Abstract

The concept of digital twins has been studied for over two decades and the core tenet lies in it being a “digital representation of a connected physical object”. Utilization of digital twins promises to enable superior decision-making, enhanced operational understanding and future predictions to enable levels of Condition Based Maintenance (CBM) through Integrated Vehicle Health Management (IVHM) which exceeds existing capabilities. Digital twins are being embraced by many industries, including aviation, and are often depicted as electronic images of an asset of interest. However, in a less visually appealing manner, they can also be described simply as a collection of data in an organized and easily accessible format from across the lifecycle which describes a feature that addresses a specific use case. This review demonstrates how the creation and maintenance of digital twins will play a critical role in enhancing IVHM to enable CBM within the aerospace industry. Through a literature review, this paper demonstrates the need for digital twins, of a sufficient level of fidelity, to facilitate the transition to being condition based through deeper levels of operational and component understanding. It emphasizes how detailed knowledge, represented through ontologies, regarding component design, manufacturing, and operational history aid in achieving the desired fidelity levels. By synthesizing insights from various industries with a focus on aerospace applications, this paper aims to provide a comprehensive understanding, focused on the aviation industry, of digital twin definitions, their creation processes, fidelity measurement, and their implications for CBM, while acknowledging the limitations of the current research landscape.

1. Introduction

While there are many nuances and abstractions of the definition of a digital twin, the central idea that has almost universal agreement is that a digital twin is a “digital representation of a physical object”. This implies that if an object exists in the physical world, it can be represented digitally, creating a digital twin. Conversely, if an object has not yet been manufactured or if a prediction is being made about the future state of an existing object, it cannot possess a digital twin. For items that are intended to exist in the future, whether they are defined by a digital model, a drawing or in an anticipated state represented by a simulation, there can be no digital twin available, as their physical counterpart does not yet exist. The level to which a physical object can be digitally represented depends on its level of complexity and connectivity in design, manufacturing, and operation. For example, a classic wooden pencil may be automatically monitored during its production to ensure quality control, and records may even exist regarding the box it was shipped in and where it was shipped. However, once the pencil has been purchased by an end user, that portion of the pencil’s lifecycle will be unknown to anyone other than the user. An example at the other end of the spectrum could be a component, such as an engine, attached to an aircraft which is manufactured and operated in a heavily regulated environment. The engine would not only have detailed manufacturing and assembly records, but data from the aircraft and operational environment that would allow the engine to be digitally represented, forming a digital twin. Unlike the pencil, the engine, and the aircraft it is attached to, are required to be monitored during operation to ensure regulatory compliance, improved levels of safety or reliability, and enable the various support and service offerings that exist. These support and service offerings can all be enhanced by the utilization of a digital twin. Like electricity, a digital twin does not achieve its potential unless it is powering something. As industry continues to strive for efficiency and optimization of processes and operations, a detailed understanding of an asset provides a solid foundation; it is from this foundation that predictions, simulations, or analysis can be based. A digital twin, of sufficient fidelity and updated at a sufficient frequency, will provide the foundational intelligence upon which optimization and advanced services can be built.

Existing research has focused on the areas of utilizing a digital twin for a point solution, describing their intended use, developing frameworks for digital twins, or separately considering the fidelity of a digital twin. It has lacked both the extent of what is required for a specific use case and the relationship between the fidelity of a digital twin and its ability to achieve that use case. This study intends to provide a comprehensive understanding and overview of existing approaches and the major components within the areas of digital twin definition, creation, maintenance, and its ability to enable and deliver a measurable improvement to the concept of CBM. Within the aviation industry it is accepted that reactive maintenance is approximately double the cost of scheduled maintenance. This aligned with the projected shortage of aircraft mechanics has resulted in the industry’s desire to move away from a fixed interval for maintenance actions to conducting maintenance based on the known condition of a component, or Condition Based Maintenance. This will require discovering a method to link CBM requirements to measurable levels of digital twin fidelity and capability, both desired and actual, and then validating that those levels are achieved and meet the initial requirements.

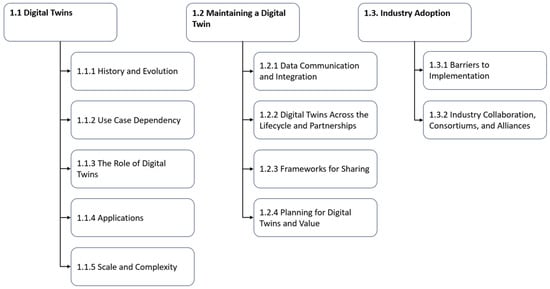

As the subject of digital twins is wide ranging and far reaching, the introduction will provide background information of digital twin concepts salient to the subject of How the Fidelity of a Digital Twin Impacts the Ability to Deliver CBM for aircraft operations. Figure 1 shows the 3 areas addressed within the introduction; An overview of digital twins’ history, use case dependance, role, application and scale, along with the different aspects of maintaining a digital twin over its lifecycle. Adoption within the industry is also covered by discussing barriers to implementation and various collaborations across the industry.

Figure 1.

Overview of Introduction.

1.1. Digital Twins

These have been a topic of interest for many years, evolving within both academic and industrial domains. As an example, being used for analyzing travel behavior, a digital twin is defined as “a virtual representation, or replica of a physical system or process that accurately mimics its real-world counterpart,” [1]. In the aerospace sector, a digital twin is referred to as a virtual representation of a “connected asset” [2]. Despite the different subjects, they share a core theme: a digital representation of a physical asset, system, or process.

1.1.1. History and Evolution

The concept of digital twins originated from a collaboration between NASA and the University of Michigan in 2003, evolving from the content of a course focused on the Lifecyle Management of a Product, or PLM. In the white paper “Digital Twin: Manufacturing Excellence through Virtual Factory Replication,” the idea of products existing in both physical and virtual spaces was born, with a connection between them for data and information [3].

Expanded definitions within the industry further refined the concept of a digital twin. NASA and the US Air Force describe a digital twin as “an integrated metaphysics, multiscale, probabilistic simulation of an as-built vehicle or system that uses the best available physics models, sensor updates, fleet history, etc., to mirror the life of its corresponding flying twin.” [4]. A more specific definition is offered, stating that a digital twin possesses full knowledge of how the aircraft has been operated [5]. The connection between the physical and the digital is a fundamental aspect of the twinning process allowing the twin to be the represent the physical.

1.1.2. Use Case Dependency

While the definition of a digital twin may seem straightforward, its complexity is highly dependent on specific use cases, or the specific goal or question it is expected to answer. These can range from simple representations to intricate systems involving multiple components. At the simple end of the spectrum could be the ability to digitally represent, or understand, how many times each aircraft in my fleet has landed at a specific airport. Expanding upon the fact that an operator may want to know how long an Auxiliary Power Unit (APU) has been operated for and in what environments, such as moisture, temperature, particulates over its lifetime. At the extreme end of the spectrum, for a critical item, a complete representation of all lifetime experiences, including detailed manufacturing steps of all sub-components, operation and maintenance actions may be required. However, there is no strict definition regarding the scale, properties, or complexity of a physical asset, which can vary from a single component to a system of systems [6]. Regardless of scale or complexity, a digital twin must be tailored to meet the requirements of its intended use case [7]. To fulfill this need, a digital twin can either be monolithic, representing the entire physical system, or consist of multiple sub-digital twins [8].

The trend of increasing complexity and varying definitions of digital twins is occurring within industry, which depends on the individual or industry describing them [9]. This requires consideration of the relationship between the digital twin and its intended use case to determine the necessary level of complexity. Consequently, the initial concept of a digital twin as a digital or virtual representation of a physical asset, system, or process has evolved to include the requirement of being adequate for achieving a desired use case. It is understood that digital twins can represent many different physical items and enable many areas, aiding production systems, optimizing factories or other industrial aspects, however relative to enabling CBM, through health management, this paper adopts the following definition:

“A Digital Twin is a digital, or virtual, representation of a connected physical asset, system, or process sufficient to achieve a desired use case.”

