Abstract

Curing plays a fundamental role in determining the mechanical performance, durability, and sustainability of concrete structures. Traditional curing practices, such as water and air curing, are widely used but often limited by long durations, high water demand, and reduced effectiveness under extreme climatic conditions. In response, advanced curing methods such as steam, microwave, electric, autoclave, and accelerated carbonation have been developed to accelerate hydration, refine pore structures, and enhance durability. This review critically examines the performance of both conventional and advanced curing strategies across a range of concrete systems. Findings show that microwave curing achieves up to 85–95% of 28-day wet-cured strength within 24 h, whilst autoclave curing enhances early strength by 40–60%. Electric curing reduces energy demand by approximately 40% compared to steam curing, and carbonation curing lowers carbon dioxide emissions by 30–50% through carbon sequestration. While steam and autoclave curing provide rapid early strength, they may compromise long-term durability through microcracking and increased porosity. No single method was identified as universally optimal; the effectiveness depends on the mix design, application, and environmental conditions. The review highlights future opportunities in smart curing systems, integrating Internet of Things (IoT), sensor technologies, and AI-driven predictive control to enable real-time optimisation of curing conditions. Such innovations represent a critical pathway for improving concrete performance while addressing sustainability targets in the building and construction industry.

1. Introduction

Precast concrete has become an essential component of modern infrastructure due to its speed of construction, quality control, and structural efficiency [1]. The performance and durability of both in situ and precast elements are highly dependent on the curing methods applied during early hydration [2]. Curing strategies such as steam curing in precast plants are effective in accelerating strength gain, but they often lead to challenges such as increased energy consumption, non-uniform internal temperatures, surface cracking, and long-term durability concerns [3]. As the construction industry pivots toward energy-efficient and sustainable solutions, the need to re-evaluate and optimize curing strategies becomes increasingly urgent. Recent advances in curing technologies, such as microwave, electric, and hybrid systems, present new opportunities for improving the performance of concrete elements. As digital technologies become more prominent in the systems utilized in the construction industry, smart concrete curing systems remain somewhat underdeveloped. Recent advancements in 3D printed concrete and automated additive construction underscore the importance of controlled curing, as moisture gradients between printed layers can affect interlayer bonding, dimensional accuracy, and strength development [4]. The integration of sensor-based monitoring, real-time feedback control, and adaptive scheduling systems offers novel ways to achieve precise and efficient curing [5].

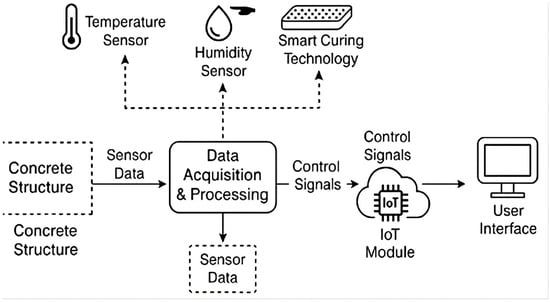

Taffese et al. [6] propose a conceptual framework for intelligent curing using embedded sensors and Internet of Things (IoT) technology. The system integrates wireless temperature and relative humidity sensors, smart water valves, sprinklers, and an IoT gateway to regulate water supply based on real-time moisture loss and hydration monitoring. Compared to manual curing, this automated approach offers higher efficiency, reduced labor and water consumption, improved uniformity, and enhanced crack resistance. Importantly, it enables real-time decision-making on formwork removal, coating application, and maintenance scheduling. By addressing the limitations of traditional curing practices and providing accurate in situ performance data. He et al. [7] investigate an IoT-based automated electric heating curing system (AEHCS) designed for temperature self-controlled concrete in cold environments. The system integrates a four-dimensional framework of perception, transfer, service, and control layers, enabling real-time monitoring and automated adjustment of curing temperatures. Field trials demonstrated that AEHCS maintained concrete temperatures around 45 °C even during cold spells, achieving stable hydration conditions with an average daily energy use of 5.98 kWh. Compared with traditional and standard curing, AEHCS specimens showed superior mechanical performance, with compressive and tensile strengths at 7 days exceeding those of standard curing at 21 days. The system also reduced pollutant emissions by more than half relative to steam curing, highlighting its environmental benefits. Al Agha et al. [8] review the application of piezoelectric patches (PZT) and electric-mechanical impedance (EMI) based methods for monitoring early-age concrete curing. Their research highlights how EMI signatures, generated from PZT sensors, can provide real-time, non-destructive insights into hydration, stiffness development, and early cracking, offering an alternative to traditional destructive tests. However, limitations were identified, such as sensitivity to environmental conditions, interference from reinforcement, and the need for standardized protocols. EMI technology has the potential to evolve into self-contained, intelligent monitoring systems capable of real-time, in situ diagnostics. Figure 1 graphically illustrates the method of smart curing technologies. As shown, the method of curing is not demonstrated; however, the data and acquisition systems depict the methodology of smart systems.

Figure 1.

Smart curing system in concrete.

Despite these developments with smart technologies and monitoring systems, there is a large variance in the most optimal curing method. This is based on mix design, location, resource availability, and application. Dong et al. [9] examine how different early thermal curing methods, such as hot water, hot air, steam, autoclave, microwave, and electric curing, affect the mechanical performance, durability, and microstructure of ultra-high performance concrete (UHPC). Their research highlights that autoclave curing delivers the most significant improvements in both early and long-term strength due to combined high temperature and pressure, though its high cost and complex equipment limit field use. Steam and hot water curing also enhance strength and microstructural densification but are mainly suited to precast applications. Hot air curing increases strength but may create porous hydration products, reducing long-term durability. Microwave curing stands out for its very high efficiency and rapid early strength gain through volumetric heating, though it requires careful management of leakage risks. Electric curing, using conductive fillers and voltage applied through steel fibers or bars, offers a practical, low-temperature, and on-site solution with potential for rapid repair and large-scale applications. In addition, Sidhu et al. [10] comparatively reviewed traditional and advanced curing techniques. Their findings determined that curing significantly affects the hydration, pore structure, shrinkage, and long-term durability of concrete. Steam and autoclave curing enable rapid early strength but can reduce later-age performance due to microcracking and coarser pore networks. Microwave curing offers faster early strength gain with lower energy demand, though long-term performance may decline. Carbonation curing improves durability and sequesters carbon dioxide (CO2), while electric curing provides efficient in situ heating for cold regions. Water curing remains the benchmark for achieving high later-age strength but is less practical in large-scale precast settings. The selection of the curing method must balance early strength needs, mechanical properties, durability, cost, and sustainability targets.

2. Research Significance and Methodologies

Concrete is one of the most versatile and durable building and construction materials. Due to its wide range of applications, it is the second most consumed substance on Earth after water, with global cement production reaching approximately 4.1 billion tons in 2021 and annual concrete consumption estimated to be about seven times higher [11,12]. The sustainability challenge in concrete construction arises from the industry’s substantial environmental impact, driven by its reliance on concrete as a core material. Portland cement is responsible for around 5–8% of worldwide CO2 emissions [13]. Beyond carbon emissions, the extraction of natural aggregates and the high demand for water place additional pressure on global resources [14]. These environmental concerns have accelerated calls for a transition toward more sustainable practices and the decarbonization of concrete production as part of broader efforts to achieve climate neutrality. Therefore, exploring the curing techniques implemented during concrete production is critical to determine the impact of those techniques on the outcome of the material. Moreover, determining the overall effect of those curing techniques can assist in discovering new methods toward sustainability and smart technologies.

The systematic review followed the PRISMA 2020 (Preferred Reporting Items for Systematic Reviews and Meta-Analyses) guidelines for this study. PRISMA is an effective method to guide systematic reviews that summarize and synthesize findings from primary research, as it is a structured and transparent reporting format [15]. This systematic review was prospectively registered on the Open Science Framework (OSF), registration “Supplementary Materials” DOI: https://doi.org/10.17605/OSF.IO/UGJPA.

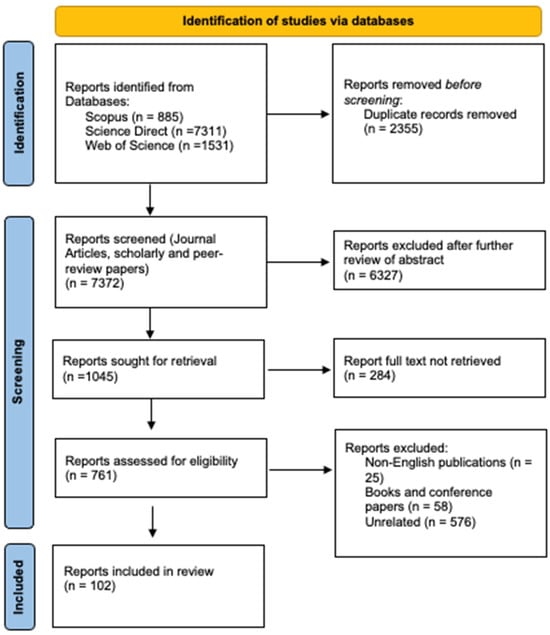

Figure 2 graphically illustrates the PRISMA methodology that was adopted in this study. The steps to prepare a PRISMA diagram are summarized below:

Figure 2.

PRSIMA systematic review methodology.

- Identification: The research articles were searched on Scopus, Web of Science, and ScienceDirect using titles, keywords, and abstracts.

- Screening: Duplicate, irrelevant, non-English, and full-text unavailability items were removed in the selected databases.

