Abstract

The present study intends to assess the ratcheting response of SA508 and SA333 steel alloys subjected to asymmetric loading cycles at various operating temperatures of 298, 573, and 623K through a hardening framework developed by Ahmadzadeh–Varvani (A-V) and the finite element analysis structured by the Chaboche hardening model (CH) in the ANSYS software program. The dynamic recovery terms in the A-V and CH hardening framework consisted of temperature-dependent parameters and functions to address the dynamic strain aging (DSA) phenomenon at high temperatures of 573 and 623 K. The DSA phenomenon reported at elevated temperatures was attributed to the interactions of solute atoms and dislocations with a certain temperature, resulting in higher material strength and lower ratcheting deformation. The coefficients of these frameworks were analytically determined through stress–strain hysteresis loops obtained from the strain-controlled cyclic tests. The FE analysis was applied to numerically evaluate backstress evolution through use of the CH model. Two popular nonlinear brick and tetrahedron element types were examined to study the convergence of the elemental system with various numbers of elements. This ensured the independence of the simulated results from the number of elements and their convergence. The simulated ratcheting responses for brick and tetrahedron solid elements were compared to those predicted analytically by the A-V hardening rule and experimentally measured values. The predicted and simulated ratcheting data were found to be in good agreement with the measured data. The predicted and simulated ratcheting results generated using the A-V and FEA approaches showed values of 0.96 and 0.85, respectively, when compared with the experimental data.

1. Introduction

Engineering components used in critical applications such as offshore platforms, pressure vessels, and aircraft landing gears are frequently exposed to cyclic loading, which can lead to catastrophic failure due to the gradual accumulation of plastic strain over repeated loading cycles. Failure in such systems is primarily caused by the irreversible inelastic progressive deformation that develops under asymmetric stress loading. This time-dependent buildup of plastic deformation under asymmetrical stress-controlled conditions is referred to as the ratcheting phenomenon. The ratcheting response of a material is strongly affected by several factors, including its microstructural characteristics, applied stress levels and rates, operating temperature, loading sequence, and step patterns [1]. Elevated temperature service conditions tend to intensify the ratcheting behavior of materials, except in certain intermediate temperature ranges, where the dynamic strain aging (DSA) phenomenon occurs and alters the response of the material temporarily [1,2].

The dynamic strain aging (DSA) phenomenon happens in some steels, including SA333 and SA508, in which the mechanical response of the material is influenced by both temperature and strain rate during material deformation. The key signs of dynamic strain aging are the presence of serrated flow or yield point elongation in the stress–strain curve, which indicates localized fluctuations in flow stress [3]. The DSA event can also be identified through other patterns, such as peaks or plateaus in strength versus temperature curves, dips in ductility with increasing temperature, and the onset of negative strain rate sensitivity (SRS) [4]. In C-Mn steels, DSA occurrence is often attributed to interactions between dislocations and solute atoms such as carbon and nitrogen [5,6]. These elements diffuse toward dislocations at elevated temperatures and form solute atmospheres that hinder the mobility of dislocations through the process of pinning [7,8]. Karimi and Varvani-Farahani [9,10] explored the influence of the DSA process on yield strength and cumulative plastic strain under cyclic loading in stainless steels at elevated temperatures. They proposed a temperature-dependent function integrated into the dynamic recovery term of the A-V hardening model. Sun et al. [11] extended the Ohno–Wang hardening model [12] to develop a single model predicting DSA effects in a temperature range of 293–823 K, showing an increase in DSA activity with rising operating temperature. Nakkalil et al. [13] presented how the DSA event had a significant impact on the mechanical properties of railway steel bars primarily under various strain rates and with high contact temperatures. At higher strain rates, steel samples with finer pearlitic structures displayed increased strength and hardness. Kumar et al. [14] investigated the ratcheting response of SA333 steel at room temperature and within the 250–350 °C temperature range. Their results indicated that ratcheting deformation was suppressed at intermediate temperatures. However, with increasing cyclic stress amplitude, greater ratcheting strain and shorter fatigue life were achieved. Li and Leslie [15] conducted cyclic tests on some carbon steel alloys of AISI 1008, 1010, 1020, 1035, and 1522 over a temperature range of 373–873 K and at various strain rates. They reported negative strain-rate sensitivity of flow stress in the DSA-active regime. To better understand the DSA mechanism, researchers have employed several techniques, including transmission electron microscopy (TEM) [16], X-ray diffraction (XRD) [17], and mechanical testing [18].

In addition to using analytical approaches to assess ratcheting behavior at elevated temperatures, the most common numerical methods, such as finite element analysis, have been widely utilized, where experimental data acquisition was found to be complex, lengthy, and costly [19,20,21]. The finite element method has also been widely used for lifespan prediction through accurate modeling of plastic strain responses due to tension, compression, bending, or large deformation leading to failure of the structure. Commercial software programs such as ABAQUS 2021, Cast3M 2025, and ANSYS 2022R1 were found to be capable tools to model the dynamic response of structures and materials successfully. FE models were categorized as sequentially coupled [22,23] and fully coupled methods [24,25], depending on how temperature and displacement degrees of freedom (DOF) were included in the system matrix. Fully coupled models are further divided into strong [26,27] and weak [25] forms, based on whether thermal and mechanical loads are applied simultaneously or sequentially. In addition to the standard plasticity models available in ANSYS and ABAQUS, several advanced models such as the modified Chaboche [28], Ohno–Wang [12,29], Abdel Karim–Ohno [30], and modified Ohno–Wang [31] hardening formulations have been incorporated into these platforms using user-defined subroutines. Chen et al. [32] discussed the latest advancements in experimental and computational research on metallic material ratcheting behavior. They predicted and modeled the ratcheting response of pressurized piping based on finite element analysis with widely accepted constitutive models employed in industrial packages such as ANSYS and ABAQUS. A cyclic plasticity model incorporating a memory surface, based on the Abdel Karim–Ohno kinematic hardening rule [30], was implemented into the ANSYS finite element code using a user-defined material subroutine (UMAT) [33]. This approach demonstrated reliable prediction of additional hardening effects under non-proportional loading paths. Bonora’s damage-coupled cyclic plastic model [34], based on true stress rather than effective stress in the yield criterion, was also integrated into the finite element program. To improve computational efficiency, the system of nonlinear equations was solved without the need for full matrix inversion using an implicit solution method with an explicit update scheme. Koo and Lee [35] modeled the ratcheting behavior of modified 9Cr–1Mo steel using a Chaboche-based inelastic model to investigate high-temperature conditions. For optimization of the Chaboche model parameters, a successive iteration-based optimization procedure was adopted, enabling accurate and effective simulation of cyclic deformation in components made of 316L-N, 316L, and 304L stainless steel components [36]. In addition, more efficient Chaboche parameters for the 7075-T6 aluminum alloy were determined using a multi-objective genetic algorithm to further enhance model predictability [37]. Pate et al. [38] performed finite element simulations to study low-cycle fatigue (LCF) behavior in homogeneous AISI 316L steel using ANSYS LS-DYNA, applying the Armstrong–Frederick kinematic hardening model to capture the material’s response. Wu et al. [39] conducted 2D simulations showing improved plastic stresses under thermal loading. Vo et al. [40] integrated a moving heat source model into a 3D FE framework to model temperature rise at the rail surface upon repeated locomotive wheel passes with the use of temperature-dependent material properties to enhance the accuracy.

