1. Introduction

Structured cabling systems (SCSs) constitute the fundamental infrastructure of data centres. It is necessary to consider the numerous elements of active equipment that require connection. A SCS comprises several principal components. These include telecommunications cabinets and racks located within cross-connect rooms of buildings, as well as copper and optical panels located inside telecommunications cabinets. Additionally, SCSs encompass telecommunication sockets installed in offices, copper, and optical cable lines that connect panels within cabinets and information sockets and cable trays and boxes for encasing and protecting these cable lines. From a logical point of view, cable lines can be regarded as information circuits that adhere to a specific set of characteristics and parameters, which define their functionality.

In the course of the SCS design, engineers encounter the following issues when utilising standard CAD systems: (i) The generation of cable trays drawings is confined to two dimensions; (ii) The formulation of cabinet façade schemes is conducted manually; (iii) The equipment specifications are manually enumerated; (iv) The enumeration of cable lines specifications is performed manually; (v) The utilization of conventional two-dimensional schemes proves to be disadvantageous with respect to the subsequent facility management; (vi) There is an instance of redundancy in the work undertaken by engineers responsible for designing a system and engineers responsible for creating a model of the same system in Building Information Modeling (BIM).

To circumvent the aforementioned issues, it is imperative to improve the methodology. To this end, the application of the BIM design concept is proposed. However, this is dependent on the existence of management systems, tools, and applications. The building industry is undergoing a period of significant transformation, largely driven by the integration of BIM and the increasing prevalence of digital technologies across the domains of construction, operation, and maintenance. The primary function of BIM tools is to facilitate the exchange of information, thereby enhancing project productivity.

The BIM concept in engineering systems is traditionally employed in the modeling and creation of projects for heating, ventilation and air conditioning systems, and pipelines and fire extinguishing systems. Power supply systems are not as frequently encountered. The potential for the implementation of BIM in the domain of structured cabling systems remains to be fully explored [

1].

In our research, a statistical analysis was performed on the available data, including three separate databases. These databases related to the constructed object, the design documentation, and the design parameters as defined by the scenario. The tables contained detailed information on the number of cable sections, their corresponding length, and the losses in each section.

To ensure the evaluation of the effectiveness of the proposed method, an experimental study was conducted. The verification was carried out on the basis of three construction projects:

Office building;

Data center;

Educational institution.

All these objects contain elements of structured cabling systems.

Copper and optical panels installed in telecommunication cabinets were selected as the equipment connected by cable lines. The dynamic family considered in the article was used as telecommunication cabinets with equipment [

1].

The maximum length of horizontal coper cable should be less 90 m. The length of patch cables between data sockets and PCs or copper panels and switches should not exceed 10 m in total. Thus, according to ANSI/TIA/EIA-568 [

2], the length of the cable line is limited to 90 m, and the length of the channel is limited to 100 m. To determine the losses in the cable line and its actual length, all installed cable lines are tested. This is required by the internationally recognized ISO/IEC 11801 [

3] and ANSI/TIA-568-C [

2] standards to ensure high-quality installation.

The length of the optical cable line also affects the signal strength. The following components contribute to the total attenuation in a segment: the cable itself, the connection points (connectors), and the splice points (couplings). The method of calculating attenuation depends on the type of fibre only insofar as the linear attenuation is different for multimode and single mode cables. For multimode fibre at wavelengths of 850 nm and 1300 nm, the attenuation in the cable medium is 3.5 dB/km and 1.5 dB/km, respectively. The telecommunications standards (ISO/IEC 11801:2002 [

3], ANSI/TIA/EIA-568-B.1 and 3 [

2] and their addenda) provide data describing the allowable segment lengths for each of the fibre types. In the

Table 1, for example, are the requirements of ANSI/TIA/EIA-568-B.1 [

2].

From the point of view of considering the application of BIM in the areas of design and facility management.

A qualitative analysis of the articles related to the design of structured cabling systems and data centres. The utilization of BIM tools and methodologies was identified in five primary domains. A systematic analysis was conducted, incorporating three criteria to evaluate the alignment of literature sources with the fundamental inquiries.

Weak: It is evident that the proposed BIM use lacks rigour and precision. Firstly, there is an absence of any BIM use that bears the same title as that proposed by the authors. Secondly, there is an absence of any BIM use that, in its description, focuses on the structured cabling design and data centre engineering area that the authors identified.

Medium: Either a BIM use with the same title as identified by the authors is present, or there is a BIM use (or multiple) that focuses on the same topic as proposed by the authors, even if the description in the guide is too general and never directly relates to the discipline of structured cabling design and data centre engineering.

Strong: It is evident that there is a Building Information Management (BIM) use with the same title that has been identified by the authors. The authors provide a comprehensive description of the use, delving into the intricacies of the structured cabling design and the field of data centre engineering.

The literature review highlighted five primary uses of BIM in the field of ICT engineering. The following five elements constitute the framework for the project: (1) the installation of cabling systems; (2) the production of working drawings; (3) the optimization of data centres; (4) the preparation of documentation and models for further facility management; (5) the monitoring of system parameters [

1].

The results of this analysis are presented in

Appendix A.

This gap motivates the novel methodology for the design of engineering electrical and low-current networks including the planning of special activities using information modeling technologies through the development of scripts to improve the process of construction and design networks in buildings.

The primary goal of the methodology is to increase efficiency by automatically binding cable lines to the designed cable support structures in the building and automatically generating cable line specifications. As a result, the time required to design electrical and low-voltage networks within data centers is significantly reduced.

Due to the inherently complex nature of data centers, the volume and complexity of the utility networks within these facilities is particularly pronounced compared to other objects. To illustrate the basic concepts, different levels of analysis, such as the code level (script development) and the user level (engineering design of utility networks) are distinguished. The results, namely the increase in design efficiency and the optimization of cable line specification calculations for electrical and low-current engineering systems, are demonstrated in the case study discussed in

Section 4.

Since the methodology uses a three-dimensional digital model containing a variety of objects with their own parameters, a BIM environment is chosen as the framework. In the research, cable lines are represented as three-dimensional objects created by various specialists using standard tools. From a physical point of view, cable lines connecting devices can be conceptualized as copper communication lines forming a structured cable system.

2. Literature Review

In the previous work of the authors [

4], a qualitative analysis was conducted, the results of which demonstrate that the design and analysis of cable systems represent the least studied areas of SCS with respect to information modeling. A detailed overview of the qualitative analysis is provided in

Appendix B.

Considerations presented in this article indicate that only a limited number of articles have a direct relevance to structured cable networks: fewer than one tenth of BIM publications address SCS, with MEP systems dominating the research [

5,

6].