- Inclusion: Articles on curing systems for concrete were included in the research.

The search keywords were used for [“Curing systems and methods for concrete”]. The search initially produced 9727 papers between 2000 and 2025. After removing 2355 duplicates, 7372 publications remained. Titles and abstracts were then screened to determine their relevance to concrete curing system research. During this stage, English, books, conference papers, and full-text non-availability sources were removed. This study concludes with a comprehensive evaluation and examination of the 102 research publications on the various traditional and advanced curing strategies for concrete. Studies were included if they reported curing regimes with defined parameters, evaluated mechanical properties, assessed durability-related characteristics, and provided insights into sustainability implications. The outcome of this study is a systematic mapping of the current literature, complemented by insights derived from traditional and advanced curing strategies. The review aims to explore the curing methods of concrete materials and to suggest the overall effect they have on the outcome of the material. Additionally, suggestions for future smart and sustainable pathways of curing in concrete will be investigated.

3. Traditional and Advanced Curing Methods

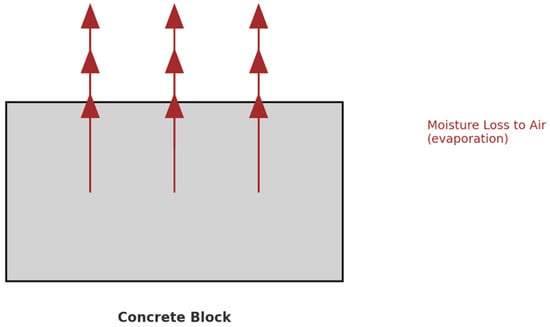

Traditional curing methods for concrete, such as water curing and air-dry curing, are widely used to maintain moisture and temperature conditions that promote cement hydration and strength development. These approaches are relatively simple and inexpensive but often require significant water use, extended curing times, and can be impractical in extreme climates or for large precast operations [16]. In contrast, advanced curing methods include microwave curing, electric curing, autoclave curing, thermal blankets, and carbonation-accelerated curing. These methods apply energy or controlled environments to accelerate hydration, enhance microstructural densification, and reduce curing time from days to hours [17]. Moreover, these advanced curing methods require significant energy consumption; however, the mechanical performance is significantly improved in a shorter duration. This promotes the acceleration of building and construction activities, which can lead to economic benefits. However, it is important to recognize the traditional eco-friendly approach toward natural air-dry curing of concrete. Cement hydration during air curing is significantly restricted due to limited moisture availability. Early evaporation reduces the hydration of tricalcium and dicalcium silicate phases, leading to incomplete formation of calcium silicate hydrate (C–S–H) gel and calcium hydroxide Ca(OH)2. The resulting microstructure can remain porous and susceptible to drying shrinkage and cracking, reducing compressive strength and long-term durability [18]. Liang et al. [19] investigate the effects of water binder ratio and steel fibers on the flexural strength of UHPC. The researchers highlighted that UHPC cured at room temperature for 28 days was still able to achieve high flexural strength and toughness, especially when the water binder ratio was kept below 0.18 and the steel fiber content exceeded 1.0%. Moreover, this research demonstrated that UHPC can still be achieved without high-energy-intensive curing systems. It is important to note that the optimal mix design is critical to ensure this can be achieved. Figure 3 schematically illustrates the method of moisture loss and evaporation in an air curing method. The red arrows indicate the moisture loss due to evaporation. It is important to note that moisture retention during curing is essential to ensure continuous hydration of the cementitious compounds [20]. This includes tricalcium silicate and dicalcium silicate, which form the C-S-H gels and Ca(OH)2 that are the principal binding phases in concrete [21]. When moisture is lost prematurely, hydration reactions cease before completion, leaving a portion of the cement unhydrated. This results in lower strength development, increased porosity, and microcracking due to the autogenous and drying shrinkage [22]. Moreover, insufficient internal moisture impedes the refinement of the pore structure, making concrete more permeable to chloride ingress and carbonation [23]. This can accelerate the deterioration of the concrete matrix.

Figure 3.

Schematic illustration of air-dry curing of concrete.

3.1. Wet Curing

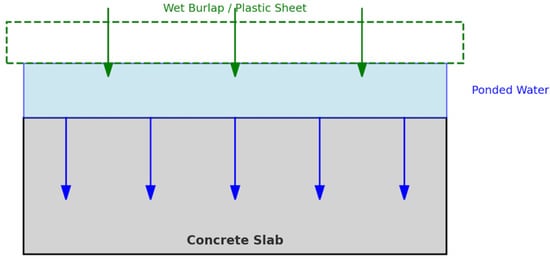

Wet curing of concrete is the process of maintaining moisture in fresh concrete for a specified period to allow cement hydration to proceed properly. Hydration is a chemical reaction between cement and water, ensuring adequate curing allows sufficient water to be available and that the concrete’s temperature and moisture loss are controlled [24]. Continuous wet curing maintains surface saturation and supports ongoing hydration of cementitious compounds. Sustained water promotes the complete formation of C–S–H gel and Ca(OH)2, refining the pore structure and enhancing long-term mechanical and durability performance [25]. Atsbha and Zhutovsky [26] investigate how different external curing techniques affect normal strength concrete. Their research included four curing methods, including air curing (AC), 7-day water curing (7W), 28-day water curing (28W), and curing compound (CC). The CC was a water-dispersed acrylic copolymer applied in two layers to the surface of the concrete to reduce moisture loss. Results showed that 28W provided the best outcomes, delivering the highest compressive and tensile strength, lowest shrinkage, and greatest resistance to chloride penetration, carbonation, and water sorptivity. Seven-day curing was acceptable, but long-term performance lagged behind 28W due to moisture loss after removal from water. In contrast, CC-treated samples behaved similarly to air-cured ones, showing significant early water loss, reduced strength, higher sorptivity, and greater carbonation rates, indicating poor durability. Microstructural analysis confirmed that wet curing refined pores and reduced permeability, while AC and CC samples had coarser pore networks. Figure 4 graphically illustrates the method of wet curing. The arrows in the Figure 4 indicate the direction of moisture. As shown in Figure 4, concrete samples are either submerged or have a wet burlap placed on top of the concrete materials. The schematic figure illustrates the method to reduce the moisture evaporation and increase the water absorption of the material, thus creating a more durable concrete material.

Figure 4.

Schematic illustration of wet curing of a concrete element.

Table 1 highlights the effect water curing has on various concrete mix designs. As shown, water curing can improve the performance of concrete across different matrices and applications. Supplementary cementitious materials (SCMs) are often utilized to improve the matrix of concrete materials. SCMs are industrial by products or natural pozzolans, such as fly ash (FA), metakaolin (MK), silica fume (SF), and ground granulated blast furnace slag (GGBFS). For lightweight concretes incorporating original Portland cement (OPC) and FA, autoclaved aerated aggregates combined with 7–90 days of curing enhanced shrinkage resistance. In UHPC, the use of SF, GGBFS, FA, and steel fibers showed that 7–28 days of curing with recycled autoclaved aerated waste reduced shrinkage, refined pore structure, and densified the microstructure, while autoclaved artificial aggregates further improved compressive strength. For in situ concretes with SF, short-term water curing (1–7 days) followed by sealing compounds provided durable performance under hot climates, while cube tests confirmed that 28-day wet curing improved compressive strength by 13% compared with air curing. In UHPC mixes containing MK, FA, SF, and steel fibers, seven days of curing under wet and dry cycling enhanced compressive strength, while in conventional OPC–FA concretes, extended curing up to 90 days reduced carbonation depth by 53.5%. These results demonstrate that varying the curing durations is essential for optimizing shrinkage resistance, microstructural densification, strength gain, and durability across diverse concrete systems.

Table 1.

Previous studies that adopted water curing.

3.2. Steam Curing

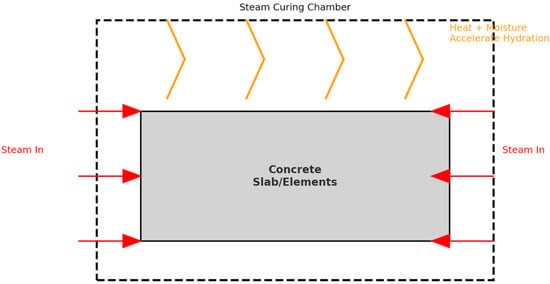

Steam curing is a common technique used in the production of precast concrete elements for a wide range of applications. The process usually begins a few hours after casting and involves heating, maintaining a constant temperature, and cooling. Standard steam curing is typically performed at 40–60 °C, while achieving ultra-high compressive strengths of 100–150 MPa requires elevated curing temperatures of 80–90 °C [34]. Steam curing accelerates hydration through elevated temperature and humidity, promoting rapid tricalcium silicate (C3S) reaction and early C–S–H formation. While high early strength is achieved, rapid thermal hydration can lead to coarser C–S–H and slightly lower long-term strength [3]. Figure 5 schematically illustrates the method of concrete within a steam curing chamber. Wang et al. [35] investigated how steam curing affects the early and long-term strength of fly ash foam concrete. This material is widely used in precast walls for its low density and insulation properties but suffers from low strength. The study varied preheating temperature, preheating duration, curing temperature, and sodium sulfate (Na2SO4) dosage as an early strength agent. Results showed that steam curing significantly improved early strength, with the optimum method of 25 °C preheating for 4 h, 50 °C curing, and 1.5% Na2SO4, yielding a 12-h strength of 1.9 MPa. Fly ash at 20% replacement provided the best balance, as steam curing activated its pozzolanic reactivity to form additional C-S-H gels. However, excessive steam temperature or too much early strength agent reduced 28-day strength due to microcracking, pore coarsening, and brittleness. Microstructural analyses confirmed accelerated hydration and activated fly ash, but also higher porosity under harsher steam applications. The study concludes that carefully optimized steam curing enables efficient template turnover and wider use of sustainable foam concrete with mineral admixtures, though trade-offs exist between early strength gains and long-term durability.

