Abstract

High pressure is an industrially established food preservation process applied for the minimal processing or cold pasteurization of chilled, fresh, or ready-to-eat products. This study aimed to quantify the effectiveness of high pressure on the inactivation of spoilage microflora and the shelf life extension of European sea bass (Dicentrarchus labrax) fillets. Fish fillets were subjected to mild, high pressure conditions (100–400 MPa; 3–25 °C; 5–10 min) and then stored at 0.0 ± 0.2 °C. Their shelf life was evaluated in terms of their microbiological, physicochemical, and sensorial quality. The results indicated that a shelf life extension of 1–5 d at 0 °C was achieved when pressures of 100 MPa were applied, whereas higher pressures resulted in an up to 5-fold increase in the shelf life of the fillets, depending on the applied pressure and temperature. A high pressure treatment combined with vacuum packaging showed an additional effect on the shelf life extension of the fillets, increasing the shelf life by 4–12 d when compared to aerobically stored products. Moreover, the high pressure treatment prevented lipid oxidation throughout the storage period, indicating no formation of secondary lipid oxidation products. The estimated shelf life of the fish fillets based on their sensorial quality was in accordance with the estimation based on the microbiological data.

1. Introduction

Fish is a food of high nutritional value, rich in proteins and polyunsaturated ω-3 fatty acids. Unprocessed fish products are perishable for several biochemical and microbiological reactions [1], with the latter mainly limiting the shelf life in chilled storage (2–4 °C) to a few days. In order to extend the shelf life, fish products can be subjected to different combinations of processing and packaging methods [2], including freezing [3], smoking [4], packing under modified atmospheres [2,5], or treatment with natural preservatives [6,7].

Novel and minimal processing technologies have been applied to fish, achieving a reduction in the initial microbial load without thermal effects on the nutritional value and sensorial attributes of the processed fish. Among these processes, high pressure (HP) is an industrially well-established minimal food processing technology [8] that is used for the cold pasteurization of several foodstuffs including milk, juices and beverages, sauces and spreads, meat products, and seafood [9]. The effectiveness of HP processing is related to the inactivation of the pathogens, spoilage microorganisms, and endogenous enzymes responsible for several biochemical reactions in foods, such as protein and lipid oxidation, while maintaining or even improving the structural, textural, rheological, biofunctional, and sensorial characteristics of the final products.

Regarding raw fish, several studies have been conducted to report the efficacy of HP treatment on the inactivation of a variety of fish spoilage bacteria, mostly including Gram-negative bacteria, i.e., Pseudomonas spp., H2S-producing bacteria, and Enterobacteriaceae and Vibrio spp. These studies also reported on the effect of HP on the quality characteristics of the fish products such as color, lipid oxidation, and texture. Recently, Roobab et al. [10] reviewed research conducted over the past six years (2016–2021) on the advantages of HP processing for the quality of fish and seafood, and Chen et al. [11] reviewed the effects of HP processing on aquatic products, emphasizing the sensorial properties of the processed fish product. Both studies revealed that HP processing has mostly been studied in albacore, cod, and salmon [12,13,14,15,16], while few works have been published concerning the European sea bass [17,18,19]. HP processing is more favorable for fish with white flesh, e.g., white tuna and cod fish, due to its “whitening” effect on the fish flesh, which is induced by the denaturation of the proteins [20], especially when fish fillets are treated instead of whole fish. Taking into consideration the different effects resulting in fish fillets from the different HP processing parameters, further research is required to determine the optimal HP conditions in terms of pressure, temperature, and holding time required for the inactivation of spoilage microflora in view of the shelf life extension of each different fish matrix while having minimal effects on other quality parameters.

The initially adopted industrial HP procedure, an alternative to thermal pasteurization, included processing at an ambient temperature and pressures of 550–600 MPa for a short processing time, i.e., 3–10 min. With a few exceptions, this was performed in the final package [21]. Under these conditions, HP is effective in inactivating both pathogenic (Listeria monocytogenes and Escherichia coli [22,23]) and spoilage microflora in fish (total aerobic and mesophilic bacteria, including Pediococcus spp. [24,25,26,27]). However, due to adiabatic heating and the temperature increase that occurs during HP processing [8,9], the current industrial practice, mainly in the meat industry, includes treatment in which the pressure-transmitting fluid (i.e., water) lays within the range of 4–8 °C to prevent the potential quality deterioration caused by a temperature increase in the treated products. Moreover, several studies have reported that the inactivation of microorganisms is promoted under low temperatures due to changes in the physical state of the cell membrane [28]. However, most of the research conducted on the effect of HP treatment on the quality deterioration of fish products concerns treatments at high pressures combined with an ambient temperature, and limited work has been performed in low [17,29] or ultra-low [30] temperatures.

The European sea bass (Dicentrarchus labrax) is one of the most important cultured species in the Mediterranean, in addition to the gilthead sea bream (Sparus aurata) [31]. European sea bass are mainly consumed as fresh fish, with little activity observed in processing the fish, i.e., packing, marinating, or smoking, at least in the most important EU producers (e.g., Greece, Spain, Italy, and Croatia). European sea bass production in the EU has been rising in past years, posting a record year in 2019 with 86,149 t and a total value of EUR 491 million [32]. Sea bass is sold as both a whole fish and as fish fillets, with the latter being traded in amounts of almost 10% of the total annual production. A European sea bass fillet is a ready-to-cook product of significant commercial interest, and its shelf life plays a crucial role in the potential to distribute it to destinations far away from the production/filleting plant. Thus, by combining mild to medium processing conditions (i.e., pressure and temperature), this work aims to systematically investigate the effect of HP processing European sea bass fillets on the reduction in the initial microbial load and the estimation of the shelf life during chilled storage (0 ± 0.2 °C), which is the common practice for the transportation and storage of fresh fish.

2. Materials and Methods

2.1. Raw Material Sources and Proximate Analysis

European sea bass were harvested and transferred to the processing plant facilities of a leading aquaculture company (Avramar S.A., Attica, Greece). There, they were filleted one day after harvest. Fish fillets were provided to the Laboratory of Food Chemistry and Technology of the School of Chemical Engineering at the National Technical University of Athens within 2 h from filleting in polystyrene boxes filled with flaked ice. The sea bass fillets were analyzed for their composition, according to official methodology and as described in Ntzimani et al. [33] and Semenoglou et al. [34]. The initial composition of the sea bass fillet consisted of 22.1% (±0.63) proteins, 7.54% (±0.79) lipids, 67.7% (±2.85) moisture, and 1.34% (±0.03) ash.

2.2. Application of High Pressure on Fish Fillets

Upon receipt, the fish fillets were individually vacuum packed into laminated film packages (PE-aluminum-PET 12) and subjected to different HP treatment conditions (pressure range: 100–400 MPa; temperature range: 3–25 °C; processing time: 5 or 10 min). The experiments were conducted in a 1.5 L pilot-scale HP unit (Food Pressure Unit FPU 1.01, Resato International BV, Assen, The Netherlands) that is capable of operating in the pressure range of 100–1000 MPa and the temperature range of 0–90 °C. The pressure and temperature were continuously monitored, and water was used as the pressure transmission fluid. HP-treated and untreated fish fillets were then stored under isothermal conditions at 0.0 ± 0.2 °C (Sanyo MIR153, JP) for further testing, described below, at predefined time intervals based on microbial spoilage. The temperature was continuously monitored with temperature data-loggers (COX TRACER, Belmont, NC, United States). Fish fillets were also stored in aerobic conditions after the aseptic opening of the laminated film packages and subsequent storage.