The digital representation could be a model of how a specific system is operating, such as the current condition of an air conditioning pack, it could be an image of the actual state of an aircraft section taken from a drone and updated from the last inspection, or it could be the cumulative count of the extend of thermal cycles of an electrical component over its life. These are all different methods of representing a physical item digitally.

1.1.3. The Role of Digital Twins

The real value of a digital twin can be described as delivering actionable information that replaces wasted resources [10] and can benefit manufacturers and users through improved logistics and on-site activities [11]. The wind turbine industry is investing in digital twin technologies to reduce costs and enhance reliability [12]. At the GE Digital User Conference, the value of digital twins is connected to tangible business outcomes [13]. The value of digital twins can be categorized into four key areas: operations management, cost reduction, business model innovation, and product improvement [14]. Digital twins can perform many roles from improving understanding to enhancing business outcomes, but to be viable they must add value and achieve their desired use case. In the area of health management, the main value of digital twins lies in the understanding and monitoring they bring to items of interest and the downstream capabilities and services they provide, rather than the twins themselves. Digital twins enhance decision-making by providing valuable information that minimizes waste and assists users in recalling detailed information throughout an asset’s lifecycle.

1.1.4. Applications

As Digital twins have progressed from academia to industry, they have expanded into many areas [14], documents 18 different industry sectors where digital twin applications are referenced in the literature. Many of these applications extend beyond conventional mechanical items, even encompassing biological subjects. While not explicitly mentioning the term “digital twin”, patient-centered care is being enabled by the integration of Electronic Medical Records, Electronic Health Records, and Personal Health Records to provide a comprehensive view of patients [15]. Many other areas are being explored focusing on individuals, considering digital twins of workers, including their personal details, health status, and position [11], digital twins of pilots to optimize flight tests [2] and the creation and use of digital twins of hearts to aid in precision cardiology [16].

Beyond mechanical components and processes, a multi-agent approach for developing a digital twin of wheat is being explored to understand plant development and enhance overall yield [17]. In the realm of infrastructure, a digital twin is being utilized to determine the Remaining Useful Life (RUL) of cable joints in the electrical power grid of the Netherlands, facilitating the transition from a centralized to a decentralized system [18]. The concept of digital twins extends beyond traditional engineering, manufacturing, and Product Lifecycle Management (PLM) applications into diverse fields such as healthcare, agriculture, and infrastructure, demonstrating their versatility and broad relevance.

1.1.5. Scale and Complexity

Digital twins can vary significantly in scale, ranging from atomic-level representations to large systems. Digital twins can be referred to at the atomic level [19], or discussed at the micro-atomic level [10]. Various factors can contribute to digital twins, from manufacturing defects at the beginning of the lifecycle to operational fleet experience [4] and considering all life behaviors and structural deflections to predict aircraft structure life [5]. At the opposite end of the scale, frameworks are proposed to enable digital twins in smart cities [20]. The concept is extended to the national level, creating a digital twin of the United Kingdom [21]. It is evident that digital twins can range in focus from very small to very large, and the need to determine the appropriate size and level of detail for each component part, which may also have its own digital twin, becomes crucial.

For instance, consider an aircraft composed of multiple structural and system components; one digital twin could represent the hydraulic system, which consists of various subsystems and actuated parts, such as the main landing gear actuation. Each actuator comprises numerous parts. The fabrication process for each part is performed by a machine operated by an individual, and each piece of material has undergone various processes since its creation, making it unique. At each step in this process, there exists the opportunity to create a digital twin at different levels of scale and complexity. The use case should guide the requirements and fidelity of the digital twin as the overall system will not require the same level.

1.2. Maintaining a Digital Twin

The creation and utilization of digital twins are desired across multiple industries and applications, with the concept of a digital representation of a connected physical instance remaining central. The link between the physical and digital must be established through the flow of data. To create a digital twin, data regarding the construction of items of interest is essential. As the physical item is operated, maintained, or repaired, the continuous flow of data is critical to maintaining the digital twin alongside its physical counterpart.

1.2.1. Data Communication and Integration

The primary purpose of the digital twin can be described to serve as a single source of truth for information from its physical asset [22]. This is achieved by establishing a trusted and repeatable linkage between the physical object and its digital twin. The concept of data for the digital twin will ideally encompass all information about the physical system; however the volume of data could be substantial [23]. The connection between the physical and the virtual through authoritative digital threads is foundational to the development and implementation of a digital twin [24]. Some applications require two-way communication between physical and digital entities, referring to the act of “twinning,” where changes to the physical result in changes to the digital, and vice versa [25]. A key aspect of a digital twin is communication between the physical and digital entities, allowing changes in one to be reflected in the other, thus maintaining the digital twin with its physical counterpart.

1.2.2. Digital Twins Across the Lifecycle and Partnerships

Digital twins require cooperation, data sharing, and collaboration for effective creation and maintenance. Creating and maintaining a digital twin relies on access to data, and it is crucial to know when and how to utilize digital twins throughout an asset’s lifecycle, as this may need to be sourced from multiple channels and continuously updated [26]. Digital twins are expected to exist across various lifecycle phases: Design/Development, Manufacturing/Deployment, Use/Modification, and Recycling/Retirement [27]. For complex assets like aircraft, these phases are interconnected, involving various manufacturers, suppliers, and maintenance organizations.

Managing digital twins becomes complex when multiple entities contribute to the lifecycle of a physical item, highlighting the need for effective data sharing. This complexity can lead to individual digital twins of specific components being created by different companies over small portions of their lifecycle. Integrating these individual digital twins into a connected structure is essential for maximizing the benefits of digital twins in complex systems [28,29].

The challenges of accessing data across the lifecycle could be achieved through co-ownership of digital twins to address data sharing and intellectual property concerns [14]. Capturing all physical environment data can pose significant challenges in data sharing among individuals and organizations [30]. With the industry’s trend toward component pools, where components move between aircraft, operators, and Maintenance, Repair, and Overhaul (MRO) organizations, the process of obtaining all relevant data will become more complicated [31].

A common theme in creating and maintaining digital twins is the necessity of obtaining and updating data from multiple sources. Collaboration among stakeholders such as manufacturers, suppliers, and maintenance organizations, is crucial, as typically no single entity possesses all the data needed for a complete digital twin.

1.2.3. Frameworks for Sharing

The complexity of digital twins and the various entities within the value chain that contribute to their development, and the introduction of a “Twin Sharing Framework” to enable collaboration are explored by [11]. Ref. [32] proposes a lifecycle digital twin collaboration framework to ensure that a digital twin instance is shared across manufacturing and operational phases. They suggest two key enabling technologies: a generic ontology modeling approach and an identification and resolution system to facilitate data sharing. The use of a knowledge graph and value network to connect various digital twins from different stakeholders, creating a unified value chain is proposed by [33].

1.2.4. Planning for Digital Twins and Value

The evaluation of requirements of digital twins, through use cases, can ensure consistency and should involve collaboration between digital twin experts and subject matter experts to clearly define and document use cases [34,35]. These requirements should be fully understood based on the digital twin’s purpose before allocating resources [36]. Ad hoc or poorly planned approaches to creating digital twins can fail due to insufficient data to create or maintain them. This lack of proper problem framing has resulted in poorly validated models and inadequate data [37]. Addressing digital twin requirements early in the design process helps designers understand use cases and available data. The value of the digital twin should be a key focus from the outset of the system’s development. Digital twins should not be treated as add-ons; they need to be considered during the initial design phase and relate to specific use cases to ensure the digital twin is correctly scoped.