Understanding and accurately predicting ratcheting behavior is essential to prevent premature failure and extend the service life of critical components in high-risk industries. The outcomes of this study can contribute to safer design practices, optimized maintenance schedules, and the development of more reliable materials for applications such as aerospace structures, offshore drilling systems, and railway systems. While previous studies have explored cyclic plasticity and ratcheting behavior using either analytical or finite element approaches, limited attention has been given to the role of mesh type and element shape in influencing ratcheting predictions at elevated temperatures. The present study intends to explore how element type, shape, and mesh density influence the ratcheting results of steel samples through use of the Chaboche model at elevated temperatures. The simulated ratcheting responses for brick and tetrahedron solid elements were compared with those predicted analytically by the A-V hardening rule and experimentally measured values. The predicted and simulated ratcheting data were found to be in good agreement with the measured data, highlighting the importance of mesh selection in accurate ratcheting simulation and offering practical guidance for future finite element modeling of cyclic deformation.

2. Mathematical Formulation

2.1. Elements of Elasticity, Plasticity, and Visco-Plasticity

Cyclic plasticity theories describe material behavior by incorporating both elastic and plastic deformation using a yield criterion, a flow rule to define the increment of plastic strain in deviatoric stress space, and a hardening rule to capture evolution of the yield surface during loading. These components work together, while ensuring that the consistency condition is maintained throughout the deformation process. The total strain is obtained by integrating the elastic strain (), plastic strain (), and visco-plastic strain () as follows [41]:

where

In Equation (2), the terms σ, I, E, G, and υ represent the applied stress, the unit tensor representing a multi-dimensional identity matrix, the elastic modulus, the shear modulus, and Poisson’s ratio, respectively. These constants describe the material properties governing elastic deformation.

The plastic strain increment is defined as [41]

where is the modulus of plasticity, and is the backstress, which quantifies the extent of the loading state beyond the elastic domain. is the deviatoric stress tensor and represents the part of the stress tensor that causes distortion (shape change) but not volume change. Perzyna [41] developed the visco-plastic flow rule to define the visco-plastic strain rate as

where the terms , , and in Equation (4) correspond to the viscous exponent, viscous stress, and drag stress, respectively. These term are determined from tensile stress–strain data.

According to the von Mises criterion, yielding begins when the material transitions from elastic to plastic behavior, defined by the following condition:

where , , are the initial yield stress, yield stress, and von Mises equivalent stress, respectively.

2.2. Hardening Framework

2.2.1. Isotropic Hardening Description

The isotropic hardening evolution was developed by Lee and Zarvel [42] in a classical way as

where is the increment of isotropic hardening. The material constant represents the saturated value of , and controls the change in rate of , which described the cyclic hardening behavior and ratcheting behavior. The coefficients in Equation (6) are determined from the curve of normalized maximum stress at each stress cycle plotted versus the accumulated plastic strain .

Voyiadjis, Song, and Rusinek (VSR) [43] proposed an advanced multivariable constitutive model to characterize yield stress as a function of plastic strain, visco-plastic strain rate, and temperature. Their formulation is expressed as

The model includes a Peiperl’s barrier τ representing lattice resistance and microstructural constants and that introduce strain rate sensitivity through , with the reference rate set at 1.0/s. The parameter n represents the strain-hardening coefficient and is taken as 0.71. is the plastic modulus. The constants and define the shape of dislocation–obstacle interactions [43]. Dynamic strain aging (DSA) effects are captured through a temperature-dependent term governed by thresholds and , with smoothing applied via [18]. For BCC alloys, τ is typically taken as 5 × 10−3 G, where G is the shear modulus [44]. and are taken as and , respectively [43].

2.2.2. Ahmadzadeh–Varvani (A-V) Kinematic Hardening Rule

Ahmadzadeh and Varvani (A-V) [45,46] proposed a kinematic hardening rule to govern backstress increments during loading within the plastic domain. To adapt the operating temperature term into the A-V model, a dynamic strain aging function is adapted in the dynamic recovery term of the A-V model as [9,47]

The internal variable regulates translation of the yield surface and adjusts the gradual evolution of backstress . The coefficients and C control the consistency condition of progressive hysteresis loops generated by stress-controlled tests. Coefficient was calibrated from uniaxial ratcheting strain data plotted versus asymmetric stress cycles. The function was defined as [48,49]

where terms and were determined from tensile stress–strain data measured at elevated temperatures. The increment of equivalent plastic strain, , is expressed as

where corresponds to the increment of plastic strain.

