Featured Application

Ecological alternative for wall–ceiling connections with cross-laminated timber elements. No additional metal fasteners are required for connecting and suspending the ceiling elements.

Abstract

In timber construction, there are still no standardized wall–ceiling system connectors made of wood for cross laminated timber construction (CLT). Based on experimental investigations of the bar-shaped dovetail connections, a wood–wood system connection was developed at the University of Innsbruck. First, the traditional dovetail connection for bar-shaped beam connections was investigated. The findings showed the high potential of force transmission in the flank area, especially for beam connections of the same height, where the height of the pre-timber is too small. To date, the load-bearing capacity of the flanks has not been taken into account in the calculation methods. To increase the force transmission paths in the base of the tenon, it was shaped in steps. This led to a load redistribution and thus delayed the failure of the connection. The knowledge gained formed the basis for an independent connecting element that resulted in the so-called “double dovetail”. The connector is a three-dimensional, statically effective double dovetail element. The wood system connector is made of block-glued laminated veneer lumber (LVL) and is manufactured in a CNC-milling process. The results of the tests showed the high performance potential of the LVL system connector, which can play an important role in future timber construction.

1. Introduction

Wood–wood connections have the potential to make an important contribution to the timber construction industry and at the same time meet all code requirements in terms of load-bearing capacity and dimensional stability. Through the specific application of wood materials, they can also be used as an independent wood–wood fastener. Therefore, they offer an alternative to metal system connectors and contribute to climate protection by reducing CO2 emissions. The use of such connectors requires more detailed scientific studies and the revision or review of valid calculation approaches. The inclusion of modern wood materials as well as multidimensional geometries, which are precisely manufactured by CNC-milling, must also be considered. The system connector made of wood is an alternative to the common metal system connectors. The wood–wood fastener can be produced in-house or industrially. This adds value to the wood construction industry. The aim is to apply the potential of the findings presented on bar-shaped connections by means of the coupling element “double dovetail pin” to surface wall–ceiling connections made of CLT.

