Abstract

In view of the problem that the research of potato friction damage is not sufficiently systematic and the characteristics of potato friction damage and energy loss are not clear, this paper investigates the initial height, potato mass, potato varieties, friction materials and temperature as experimental factors and the epidermal damage proportion as the evaluation index, filtering for significant factors by a factorial test. On this basis, the proportion of epidermal damage and the ratio of energy consumption loss were used as evaluation indicators to conduct a single factor test for significant factors. Thereby, the influence of these factors on friction damage and energy loss characteristics of potato were further investigated. The results show that the initial height, potato mass and potato varieties were the significant factors affecting the proportion of epidermal damage of potatoes. With the increase in initial height, the proportion of epidermal damage and ratio of energy consumption loss gradually increased. With the increment in potato mass, the proportion of epidermal damage gradually increased, and the energy consumption loss ratio gradually decreased. The epidermal damage proportion and energy consumption loss ratio of potato varieties were ranked as Xisen 1 > Jizhang 12 > Xisen 6 > Xuechuanhong > Netherlands 15, and Netherlands 15 > Xisen 6 > Xisen 1 > Xuechuanhong > Jizhang 12, respectively. The energy loss ratio and epidermal damage proportion were highly correlated at initial height and potato mass. A mathematical model for predicting the proportion of epidermal damage using energy consumption loss ratio is proposed: η1 = 0.8861ζ − 0.2062 (R2 = 0.8626), η2 = −0.5813ζ + 0.2394 (R2 = 0.8537).

1. Introduction

The mechanized potato harvesting industry has experienced rapid development since China launched the strategy to process potatoes as a staple food in 2015 [1]. The harvest efficiency of potatoes has greatly improved due to research and development as well as the popularization of potato harvesting machinery [2,3,4]. However, the problem of epidermal damage due to potato soil separation and transport during harvest has also become increasingly prominent [5]. Epidermal damage directly affects the appearance and quality of potatoes, and their economic value is also reduced [6,7,8]. In addition, potatoes with a damaged epidermis are not resistant to storage as they are highly susceptible to bacterial infection, causing softening and decay [9,10].

At present, there are many reports on potato damage in China and in other countries, most of which are based on tests by potato drop collision and impact test rigs. Different researchers have selected different test factors and evaluation indicators. Some research teams have established the relationship among impact acceleration, drop height and damage severity, and obtained the influence of tuber size and temperature on potato damage [11]. Other research teams also determined linear regression models for a comprehensive potato damage index through single factor tests [12]. The research of Weigang Deng shows that the order of importance for the factors affecting the severity of potato collision damage is falling height, impact materials, impact times and potato mass [13]. Similarly, it was also found by Tianci Huang that the significant factors affecting the comprehensive index of potato damage are impact materials and potential energy [14]. Different from others, Shengshi Xie adopted an acceleration acquisition system and concluded that the primary and secondary order of factors affecting the volume of potato collision damage was initial height, potato mass, potato temperature and collision material, and the variation in the relationship between collision acceleration and damage area under different factors was determined [15]. In addition, some researchers obtained the critical damage value of potato under different conditions through response surface analysis in an orthogonal experiment of potato combinations [16]. Apart from these studies, other scholars have studied the friction characteristics of some agricultural materials. Most of these studies focus on the determination of the static friction coefficient and dynamic friction coefficient of materials, including the determination of the friction coefficient of apples with plexiglass and kraft paper, respectively [17]. Some studies have also been carried out on potato skins and different varieties, and the friction coefficient of potatoes has also been acquired [18,19,20].

Through the analysis of existing studies, it can be seen that the relevant studies focus on the damage caused by potato collision. The research on friction paid close attention to the measurement of the friction coefficient between potato and different materials, and systematic research on the characteristics of potato friction damage was rarely reported. Meanwhile, the effects of different experimental factors on friction damage and related characteristic parameters of potatoes have not been reported.

Based on the above analysis, this paper uses a single pendulum friction test rig to select the significant factors affecting potato friction damage through a factorial test. It then explores the effect of significant factors on potato friction damage and energy loss characteristics through a single factor test. The regression equation and correlation coefficients between significant factors and evaluation indicators as well as between evaluation indicators were obtained, taking the proportion of epidermal damage and the ratio of energy consumption loss as evaluation indicators. Through the above experiments and analysis, the significant factors affecting potato friction damage are systematically assessed, and the effects of significant factors on potato friction damage, friction energy loss and other characteristics are analyzed in order to provide a theoretical basis and technical support for the mechanisms of potato epidermal damage and the design and optimization of potato harvest and delivery devices.

