Numerical Investigation on the Effect of the Ignition Changes on the Combustion Process of a Free Piston Engine Generator Through Computational Fluid Dynamics

Abstract

1. Introduction

2. Materials and Methods

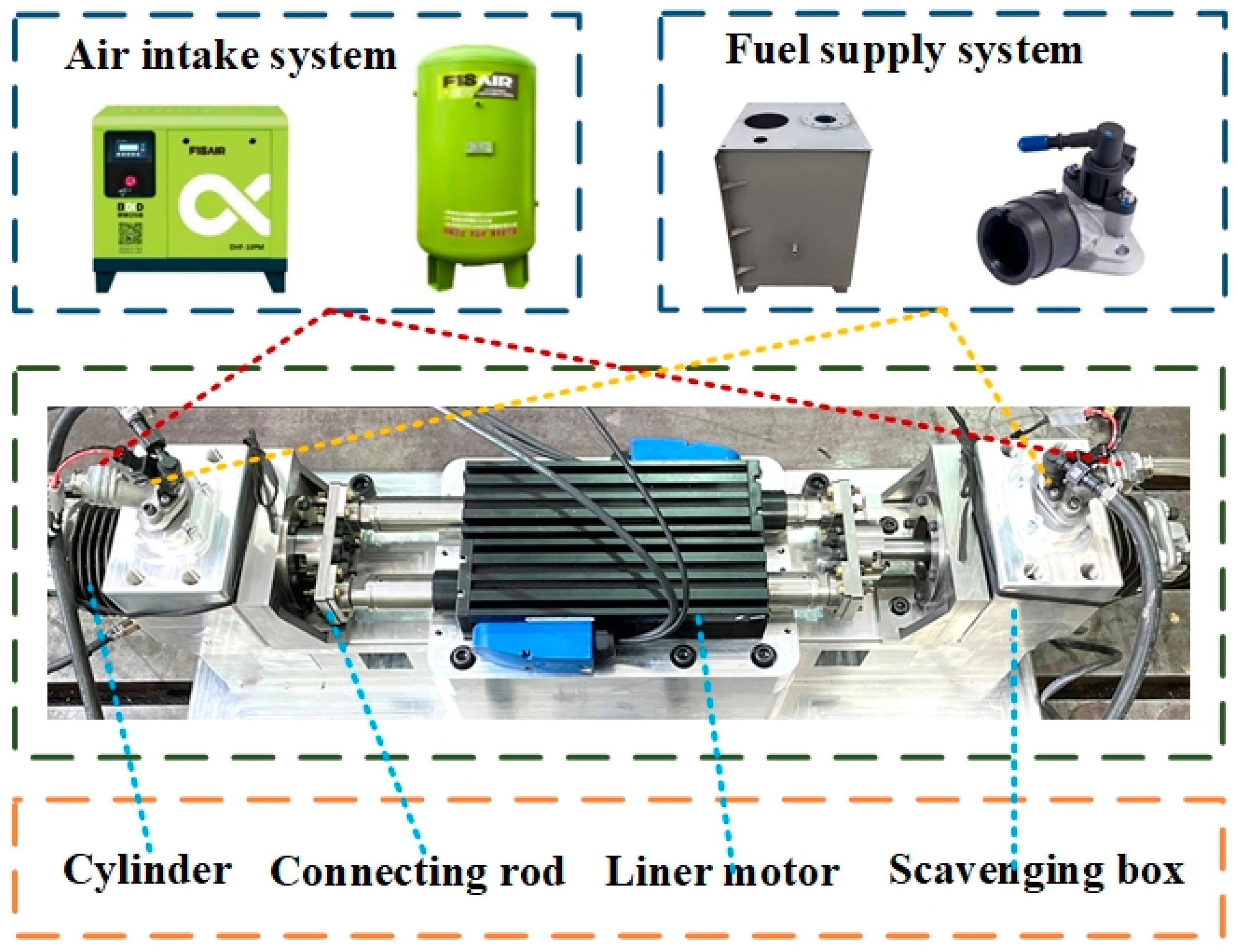

2.1. Experimental Bench

2.2. Principle of Operation

- (a)

- Free scavenging phase: The exhaust port opened until the intake port opened. Following the in-cylinder combustion stage, the gas within the cylinder is at high temperature and pressure, causing the residual exhaust gases to be rapidly expelled through the exhaust port. As the exhaust port gradually opens, the pressure and temperature inside the cylinder decrease, leading to a gradual reduction in the flow rate of the residual exhaust gases.