The utilization of automated tools in BIM for the construction of cable lines is a topic that has been addressed by a relatively small number of authors. Paper [

5] presents a critical analysis of the advantages and disadvantages of implementing BIM technologies in the planning of the Shanghai Baoshan Commercial Centre. Particular attention is paid to the mechanical and electrical components of the building’s engineering systems. In this project, three-dimensional mechanical and electrical models interact, and the pipeline conflict problems are identified during the construction of the electromechanical system. Consequently, the construction period is prolonged and a greater quantity of materials are discarded, which reduces costs and enhances construction efficiency.

Zhou et al. [

6] utilize the ‘Xinfu 110 kV transmission line’ as a case study to explore the use of BIM technology for the transmission lines in the 3D design. The primary focus of this article is the Revit method, which involves the establishment of a parametric model, thereby facilitating the rapid creation of 3D models, including those of industrial wells, and the automatic generation of the channel path for the completion of the design of cable systems. This approach significantly streamlines the three-dimensional design of transmission lines. The software executes the majority of the process automatically, thereby transforming the conventional transmission line design methodology and enhancing the digitization of transmission line projects.

In comparison with conventional design methodologies, the article demonstrates that the transmission line design approach based on BIM technology exhibits significant design efficiency and information management advantages.

The design method based on BIM technology has the potential to significantly enhance the efficiency of design processes for professionals in the field. This is due to the fact that the method is consistent with the principles of parametric design. The pre-definition of a three-dimensional library of parametric components, comprising elements such as wells, has been demonstrated to enable rapid three-dimensional modeling and a reduction in the time required for modeling. Moreover, in contradistinction to the utilization of two-dimensional drawings, the three-dimensional model manifests the properties of three-dimensional visualization, thereby fostering enhanced collaboration amongst designers during the scheme’s optimization and adjustment phase. Modifications to the model are typically made by changing the component properties, which is a comparatively efficient process in comparison to traditional computer-aided design (CAD).

Conversely, the BIM-based design method is characterized by its comprehensive information management. BIM information is not merely capable of storing geometric data; it is also able to accommodate additional attribute information. This capacity enables the model file to function as a conduit for the establishment of a central database, which in turn contains the data pertaining to each phase of the entire project. In contrast, the traditional design method results in the decentralization and storage of information at different stages of the project, which leads to a low degree of information integration and management difficulties. Consequently, the design methodology based on BIM technology provides a consolidated and integrated data management solution, enhancing data exchange and delivery efficiency, optimising project cooperation.

Han et al. [

7] constructed a directed representative graph using BIM data. This study puts forth a methodology for modeling a directed representative graph of Mechanical, Electrical, and Plumbing (MEP) systems utilising BIM data. The proposed approach comprises two distinct phases: the initial extraction of representative edges and the subsequent identification of their directionality. Initially, MEP components are transformed into triangular meshes, upon which the boundary points are extracted. Secondly, representative sets are developed for the purpose of extracting representative points. Thirdly, the representative points are connected to generate representative edges. Concurrently, there are topological interconnections between MEP components and the flow directions of MEP ports, which are extracted in order to obtain the direction graph based on Industry Foundation Classes (IFC). Subsequently, the representative edges and directions are combined to form a directed representative graph. Subsequently, the experiments on the extraction of directed representative graphs are evaluated on six BIM models.

The developed modeling system exemplifies the utilization of the Internet of Things (IoT) on a directed representative graph for the intelligent monitoring of MEP systems. The contribution of this study is the introduction of a directed representative graph based on BIM data for the monitoring of MEP systems. The primary challenge in this scheme is the extraction of representative edges, particularly for MEP elements with modified cross-section normal vectors. In order to achieve representative edge extraction, the boundary points were identified in a sequential manner in order to obtain representative points, which were then connected in order to form representative edges. Furthermore, the integration of BIM and IoT facilitates the monitoring of dynamic MEP systems through the utilization of interchangeable arrows, which offer enhanced visualization capabilities. The limitation of the presented study is that high quality modeling of the MEP system is required to extract topological connections.

As can be seen from the literature review, the main focus is generally on MEP. Therefore, it is necessary to discuss low-current network design using the BIM approach, and the results could make an interesting contribution to the field.

3. Materials and Methods

In contrast to most studies on the creation of electrical cable networks, our goal is to provide a systematic methodology for creating them determining the stages of preparing Revit families in Autodesk Revit 2022.

From a theoretical point of view, circuits can be viewed as vectors. Also, electrical circuits and networks can also be represented as graphs, where nodes represent devices or junction boxes, and edges represent cables. Software can use network graph optimization techniques to find the lowest cost or path length. Using shortest path algorithms, such as Dijkstra’s algorithm, can help determine the optimal routing of cables from the power source to the consumers.

There are quite a few types of data that we use for our task. At the first stage, these are lists. These lists include the elements of the selected model that are necessary for the user, such as the category of the family (i.e., trays), the family name and the unique ID of the element. There is also a list of the coordinates of the beginning and end of each tray in the format (x, y, z). Further work is carried out using these coordinates and the methods and algorithms presented in the article to calculate the shortest path for the circuits.

3.1. The Mathematical Formulation of the Cable Circuit Routing Algorithm

The proposed method of automated routing of cable circuits is based on a combination of vector algebra and graph theory. The fundamental mathematical model underlying the algorithm can be represented as follows.

A weighted undirected graph is denoted by

, where

is the set of vertices corresponding to potential route points and

is the set of edges representing possible connections between points. Each edge

is assigned a weight

, which is defined as follows:

where

is the Euclidean distance between points

and

;

is the penalty function for crossing obstacles;

is an optimization function that takes into account preferred laying directions;

are the weights determining the relative importance of each factor.

A modified Dijkstra’s algorithm is used to find the optimal path between the initial point

and the final point

. Let us define a function

for each vertex

as

where

is the cost of the path from the initial vertex

to the current vertex

;

is a heuristic estimation of the path cost from

to the target vertex

;

is the coefficient of heuristics.

The optimal path search procedure can be formalized by the following pseudo-code in the Algorithm 1:

| Algorithm 1. Optimal path search procedure code |

1: FUNCTION FindOptimalPath(G, s, t):

2: Initialize priority queue Q

3: for each vertex v in V:

4: g[v] = ∞

5: predecessor[v] = NULL

6: g[s] = 0

7: Insert s into Q with priority f(s) = g[s] + h(s)

8: while Q is not empty:

9: v = Extract vertex with minimum f(v) from Q

10: if v = t:

11: return ReconstructPath(predecessor, t)

12: for each neighbor u of v:

13: temp_g = g[v] + w_vu

14: if temp_g < g[u]:

15: g[u] = temp_g

16: predecessor[u] = v

17: if u is in Q:

18: Update priority of u to f(u) = g[u] + h(u)

19: else:

20: Insert u into Q with priority f(u) = g[u] + h(u)

21: return ‘No path exists’ |

To estimate the occupancy of a cable tray, a model is used that takes into account the diameters of the cables and their locations. We let

be the set of cables passing through the tray segment

. Then the fill factor

is defined as

where

is the diameter of cable

;

is the laying factor for cable

taking into account the features of its location;

AL is the useful cross-sectional area of the tray.