2.2.3. The Chaboche Kinematic Hardening Rule

Chaboche [50] introduced a kinematic hardening model to govern incremental evolution of backstress in the deviatoric stress space for loading beyond the elastic domain. They proposed integrating backstress increments (i = 1, 2, 3) when loading is within the plastic domain. The Chaboche nonlinear hardening rule is expressed as

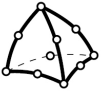

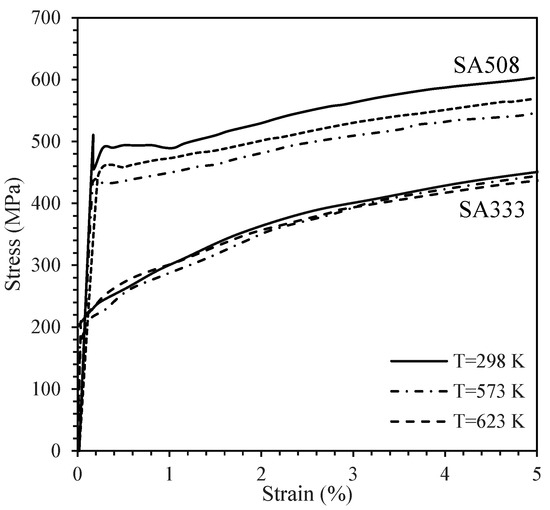

where the terms and are material-dependent coefficients determined from strain-controlled cyclic tests. The coefficients and were extracted from the slope of the linear part of the strain-based hysteresis loop. While controls the early, nonlinear accumulation of ratcheting strain during the first few cycles (typically 5–10 cycles), governs the steady ratcheting rate observed in the later stages (around 20–50 cycles). Both coefficients are obtained by fitting the model to measured uniaxial ratcheting data over the corresponding cycle ranges. The terms and are acquired through a trial-and-error procedure. The function was adapted into Equation (11c) to address the effect of dynamic strain aging (DSA) at elevated operating temperatures. Figure 1 presents a flowchart to address the procedure to assess ratcheting through the A-V and Chaboche hardening frameworks in the present study.

Figure 1.

The developed flowchart to address the procedure for ratcheting assessment through the A-V and Chaboche hardening rules in the present study.

3. Results and Discussion

3.1. Tensile and Cyclic Test Data

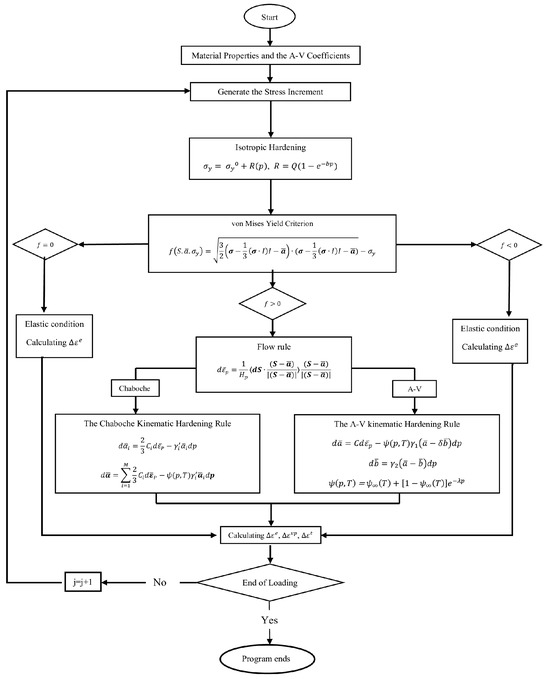

Experimental data for the SA508 and SA333 alloys were adopted from well-established literature sources to assess the cyclic response of steels at different temperatures [51,52]. Both materials contain approximately 0.2% carbon and possess a ferrite–pearlite microstructure. Both steels are applied in various applications in high-temperature and high-pressure services, such as steam piping systems. Tensile tests were conducted at a constant strain rate of 0.2%/s on solid hot-rolled cylindrical specimens. For SA508 samples, the specimens had a gauge length of 30 mm and a diameter of 10 mm, while for SA333 samples, the gauge length was 15 mm, and the diameter was 8 mm. Cyclic and ratcheting tests were performed under the stress-controlled conditions using a CRIMS-RPL100 fatigue testing machine for SA508 specimens and an Instron 8862 testing machine for SA333 specimens. The stress rates for cyclic tests in the SA508 and SA333 samples were respectively kept at 100 MPa/s and 115 MPa/s. The cyclic tests were conducted through the use of a cylindrical heat oven integrated into the testing machine, preserving operating temperatures over the loading cycles. Figure 2 demonstrates the tensile stress–strain behavior of (a) SA508 and (b) SA333 at different temperatures (298 K, 573 K, 623 K). As the temperature increases, the yields and ultimate tensile strengths reduce. Notably, the strength levels were highest at room temperature (298 K), where the materials displayed limited plastic deformation. At 573 K and 673 K, the occurrence of dynamic strain aging (DSA) temporarily enhanced the work-hardening rate, evident in the intermediate rise in flow stress. However, temperatures beyond 873 K resulted in noticeable softening, as seen by the overall reduction in flow resistance and ductility increase.

Figure 2.

Stress–strain curves for SA508 and SA333 steel samples tested at various temperatures [51,52].

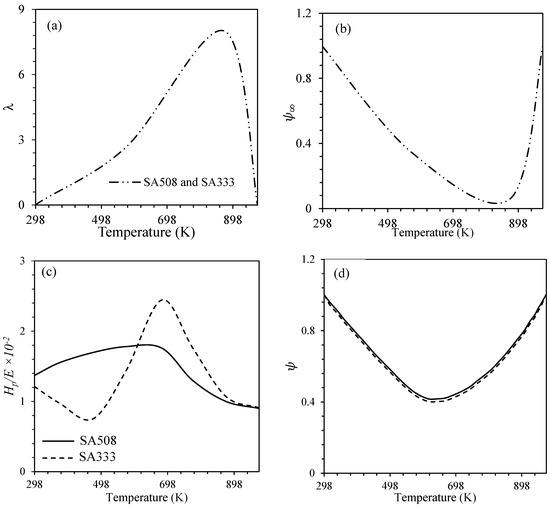

3.2. Dynamic Strain Aging (DSA) and Temperature Domain

The mechanical response of steels, particularly under ratcheting conditions, is significantly influenced by operating temperature. Within the domain of dynamic strain aging (DSA), typically observed between 473 K and 873 K, dislocation motion is hindered due to solute–atom interactions, resulting in an abrupt increase in material strength and a pronounced hardening response [53]. To capture the influence of this phenomenon, an exponential temperature-dependent function, , was incorporated into the dynamic recovery term of the Ahmadzadeh–Varvani (A-V) hardening model. For both monotonic and cyclic loading, elevated temperatures led to a pronounced reduction in the elastic modulus, while the plastic modulus exhibited a rising trend and then a noticeable drop at magnitudes within the DSA temperature range. The exponent λ in this function plays a central role, reaching its peak within the DSA domain, thereby minimizing . At higher temperatures, such as above 900 K, λ decreases significantly, leading to 1.0, indicating the vanishing effect of DSA on material behavior. Figure 3 presents the variations in terms , , , , , and for steel samples versus operating temperatures.