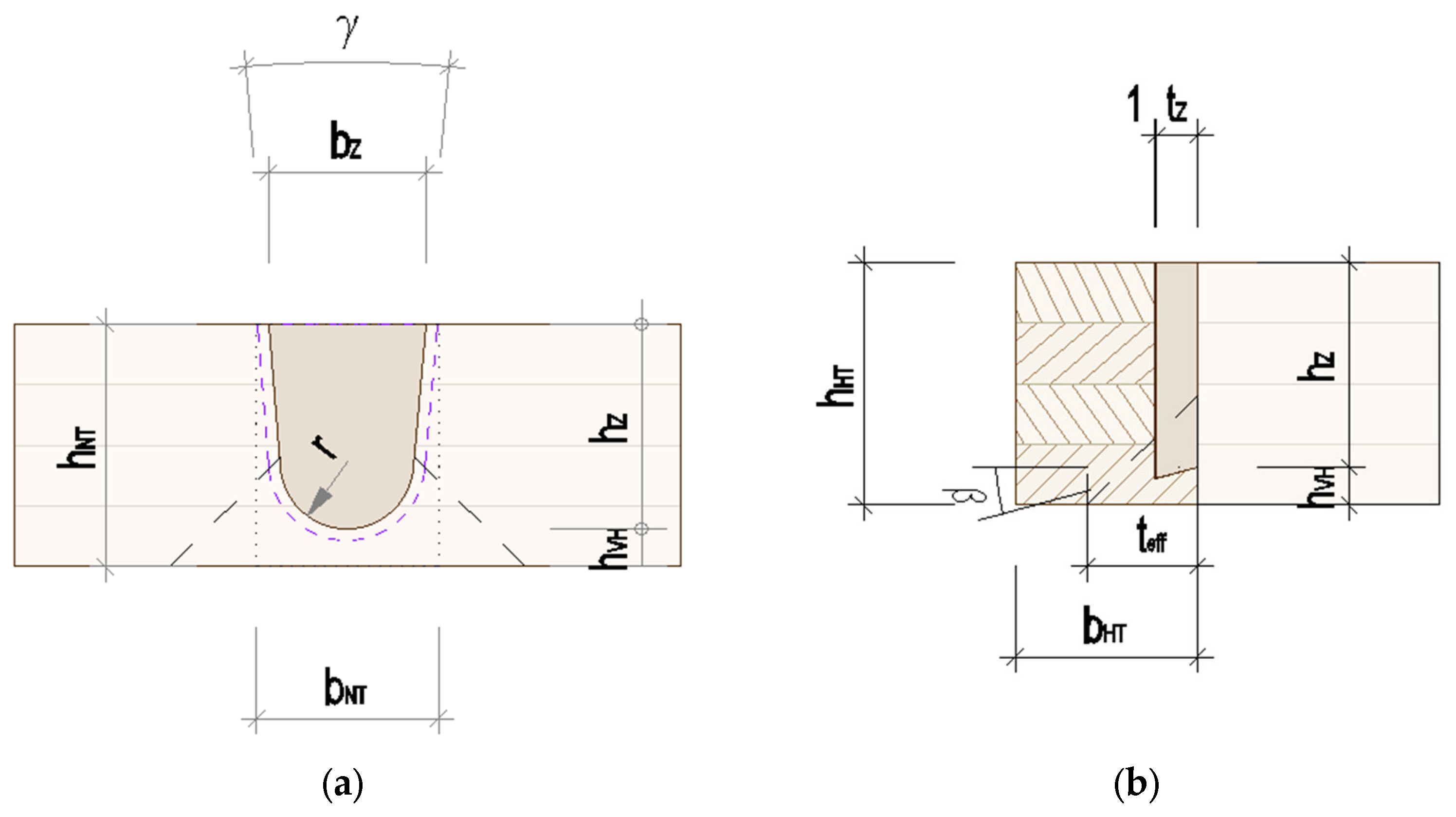

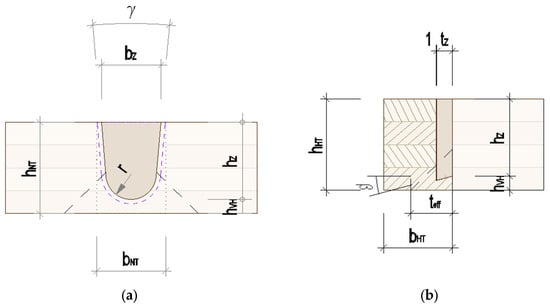

The structural design of a dovetail connection is based on calculation formulas that distinguish between the failure of a transverse connection of the main girder (mode 1) and a notching failure of the secondary girder (mode 2). The current version of the building authority approval (ABZ) Z-9.1-649 [1] already takes into account the use of glued laminated veneer lumber (LVL) as a material for bar-shaped connections. However, the wood connection is milled into the beams and thus its position depends on the connection placement. In new Eurocode 5 formulas [2], the rounded dovetail connection within bar-shaped connections will be introduced. The calculation formula is given for mode 2—notching failure of the secondary girder—but not for mode 1—transverse tensile failure of the main girder—which can occur even earlier with same-level beam connections. In his work, Tannert [3] dealt in depth with the dovetail connection and its beneficial form and also recognized the potential of alternative load transfer paths and multi-step load application. In a topic related publication, Tannert et.al. also described experimental and numerical investigations on the rounded dovetail joint (RDJ) in bar-shaped connections [4]. Furthermore, reinforcement measures with self-tapping screws by Tannert and Lam [5] and an adhesive layer on beam connections by Tannert [6] were investigated. Schickhofer et.al. [7] also investigated experimental geometries of dovetail connections in tests and FE-simulations of bar combinations. Blaß and Enders-Comberg [8] experimented with measures to increase friction within the tenon contact by special shaping of the flanks of RDJ and they also showed the possibilities of multi-step load transfer paths within a stepped connection for truss nodes of timber constructions. Also, the experimental investigations described in Braun et.al. [9] show the potential of CNC-manufactured wood–wood joints with experimental geometries and multi-step load transfer paths. All geometry parameters of the main beam and the secondary beam of a rounded dovetail joint (RDJ) are illustrated in Figure 1.

Figure 1.

Geometry parameters of the main beam (HT) and secondary beam (NT) according to [1] (a) View with assumed load dispersion (b) Section showing connection depth teff.

The description of the connection failure is based on equivalent formulas of ÖNORM EN 1995-1-1 [10], introduced by Ehlbeck and Görlacher for the transverse connection [11] and Gustafsson for the notching [12]. An important parameter of the cross connection (mode 1) is the effective connection depth teff. Particularly in the case of small pre-timber heights hVH below the base of the mortise—as occurs with beam combinations of the same height hHT and hNT—this mode of failure and thus the parameter teff is decisive. The greater the connection depth teff, the higher the load-bearing capacity and, at the same time, the higher the ductility of the connection. In order to improve this failure mode without reinforcing mechanical fasteners (e.g., with screws), adjustments are required with regard to permissible and calculable shapes and forms. That means, connections with small pre-timber heights hVH result in very low effective connection depths teff, which is caused by a low resisting transverse tension volume. In this case, the connection failure happens in a rather brittle way and leads to large covariances (COV) and thus lowers the characteristic calculation value. The investigations presented below show that premature failure, due to flaws or non-existent redistribution possibilities (e.g., small pre-timber height), can be prevented within the connection by a multi-step shape of the tenon base. This redistribution possibility is created by the application of force to several higher levels, which leads to a delayed, more ductile load-bearing connector behavior. Increasing the flank load-bearing capacity by widening the notch taper angle γ could also ensure optimal load-bearing behavior for beam combinations of the same height. In this case, the redistribution forces are directed toward the flank surfaces and thus the effective connection depth teff is also increased. This increase also has a favorable effect on the potential residual load-bearing capacity and robustness of the construction.

With the two variants mentioned, the stepped shape of the tenon base and widening of the notch taper angle, means improved force redirection possibilities are created and thus a larger resisting transverse tension volume can be achieved. The decisive factor here is ultimately a bigger effective connection depth teff. The weak points mentioned are not or only inadequately taken into account in current calculation formulas. This publication intends to provide additional input for improved techniques.

Based on the knowledge gained from experiments with bar-shaped dovetail tenon joints, and taking into account assembly and material-related properties, a wood–wood system joint in the form of a “double dovetail” for cross laminated timber (CLT) elements was developed. Due to the cross-layer arrangement of the board layers, CLT offers new possibilities for wood–wood connections. This means that the surface components enable wider notch taper shapes, and the crosswise arrangement allows a locking effect of the board layers, which helps to ensure the force transmission paths via the flanks. Therefore, not only the stability but also the long-term serviceability of the structure is given. The separation of the wood–wood connection from the load-bearing element (CLT) as an independent coupling element not only provides an economical solution, but also a variety of possible shapes based on applied mechanics.

The decisive factor for the need to design a “double dovetail” system connector was that there had been no standardized and economical wood–wood connection for CLT that could absorb and transmit the loads that occur. The current main application of the wood–wood connector made of LVL-C according to LVL Merkblatt [13] is for the wall–ceiling connection in CLT element construction as shown in Figure 2.