Figure 5.

Schematic illustration of steam curing of a concrete element.

Liu et al. [36] investigate how nano-silica improves the performance of concrete under different curing conditions. Five mixes with 0–2% NS were tested for compressive strength, impermeability, and sulfate corrosion resistance. Results showed that nano-silica increased strength under both steam and traditional curing conditions. The optimum mix included 1.5% nano-silica, which enhanced early strength and reduced long-term strength loss from steam thermal damage. Steam curing alone improved early strength but reduced 28- and 56-day performance due to microcracking and coarser pore structures. However, nano-silica mitigated these effects by consuming Ca(OH)2, refining pores, and densifying hydration products. For durability, nano-silica significantly lowered water permeability and sulfate attack damage, restoring steam-cured concrete performance to near standard-cured levels. The study concludes that there is a synergistic effect with steam curing, enabling higher early strength and improved durability, while offsetting many of the negative effects of thermal curing.

Li et al. [37] investigate how steam curing conditions affect durability against chloride ingress in concrete. Using the Rapid Chloride Migration test, the results showed that steam curing significantly increases chloride diffusion compared to standard curing, weakening long-term resistance. Optimal conditions included a stop time of 3 h, heating and cooling rates under 20 °C/h, constant temperature below 60 °C, and holding time within 8 h. The study concludes that carefully controlling steam curing temperatures is crucial to ensure durability in aggressive environments. Su et al. [38] investigate how recycled brick aggregates can mitigate the heat damage effects of steam curing in precast concrete. Steam curing accelerates early strength but often reduces long-term durability due to pore coarsening, microcracks, and weakened impermeability. This study tested fine and coarse brick aggregates, showing that 10–20% integration can improve 28-day compressive strength by 2.5–11.3%. Microstructural analysis confirmed tighter interfacial transition zones and refined pores due to the internal curing and pozzolanic reactivity. Additionally, life cycle assessment showed that concrete with 10% recycled fine brick aggregates reduced costs by 12% and CO2-equivalent emissions by 10%, compared to plain steam-cured concrete. The addition of recycled brick aggregates in concrete reduced the negative effects of steam curing on traditional concrete materials.

Table 2 shows previous studies that have adopted steam curing in concrete mix designs. As shown, moderate temperatures and shorter curing times boost early performance, while higher temperatures and longer times tend to harm later mechanical strength properties. Cycles around 50–60 °C for approximately 10 h raise compressive strength and elastic modulus. However, 20–60 °C for 12 h durations showed mixed outcomes, with early strength gains and increased porosity. Increased temperature and/or duration further increased porosity, internal damage, and strength loss. Optimized steam curing methods demonstrate both moderate temperatures and time durations to ensure early strength increases while avoiding the porosity growth, microdamage, and long-term strength penalties associated with hotter or longer treatments.

Table 2.

Previous studies that adopted steam curing in concrete mix designs.

3.3. Microwave Curing

Microwave-assisted curing systems for concrete can significantly reduce the curing time compared with conventional water and air methods. This method generates internal heat that accelerates hydration, leading to faster early-age strength development. Moreover, microwave curing induces volumetric heating by affecting the water molecules in the cement matrix, accelerating dissolution and diffusion during hydration. This leads to rapid C–S–H formation and strength gain, though excessive exposure can cause non-uniform temperature fields and microcracking [51]. Phadungsak et al. [52] utilized a horn-shaped cavity model and a mobile curing prototype operating at 2.45 GHz and 400–800 W. The research examined temperature evolution, moisture loss, and compressive strength of concrete under different curing regimes. Results showed that microwave heating rapidly raised concrete temperatures, with early-age strength being higher than conventional curing. However, continuous curing beyond 90 min at temperatures over 80 °C reduced compressive strength due to internal damage. The most effective approach was discontinuous microwave curing (30 min preheating followed by cycles of 15 min heating and 60 min pause), which achieved compressive strengths up to 85% of the 28-day water curing strength in 13 h. Kastiukas et al. [53] comparatively researched microwave and oven curing of precast geopolymer concrete elements. This was conducted using oven curing (60–120 °C for 7–24 h) and microwave curing (350–750 W for 5 min) with the integration of pulverized fly ash (PFA) and ground granulated blast furnace slag (GGBS) as precursors. Results showed that microwave curing significantly reduced curing time while achieving comparable strengths. The GGBS mixes demonstrated higher reactivity and strength than unregulated PFA mixes. Regulated PFA also outperformed unregulated PFA due to better quality control and lower carbon content. Microstructural analysis confirmed that microwave curing enhanced gel formation and densification, while excessive heat or power caused microcracking.

Zhang et al. [54] investigate the effects of short-term microwave pre-curing (60–240 s at 700 W) on UHPC and fiber-reinforced UHPC. Results showed that microwave pre-curing significantly accelerated early hydration, with compressive strength reaching up to 105 MPa at 8 h, comparable to 28-day standard curing. Steel fibers reduced microwave effectiveness due to reflection and shielding. Microstructural analysis confirmed that short microwave times mainly promoted cement hydration, while longer exposure enhanced pozzolanic reactions and generated more polymerized C-S-H gels. Moreover, microwave curing created denser interfacial zones and significantly reduced porosity by 28%. Microwave energy has been applied to accelerate curing for in situ repair techniques of concrete structures [55]. This study evaluated different commercial repair mortars, focusing on the relationships between microwave power, curing time, repair volume, and temperature rise. Results showed that microwave curing produces a linear increase in temperature with time and power for normal, non-rapid setting mortars, while rapid-setting mixes overheated and proved unsuitable. It is important to note that the presence of steel reinforcement, even at very low cover (5 mm) or with protruding bars, did not cause arcing under microwave exposure, addressing key safety concerns. Internal temperature monitoring confirmed that microwave curing accelerates hydration, reducing the time to reach peak heat hydration from over 13 h (normal curing) to under 5 h. The study concluded that microwave curing is a safe, efficient, and energy-saving technique for in situ concrete repairs, capable of delivering rapid early strength while minimizing reliance on chemical accelerators.

Mohammed et al. [56] examine the use of waste and virgin plastics as aggregates or fibers in concrete. Plastic integration led to lower compressive, flexural, and tensile strength, due to poor bonding at the interfacial transition zone. Additionally, durability issues were also shown with increased porosity, water absorption, permeability, and chloride ingress. However, microwave heating accelerated hydration, densified the microstructure, and improved bonding between cement paste and plastics by melting plastic aggregates in situ. The researchers conclude that although plastic-modified concrete can suffer from mechanical and durability drawbacks, combining surface treatments with microwave curing offers a promising pathway to achieve stronger, more durable, and sustainable concrete. Microwave curing is a promising accelerated method for concrete, provided the process is carefully controlled to balance rapid hydration with structural integrity.

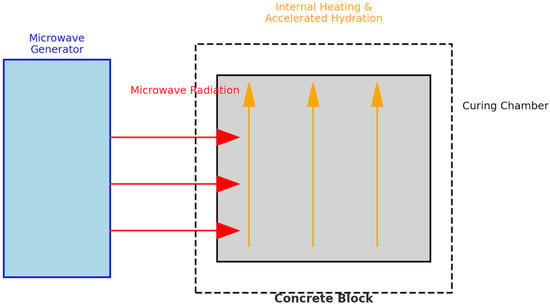

Table 3 shows previous studies that have adopted microwave curing for concrete elements. OPC matrices are often blended with supplementary materials such as slag, fly ash, silica fume, carbide slag, or recycled aggregates, and have been tested under curing methods ranging from 30 °C to 110 °C and lasting from a few minutes to several hours. Microwave curing was mostly shown to accelerate hydration, foaming, and microstructural densification, leading to early strength gains. For example, 30 min curing of OPC with steel fibers achieved 45% of the 28-day strength, while OPC coal gangue systems reached up to 79% higher compressive strength compared to standard curing. In UHPC, microwave curing promoted denser matrices and enhanced durability, and in self-healing concretes, rapid crack closure and near-complete strength recovery were observed. However, higher curing intensities induced microcracking, shrinkage, and long-term strength reduction, highlighting the importance of carefully controlling temperature and duration. Previous research demonstrates that microwave curing can significantly improve early-age performance and durability; however, optimization is required to avoid detrimental long-term effects. Figure 6 schematically illustrates the method of microwave curing on a concrete element. As illustrated, time and temperature are omitted from the figure due to the variation in microwave curing that can be applied.

Table 3.

Previous studies that adopted microwave curing.

Figure 6.

Schematic illustration of microwave curing of a concrete element.