2. Materials and Methods

2.1. Test Materials and Equipment

The potatoes used in this experiment were the varieties under mass production in the current season in Hohhot, China. The varieties used in the factorial test were Xuechuanhong and Xisen 1, with about 100 in each variety, and the varieties used in the single factor test were Xisen 1, Xisen 6, Xuechuanhong, Netherlands 15 and Jizhang 12, with about 100 potatoes for each variety. Before the test, the potatoes were wiped with a wet cloth, and those with a non-damaged epidermis were selected for the experiment.

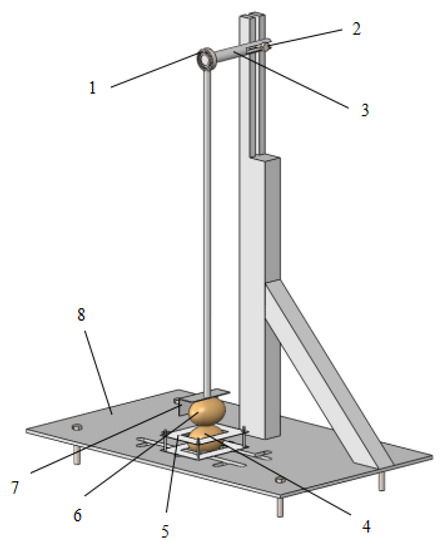

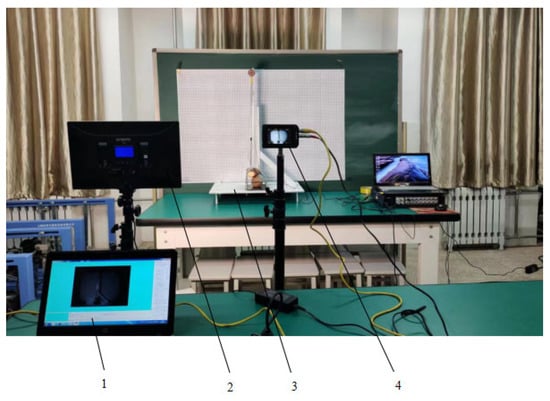

The equipment used in this test included the self-built single pendulum friction test device as shown in Figure 1 and the friction image acquisition system as shown in Figure 2.

Figure 1.

Single pendulum friction test device. 1. Rolling bearing. 2. Adjusting nut. 3. Supporting shaft. 4. Friction material. 5. Fixture 1. 6. Potato. 7. Fixture 2. 8. Test bench support.

Figure 2.

Friction image acquisition system. 1. Computer. 2. Flat panel light supplement. 3. Single pendulum friction test device. 4. High-speed digital camera.

The friction image acquisition system included a high-speed digital camera and a computer. The Phantom Miro2 high-speed digital camera manufactured by Vision Research Company of the United States was used in this experiment. Its function is to capture an image of friction process so as to realize the study of friction energy loss. After the camera was installed and powered on, the photo acquisition control software Phantom-675.2 matched with the high-speed camera was opened. The first option “Setup and Recording…” under the Acquisition menu was selected and the main parameters of the Phantom high-speed camera were set. The resolution was set to 640 × 480 and the number of frames was set to 200.

2.2. Evaluation Indicators

2.2.1. Epidermal Damage Proportion

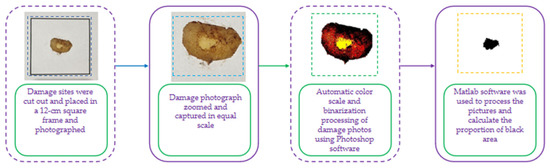

Epidermal damage on potatoes is inevitable during friction, and its area is traditionally measured using an area calculation formula based on the length and width of the damage site measured by vernier calipers [21]. According to a subsequent study, this method may result in errors. A new method that can characterize the damage area on a potato was thus designed as the evaluation index in this experiment [22].

The photo processing of potato damage is shown in Figure 3. Firstly, the damaged parts of the potato after a friction test were cut and placed in a square frame with a side length of 12 cm for photography. In order to exclude the problem of inconsistency in the ratio of the number of pixels in the black area to the blank area caused by the height, angle and light of the photo, the phone was fixed on a stand and the fill light was fixed above the photo area. The angle was adjusted and the photo was taken. The structure of the photo was kept unchanged until the test was completed. Then, the damage photos were enlarged and cropped in equal proportions. Automatic color gradation and binarization processing were carried out in Photoshop software to highlight the damaged parts so as to obtain pictures which allowed easy identification of the damaged area. The threshold value for the color scale process was 0.6, and the threshold value for the binarisation process was 0.7. Finally, the pictures were processed in Matlab software to calculate the proportion of the black area, which was also the proportion of the epidermal damage, that could be expressed with the formula below:

where, η is the proportion of epidermal damage (%), S1 is the number of pixels in the black area, and S2 is the number of boxed pixels.