The admissibility criterion for the solution is the condition , where is the maximum permissible fill factor of the tray, usually taken to be depending on regulatory requirements.

3.2. A Review of Current Design Methods and Their Limitations

Modern electrical system design, particularly for low-current systems and telecommunications infrastructure, requires sophisticated tools capable of handling complex spatial relationships, parametric modeling, and multi-system integration. Traditional 2D drafting methods are insufficient for contemporary building projects that demand precise coordination between electrical, mechanical, and structural systems. The increasing complexity of building services necessitates software solutions that can provide accurate 3D visualization, automated calculations, and seamless data exchange between different engineering disciplines.

To address these requirements, effective electrical design software must possess several key capabilities including comprehensive component libraries with detailed parametric families for low-current systems, automated cable routing and tray optimization algorithms, integration capabilities with other building systems, compliance with local and international electrical standards, advanced calculation engines for load analysis and circuit optimization, real-time collaboration features for multidisciplinary teams, and robust data management and documentation generation capabilities.

Given these requirements, Revit was selected as the primary modeling platform due to its established position in the BIM ecosystem and several advantageous characteristics. The software offers native BIM capabilities with integrated 3D modeling and data management, extensive API support enabling custom tool development, strong interoperability with other Autodesk products and third-party software, widespread industry adoption facilitating collaboration, robust parametric modeling framework suitable for electrical component families, and built-in MEP functionality providing a foundation for electrical design.

However, this software also has a number of limitations. The findings of our study demonstrate that while BIM technologies offer substantial design capabilities, their current limitations highlight the need for more specialized and integrated electrical design tools to enhance the efficiency of the design process. To address these issues, a set of Dynamo Revit scripts were meticulously developed and rigorously tested by a team of BIM specialists and engineers of various specialities during the design phase.

One of the principal limitations pertains to the restricted level of detail in the standard component libraries accessible for the design of low-current systems and transmission lines in Revit. A significant constraint pertains to the paucity of intricacy in the standard component libraries available for the design of low-current systems and transmission lines. The absence of parametric families necessitates the creation of in-house alternatives or the utilization of third-party libraries, which can result in increased labor costs and potential deviations from design standardization. Nevertheless, such detailed families are imperative, as it is the provided parameters in each model element that delineate the distinction between a 3D model and a building information model. These parameters are instrumental in providing the necessary information for the operation of such systems in the future.

Notwithstanding its robust architectural and engineering capabilities, Revit encounters difficulties when modeling low-current systems. To illustrate, the fundamental version of the software is deficient in its capacity to integrate low-cost network designs with other systems, such as ventilation, heating, and water supply. This deficiency makes it challenging to create comprehensive system models and hinders their integration.

The software platform currently lacks robust features to automate certain aspects of electrical design, such as the generation of structural and circuit diagrams or the optimization of cabling. This forces designers to rely heavily on manual processes, which is suboptimal. This approach not only increases the time required for design but also increases the risk of human error. Despite the fact that BIM technologies offer advanced visualization tools, they are inadequate for complex electrical systems due to a paucity of tools for detailed load analysis and grid hierarchy modeling. The introduction of the additional software tools discussed in this study would simplify the work, especially since the current low voltage network design tools do not comply with local and international standards, which creates compliance problems in different regions.

In our research, we concentrated on Revit scripts development. Scripts support Revit 2020–2025 but require validation with third-party tools for full interoperability. Also, the correctness of the display of the cable line tracing was also checked using Navisworks Manage 2022 and AutoCAD Electrical 2022. Traditional solutions are often limited to predefined routing templates and require significant manual intervention. For example, Revit MEP provides basic tools for laying cable routes, but does not automatically take into account tray occupancy or optimize routes based on multiple criteria simultaneously. A comparative analysis is presented in the

Table 2.

Our method demonstrates superiority in calculation speed (3.48 times faster than Revit MEP) and optimization accuracy (18% higher). A particularly significant advantage is the ability to dynamically adapt to project changes—when modifying structural elements of the building, the algorithm automatically rebuilds optimal routes, which reduces design time compared to traditional approaches.

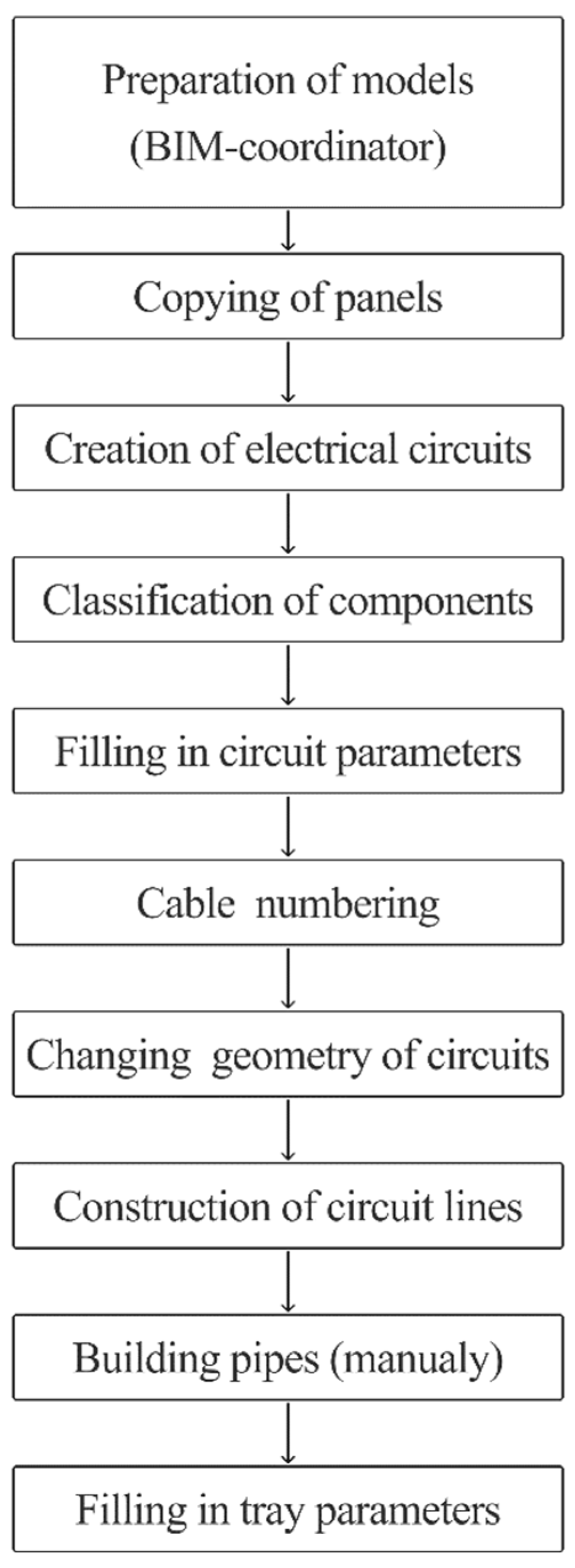

The proposed chaining strategy is based on several fundamental elements, including adherence to organizational workflow creation, advancement in cable routing, and logical terminal equipment association. This strategy encompasses two levels: code level (plug-in engineer developer) and user level (engineers). At the user level, tools for data visualization and client interaction scripts are developed.