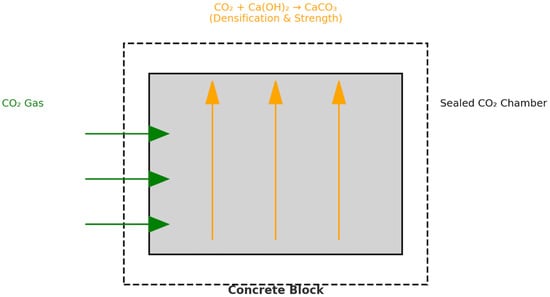

3.4. Carbonation Curing

Accelerated carbonation curing, or CO2 curing, is a widely researched strategy to lower carbon emissions in the concrete industry. Unlike natural carbonation, accelerated carbonation exposes fresh concrete or mortar to high concentrations of CO2 gas (5–99%) for a short duration. This process often makes use of CO2 captured from industrial exhaust streams and has been shown to enhance both the strength and durability of concrete [72]. As a result, the carbonation curing process is recognized as an effective method for carbon sequestration and curing of concrete materials. Moreover, carbonation curing exposes early-age concrete to concentrated CO2, which reacts with Ca(OH)2 and partially hydrated silicates to form calcium carbonate (CaCO3) and silica gel, densifying the matrix and improving early strength [73].

Xian et al. [74] researched the ambient pressure for carbonation curing of reinforced concrete. Using a flexible enclosure system, concrete specimens were carbonated at low pressure (0.014 bar) for 12 h, achieving up to 11% CO2 uptake without significantly lowering pH at the rebar depth. Tests showed enhanced early compressive strength, higher surface resistivity, and increased ultrasonic pulse velocity, indicating a denser surface layer rich in calcium carbonate. The study demonstrated that ambient pressure carbonation curing contributes to CO2 sequestration and enhances corrosion resistance, offering a practical and sustainable curing method for precast and reinforced concrete products. Other studies focused on the carbonation-cured cement paste with recycled concrete slurry waste substitution [75]. Cai et al. [75] investigate how substituting cement with recycled concrete slurry waste and applying early-age carbonation curing can improve strength while reducing CO2 emissions. Substitution rates of 15%, 30%, and 45% were tested under standard and carbonation curing. Results showed that 15% substitution with carbonation curing delivered the best performance, improving 1-day compressive strength by up to 98.6% compared with standard curing, with higher replacement ratios weakening the ultimate strength. Carbonation curing produced more CaCO3, reduced porosity, refined pore size distribution, and enhanced microstructural densification, leading to better strength and durability. It also significantly reduced drying shrinkage compared with standard curing. Environmental assessment showed that carbonation curing with recycled content lowered CO2 emissions per unit strength, with 15% substitution proving more eco-efficient than 45%.

Shang et al. [76] evaluated the environmental performance of producing recycled aggregate concrete blocks under standard curing, autoclave curing, pressurized carbonation curing, and wet carbonation curing. Using a cradle-to-gate life cycle assessment (LCA), the study analyzed raw material processing, transportation, block manufacture, and curing stages, with CO2 absorption modelled and incorporated into the results. Findings showed that accelerated carbonation curing (especially wet carbonation curing) significantly lowered environmental impacts compared with traditional curing. Global warming potential (GWP) decreased by 33.3% for pressurized carbonation curing and 52.8% for wet carbonation curing relative to standard curing, with wet carbonation blocks recording the lowest GWP (254.7 kg CO2-eq/m3) versus the highest under standard curing (539.5 kg CO2-eq/m3). CO2 absorption was also substantial: −73.0 kg CO2-eq for pressurized and −99.3 kg CO2-eq for wet carbonation, sequestering 17–28% of emissions. Contribution analysis revealed cement as the dominant impact source, while energy consumption during long curing cycles drove up emissions in conventional methods. Sensitivity analysis confirmed that carbonation curing is far less sensitive to curing time variations than standard or autoclave curing. Although carbonation curing can meet sustainability targets, it is important to analyse the mechanical properties because of the curing method. Han et al. [77] researched how different pre-curing times and carbonation durations influenced the strength, CO2 sequestration, and microstructure of 3D printed concrete specimens. Results showed that CO2 uptake ranged from 7.5% to 13.5%, with maximum efficiency at 35% water loss during pre-curing. Early-age compressive strength improved significantly, with a 39.9% increase at 3 days and 21% at 7 days under optimal 10-h pre-curing and 12–16-h carbonation. However, prolonged curing greater than 36 h reduced strength due to dense carbonated layers hindering hydration. Microstructural analyses confirmed pore refinement, reduced porosity, and increased dicalcium silicate (C2S) reactivity by 369% compared to standard curing. This study highlighted that the optimal method is 10 h of pre-curing and 16 h of carbonation, balancing CO2 uptake with mechanical performance.

In addition to the improved mechanical performance, Beltrame et al. [78] evaluated how carbonation curing influences the performance of metakaolin-based geopolymer concrete. Specimens were pre-conditioned, carbonated under 15 psi CO2 for 6 h, and then post-conditioned for 27 days. Results showed that geopolymer and Portland cement concretes developed similar carbonation depths of 7–8 mm, though CO2 uptake was lower in geopolymers due to reduced free alkalis from sodium silicate activators. Carbonation formed Na2CO3 in geopolymers and CaCO3 in Portland cement, refining pore structure, reducing water absorption, lowering void ratios, and increasing closed pore content. Compressive strength increased initially after carbonation, 25% in geopolymers and 22% in Portland cement. However, 28-day strengths remained statistically unchanged compared to non-carbonated controls. Importantly, carbonation curing reduced permeability without compromising long-term strength, indicating its potential to improve the durability of geopolymer concretes through pore densification while also enabling CO2 sequestration.

Table 4 highlights the diverse applications of carbonation curing across a wide range of cementitious matrices, demonstrating its potential to enhance both early and long-term performance. In precast systems, OPC blended with GGBS, phosphogypsum, or calcium carbide residue achieved significant pore refinement, CaCO3 densification, and improved durability within short durations. For UHPC and HPC, incorporating silica fume, limestone powder, or polypropylene fibers under short- to long-term carbonation (5 min–30 days) yielded denser microstructures and higher late-age strength. Similarly, aerated concretes with OPC, fly ash, and gypsum benefited from 2–48 h CO2 exposure and showed improved pore structure and compressive strength. Long-term carbonation demonstrated notable strength gains, refined ITZs, enhanced freeze–thaw and acid resistance, and reduced alkalinity. Special applications in stormwater treatment pipes and repair materials showed improved bonding, surface durability, and microstructural refinement. Collectively, these findings confirm carbonation curing as a versatile strategy capable of accelerating strength development, mitigating ASR, reducing porosity, improving acid resistance, and extending service life, while simultaneously contributing to CO2 sequestration in both structural and non-structural concretes. Figure 7 schematically illustrates the method of carbonation curing of a concrete element. As illustrated, time and temperature are omitted from the figure due to the variation in microwave curing that can be applied.

Table 4.

Previous studies that adopted carbonation curing.

Figure 7.

Schematic illustration of carbonation curing of a concrete element.

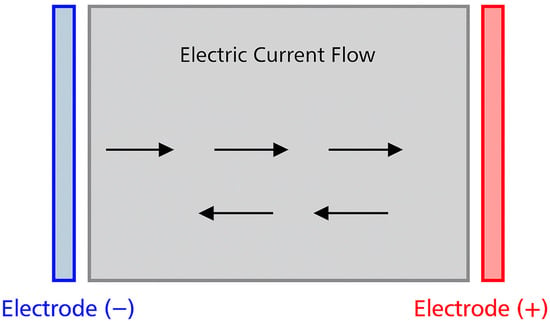

3.5. Electric Thermal Curing

Electric curing, also known as electric heating curing, is an emerging technique that accelerates cement hydration by passing an electric current directly through fresh or early-age concrete. The current generates heat internally via the Joule effect, raising the concrete temperature uniformly without the need for external heating chambers. This method accelerates the hydration of silicate and aluminate phases. The process enables rapid strength gain in cold conditions but requires careful control to prevent uneven hydration [97]. This method provides an effective solution to the challenge of slow or incomplete hydration in low-temperature environments, where conventional curing is often inadequate. By maintaining the necessary thermal conditions for hydration, electric curing enables in situ application, reduces reliance on energy-intensive steam or oven curing, and offers a more environmentally sustainable option for concrete construction in cold climates [7]. Figure 8 demonstrates the method by which concrete is electrically cured. Mao et al. [98] investigate electric curing for constant-temperature hardening as an alternative to steam or microwave curing in cold climates. Laboratory and field tests placed concrete specimens and reinforced slabs at sub-zero and low outdoor temperatures, using an alternating current to maintain the internal temperature at 20 °C. Results showed that 28-day strengths of electrically cured specimens were comparable to standard curing, while early strength reached 13.9 MPa at 3 days, meeting freeze–thaw durability requirements. Microstructural analyses confirmed that hydration and pore structure were unaffected by the electric field. Energy use was highly efficient at 20.1 kWh over 3 days for a slab, which is about one-tenth of steam curing. Numerical simulations revealed non-uniform current density due to reinforcement cages, but heat conduction balanced the temperature field, confirming practical feasibility. The study concludes that electric curing is a safe, energy-efficient, and low-carbon curing method for cold-region construction, though further validation is needed for more complex structural forms.

Figure 8.

Schematic illustration of electric heating with electric current of a concrete element.