Figure 3.

Flow chart of photo processing of potato damage.

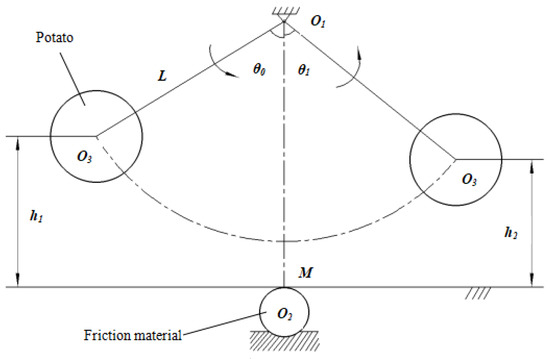

2.2.2. Energy Loss Ratio

During the process of the potato contacting the friction materials, the energy loss caused by friction inevitably changes the swing angle and height before and after potato friction, and this energy loss ratio was taken as an index to evaluate the energy loss due to friction. The energy loss of the single pendulum itself during a swing was ignored for its mass was much smaller than that of potato [23]. Figure 4 shows the position of the potato before and after contact with the friction material. The potato was released after lifting to height h1 at the beginning of the experiment; it then rubbed against the friction material in the lowest position and continued to swing forward to the highest position h2.

Figure 4.

Positions of beginning and end of the potato friction test.

From Figure 4, the energy loss before and after friction can be calculated using the following formula:

where ΔE is the energy loss before and after friction (J), m is the potato mass (kg), h1 is the potato lift height at the start of the friction test (m), h2 is the potato swing height at end of the friction test (m), and g is gravity acceleration (m/s2).

According to the geometric relationship in Figure 4, further analysis shows that:

where L is the distance from the pendulum center to the potato center (m), θ0 is the potato lift swing angle at start of the friction test (°). Then h2 is calculated as:

where θ1 is the potato swing angle at the end of the friction test (°).

Bringing (2) and (3) into (1) gives:

In order to facilitate analyzing and comparing the energy loss of the potato during friction, the energy loss ratio of friction is defined as the ratio of energy loss before and after friction to the initial kinetic energy, and formula is obtained as below:

where ζ is the energy loss ratio (%).

The values of L and h1 can be determined according to the test conditions, and θ0 and θ1 are determined by the angle measurement tool provided by the high-speed camera data processing software [23].

2.3. Test Design and Methods

A factorial experiment was conducted to identify the significant factors affecting friction damage of potatoes among five factors: initial height, potato mass, potato varieties, friction materials and temperature. Then, through a single factor test, the influence of significant factors on the friction damage and energy loss characteristics of potatoes were explored, and the regression equation and correlation coefficient between significant factors and test indicators and between indicators were obtained.

Based the common height differences between potato soil separation devices and potato conveying devices, five levels (300, 400, 500, 600, and 700 mm) were tested [24]. The potato masses tested were 150 ± 5, 250 ± 5, 350 ± 5, 450 ± 5 and 550 ± 5 g according to Quality Standard for Fresh Potato Grade (Trial) of China. The potato varieties were selected based on those in mass production in the current season, namely, Xisen 1, Xisen 6, Xuechuanhong, Netherlands 15 and Jizhang 12. Based on materials that may cause friction damage on potato during harvest, 65Mn steel and potato were selected as friction materials. A temperature of 4 °C is suitable for storage of potatoes; however, due to limited storage conditions, sometimes potatoes are also stored indoors at 22 °C. Therefore, 4 ± 1 °C and 22 ± 1 °C were selected as the temperature levels for testing [25]. A constant temperature and humidity box was used to maintain the required temperature in this experiment.

2.3.1. Factorial Test Method

The purpose of the factorial experiment is to identify the significant factors affecting the friction damage in potatoes. To carry out the experiment, the highest and lowest points of the experimental factors were selected according to the design method of the factorial experiment. The test factors and levels are shown in Table 1.

Table 1.

Table of factorial test factors and levels.

The equipment used for the test was a single pendulum friction test rig as shown in Figure 1. Before the test started, the potato was fixed to fixture 2 at the end of the lightweight pendulum bar with waterproof tape, and the friction material was fixed to fixture 1 below the test rig. The position of the supporting axis was adjusted along the horizontal direction and the contact site between potato and friction materials was determined. In order to induce mutual friction between the potato and the friction material, the adjusting nut was adjusted so that the potato and friction material fitted closely together. After determining the position, the height required was measured using a tapeline, and the adjusting nut was fixed. The potato was then raised to the test height and released without initial velocity to generate epidermal friction. Finally, the falling potato was caught in time to prevent secondary friction.