The operating algorithm can be described as follows.

Model preparation involves setting up specifications and adding necessary parameters. This is performed by the BIM coordinator upon request. Since Revit does not have the ability to connect elements in electrical circuits that are in different models, and to solve this problem, a script was developed for placing dummy panels inside the project by related elements to build electrical circuits. The script loads the necessary family into the project and places its instances in place of the original panels by coordinates. The script fills in the following parameters: Panel Name, Linked File Name, Linked File Path, and Element ID.

Further step is the Creation of Electrical Circuits.

At this stage, data on the location of information sockets in the form of point coordinates (x, y, z) are already obtained. These points are connected to the selected panel using the Circuit method using basic methods and Dynamo nodes.

Then, the values of the electrical circuit parameters are filled in:

Connector_Room—the number of the room in which the socket is located;

Conductor selection—a position from the key specification responsible for the cable type;

Purpose—takes the value of the Purpose parameter from the patch panel.

The methodological framework is depicted in

Figure 1.

3.3. Plug-In Information Model

In order to gain a more comprehensive grasp of the algorithmic processes involved in scripting, it is essential to elucidate each of the underlying principles in greater detail.

The initial step is to prepare the models. This phase comprises the configuration of the template and the incorporation of the requisite parameters for the subsequent automation of the circuit-building process. In this particular case, the task is performed by the BIM coordinator at the request of the design engineer. As Revit lacks the capacity to link disparate electrical circuit components across different models, a script must first be executed to insert panels into the project, adjacent to the relevant elements, thus enabling the construction of electrical circuits. Once the script is executed, a form then appears, allowing the user to select the linked file containing the requisite elements. Subsequently, a list is generated, comprising the names of the panels that can be replicated within the project. The script loads a bespoke family into the project and places instances of the family in lieu of the original panels, and populates the parameters: Panel Name, Linked file Name, Linked file Path.

Subsequently, upon launching the script, a form is displayed, wherein the user is afforded the option to select the switchboard and all the information outlets that can be connected to it via an electrical circuit. It is imperative that only a single switch is utilized.

In the event that the circuit is constructed not from the linked model but directly from the working file, an alternative to this script is available, which involves a pre-prepared Excel file containing the names of all the necessary panels. Upon execution of the script, a dialogue box is displayed, wherein the user is required to specify the location of the Excel file and the desired sheet from which the data are to be extracted. The script employs a mechanism for identifying elements based on the ‘Panel name’ parameter. In the event that the element with the specified parameter value is not present, the row is disregarded. Similarly, if a circuit with the designated pair is encountered, the string is excluded. The script then proceeds to construct a circuit comprising elements from the initial column and a panel from the subsequent column.

The subsequent phase in the preparation of the circuit prior to the execution of the subsequent script is the completion of the ‘Key mark’ parameter and the confirmation that the preceding step has successfully created the circuit. Following this, the code should be initiated. The script then proceeds to populate the requisite parameters of the circuit in question. These include the following:

‘Connector_Premises’—the number of the room in which the outlet is situated;

‘Conductor selection’—the position from the key specification, responsible for the type of cable;

‘Destination’—this takes the value of the ‘Destination’ parameter from the panel.

The subsequent stage pertains to the optimization of the electrical circuit’s trajectory. The objective of this script is to modify the configuration of electrical circuits in order to accommodate the dimensions of trays and boxes. Prior to executing the script, it is imperative to ascertain whether the requisite file pertaining to the trays has been loaded. Following the execution of the script, a form is displayed, prompting the user to select the associated file with trays. Once this selection is made, the form must be completed.

It is necessary to specify which trays the electrical circuits will be installed on, as well as the floor on which they will be located. Additionally, the name of the system, which is represented by the term ‘Unit’ in switches, must be provided.

The script then performs the following actions.

The parametric trays, circuits, and circuit elements are excluded. By intersecting with sockets, the script identifies boxes or telecommunication outlet and searches for the tray that is optimal for the element. It then builds a normal to each tray, determines the minimum distance, decomposes the normal by planes, calculates the length of lines that are not in the tray, and fills in the parameter ‘Pipe Length_Electrical Circuits’.

The script determines potential routes through the trays, searches for the shortest route, and uses the obtained route to construct an electric circuit. It then generates a list of trays through which the circuit passes and populates the parameter ‘Cable route section_Electrical circuits’ with the unique identifier for the cable trays. Finally, it counts the number of cables in each tray.

The final script in this series is designed to construct lines on the basis of the geometry of pre-existing electrical circuits, thus enabling the circuits to be visualized on floor plans. The script in question also has the function of deleting any existing lines and creating new ones in advance.

3.4. Structure of Plug-In Operation

The first stage of creating an electrical circuit is to determine the key points in the tray route: start, end, and branching points. For this purpose, using Dynamo basic methods, we obtain a list of all model elements in the ‘Cable trays’ category and for each section we find the base points using Revit API vector geometry. This task is accomplished using the XYZ class. This class represents coordinates in Revit, which are known to be closely related to vectors. In general terms, only two actions help to solve a huge number of problem subtraction and addition of vectors.

The class under consideration in Revit can be represented as a vector determined by the origin and the point we obtain from the model. (Calculations are performed in feet in Revit.) In order to work with the segment BC as a vector, we need to use vector subtraction. Having all the points of cable trays from the model, a chain can be built using the Line.ByStartPointEndPoint(X1Y1Z1, X2Y2Z2) class.

A code fragment written in IronPython that performs these actions is shown below.