Zhang et al. [99] investigate the long-term flexural performance of reinforced concrete (RC) beams subjected to electric activation (EA) curing at subzero temperatures, followed by 800 days of natural environmental exposure. EA curing was found to prevent early frost damage, accelerate hydration, and enhance early-age strength, achieving a 15.3% increase in ultimate load-bearing capacity compared with beams cured under standard conditions (SC). Four-point bending tests confirmed that both curing methods produced comparable ductile failure modes, while EA curing promoted more uniform crack dispersion and reduced crack widths. Electric cured beams showed initial improvements in stiffness, ductility, and energy absorption, with up to 95% greater total energy dissipation at 28 days. These advantages converged with SC beams after prolonged exposure due to environmental degradation of concrete and reinforcement. It is important to note that EA curing did not accelerate long-term deterioration, alleviating concerns regarding its structural safety. Moreover, energy assessments demonstrated that EA curing reduced curing energy demand by approximately 40% compared with conventional steam curing.

Cecini et al. [100] investigate the use of direct electric curing (EC) as an alternative to steam curing for steel fiber reinforced concrete. EC generates heat throughout the concrete volume via the Joule effect, offering potential advantages in energy efficiency and on-site applicability. An experimental program compared electric curing, steam curing, and normal curing on 108 prismatic steel fiber-reinforced concrete specimens with varying fiber dosages. Mechanical tests included flexural strength, residual tensile response, compressive strength, and microstructural analysis of the fiber matrix. Results showed that both electric curing and steam curing effectively accelerated early age strength development, with 1-day strengths about 50% higher than normal curing. This was comparable to normal curing at 28 days. Compressive and cracking flexural strengths were largely unaffected by electric curing compared to steam curing. However, electric curing specimens consistently displayed slightly lower post-cracking residual flexural strengths than steam curing specimens, though differences were not statistically significant. Microstructural analysis revealed a more porous fiber matrix interface in electric curing specimens, potentially explaining the minor reduction in residual performance. The researchers determined that electric curing produced mechanical properties comparable to steam curing while avoiding the energy inefficiencies of steam curing. Moreover, the researchers confirmed the feasibility of electric curing; however, optimisation of electrode design and further studies of interfacial effects are recommended.

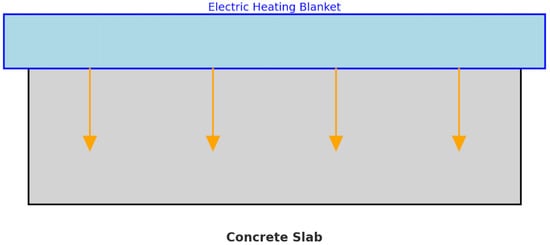

Electric Blanket Curing

Wang et al. [101] utilize an electrical-blanket covering curing (EBCC) as a practical on-site method for curing cementless ultra-high performance concrete (UHPC) activated by calcium carbide residue. Due to the traditional high-temperature curing of UHPC requiring large ovens, chambers, or autoclaves, in situ use is restricted. EBCC employs flexible electric heating blankets to provide localized, adaptable thermal curing at 200 °C. Their investigations compared EBCC with electric oven curing on concrete specimens made with geopolymers and steel fibers. Results showed that EBCC achieved comparable mechanical performance to oven curing. EBCC compressive strength achieved 132.5 MPa, while oven curing achieved 140.2 MPa. Additionally, EBCC flexural strength resulted in 19.3 MPa, whilst oven curing achieved 19.2 MPa. Comparatively, EBCC and oven curing direct tensile strength resulted in 8.5 MPa and 9.8 MPa, respectively. Microstructural tests revealed similar hydration products in both methods; however, EBCC specimens had slightly coarser pores, potentially impacting long-term durability. Figure 9 demonstrates the EBCC application, which can enable high-performance on-site curing without the reliance on large curing chambers, making it a promising, scalable alternative in practical applications such as bridge elements and structural repair. The arrows in the figure represent the direction of heat being applied to the concrete material. As illustrated, time and temperature are omitted from the figure due to the variation in microwave curing that can be applied.

Figure 9.

Schematic illustration of electric heating with a heating blanket of a concrete element.

Table 5 summarizes previous studies utilizing electric curing. The accelerated curing method on a variety of concrete matrices yields notable improvements in both early-age and long-term performance, with curing durations ranging from a few hours to several weeks. For in situ concretes, extended intermittent curing promoted hydration, refined microstructures, and achieved better mechanical results with lower energy demand compared to steam curing. In reinforced concrete beams and columns, short-term microwave curing enhanced flexural capacity, ultimate load resistance, and durability under marine conditions. Geopolymer concretes incorporating FA or SF demonstrated mixed effects. While FA concretes gained early strength and higher flexural performance, some mixes exhibited increased porosity. In steel fiber concretes and UHPC, shorter curing regimes produced significant gains in early flexural and compressive strength, though often accompanied by greater pore development. Similarly, alkali-activated FA concretes benefited from 2–8 h of curing, achieving rapid strength gain. This research highlights that electric and accelerated curing is effective in achieving rapid strength development and enhanced structural performance, and is an alternative energy-efficient curing system. It is important to note that the optimization is necessary to balance strength gains with porosity control.

Table 5.

Previous studies that adopted electric curing in concrete.

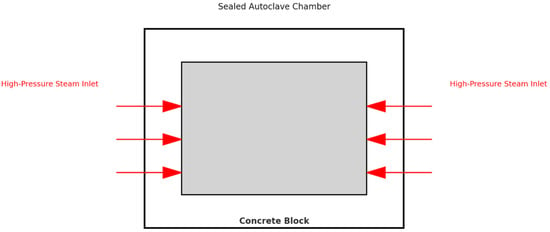

3.6. Autoclave Curing

Autoclave curing is an accelerated concrete curing technique widely applied in the production of high-strength precast components. By combining elevated temperature and pressure, autoclave curing enables concrete to achieve high early strength in a short period, thereby enhancing the efficiency and productivity of prefabrication processes [109]. This process induces hydrothermal reactions, producing crystalline hydrates such as tobermorite and xonotlite. These products provide a dense microstructure and exceptional mechanical stability [110]. Researchers [111] investigated the use of coal bottom ash (BA) and silica fume (SF) in structural lightweight concrete under air and autoclave curing. Results showed that autoclaving for 6 h produced compressive strength comparable to 28-day air curing, demonstrating significant time savings. The optimum mix was 20% BA and 5% SF, achieving the highest strength of 18.8 MPa. SF enhanced pozzolanic reactions, densifying the matrix, reducing voids, and increasing both strength and thermal conductivity. The thermal conductivity of BA+SF mixes was slightly higher than control concretes, reflecting denser microstructures. This study highlighted the significant time savings that can be achieved when curing under autoclave conditions. Chen et al. [112] investigate how the effects of fly ash (FA) content, autoclave pressure, and curing duration affect the strength, toughness, and microstructure of UHPC containing SF. Results showed that compressive and flexural strength increased with higher FA content (up to 20%) and appropriate autoclave pressure (1.0–1.5 MPa), with strength improvements up to 37.5% compared to standard curing. Longer curing durations, greater than 10 h, or excessive pressure reduced strength due to microcracking and unfavorable crystalline hydrates. Incorporating steel fibers significantly improved flexural strength (20–30%) but had a limited effect on compressive strength. Autoclave curing reduced fracture toughness in pure cement UHPC, but the addition of FA mitigated or eliminated this negative effect. Microstructural analysis showed that FA reduced porosity, refined pore structures, and promoted the formation of crystalline products, while lowering portlandite content. The optimal combination of fly ash, autoclave pressure, and duration enhances both strength and durability, making FA a valuable additive for improving UHPC under autoclave curing.

Autoclaved Alternative Material Integration

Luo et al. [113] investigate how recycled concrete powder (RCP), calcium carbide slag (CCS), fly ash (FA), and phosphogypsum (PG) can be used to produce sustainable autoclaved aerated concrete (AAC). Samples were cured at 180 °C for 1–10 h, and results showed compressive strength peaked at 8.2 MPa after 9 h. A 127.8% increase was seen over 1 h curing, before slightly declining due to tobermorite converting into weaker xonotlite. Pore sizes initially refined but coarsened with over-curing. Microstructural analysis revealed the transformation of C-S-H into tobermorite, evolving from sheet-like to plate-like to fibrous morphologies, with fibrous tobermorite densifying the matrix and enhancing strength. Additionally, nitrogen adsorption confirmed that optimized curing time promotes dense microstructures and reduced porosity, while prolonged exposure leads to pore coarsening and reduced strength. This research study demonstrated that AAC produced with multiple solid wastes can achieve both high strength and sustainability, but curing duration must be carefully optimized to maximize tobermorite formation without triggering its degradation. Moreover, this study highlighted the optimization and use of waste substitute materials within cementitious composite matrices when utilizing alternative curing methods.

Alhozaimy et al. [114] also demonstrated the use of alternative materials in concrete when utilizing the autoclave technique. Their research investigated the potential of white sand (WS) and dune sand (DS) as partial cement replacements (30%) in high-strength concrete under normal and autoclave curing. Under normal curing, both sands reduced compressive strength since they acted mainly as inert fillers. However, under autoclave curing (180 °C, 10 bar, 4–5 h), compressive strength increased significantly, demonstrating a 38% increase for DS and 36% for WS. This was in comparison to normal curing. This strength gain was attributed to the pozzolanic reaction between ground sands and Ca(OH)2, forming additional C–S–H products, particularly tobermorite, which densified the microstructure. X-ray diffraction (XRD) confirmed the elimination of Ca(OH)2 peaks and formation of crystalline tobermorite in autoclaved mixes, while scanning electron microscope (SEM) revealed denser, compact hydration products compared to fibrous structures in normal curing. Thermogravimetric analysis (TGA) results further showed higher Ca(OH)2 consumption under autoclave curing, indicating enhanced reactivity of silica in WS and DS at high temperature and pressure. This study highlights the activation process of inert sands into reactive pozzolans because of the autoclave curing process. Moreover, this enables the inert sands to partially replace cement effectively while improving the strength and durability of the concrete material.