1.3. Industry Adoption

Despite significant advancements in academic research, the adoption of digital twins in corporate settings has been slower than anticipated. The transition from theory to practice has not progressed as swiftly as expected, despite the potential for substantial value. This slow uptake can be attributed to a lack of comprehension regarding the benefits of digital twins [14]. Additionally, a low awareness of the interrelationships among the various components of a digital twin can contribute to limited adoption [38].

1.3.1. Barriers to Implementation

Several barriers hinder the widespread adoption of digital twins, including a lack of awareness regarding the relationships among digital twin components, insufficient trust, and a tendency for companies to develop isolated point solutions rather than integrated systems. This lack of trust can be considered a significant obstacle and an area where defined frameworks and industry standards can address this issue [39]. These challenges can lead to implementation difficulties and impede the broader adoption of digital twins throughout their lifecycle.

1.3.2. Industry Collaboration, Consortiums, and Alliances

Early effort to document and unify major aerospace OEMs in this domain was undertaken [40], followed by the formation of a “Digital Twin Consortium” [41]. This consortium’s mission is to bring companies together to collaborate on digital twin initiatives. The concept of industry alignment in the digital space is further exemplified by Airbus’s announcement in 2025 of an aviation digital alliance with Delta TechOps, GE Aerospace, Liebherr and Collins Aerospace [42], aimed at leveraging their combined expertise in aircraft systems, airline and maintenance operations, digital analytics, and operational data.

The aviation industry has recognized both the benefits and challenges associated with digital twin adoption, leading to the establishment of consortiums and partnerships aimed at standardization and fostering a common understanding to advance digital twin initiatives.

2. Problem Statement

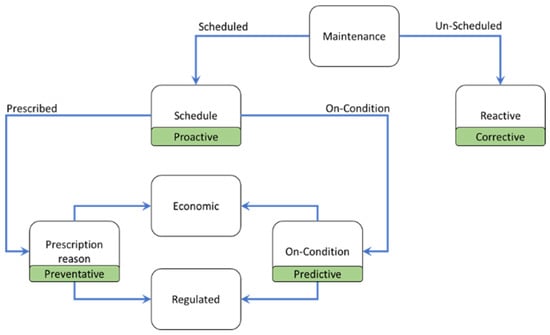

The aviation industry is increasingly adopting Condition-Based Maintenance (CBM) strategies to enhance operational reliability, control costs, and improve aircraft availability by transitioning from unscheduled to scheduled maintenance based on component condition rather than fixed time intervals. This shift necessitates the development of capabilities that leverage engineering expertise and data science techniques to deliver servicing, diagnostic, and predictive alerts, enabling proactive measures to prevent component failures. However, the successful implementation of CBM is contingent upon accurate Integrated Vehicle Health Management (IVHM) capabilities, which must operate not only at the aircraft level but also at the component and failure mode levels.

Despite the potential benefits of digital twins in enhancing CBM accuracy through personalized alerts based on real-world component experiences, the specific requirements for the fidelity of digital twins to support particular use cases remain inadequately explored. Existing digital twins are often developed post-design and production, relying on data and resources available to the organization, which may not align with the rigorous demands of regulatory compliance and operational reliability.

Moreover, a significant barrier to the widespread adoption of digital twins in the aviation sector is the availability and quality of data throughout the asset lifecycle. Companies must ascertain whether existing data is sufficient to create a digital twin of the desired fidelity to meet their intended use case. This challenge necessitates strategic alliances, agreements, or data rights access across the operational lifecycle of the asset. However, there is currently no clear, defined, or measurable approach to determine the appropriate actions required to enhance data sources or resolution, nor to assess the necessary levels of domain knowledge and data fusion methods.

The lack of a comprehensive understanding of the relationship between IVHM, digital twins, and their impact on operational reliability and availability metrics, combined with the challenges of data availability and fidelity requirements, presents significant gaps in the literature and practical implementation of CBM in the aviation industry. Addressing these shortcomings is essential for realizing the full potential of digital twins in supporting effective CBM strategies.

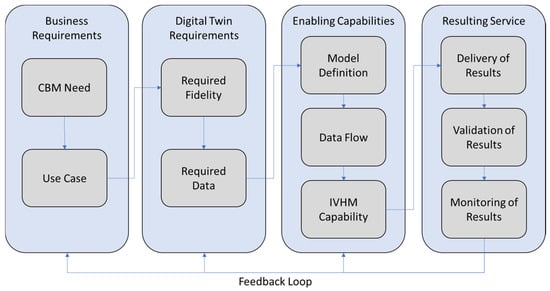

2.1. Applying a Digital Twin to Enable CBM

An ecosystem to produce a digital twin of sufficient resolution to achieve a CBM need is depicted in Figure 2. It illustrates various aspects and capabilities to understand the business needs, understand digital twin requirements, ensure sufficient data, models, and IVHM capacities exist to deliver on the requirements. Figure 2 illustrates the approach to a digital twin ecosystem which can enable a CBM business need to be realized by fully understanding the use case. This will drive the requirements of the digital twin to enable the desired outcome. The required level of fidelity of a digital twin will not be constant across all components of an aircraft and it is anticipated that varying levels of fidelity will exist from one part to the next. A digital twin of a rivet attaching a secondary structure bracket will be significantly lower fidelity than a flight and safety critical component.

Figure 2.

Potential Ecosystem of a digital twin enabled business requirement.

2.2. Define Business Requirements

This initial task will be to determine the business requirements of a CBM need, addressing items such as anticipated maintenance burden, frequency and difficulty of tasks which will result in a use case.

2.3. Digital Twin Requirements

After understanding the initial need, the digital twin requirements must be obtained to inform the required fidelity and the data needed to achieve that fidelity. This step must consider how detailed the data needs to be, how it will be defined, the resolution or frequency, the data sources that are needed to digitally represent the physical item.

2.4. Enabling Capabilities

With the business and Digital Twin requirements defined, the various capabilities to achieve the use case must be designed, developed, or utilized to develop a system that will deliver on the initial requirements. This will include if sufficient models exist to define the digital twin, are the data streams sufficient to create or maintain the digital twin and is the IVHM capability accurate enough to achieve the defined use case.

2.5. Resulting Service

Once a digital twin is created and maintained at the intended level, it will ultimately enable a service which meets the initial use case and business requirements.

2.6. Feedback Loop

The delivered results of the service need to be monitored for accuracy and their ability to achieve the initial requirements. Any unacceptable deviations from these requirements will require an update to the business or digital twin requirements or the underlying enabling capabilities.

3. Scope and Structure

3.1. Scope

The focus of this review is the aviation industry and specifically how digital twins can enable regulatory approved condition based maintenance through deeper understanding of relevant features and operational history. To achieve this understanding efforts from outside the aviation industry will be included as a comparable, complex system of systems also exists in the building, power generation and maritime industries.

This review focuses on understanding what a digital twin is and how it is created and maintained. It will also recognize the importance domain knowledge, ontologies, and the role data play in realizing the fidelity of a digital twin and ultimately is ability to achieve a desired need. To achieve the goal of a Digital Twin enabled CBM program the link between digital twins and their ability to enhance levels of IVHM and the subsequent effect on aircraft maintenance will be considered.

While the creation and maintenance of digital twins, along with measuring fidelity, will be considered within this study, their method of delivery to downstream customers and their deployment within services will not be addressed. The use of AI technology in the creation of digital twins will not be considered within this study as it is focused on the fundamental aspects for the creation of a digital twin.

3.2. Structure

The objective and overall motivation of this work is to apply an academic approach to solving an industry-relevant question regarding how to deliver superior levels of CBM using individualized understanding of assets through digital twins. This industry-driven need has influenced the literature review to include industry publications to understand how these techniques are being discussed and applied. This industry-related scope was achieved through publications from institutions such as SAE, IEEE and AIAA, and conference papers by those sponsored organizations and others such as the Prognostics and Health Management (PHM) Society. These conference papers have also provided the segue to academia through SCOPUS.