- (b)

- Forced scavenging phase: The inlet port transitions from being fully open to closed. During this phase, both the intake and exhaust ports are fully open, allowing a substantial amount of fresh air from the scavenging box to flow into the cylinder, effectively sweeping out residual exhaust gases. Simultaneously, this fresh air replenishes the cylinder in preparation for the upcoming combustion phase. The forced air scavenging phase greatly enhances the efficiency of the engine’s air-sweeping process, thereby improving overall engine performance.

- (c)

- Final scavenging phase: The intake port remains closed while the exhaust port is closed. During this phase, fresh air from the scavenging air box is not injected into the cylinder. As the piston moves towards TDC, the cylinder gas is also compressed, and the pressure inside the cylinder increases. Once this pressure surpasses that in the exhaust, the gas in the cylinder is expelled through the exhaust port.

2.3. The CFD Model of FPEG and Simulation Strategies

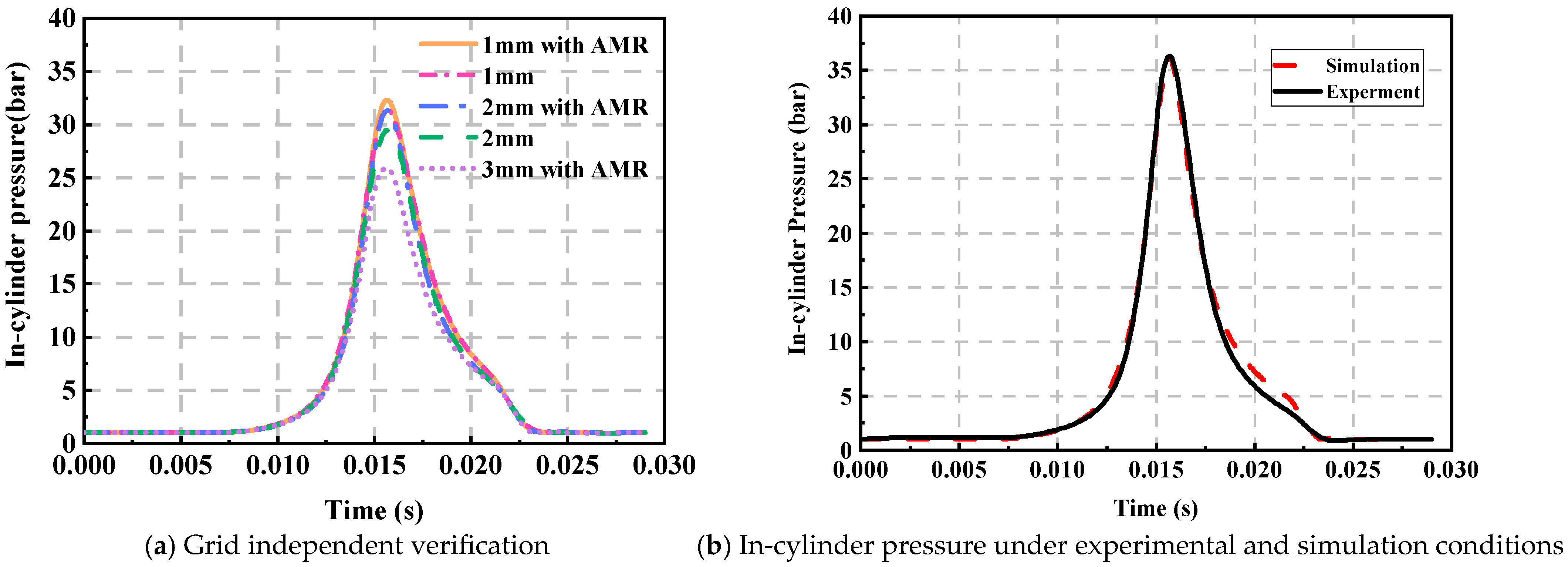

2.4. Model Verification

3. Results and Discussion

3.1. Effect of Synchronous and Asynchronous Changes on Combustion Characteristics

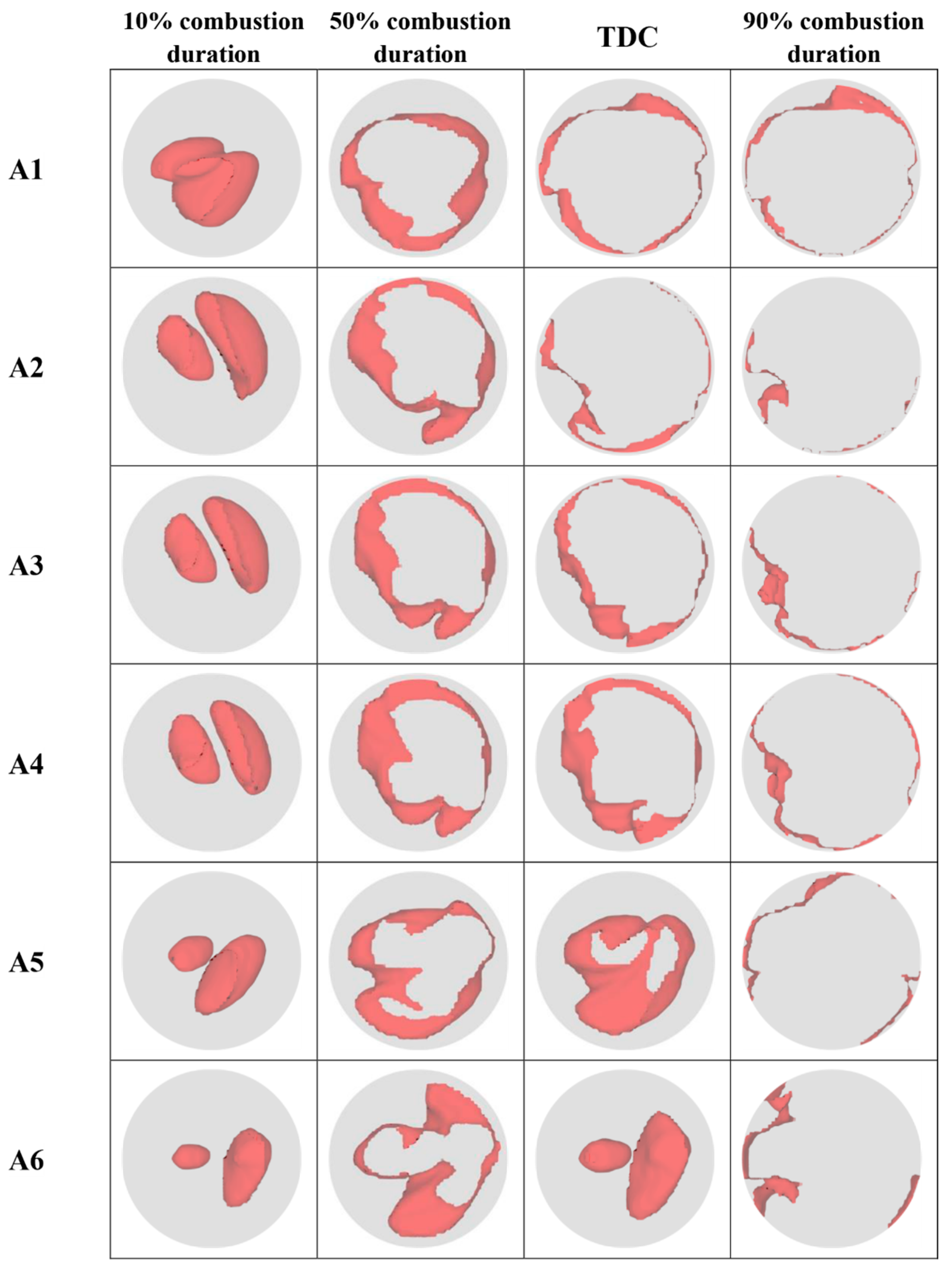

3.2. Effects of Synchronous and Asynchronous Ignition Strategies on Flame Development and Flame Propagation

3.3. Effects of Synchronous and Asynchronous Changes on Emissions

4. Conclusions

- (1)

- Whether employing synchronous or asynchronous ignition, changing the ignition position considerably impacts the in-cylinder pressure. Under Case A2, the peak pressure achieved by the synchronous scheme can reach up to 62.5 bar, reflecting a 10.8% improvement over the base case and showing a significant growth trend as the ignition position is advanced. In contrast, the asynchronous scheme exhibits significant nonlinear characteristics in its pressure variations, due to the negative effects of in-cylinder airflow action and fire core collision, and the trend is quite different from that of the synchronous ignition scheme.

