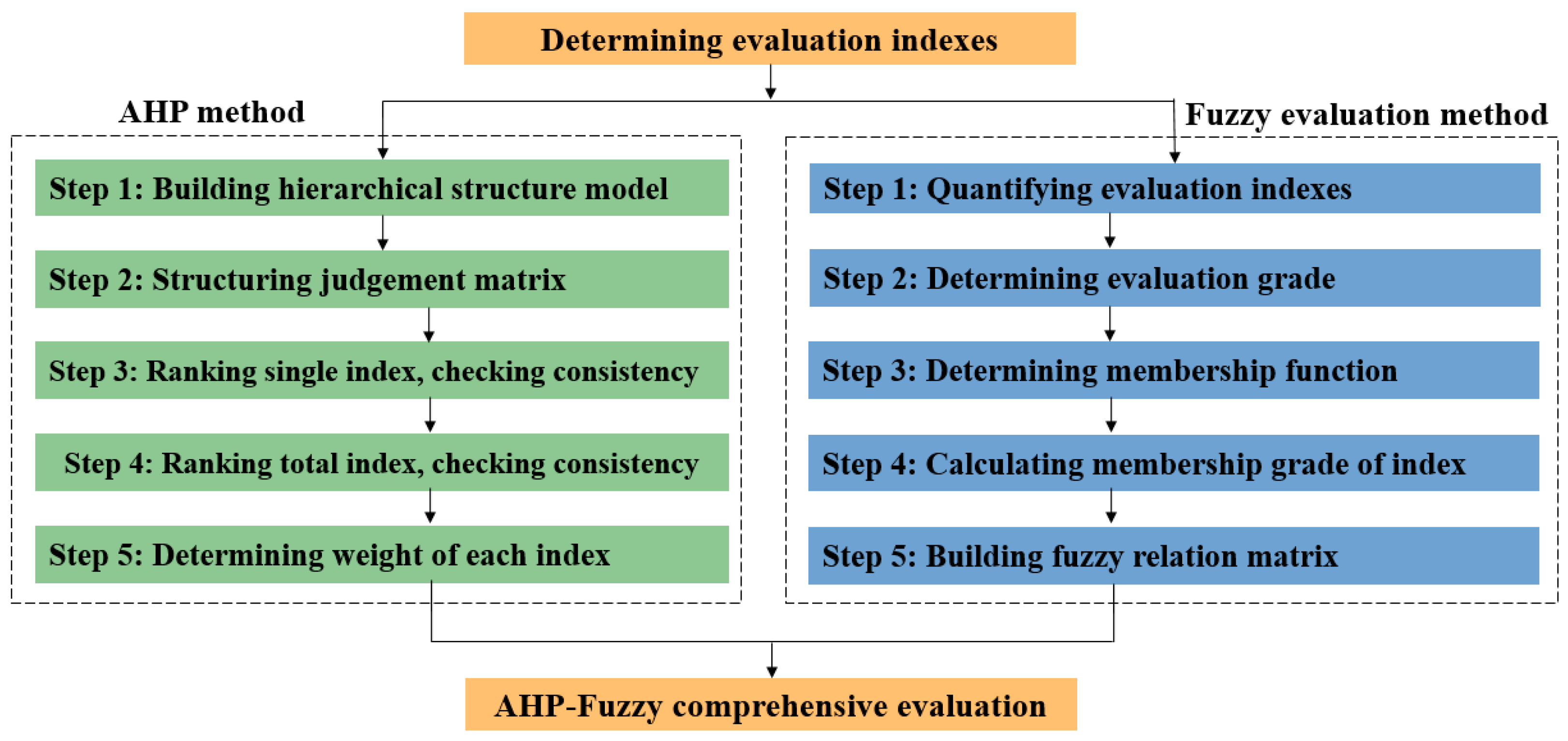

The AHP-fuzzy comprehensive evaluation method was rarely used to predict rockburst. However, it has been widely applied in other fields. Based on the risk management process and fuzzy logic theory, Khodadadi proposed the AHP-fuzzy comprehensive evaluation method to determine and evaluate the risk propensity of contractors in construction projects [

63]. Based on the AHP-fuzzy comprehensive evaluation method, the collaborative traffic predicting method for snow disasters was developed by Han [

64]. Based on the AHP method and fuzzy Delphi method (FDM), Yoo proposed the rock behavior index (RBI) to identify quantitatively the mechanical behavior of rocks in shallow tunnels [

65]. Ye introduced the AHP-fuzzy comprehensive evaluation method to evaluate the stability assessment of rockfalls [

66]. Based on the AHP method, Ren developed a multi-level hierarchical model to analyze campus fire risk [

67]. Liang introduced the AHP method to determine the component weighting factors for the integrity assessment units of natural gas compressors [

68]. Hu used the AHP method to determine the weights of the evaluation indexes in the assessment system of enterprise wastewater treatment [

69].