Table 6 summarizes studies that demonstrate the diverse effects of autoclave temperature curing on cementitious systems. In lightweight OPC concretes, the autoclave curing technique reduced shrinkage, improved density, and enhanced strength. Alternative mix design concretes that incorporated recycled concrete powder and natural fibers achieved improved water resistance and stronger fiber matrix bonding. Additionally, autoclaved aerated concretes delayed cracking, reduced shrinkage, and refined the microstructure, while higher-temperature autoclaving with additives produced denser pore structures and improved durability. Autoclaved blocks generally yielded higher strength and more compact microstructures. The high-temperature curing promoted strength development, microstructural densification, shrinkage reduction, and durability enhancement, though performance was highly dependent on mix design and supplementary materials. Figure 10 schematically illustrates the autoclave curing technique of a concrete element. As illustrated, time and temperature are omitted from the figure due to the variation in microwave curing that can be applied.

Table 6.

Previous studies that adopted autoclave curing.

Figure 10.

Schematic illustration of autoclave curing method of a concrete element.

4. Discussion

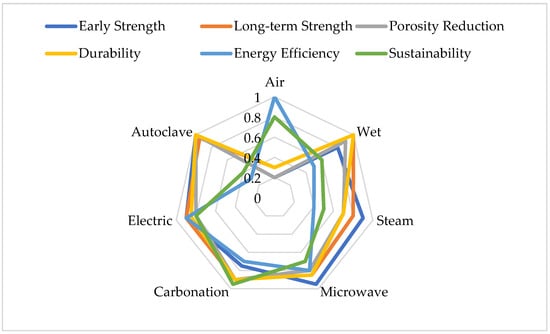

The performance differences observed across the curing regimes are primarily governed by the availability of moisture, temperature exposure, and their influence on cement hydration, pore structure, and microcrack formation. Air curing produced the weakest results because rapid surface evaporation halted hydration prematurely, leaving unreacted cement grains and a porous matrix with microcracks. This led to an approximate reduction of 20–40% lower compressive strength and 25–35% higher total porosity than water-cured concrete. In contrast, continuous wet curing maintained full saturation, allowing uninterrupted formation of C–S–H and Ca(OH)2, which refined the pore structure and yielded the highest strength and durability. This increased the chloride resistance by 30–50% and resulted in a 40% lower carbonation rate relative to air-cured specimens. Steam curing accelerated hydration by raising temperature and humidity, producing rapid early-age C–S–H formation and 25–35% higher early strength than air curing, but the resulting coarser microstructure caused a 10–15% increase in porosity and slightly lower long-term durability (90–95% of 28-day wet-cured strength). Microwave curing achieved similar acceleration through volumetric heating of internal moisture. Controlled exposure produced uniform hydration and up to 90–95% of wet-cured strength within 24 h. It is important to note that overheating occasionally induced microcracks and had a 20% rise in porosity. Carbonation curing, involving early CO2 exposure, enhanced surface densification through CaCO3 formation and improved impermeability by 15–25% over air curing, but partial consumption of Ca(OH)2 reduced long-term hydration potential, yielding 5–10% lower ultimate strength than water curing. Electric thermal curing generated uniform internal heat via the Joule effect, accelerating hydration of silicate and aluminate phases and achieving 20–30% higher early strength than air curing, though minor local overheating led to 10% higher porosity relative to wet curing. Autoclave curing, combining high-pressure steam and temperature, promoted hydrothermal reactions and the formation of crystalline tobermorite and xonotlite. This gave a 40–60% higher early strength and 30–40% lower porosity than conventional curing, with outstanding durability despite limited long-term strength gain. This confirms that curing effectiveness is governed primarily by sustained internal humidity and controlled thermal exposure, which together dictate hydration completeness, pore refinement, and long-term performance. It is important to note that this is based on curing conditions and characteristics, rather than mix design variations.

The applicability of curing techniques varies considerably with the type, composition, and performance requirements of concrete. Wet curing remains the reference method for OPC and blended concretes, as continuous moisture promotes full hydration and long-term strength development. Steam and autoclave curing are best suited to precast and UHPC that demand rapid strength gain and dimensional stability. The elevated temperature and humidity promote accelerated C–S–H formation and, in the case of autoclaving, crystalline tobermorite generation. Microwave and electric thermal curing exhibit high adaptability to field-cast elements, repair works, and low-temperature concrete applications. This is where rapid and controllable heating is advantageous and where minimal external infrastructure is required. Carbonation curing demonstrates promise for low-lime, alkali-activated, and recycled aggregate concretes, as the CO2 uptake densifies the pore structure and compensates for lower clinker content, simultaneously improving sustainability. In contrast, air or membrane curing compounds may be suitable only for non-structural or low-exposure concretes where water curing is impractical. The selection of curing method should therefore be governed by a balance between mechanical performance targets, material composition, production scale, and environmental objectives, ensuring that the curing regime complements both the mix design and the intended service conditions.

Figure 11 graphically illustrates the concrete curing regimes showing relative performance across six key indicators: early strength, long-term strength, porosity reduction, durability, energy efficiency, and sustainability. Each polygon represents the normalized (0–1) performance profile of a curing method relative to the others. Larger and more outward shapes denote higher overall performance. Autoclave curing demonstrates superior early strength and porosity reduction but lower energy efficiency, while wet curing provides a balanced performance across all parameters. Microwave and electric curing exhibit strong early-age efficiency with moderate sustainability, whereas carbonation curing achieves high durability and sustainability through CO2 sequestration. Air curing performs the poorest due to limited hydration and high porosity. The chart highlights the trade-offs and complementary characteristics of traditional and advanced curing systems in balancing mechanical performance and sustainability outcomes.

Figure 11.

Curing systems and the associated benefits.

5. Conclusions

Curing is one of the most critical processes in concrete construction, directly influencing the material’s strength development, durability, and service life. The most optimal curing method is determined by various factors such as resource availability, location, application, and technology. The findings within this current study aimed to review the traditional and advanced curing methods of concrete materials. The curing method is a decisive factor in the total outcome of the mechanical performance, durability, and sustainability of concrete elements across both traditional and advanced applications. Traditional methods such as water curing and air curing remain simple and effective, particularly for achieving long-term strength, though they are often impractical in extreme environmental conditions. Advanced methods such as steam, microwave, electric, autoclave, and carbonation curing offer significant advantages in accelerating early-age strength and refining microstructures. However, they present trade-offs such as higher energy consumption, thermal damage, or cost-intensive setups. Among these, microwave and autoclave curing demonstrate outstanding early strength performance; however, their practical application remains limited by high equipment cost, energy intensity, and safety considerations, especially for large-scale or in situ applications. Electric curing shows promise for in situ applications in cold climates, delivering energy-efficient performance compared to conventional steam regimes.

It is evident that no single curing method can be universally applied as optimal. Instead, the choice depends on the mix design, resource availability, environmental context, and application. Future opportunities lie in the development of smart, adaptive curing systems integrating IoT, sensors, and AI/ML predictive control, enabling precise regulation of curing parameters in real-time. Such systems, combined with hybrid curing strategies, have the potential to maximize mechanical performance, enhance durability, and deliver measurable sustainability benefits. The transition toward energy-efficient, digitally controlled curing represents a critical pathway for advancing both the resilience and environmental performance of modern concrete infrastructure.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/app152011055/s1, This systematic review was prospectively registered on the Open Science Framework (OSF), registration DOI: https://doi.org/10.17605/OSF.IO/UGJPA. Reference [126] is cited in the supplementary materials.

Author Contributions

Conceptualization, R.H.; methodology, R.H.; software, R.H.; validation, R.H.; formal analysis, R.H.; investigation, R.H.; resources, R.H.; data curation, R.H.; writing—original draft preparation, R.H.; writing—review and editing, R.H. and O.A.S.; visualization, R.H.; supervision, R.H.; project administration, R.H. All authors have read and agreed to published version of the manuscript.