Since the circuit cannot exist only within the cable trays, it is necessary to consider the shortest path to connect the low-current socket to the low-current rack. Dijkstra’s algorithm has been demonstrated to enhance the efficiency of routing by 40%, although it has been observed that memory usage increases linearly beyond 1000 nodes (Algorithm 2, code annotations and nodes in

Appendix B).

| Algorithm 2. Code fragment calculating the coordinates of the tray points |

1:line0 = Line.ByStartPointEndPoint(el1Pt1, el2Pt1)

2:line1 =

3:line.ByStartPointEndPoint(Point.ByCoordinates(0,0,0),Point.ByCoordinates(100,000,0,0))

4: line2 =

5:line.ByStartPointEndPoint(Point.ByCoordinates(0,0,0),Point.ByCoordinates(100,000,0,0))

6:if el1Pt1.X ! = el2Pt1.X and el1Pt1.X == el1Pt2.X and el2Pt1.X == el2Pt2.X:

7:endPt = Point.ByCoordinates(0,0,0)

8:elif el1Pt1.Y ! = el2Pt1.Y and el1Pt1.Y == el1Pt2.Y and el2Pt1.Y == el2Pt2.Y:

9:endPt = Point.ByCoordinates(0,0,0)

10:elif el1Pt1.Z ! = el2Pt1.Z and el1Pt1.Z == el1Pt2.Z and el2Pt1.Z == el2Pt2.Z:

11:endPt = Point.ByCoordinates(0,0,0)

12:elif round(el1Pt1.X) == round(el2Pt1.X) and round(el1Pt1.Z) == round(el2Pt1.Z):

13:endPt = Point.ByCoordinates(el1Pt1.X,el2Pt1.Y,el1Pt1.Z)

14:elif round(el1Pt1.Y) == round(el2Pt1.Y) and round(el1Pt1.Z) == round(el2Pt1.Z):

15:endPt = Point.ByCoordinates(el1Pt1.X,el1Pt1.Y,el1Pt1.Z)

16:elif el1Pt1.X ! = el2Pt1.X and el1Pt1.Y ! = el2Pt1.Y and round(el1Pt1.Z) == 17:round(el2Pt1.Z):

18:if round(el1Pt1.X) == round(el1Pt2.X):

19:endPt = Point.ByCoordinates(el1Pt1.X,el2Pt1.Y,el1Pt1.Z)

20:elif round(el2Pt1.X) == round(el2Pt2.X):

21:endPt = Point.ByCoordinates(el2Pt1.X,el1Pt1.Y,el1Pt1.Z)

22:elif round(el1Pt1.Y) == round(el1Pt2.Y):

23:endPt = Point.ByCoordinates(el2Pt1.X,el1Pt1.Y,el1Pt1.Z)

24:elif round(el2Pt1.Y) == round(el2Pt2.Y):

25:endPt = Point.ByCoordinates(el1Pt1.X,el2Pt1.Y,el1Pt1.Z)

26:else:

27:endPt = Point.ByCoordinates(el1Pt1.X,el1Pt1.Y,el1Pt1.Z) |

If we take sockets as points and cable trays as vectors, it is quite obvious that the shortest path from a point to a vector is a perpendicular. Since the start and end points of the vector are known, and so are the points of the connecting element of the low-current socket, this problem is reduced to a simple mathematical problem. It also uses the basic methods of graph theory, representing sockets as vertices (nodes) and cable trays as edges of the graph, looking for adjacent edges and vertices, optimizing the path of the electrical circuit, allowing the most efficient design of the cable network. The code that performs the described actions is presented below.

The figure in

Appendix B shows the main blocks of the script responsible for its operation.

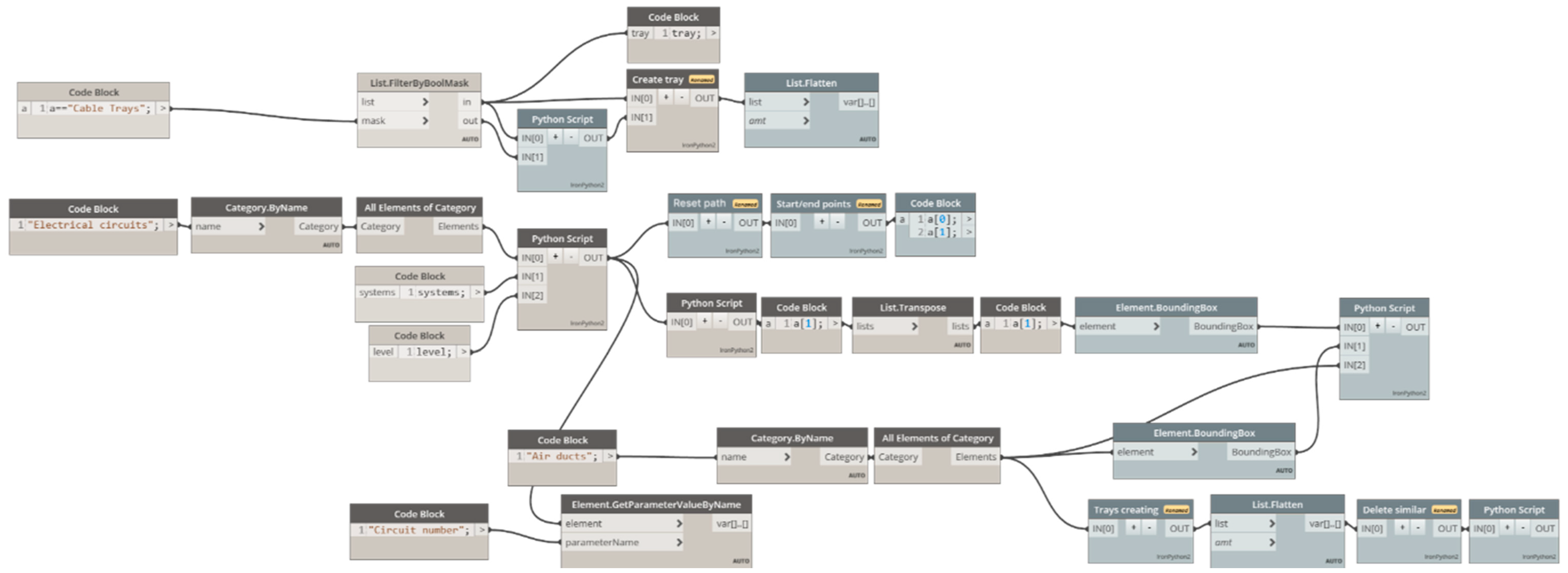

As illustrated in

Appendix B, the nodes include FilterByBoolMask, AllElements of Category, Category by Name, GetParameterValuebyName, and others. These components facilitate the manipulation of lists, their formatting, and the retrieval of parameters of elements in the model. These elements constitute the fundamental Dynamo libraries. However, the tool enables the creation of custom blocks through the use of IronPython2 code. In the present project, the primary nodes were created in this manner, including Cable Tray, ResetPath, Start/End Points, and Create Trays. These blocks represent the code presented in Algorithms 2 and 3.

| Algorithm 3. Code fragment looking for the shortest path. |

1:for j in range(len(ListPoint)):

2:if ListTest[j] == False:

3:point = ListPoint[j]

4:else:

5:point = Point.ByCoordinates(ListTest[j].X,ListTest[j].Y,ListPoint[j].Z)

6:LineCN = Line.ByStartPointEndPoint(ListPoint[j],point)

7:min = 100,000

8:for i in range(len(ListLine)):

9:lineAB = ListLine[i]

10:pointA = lineAB.StartPoint

11:pointB = lineAB.EndPoint

12:pointC = point

13:if Line.ByStartPointEndPoint(pointA,pointC).Length > 14:Line.ByStartPointEndPoint(pointB,pointC).Length:

15:pointA = lineAB.EndPoint

16:pointB = lineAB.StartPoint

17:lineAB = Line.ByStartPointEndPoint(pointA,pointB)