Figure 3.

Variations in the (a), (b) , (c) , (d) , (e) , and (f) variables for steel samples tested at different operating temperatures [51,52].

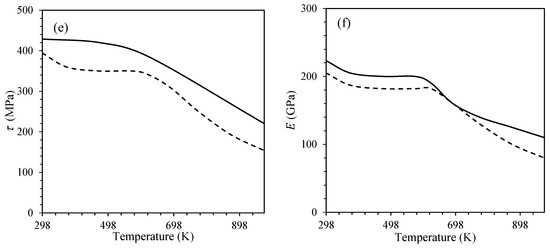

3.3. A-V Kinematic Hardening Rule Coefficients

Figure 4 illustrates stress–strain hysteresis loops and the evolution of ratcheting strain for SA333 steel samples at different temperatures. The coefficients C, , and in the Ahmadzadeh–Varvani (A-V) model were determined by regression of the model to experimental values. The coefficients C and calibrate the slope and size of the initial stress–strain hysteresis loops generated through stress-controlled loading cycles. The coefficient controls the ratcheting strain rate, determining it from ratcheting data plotted versus asymmetric stress cycles.

Figure 4.

Kinematic hardening coefficients (a) C, , and (b) determined for SA333 [52] steel samples at various temperatures.

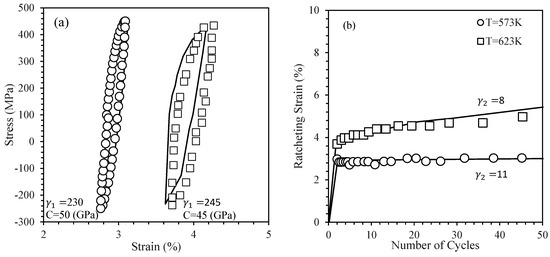

3.4. Chaboche’s Coefficients

The material coefficients for the Chaboche nonlinear kinematic hardening model were calibrated using experimental hysteresis loops obtained from strain-controlled fatigue tests on steel samples. To ensure that the proper parameters were determined, the simulated loops needed to closely agree with the experimental results in both shape and area. Smaller values of the coefficients and result in narrower loops, which indicates slower hardening and less ratcheting. Larger coefficient values resulted in wider loops and higher ratcheting strains. Figure 5 shows the comparison between simulated and experimental stress–strain loops at three different temperatures under a constant strain amplitude of for SA333. The agreement between the loops confirms the adequacy of the selected coefficients and for the cyclic behavior of SA333. The coefficients and represent the plastic modulus at yielding and the slope of the linear part of the hysteresis loop, respectively. The backstress values during loading, unloading, and reloading are noted as , , and . These are calculated from Equation (11) and then used as initial values (, , and ) for the next loading cycle. The parameters and are obtained from uniaxial ratcheting data, where helps to stabilize hardening in the early cycles, and controls the steady rate of ratcheting strain. The constants and are selected through a trial-and-error process to satisfy Equation (12):

where is the applied stress amplitude, and is the plastic strain range.

Figure 5.

Chaboche’s coefficients and for SA333 steel samples tested at (a) 298 K, (b) 573 K, and (c) 623 K [54].

The loop is widest at 298 K, indicating strong kinematic hardening and limited dislocation mobility due to lower thermal activation. At 573 K, the loop narrows significantly, suggesting that dynamic strain aging (DSA) begins to influence the material response. The DSA effect, attributed to the interaction between diffusing interstitial carbon atoms and dislocations, temporarily hinders dislocation motion. This results in increased cyclic hardening but reduced plastic strain accumulation. Interestingly, at 623 K, the loop becomes slightly broader again, which may be due to the partial relaxation of DSA effects and increased thermal softening at higher temperatures. The evolution of loop width across the temperatures reflects the interplay among dislocation mobility, backstress evolution, and diffusion mechanisms. The final set of Chaboche coefficients used for each case is provided in the figure captions and further summarized in Table 1.

Table 1.

Coefficients of hardening rules to assess ratcheting.

3.5. Finite Element Method

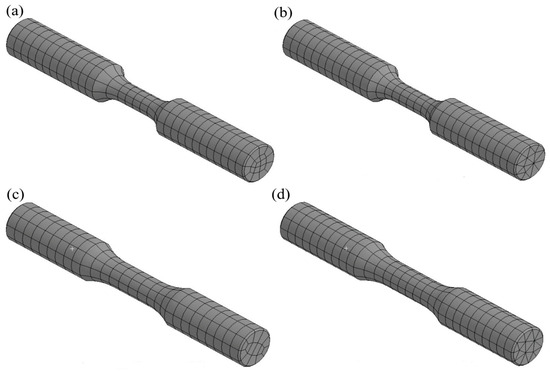

To simulate the ratcheting behavior of the SA508 and SA333 steel samples, finite element models were constructed using ANSYS 2022 R [55]. As shown in Figure 6, two different element types were examined to evaluate mesh sensitivity in the analysis. Each sample has a different geometry because the data were obtained from different experimental studies, and the specimen designs reflect the original configurations used in those sources [51,52]. The geometries correspond to standard axisymmetric tensile specimens, and both nonlinear brick and tetrahedral solid elements were implemented. The solid elements were generated using the sweep mesh technique, which involves creating a mapped mesh on a source face and extruding it through the volume to form structured meshing. The mesh structures were designed with brick and tetrahedron elements containing 20 and 10 nodes, respectively. The details of the element type, shape, and nodal features employed in this study are provided in Table 2. The models were constrained at one end to restrict motion in all directions, and cyclic boundary conditions were applied at the opposite end to replicate consistent sinusoidal loading patterns.

Figure 6.

Mesh structures of (a,b) SA508 and (c,d) SA333 steel with (a,c) brick solid elements and (b,d) tetrahedron solid elements.

Table 2.

Different mesh structures employed in this study [55].