2.3. Microbiological Analysis

A sample of 10 g of fish (both flesh and skin, including both trunk and belly muscles) was diluted and homogenized in aseptic bag with 90 g of sterilized Ringer’s solution (Ringer tablets, Merck, Darmstadt, Germany) in a bag stomacher (Interscience, Paris, France). The enumeration of the remaining viable cells of selected microorganisms [total viable count (TVC), Pseudomonas spp., Brochothrix thermosphacta, lactic acid bacteria (LAB), H2S-producing bacteria (e.g., Shewanella spp.), and Enterobacteriaceae spp.] from 10-fold serial dilutions of fish sample homogenates was conducted using the appropriate plate methodology. Two replicates of at least three appropriate dilutions were enumerated for two raw fish fillets [35].

- TVCs were enumerated using spread plate methodology on tryptic glucose yeast agar (Biolife, IT) after aerobic incubation at 25 °C for 72 h;

- Pseudomonas spp. were enumerated using spread plate methodology on Cetrimide agar (CFC, Merck, Darmstadt, Germany) after aerobic incubation at 25 °C for 48 h;

- Brochothrix thermosphacta was enumerated using spread plate methodology on Streptomycin Thallous Acetate agar (STAA, Oxoid, Lenexa, KS, United States) after aerobic incubation at 25 °C for 48 h;

- LABs were enumerated using pour plate methodology in Mann, Rogosa, and Sharpe agar (MRS, Merck, Darmstadt, Germany) after incubation under a facultatively anaerobic condition at 25 °C for 96 h;

- H2S-producing bacteria were enumerated using pour plate methodology in LYNGBY Iron Agar (Condalab, Madrid, Spain) after incubation under a facultatively anaerobic condition at 25 °C for 72 h;

- Enterobacteriaceae spp. were enumerated using pour plate methodology in Violet Red Bile Glucose agar (VRBG, Merck, Darmstadt, Germany) after incubation under a facultatively anaerobic condition at 37 °C for 24 h.

2.4. Physicochemical Analyses

The pH value of the fish samples was determined in a 1:10 dilution with Ringer’s solution, using a pH meter (AMEL 338, Amel Instruments, Milano, Italy) with a glass electrode (HI1131, HANNA instruments, Woonsocket, RI, USA).

The color parameters of the samples during storage were determined by measuring the CIELab values (L-value: darkness/lightness; a-value: redness/greenness; b-value: yellowness/blueness) using a CR200-Minolta Chromameter (Minolta Co., Chuo-Ku, Osaka, Japan) with an 8 mm measuring area. The instrument was calibrated using a white reference tile (Minolta Co., Chuo-Ku, Osaka, Japan). All measurements were carried out in triplicate.

A texture profile analysis (TPA) was performed using a TA-XT Plus texture analyzer with a 5 kg load cell (Stable Micro Systems, Surrey, United Kingdom). Briefly, fish samples were subjected to a double compression test using a stainless steel cylinder probe, SMS P/20 (20 mm diameter and 35 mm length; Stable Micro Systems, Surrey, United Kingdom). The textural parameters (hardness, cohesiveness, adhesiveness, gumminess, chewiness, and elasticity index) of the fish fillets were estimated using Exponent software, V6.1.26 (Stable Micro Systems, Surrey, Godalming, UK).

Lipid oxidation was evaluated through the 2-thiobarbituric acid reactive substances (TBARs) assay, according to the methodology described by Ntzimani et al. [33].

2.5. Sensory Evaluation

Eight trained members of the Laboratory of Food Chemistry and Technology assessed the fish fillets in our accredited (according to ISO standard 17025) Sensory Laboratory [36,37], which has a standardized room equipped with separate booths [38]. Samples were presented in plastic, coded (three-digit random codes) cups containing 10–20 g of fish samples. The panelists were asked to evaluate both raw and cooked (180 °C for 20 min in a domestic oven) samples using a 9-point intensity (1—lowest intensity; 9—highest intensity) and/or hedonic scale (1—dislike extremely; 2—dislike very much; 3—dislike moderately; 4—dislike slightly; 5—neither like nor dislike; 6—like slightly; 7—like moderately; 8—like very much; 9—like extremely), based on pre-selected sensory modalities (Table 1). The panelists were instructed to cleanse their palate with low-sodium spring water (Zagori, Greece). The evaluation data were collected in specifically designed ballots. The panelists were also asked to note any comments on the tested products.

Table 1.

Selected sensorial modalities [9-point intensity (1—lowest intensity; 9—highest intensity) and/or hedonic (1—dislike extremely; 9—like extremely)] for raw and cooked fish fillets.

2.6. Data and Statistical Analyses

The microbial load (log CFU/g) was plotted against the storage time, and the growth kinetics parameters were estimated using the Baranyi and Roberts [39] microbial growth model through the DMFit v3.5 Microsoft Excel Add-in.

The shelf life of the sea bass fillets, with the limit of acceptance for the microbial load set at 7 log CFU/g, was estimated according to the equation:

where logNlimit is the limit of acceptance for the microbial load (7 log CFU/g), logN0 is the initial microbial load of the TVC, kTVC is the growth rate (d−1) of the TVC under each treatment condition, and the second factor represents the sum of the lag phase and the two days that mediate between the harvesting of the fish and the storage of the fillets.

An analysis of variance (ANOVA) at a significance level of 95% was performed to analyze the quality degradation rates of the untreated and HP-treated fish fillets (STATISTICA® 7.0, StatSoft Inc., Tulsa, OK, United States). A Duncan’s mean post hoc comparison test (a = 0.05) was performed in order to evaluate when significant differences were observed.

3. Results and Discussion

3.1. Effect of HP Treatment on the Reduction of Initial Microflora

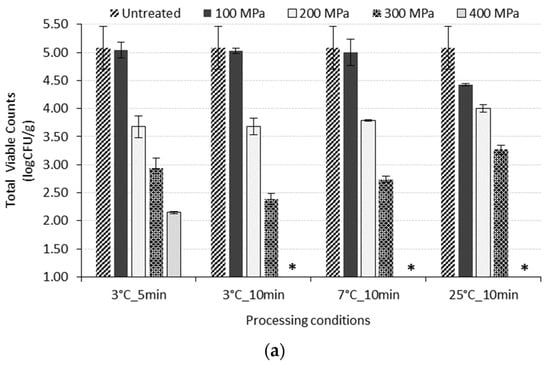

The initial microbial load (log CFU/g) for untreated sea bass fillets was 5.05 (±0.40) for TVC, 4.58 (±0.06) for Pseudomonas spp., 3.25 (±0.11) for Brochothrix thermosphacta, 2.52 (±0.09) for Enterobacteriaceae spp., 4.09 (±0.10) for LAB, and 4.77 (±0.11) for H2S-producing bacteria (Figure 1b). The application of HP treatment did not significantly affect the initial TVC load of the treated sea bass fillets when low pressures (100 MPa) were applied in combination with low treatment temperatures (3–7 °C), regardless of the processing time, while an ambient temperature at low pressures resulted in a significant (p < 0.5) TVC load reduction of up to 0.7 log CFU/g, as depicted in Figure 1a. When fillets were processed at 200 and 300 MPa, a decrease of 1.4 and 2.1 log CFU/g, respectively, was measured. An increase in the process pressure to 400 MPa reduced microflora by more than 3 log cycles to non-measurable levels (<2.0 log CFU/g) of TVC, regardless of the processing temperature.

Figure 1.

(a) Initial microbial load of untreated European sea bass fillets and after HP processing at different pressure–temperature–time conditions. (b) Microbial load of all tested microorganisms of untreated European sea bass fillets and after HP processing at different pressures and 25 °C for 10 min. Symbol (*) refers to non-measurable levels of microorganisms, i.e., <2.0 log CFU/g for TVC, Pseudomonas spp., and Brochothrix thermosphacta or <1 log CFU/g for Enterobacteriaceae spp., LAB, and H2S producing bacteria. Each bar shows the mean and the standard deviation of four replicates (n = 4).