- (2)

- As the ignition position continues to advance, the ignition delay period for both the synchronous and asynchronous schemes shows an increasing trend. In the synchronous ignition scheme, the combustion duration shows a trend of decreasing and then increasing, with a maximum shortening of 1.5 ms. The combustion duration of the asynchronous scheme increases compared with that of the synchronous, and the difference in the cases gradually decreases with the change in the ignition position, with a maximum shortening of 0.135 ms. When the ignition is set to L-24 mm/R-26 mm, the indicated thermal efficiency reaches a peak of 37.6%.

- (3)

- Regardless of the ignition scheme employed, the two separate flame cores formed by the spark plugs are affected by the ignition arrangement and the strong counterclockwise return flow within the cylinder, and the flame cores gradually develop from the right side to the left side. In this process, the right-side flame core will gradually engulf the left-side flame core. At 50% combustion duration and TDC moment, the flame cloud map of the asynchronous ignition scheme shows more uniform propagation characteristics, and the flame front tends to be round.

- (4)

- Delaying the synchronized ignition to L-32 mm/R-30 mm, the NOx mole fraction reaches its lowest value due to the lower temperature in the cylinder. However, CO and HC emissions increased significantly due to incomplete combustion. Compared to the synchronous schemes, the asynchronous schemes showed less difference in emissions and did not exhibit significant emission fluctuations, and the overall emissions were low.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| FPEG | Free piston engine generator |

| OSFPG | Opposed single-cylinder free piston generator |

| CFD | Computational fluid dynamics |

| TDC | Top dead center |

| BDC | Bottom dead center |

| ATDC | After top dead center |

| NOx | Nitrogen oxide |

| HCCI | Homogeneous charge compression ignition |

| SDI | Semi-direct injection system |

| PFI | Port fuel injection |

| HC | Hydrocarbon |

| HRR | Heat release rate |

| AMR | Adaptive mesh refinement |

| SP | Spark position |

| MBF | Mass burn fraction |

References

- Gao, J.; Chen, H.; Li, Y.; Chen, J.; Zhang, Y.; Dave, K.; Huang, Y. Fuel consumption and exhaust emissions of diesel vehicles in worldwide harmonized light vehicles test cycles and their sensitivities to eco-driving factors. Energy Convers. Manag. 2019, 196, 605–613. [Google Scholar] [CrossRef]

- Meng, H.; Ji, C.; Xin, G.; Yang, J.; Chang, K.; Wang, S. Comparison of combustion, emission and abnormal combustion of hydrogen-fueled Wankel rotary engine and reciprocating piston engine. Fuel 2022, 318, 123675. [Google Scholar] [CrossRef]

- Gao, J.; Tian, G.; Sorniotti, A.; Karci, A.E.; Di Palo, R. Review of thermal management of catalytic converters to decrease engine emissions during cold start and warm up. Appl. Therm. Eng. 2019, 147, 177–187. [Google Scholar] [CrossRef]

- Guo, C.; Zuo, Z.; Feng, H.; Jia, B.; Roskilly, T. Review of recent advances of free-piston internal combustion engine linear generator. Appl. Energy 2020, 269, 115084. [Google Scholar] [CrossRef]

- Guo, C.; Feng, H.; Jia, B.; Zuo, Z.; Guo, Y.; Roskilly, T. Research on the operation characteristics of a free-piston linear generator: Numerical model and experimental results. Energy Convers. Manag. 2017, 131, 32–43. [Google Scholar] [CrossRef]

- Feng, H.; Guo, C.; Jia, B.; Zuo, Z.; Guo, Y.; Roskilly, T. Research on the intermediate process of a free-piston linear generator from cold start-up to stable operation: Numerical model and experimental results. Energy Convers. Manag. 2016, 122, 153–164. [Google Scholar] [CrossRef]

- Hung, N.B.; Lim, O. A review of free-piston linear engines. Appl. Energy 2016, 178, 78–97. [Google Scholar] [CrossRef]

- Hanipah, M.R.; Mikalsen, R.; Roskilly, A.P. Recent commercial free-piston engine developments for automotive applications. Appl. Therm. Eng. 2015, 75, 493–503. [Google Scholar] [CrossRef]

- Guo, C.; Zuo, Z.; Feng, H.; Roskilly, T. Advances in free-piston internal combustion engines: A comprehensive review. Appl. Therm. Eng. 2021, 189, 116679. [Google Scholar] [CrossRef]