Figure 2.

Wood–wood system connection for CLT wall–ceiling joints.

2. Materials and Methods

This section describes the materials and methods used in the investigations carried out. In order to keep the scope of the investigation within feasible limits, the research results on moisture behavior are not completed yet and therefore cannot be presented in this paper. All wood materials used in the tests were conditioned in a reference climate (relative humidity 65% at 20 °C) for more than 4 weeks before the laboratory tests were carried out. Wood moisture contents ω and the respective wood densities ρ of all specimens were examined after the tests according to EN 13183-1 [14]. They are listed together with the ultimate loads Fv and initial stiffnesses Kser for all test series.

2.1. Bar-Shaped Investigations on Load Bearing Optimization of RDJ

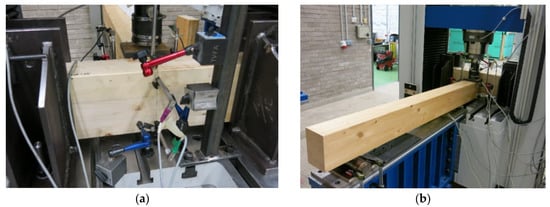

The aim of the tests was to demonstrate the performance of the dovetail joint as a new option for wood–wood joints. In particular, the properties of the individual geometry components can be demonstrated on equal-height beam connections, which are realized by means of glulam beam combinations. The test setup shown in Figure 3 was used for all laboratory tests carried out according to EN 26891 [15] on the bar-shaped beam combinations of wood grade GL24h classified in EN 14080 [16].

Figure 3.

Test setup for bar-shaped connections (a) Front view (b) Side View.

In order to eliminate the effects of notching and to provoke purely main girder-side failure, shear tests were carried out. For the tests, a secondary girder with L = 1600 mm was connected in the middle of the main girder L = 800 mm by means of a traditional milled dovetail joint. The joints were milled with the CNC-milling machine Hundegger Robot Drive© 5-axis. The load induction takes place close to the connection via a steel plate 100 × 100 mm. The support points of the beam are also underlaid with steel plates of the same size to avoid local press-in. To absorb torsion due to eccentric load application, a fork support with steel angle structures is attached. The vertical deformations at the connection as well as the torsion rigid support of the main girder are recorded by means of displacement transducers. For each series, five tests were carried out at the Technical Testing and Research Institute (TVFA) Innsbruck, Austria. All test specimens were stored in a reference climate (relative humidity 65% at 20 °C) until equilibrium moisture content was reached.

- FEM—Model Data Values

All test results of the bar-shaped connections were compared with FEM simulations created with Ansys© Mechanical 2022 R1. The rounded dovetail joint (RDJ) was modelled with a frictional contact with a coefficient of friction of μ = 0.2. Quadratic Solid 187 elements for the connection area and quadratic Solid 186 elements for the beam sections outside the connection area were used for the mesh.

Stiffness values for solid spruce wood C24 according to EN 338 [17] and yield stresses according to Sandhaas and van de Kuilen [18] are applied for the bilinear material model with Hill yield criterion and isotropic hardening in the course of the simulations. The following values, listed in Table 1, were used within all simulations of the bar-shaped connections.

Table 1.

Material values in FEM—simulations of bar-shaped connections.