2.3.2. Single Factor Test Method

The single factor experiment was conducted in order to further investigate the effect of significant factors on friction damage and friction loss energy characteristics of potatoes. The device used for the test was the friction image acquisition system shown in Figure 2. The preparation of the experiment was the same as that for the factorial experiment, except that the high-speed camera was used to capture an image of potato friction process. Therefore, it was necessary to ensure safe storage of the image acquisition data after the experiment.

3. Results and Discussion

3.1. Factorial Test Results and Discussion

The factors and their levels in the factorial test are shown in Table 1. After determining the factor level, Minitab software was used to design the trial in the form of −1 and + 1 codes. The 2V5-1 trial design was used and a total of 16 groups of trials were required. At the same time, the proportion of epidermal damage was taken as the test index. Each group of trials was repeated 10 times, and the average value was taken as the test result. The design scheme and results are shown in Table 2.

Table 2.

Factorial testing design scheme and results table.

The analysis of variance was carried out under the condition that the data conformed to a normal distribution. The data were first subjected to the Shapiro–Wilk test using SPSS software, and the sample data were all found to conform to a normal distribution. Then the variance of the test results was analyzed by Minitab software, and the results are shown in Table 3.

Table 3.

Variance analysis of factorial test results.

According to Table 3, the significant factors affecting friction damage to potatoes are initial height, potato mass and potato varieties. Among them, the effect of initial height is extremely significant, and the effects of potato mass and varieties are significant.

There are many studies on the significant factors affecting the damage characteristics of potatoes, most of which were obtained through the potato drop impact test. Among them, some studies showed that the significant factors affecting the impact recovery coefficient of potatoes were the impact material, falling height, potato mass and moisture content [26]. Another study concluded that the order of factors affecting the depth of potato collision damage was: falling height, impact material, impact times and potato mass [13]. Similarly, the initial height, potato mass, potato temperature and collision materials were identified as significant factors affecting the collision damage volume of potatoes [27]. Chen also concluded that the significant factors affecting the impact compression deformation of potatoes were collision materials, falling height and potato mass [16]. Like them, other scholars have found that collision materials and potential energy are the significant factors affecting the comprehensive index of potato damage [14].

This experiment, consistent with previous studies, shows that the initial height and potato mass are significant factors, indicating that these two factors should be the focus of attention in exploring potato damage characteristics. Different from this experiment, potato varieties were not significant in previous studies. However, because potato varieties are different with obviously different surface texture, there were significant differences in epidermal damage in different varieties under the same friction conditions in this experiment, leading to potato variety being identified as a significant factor.

3.2. Single Factor Test Results and Discussion

Five levels of three significant factors were selected as factor levels in the single factor test, while the proportion of epidermal damage and the ratio of energy consumption loss were selected as evaluation indicators. Each group of tests was repeated 10 times, and the final test results were the average of 10 tests. The test scheme is shown in Table 4.

Table 4.

Single factor test scheme.

3.2.1. Effect of Initial Height on Friction Damage and Energy Loss of Potato

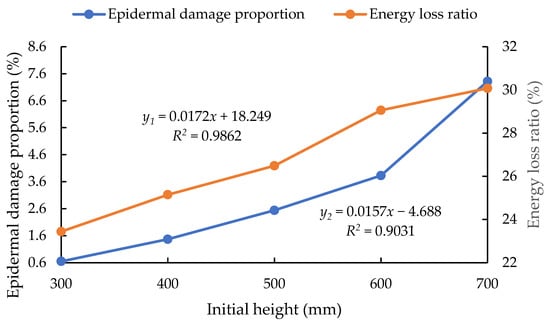

The relationship curves for the proportion of epidermal damage and energy consumption loss ratio with initial height are shown in Figure 5. It can be seen from Figure 5 that both the proportion of epidermal damage and the energy consumption loss ratio increase with the initial height. The main reason is that, with the increase in initial height, the gravitational potential energy of potato increases, which causes more kinetic energy of the potato to convert when it reaches the lowest point, thus increasing the proportion of epidermal damage and energy loss at the moment of friction.

Figure 5.

Relationship between initial height and evaluation indexes. Note: The standard deviation range for the proportion of epidermal damage is 0.1–0.5, and the standard deviation range for the energy loss ratio is 2–6.