- Zhao, Z.; Wang, S.; Zhang, S.; Zhang, F. Thermodynamic and energy saving benefits of hydraulic free-piston engines. Energy 2016, 102, 650–659. [Google Scholar] [CrossRef]

- Atkinson, C.M.; Petreanu, S.; Clark, N.N.; Atkinson, R.J.; McDaniel, T.I.; Nandkumar, S.; Famouri, P. Numerical Simulation of a Two-Stroke Linear Engine-Alternator Combination. In Proceedings of the International Congress & Exposition, Detroit, MY, USA, 1–4 March 1999; pp. 1416–1430. [Google Scholar]

- Mikalsen, R.; Roskilly, A.P. A review of free-piston engine history and applications. Appl. Therm. Eng. 2007, 27, 2339–2352. [Google Scholar] [CrossRef]

- Mikalsen, R.; Roskilly, A.P. A computational study of free-piston diesel engine combustion. Appl. Energy 2009, 86, 1136–1143. [Google Scholar] [CrossRef]

- Nigro, A.; Algieri, A.; De Bartolo, C.; Bova, S. Fluid dynamic investigation of innovative intake strategies for multivalve internal combustion engines. Int. J. Mech. Sci. 2017, 123, 297–310. [Google Scholar] [CrossRef]

- Zhang, S.; Duan, X.; Liu, Y.; Guo, G.; Zeng, H.; Liu, J.; Lai, M.-C.; Talekar, A.; Yuan, Z. Experimental and numerical study the effect of combustion chamber shapes on combustion and emissions characteristics in a heavy-duty lean burn SI natural gas engine coupled with detail combustion mechanism. Fuel 2019, 258, 116130. [Google Scholar] [CrossRef]

- Feng, H.; Lai, K.; Zheng, Z.; Lin, S.; Wu, X.; Tang, Q. Effects of methanol direct injection and high compression ratio on improving the performances of a spark-ignition passenger car engine. Fuel 2024, 357, 130052. [Google Scholar] [CrossRef]

- Yilmaz, I.T. The effect of hydrogen on the thermal efficiency and combustion process of the low compression ratio CI engine. Appl. Therm. Eng. 2021, 197, 117381. [Google Scholar] [CrossRef]

- Calam, A. An experimental research on the determination of the combustion characteristics of ABE fuel in a port injection HCCI engine. Energy Convers. Manag. 2024, 321, 119087. [Google Scholar] [CrossRef]

- Wang, B.; Xie, F.; Hong, W.; Du, J.; Chen, H.; Su, Y. The effect of structural parameters of pre-chamber with turbulent jet ignition system on combustion characteristics of methanol-air pre-mixture. Energy Convers. Manag. 2022, 274, 116473. [Google Scholar] [CrossRef]

- Wang, B.; Xie, F.; Hong, W.; Du, J.; Chen, H.; Li, X. Extending ultra-lean burn performance of high compression ratio pre-chamber jet ignition engines based on injection strategy and optimized structure. Energy 2023, 282, 128433. [Google Scholar] [CrossRef]

- Duan, X.; Zhang, S.; Liu, Y.; Li, Y.; Liu, J.; Lai, M.-C.; Deng, B. Numerical investigation the effects of the twin-spark plugs coupled with EGR on the combustion process and emissions characteristics in a lean burn natural gas SI engine. Energy 2020, 206, 118181. [Google Scholar] [CrossRef]

- Chang, K.; Ji, C.; Wang, S.; Yang, J.; Meng, H.; Wang, H.; Xin, G. Comparative study on different spark plug positions of a rotary engine with gasoline port and direct injection. Fuel 2022, 310, 122376. [Google Scholar] [CrossRef]

- Duan, H.; Hu, W.; Wang, J.; Yin, X.; Hu, E.; Zeng, K. Effects of diesel pilot-injection strategy on a methanol/diesel dual-direct injection engine. Appl. Therm. Eng. 2024, 261, 125106. [Google Scholar] [CrossRef]

- Yu, J.; Zhou, F.; Fu, J.; Huang, D.; Wu, C.; Liu, J. Research on the influence of injection strategies on the in-cylinder combustion process and emissions of methanol. Biomass Bioenergy 2024, 188, 107340. [Google Scholar] [CrossRef]