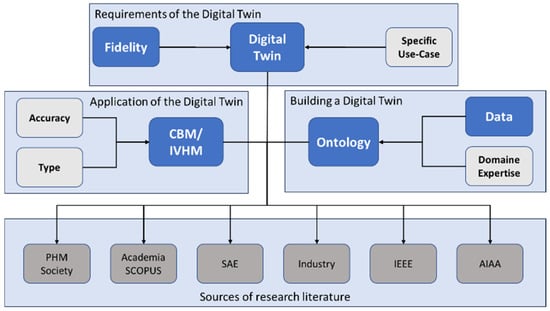

A graphical representation of the review can be seen in Figure 3. The subject areas that drove the research are based on the interaction between digital twins and CBM/IVHM, and the data required to enable the creation and maintenance at a level required to achieve a desired aim. The research resulted in five major elements, highlighted in Figure 3 and their focus areas.

Figure 3.

Focus areas and research sources.

- Digital Twin—Details in Section 4.

- Ontology—Details in Section 5

- Fidelity—Details in Section 6

- CBM/IVHM—Details in Section 7

- Data—Details in Section 8

Initial searches were based on the combination of keywords of the areas identified in Figure 3; Data, CBM/IVHM, Digital Twin, Fidelity, and Ontology. These combinations were applied to each of the sources of research literature. These searches resulted in over 30,000 papers, necessitating the need to apply filtering beyond searches for the individual elements as defined below:

Initially, date filters were applied to the searches of the various elements based on the levels of research, effort, and movement of research within the areas. The date cut off for CBM/IVHM, Data, and Fidelity elements were set to 10 years, for digital twin definition. For Ontology the date cut-off was reduced to the last four years. Exceptions to these date cutoffs were applied based upon the investigation of references from initial or referenced papers.

Further filtering was also applied to reduce papers that only addressed a single element related to data, ontology or resolution as these elements exist outside of the subject of digital twins and CBM/IVHM. The application of these filters further reduced the number of papers to 3199.

Papers were then reviewed for relevancy and applicability by title. More detailed filtering was completed by reviewing the abstract for detailed paper content, followed by examining the conclusions for additional understanding and results, then reading the paper for deep understanding, resulting in 211 papers. Finally, relevant citations, and where the paper had been cited, were further reviewed for relevancy.

As the literature review continued it became apparent that the focus is the intersection of digital twin, ontology and IVHM/CBM and the interaction between all three is the potential to optimize maintenance for aircraft operation, with only four papers addressing all three areas.

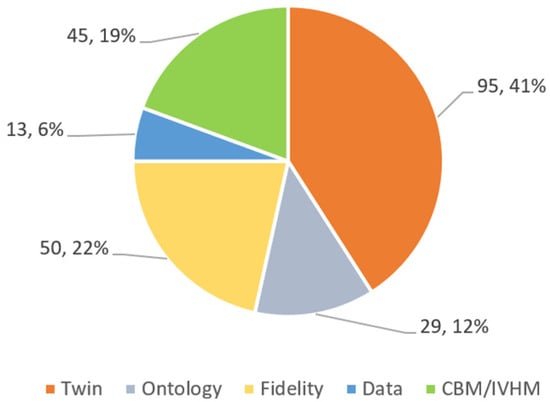

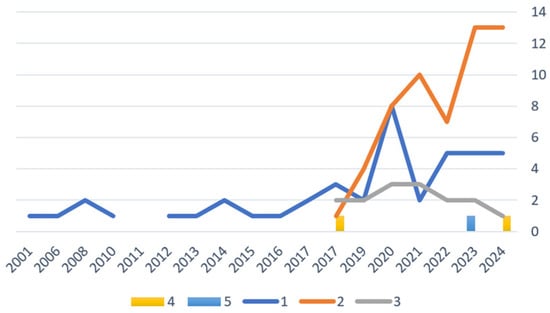

Due to the interdependence between the five focus areas, depicted in Figure 3, an overlap between the papers was expected and few focused on an individual area. Figure 4 shows the distribution of papers used for this review and their focus area, both by number and percentage of overall papers referenced. The subject of digital twins was the largest based on being the main focus of this paper. Ontology and fidelity are the second main areas due to the importance of ontologies in defining digital twins and the desire to understand fidelity relating to digital twins. Figure 5 depicts the number of focused areas covered by each paper and the year the paper was published. The increase in more than one area being covered by a single paper in the most recent years illustrates the increased linkages between the subject areas, with two papers covering four areas and one all five. These aspects will be further explored, in detail, regarding the current state of the art and approaches from both academia and industry.

Figure 4.

Number of publications addressing each focus area.

Figure 5.

Number of focus areas covered in each paper.

4. Digital Twins

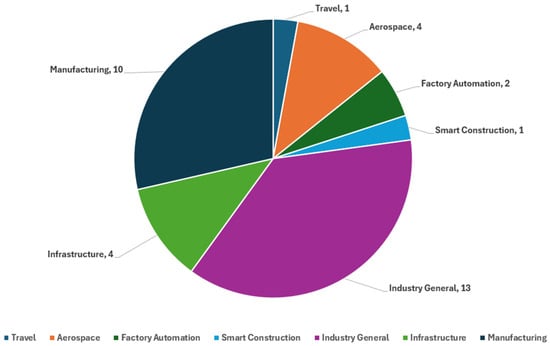

Digital twins are being considered and researched across Industry 4.0 from many sectors. While focused on aviation, this section draws on papers from across various parts of the industry to address component parts of a digital twin methods of measuring maturity of digital twins and frameworks to create digital twins. Figure 6 illustrates the industry sectors that have contributed to this section.

Figure 6.

Contributing Industry sectors.

Digital twins require data to create and maintain them, they also enable various support and services activities, all of which are enabled by core and component parts. This section dissects the concept of the digital twin into its component parts, discussing how maturity is considered and measured, and how frameworks are created to enable digital twins.

4.1. Component Parts of a Digital Twin

As digital twins have become more popular, their key components have been identified and defined to improve understanding and focus. While these components can function independently, some are essential for creating and maintaining a comprehensive digital twin. For instance, data acquisition and storage for analytics and insights are important but do not alone define a digital twin. Just as data is important to enable a digital twin, the services built upon it are important but not necessary for a digital twin to exist. The value of a digital twin is to be able to interrogate and understand the physical, at scale and throughout the lifecycle. To enable this, it needs to persist and be enabled by a suite of capabilities.

The many components of digital twins have been explored. Ref. [14] identified nine dimensions, while [22] outlined ten features, including Data Link, Security, and Artificial Intelligence, to create a framework for comparing digital twins. Ref. [43] proposed “function modules” as central capabilities that unify the operation of digital twins, a concept supported by many others.

The various capabilities to enable digital twins are summarized in Table 1, which can be categorized into three areas by function of the capability and dimensions: data management, core functionality, and delivery. These capabilities, along with security, which in any data related environment is a necessity and therefore considered part of doing business, are essential for maintaining a digital twin alongside its physical counterpart.

Within the Data Management category, all papers considered data acquisition or connection an essential element of a digital twin, most listed data storage/processing. Within the delivery category, many considered services a component part, while some cited the need for a user-interface to interact with a digital twin.

While not all capabilities are desired by each application, many are common and alignment around these areas is occurring. Under Data Management the digital twin is not only created but also maintained alongside its physical counterpart throughout its lifecycle, necessitating consistent and reliable access to data. This requirement is underscored by the processes of data acquisition, connection, and storage, which are prevalent in most studies. The importance of “data synchronization,” particularly highlighting the “data exchange” dimension and the need to maintain synchronization between the physical and digital entities must be considered [35,44].

The concept of digitally tracking a physical component’s experiences throughout its lifecycle, is addressed by the role of “Domain Ontology” for effective data and model management [32]. Ontology management is vital for ensuring model consistency, as is the importance of agreed-upon ontologies for fostering trust and facilitating the sharing of digital twins [45,46].