Wu found in a drop test of fragrant pear that the damage area of fragrant pear increases linearly with the increase in drop height [28]. Guo conducted rigid-soft body collision damage test on fresh potatoes and concluded that the damage depth increases with fall height [29]. Bao concluded through a drop impact damage characteristic test of sweet potato that the damage area increased with the initial height [30]. These findings are consistent with the results obtained in this experiment and also show that the initial height is critical for studying the damage characteristics in potatoes. The linear regression equations between initial height and the proportion of epidermal damage as well as the energy consumption loss ratio are shown in Figure 5, with correlation coefficients R2 of 0.9862 and 0.9031, respectively, indicating that initial height is highly correlated with the two indicators.

In summary, the initial height is particularly important for optimizing the design of potato soil separation devices and conveyor drop heights and their related parameters. Therefore, in order to reduce the epidermal damage of potatoes, the height should be considered closely when designing the relevant structures of potato harvesters and conveyors.

3.2.2. Effect of Potato Mass on Friction Damage and Energy Loss of Potato

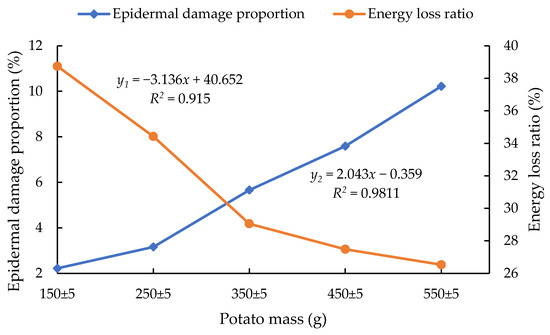

The relationship curves of epidermal damage proportion and energy consumption loss ratio with potato mass are shown in Figure 6. As seen in the figure, the proportion of epidermal damage increases with the increase in potato mass, while the energy consumption loss ratio decreases with the increase in potato mass. The main reason is that the larger the mass of potato, the larger the radius of the curvature of potato [31], which leads to an increase in contact area in potato–potato friction instant, and finally leads to the increase in epidermal damage. Meanwhile, the larger the radius of curvature, the smaller the depth of instantaneous embedding of potato friction into the rubbed potato [32], resulting in reduced energy loss and gradually reduced energy consumption loss ratio during potato–potato friction. M. O. Geyer and Xie concluded in a study of potato drop impact tests that the buffer thickness of tuber tissue increases with tuber mass, resulting in a decrease in collision acceleration with increasing potato mass. The decrease in energy consumption loss ratio thus may also be related to the friction acceleration of the potato [15,33].

Figure 6.

Relationship between potato mass and evaluation indexes. Note: The standard deviation range for the proportion of epidermal damage is 0.5–1, and the standard deviation range for the energy loss ratio is 3–7.

Thomson showed that the damage area increased with the increase in potato mass in potato drop damage tests [11]. He determined that the greater the mass of an apple, the greater the damage volume in an apple collision experiment [34]. This is consistent with the results of this experiment, which also show that there is an important relationship between potato mass and damage degree during potato harvest. Figure 6 shows the linear regression equations between potato mass and the proportion of epidermal damage as well as energy consumption loss ratio, with correlation coefficients R2 of 0.9811 and 0.915, respectively, indicating that potato mass is highly correlated with both indicators.

3.2.3. Effect of Potato Varieties on Friction Damage and Energy Loss of Potato

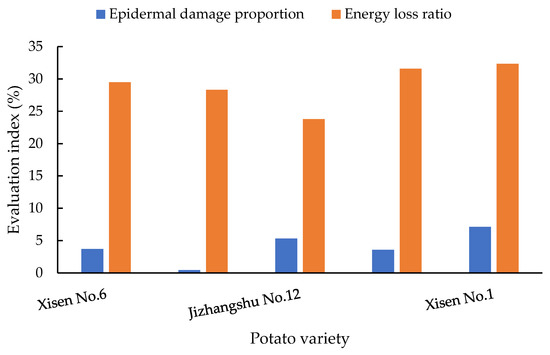

The relationships between potato varieties and the proportion of epidermal damage as well as energy consumption loss ratio are shown in Figure 7, where it can be seen that the descending order of epidermal damage is: Xisen 1 > Jizhang 12 > Xisen 6 > Xuechuanhong > Netherlands 15. Additionally, the energy consumption loss ratios from largest to smallest were as follows: Xisen 1 > Xuechuanhong > Xisen 6 > Netherlands 15 > Jizang 12.

Figure 7.

Relationship between potato varieties and evaluation indexes. Note: The standard deviation range for the proportion of epidermal damage is 0–1, and the standard deviation range for the energy loss ratio is 1–6.