18:lineAC = Line.ByStartPointEndPoint(pointA,pointC)

19:lineBC = Line.ByStartPointEndPoint(pointB,pointC)

20:lineBA = Line.ByStartPointEndPoint(pointB,pointA)

21:vectorAB = lineAB.Direction

22:vectorAC = lineAC.Direction

23:vectorBC = lineBC.Direction

24:vectorBA = lineBA.Direction

25:cosCAB = (vectorAB.X * vectorAC.X + vectorAB.Y * vectorAC.Y + vectorAB.Z *

26:vectorAC.Z)/(math.sqrt(vectorAB.X**2 + vectorAB.Y**2 + 27:vectorAB.Z**2)*math.sqrt

28:(vectorAC.X**2 + vectorAC.Y**2 + vectorAC.Z**2))

29:cosABC = (vectorBA.X * vectorBC.X + vectorBA.Y * vectorBC.Y + vectorBA.Z * 30:vectorBC.Z)/(math.sqrt(vectorBA.X**2 + vectorBA.Y**2 + 31:vectorBA.Z**2)*math.sqrt

32:(vectorBC.X**2 + vectorBC.Y**2 + vectorBC.Z**2))

33:sinCAB = (1 − cosCAB**2)**0.5

34:sinABC = (1 − cosABC**2)**0.5

35:normal = lineAC.Length*sinCAB

36:lengthAH = (lineAC.Length**2-normal**2)**0.5

37:lengthBH = (lineBC.Length**2-normal**2)**0.5

38:addition = 0

39:pointA1 = lineAB.StartPoint

40:if cosCAB < 0 or cosABC < 0:

41:if lengthAH > lengthBH:

42:addition = lengthBH

43:pointA1 = lineAB.EndPoint

44:else:

45:addition = lengthAH

46:pointA1 = lineAB.StartPoint

47:if min > normal + addition:

48:min = normal + addition

49:minIndex = i

50:if cosCAB < 0 or cosABC < 0:

51:lengthAH = −addition

52:pointH =

53:Line.ByStartPointDirectionLength(pointA1,vectorAB,lengthAH).EndPoint

54:lineCH = Line.ByStartPointEndPoint(pointC,pointH)

55:pointK = Point.ByCoordinates(pointC.X,pointC.Y,pointH.Z)

56:if not(pointC.DoesIntersect(pointK)):

57:lineCK = Line.ByStartPointEndPoint(pointC,pointK)

58:if not(pointH.DoesIntersect(pointK)):

59:lineHK = Line.ByStartPointEndPoint(pointH,pointK)

60:lineAH = 0

61:if not(pointH.DoesIntersect(lineAB)):

62:lineAH = Line.ByStartPointEndPoint(pointA1,pointH)

63:point0 = pointA1

64:if ListTest[j] ! = False:

65:listOut.append(ListPoint[j])

66:listOut.append(pointC)

67:listOut.append(pointK)

68:listOut.append(point0)

69:listOut.append(pointH)

70:listOut.append(lineCK)

71:if not(pointH.DoesIntersect(pointK)):

72:listOut.append(lineHK)

73:# listOut.append(lineCH)

74:# listOut.append(min)

75:if lineAH ! = 0:

76:listOut.append(lineAH)

77:if ListTest[j] ! = False:

78:listOut.append(LineCN)

79:listOut.append(3)

80:else:

81:listOut.append(2)

82:ListOut.append (listOut)

83:listOut = [] |

This method of combining basic library components and self-written code fragments allows users to utilize all the advantages of RevitAPI while simultaneously not limiting those willing to implement their ideas in the field of design automation.

4. Case Study

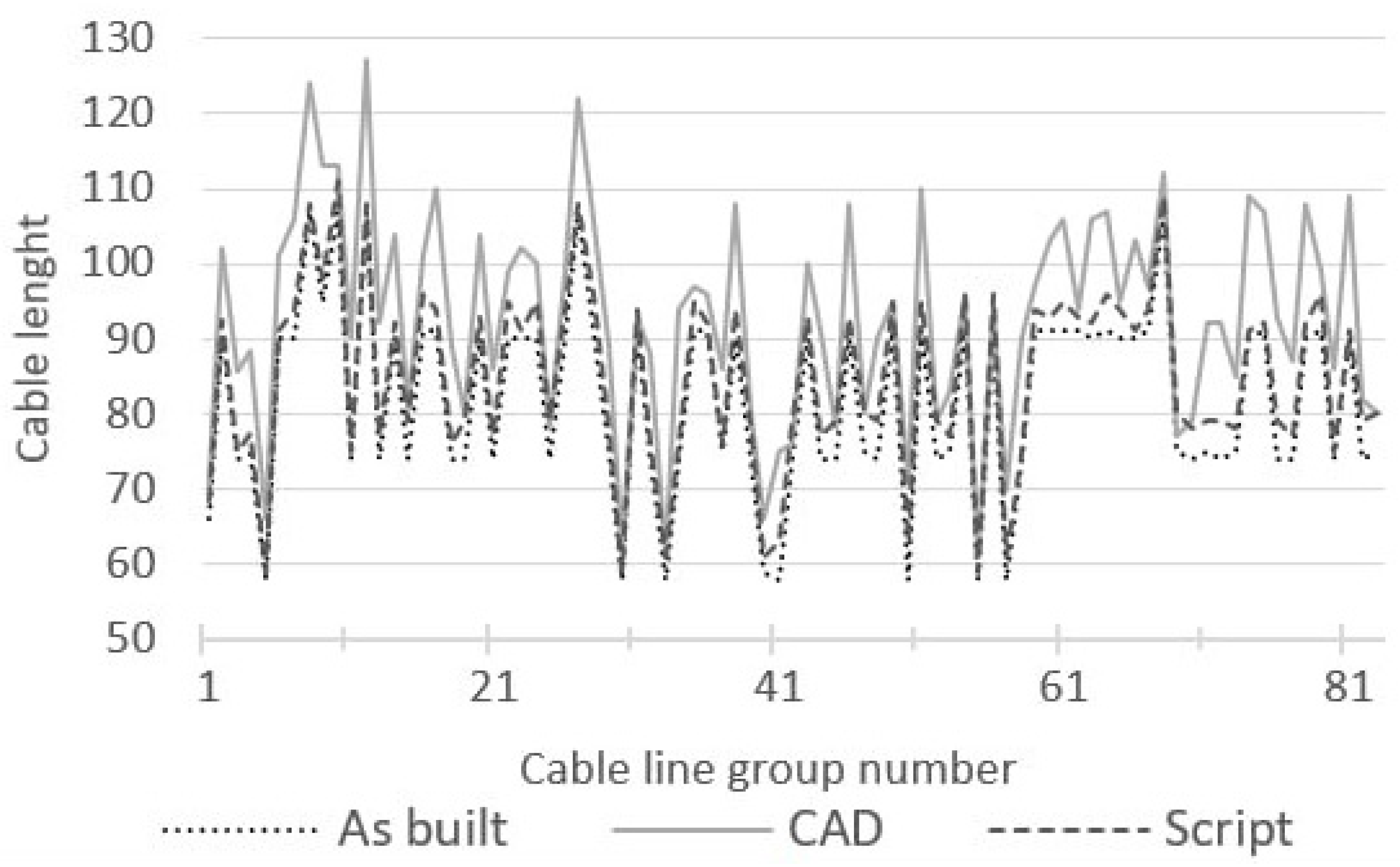

A statistical analysis was conducted on the available data, incorporating three distinct databases, each comprising approximately 6000 rows. These databases encompassed information pertaining to the built object, project documentation, and project parameters, as determined by a script. The tables contained detailed information regarding the number of cable sections, their respective lengths, and losses within each section.