With respect to the effect of HP processing on the mitigation of different microorganisms, the Pseudomonas spp. load was significantly decreased when low pressures of 100–200 MPa were applied, whereas the application of higher pressures of 300–400 MPa decreased the load to non-measurable limits (Figure 1b). These findings are in agreement with those reported by Castrica et al. in which high pressure treatment at 500 MPa for 2 min at 4 °C reduced the microbial load of Pseudomonas spp. to below measurable limits in fresh salmon and plaice fillets, exhibiting a lag phase of growth of 6–8 d when the fillets were stored at 4 °C [40]. Similar results were also observed for LAB in which applied pressures of above 200 MPa led to non-measurable levels of LAB at all temperatures tested. On the other hand, the Brochothrix thermosphacta load was decreased to non-measurable limits when pressures equal to or higher than 200 MPa were applied. Previous studies demonstrated that Brochothrix thermosphacta may be a dominant microorganism following treatment under HP conditions in food products of animal origin [41]. However, this was not confirmed in this study, and other microorganisms played a more crucial role in the shelf life determination of sea bass fillets. The most HP-resistant microorganisms, in descending order, were Enterobacteriaceae spp. and H2S-producing bacteria, requiring a pressure above 300 MPa for a significant microbial load reduction (2.0–3.0 log CFU/g). These results are in accordance with those previously reported for HP-treated mackerel fillets at 100–500 MPa [42]. This study reported that the HP processing at low pressure levels (100 MPa) did not significantly affect the counts of H2S-producing bacteria, whereas the application of higher pressures (300–500 MPa for 2 or 5 min at 17–22 °C) led to non-measurable levels of H2S-producing bacteria.

3.2. Effect of HP on the Bacterial Growth and the Shelf Life of Sea Bass Fillets

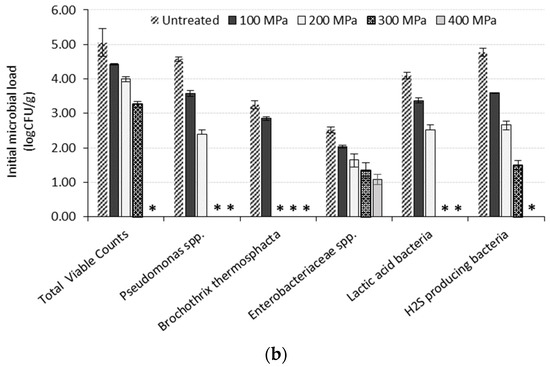

Untreated and HP-treated sea bass fillets were stored in ice (0.0 ± 0.2 °C) in the vacuum packaging used for HP processing. Fish samples that were treated at different pressures and at ambient temperature for 10 min were also stored in the same temperature but under aerobic conditions, after the laminated film packages were opened aseptically to simulate current commercial practices of distributing and selling fish in retail. Figure 2 shows the TVC growth of untreated and HP-treated sea bass fillets under different HP conditions, and Table 2 summarizes their growth parameters as they were estimated using the Baranyi and Roberts microbial growth model [39].

Figure 2.

Growth of TVC of (a) untreated and HP-treated sea bass fillets at (b) 100–400 MPa/3 °C/5 min, (c) 100–400 MPa/3 °C/10 min, (d) 100–400 MPa/7 °C/10 min, (e) 100–400 MPa/25 °C/10 min, and (f) 100–400 MPa/25 °C/10 min—stored aerobically. Symbols indicate (●)—HP at 100 MPa, (▲)—HP at 200 MPa, (■)—HP at 300 MPa, and (♦)—HP at 400 MPa. Hollow symbols refer to aerobic storage of the fillets, while solid symbols refer to vacuum-packed fillets. Each point shows the mean and the standard deviation of four replicates (n = 4).

Table 2.

Estimated microbial growth parameters and shelf life of untreated and HP-treated vacuum-packed sea bass fillets based on TVC values as the dominant spoilage microflora.

Regarding the effect of applied pressure on the growth of TVC under storage, it was observed that, in general, the higher the applied pressure, the lower was the estimated growth rate obtained (Table 2). An exception to this was the process with a pressure range above 200 MPa at 3 °C and 25 °C for 10 min. Under these processing conditions, a significantly longer lag phase was observed. These results are in accordance with previous studies which also confirmed that the application of pressure in the range of 200–400 MPa decreases the initial microbial counts by approximately 0.5–2.5 log CFU/g [20,42,43,44,45] and affects the growth rate and lag phase of the dominant microflora, thus extending the shelf life of the final fish products.

With respect to processing time, two different experiments in the pressure range of 100–400 MPa at a constant treatment temperature of 3 °C were performed, one for 5 min and one for 10 min (Figure 2b,c). An increase in the processing time by 5 min led to a significant (p < 0.001) decrease in the growth rate or an increase in the duration of the lag phase (Table 2) and hence a significant (p < 0.001) increase in the shelf life of the final product at 0 °C. Thus, in all other studied pressure–temperature combinations, HP treatment for 5 min was not investigated. Similar results have also been reported for mackerel fillets treated at 100–300 MPa for 2 and 5 min, showing that an increase of 3 min in the pressure holding time led to a slight yet significant decrease (i.e., 0.5 log CFU/g) in the total viable counts (TVCs) when a pressure of 100–300 MPa was applied, whereas when higher pressures were used, i.e., 500 MPa, the decrease in TVCs was higher than 1.0 log CFU/g, and for other spoilage microorganisms, e.g., H2S-producing bacteria, the corresponding decrease was equal to the non-measurable load [42].

Regarding the processing temperature, it was observed that a temperature decrease led to a significant (p < 0.001) decrease in the growth rate of TVC. An exception was observed only in the case in which 300 MPa was applied at the lowest temperature tested (3 °C), for which the highest growth rate was obtained. Alpas et al. [46] reported that the temperature of both the food and the pressure fluid play a significant role in the sensitivity of microorganisms under HP conditions and thus in their inactivation, with higher inactivation rates obtained either below or above the ambient temperature for mesophilic microorganisms. In fact, the pressure resistance of most microorganisms, spoilage and/or pathogens, is highest at their optimal growth temperature range, leading to higher inactivation at temperatures significantly lower or higher than their optimal growth temperature [47]. This is a result of the disruption of the cytoplasmic membrane, which becomes more rigid and changes from a liquid crystalline state to a semicrystalline gel state [28]. Similar results were also reported for the growth of psychrotropic bacteria in fresh gilthead sea bream treated at 250 MPa at 3 or 15 °C for 5 min [29], in the inactivation of Escherichia coli in beef mince pressurized at 300 MPa for 5 min and combined with temperatures of 0–20 °C [48], and for the total aerobic counts in minced chicken meat treated at 200–400 MPa and 0–40 °C for 5–15 min [49].

Comparing the growth of TVC under different storage conditions, similar growth rates were obtained in all cases with the exception of 400 MPa, which demonstrated a significant (p < 0.001) increase in the growth rate. Since the growth of the dominant spoilage microorganisms, including the aerobic Pseudomonas spp. and the facultative anaerobic Brochothrix thermosphacta, is promoted in aerobic conditions, as expected, the shelf life of samples stored aerobically was significantly lower than the corresponding shelf life of samples stored in a vacuum, particularly for samples treated at 200–400 MPa.