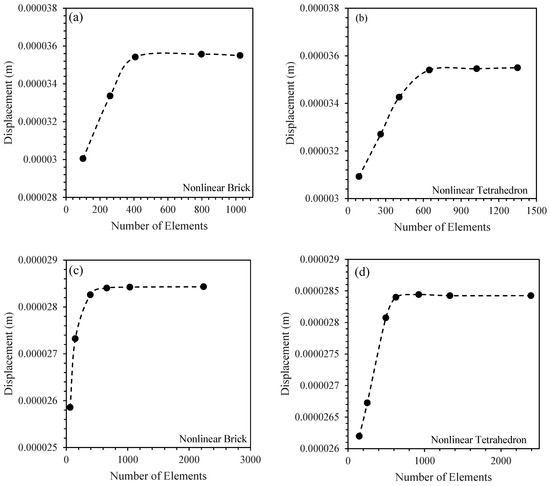

To ensure mesh-independent results in simulation of the ratcheting response, convergence studies were carried out for the SA508 and SA333 steel samples using different element types. Figure 7 illustrates the displacement values recorded for varying number of elements. Figure 7a,b display the convergence results for SA508 samples meshed with nonlinear brick and tetrahedron elements, respectively. In both cases, the displacement response stabilized with increasing number of elements, indicating acceptable convergence. Specifically, the displacement variation became negligible beyond approximately 800 elements for the brick type and 1200 elements for the tetrahedral mesh. Similarly, Figure 7c,d present the convergence for SA333 samples, showing that the response remained unchanged when more than 660 and 925 elements were employed, respectively. These findings confirm that the selected mesh structure is sufficient to capture accurate displacement predictions in the gauge section, ensuring independence of the results from mesh structure.

Figure 7.

Convergence trials for (a,b) SA508 and (c,d) SA333 steel samples for the quadratic brick and the quadratic tetrahedron elements.

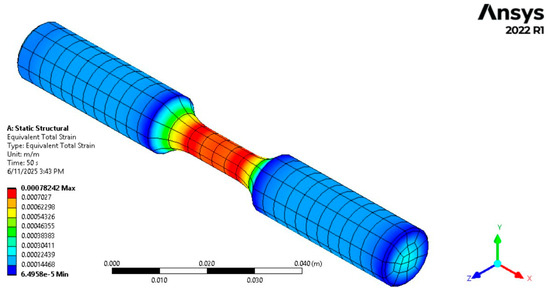

Figure 8 displays the distribution of total strain across the SA333 steel sample subjected to cyclic loading. The equivalent total strain contour reveals that the maximum deformation is concentrated at the gauge section, where the smallest cross-sectional area exists. This location recorded a peak total strain value of approximately 7.82 × 10−4, while the minimum strain, occurring at the outer ends of the specimen, remained close to 6.49 × 10−5. The strain gradients diminish progressively as the distance from the gauge region increases, indicating the local concentration of plastic deformation. These results were derived by finite element simulation in ANSYS 2022 R1. The strain values are computed at the Gaussian integration points and then extrapolated to nodal locations for contour visualization. This procedure relies on element shape functions to interpolate the results, providing smooth and representative strain distribution along the sample geometry.

Figure 8.

Distribution of total strain throughout the sample during cyclic loading.

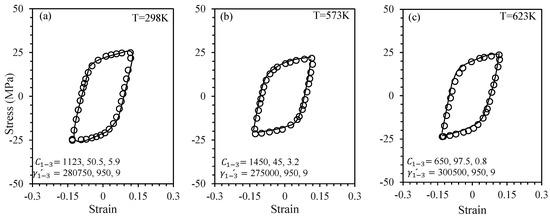

3.6. Backstress Increments

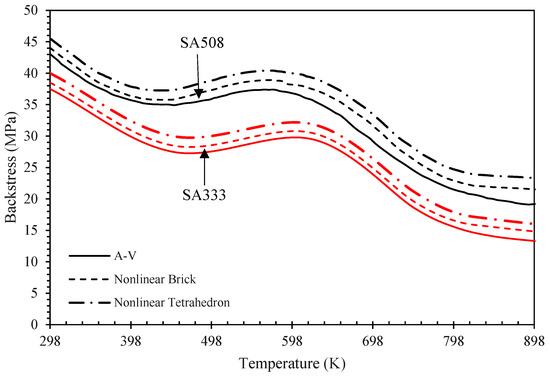

Figure 9 presents the evolution of backstress as a function of temperature for both the SA508 and SA333 steel alloys under different element structures. The numerical results obtained for the nonlinear brick elements and nonlinear tetrahedral elements were compared by the analytical (A-V) method. Across all element types, SA508 consistently exhibited higher backstress levels than SA333 due to its greater resistance to plastic deformation. A decreasing trend in backstress was observed as the temperature increased from 298 K to 898 K, which corresponds to the typical thermal softening behavior of steels. However, a slight elevation in the backstress magnitude was identified within the intermediate temperature range, suggesting the influence of dynamic strain aging (DSA). This temporary increase is attributed to solute dislocation interactions that restrict dislocation motion, requiring higher backstress to maintain cyclic plasticity. At temperatures below 473 K, solute atoms do not diffuse rapidly enough to influence dislocation dynamics, and DSA remains inactive. Above 873 K, dislocations move too quickly, and dynamic recovery dominates, causing DSA effects to disappear. The difference in backstress evolution between the two materials is also influenced by their microstructures and alloying content. SA508, with higher carbon and alloying element contents, typically forms a finer martensitic or bainitic structure that resists dislocation movement more effectively than the ferritic–pearlitic microstructure of SA333. As a result, SA508 maintains a higher backstress level under similar thermal and loading conditions. Overall, the predicted values using different element types showed close agreement, confirming the robustness of the hardening model and its implementation in various mesh schemes.

Figure 9.

Initial backstress increments over a range of temperatures for different element types at different stress levels.