Digital Twin Models (DTMs) are essential for ensuring accurate representation, validation, and adaptability throughout the lifecycle of a digital twin. They encompass four main dimensions: geometry, physics, behavior, and rules. DTMs are considered critical for the successful application of digital twins [47], along with the information model as the backbone of digital twin representation, providing necessary input and output requirements [8]. Various modeling approaches can be employed, but the selected model must yield results that are equivalent to measured quantities. Appropriate model type, and selection, is critical and needs to be both accurate and validated, whether they are data-driven or physics-based [48]. As digital twins evolve, their models must adapt to new capabilities and changing circumstances to maintain relevance and accuracy. This could be addressed by different models throughout the lifecycle [49] or by updating existing models with new insights [50]. Validation of digital twin models is critical to ensure they are believable, actionable, and accurate, especially when transitioning from providing advice to enabling data-driven decision-making. The validation of these models, especially as digital twins increasingly play a role in automation and engineering operations, is critical [51].

System configuration and streamlined runtime for a digital twin-based enabled capabilities can be achieved by consolidating core functions into “Function Modules” [43]. The concept of function modules serves as a centralized capability to ensure harmonious operation, a notion echoed by other researchers [52,53]. Delivery of insights from a digital twin is enabled by services which integrate various services around the digital twin to provide valuable business insights [54]. Boeing utilizes a “Digital Value Chain”, which begins with data and is empowered by the digital twin, ultimately leads to insights and data-driven decisions [46]. Additional details and examples of the various dimensions of the component parts of the digital twin are detailed in Table 1.

To create and maintain digital twins, and enable the various capabilities, multiple technologies are needed. Various efforts have been undertaken to collect and collate these efforts; Ref. [14] listed 40 technologies, ref. [55] refers to 29 key technologies in their review of smart manufacturing, whereas [47] lists 25 technologies and 33 tools in their review of digital twin modeling. Ref. [27] Provides a digital twin support technology matrix that contains 46 support technologies spread across six dimensions of the digital twin. These lists range from individual sensor types to IBM Watson and from spreadsheets to neural networks.

A digital twin is not always a deliverable itself but does enable analytics and data driven decision-making, making it part of a digital value chain enabling downstream services. As digital twins have gained popularity, essential components have been identified to enhance understanding; while some can function independently, others are crucial for creating and maintaining a comprehensive digital twin, such as data acquisition and storage.

As the component parts of digital twins continue to coalesce and interact, a vast array of tools and technologies are required to enable them. As digital twins have begun to be implemented across industries, the process of implementation and execution has resulted in thinking about them as component pieces which, when assembled, produce business value.

Table 1.

Examples of digital twin component parts.

Table 1.

Examples of digital twin component parts.

| Function | Dimension | Use | Activities/ Examples |

|---|---|---|---|

| Data Management | Data Acquisition and Connection [6,8,14,19,22,30,32,35,43,44,45,52,56,57,58,59] | The collection and transmission of data which describes both the physical and digital asset, its operation, condition and environment |

|

| Data Storage and Processing [6,14,19,22,30,32,43,44,52,56,57,58,59] | The ability to make the required data available in an efficient and optimised manner |

| |

| Core Functions | Ontologies [19,32,43,45,56,57] | The instructions and definition to correctly integrate the data into a digital twin |

|

| Models [6,14,30,32,35,44,45,52,56,57,58,59] | The ability to programmatically store and execute the information and process required for the creation and maintenance of a digital twin |

| |

| Function Modules [8,14,19,22,43,44,52,56,59] | Core technology to enable creation and maintenance of a digital twin |

| |

| Delivery | Services [6,14,19,22,30,32,44,45,52,56,57,59] | The ability to deliver create and deliver insights through the interrogation and use of the digital twin |

|

| User Interface/Collaboration [6,14,22,32,52,56,58,59] | Provides an appropriate and intuitive method of interacting with the twin |

| |

| Security and Privacy [14,22,32] | Ensures that all aspects and functions are completed in a secure way that protects data, IP and privacy |

| |

4.2. Digital Twin Maturity

As digital twins have transitioned from research to implementation, the focus has extended to their level of maturity and how to compare them with each other. A lack of systematic methods for evaluating the functionalities and capabilities of digital twins has resulted in confusion and hindered adoption [27]. Since 2021, various methods have been created to describe and measure the maturity of digital twins [1,27,29,39,44,52]. All have defined various maturity levels by which to measure individual digital twins. Each suggests that higher maturity correlates with greater value but has not proposed a method to quantify these levels.

Several studies [28,34,53,60] have introduced frameworks to describe, quantify, and compare digital twins. These frameworks provide a repeatable method for defining maturity based on initial dimensions. Each method identifies contributing features, or attributes, and assigns a value. These can then be future assigned importance weightings resulting in a maturity score for a digital twin.

For example, ref. [28] identified ten dimensions to consider when implementing digital twins in the commercial aerospace OEM industry. For nine of these dimensions, they define four levels of maturity, while the tenth has three levels. Each dimension and maturity level includes guidance on what is needed to reach that level, allowing for objective comparisons of digital twins created by different companies. The dimensions considered are 1. Lifecycle integration, 2. Level of DT individualization, 3 Data collection frequency, 4. Analytical capability, 5. Decision implementation, 6. Model update frequency, 7. Modelling scope, 8. Stage of implementation, 9. Operational Data accessibility, and 10 Business level affected.

Moving from scoring companies that their digital twin implementation to the twins themselves, ref. [34] identified seven components of a digital twin and assessed each with two to six attributes. They developed a method to calculate maturity by scoring each dimension, allowing for the comparison of multiple digital twins’ maturity levels.

These studies have resulted in various approaches to categories digital twins and compare them to each other by defining dimensions, categories, rubrics and levels. These provide descriptive attributes and guidance resulting is methods to quantify levels of maturity from basic to “ideal”. As the understanding of digital twin maturity has developed, it continued to align with the original definitions and components of a digital twin. Key aspects of the features include having a model, processing capabilities, data input, a lifecycle, and the ability to connect with other services and digital twins. These factors can be quantified to assess how complete a digital twin is and measure its maturity. Overall, there is a growing consensus on the dimensions and attributes of digital twins, and methods for measuring maturity are being established.

4.3. Digital Twin Framework

As we move from the description of a digital twin, its component parts and the importance of the various models within the digital twin, the consideration becomes how to integrate them.

An approach to enable this complex integration of multiple nodes, capabilities, and relationships can be though using property graphs and ontologies to facilitate the required sharing and coordination [56]. A collaboration framework which supports lifecycle sharing of digital twins is an area that needs to be considered [32]. Their framework includes four key elements: a generic digital twin model, a lifecycle ontology, data collection technology, and a distributed collaboration system. This framework relies on a cloud-based digital twin server that collects and shares data from manufacturers, integrators, and users.

To enable digital twin sharing between companies within the smart construction industry a framework which fosters collaboration throughout an asset’s lifecycle has been implemented [11], with full integration representing the highest maturity level. These higher maturity levels require effective linking and interaction between digital twins and models. Ref. [36] proposes a framework based on the 4R’s: Representation, Replication, Reality, and Relational, where each element builds on the previous one, increasing capability and complexity.

With complex machines spanning large portions of an assets’ lifecycle and being represented by digital twins the need for cooperation and collaboration is clear. This is being recognized within industry and the concept of structured frameworks is being employed in some areas. To successfully implement digital twins, there must be more common frameworks, or at lease agreements, and standards in place.