Regarding the effect of processing time on the growth of TVC, as presented in Table 2, the highest estimated shelf life was obtained for samples treated for 10 min. It is well established that holding time, as well as the rates of pressure compression and decompression, are key factors of HP effectiveness on bacterial inactivation, and that an increase in either the holding time or the aforementioned rates leads to higher bacterial inactivation levels under HP conditions [50]. Among the samples treated for 10 min, the highest estimated shelf life values were observed for samples treated at either 3 or 7 °C, especially when pressures of 400 MPa were applied. It is worth noting that for samples treated at 100 MPa, only in the case where a low treatment temperature was applied (i.e., 3 °C) was an extension in the shelf life observed compared to untreated samples, indicating the positive effect of a low treatment temperature on the microbial inactivation under HP conditions as a result of the changes in the physical state of the cell membranes.

3.3. Effect of HP on the Physicochemical Characteristics of Sea Bass Fillets

The pH value of untreated and HP-treated sea bass fillet did not significantly differ among aerobic and anaerobic storage conditions or various processing temperatures (Table 3). However, it did exhibit significant differences (p < 0.05) with respect to different applied pressures (statistical mean pH value: 6.58 and 6.73 for HP-treated samples at 100–300 and 400 MPa, respectively) and processing times (statistical mean value: 6.65 and 6.59 for HP-treated samples for 3 and 10 min, respectively). However, during storage, none of the untreated or HP-treated samples showed significant changes in pH value [40,51] as this parameter is directly dependent to the type of demonstrating dominant growth at each sampling interval, leading to either a slight increase when Pseudomonas spp. are the dominant microorganisms or a slight decrease when species such as Enterobacteriaceae spp., LAB, or Shewanella spp. dominate [52].

Table 3.

Physicochemical characteristics of untreated and HP-treated sea bass fillets at the beginning of their shelf life.

Among the calculated textural attributes of sea bass fillets, those of hardness and adhesiveness showed the highest variations between tested samples (Table 3). Cohesiveness and the index of elasticity (springiness) showed no differences between samples. Regarding the parameters of gumminess and chewiness, as their values are numerical products of the hardness, they followed the same trend as the hardness. Thus, the textural parameters of both hardness and adhesiveness, which are also strongly related to the sensorial acceptance of the fillets, discussed later, were found to be strongly affected by all the designing parameters, i.e., pressure, temperature, and time.

In general, untreated fillets and those treated at low pressures (100 MPa) exhibited the lowest hardness and highest adhesiveness in comparison to all other fillets, indicating that HP processing fish fillets at pressures below 200 MPa results in fish fillets with very similar characteristics to raw ones (similar results have been obtained for HP processing at 150–180 MPa within the context of this study), which is in accordance with previous studies [12]. The HP treatment of fish fillets at pressures above 200 MPa showed increasing values of hardness as the applied pressure increased up to 400 MPa, which almost doubled in the case of the fillets pressurized at 400 MPa, when compared to untreated ones or those treated at 100 MPa (statistical mean values of hardness: 182, 231, 272, and 317 g for sea bass fillets treated at 100, 200, 300, and 400 MPa, respectively). It has been reported that the increase in hardness is related to the inactivation of the proteolytic enzymes in HP-treated fish samples, inducing denser structures, especially when pressures above 200 MPa are applied [43]. Regarding the effect of the processing temperature, it was observed that the fillets which were HP treated in combination with low temperatures (3 or 7 °C) showed a significantly (p < 0.001) higher hardness than those treated in an ambient temperature (statistical mean value of hardness: 278 and 240 g for sea bass fillets treated at 3 and 25 °C, respectively). Additionally, it was also observed that the increase in processing time led to higher values of hardness (statistical mean value of hardness: 198 and 278 g for sea bass fillets treated for 5 and 10 min, respectively). The effect of HP treatment on the increase in hardness values of the fish were also reported for a variety of fish products, e.g., salmon, cod, hilsa, mackerel, sea bream, rainbow trout, and mahi mahi [12,27,52,53,54,55,56], particularly at pressures above 200 MPa. At these conditions, the denaturation of fish proteins is more likely to occur and is in direct relation to the food matrix since it has been reported that, e.g., the hardness of salmon is less susceptible to pressure changes compared to cod, especially when low pressures are applied [12].

In contrast to untreated sea bass fillets for which the hardness values exhibited a significant (p < 0.001), almost 4-fold, increase during storage (statistical mean value of hardness: 140 and 410 g at day 0 and 15, respectively), the hardness of the HP-treated sea bass fillets did not significantly change during storage, regardless of the applied pressure, processing temperature and time, and the storage conditions, which is in agreement with previous studies [12,27].

Regarding adhesiveness, both untreated fillets and sea bass fillets pressurized at a pressure of 100 MPa showed the highest values, while the lowest values were obtained for samples pressurized at 400 MPa, regardless of any other processing or storage parameter. Overall, it was observed that as the applied pressure increases, the value of adhesiveness decreases, which is also related to the increase in hardness values and the loss of stickiness of the fish fillets. An increase in the processing temperature led to a significant decrease in the adhesiveness, mainly for fish fillets treated at pressures above 300 MPa combined with temperatures above 3 °C (statistical mean value of adhesiveness: 22.0, 27.1, 6.6, and 6.1 g·s for sea bass fillets treated at 100, 200, 300, and 400 MPa, respectively, and, statistical mean value of adhesiveness: 21.6 and 14.7 g·s for sea bass fillets treated at 3 and 25 °C, respectively). Finally, processing time did not affect the adhesiveness parameter, at least in the low temperature range studied (3 °C) where it was the case that the highest value of adhesiveness, higher than that of the untreated fillets, was observed for the fillets that were pressurized at 200 MPa.

Similar to the hardness results, the adhesiveness of the HP-treated fish fillets did not exhibit any significant change during storage. However, the adhesiveness of the untreated fillets exhibited a 2-fold increase during storage (statistical mean value of adhesiveness: 15.5 and 33.0 g·s at day 0 and 15, respectively); this is probably related to the gradual softening of the fish muscle during storage under chilled conditions.

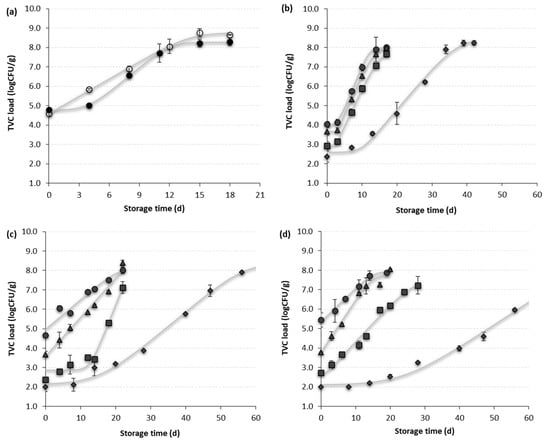

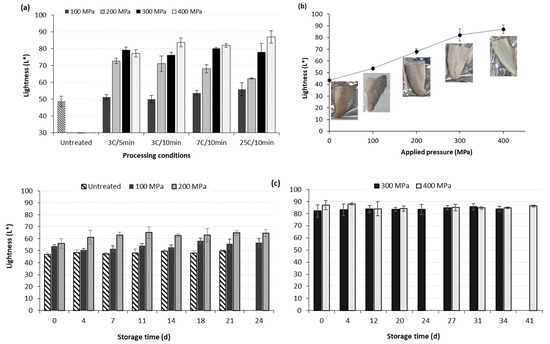

As it is related to the freshness of the product, color is considered a fundamental attribute of raw fish and plays a significant role in consumer acceptance [49,50]. The initial color parameter of the lightness (L*) of fish samples was 43.6 ± 2.19, 53.7 ± 1.43, 68.0 ± 2.37, 82.2 ± 5.22, and 87.1 ± 3.70 for untreated or HP-treated fillets at 100, 200, 300, and 400 MPa, respectively, indicating the significant (p < 0.01) whitening effect of HP processing on fish flesh, especially at pressures above 100–150 MPa (Figure 3b).