3.7. Ratcheting Results

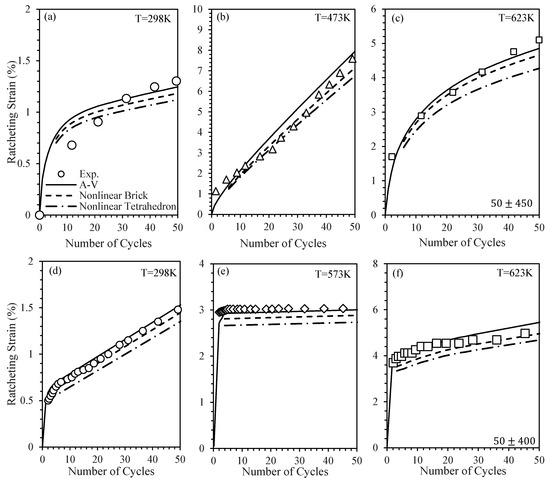

The Chaboche kinematic hardening rule in ANSYS software was employed to assess the ratcheting response of steel samples with two different element types. Figure 10 compares the measured [51,52], predicted, and simulated ratcheting behavior of the SA508 and SA333 steel samples at various temperatures using different element types. Panels (a) to (c) present the ratcheting strain progression of SA508 at 298 K, 473 K, and 623 K, respectively, while panels (d) to (f) illustrate the ratcheting behavior for SA333. In each case, the predicted curves obtained from the A-V hardening model, simulated results for nonlinear brick elements, and nonlinear tetrahedral elements are compared against the experimental data. In these figures, the predicted and simulated ratcheting curves obtained through the A-V model and the FE method demonstrate close agreement with those of the experimentally measured values. The deviation of the simulated and predicted ratcheting strain from the measured data in these figures was found to be less than 16%. The results obtained using the tetrahedron elements yielded an value of 0.85, while the brick-type elements achieved a higher of 0.91, indicating better agreement with the experimental data. Among the models, the A-V formulation demonstrated the highest accuracy, with an of 0.96, representing closer agreement to experimental results. At 298 K, the ratcheting response showed rapid initial accumulation followed by gradual saturation in both materials, with SA333 demonstrating a higher strain amplitude than SA508. At 473 K, the ratcheting rate increased due to a noticeable decrease in yield strength. The smaller yield strength at this temperature resulting in higher accumulation of plastic strain. At 623 K, despite thermal softening effects, SA333 continued to exhibit higher ratcheting levels, reflecting its lower resistance to cyclic plastic deformation. Among the different element types, the nonlinear tetrahedral elements showed slightly more deviation from the experimental results compared to the brick elements. The simulation results confirm that both material composition and temperature significantly influence ratcheting strain evolution under cyclic loading.

Figure 10.

Simulated and measured [51,52] ratcheting curves for (a–c) SA508 (d–f) SA333. The simulation was conducted for two different element types.

4. Conclusions

The proposed model is particularly applicable for predicting the ratcheting behavior of SA508 and SA333 steel samples subjected to cyclic loading at elevated temperatures. This offers a suitable framework for components used in petrochemical equipment and high-temperature pipelines. The ratcheting behavior of the SA508 and SA333 alloys at elevated temperatures was evaluated under uniaxial asymmetric loading cycles by means of the A-V hardening model and the FE method. The Chaboche hardening rule was employed in ANSYS to study the effect of meshing structure on the cyclic behavior of steel alloys at elevated temperatures. Two element types, nonlinear brick elements with 20 nodes and the quadratic tetrahedron with 10 nodes, were used. Brick elements (9.2% deviation) provided more accurate ratcheting predictions compared to tetrahedral elements (16% deviation). These findings emphasize the critical role of mesh selection and model calibration in enhancing the reliability of numerical ratcheting simulations. In both meshing structures, SA508 possesses higher backstress values than SA333, which relates to its greater resistance to plastic deformation. At elevated temperatures, due to the thermal softening behavior of steels, the samples demonstrate lower resistance to cyclic plastic deformation. However, within a specific temperature range of 473–873 K, the DSA phenomenon occurred, resulted in enhanced material strength. Through comparison of the effect of different element types on the cyclic response of steel samples, it was revealed that the simulated ratcheting strain obtained from nonlinear brick elements showed slightly less deviation from the measured values. Although thermal softening effects were present at elevated temperatures beyond the DSA domain, SA333 still demonstrated higher ratcheting levels, indicating its lower resistance to cyclic plastic deformation. The predicted and simulated ratcheting curves obtained through the A-V and Chaboche hardening frameworks closely agreed with those of experimental values. The model has been promising in the assessment of ratcheting of steel samples undergoing uniaxial loading cycles at elevated temperatures. Under complex multiaxial loading or for steels with significantly different microstructural features, more investigation is required to evaluate the capability of the framework and its algorithm.

Author Contributions

Conceptualization, M.K. and A.V.-F.; methodology, M.K. and A.V.-F.; software, M.K. and A.V.-F.; validation, M.K. and A.V.-F.; formal analysis, M.K.; investigation, M.K. and A.V.-F.; data curation, M.K. and A.V.-F.; writing—original draft preparation, M.K. and A.V.-F.; writing—review and editing, M.K. and A.V.-F.; visualization, M.K. and A.V.-F.; supervision, A.V.-F.; project administration, A.V.-F.; funding acquisition, A.V.-F. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Natural Sciences and Engineering Research Council of Canada (NSERC), through A.V.-F. (RGPIN-2021-03047).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Acknowledgments

The authors wish to acknowledge financial support from the Natural Sciences and Engineering Research Council of Canada (NSERC) to A. Varvani (RGPIN-2021-03047).

Conflicts of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

References

- Varvani-Farahani, A.; Nayebi, A. Ratcheting in pressurized pipes and equipment: A review on affecting parameters, modelling, safety codes, and challenges. Fatigue Fract. Eng. Mater. Struct. 2018, 41, 503–538. [Google Scholar] [CrossRef]

- Kaya, Ö.; Cavusoglu, O.; Güral, A. Investigation of mechanical property alterations in DP600 steel under cyclic static strain aging. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2025, 14644207241310410. [Google Scholar] [CrossRef]

- Rodriguez, P. Serrated plastic flow. Bull. Mater. Sci. 1984, 6, 653–663. [Google Scholar] [CrossRef]

- Hong, S.G.; Lee, S.B. The tensile and low-cycle fatigue behavior of cold worked 316L stainless steel: Influence of dynamic strain aging. Int. J. Fatigue 2004, 26, 899–910. [Google Scholar] [CrossRef]

- Huang, Z.Y.; Chaboche, J.L.; Wang, Q.Y.; Wagner, D.; Bathias, C. Effect of dynamic strain aging on isotropic hardening in low cycle fatigue for carbon manganese steel. Mater. Sci. Eng. A 2014, 589, 34–40. [Google Scholar] [CrossRef]