5. Ontologies

The creation of a digital twin requires the connection of many different pieces of data, models and capabilities in a structured, trusted, and repeatable manner. An ontology allows for the codification of knowledge in a standard and repeatable method, defining relationships and instructions to integrate data to create a digital twin. When employing a digital twin to enable a regulatory approved CBM program not only does a defined level of “correctness” need to be achieved but also maintained. Through the utilization of ontologies and the structure enabled by them, the potential exists to create a high quality digital twin, based upon the combined knowledge and expertise of multiple companies from across an asset’s lifecycle. This organization can be completed using ontologies [56]. When considering ontologies and their relationship to digital twins, there are five main areas to be considered: how they are defined, how ontologies are used in the creation of digital twins, how domain expertise influences the creation of an ontology, the necessity of sharing ontologies across the lifecycle, and how standards can assist in using ontologies.

5.1. Definition of Ontologies

Originating from philosophy, they are used to describe the characteristics of objects and their relationships between them. Their main goal is to capture knowledge from related fields and provide a common understanding to facilitate knowledge sharing [45]. This knowledge can be broken down into units and relationships, allowing it to be recorded consistently for reuse. By formalizing domain knowledge, ontologies give the user of an ontology the confidence that a level of “correctness” can be expected from the domain knowledge.

Ontologies are used to improve knowledge representation in digital twins, making complex knowledge understandable for both machines and humans [61]. They formally describe a specific domain by listing relevant concepts and their relationships [62] and can be considered to describe collections of classes and properties that represent facts about a domain [21]. Ontologies can be used to help formalize a company’s knowledge and ensure data exchange between different systems [25] and be used as frameworks which consist of defined classes, relationships, and properties [2].

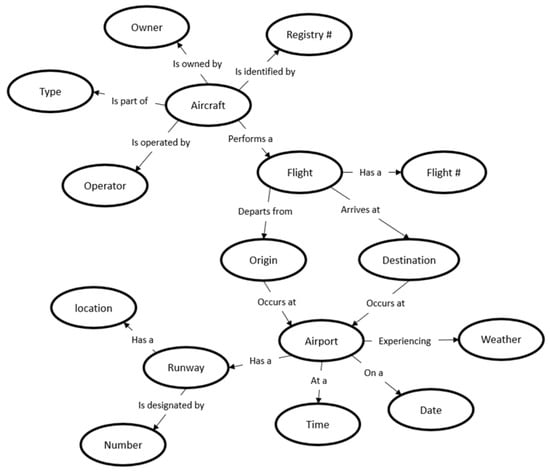

Ontologies can be described as a formal specification that model’s entities, relationships, and attributes in a way that both machines and humans can understand and describe how they can align with graph and knowledge base models to create a Universal digital twin [56]. Ontologies allow knowledge to be structured so that both humans and machines can interact with data from physical objects. By defining relationships and semantics, any entity with access can represent domain knowledge in a standard way that can be used across different groups. For example, Figure 7 illustrates a simple ontology describing a flight from one airport to another. It includes details about the aircraft, such as type, registry, and airline, which are relatively stable. While aircraft ownership may change infrequently, flights occur regularly. Each flight has a flight number and defined relationships, such as “departs from” or “arrives at” an airport. Additional relationships describe the locations of the airports, and the aircraft involved.

Figure 7.

Example ontology to define a flight.

While this ontology is basic and limited in its attributes and relationships, it provides a consistent framework for describing a flight. This ontology has been created by the author and codifies my domain knowledge within that space and for an intended purpose. The values in the nodes can change, but provided the relationships remain the same, multiple flights can be defined, stored, and compared by anyone that has the ontology and data to populate it. By utilizing an approved ontology, a repeatable product can be achieved.

5.2. Ontologies to Enable the Digital Twin

Using an ontological approach to define the component parts of an event and their relationships provides a consistent method for representing physical events with data. Ontologies can help identify various domains and layers involved in creating digital twins, particularly in describing physical components and their attributes [61].

Utilizing a digital twin for a specific asset enhances business value by quantifying knowledge and leveraging models, rather than depending solely on individual expertise, particularly as systems grow increasingly complex [24]. This approach is especially pertinent in the aviation sector, where multiple teams, and companies, collaborate in the design, development, and operation of intricate systems. To effectively manage these complexities, it is essential to comprehend the interconnections and interactions among various components, establish frameworks for knowledge sharing, and distill documentation from human insights.

A Digital Twin Ontology (DTO) is proposed by [19], focused on describing digital twins and their dynamic physical counterparts. They also suggest a Data Conversion Ontology (DCO) to address data integration issues and siloed data. The importance of ontologies for managing digital twin data and integrating it into PLM is highlighted by [45]. They provide an example of a “lifecycle data evolution model,” arguing that without it, digital twin technology cannot reach its full potential. They also propose an “ontology-based digital twin management architecture” to manage data throughout the asset’s lifecycle. Ontologies can be used to represent both static and dynamic information as demonstrated in the creation of an ontology-based digital twin for machine tool modeling, where the ontology represents both static and dynamic information [57]. While each of the authors discuss the ontologies slightly differently it is clear that the ability to digitally represent a physical entity and create a digital twin depends on effectively integrating data. This integration requires a relational and semantic approach, which can be achieved using ontologies. The simple ontology depicted in Figure 7 illustrates a method for describing a physical event, in this case a flight from one location to another. By applying a source of data to the relevant nodes in the ontology a digital representation of the flight can be created and maintained, creating a digital twin via an ontology.

5.3. Domain Expertise

The concept of trust in digital twins was discussed in Section 1.3.1, emphasizing the need for digital twins to be reliable and accurate, having an expected level of “correctness” [20,22,39]. Ontologies help define and organize knowledge through semantic representation and relationships and can serve as a “roadmap” that connects data from an asset’s operations to create a digital twin. By developing these ontologies, domain knowledge can be integrated into the digital twin, ensuring a consistent and trustworthy final product. The importance of domain expertise in creating ontologies and the content within them is highlighted by [63], who suggest involving both ontology and domain experts, as well as end users, in the ontology creation process to ensure accurate and trustworthy representations. The potential for domain experts to share ontologies can enhance understanding across different enterprises through a unified ontology [32].

Domain-specific assets can be considered as essential for automating digital twin modeling, and ontologies are needed to describe various aspects of production systems and products [25]. They suggest a method to achieve this by involving domain experts to ensure the correct ontologies are created or used for specific digital twin needs. A lifecycle evolution model can provide a logical and comprehensive definition of a digital twin at different design stages, highlighting the importance of an ontological approach for detail and accuracy [45]. The expertise needed to define, create, or maintain an ontology is not limited to one entity and companies can gain a competitive advantage by integrating their processes and sharing common vocabulary and data models [64]. They found that using ontologies helps reuse knowledge, maintain consistency, resolve semantic ambiguities, and integrate different systems.

An ontology allows for the codification of knowledge in a standard and repeatable method and provides relationships and instructions to integrate data into a digital twin. The creation of the ontologies, and the resultant “quality” of the digital twin produced, are dependent upon the knowledge and expertise of the ontology creators. When considering using a digital twin to enable CBM the need for accuracy will require the codification of domain knowledge. This requirement will be enhanced when a regulatory approved program is desired. While some ontologies may only require a single person to develop, others may require deep domain from multiple people, or companies to contribute to a unified ontology.

5.4. Sharing Ontologies and Linking

Just as physical assets have a lifecycle and are managed by different entities throughout that lifecycle, their digital twins also exist in various forms throughout their lifecycle. Ontologies are used in Building Information Modeling to manage complexity and large amounts of data generated by multiple stakeholders [65]. These ontologies are a knowledge base developed by experts, detailing how different elements within a system relate to each other. As assets become more complex, and ontologies grow in scale, managing a single ontology can become overwhelming. Modularization can simplify management by structuring them into modules, such as manufacturing, context, and condition monitoring [66].

Complexity can lead to the duplication of ontologies in the same area and documenting requirements systematically for comparison across projects is recommended to prevent duplication [64]. They advocate for pairing ontology and domain experts and end users to ensure accurate requirements are captured from the start. With multiple ontologies being created, whether within a company or shared across companies, it is crucial to consider how to link these ontologies. This can be achieved by layered ontologies, using a top-level ontology to describe core concepts and lower-level ontologies for more detailed descriptions [67]. Demonstrating this in the building industry, a “Building Topology Ontology” with sub-ontologies for specific areas, is proposed [68]. They introduce a “Semantic Digital Twin” to integrate various information sources using semantic technologies like ontologies and knowledge graphs.