- Xu, L.; Wei, Y.; Liu, C.; Jia, B.; Zhang, Z.; Qin, S.; Hu, X.; Feng, H.; Zuo, Z. Research on the implementation of free piston engine generator at various compression ratios and combustion performance of multiple fuels. Energy 2024, 313, 133690. [Google Scholar] [CrossRef]

- Wang, J.; Zhou, J.; Kong, L.; Qin, Z.; Zhang, H.; Li, T.; Xu, Z.; Zhang, W. Effect of injection position on in-cylinder airflow motion and combustion in a diesel-ignited hydrogen free-piston engine. Case Stud. Therm. Eng. 2025, 74, 106960. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, Z.; Zhang, C.; Liu, L. Combustion optimization of a hydrogen free-piston engine with high-energy ignition. Int. J. Hydrogen Energy 2024, 49, 483–494. [Google Scholar] [CrossRef]

- Chiang, C.-J.; Yang, J.-L.; Lan, S.-Y.; Shei, T.-W.; Chiang, W.-S.; Chen, B.-L. Dynamic modeling of a SI/HCCI free-piston engine generator with electric mechanical valves. Appl. Energy 2013, 102, 336–346. [Google Scholar] [CrossRef]

- Chiang, C.J.; Yang, J.L.; Lan, S.Y.; Shei, T.W.; Chiang, W.S.; Chen, B.L. Dynamic modeling of SI/HCCI free-piston engine generators. In Proceedings of the 6th IEEE Conference on Industrial Electronics and Applications (ICIEA 2011), Beijing, China, 21–23 June 2011; pp. 1615–1620. [Google Scholar]

- Liu, C.; Zhang, Z.; Ren, P.; Wei, Y.; Jia, B.; Zuo, Z.; Wang, W.; Feng, H. Application of semi-direct fuel injection system to free piston engine generator for better performance: Simulation approach with validation results. Energy 2024, 298, 131362. [Google Scholar] [CrossRef]

- Chang, K.; Ji, C.; Wang, S.; Yang, J.; Wang, H.; Meng, H.; Liu, D. Numerical investigation of the synchronous and asynchronous changes of ignition timing in a double spark plugs direct injection rotary engine. Energy 2023, 268, 126688. [Google Scholar] [CrossRef]

- Li, Y.; Yang, F.; Linxun, X.; Liu, J.; Wang, J.; Duan, X. Influences of the control parameters and spark plug configurations on the performance of a natural gas spark-ignition engine. Fuel 2022, 324, 124728. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, X.; Wang, Y.; Sun, J.; Fan, X. Experimental study on premixed combustion characteristics of methane-air under dual spark plug ignition strategy in a closed spherical chamber. Fuel 2022, 314, 123093. [Google Scholar] [CrossRef]

- Mikalsen, R.; Roskilly, A.P. The design and simulation of a two-stroke free-piston compression ignition engine for electrical power generation. Appl. Therm. Eng. 2008, 28, 589–600. [Google Scholar] [CrossRef]

- Raj, A.G.S.; Mishra, C.S. Simulation and experimental data resemblance of darmstadt spark ignition engine with different turbulence models–A computational fluid dynamics cold flow data. Data Brief 2022, 43, 108340. [Google Scholar] [CrossRef]

- Akhlaghi, H.; Roohi, E.; Stefanov, S. On the consequences of successively repeated collisions in no-time-counter collision scheme in DSMC. Comput. Fluids 2018, 161, 23–32. [Google Scholar] [CrossRef]

- Mehl, M.; Pitz, W.J.; Westbrook, C.K.; Curran, H.J. Kinetic modeling of gasoline surrogate components and mixtures under engine conditions. Proc. Combust. Inst. 2011, 33, 193–200. [Google Scholar] [CrossRef]

- Ihsan Shahid, M.; Rao, A.; Farhan, M.; Liu, Y.; Ma, F. Comparative analysis of different heat transfer models, energy and exergy analysis for hydrogen-enriched internal combustion engine under different operation conditions. Appl. Therm. Eng. 2024, 247, 123004. [Google Scholar] [CrossRef]

- Benim, A.C.; Korucu, A. Computational investigation of non-premixed hydrogen-air laminar flames. Int. J. Hydrogen Energy 2023, 48, 14492–14510. [Google Scholar] [CrossRef]

- Wang, J.; Duan, X.; Liu, Y.; Wang, W.; Liu, J.; Lai, M.-C.; Li, Y.; Guo, G. Numerical investigation of water injection quantity and water injection timing on the thermodynamics, combustion and emissions in a hydrogen enriched lean-burn natural gas SI engine. Int. J. Hydrogen Energy 2020, 45, 17935–17952. [Google Scholar] [CrossRef]