Funding

This research received no external funding.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Pang, R.; Jiang, H.; Dang, L.; Lei, H.; Chen, L.; Jia, H. Shear resistance of high strength soft wire rope loop-UHPC joint for precast concrete components. Structures 2025, 80, 109871. [Google Scholar] [CrossRef]

- Machado, B.R.; Silva, L.S.; Amario, M.; Haddad, A.N.; de Vargas, A.S.; Stolz, C.M. Effect of curing methods on the long-term properties of concrete containing crystallizing additives. Next Mater. 2025, 8, 100759. [Google Scholar] [CrossRef]

- Si, P.; Ding, C.; Xue, K.; Zhou, Z.; Li, S.; Yan, X. Research on the influence of steam curing on the strength, hydration reaction and high temperature resistance of barite radiation-shielding concrete. Constr. Build. Mater. 2025, 494, 143408. [Google Scholar] [CrossRef]

- Bai, M.; Wu, Y.; Xiao, J.; Ding, T.; Yu, K. Workability and hardened properties of 3D printed engineered cementitious composites incorporating recycled sand and PE fibers. J. Build. Eng. 2023, 71, 106477. [Google Scholar] [CrossRef]

- Li, Y.; Xu, K.; Wang, S.; Gao, J.; Maropoulos, P. A step-wise numerical thermal control method for advanced composite curing process using digital image based programming. CIRP Ann. 2023, 72, 441–444. [Google Scholar] [CrossRef]

- Taffese, W.Z.; Nigussie, E. Automated concrete curing and assessment of strength and durability using IoT system. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- He, Y.; Li, W.; Zhang, M.; Li, S.; Li, M.; Tian, D.; Deng, G.; Sarmah, A.K. Automated electric heating and curing system for concrete in actual cold environments based on the Internet of Things. Constr. Build. Mater. 2025, 489, 142344. [Google Scholar] [CrossRef]

- Al Agha, W.; Pal, S.; Dev, N. Challenges for structural health monitoring of concrete curing using piezoelectric sensor and electromechanical impedance (EMI) technique: A critical review. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- Dong, S.; Ouyang, X.; Yoo, D.-Y.; Han, B. Influence of early thermal curing regimes on properties of ultra-high performance concrete: A review. J. Build. Eng. 2024, 96, 110494. [Google Scholar] [CrossRef]

- Sidhu, A.S.; Siddique, R. Review on effect of curing methods on high strength concrete. Constr. Build. Mater. 2024, 438, 136858. [Google Scholar] [CrossRef]

- Haigh, R.; Sandanayake, M.; Bouras, Y.; Vrcelj, Z. A life cycle assessment of cardboard waste in low stress grade concrete applications. Environ. Manag. 2024, 354, 120428. [Google Scholar] [CrossRef]

- Monteiro, P.J.M.; Miller, S.A.; Horvath, A. Towards sustainable concrete. Nat. Mater. 2017, 16, 698–699. [Google Scholar] [CrossRef]

- Haigh, R.; Sandanayake, M.; Joseph, P.; Yaghoubi, E.; Vrcelj, Z. The mechanical and microstructural performance of waste textile and cardboard materials in concrete. Struct. Concr. 2024, 25, 4033–4047. [Google Scholar] [CrossRef]

- Chen, L.; Huang, Z.; Pan, W.; Su, R.K.L.; Zhong, Y.; Zhang, Y. Low carbon concrete for prefabricated modular construction in circular economy: An integrated approach towards sustainability, durability, cost, and mechanical performances. J. Build. Eng. 2024, 90, 109368. [Google Scholar] [CrossRef]

- Haigh, R. A Decade Review of Research Trends Using Waste Materials in the Building and Construction Industry: A Pathway towards a Circular Economy. Waste 2023, 1, 935–959. [Google Scholar] [CrossRef]

- Zheng, Y.; Li, R.; Wang, J.; Pan, H.; Zhang, G.; Cheng, L. Innovative and environmentally friendly MICP surface curing: Enhancing mechanical and durability properties of concrete. J. Clean. Prod. 2024, 478, 143962. [Google Scholar] [CrossRef]

- Chen, B.; Tang, G.; Lu, X.; Xiong, B.; Guan, B.; Tian, B. Thermal property evolution and prediction model of early-age low-heat cement concrete under different curing temperatures. J. Build. Eng. 2024, 82, 108020. [Google Scholar] [CrossRef]

- Zeng, J.; Feng, D.; Liu, C.; Ye, G.; Ma, C.; Tian, J.; Mu, Y. Effect of ageing on the hydration and carbonation reactivity of ordinary Portland cement. J. Build. Eng. 2025, 111, 113598. [Google Scholar] [CrossRef]

- Liang, L.; Wang, Q.; Shi, Q. Flexural toughness and its evaluation method of ultra-high performance concrete cured at room temperature. J. Build. Eng. 2023, 71, 106516. [Google Scholar] [CrossRef]

- Wang, D.; Sas, G.; Das, O. The importance of volumetric w/c for porous supplementary cementitious materials in concrete. J. Build. Eng. 2025, 111, 113290. [Google Scholar] [CrossRef]

- Gong, P.; Mei, K.; Zhang, L.; Xue, Q.; Wang, X.; Wei, T.; Zhang, C.; Cheng, X. Hydration and carbonation reaction dynamics in CO2-rich environment for tricalcium silicate (C3S) and dicalcium silicate (C2S). Powder Technol. 2025, 452, 120535. [Google Scholar] [CrossRef]

- Haigh, R.; Sandanayake, M.; Yaghoubi, E.; Joseph, P.; Vrcelj, Z. The mechanical and microstructural investigations of concrete incorporating waste textile and cardboard fibers following thermal and freeze–thaw cycles. Struct. Concr. 2025; preprint. [Google Scholar] [CrossRef]

- Haigh, R.; Sandanayake, M.; Bouras, Y.; Vrcelj, Z. The durability performance of waste cardboard kraft fibre reinforced concrete. J. Build. Eng. 2023, 67, 106010. [Google Scholar] [CrossRef]

- Kumar, G.; Bansal, T.; Sharma, D. Monitoring hydration and strength development of E-waste concrete: A passive sensing approach using piezo sensors. Clean. Mater. 2025, 17, 100326. [Google Scholar] [CrossRef]

- Zheng, H.; Duan, Y.; Liu, L.; Wang, P.; Pang, B.; Duan, H.; Hou, D. Molecular structure and dynamics of water on the surfaces of cement hydration products and associated Minerals: Nanoscale wettability behavior. Appl. Surf. Sci. 2025, 687, 162274. [Google Scholar] [CrossRef]

- Gereziher Atsbha, T.; Zhutovsky, S. The effect of external curing methods on the development of mechanical and durability-related properties of normal-strength concrete. Constr. Build. Mater. 2022, 324, 126706. [Google Scholar] [CrossRef]

- Poongodi, K.; Murthi, P. Effects of using autoclaved aerated concrete block debris as lightweight aggregate on internal curing of concrete. Mater. Today Proc. 2023; in press. [Google Scholar] [CrossRef]

- Zou, D.; Que, Z.; Su, D.; Liu, T.; Zhou, A.; Li, Y. Sustainable use of recycled autoclaved aerated concrete waste as internal curing materials in ultra-high performance concrete. J. Clean. Prod. 2022, 373, 133910. [Google Scholar] [CrossRef]

- Guan, Q.; Zhou, Y. Utilizing ferrochrome slag and autoclaved artificial aggregates for eco-friendly and economical ultra-high-performance concrete: Mechanical performance and shrinkage control. Case Stud. Constr. Mater. 2025, 22, e04234. [Google Scholar] [CrossRef]

- Ibrahim, M.; Shameem, M.; Al-Mehthel, M.; Maslehuddin, M. Effect of curing methods on strength and durability of concrete under hot weather conditions. Cem. Concr. Compos. 2013, 41, 60–69. [Google Scholar] [CrossRef]

- Atiş, C.D.; Özcan, F.; Kılıç, A.; Karahan, O.; Bilim, C.; Severcan, M.H. Influence of dry and wet curing conditions on compressive strength of silica fume concrete. Build. Environ. 2005, 40, 1678–1683. [Google Scholar] [CrossRef]

- Lü, C.; Liu, D.; Ding, Y.; Lü, X.; Zhou, Z.; Mu, S.; Sun, Y. Effect of early dry-wet cycles on the mechanical performance and microstructure characteristics of ultra-high performance concrete (UHPC) with varying metakaolin (MK) contents. Constr. Build. Mater. 2025, 490, 142471. [Google Scholar] [CrossRef]

- Zhao, Q.; He, X.; Zhang, J.; Jiang, J. Long-age wet curing effect on performance of carbonation resistance of fly ash concrete. Constr. Build. Mater. 2016, 127, 577–587. [Google Scholar] [CrossRef]

- Zheng, Y.; Wang, Y.; Jiang, S.; Xia, Z.; Zhang, Q. Effect of silica fume with various fineness levels on the strength degradation of concrete after steam curing. Constr. Build. Mater. 2025, 464, 140169. [Google Scholar] [CrossRef]

- Wang, T.; Gao, X.; Li, Y.; Liu, Y. An orthogonal experimental study on the influence of steam-curing on mechanical properties of foam concrete with fly ash. Case Stud. Constr. Mater. 2024, 20, e02665. [Google Scholar] [CrossRef]

- Liu, C.; Chen, F.; Deng, X.; Wu, Y.; Zheng, Z.; Yang, B.; Yao, D.; Yang, J.; Yang, J. Comparison of nano-silica-modified manufactured-sand concrete under steam curing and standard curing. J. Build. Eng. 2023, 72, 106443. [Google Scholar] [CrossRef]

- Li, C.; Hu, S.; Hu, Y.; Ye, Y. Investigating the impact of steam curing parameters on the chloride ion penetration resistance of the prestressed concrete cylinder pipe (PCCP) protective layer. J. Build. Eng. 2024, 92, 109777. [Google Scholar] [CrossRef]

- Su, C.; Shi, J.; Tambara, L.U.D., Jr.; Yang, Y.; Liu, B.; Revilla-Cuesta, V. Improving the mechanical properties and durability of steam-cured concrete by incorporating recycled clay bricks aggregates from C&D waste. Powder Technol. 2024, 438, 119571. [Google Scholar] [CrossRef]

- Wang, P.; Li, X.; Huo, X.; Ali, S.; Sun, J.; Qin, J.; Liang, K.; Liu, Y. Early hydration and compressive strength of steam cured high-strength concrete based on simplex centroid design method. Case Stud. Constr. Mater. 2022, 17, e01583. [Google Scholar] [CrossRef]