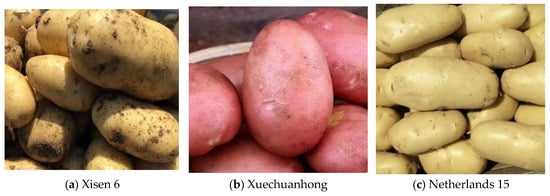

Gao conducted a drop damage test to determine the effect of potato varieties on the size of the impact damage volume and obtained the following relationship: Xuechuanhong > Jizhang 12 > Netherlands 15 [35]. The result was mainly due to the hardness of potato, as the higher the hardness, the larger the damage volume. This is not consistent with the results obtained in this experiment, due to the fact that the above research focuses on collision tests with different varieties of potato. However, this experiment is a friction test, which is directly related to the epidermal roughness characteristics of different varieties of potato. As shown in Figure 8, the epidermis of potatoes was rougher in Xuechuanhong and Xisen 6 and was smoother in Netherlands No. 15, resulting in a significant difference in the proportion of potato epidermal damage.

Figure 8.

Appearance of different varieties of potatoes.

3.2.4. Correlation Analysis between Test Indicators

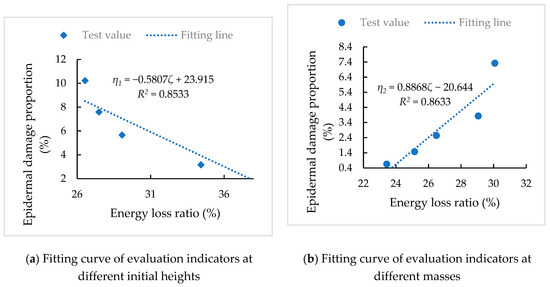

The proportion of epidermal damage and energy consumption loss ratio obtained from the tests were used for correlation analysis with SPSS 19.0 software, and the correlation coefficient and significance test results obtained are shown in Table 5. As can be seen in the table, there was a significant positive correlation between the proportion of epidermal damage and the ratio of energy consumption loss under the initial height factor (p < 0.05, r = 0.929). There was a significant negative correlation between the proportion of epidermal damage and the energy consumption loss ratio under potato mass factors (p < 0.05, r = −0.924), and no significant correlation was found between the proportion of epidermal damage and energy loss ratio under potato varieties factors. Therefore, in the further study of potato friction damage, the degree of potato friction damage can be accurately assessed and predicted by finding a regression model between the proportion of epidermal damage and the ratio of energy consumption loss.

Table 5.

Correlation coefficients and significant results of epidermal damage proportion and energy consumption loss ratio.

The proportion of epidermal damage is significantly related to the energy consumption loss ratio under different initial heights and potato mass conditions from the above analysis. Hence, to predict the proportion of potato epidermal damage under different experimental conditions, a regression model between the proportion of epidermal damage and the ratio of energy consumption loss was constructed. The data points and fitted lines are shown in Figure 9, and the linear regression equation and correlation coefficient are as follows: η1 = −0.5807ζ + 23.915 (R2 = 0.8533); η2 = 0.8868ζ − 20.644 (R2 = 0.8633).

Figure 9.

Linear analysis of epidermal damage proportion and energy loss ratio.

4. Conclusions

In this paper, three significant factors affecting the friction damage characteristics of potato were identified by a factorial test using a single pendulum friction test bench with initial height, potato mass, potato varieties, friction materials and temperature as test factors and epidermal damage as the evaluation indicator. The effects of significant factors on friction damage and energy loss characteristics of potato were further investigated through single factor experiments using epidermal damage ratio and energy loss ratio as evaluation indicators. The main conclusions are as follows:

(1) The significant factors affecting the friction damage characteristics of potato were initial height, potato mass and potato varieties, among which the initial height was extremely significant, while the potato mass and varieties were significant.

The proportion of epidermal damage and energy consumption loss ratio gradually increase with the initial height. With the increase in potato mass, the proportion of epidermal damage gradually increases, and the energy consumption loss ratio gradually decreases. The order of epidermal damage proportion for potato varieties was: Xisen 1 > Jizhang 12 > Xisen 6 > Xuechuanhong > Netherlands 15. The order for the energy consumption loss ratio was: Netherlands 15 > Xisen 6 > Xisen 1 > Xuechuanhong > Jizhang 12. On this basis, a mathematical model for predicting the proportion of epidermal damage area using the energy consumption loss ratio is proposed: at different initial heights, η1 = −0.5807ζ + 23.915 (R2 = 0.8533); η2 = 0.8868ζ − 20.644 (R2 = 0.8633).