Figure 3.

(a) Values of lightness (L*) of untreated European sea bass fillets and after HP processing at different pressure–temperature–time conditions, (b) visual appearance compared to lightness (L*) values of untreated and HP-treated fish fillets, and (c) evolution of lightness (L*) during storage for fish samples treated at different pressure levels at 25 °C for 10 min. Each bar shows the mean and the standard deviation of four replicates (n = 4).

These results are in agreement with previous results obtained in gilthead seabream fillets [27] and the results of other research on salmon and plaice fillets [49], cod (Gadus morhua) fillets [12], haddock and mackerel [51,56], hilsa shad (Tenualosa ilisha) fillets [55], and milkfish (Chanos chanos) fillets [45]. This phenomenon is related to the denaturation of the proteins of the fish muscles, leading to an increase in the light reflection. It seems to be recognized as the main issue in the commercialization of HP in the seafood industry and the reason why HP treatment is only used commercially in the muscles of fish with fairly white flesh, such as cod products (ALKORTA company in Basque Country, Spain). As depicted in Figure 3a, neither the temperature nor the processing time affected the color parameter of the lightness (L*) of the fish samples. These findings are in accordance with the results reported by Erkan et al. [17,29] for cold smoked salmon and fresh gilthead sea bream treated with various combinations of pressure, temperature, and holding time (220, 250, and 330 MPa at 3, 7, 15, and 25 °C for 5 and 10 min). The color coordinates a and b (indices of redness and yellowness, respectively) were not affected by any of the processing parameters, including the pressure level. Finally, the color parameters did not change over the storage time except for small increases and decreases, which were likely related to sample variability (Figure 3c).

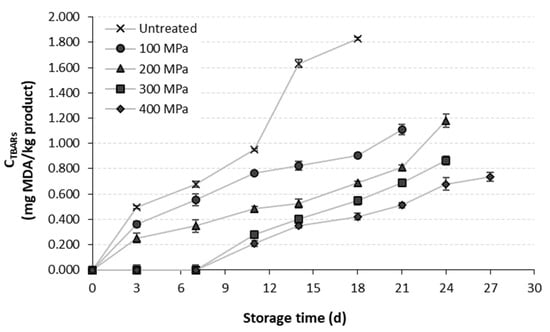

As far as lipid oxidation is concerned, this was evaluated through the TBARs index, representing the formation of secondary oxidation products, with the maximum acceptable level set at 1 mg MDA/kg of product. Lipid oxidation developed only in the case where fish fillets were aerobically stored, since no evolution of lipid oxidation was observed during the corresponding storage period for samples stored under vacuum conditions. As can be seen in Figure 4, the untreated sea bass fillets exhibited the highest TBARs values, followed by the samples treated at 100 and 200 MPa. Regarding the samples that were treated at pressures above 300 MPa, a lag phase in the development of secondary lipid oxidation products was observed. At the same time, these samples had significantly lower TBARs values than those treated at lower pressures (100–200 MPa), indicating the inhibitory effect of HP treatment on the formation of secondary lipid oxidation products. Previous studies have reported that the HP treatment of seafood at pressures above 300 MPa may lead to the inactivation of the endogenous prooxidative enzymes, which leads to oxidation development. The increased TBARs values of the samples that were treated below 200 MPa can be explained by the pressure-induced denaturation of iron-containing proteins, increasing the free metal iron [20,57].

Figure 4.

Evolution of lipid oxidation (in terms of malonic aldehyde concentration, mg MDA/kg product) of untreated European sea bass fillets and after HP processing at different pressures and ambient temperature for 10 min, and under aerobic storage. Each bar shows the standard deviation of four replicates (n = 4).

The formation of secondary oxidation products significantly increased during the storage time for all tested samples, following zero-order kinetics. The kinetic parameters of lipid oxidation were estimated through linear regression (Table 4, R2 > 0.95). The lipid oxidation rate of untreated fillets was significantly (p < 0.001) higher than that of the HP-treated fillets, exhibiting a similar shelf life to what was calculated based on microbiological data considering a TBARs index level of acceptability of 1 mg MDA/kg product [33] (10 ± 0.8 vs. 9.7 ± 1.0 d based on microbiological and oxidation data, respectively). Although fish samples treated at 100–300 MPa obtained similar rates of lipid oxidation, sea bass fillets treated at 300 MPa exhibited a significantly (p < 0.001) longer shelf life (based on oxidation data) due to the observed lag phase in the oxidation development. Overall, based on the obtained results, it seems that the lipid oxidation cannot be considered a suitable quality index for the estimation of the shelf life of HP-treated sea bass fillets under storage at 0.0 ± 0.2 °C since it leads to a significant overestimation of the shelf life when compared to the estimation based on microbiological data (shelf life estimation: 10 vs. 20 d, 14 vs. 23 d, 18 vs. 27 d, and 25 vs. 34 d, based on microbiological data vs. oxidation data, for samples at 100, 200, 300, and 400 MPa, respectively). Another chemical index that has been considered in relevant studies is the trimethyl amine oxide (TMAO) to trimethyl amine (TMA) conversion. As the application of HP in sea food can lead to lower values of TMA after processing and in cold storage (Roobab et al. 2021 [10]), TMA was not quantified in this study.

Table 4.

Kinetic parameters of TBARs development for different treated sea bass fillets aerobically stored.

3.4. Effect of HP on the Sensorial Characteristics of Fish Fillets

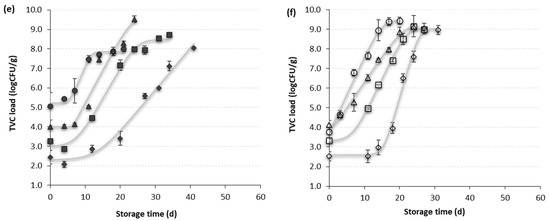

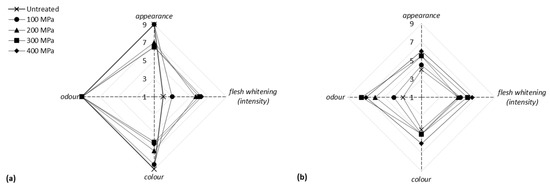

The sea bass fillets were evaluated both raw and cooked in order to investigate the effect of HP treatment on selected sensorial attributes of the samples. Regarding the case of raw untreated and raw HP-treated fillets, the samples were presented to the panelists as a ready-to-cook product. Results indicated that the application of HP at pressures above 100 MPa led to fish fillets with a significantly lighter surface and consequently lower scores for color and appearance (as they were evaluated on a hedonic scale). However, they did not reach unacceptable levels (set level of acceptance: 5), at least at the beginning of the storage period (Figure 5a). However, it is worth noting that at the end of the storage period, both the untreated samples and those treated at 100 MPa exhibited the most intense changes in terms of appearance and color when compared to samples treated at pressures above 200 MPa, which achieved similar results throughout the storage period (Figure 5b). Moreover, the latter samples exhibited the least changes regarding odor, maintaining it above acceptable levels until the end of their shelf life. This might be attributed to the bacterial mitigation after HP processing and consequently to the inhibited production of off-odor products, e.g., trimethylamine, biogenic amines, and volatile nitrogen, leading to odor stability and an improved consumer acceptability of the HP-treated fish products [40].

Figure 5.

Radar charts of sensorial attributes of raw sea bass fillets (a) at day 0 and (b) at the end of the corresponding storage period for each sample. HP treatment was performed at 7 °C for 10 min. Each point value is the mean of eight replicates (n = 8 panelists).