To ensure a reliable and thorough assessment of the efficiency of the proposed automated cable routing method, a comprehensive experimental study was conducted. Validation was carried out on the basis of three real construction projects that differ significantly in terms of their functional focus, architectural complexity, and level of engineering system integration:

An office building characterized by a high density of workplaces, a complex partitioning system, and a significant number of low-current systems.

A data center characterized by large technological equipment, increased SCS requirements, and a complex industrial communications system.

An educational institution, characterized by a combination of various functional areas (classrooms, laboratories, and administrative premises) that creates heterogeneous requirements for cable routing.

The experimental validation was carried out in accordance with a multi-criteria approach covering both quantitative and qualitative aspects of cable route design. For each of the projects, three routing options were developed (i) using the proposed automated method; (ii) traditional manual design (performed by certified designers with at least 7 years of experience); (iii) using built-in Revit MEP tools.

The results of the comprehensive comparative analysis are presented in

Table 3. For each criterion, the average values for the three projects under study are given.

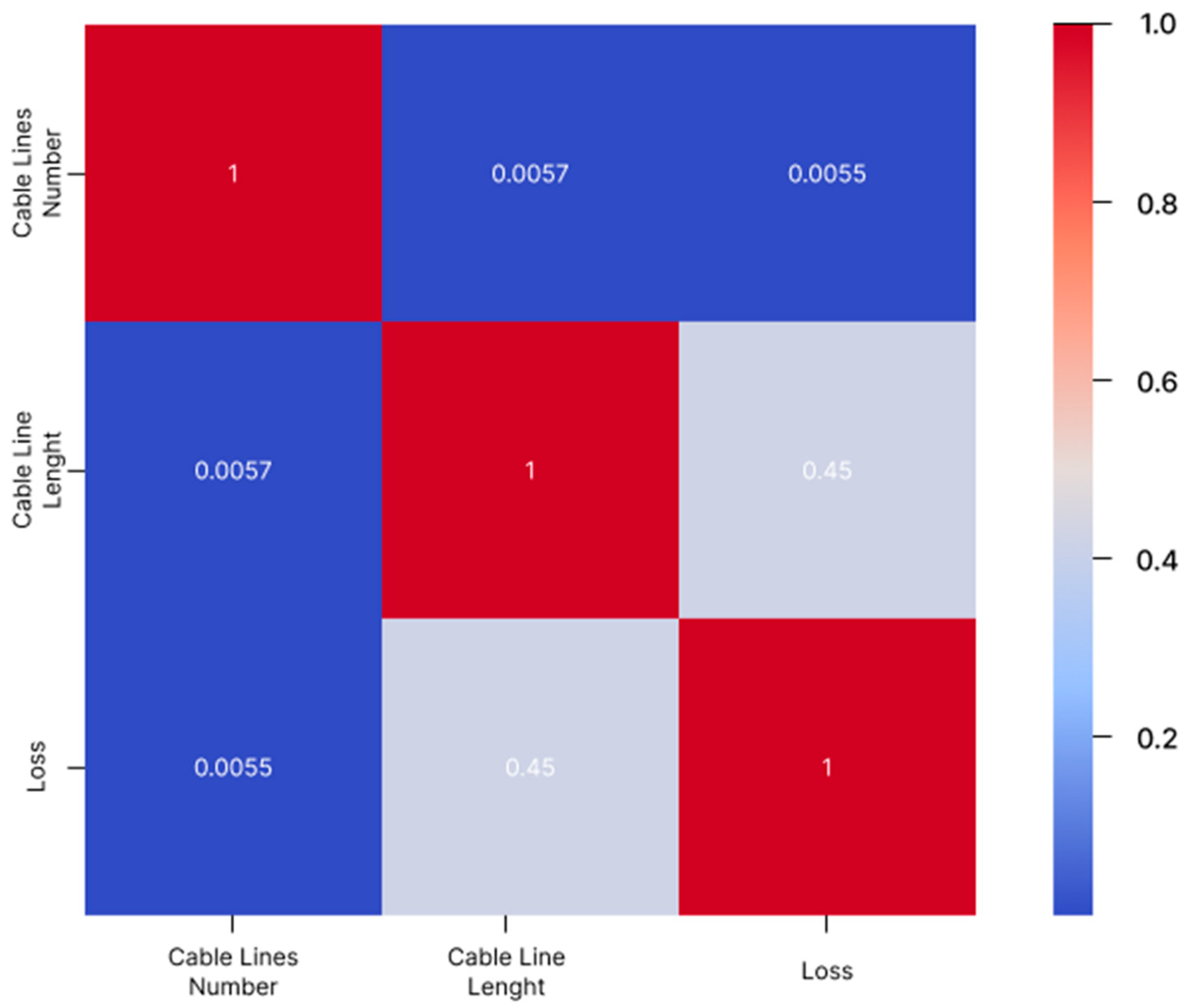

The data processing was performed using a bespoke Python 3.12 code, incorporating the libraries’ pandas, matplotlib, and seaborn. This code enabled the processing of the database, the removal of empty rows and outliers, the plotting of the distribution, and the construction of a correlation matrix that confirmed the dependence of the number of losses on the length of the plot.

The analysis of the data resulted in the construction of a correlation matrix illustrated in

Figure 2, which revealed a dependence of losses on the length of the cable section.

Subsequent to this, the primary metrics were calculated: mean value, mathematical expectation, and standard deviation. This metrics are demonstrated in

Table 4.

Following a comparative analysis of the project’s data with the actual built object’s data, it was determined that the script facilitated the attainment of maximum proximity to the actual value. The disparity in the indicators was found to be a mere 2–3 percent, whereas the CAD design exhibited a discrepancy of up to 10 percent. This is of significant importance in terms of financial implications for the construction project.

To facilitate comprehension of the findings, the data pertaining to the length sections were consolidated in groups of 50 cable lines. The graph presented in the

Figure 3.