Author Contributions

Conceptualization, S.X. and Y.G.; methodology, Y.G.; software, J.L.; validation, X.J.; formal analysis, Y.G.; investigation, Z.S.; resources, X.G.; data curation, Y.G.; writing—original draft preparation, Y.G.; writing—review and editing, S.X.; visualization, J.L.; supervision, W.D.; project administration, K.L.; funding acquisition, S.X. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Found of China (31901409), the Natural Science Foundation of Inner Mongolia Autonomous Region of China (2019BS05013, 2022MS05027), and the Program for Improving the Scientific Research Ability of Youth Teachers of Inner Mongolia Agricultural University (BR220127). https://search.crossref.org/funding (accessed on 15 February 2023).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are contained within the article. All the code generated or used during the study are available from the corresponding author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Wang, Q.; Wu, G. Research on the Comparative Advantages of Guizhou’s Potato Production Layout under the Background of Staple Food. Tillage Cultiv. 2022, 42, 123–128. [Google Scholar] [CrossRef]

- Ovchinnikova, N.I.; Bonnet, V.V.; Kosareva, A.V. Technical condition diagnostics of potato combine harvester. IOP Conf. Ser. Earth Environ. Sci. 2021, 839, 052051. [Google Scholar] [CrossRef]

- Li, Z.; Chang, Q.; Liu, J.; Dong, X. Development Status and Trend of Domestic and Overseas Potato Harvesters. Mod. Manuf. Technol. Equip. 2020, 56, 207–208. [Google Scholar] [CrossRef]

- Zhao, Q. Research Status and Development Prospect of Potato Harvesting Machinery at Home and Abroad. Agric. Eng. 2020, 10, 7–10. [Google Scholar]

- Jaiswal, A.K.; Singh, B.; Mehta, A.; Lal, M. Post-Harvest Losses in Potatoes from Farm to Fork. Potato Res. 2022, 66, 51–66. [Google Scholar] [CrossRef]

- Caprara, C.; Martelli, R. Image analysis implementation for evaluation of external potato damage. Appl. Math. Sci. 2015, 9, 4029–4041. [Google Scholar] [CrossRef]

- Gao, Y.; Song, C.; Rao, X.; Ying, Y. Image processing-aided FEA for monitoring dynamic response of potato tubers to impact loading. Comput. Electron. Agric. 2018, 151, 21–30. [Google Scholar] [CrossRef]

- Li, Y.; Hu, Z.; Gu, F.; Fan, J.; Wang, B.; Wu, F.; Yang, H. An experimental study on the physical mechanics and collision characteristics of potato tubers in different haulm removal times. Int. J. Food Prop. 2022, 25, 2009–2021. [Google Scholar] [CrossRef]

- Ping, Z.; Ruijin, G.; Tianci, J.; Guozhi, Z.; Ning, X. Collision simulation of potato tubers for mechanized harvesting. J. Food Process Eng. 2023, 46, e14278. [Google Scholar] [CrossRef]

- Bentini, M.; Caprara, C.; Martelli, R. Harvesting damage to potato tubers by analysis of impacts recorded with an instrumented sphere. Biosyst. Eng. 2006, 94, 75–85. [Google Scholar] [CrossRef]

- Thomson, G.E.; Lopresti, J.P. Size and temperature characteristics of potatoes help predict injury following impact collisions. N. Z. J. Crop Hortic. Sci. 2018, 46, 1–17. [Google Scholar] [CrossRef]

- Feng, B.; Sun, W.; Sun, B.; Zhang, T.; Wu, J.; Shi, L. A study on dropping impact characteristics and damage regularity of potato tubers during harvest. J. Vib. Shock 2019, 38, 267–274. [Google Scholar] [CrossRef]

- Deng, W.; Wang, C.; Xie, S. Test research on the impact peak force and damage depth of potato. INMATEH-Agric. Eng. 2020, 61, 105–114. [Google Scholar] [CrossRef]

- Huang, T.; Wu, B.; Li, L.; Zuo, T.; Xie, F. Construction of impact mechanics model and experimental study on impact damage of potato tuber. INMATEH-Agric. Eng. 2022, 66, 139–149. [Google Scholar] [CrossRef]

- Xie, S.; Wang, C.; Deng, W. Experimental study on collision acceleration and damage characteristics of potato. J. Food Process Eng. 2020, 43, e13457. [Google Scholar] [CrossRef]

- Chen, Z.; Duan, H.; Cai, X.; Wang, J.; Xu, T.; Yu, C.; Yao, F.; Yan, F. Distribution characteristics of potato contact stress during the drop impact. J. South China Agric. Univ. 2020, 41, 99–108. [Google Scholar]