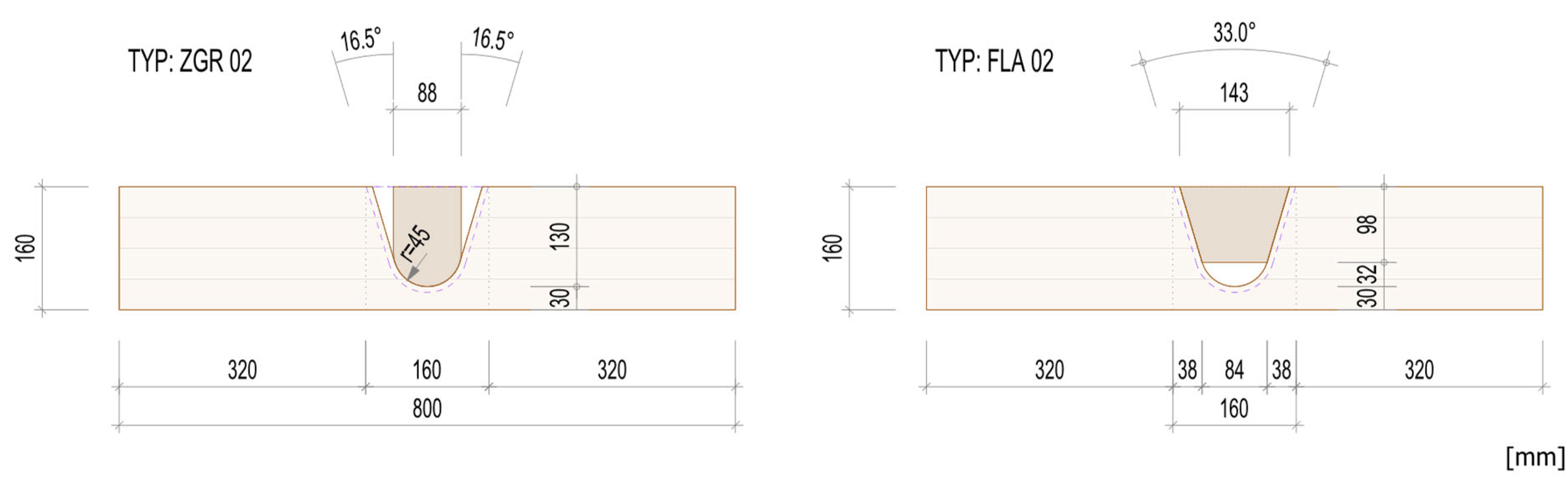

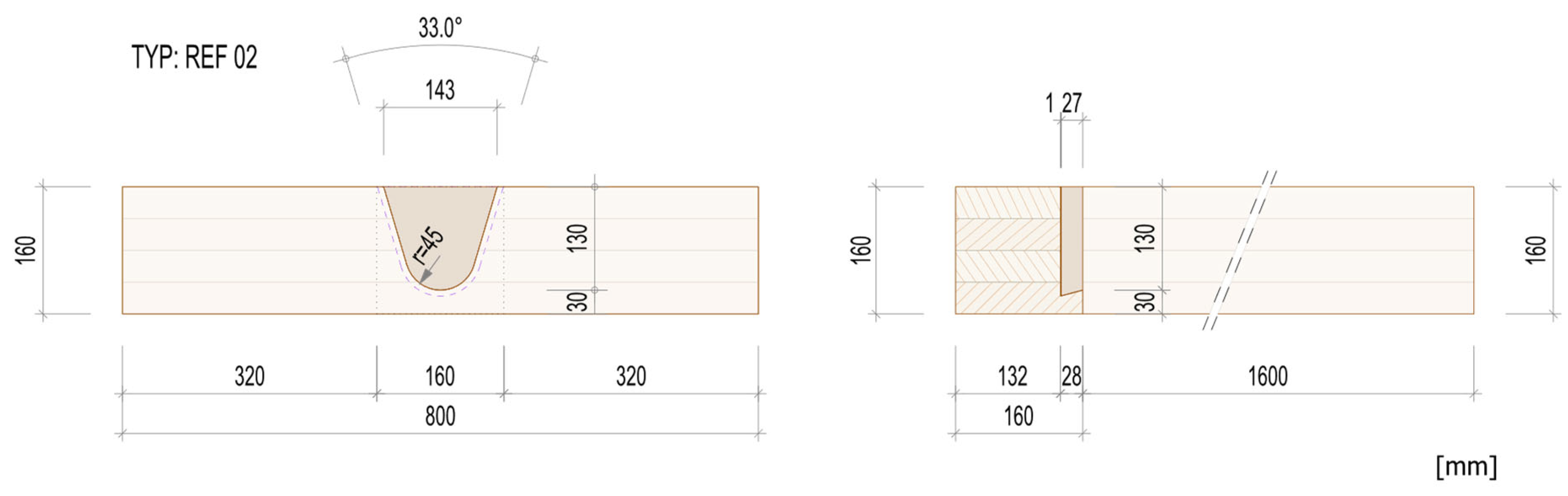

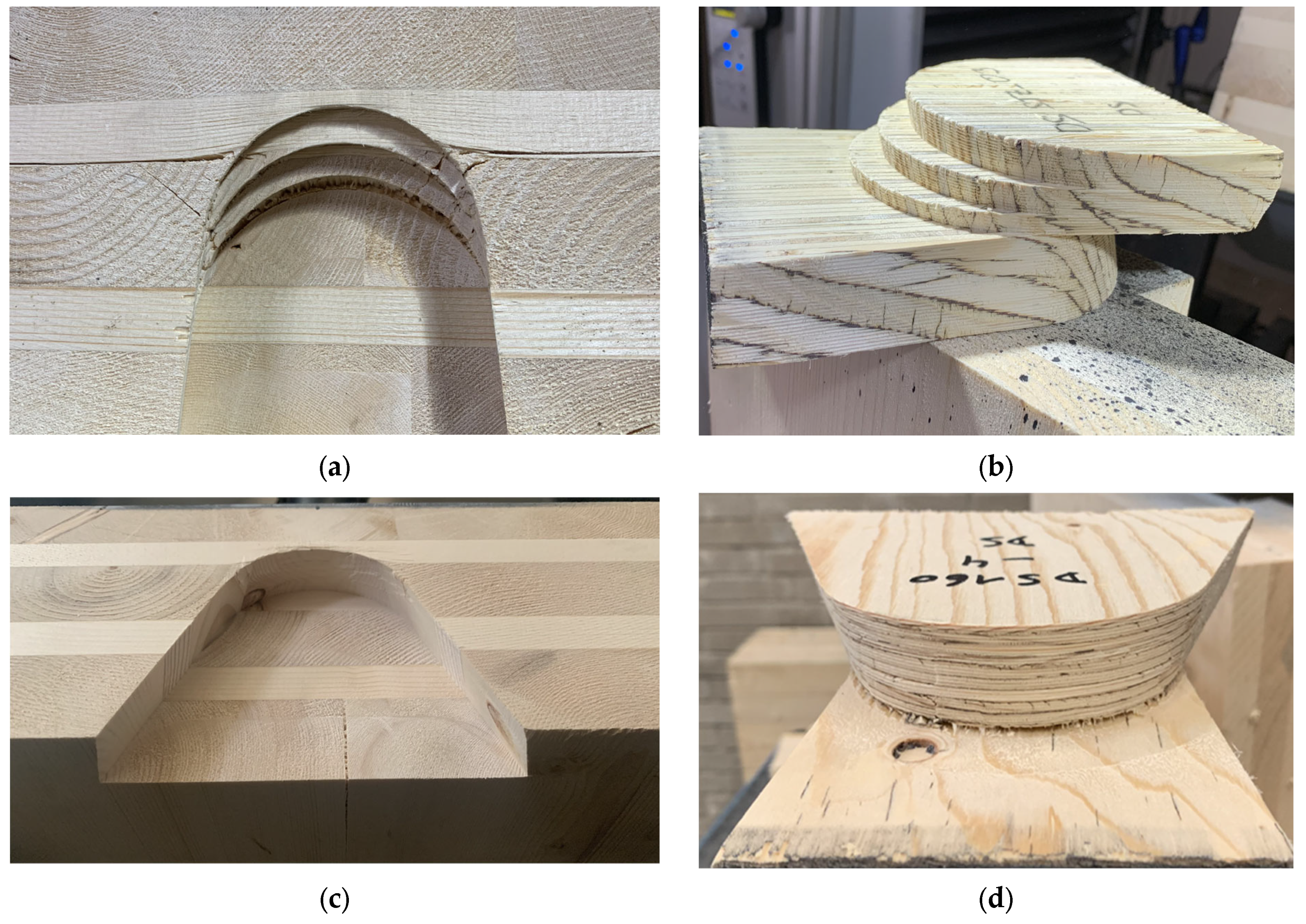

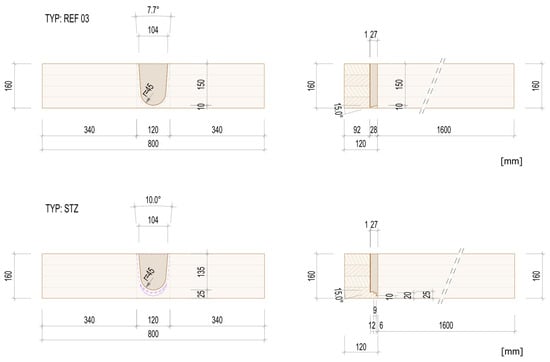

2.1.1. Load-Bearing Capacity of the Tenon Base and Flanks

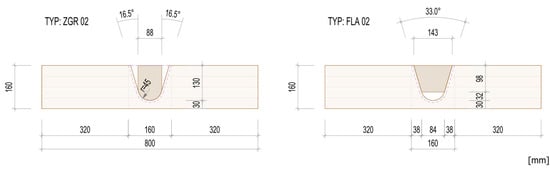

For this purpose, glulam beam combinations with cross sections of the main and secondary beam of 120 × 160 mm (series REF 01, ZGR 01 and FLA 01) and with cross sections of 160 × 160 mm (series REF 02, ZGR 02 and FLA 02)—all with strength grade GL24h—were investigated for their load-bearing capacity and post-cracking behavior. Figure 4 features series ZGR 02 and FLA 02 which represent the load bearing components of series REF 02, which is shown in Figure 5.

Figure 4.

Tenon base shape ZGR 02 without flanks; flank shape FLA 02 without tenon base.

Figure 5.

REF 01 and REF 02 reference series—investigation of load-bearing components.