The use of knowledge graphs has been used to connect ontologies and lead to comprehensive digital twin implementations and graph technology used to connect ontologies and digital twins, aligning with the complex relationships described by ontologies [21,56].

The complexity of assets throughout their lifecycle cannot be captured by a single ontology due to varying detail levels and distributed domain expertise. Therefore, multiple ontologies are necessary to describe a physical item across its entire lifecycle. To ensure consistency and interoperability of digital twins, identifying, cataloging, and linking these ontologies within companies and across the industry is essential. The use of graph technology has been successfully used to effectively facilitate this linking.

5.5. Industry Standards

The need to share and link ontologies arises from the complexity of assets. As the details of a physical asset increase, so do the complexity of its digital twin and the way it is described using ontologies. With multiple organizations, companies, industries, or even countries involved in providing data and expertise, some level of interoperability or standards is necessary. For example, NASA created the Air Traffic Management (ATM) Ontology to connect various aviation data models and enable cross-data source querying, serving as a foundation for integrating data from multiple sources [69].

The need for a universal approach to standardizing and sharing ontologies exists within different industries. Within the area of digital twins for machine tools it is suggested that creating a basic ontology for monitoring machine tools and using a dictionary of important terms from textbooks, professional dictionaries, and international standards to enhance reusability [57]. Similarly, the call for a common taxonomy of parts and an ontology for parts is required within the aviation industry [24]. The need for common industry standards for an ontology-based approach to condition monitoring is desired to help implementation [66].

In the building industry, a system ontology is being developed to represent the various interconnected systems within a building. The use of ontologies to aid the integration of digital twins and representation of building service systems for automatic energy control, is expected to improve energy efficiency [70]. Sharing is essential for ontology-based digital twins to succeed throughout their lifecycle and to establish trust and accuracy. This need is recognized and advocated within the building industry. Examples of common approaches are emerging, such as Building Information Modeling efforts around the TUBES ontology and NASA’s public ATM ontologies.

Although ontologies originated in philosophy to describe characteristics of items, their value in creating and maintaining digital twins is clear. They help codify domain expertise from one or more companies into a digital description of a physical item. Table 2 outlines the key aspects and contributions of ontologies in enabling the creation, maintenance, and use of digital twins.

Table 2.

Key aspects of ontologies to enable digital twins.

An ontology can be used to form the backbone of a digital twin. It provides a standardized method of defining the various elements that are used to digitally describe its physical object. It codifies the domain knowledge from various contributors, these may be within an individual company, or from many entities within an industry, and links them together in a standardized and repeatable method.

Thorough the use of ontologies, a physical item can be described, through data, by populating the various nodes at a frequency that is determined by a use case. Ontologies can be created, and the domain knowledge codified, in preparation of a digital twin being required. For example an ontology of an maintenance check may include the facility, the maintenance personal, the tools, the environment within the building and inventory of all parts help that the facility, but if the use case requires a digital twin of how many aircraft were maintained over a period of time, what type of maintenance was performed, how many task cards were loaded and how many resulted in findings, only a portion of an ontology would be required. Using standard ontologies, the ability to create shared digital twins will become a reality. This, however, will require the industry groups to contribute and agree to standard ontologies. With these agreed upon standard ontologies digital twins can be created at a sufficient level to enable CBM decisions to be made based on their insights.

6. Fidelity

The need to quantify the level of how closely a digital twin represents its physical component can be described by many means. For example, does it look the same? Is it updated regularly? But the need to describe that likeness also exists, which can be defined by its level of fidelity. Within this section there are five main areas covering fidelity; how fidelity, resolution and detail interact, how fidelity is described, how fidelity is defined in relation to digital twins, what methods are employed to measure fidelity, and the various approaches to add a value to fidelity.

6.1. Fidelity, Resolution and Detail

The “content” of a digital twin should be determined, or shaped by, the desired use cases [9]. When we talk about the “content” of a digital twin, we can think about its completeness and quality, which can be described using the terms “fidelity,” “resolution,” and “detail.” The Cambridge Dictionary defines these terms as follows:

- -

- Fidelity: The degree to which the detail and quality of an original is copied accurately.

- -

- Resolution: The ability of a device to show things clearly and in detail, which can be low or high.

- -

- Detail: The inclusion of all information or parts about something

While fidelity is important for accurately representing a physical object, resolution, how distinguishable the various details are, and detail, how much the reproduction matches the original, are also crucial. Together, these three factors describe the quality of the representation. Although many methods exist to assess the completeness and quality of a reproduction, “fidelity” is commonly used to describe how well a digital twin represents its physical counterpart. Therefore, in this paper, fidelity will be used to indicate the degree to which the digital twin reflects the physical object.

6.2. How Fidelity Is Described

Fidelity is a crucial factor that affects the effectiveness and advantages of digital twins, as it determines how accurately a digital twin represents its physical counterpart. The concept of high-fidelity physical models can be considered, by some, a necessity for digital twins [4]; for others fidelity significantly influences the benefits derived from digital twins [38]. Regardless of its use, the level of fidelity is a key element, being described as the level of detail and realism in the virtual representation [35]. who point out that the lack of clear methods for quantifying fidelity has led to varied interpretations and misunderstandings. Taking a more generic approach [26] considers fidelity should be a “reasonable” estimation.

The concept of measuring and quantifying fidelity presents challenges, with various interpretations and scales discussed in the literature. Fidelity can be described as the extent to which digital twin measurements align with true observations [72]. Fidelity is considered a core theme of digital twins and can be defined as a highly accurate replication of the physical entity [30]. Expanding beyond highly accurate fidelity can become a major cost driver for digital twins and affects their capabilities and introduce a category above “ultra-high fidelity,” termed “Fully Consistent,” indicating that the digital representation perfectly aligns with the physical world [73].

Increasing levels of fidelity can lead to increased computational and operational costs and achieving high fidelity may not always be practical or necessary. Considering these factors when determining fidelity is important to control costs and models should be sufficiently accurate without excessive complexity [48]. Modeling physical reality requires some level of abstraction, and the appropriate fidelity level should depend on the use case and associated computational costs [74]. There is a trade-off between fidelity and computational expenses.

Balancing fidelity with computational costs and complexity is essential, with the idea of “suitable fidelity” tailored to specific use cases, which can be completed by evaluating components based on their importance and balancing accuracy with modeling effort [75]. Fidelity can be a double-edged sword, where high fidelity can enhance accuracy but may also deter the use of digital twins due to high costs or complexity [61]. Pursuing high fidelity can lead to unnecessary complexity and advocate for finding a balance between fidelity, consistency, and cost [76]. The balance between model fidelity and simplification to manage data size effectively is something that needs to be considered during the planning for digital twins [47].

This balancing of fidelity introduces the approach of different models of the same physical entity existing at varying levels of fidelity, providing flexibility based on need requirements. Matching levels of fidelity to use cases can result in using different fidelity levels throughout the lifecycle [77] and is expected that fidelity levels will vary based on use, need, and precision at different system levels [78]. This can be achieved by using “multi-fidelity” digital twins, where multiple models of one physical item exist at different fidelity levels, allowing selections based on specific use cases [79]. The use of varying complexity and fidelity based on the use case provides the ability to control costs and ensure explainability and acceptance of digital twins.

A digital twin can be considered more authentic if it captures detailed characteristics of the physical object, enhancing the richness of its representation. This authenticity can add to the acceptance of digital twins. While the term “Digital Twin” implies some level of similarity, not all parts need to be identical [37]. There is an expectation of completeness and consistency between the digital and physical twins, and higher fidelity may indicate a more credible digital twin. The concept of “authenticity” can be considered a measure of fidelity, focusing on how well the digital twin captures fine details and characteristics of the original [34].