- Yang, L.; Song, X.; Li, Y.; Shan, H. Study on the surface friction coefficient of apple. J. Anhui Agric. Sci. 2015, 43, 220–221+224. [Google Scholar] [CrossRef]

- Junwei, L.; Yunhai, M.; Jin, T.; Zichao, M.; Lidong, W.; Jiangtao, Y. Mechanical properties and microstructure of potato peels. Int. J. Food Prop. 2018, 21, 1395–1413. [Google Scholar] [CrossRef]

- Liu, W.; He, J.; Li, H.; Li, X.; Zheng, K.; Wei, Z. Calibration of simulation parameters for potato minituber based on EDEM. Trans. Chin. Soc. Agric. Mach. 2018, 49, 125–135+142. [Google Scholar]

- Yu, C.; Duan, H.; Cai, X.; Xu, T.; Yao, F.; Chen, Z.; Yan, F. Discrete element simulation parameters-based measurement of materials for potato minituber. J. Huazhong Agric. Univ. 2021, 40, 210–217. [Google Scholar] [CrossRef]

- Wang, X. Analysis of Potato Drop Test and the Prevention of Drop Injury of Conveyor Arm. Master’s Thesis, Northeast Agricultural University, Heilongjiang, China, 2020. [Google Scholar]

- Słupska, M.; Syguła, E.; Komarnicki, P.; Szulczewski, W.; Stopa, R. Simple method for apples’ bruise area prediction. Materials 2022, 15, 139. [Google Scholar] [CrossRef] [PubMed]

- Deng, W. Study on the Collision Damage Characteristics and Peel Friction Damage Mechanisms of Potato Tubers. Ph.D. Thesis, Inner Mongolia Agricultural University, Hohhot, China, 2021. [Google Scholar]

- Wu, D. Experimental Study on Collision Damage of Rod Lifting Chain to Potato and Parameter Design. Master’s Thesis, Northwest A&F University, Shanxi, China, 2022. [Google Scholar]

- Chen, G. Effect of Storage Temperature on Potato Quality and Postharvest Physiology. Jiangxi Agric. 2019, 51. [Google Scholar] [CrossRef]

- Feng, B.; Sun, W.; Shi, L.; Sun, B.; Zhang, T.; Wu, J. Determination of restitution coefficient of potato tubers collision in harvest and analysis of its influence factors. Trans. Chin. Soc. Agric. Eng. 2017, 33, 50–57. [Google Scholar]

- Xie, S.; Wang, C.; Deng, W. Collision damage test and acceleration characteristic analysis of potato. J. China Agric. Univ. 2020, 25, 163–169. [Google Scholar]

- Wu, J.; Guo, K.; Ge, Y.; Wang, Y. Contact pressure distribution characteristics of Korla pear fruit at moment of drop impact. Trans. Chin. Soc. Agric. Eng. 2012, 28, 250–254+300. [Google Scholar]

- Guo, S.; Wang, W.; Li, M.; Chen, S.; Li, J. Research on the test of potato mechanism and finite element analysis for crash. Mach. Des. Manuf. Eng. 2016, 45, 56–59. [Google Scholar]

- Bao, G.; Wang, G.; Wang, B.; Hu, L.; Xu, X.; Shen, H.; Ji, L. Study on the drop impact characteristics and impact damage mechanism of sweet potato tubers during harvest. PLoS ONE 2021, 16, e0255856. [Google Scholar] [CrossRef]

- Yeşiloğlu Cevher, E. Determination of bruise preventing capacity of the cushioning material in persimmon fruit under pendulum impact test. J. Food Process Eng. 2022, 45, e14162. [Google Scholar] [CrossRef]

- Yeşiloğlu Cevher, E.; Öztekin, Y.B. Prediction of bruise in peach with impact energy. J. Food Process Eng. 2022, 45, e13969. [Google Scholar] [CrossRef]

- Geyer, M.O.; Praeger, U.; König, C.; Graf, A.; Truppel, I.; Schlüter, O.; Herold, B. Measuring behavior of an acceleration measuring unit implanted in potatoes. Trans. ASABE 2009, 52, 1267–1274. [Google Scholar] [CrossRef]

- He, X.; Zhu, D.; Zhu, J.; Xue, K.; Yu, C.; Liu, J. Study on the influencing factors of collision damage in apple postharvest processing. J. Chin. Agric. Mech. 2021, 101–108. [Google Scholar]

- Gao, Z. Investigation of the Dropping Damage and the Kinematics Characteristics of Potatoes. Master’s Thesis, Inner Mongolia Agricultural University, Hohhot, China, 2021. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).