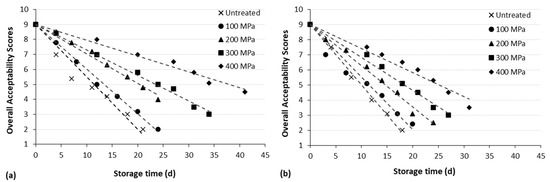

Figure 6 presents the overall acceptability scores for untreated and HP-treated fish samples, with the latter being treated at different pressure levels and at an ambient temperature for 10 min as it was observed that both the processing temperature and time had no effect on the sensorial characteristics of the fillets. This is in agreement with previous studies in which no effect of temperature and processing time was observed on the sensorial attributes of cold smoked salmon and fresh gilthead sea bream stored at 2 °C after undergoing HP treatment at 220, 250, and 330 MPa at 3–25 °C for 5 and 10 min [17,29].

Figure 6.

Overall acceptability scores of cooked untreated and HP-treated sea bass fillets at (a) 100–400 MPa/25 °C/10 min and (b) 100–400 MPa/25 °C/10 min—stored aerobically, where symbols indicate (✕) untreated sample, and HP treated samples at (●) 100 MPa, (▲) 200 MPa, (■) 300 MPa, and (♦) 400 MPa during storage. Each point value is the mean of eight replicates (n = 8 panelists).

The degradation of the sensorial quality of the sea bass fillets followed zero-order kinetics, and the rates of sensorial degradation were estimated at 0.341 ± 0.023, 0.323 ± 0.021, 0.216 ± 0.006, 0.187 ± 0.009, and 0.119 ± 0.010 d−1 for untreated and HP-treated fillets at 100, 200, 300, and 400 MPa, respectively, when samples were stored in a vacuum (Figure 6a) and at 0.405 ± 0.029, 0.347 ± 0.023, 0.273 ± 0.011, 0.224 ± 0.014, and 0.178 ± 0.009 d−1 for untreated and HP-treated fillets at 100, 200, 300, and 400 MPa, respectively, when samples were aerobically stored (Figure 6b). The results indicated that when samples are stored aerobically, as previously also obtained from microbiological data, the overall quality deterioration is enhanced, relating to both the development of lipid oxidation under aerobic storage conditions and the growth of aerobic and facultative anaerobic microorganisms such as Pseudomonas spp. and Brochothrix thermosphacta, leading mainly to the development of off-odor and off-taste.

For the untreated and HP-treated fish samples at an ambient temperature for 10 min, regardless of the storage conditions, the shelf life was also estimated based on the data obtained through the sensorial evaluation. Taking into account a level of overall acceptability score of 5 [27], the point at which the main off-odor and off-taste begin to develop due to high bacterial growth and hence the sensorially negative metabolites accumulate, the estimated shelf life was 11 ± 0.9, 13 ± 0.4, 20 ± 0.8, 23 ± 0.8, and 38 ± 4.2 d for untreated and HP-treated fillets at 100, 200, 300, and 400 MPa, respectively, when the samples were stored in a vacuum, and 10 ± 0.3, 11 ± 0.8, 14 ± 0.6, 18 ± 0.8, and 25 ± 1.8 d for untreated and HP-treated fillets at 100, 200, 300, and 400 MPa, respectively, when the samples were aerobically stored. These results are well correlated to the results obtained based on the microbiological data for only the HP-treated fish fillets in pressures above 200 MPa, and they could be equally used for the estimation of the shelf life. Nevertheless, the obtained rates of sensorial degradation of the untreated and the HP-treated fish fillets at pressures below 200 MPa led to an overestimation by 1–3 d of the shelf life of the products under the studied storage conditions.

4. Conclusions

Although the application of HP technology in the food industry is related to a high capital cost, it has a low environmental impact in terms of energy and water consumption as no additional energy is required except what is needed for pressure build-up, and the water used during the process can be recycled. Regarding the fish fillets, our study confirmed that mild HP technology can enhance the quality of the final products, achieving the inactivation of the spoilage microorganisms related to quality deterioration, improved textural attributes, the delay of lipid oxidation, and the maintenance of pH stability. The HP processing of sea bass fillets at low pressure levels of 100–200 MPa for 10 min leads to a shelf life extension of up to 10 d when products are stored at 0.0 ± 0.2 °C, whereas the application of higher pressures, i.e., 300–400 MPa, can further increase the shelf life by 10–40 d, depending on the applied treatment temperature. Moreover, the combination of HP treatment with vacuum packaging may act additively on the shelf life extension of sea bass fillets, increasing their shelf life by 4–12 d when compared to the shelf life of aerobically stored products, depending on the applied pressure, while maintaining the quality characteristics of raw fish and the sensorial attributes of the final cooked products. In conclusion, the HP processing of fish fillets that exhibit flesh whitening could potentially be promoted as a positive aspect of product marketing, since products with this characteristic exhibit several advantages, such as a significantly longer shelf life than untreated products. This significant shelf life extension allows for commercial distribution to long-distance markets, ensuring the exportability of acceptable-quality products with an extended remaining shelf life for producers.

Author Contributions

Conceptualization, M.T., G.D., A.L., I.S., T.T. and P.T.; methodology, M.T., I.S. and T.T.; validation, M.T., G.D. and A.L.; investigation, M.T., G.D., A.L. and I.S.; resources, P.T.; data curation, M.T., G.D., A.L. and I.S.; writing—original draft preparation, M.T. and T.T.; writing—review and editing, M.T. and T.T.; visualization, M.T., G.D. and A.L.; supervision, M.T. and P.T.; project administration, M.T. and P.T.; funding acquisition, T.T. and P.T. All authors have read and agreed to the published version of the manuscript.

Funding

This research was co-financed by Greece and the European Union, European Maritime and Fisheries Fund in the context of the implementation of the Greek Operational Programme for Fisheries, Priority Axis “Innovation in Aquaculture”, Project title: Application of High Pressure and Cold Atmospheric Plasma Technologies for the Production of High Quality and Extended Shelf Life Fish Fillets (2019–2023) (MIS 5019170), http://www.novish.itap.com.gr (accessed on 12 April 2019).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors would like to kindly thank the project partner AVRAMAR S.A. for the supply of the raw fish fillets.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ghaly, A.E.; Dave, D.; Budge, S.; Brooks, M.S. Fish spoilage mechanisms and preservation techniques: Review. Am. J. Appl. Sci. 2010, 7, 859–877. [Google Scholar] [CrossRef]

- Tsironi, T.; Houhoula, D.; Taoukis, P. Hurdle technology for fish preservation. Aquac. Fish. 2020, 5, 65–71. [Google Scholar] [CrossRef]

- Tavares, J.; Martins, A.; Fidalgo, L.G.; Lima, V.; Amaral, R.A.; Pinto, C.A.; Silva, A.M.; Saraiva, J.A. Physical emerging technologies. Foods 2021, 10, 1–20. [Google Scholar]

- Adeyeye, S.A.O. Smoking of fish: A critical review. J. Culin. Sci. Technol. 2019, 17, 559–575. [Google Scholar] [CrossRef]

- Tsironi, T.; Taoukis, P.S. Modeling microbial spoilage and quality of gilthead seabream fillets: Combined effect of osmotic pretreatment, modified atmosphere packaging and nisin on shelf life. J. Food Sci. 2010, 75, 243–251. [Google Scholar] [CrossRef]

- Choulitoudi, E.; Ganiari, S.; Tsironi, T.; Taoukis, P.; Oreopoulou, V. Edible coating enriched with rosemary extracts to enhance oxidative and microbial stability of smoked eel fillets. Food Packag. Shelf Life 2017, 12, 107–113. [Google Scholar] [CrossRef]

- Laub-Ekgreen, M.H.; Martinez-Lopez, B.; Frosch, S.; Jessen, F. The influence of processing conditions on the weight change of single herring (Clupea herengus) fillets during marinating. Food Res. Int. 2018, 108, 331–338. [Google Scholar] [CrossRef] [PubMed]