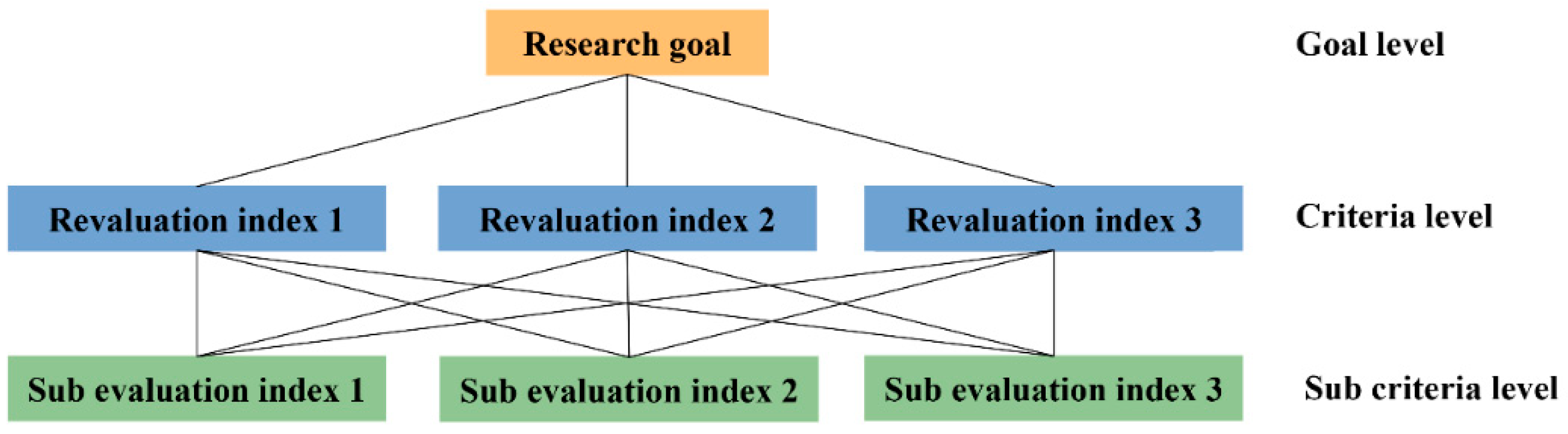

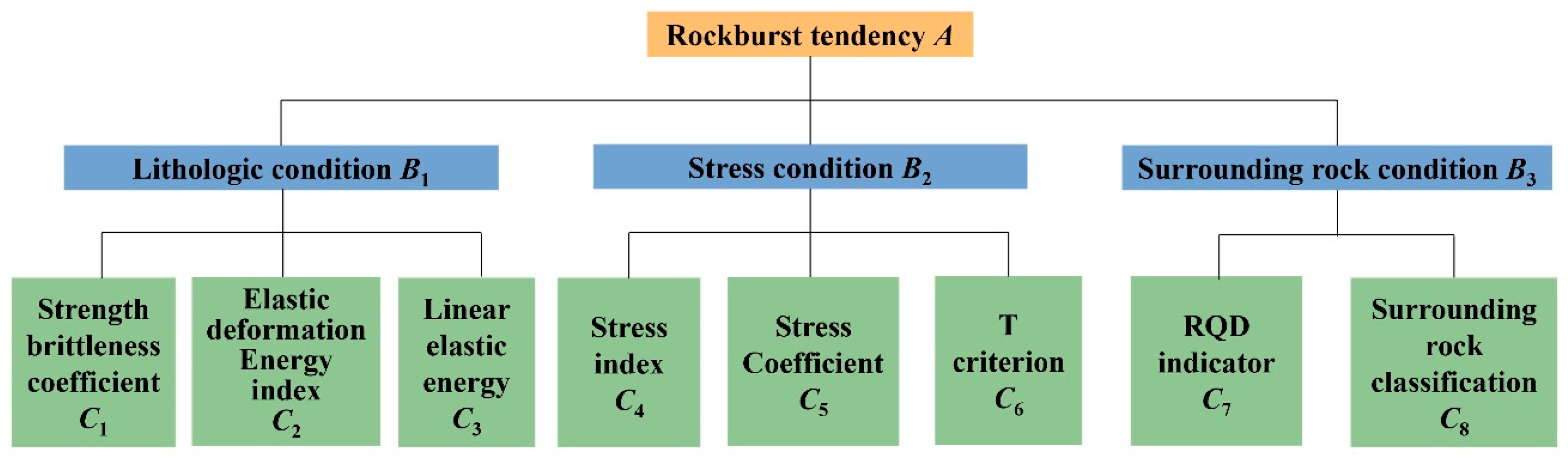

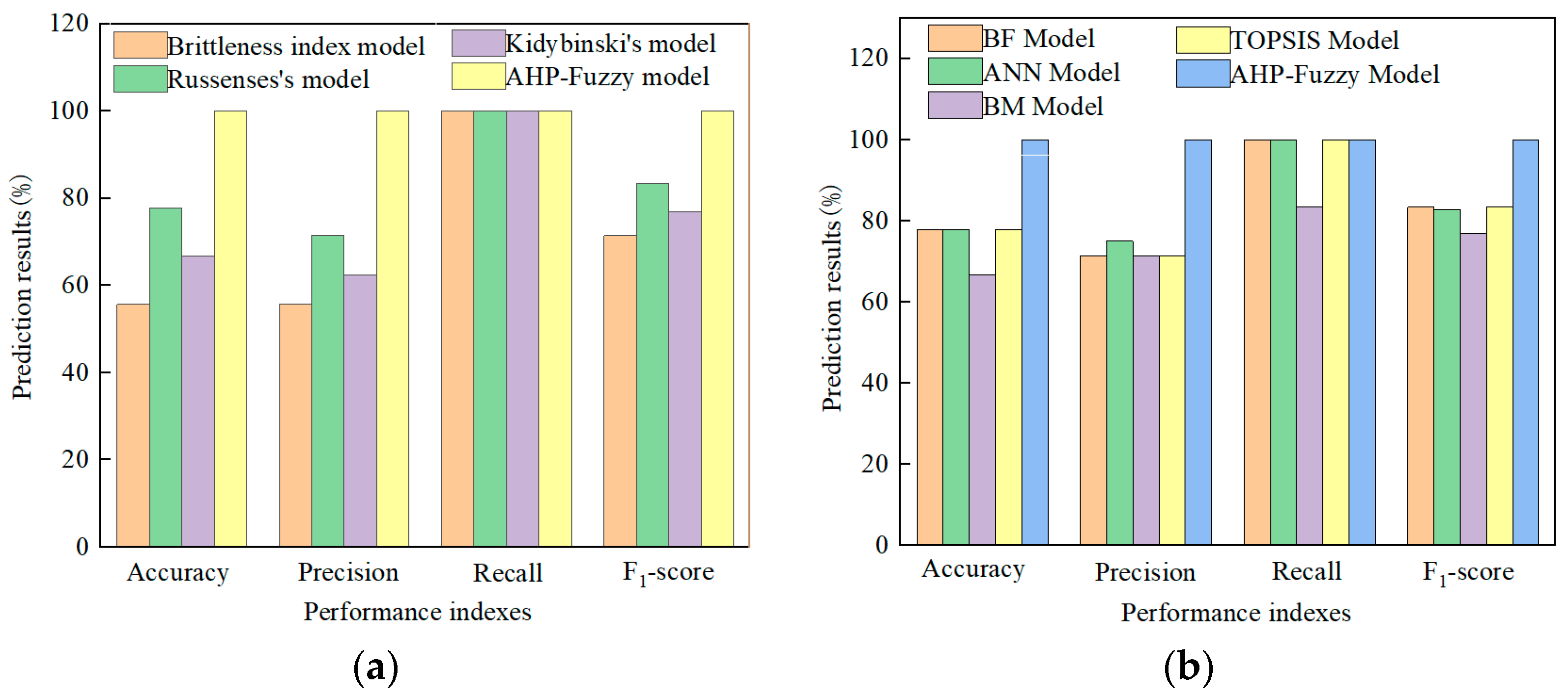

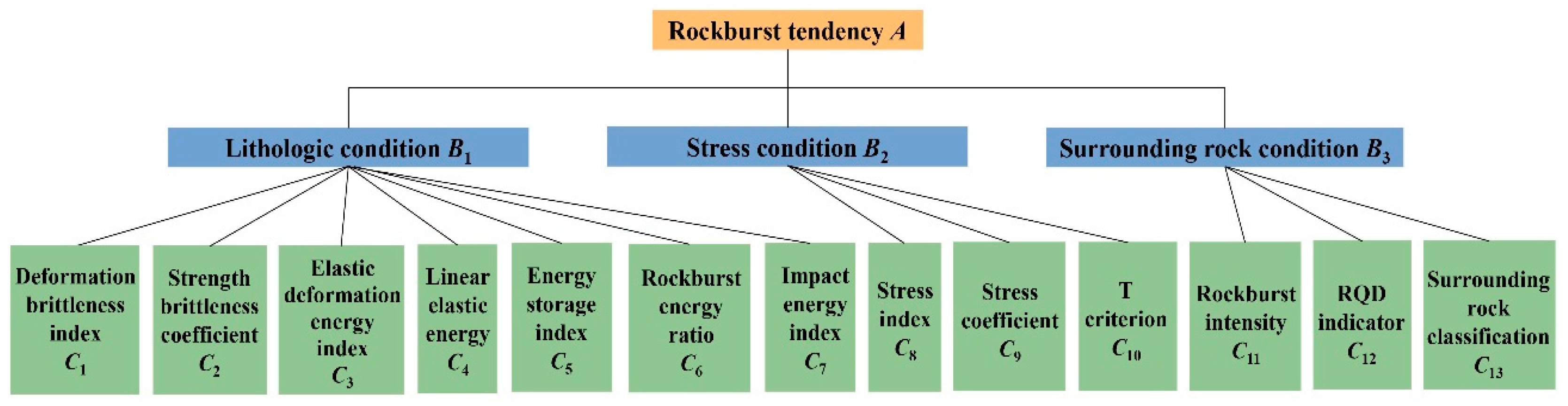

Based on the above studies, it can be concluded that the single-index rockburst prediction methods select relatively few indexes and thus cannot comprehensively reflect the main factors influencing rockbursts, resulting in inherent limitations and low prediction accuracy. The multi-index rockburst prediction approaches consider only lithological condition and stress condition while neglecting the surrounding rock structural condition, so the accuracy of rockburst prediction remains insufficient. At present, the weights of evaluation indexes are usually determined by the expert scoring method, the Artificial Neural Network method, and the Grey Relational analysis method; these methods are characterized by high subjectivity and low evaluation precision. However, the AHP-fuzzy comprehensive evaluation model can comprehensively account for multiple factors affecting rockbursts, including the lithological condition, stress condition, and surrounding rock structural condition. This method can realize the quantitative analysis for evaluation indexes, reduce the subjectivity in determining weights and increase the accuracy of the predicting model. Therefore, based on the Analytical Hierarchy Process (AHP) method and the fuzzy mathematics theory, the eight evaluation indexes (strength brittleness index, stress coefficient, elastic energy index, surrounding grade, etc.) were selected to establish the new AHP fuzzy comprehensive evaluation model. Based on the field case studies of Jinping II Hydropower Station, the feasibility and accuracy of the model were validated. The results indicate that the proposed multi-index prediction model demonstrates strong feasibility and high predictive accuracy and that the model has promising application prospects. Meanwhile, the 13 recognized evaluation indexes were summarized, and an approach for accurate rockburst prediction was proposed. The predicting model and predicting approach proposed in this paper are of great significance for improving the accuracy of rockburst prediction.