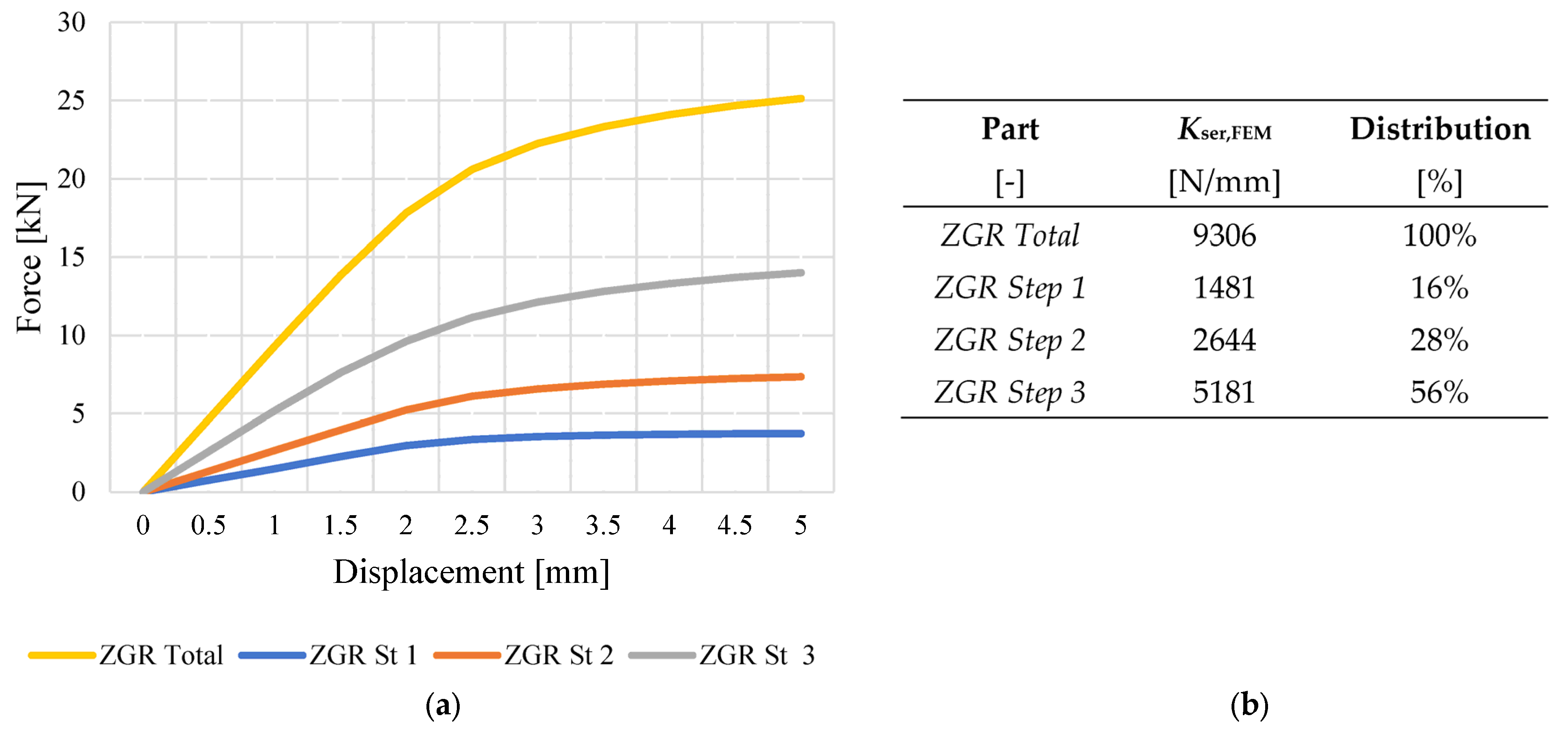

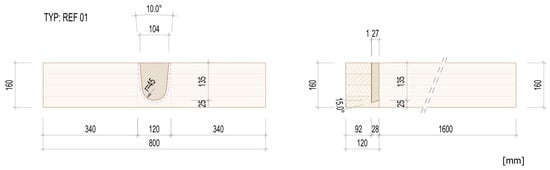

Series REF 01 (see Figure 5) is computed based on calculation formulas in Z-9.1-649 [1] for transverse connection failure (mode 1). This includes an open tenon geometry with a 10° notch taper angle γ, which is still permissible in the design approach based purely on the load-bearing capacity of the tenon base. A statically optimized dovetail connection based on [1] is obtained for equal-height, 160 mm high girder combinations by equal ultimate load values of the main and secondary girder-side failure modes with a pre-timber height of 25 mm and a tenon height in the shear joint of hZ = 135 mm. The tenon width and the opening angle of the notch taper are determined by using the full beam width, as recommended in [1]. Series REF 02 cannot be calculated on the basis of existing calculation methods because with a notch taper angle of 33°, the permissible opening dimension of the tenon geometry is exceeded. On the safe side, however, the calculated value of series REF 01 can be taken into account, as there is an almost identical tenon base area with the same fillet radius. The two reference geometries, series REF 01 and series REF 02, each represent a combination of two bearing components: that of the tenon base and that of the flanks. They are then divided into their bearing components by examining only the tenon base and only the flanks, respectively. Since the bearing loads of the reference shapes are divided according to the stiffnesses on the respective transmission paths, a corresponding division ratio of the force transmission on the reference geometries can be defined.

The laboratory tests include the determination of load capacities, joint stiffness and post-failure behavior. The results of the reference forms were compared with the calculation according to Z-9.1-649 [1]. In principle, the basic tenon form series ZGR 01 is to be used for the calculation design purpose, because only this reflects the (time-independent) load-bearing capacity of the dovetail geometry. If the pre-timber height of the main girder is low, e.g., the girder combinations are the same height, the calculated value must be questioned. In these cases, depending on the respective ratio of the stiffnesses, redistribution processes towards the flanks take place. This is the only way to achieve the calculated value. When the bottom of the tenon begins to fail, the residual load-bearing capacity is finally ensured by the flanks, which are then in a full friction state.