- Zou, P.; Chang, H.-J.; Wang, F.; Cai, Y.-L.; Zhang, Z.; Zhao, Z.; Lv, Z.-D. Effect of steam curing scheme on the early-age temperature field of a prefabricated concrete T-beam. Case Stud. Constr. Mater. 2024, 20, e02787. [Google Scholar] [CrossRef]

- Shen, D.; Yu, Y.; Jin, Z.; Li, N. Effects of crumb rubber particles on the evolution of pore structure in steam-cured concrete under freeze-thaw cycles. J. Build. Eng. 2025, 103, 112138. [Google Scholar] [CrossRef]

- Liu, B.; Jiang, J.; Shen, S.; Zhou, F.; Shi, J.; He, Z. Effects of curing methods of concrete after steam curing on mechanical strength and permeability. Constr. Build. Mater. 2020, 256, 119441. [Google Scholar] [CrossRef]

- An, J.; Yu, Y.; Jin, Z.; Li, N.; Shen, D.; Xiong, C. Experimental and simulation study on capillary water absorption of modified crumb rubber concrete with steam-cured. J. Build. Eng. 2023, 73, 106756. [Google Scholar] [CrossRef]

- Ogawa, Y.; Suzuki, S.; Kawai, K. Impact of air exposure post-steam curing on the internal curing efficiency of porous ceramic roof-tile waste fine aggregate in steam-cured fly ash concrete. Mater. Lett. 2024, 366, 136576. [Google Scholar] [CrossRef]

- Qian, Y.; Yang, D.; Zhao, J.; Mao, X.; Ren, G.; Cao, Z. Development of cementless alkali-activated ultra-high performance concrete under various steam curing regimes: Mechanical properties, permeability, and microstructure. J. Build. Eng. 2025, 101, 111857. [Google Scholar] [CrossRef]

- Yao, B.; Ren, G.; Huang, J.; Gao, X. Influence of self-ignition coal gangue on properties of foam concrete with steam curing. Case Stud. Constr. Mater. 2022, 17, e01316. [Google Scholar] [CrossRef]

- Zhu, X.; Lei, P.; Chen, X.; Bu, J. Influence of steam curing on cyclic triaxial characteristics of recycled aggregate concrete: Experimental analysis and DEM simulation. Eng. Fract. Mech. 2024, 312, 110643. [Google Scholar] [CrossRef]

- Nguyen, H.V.; Nakarai, K.; Okazaki, A.; Karasawa, H.; Tadokoro, Y.; Tsujino, M. Applicability of a simplified estimation method to steam-cured expansive concrete. Cem. Concr. Compos. 2019, 95, 217–227. [Google Scholar] [CrossRef]

- Davraz, M.; Isildar, N.; Kaplan, A.N. Investigation of the effects of steam curing of concrete at different temperatures on cost and compressive strength by response surface methodology. Constr. Build. Mater. 2025, 489, 140589. [Google Scholar] [CrossRef]

- Han, X.; Wei, D.; Wang, P.; Wang, M.; Du, Z.; Ling, Z. Microstructure characteristics and evolution of pipe pile concrete under centrifugation and steam curing. Constr. Build. Mater. 2024, 450, 138554. [Google Scholar] [CrossRef]

- Kong, Y.; Liu, S.; Wang, P. Effects of microwave curing on the compressive strength development and hydration of cement-granulated blast furnace slag composite system. Constr. Build. Mater. 2021, 270, 121432. [Google Scholar] [CrossRef]

- Rattanadecho, P.; Makul, N.; Pichaicherd, A.; Chanamai, P.; Rungroungdouyboon, B. A novel rapid microwave-thermal process for accelerated curing of concrete: Prototype design, optimal process and experimental investigations. Constr. Build. Mater. 2016, 123, 768–784. [Google Scholar] [CrossRef]

- Kastiukas, G.; Ruan, S.; Liang, S.; Zhou, X. Development of precast geopolymer concrete via oven and microwave radiation curing with an environmental assessment. J. Clean. Prod. 2020, 255, 120290. [Google Scholar] [CrossRef]

- Zhang, J.; Yu, R.; Shui, Z.; Liu, K. Hydration kinetics and microstructure development of Ultra-High Performance Concrete (UHPC) subjected to microwave pre-curing. Cem. Concr. Compos. 2022, 129, 104484. [Google Scholar] [CrossRef]

- Mangat, P.S.; Grigoriadis, K.; Abubakri, S. Microwave curing parameters of in-situ concrete repairs. Constr. Build. Mater. 2016, 112, 856–866. [Google Scholar] [CrossRef]

- Mohammed, H.; Sadique, M.; Shaw, A.; Bras, A. The influence of incorporating plastic within concrete and the potential use of microwave curing; A review. J. Build. Eng. 2020, 32, 101824. [Google Scholar] [CrossRef]

- Han, Y.; Meng, L.-Y.; Lin, R.; Kim, S.; Kim, T.; Wang, X.-Y. Evaluating the sustainability of microwave pre-cured high-volume slag concrete: Mechanical properties, environmental impact and cost-benefit analysis. J. Build. Eng. 2024, 96, 110663. [Google Scholar] [CrossRef]

- Deng, P.; Chang, Z.; Leng, H.; Zhong, H.; Chen, Y.; Ren, Y. Experimental investigation on properties of gold tailings recycled brick-concrete aggregate concrete under microwave curing. J. Build. Eng. 2024, 95, 110104. [Google Scholar] [CrossRef]

- Tang, T.; Cai, L.; You, K.; Liu, M.; Han, W. Effect of microwave pre-curing technology on carbide slag-fly ash autoclaved aerated concrete (CS-FA AAC): Porosity rough body formation, pore characteristics and hydration products. Constr. Build. Mater. 2020, 263, 120112. [Google Scholar] [CrossRef]

- Zhou, F.; Pan, G.; Meng, H.; Mi, R. Effect of secondary curing on the performance of microwave cured concrete. Constr. Build. Mater. 2022, 330, 127256. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, Y.; Li, S. Effects of isothermal microwave curing on steel fibre-reinforced reactive powder concrete: Strength, microstructure and hydration products. Constr. Build. Mater. 2021, 302, 124435. [Google Scholar] [CrossRef]

- Han, Y.; Park, K.-B.; Yang, B.; Wang, X.-Y. Optimizing and designing the effects of microwave pre-curing on the properties of ternary blended concrete with slag and fly ash using the simplex centroid method. Constr. Build. Mater. 2024, 419, 135443. [Google Scholar] [CrossRef]

- Chen, J.; Li, S.; Gao, X.; Li, X. Study of the effects of microwave curing on ultra-high-performance concrete based on dielectric properties. Case Stud. Constr. Mater. 2024, 21, e04104. [Google Scholar] [CrossRef]

- Liu, X.; Guo, Y.; Zhang, Y.; Xia, J.; Ma, G. Synergistic integration of electromagnetic wave absorption and microwave curing technologies: Early-strength optimization in microwave-cured concrete with absorbent materials. Constr. Build. Mater. 2025, 489, 142229. [Google Scholar] [CrossRef]

- Li, Q.; Wang, H.; Xue, H.; Zhang, Q.; Dong, H. The effect of microwave curing on the static and dynamic mechanical properties and thermal brittleness of coal gangue concrete. Constr. Build. Mater. 2025, 463, 140025. [Google Scholar] [CrossRef]

- Rashid, K.; Fatima, N.; Ul Haq, E.; Shaheen, N.; Ju, M. Feasibility assessment of microwave-cured lightweight aggregate concrete by mineral encapsulated self-healing. J. Build. Eng. 2023, 76, 107084. [Google Scholar] [CrossRef]

- Yuan, C.; Yong, L.; Ziao, C.; Tianyi, Y.; Rui, Y. Development of Ultra-High Performance Concrete (UHPC) matrix based on recycled concrete fines subjected to coupling curing of microwave and wet carbonation. J. Build. Eng. 2024, 95, 110038. [Google Scholar] [CrossRef]

- Prommas, R.; Rungsakthaweekul, T. Effect of Microwave Curing Conditions on High Strength Concrete Properties. Energy Procedia 2014, 56, 26–34. [Google Scholar] [CrossRef]

- Cai, L.; Tang, T.; Liu, M.; Xie, D. Comparative study of carbide slag autoclaved aerated concrete (AAC) manufactured under thermal oven and microwave pre-curing process: Foaming course, rough body strength and physic-mechanical properties. Constr. Build. Mater. 2020, 236, 117550. [Google Scholar] [CrossRef]

- Makul, N.; Rattanadecho, P.; Pichaicherd, A. Accelerated microwave curing of concrete: A design and performance-related experiments. Cem. Concr. Compos. 2017, 83, 415–426. [Google Scholar] [CrossRef]

- Li, Q.; Wang, H.; Xue, H.; Su, H.; Tang, C. The impact of microwave curing on the strength and microstructure of coal gangue concrete. Constr. Build. Mater. 2024, 443, 137802. [Google Scholar] [CrossRef]

- Jeon, S.-M.; Liyew, G.; Kim, H.-K. Service life assessment of accelerated carbonation-cured concrete considering weathering carbonation and chloride ingression. J. Build. Eng. 2025, 103, 112094. [Google Scholar] [CrossRef]

- Adem, J.K.; Seo, J.; Park, S.; Kim, G.M. Effects of low-lime calcium silicate cement addition on the hydration, carbonation, and microstructural characteristics of OPC pastes by carbonation curing. J. Build. Eng. 2025, 107, 112683. [Google Scholar] [CrossRef]