- Huang, Z.; Wagner, D.; Bathias, C. Some metallurgical aspects of Dynamic Strain Aging effect on the Low Cycle Fatigue behavior of C–Mn steels. Int. J. Fatigue 2015, 80, 113–120. [Google Scholar] [CrossRef]

- Avalos, M.; Alvarez-Armas, I.; Armas, A.F. Dynamic strain aging effects on low-cycle fatigue of AISI 430F. Mater. Sci. Eng. A 2009, 513, 1–7. [Google Scholar] [CrossRef]

- Caillard, D. Dynamic strain ageing in iron alloys: The shielding effect of carbon. Acta Mater. 2016, 112, 273–284. [Google Scholar] [CrossRef]

- Karimi, M.; Varvani-Farahani, A. Ratcheting prediction of stainless steel 304 and 316L samples undergoing asymmetric loading cycles at elevated temperatures incorporating dynamic strain aging phenomenon. Mater. Today Commun. 2024, 38, 107805. [Google Scholar] [CrossRef]

- Karimi, M.; Varvani-Farahani, A. Ratcheting Assessment of Rail Steel at Elevated Temperatures in the Presence of Dynamic Strain Aging. J. Mater. Eng. Perform. 2024, 34, 6817–6827. [Google Scholar] [CrossRef]

- Sun, X.; Xing, R.; Yu, W.; Chen, X. Uniaxial ratcheting deformation of 316LN stainless steel with dynamic strain aging: Experiments and simulation. Int. J. Solids Struct. 2020, 207, 196–205. [Google Scholar] [CrossRef]

- Ohno, N.; Wang, J.D. Kinematic hardening rules with critical state of dynamic recovery, part I: Formulation and basic features for ratchetting behavior. Int. J. Plast. 1993, 9, 375–390. [Google Scholar] [CrossRef]

- Nakkalil, R.; Hornaday, J.R., Jr.; Bassim, M.N. Characterization of the compression properties of rail steels at high temperatures and strain rates. Mater. Sci. Eng. A 1991, 141, 247–260. [Google Scholar] [CrossRef]

- Kumar, G.; Kumar, A.; Bar, H.N. Low Cycle Fatigue and Ratcheting Behavior of SA333 Gr-6 Steel at 300° C Temperature. SAE Int. J. Mater. Manuf. 2019, 12, 73–82. [Google Scholar] [CrossRef]

- Li, C.C.; Leslie, W.C. Effects of dynamic strain aging on the subsequent mechanical properties of carbon steels. Metall. Trans. A 1978, 9, 1765–1775. [Google Scholar] [CrossRef]

- Kumar, G.; Bar, H.N.; Kumar, A. Effect of dynamic strain aging on cyclic deformation in piping material SA333 Gr-6 steel. Int. J. Press. Vessels Pip. 2021, 194, 104529. [Google Scholar] [CrossRef]

- Kumar, G.; Bar, H.N.; Kumar, A. Influence of dynamic strain aging on ratcheting deformation behavior of SA333 Gr-6 steel. J. Mater. Eng. Perform. 2022, 31, 10332–10342. [Google Scholar] [CrossRef]

- Voyiadjis, G.Z.; Song, Y.; Rusinek, A. Constitutive model for metals with dynamic strain aging. Mech. Mater. 2019, 129, 352–360. [Google Scholar] [CrossRef]

- Servatan, M.; Hashemi, S.M.; Varvani-Farahani, A. Ratcheting Simulation of Additively Manufactured Aluminum 4043 Samples through Finite Element Analysis. Appl. Sci. 2023, 13, 11553. [Google Scholar] [CrossRef]

- Zhang, J.; Gu, Z.; Cao, G.; Jin, Y.; Liu, J. A modified continuum damage model considering cryogenic temperatures and its application in corrugated plates of the LNG membrane storage tank. Int. J. Press. Vessel. Pip. 2025, 214, 105412. [Google Scholar] [CrossRef]

- Shit, J.; Dhar, S.; Acharyya, S. Modeling and finite element simulation of low cycle fatigue behaviour of 316 SS. Procedia Eng. 2013, 55, 774–779. [Google Scholar] [CrossRef]

- Bosso, N.; Cantone, L.; Falcitelli, G.; Gjini, R.; Magelli, M.; Nigro, F.M.; Ossola, E.; Zampieri, N. Simulation of the thermo-mechanical behaviour of tread braked railway wheels by means of a 2D finite element model. Tribol. Int. 2022, 178, 108074. [Google Scholar] [CrossRef]

- Walia, M.S.; Esmaeili, A.; Vernersson, T.; Lundén, R. Thermomechanical capacity of wheel treads at stop braking: A parametric study. Int. J. Fatigue 2018, 113, 407–415. [Google Scholar] [CrossRef]

- Dong, Y.G.; Yi, S.; Huang, X.L.; Zheng, J.; Du, X.; Li, S. Prediction of fatigue crack initiation life of wheel tread during emergency braking of heavy haul train. China Railw. Sci. 2021, 42, 123–131. [Google Scholar]

- Li, L.; Chang, C. Thermal load analysis of wheel tread for heavy axle load freight car under braking conditions on the basis of thermal-mechanical coupling model. Railw. Locomot. Car 2014, 34, 25–30. [Google Scholar]

- Suresh Babu, A.; Siva Prasad, N. Coupled field finite element analysis of railway block brakes. Proc. Inst. Mech. Eng. Part F J. Rail. Rapid Transit. 2009, 223, 345–352. [Google Scholar] [CrossRef]

- Vernersson, T.; Lundén, R. Wear of brake blocks for in-service conditions—Influence of the level of modelling. Wear 2014, 314, 125–131. [Google Scholar] [CrossRef]

- Bari, S.; Hassan, T. An advancement in cyclic plasticity modeling for multiaxial ratcheting simulation. Int. J. Plast. 2002, 18, 873–894. [Google Scholar] [CrossRef]

- Ohno, N.; Wang, J.D. Kinematic hardening rules with critical state of dynamic recovery, part II: Application to experiments of ratchetting behavior. Int. J. Plast. 1993, 9, 391–403. [Google Scholar] [CrossRef]

- Abdel-Karim, M.; Ohno, N. Kinematic hardening model suitable for ratchetting with steady-state. Int. J. Plast. 2000, 16, 225–240. [Google Scholar] [CrossRef]