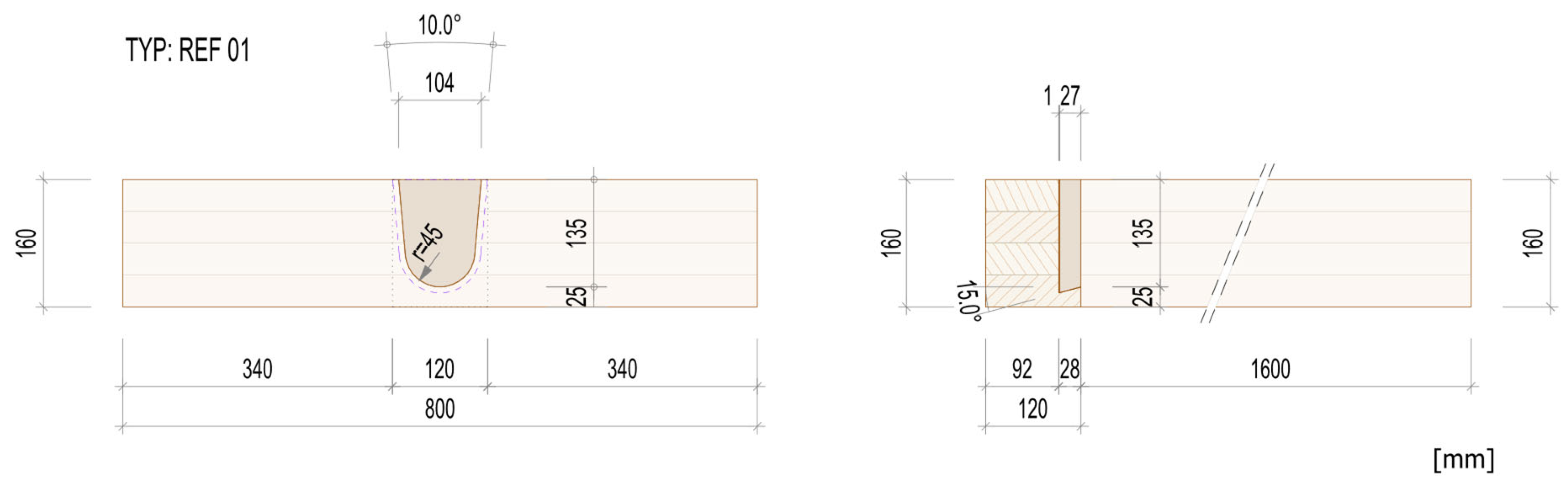

2.1.2. Stepped Tenon Base

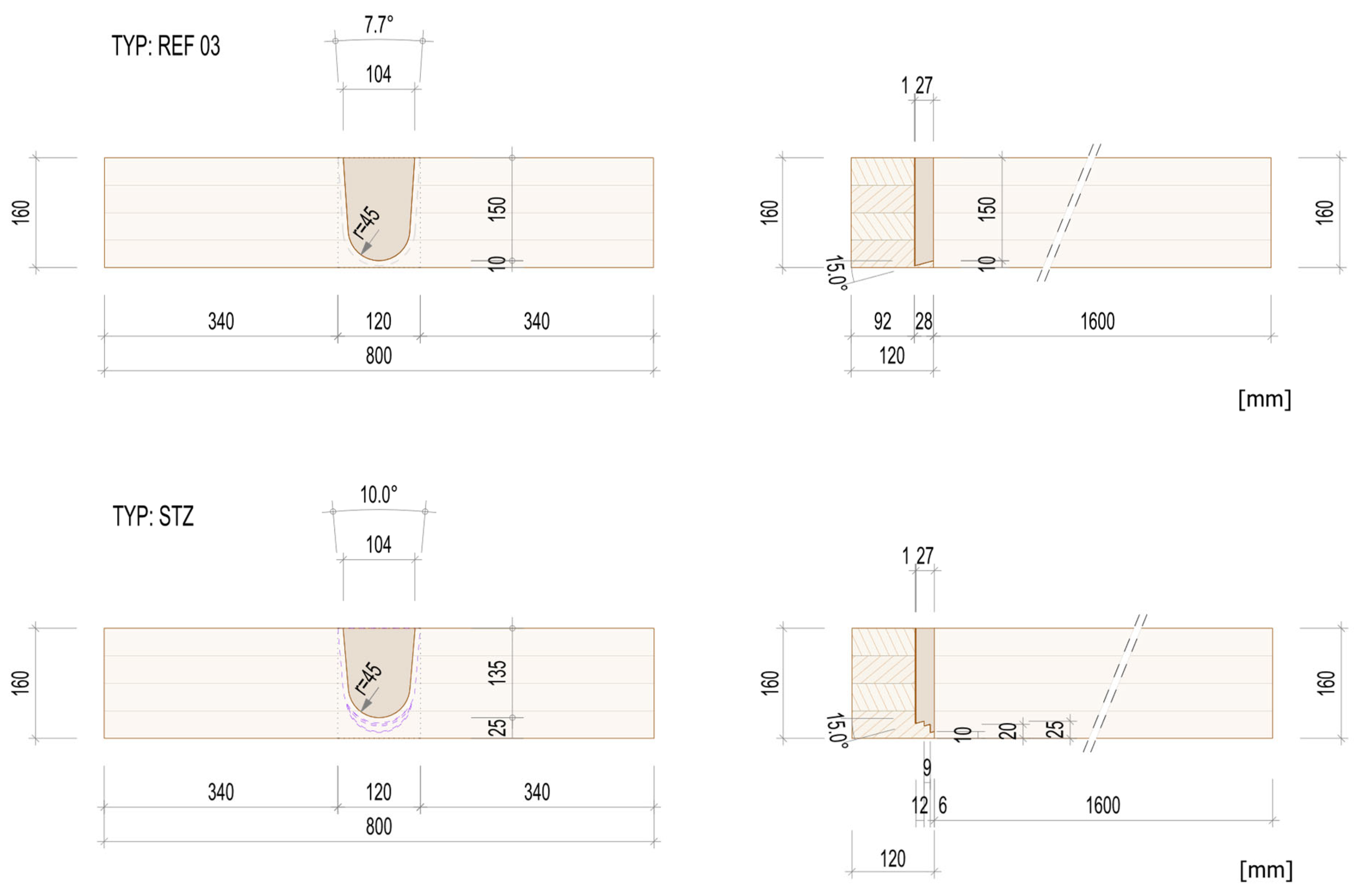

An equal-height glulam beam combination GL24h with a cross-section of the main and secondary beam of 120 × 160 mm—all with strength grade GL24h—and the geometrically smallest possible pre-timber height hVH series REF 03 illustrated in Figure 6 was also tested. It can be assumed that the bottom of the spigot already has such low stiffness that the loads are transferred, to a large extent, via the upper area of the fillet. The flanks also contribute to the load transfer and provide a redistribution option in the event of failure. Due to the lack of alternative transfer paths, a classic tenon with orthogonal dimensions would be critical here. However, the dovetail tenon shows a considerable load capacity in series REF 03. Its geometry will be compared in the following, with the developed stepped tenon base series STZ (see Figure 6), in order to explore the transition to the reference geometry series REF 01. The multi-step tenon base is a further alternative for improving the properties of the dovetail tenon joint. All geometries of this investigation comply with the specifications regarding the notch taper angle according to Z-9.1-649 [1].

Figure 6.

Test series REF 03 and STZ of the study on the stepped tenon base.