- Tsevdou, M.; Gogou, E.; Taoukis, P. High hydrostatic pressure processing of foods. In Green Food Processing Techniques: Preservation, Transformation and Extraction; Vorobiev, E., Chemat, F., Eds.; Academic Press: London, UK, 2019; pp. 87–137. [Google Scholar]

- Tonello, C. Case Studies on High Pressure Processing of Foods. In Nonthermal Processing Technologies for Food; Zhang, H.Q., Barbosa-Cánovas, G.V., Balasubramaniam, V.M., Dunne, C.P., Farkas, D.F., Yuan, J.T.C., Eds.; Blackwell Publishing Ltd.: Hoboken, NJ, USA, 2011; pp. 36–50. [Google Scholar]

- Roobab, U.; Fidalgo, L.G.; Arshad, R.N.; Khan, A.W.; Zeng, X.-A.; Bhat, Z.F.; Bekhit, A.E.-D.A.; Batool, Z.; Aadil, R.M. High pressure processing of fish and shellfish products: Safety, quality, and research prospects. Compr. Rev. Food Sci. Food Saf. 2021, 21, 3297–3325. [Google Scholar] [CrossRef]

- Chen, L.; Wang, Y.; Zhu, C.; Zhang, D.; Liu, H. Effects of high pressure processing on aquatic products with an emphasis on sensory evaluation. Int. J. Food Sci. Technol. 2022, 57, 6980–6996. [Google Scholar] [CrossRef]

- Arnaud, C.; de Lamballerie, M.; Pottier, L. Effect of high pressure processing on the preservation of frozen and re-thawed sliced cod (Gadus morhua) and salmon (Salmo salar) fillets. High Press Res. 2018, 38, 62–79. [Google Scholar] [CrossRef]

- Zhang, Y.; Bi, Y.; Wang, Q.; Cheng, K.-W.; Chen, F. Application of high pressure processing to improve digestibility, reduce allergenicity, and avoid protein oxidation in cod (Gadus morhua). Food Chem. 2019, 298, 125087. [Google Scholar] [CrossRef] [PubMed]

- Cartagena, L.; Puértolas, E.; Martínez de Marañón, I. High pressure processing (HPP) for decreasing weight loss of fresh albacore (Thunnus alalunga) steaks. Food Bioprocess Technol. 2019, 12, 2074–2084. [Google Scholar] [CrossRef]

- Cartagena, L.; Puértolas, E.; Martínez de Marañón, I. Evolution of quality parameters of high pressure processing (HPP) pretreated albacore (Thunnus alalunga) during long-term frozen storage. Innov. Food Sci. Emerg. Technol. 2020, 62, 102334. [Google Scholar] [CrossRef]

- Cartagena, L.; Puértolas, E.; Martínez de Marañón, I. High pressure pretreatment in albacore (Thunnus alalunga) for reducing freeze-driven weight losses with minimal quality changes. J. Sci. Food Agric. 2020, 101, 2704–2711. [Google Scholar] [CrossRef]

- Erkan, N.; Üretener, G.; Alpas, H.; Selçuk, A.; Özden, Ö.; Buzrul, S. The effect of different high pressure conditions on the quality and shelf life of cold smoked fish. Innov. Food Sci. Emerg. Technol. 2011, 12, 104–110. [Google Scholar] [CrossRef]

- Teixeira, B.; Fidalgo, L.; Mendes, R.; Costa, G.; Cordeiro, C.; Marques, A.; Saraiva, J.A.; Nunes, M.L. Effect of high pressure processing in the quality of sea bass (Dicentrarchus labrax) fillets: Pressurization rate, pressure level and holding time. Innov. Food Sci. Emerg. Technol. 2014, 22, 31–39. [Google Scholar] [CrossRef]

- Tsironi, T.; Anjos, L.; Pinto, P.I.S.; Dimopoulos, G.; Santos, S.; Santa, C.; Manadas, B.; Canario, A.; Taoukis, P.; Power, D. High pressure processing of European sea bass (Dicentrarchus labrax) fillets and tools for flesh quality and shelf life monitoring. J. Food Eng. 2019, 262, 83–91. [Google Scholar] [CrossRef]

- Cropotova, J.; Mozuraityte, R.; Standal, I.B.; Ojha, S.; Rustad, T.; Tiwari, B. Influence of high pressure processing on quality attributes of haddock and mackerel minces during frozen storage, and fishcakes prepared thereof. Innov. Food Sci. Emerg. Technol. 2020, 59, 102236. [Google Scholar] [CrossRef]

- Roobab, U.; Afzal, R.; Ranjha, M.M.A.N.; Zeng, X.-A.; Ahmed, Z.; Aadil, R.M. High pressure-based hurdle interventions for raw and processed meat: A clean-label prospective. Int. J. Food Sci. 2022, 57, 816–826. [Google Scholar] [CrossRef]

- Lakshmanan, R.; Dalgaard, P. Effects of high -pressure processing on Listeria monocytogenes, spoilage microflora and multiple compound quality indices in chilled cold-smoked salmon. J. Appl. Microbiol. 2004, 96, 398–408. [Google Scholar] [CrossRef]

- Ramaswamy, H.S.; Zaman, S.U.; Smith, J.P. High pressure destruction kinetics of Escherichia coli (O157:H7) and Listeria monocytogenes (Scott A) in a fish slurry. J. Food Eng. 2008, 87, 99–106. [Google Scholar] [CrossRef]

- Ramirez-Suarez, J.C.; Morrissey, M.T. Effect of high pressure processing (HPP) on shelf life of albacore tuna (Thunnus alalunga) minced muscle. Innov. Food Sci. Emerg. Technol. 2006, 7, 19–27. [Google Scholar] [CrossRef]

- Panagou, E.; Tassou, C.C.; Manitsa, C.; Mallidis, C. Modelling the effect of high pressure on the inactivation kinetics of a pressure-resistant strain of Pediococcus damnosus in phosphate buffer and gilt-head seabream (Sparus aurata). J. Appl. Microbiol. 2007, 102, 1499–1507. [Google Scholar] [CrossRef] [PubMed]

- Yagiz, Y.; Kristinsson, H.G.; Balaban, M.O.; Welt, B.A.; Ralat, M.; Marshall, M.R. Effect of high pressure processing and cooking treatment on the quality of Atlantic salmon. Food Chem. 2009, 116, 828–835. [Google Scholar] [CrossRef]

- Tsironi, T.; Maltezou, I.; Tsevdou, M.; Katsaros, G.; Taoukis, P. High Pressure Cold Pasteurization of Gilthead Seabream Fillets: Selection of Process Conditions and Validation of Shelf Life Extension. Food Bioprocess Technol. 2015, 8, 681–690. [Google Scholar] [CrossRef]

- terSteeg, P.F.; Hellemons, J.C.; Kok, A.E. Synergistic actions of nisin, sublethal ultrahigh pressure and reduced temperature on bacteria and yeast. Appl. Environ. Microbiol. 1999, 65, 4148–4154. [Google Scholar] [CrossRef]

- Erkan, N.; Üretener, G. The effect of high hydrostatic pressure on the microbiological, chemical and sensory quality of fresh gilthead sea bream (Sparus aurata). Eur. Food Res. Technol. 2010, 230, 533–542. [Google Scholar] [CrossRef]

- Boziaris, I.S.; Parlapani, F.F.; DeWitt, C.A.M. High pressure processing at ultra-low temperatures: Inactivation of foodborne bacterial pathogens and quality changes in frozen fish fillets. Innov. Food Sci. Emerg. Technol. 2021, 74, 102811. [Google Scholar] [CrossRef]