- Glassman, I.; Yetter, R.A. Combustion; Elsevier Inc.: Waltham, MA, USA, 2008. [Google Scholar]

- Siegmund, T.; Gollmer, C.; Scherzinger, M.; Kaltschmitt, M. A review of CO emissions during solid biofuel combustion–Formation mechanisms and fuel-related reduction measures. J. Energy Inst. 2024, 116, 101762. [Google Scholar] [CrossRef]

| Parameters | Unit | Value |

|---|---|---|

| Cylinder bore | mm | 52.5 |

| Design stroke | mm | 60 |

| Engine displacement | cc | 130 |

| Equivalence Engine speed | r/min | 2000 |

| Compress ratio | - | 8 |

| Fuel type | - | Gasoline |

| Equivalence ratio | - | 1.0 |

| Ignition mode | - | Spark Ignition |

| Fuel supply system | - | PFI |

| Parameters | Unit | Value |

|---|---|---|

| Cylinder pressure sensor | Kistler 6052C | 0–250 bar; −50–350 °C; ±0.3% FS |

| Charge amplifier | Type 5064E | ±102–105 pC; −30–50 °C; ±0.1% FS |

| Air intake mass flow meter | Sevenstar D07-60B | 0–500 LSM; ±1% FS |

| Air intake temperature sensor | Booen BEQT-3 | ≤400 °C; ≤1 °C |

| Position sensor | Copley Sin/Cos | 0–100 mm; ±20 μm; |

| Power analyzer | Yokogawa DL950 | 0–150 A; ±0.02% FS |

| Data collection | NI PXIe-1071 | 1.25 MS/s/channel; 16 bits |

| Boundary Conditions | Unit | Value |

|---|---|---|

| Inlet mass flow | kg/s | 0.0086 |

| Inlet temperature | K | 313 |

| Outlet pressure | bar | 1 |

| Outlet temperature | K | 600 |

| Cylinder wall temperature | K | 480 |

| Piston head temperature | K | 450 |

| Description | Models and Mechanism |

|---|---|

| Turbulence Model | RNG k-ε model [35] |

| Combustion model | SAGE model [36] |

| Heat transfer model | Wall-function model [38] |

| Reaction kinetics model | PRF skeletal mechanism [37] |

| Ignition model | Sphere selection module |

| NOx formation model | Extended Zeldovich model [39] |

| Case | L sp/mm | R sp/mm |

|---|---|---|

| A1 | 22 | 20 |

| A2 | 24 | 22 |

| A3 | 26 | 24 |

| A4 | 28 | 26 |

| A5 | 30 | 28 |

| A6 | 32 | 30 |

| B1 | 22 | 26 |

| B2 | 24 | 26 |

| B3 | 26 | 24 |

| B4 | 26 | 22 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, X.; Feng, H.; Liu, C.; Jia, B.; Lei, Q.; Xu, L.; Wei, Y. Numerical Investigation on the Effect of the Ignition Changes on the Combustion Process of a Free Piston Engine Generator Through Computational Fluid Dynamics. Appl. Sci. 2025, 15, 10907. https://doi.org/10.3390/app152010907

Hu X, Feng H, Liu C, Jia B, Lei Q, Xu L, Wei Y. Numerical Investigation on the Effect of the Ignition Changes on the Combustion Process of a Free Piston Engine Generator Through Computational Fluid Dynamics. Applied Sciences. 2025; 15(20):10907. https://doi.org/10.3390/app152010907

Chicago/Turabian StyleHu, Xiaoxu, Huihua Feng, Chang Liu, Boru Jia, Qiming Lei, Lei Xu, and Yidi Wei. 2025. "Numerical Investigation on the Effect of the Ignition Changes on the Combustion Process of a Free Piston Engine Generator Through Computational Fluid Dynamics" Applied Sciences 15, no. 20: 10907. https://doi.org/10.3390/app152010907

APA StyleHu, X., Feng, H., Liu, C., Jia, B., Lei, Q., Xu, L., & Wei, Y. (2025). Numerical Investigation on the Effect of the Ignition Changes on the Combustion Process of a Free Piston Engine Generator Through Computational Fluid Dynamics. Applied Sciences, 15(20), 10907. https://doi.org/10.3390/app152010907