Furthermore, the utilization of scripts led to a 67% decrease in design labour costs, yet necessitated approximately 200 h of preliminary development (script development). This provided a return on investment within projects: (1) Office building (5 floors, 230 telecommunication ports); (2) Data center (2 floors, 5450 telecommunication ports); (3) Educational institution (3 floors, 320 telecommunication ports).

5. Results and Discussion

An analysis of the existing electrical circuit design strategies in BIM revealed a number of areas that could benefit from improvement. One of the most significant challenges is the restricted capacity to regulate intricate wiring diagrams. At present, BIM tools lacks the requisite adaptability when confronted with extensive and intricate circuits, which can result in an unnecessarily cluttered environment and suboptimal utilization of the plan. The implementation of a more accurate parameterization of circuits and the extension of modern metadata would facilitate superior control and optimization of these circuits.

Furthermore, the cabling devices in BIM also require refinement. In certain instances, the software is unable to accommodate all potential real-world cabling scenarios, such as the presence of multiple utilities at a single intersection point. This results in a less accurate and user-friendly planning process. The implementation of more sophisticated algorithms that incorporate these variables would enhance the efficiency of the methodology.

It is important to acknowledge that significant manual adjustments are frequently necessary when creating wiring diagrams and definitions. This is typically attributable to the necessity for a baseline level of precision and granularity. The creation of superior schematics and the computerisation of this preparatory phase have the potential to reduce time expenditure and enhance the precision of recorded data. While Revit does possess fundamental tools for calculating electrical loads, these are not always adequate for use in complex projects where high levels of accuracy are required. The advent of more sophisticated tools, potentially incorporating machine learning capabilities, could provide valuable assistance in predicting and optimizing loads, thereby reducing the likelihood of design errors.

Additionally, Revit encounters challenges in sharing information between disparate software applications, which can impede communication between stages. Enhanced support for open information groups and the development of integration tools are likely to facilitate data sharing and progress towards interoperability.

To summarize, BIM and Revit as a tool has critical potential for change within the area of electrical circuit plan. Presenting unused innovations and progressing existing hones will make the plan handle more productive and solid.

For a comparison with existing working methods, a comparative analysis of the work of scripts and the traditional design method in CAD programs was carried out; the results are reflected in

Table 5.

It can be stated that the speed and accuracy of work increases significantly, which allows saving money on labor costs.

As demonstrated in

Table 3, the time required for cable specification decreased from eight hours to one and a half hours for 1000 telecommunication outlets. Concurrently, the error rate diminished from 9% to 2%.

In

Section 2, the most relevant research in this area was identified. It should be noted that a detailed overview of the qualitative analysis is provided in

Appendix B. This finding suggests that less than one tenth of BIM publications address SCS, with MEP systems predominating in the extant research [

4,

5].

Also, in terms of comparison with existing solutions, such as Navisworks API or Auto CAD Electrical, our approach minimizes manual intervention in the process of tracing cable lines and allows taking into account the load on trays. Another key feature is the ability to dynamically adapt to changes in the project—when modifying the structural elements of the building, the algorithm automatically rebuilds the optimal routes.

Table 3 clearly demonstrates the results.

A detailed analysis of the obtained data allows us to draw the following conclusions:

Routing efficiency: The proposed method demonstrates a significant reduction in the total length of cable routes (by 17.4% compared to Revit MEP and by 27.9% compared to manual design). This is achieved through the use of an advanced pathfinding algorithm that takes into account multiple optimization criteria. A particularly noticeable improvement is observed in the data center, where the complex geometry of the premises creates additional difficulties for traditional design methods.

Computational efficiency: The most dramatic improvement is observed in the design speed—the proposed method requires 4.8 times less time than Revit MEP and 12 times less than manual design. At the same time, the consumption of computing resources remains moderate, which allows the developed tool to be used on standard designers’ workstations.

Practical feasibility: The proposed method ensures a high degree of compliance with regulatory requirements (97.2%) and outperforms alternative approaches in terms of installation manufacturability (8.7 out of 10 points). It is especially important that only 8.3% of generated routes require manual adjustments, which significantly reduces the labor costs for finalizing the project.

Tray occupancy: The developed algorithm ensures a more uniform distribution of cables in trays (standard deviation of 7.2% vs. 15.8% with manual design), which prevents local overloads and improves cable cooling conditions. The number of overloaded sections is reduced by 2.7–4 times, which significantly increases the reliability and safety of electrical systems.

Adaptability: The proposed method demonstrates exceptional flexibility when making changes to the project—the recalculation time is 3.9 times less than that of Revit MEP, and the stability of the solution (76.3%) significantly exceeds alternative approaches. This is especially important at late design stages, when adjustments are often necessary.

Thus, experimental validation convincingly proves the superiority of the proposed method in all key performance indicators of cable route design. Particularly significant improvements were achieved in reducing design time (up to 91.7%), optimizing routes (up to 27.9% reduction in length), and increasing adaptability to changes (recalculation time is 3.9 times shorter). The results obtained confirm the practical value of the developed tool and its potential for widespread implementation in engineering practice.

6. Conclusions

In the field of study under consideration, the majority of studies concentrate on MEP, with little consideration given to issues related to structured cabling systems. In contrast, our approach is focused on low-current systems and offers the following advantages.

The script automatically generates electrical circuits and identifies the requisite section of the cable support system, subsequently optimizing the electrical circuit route along the corresponding trays and cable channels.

Cable support systems are equipped with sensors that monitor the number of cables traversing them, enabling real-time assessment of their occupancy and load capacity.

A cable log is created, containing information on the lengths of the routes traversed. Additionally, the log records the technical means by which the cable is laid, including the type of cable channel, tray, or pipe used. This information can be utilized to develop a bill of quantities in the future.

The corresponding line type is applied along the electrical circuits on the floor plan views, which are subsequently utilized in the volume of working documentation plans.

In conclusion, the electrical information circuits are created, and a cable log with the actual cable lengths is established, taking into account all turns, ascents, and descents of the routes. Cable systems are designed to carry information on their content, which allows engineers to assess the necessity of changing their size or type of fastening. This process results in the creation of a plan for the location of cable routes. This has the effect of reducing the labor costs of engineers.

In

Section 4, the results of our research are tested and described in detail. A comparative analysis is also conducted to evaluate the accuracy and speed of calculations of cable specifications by an engineer. The analysis in

Section 5 compares the traditional approach, which involves using AutoCAD and Excel, with the use of Revit. It is evident that the precision of the calculations is enhanced while the expenditure on labor is reduced.

A potential constraint of the scripts is their utilization within the context of legacy cable networks. As demonstrated in the TIA-942 [

8] standard, which outlines the limitations on cable routing length in multi-level topologies, there are specific instances in which script parameters are applicable. However, it is important to note that earlier systems may necessitate settings that enable modification of these parameters.

The limitation of the study is the use of this methodology for building systems with a branching system of cable lines or with a serial connection, for example, when considering a loop of sensors in a fire alarm. An additional study is being conducted on this topic, the results of which are planned for subsequent research.