- Wirtz, C. Agriculture, forestry and fishery statistics. In Eurostat Products Statistical Books; Publications Office of the European Union: Luxembourg, Luxembourg, 2020. [Google Scholar]

- European Market Observatory for Fisheries and Aquaculture Products (EUMOFA). Species Profile: European Seabass; EUMOFA: Brussels, Belgium, 2022. [Google Scholar]

- Ntzimani, A.; Angelakopoulos, R.; Semenoglou, I.; Dermesonlouoglou, E.; Tsironi, T.; Moutou, K.; Taoukis, P. Slurry ice as an alternative cooling medium for fish harvesting and transportation—Study of the effect on seabass flesh quality and shelf life. Aquac. Fish. 2023, 8, 385–392. [Google Scholar] [CrossRef]

- Semenoglou, I.; Eliasson, L.; Uddstål, R.; Tsironi, T.; Taoukis, P.; Xanthakis, E. Supercritical CO2 extraction of oil from Arctic charr side streams from filleting processing. Innov. Food Sci. Emerg. Technol. 2021, 71, 10212. [Google Scholar] [CrossRef]

- Koutsoumanis, K.P.; Taoukis, P.S.; Drosinos, E.H.; Nychas, G.-J.E. Applicability of an Arrhenius Model for the Combined Effect of Temperature and CO2 Packaging on the Spoilage Microflora of Fish. Appl. Environ. Microbiol. 2000, 66, 3528–3534. [Google Scholar] [CrossRef]

- ISO 13300-1; Sensory Analysis—General Guidance for the Staff of a Sensory Evaluation Laboratory—Part 1: Staff Responsibilities. International Organization for Standardization (ISO): Geneva, Switzerland, 2006.

- ISO 13300-2; Sensory Analysis—General Guidance for the Staff of a Sensory Evaluation Laboratory—Part 2: Recruitment and Training of Panel Leaders. International Organization for Standardization (ISO): Geneva, Switzerland, 2006.

- ISO 8589; Sensory Analysis—General Guidance for the Design of Test Rooms. International Organization for Standardization (ISO): Geneva, Switzerland, 2007.

- Baranyi, J.; Roberts, T.A. Mathematics of predictive food microbiology. Int. J. Food Microbiol. 1995, 26, 199–218. [Google Scholar] [CrossRef]

- Castrica, M.; Pavlovic, R.; Balzaretti, C.M.; Curone, G.; Brecchia, G.; Copelotti, E.; Panseri, S.; Pessina, D.; Arnoldi, C.; Chiesa, L.M. Effect of High Pressure Processing on Physico-Chemical, Microbiological and Sensory Traits in Fresh Fish Fillets (Salmo salar and Pleuronectes platessa). Foods 2021, 10, 1775. [Google Scholar] [CrossRef]

- Argyri, A.A.; Papadopoulou, O.S.; Sourri, P.; Chorianopoulos, N.; Tassou, C.C. Quality and Safety of Fresh Chicken Fillets after High Pressure Processing: Survival of Indigenous Brochothrix thermosphacta and Inoculated Listeria monocytogenes. Microorganisms 2019, 7, 520. [Google Scholar] [CrossRef]

- de Alba, M.; Pérez-Andrés, J.M.; Harrison, S.M.; Brunton, N.P.; Burgess, C.M.; Tiwari, B.K. High pressure processing on microbial inactivation, quality parameters and nutritional quality indices of mackerel fillets. Innov. Food Sci. Emerg. Technol. 2019, 55, 80–87. [Google Scholar] [CrossRef]

- Kumar, V.; Rao, P.S.; Purohit, S.R.; Kumar, Y. Effects of high pressure processing (HPP) and acid pre-treatment on quality attributes of hilsa (Tenualosa ilisha) fillets. LWT Food Sci. Technol. 2019, 111, 647–652. [Google Scholar] [CrossRef]

- Romulo, A. The impact of high pressure processing treatment on microbial inactivation of seafood—A review. Food Res. 2021, 5, 38–44. [Google Scholar] [CrossRef]

- Kung, H.-F.; Lin, C.-S.; Liu, S.-S.; Huang, C.-Y.; Chiu, K.; Lee, Y.-C.; Tsai, Y.-H. High pressure processing extend the shelf life of milkfish flesh during refrigerated storage. Food Control 2022, 134, 108768. [Google Scholar] [CrossRef]

- Alpas, H.; Kalchayanand, N.; Bozoglu, F.; Ray, B. Interactions of high hydrostatic pressure, pressurization temperature and pH on death and injury of pressure-resistant and pressure-sensitive strains of foodborne pathogens. Int. J. Food Microb. 2000, 60, 33–42. [Google Scholar] [CrossRef]

- Moussa, M.; Perrier-Cornet, J.M.; Gervais, P. Damage in Escherichia coli cells treated with a combination of High Hydrostatic Pressure and subzero temperature. Appl. Environ. Microbiol. 2007, 73, 6508–6518. [Google Scholar] [CrossRef]

- Bulut, S. The effects of high pressure processing at low and subzero temperatures on inactivation of microorganisms in frozen and unfrozen beef mince inoculated with Escherichia coli strain ATCC 25922. Food Bioprocess Technol. 2014, 7, 3033–3044. [Google Scholar] [CrossRef]

- Bulut, S.; Chapleau, N.; de Lamballerie, M.; Le-Bail, A. High Pressure Processing of chicken meat: Change in total aerobic counts after pressure treatment and during chilled storage. Br. Microbiol. Res. J. 2014, 4, 540–549. [Google Scholar] [CrossRef]

- Chapleau, N.; Ritz, M.; Delépine, S.; Jugiau, F.; Federighi, M.; de Lamballerie, M. Influence of kinetic parameters of high pressure processing on bacterial inactivation in a buffer system. Int. J. Food Microbiol. 2006, 106, 324–330. [Google Scholar] [CrossRef] [PubMed]

- Rode, T.M.; Hovda, M.B. High pressure processing extend the shelf life of fresh salmon, cod and mackerel. Food Control 2016, 70, 242–248. [Google Scholar] [CrossRef]

- Truong, B.Q.; Buckow, R.; Stathopoulos, C.E.; Nguyen, M.H. Advances in High Pressure Processing of Fish Muscles. Food Eng. Rev. 2015, 7, 109–129. [Google Scholar] [CrossRef]

- Cheftel, J.C. Review: High pressure, microbial inactivation and food preservation. Food Sci. Technol. Int. 1995, 1, 75–90. [Google Scholar] [CrossRef]

- Yagiz, Y.; Kristinsson, H.G.; Balaban, M.O.; Marshall, M.R. Effect of high pressure treatment on the quality of rainbow trout (Oncorhynchus mykiss) and mahi mahi (Coryphaena hippurus). J. Food Sci. 2007, 72, C509–C515. [Google Scholar] [CrossRef]

- Chouhan, A.; Kaur, B.P.; Rao, P.S. Effect of high pressure processing and thermal treatment on quality of hilsa (Tenualosa ilisha) fillets during refrigerated storage. Innov. Food Sci. Emerg. Technol. 2015, 29, 151–160. [Google Scholar] [CrossRef]

- Christensen, L.B.; Hovda, M.B.; Rode, T.M. Quality changes in high pressure processed cod, salmon and mackerel during storage. Food Control 2017, 72, 90–96. [Google Scholar] [CrossRef]

- Pazos, M.; Mendez, L.; Fidalgo, L.; Vásquez, M.; Torres, J.A.; Aubourg, S.P.; Saraiva, J.A. Effect of high pressure processing of Atlantic mackerel (Scomber scombrus) on biochemical changes during commercial frozen storage. Food Bioprocess Technol. 2015, 8, 2159–2170. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).