4. Engineering Case Application

The auxiliary hole of the Jinping-II Hydropower Station is characterized by complex geological structures, well-developed faults, deep burial depth, and relatively high in situ stress. Tunnel excavation is likely to cause stress redistribution and energy concentration. The study area presents the typical physical conditions associated with frequent rockbursts. On the one hand, the tunnel is characterized by its long length and large cross-section, representing the engineering conditions of similar deeply buried large-scale energy infrastructures both domestically and internationally. The tunnel faces a long-term risk of surrounding rock failure during the construction and operation stages, making it an appropriate object for rockburst prediction research. On the other hand, there are ample historical events and representative cases of rockburst. It provided real labeled samples for model training and validation, and it was helpful for the evaluation of the model’s robustness and its applicability in engineering practice. Research on the rockburst prediction in this region carries significant engineering, social, and economic implications and therefore has high research value. Rockburst disasters can cause major casualties, equipment damage, and production stoppages, so predicting outcomes for this project has immediate engineering value and potential for broader application. Therefore, the case of an auxiliary hole in the Jinping-II Hydropower Station was selected for the study. It both reflects the core technical challenges of rockburst prediction and ensures that the study’s conclusions have practical engineering applicability.

The AHP-fuzzy comprehensive evaluation model was applied to predict rockburst in the auxiliary hole of the Jinping-II Hydropower Station. The geological condition is as follows. The tunnel of the auxiliary hole has a length of 17.23 km. The mechanical property of the surrounding rock is very complex, mainly composed of marble, sandstone, and slate. The faults are well developed, and the tunnel is located in a high-stress zone. The tunnel was divided into nine stages to predict rockburst, including the

K0~550 m,

K550~1500 m,

K1500~5000 m,

K5000~8100 m,

K8100~10,000 m,

K10,000~13,500 m,

K13,500~15,000 m,

K15,000~16,200 m, and

K16,200~17,230 m. The rock mechanical parameters of each stage are shown in

Table 7 [

88].

Based on rock physical-mechanics test, the measurement in situ stress and the engineering geological analogy method, the measured values of the eight evaluation indexes were determined in each stage of the tunnel, as shown in

Table 8. In the paper, the quantitative criteria of surrounding rock classification are as follows. Grade I~V of the surrounding rock was quantified to 1~5, respectively. If the research area has both Grade II of the surrounding rock and Grade III of the surrounding rock, the quantitative value was defined as 2.5.

Taking the K0~550 m stage of the tunnel as an example, we conducted the prediction of rockburst proneness.

- (1)

The critical values of the eight evaluation indexes in

Table 3 were substituted into Equation (33). The membership function equation was obtained. Then, the measured values of the evaluation index in

K0~550 m stage were substituted into the membership function equation to obtain the fuzzy relation matrix.

The fuzzy relation matrix

R and the weight

W of the evaluation index were substituted into Equation (16) to obtain the comprehensive evaluation set

A. The comprehensive evaluation set in the test section of the tunnel for predicting rockburst was expressed as follows.

Based on the maximum membership principle, the maximum value of the comprehensive evaluation set A550 is equal to 0.7793. Therefore, the predicted result of rockburst is no rockburst in the K0~550 m stage of the tunnel. The maximum value of the comprehensive evaluation set A1500 is equal to 0.8602, and the predicted result of rockburst is weak rockburst in the K500~1500 m stage of the tunnel. The maximum value of the comprehensive evaluation set A5000 is equal to 0.6725, and the predicted result of rockburst is medium rockburst in the K1500~5000 m stage of the tunnel. The maximum value of the comprehensive evaluation set A8100 is equal to 0.8176, and the predicted result of rockburst is medium rockburst in the K5000~8100 m stage of the tunnel. The maximum value of the comprehensive evaluation set A10,000 is equal to 0.7139, and the predicted result of rockburst is medium rockburst in the K8100~10,000 m stage of the tunnel. The maximum value of the comprehensive evaluation set A13,500 is equal to 0.6970, and the predicted result of rockburst is medium rockburst in the K10,000~13,500 m stage of the tunnel. The maximum value of the comprehensive evaluation set A15,000 is equal to 0.7670, and the predicted result of the rockburst is a medium rockburst in the K13,500~15,000 m stage of the tunnel. The maximum value of the comprehensive evaluation set A16,200 is equal to 0.8580, and the predicted result of rockburst is medium rockburst in the K15,000~16,200 m stage of the tunnel. The maximum value of the comprehensive evaluation set A17,230 is equal to 0.7793, and the predicted result of rockburst is medium rockburst in K16,200~17,230 m stage of the tunnel.

Therefore, the AHP-fuzzy comprehensive evaluation method proposed in the paper was used to predict the rockburst proneness in the nine stages of the 17.23 km auxiliary hole in the Jinping-II Hydropower Station.