The concept and need for a desired level of fidelity should be considered early in the design and development phases, including planning for data collection and model parameters. Sensor data collection should be planned during the design phase to determine the necessary level of representation and frequency [23] to ensure a complete picture. Also, consideration of fidelity early in the design process, along with identifying model parameters and ensuring sufficient data for updates [48] will ensure an accurate representation can be achieved.

Fidelity is crucial for the effectiveness of digital twins, as it determines how accurately a digital twin represents its physical counterpart, influencing the benefits derived from its use. However, there is a lack of clear methods for quantifying fidelity, leading to varied interpretations and challenges in measuring how well digital twin measurements align with true observations. Defining the level of fidelity is important as increasing it can lead to higher computational and operational costs, making it essential to balance accuracy with complexity and ensure models are sufficiently accurate without unnecessary complexity. This can also be addressed by utilizing “multi-fidelity” digital twins allows for different models of the same physical entity at varying fidelity levels, providing flexibility based on specific use cases and controlling costs. To further ensure costs are controlled the desired level of fidelity should be considered early in the design and development phases, including planning for data collection and model parameters to ensure an accurate representation of the physical object. The level of fidelity should be matched to the intended use of the digital twin.

6.3. How Fidelity Is Defined

While acknowledging that fidelity of a digital twin may change over the lifecycle of the physical item, it needs to be based on key use cases and how well the digital replica reflects the parameters, accuracy, and level of abstraction of the data exchanged between the physical and digital entities [72].

The complexity of a digital twin can be defined by the precision of its outputs [36] who propose a framework with two key requirements, “representation” and “replication”, addressing how closely the digital twin matches the physical object. They introduce the concepts of “detail” (the complexity of variables in the digital twin) and “dynamic” complexity (how these variables change over time).

The frequency at which digital twins are updated is important, a digital twin can become inaccurate if it is isolated from real-time data from its physical twin [19,35,76]. This time lag can be described by the term “twinning,” which refers to the point at which the physical and digital twins are considered equal, and they measure the “twinning rate” as the frequency of updates [30]. Gaps in operational data flow an also reduce effectiveness of the digital twin with may require a certain flow be maintained to ensure the level of desired fidelity [74].

The concept that a digital twin can lag its physical asset can be a concern depending upon the use case, this relationship between updates and fidelity is influenced by the timing of data collection [28]. For example, if flight data is updated immediately after a flight, the digital twin will be more accurate than if updates are delayed. They also emphasize that the rate of data collection must meet the digital twin’s requirements; for instance, if the model expects data at 10 Hz but only receives it at 1 Hz, the update rate will result in insufficient fidelity for the use case.

It is not just the speed at which data is received that can define the digital twin, the quality of information needed to represent an object with the types of data collected must also be considered, along with the challenges of determining the necessary data types, sources, and frequencies for effective decision-making [71,80].

Moving beyond just data itself, data granularity can be divided into three areas: attribute granularity (how object attributes are described), object granularity (how the object is broken down into components), and services granularity (data provided by services) [45]. Fidelity can be described as consisting of three main components: data, models, and parameters [73]. The accuracy of the data directly affects the fidelity of the digital twin. The models form the foundation of the digital twin, and both the number and accuracy of parameters also influence fidelity. The concept of models is broken down further by [81] in their work on digital twin-driven prognostics they define a “Virtual Equipment Model” as a high-fidelity representation of physical equipment, consisting of four parts: geometric, physics, behavior, and rule models. This comprehensive approach creates a complete digital twin.

One common defining factor for establishing fidelity is the data that flows from the physical to the digital. Various aspects of data, including its type, the items being sensed, and the rate of data recording and ingestion, all play a role. Five main attributes to fidelity in digital twins are:

- -

- The amount of data from the physical object.

- -

- The type of data collected.

- -

- The accuracy of the digital representation compared to the physical object.

- -

- The degradation of the digital twin and its fidelity can occur over time based on data updates.

- -

- The combination of data, models, and parameters.

6.4. The Measurement of Fidelity

Moving from describing or defining fidelity to measuring can be addressed by either passing tests or obtaining levels. The “Grieves test,” while binary can be used to determine if someone can distinguish between a physical object and its virtual counterpart, if the difference cannot be detected, the virtual object is considered “virtualized” [82].

While many may advocate for the highest fidelity, it can be viewed on a scale from abstract (low) to precise (high), with medium in the middle [30]. This can be achieved by defining targets to measure how well the physical and digital twins match, expressed as a percentage of actual features [77]. The comparison between physical and virtual models, can be achieved using “tolerance corridors” to measure acceptability between the two and the measure between the physical and the digital tolerance corridors used to determine a level of acceptability [3].

A systems engineering approach can be used to define digital twin fidelity levels in manufacturing through a “Digital Twin Fidelity Requirements Model” (DT-FRM). This model breaks down requirements into variables, assigns priorities, and results in a fidelity matrix categorizing fidelity as high, medium, or low [83]. There is a relationship between potential savings and digital twin fidelity, which can be described with digital twin benefit curves illustrating the relationship between value, benefits, or costs and the level of effort required [38]. These curves were refined through expert interviews, showing optimal fidelity exists between minimum and maximum levels.

Ultimately, a digital twin’s objective is to provide an accurate representation of the physical object. It can be considered binary: it either contains sufficient information to fulfill its intended purpose, or it does not. This can lead to a more descriptive approach to quantifying fidelity levels, ranging from low to ultra-high, allowing for comparisons between different digital twins and setting expectations for their capabilities. There is a desire to measure fidelity as a relationship between potential savings and digital twin fidelity, illustrated by digital twin benefit curves that show the optimal fidelity level exists between minimum and maximum thresholds, refined through expert insights.

6.5. Adding a Value to Fidelity

Measuring the fidelity of a digital twin is much more complex than simply counting the pixels in an image. With the increasing use and expectations of digital twins, their ability to accurately represent physical objects is becoming a key differentiator. Fidelity can be described as how well a digital twin reproduces the actual state and behavior of its physical counterpart.

An approach to model fidelity can include three key attributes: data, models, and parameters. By adding values to these attributes, the fidelity of a digital twin can be defined, allowing for the comparison of one digital twin to another using specific codes [73]. To quantify a digital twin’s representation, a basic approach can be where the digital representation is based on the attributes and operations of the physical instance [8]. They propose aligning variables and inputs from the physical twin with the digital twin’s attributes, then mapping the outputs to the operations, demonstrated through modeling robot arms. They also suggest that as complexity increases, additional models and semantic relationships should be considered to enable cooperative systems within the digital twin context.

Expanding from this approach, ref. [84] introduces a Digital Twin Fidelity Calculation Method (DT-FCM) that estimates savings and costs to determine “optimum” fidelity. This optimum fidelity is quantified using a normalized scale from 0 to 1 across four dimensions: tolerance, frequency, latency, and level of integration. As the importance of fidelity in digital twins grows, so does the need to quantify it, leading to the development of frameworks. Two main approaches have emerged: measuring the difference (or delta) between the digital and physical twins or assigning values to key features that define the digital twin.

Efforts to quantify fidelity show that it can exist along a scale and that fidelity is linked to the digital twin’s ability to meet its intended use case. It is easier to describe fidelity than to define it, easier to define it than to measure it, and easier to measure it than to quantify it. Table 3 summarizes the key points and contributors related to digital twin fidelity.

Table 3.

Descriptors of digital twin fidelity.

Fidelity significantly influences the usefulness and success of a digital twin. A digital twin that does not accurately reflect its physical counterpart will have limited practical application. While higher fidelity is generally preferred, it comes with associated costs. Maintaining high fidelity throughout the lifecycle of the physical twin can be challenging, and at times, lower fidelity may be accepted.