- Chen, X.; Jiao, R.; Kim, K.S. On the Ohno–Wang kinematic hardening rules for multiaxial ratcheting modeling of medium carbon steel. Int. J. Plast. 2005, 21, 161–184. [Google Scholar] [CrossRef]

- Chen, X.; Chen, X.; Yu, D.; Gao, B. Recent progresses in experimental investigation and finite element analysis of ratcheting in pressurized piping. Int. J. Press. Vessels Pip. 2013, 101, 113–142. [Google Scholar] [CrossRef]

- Halama, R.; Markopoulos, A.; Jančo, R.; Bartecký, M. Implementation of MAKOC cyclic plasticity model with memory. Adv. Eng. Softw. 2017, 113, 34–46. [Google Scholar] [CrossRef]

- Bonora, N.; Majzoobi, G.H.; Khademi, E. Numerical implementation of a new coupled cyclic plasticity and continuum damage model. Comput. Mater. Sci. 2014, 81, 538–547. [Google Scholar] [CrossRef]

- Koo, G.H.; Lee, J.H. Investigation of ratcheting characteristics of modified 9Cr–1Mo steel by using the Chaboche constitutive model. Int. J. Press. Vessels Pip. 2007, 84, 284–292. [Google Scholar] [CrossRef]

- Dalla Palma, M. Modelling of cyclic plasticity for austenitic stainless steels 304L, 316L, 316L (N)-IG. Fusion Eng. Des. 2016, 109, 20–25. [Google Scholar] [CrossRef]

- Agius, D.; Kajtaz, M.; Kourousis, I.; Wallbrink, C.; Wang, H.; Hu, W.; Silva, J. Sensitivity and optimisation of the Chaboche plasticity model parameters in strain-life fatigue predictions. Mater. Des. 2017, 118, 107–121. [Google Scholar] [CrossRef]

- Pate, S.B.; Dundulis, G.; Griskevicius, P. Modeling of LCF Behaviour on AISI316L Steel Applying the Armstrong–Frederick Kinematic Hardening Model. Materials 2024, 17, 3395. [Google Scholar] [CrossRef]

- Wu, L.; Wen, Z.; Li, W.; Jin, X. Thermo-elastic–plastic finite element analysis of wheel/rail sliding contact. Wear 2011, 271, 437–443. [Google Scholar] [CrossRef]

- Vo, K.D.; Tieu, A.K.; Zhu, H.T.; Kosasih, P.B. The influence of high temperature due to high adhesion condition on rail damage. Wear 2015, 330, 571–580. [Google Scholar] [CrossRef]

- Perzyna, P. The Constitutive Equation for Work-Hardening and Rate Sensitive Plastic Materials. Appl. Math. 1963, 20, 321–324. [Google Scholar]

- Lee, D.; Zavrel, F., Jr. A generalized strain rate dependent constitutive equation for anisotropic metals. Acta Metall. 1978, 26, 1771–1780. [Google Scholar] [CrossRef]

- Abed, F.H.; Voyiadjis, G.Z. Plastic deformation modeling of AL-6XN stainless steel at low and high strain rates and temperatures using a combination of bcc and fcc mechanisms of metals. Int. J. Plast. 2005, 21, 1618–1639. [Google Scholar] [CrossRef]

- Calhoun, R.B.; Dunand, D.C. Dislocations in metal matrix composites. In Comprehensive Composite Materials: Metal Matrix Composites; Kelly, A., Zweben, C., Eds.; Elsevier: Amsterdam, The Netherlands, 1999. [Google Scholar]

- Ahmadzadeh, G.R.; Varvani-Farahani, A. Ratcheting assessment of materials based on the modified A–F hardening rule at various uniaxial stress levels. Fatigue Fract. Eng. Mater. Struct. 2013, 36, 1232–1245. [Google Scholar] [CrossRef]

- Karimi, M.; Varvani-Farahani, A. The concurrent ratcheting and stiffness degradation-based damage variable in SA508 steel samples undergoing stress cycles at room and elevated temperatures. J Mater. Res. Express, 2025; under reviewed. [Google Scholar]

- Karimi, M.; Varvani-Farahani, A. Ratcheting-fatigue interaction in SA508 and SA333 steels subjected to uniaxial asymmetric stress cycles at room and elevated temperatures. J. Fail. Anal. Prev. 2025, 1–17. [Google Scholar] [CrossRef]

- Gao, Q.; Kang, G.Z.; Yang, X.J. Uniaxial ratcheting of SS304 stainless steel at high temperatures: Visco-plastic constitutive model. Theor. Appl. Fract. Mech. 2003, 40, 105–111. [Google Scholar] [CrossRef]

- Chaboche, J.L. Constitutive equations for cyclic plasticity and cyclic viscoplasticity. Int. J. Plast. 1989, 5, 247–302. [Google Scholar] [CrossRef]

- Chaboche, J.L. On some modifications of kinematic hardening to improve the description of ratchetting effects. Int. J. Plast. 1991, 7, 661–678. [Google Scholar] [CrossRef]

- Tian, J.; Zhang, P.; Shao, J.; Du, J.; Kan, H. Ratcheting behavior of SA508-3 steel at elevated temperature: Experimental observation and simulation. Acta Metall. Sin. (Engl. Lett.) 2017, 30, 822–828. [Google Scholar] [CrossRef]

- Kumar, G.; Kumar, A.; Bar, H.N. Asymmetric cyclic deformation behavior of SA 333 steel at elevated temperatures. World J. Eng. 2020, 16, 78–86. [Google Scholar] [CrossRef]

- Dai, R.J.; Deng, K.K.; Wang, C.J.; Nie, K.B.; Zhang, G.W.; Liang, W. Effects of precipitates and solute atoms on the work hardening and softening behavior of Zn-rich aluminum alloy. Mater. Sci. Eng. A 2022, 848, 143388. [Google Scholar] [CrossRef]

- Samuel, K.G.; Ganesan, V.; Rao, K.B.S.; Mannan, S.L.; Kushwaha, H.S. Strain controlled LCF behaviour of SA-333 Gr 6 piping material in the range 298–673 K. Int. J. Press. Vessel. Pip. 2004, 81, 973–981. [Google Scholar] [CrossRef]

- Static Structural Analysis Guide, ANSYS® Workbench Release 22.1, Help System; ANSYS, Inc.: Canonsburg, PA, USA, 2022.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).