2.2. Coupling Element for CLT Wall–Ceiling Connections—Double Dovetail

The aim of our considerations was to detach the connection from the supporting element and enable the creation of a separate connector made of laminated veneer lumber (LVL), which can be integrated into the surface components. The coupling element “Double dovetail” is produced from panel elements of the wood-based material Kerto©Q (Metsä, Finland) approved in Z-9.1-847 [19] by means of CNC manufacturing. The connector consists of two dovetail tenon shapes, which are arranged in opposite directions at their overlapping surface. It can be machined in Edgewise (HK) and Flatwise (FK) arrangements of the veneers. The fiber orientations of the longitudinal and transverse layers are arranged Edgewise to ensure eccentric force application in combination with high stiffness in the insertion direction. Flatwise, the coupling element is additionally reinforced with 12 × ϕ10 beech dowels to prevent shear failure.

Cross laminated timber (CLT) offers optimum conditions for geometries with wide notch taper angles due to the dimensional stability provided by the locked board lamellas. On the wall side, the load is usually transferred from the connection via the top layer end grain of the wall element. The wall element can theoretically only fail in transverse tension as a result of large support rotations. This could be proven by pure rotation tests on cantilevers. However, for single span girder systems up to l = 5.0 m, lower support rotations occur than the permissible limit torsion, so that this failure mode does not happen in practice. The slab-side connection combination is relevant for the design. This consists of ceiling-side tenons as well as the CLT ceiling element, which is comparable to an equal-height connection of a beam connection.

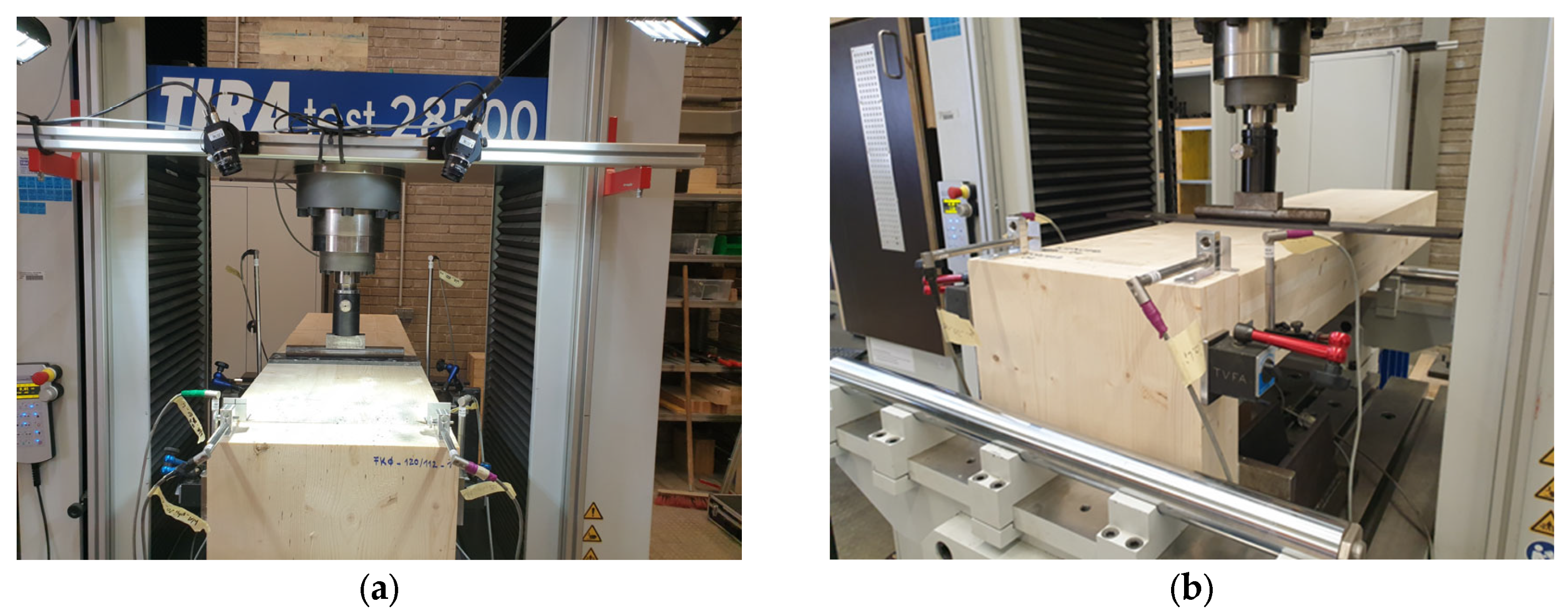

For geometric optimization of the ceiling–side tenon connection, load-bearing tests are carried out on CLT combinations with wall elements CLT 5 s 100 mm (5 × 20 mm) and ceiling elements CLT 5 s 160 mm (40/20/40/20/40 mm). The board lamellas of all CLT elements are of C24 quality classified in EN 338 [17]. From the test specimens, the effective bending stiffness and shear stiffness are first determined by global Young’s modulus measurement and shear field measurement according to EN 408 [20]. As a test setup, 3-point bending tests (test setup shown in Figure 7) according to EN 26891 [15] are performed on both side tested 1.5 m long CLT elements with an effective span during testing of 1.0 m. The load is applied in the center of the field via a steel plate. The CLT elements for the tests are 400 mm wide. The selected width represents the assumption of a connector spacing value and at the same time complies with the edge and center distances according to the specifications of valid calculation models for bar-shaped connections [1]. The connection in the tests is made by a floor element suspended on one side in a wall element. On the opposite side, the CLT element is supported on a sliding roller bearing. The wall element is mounted torsion-rigid in the test by means of a fork bearing. Both the vertical deformation at the connection and the torsion of the ceiling element at the connection are recorded during the tests by means of displacement transducers. For vertical displacement measurements, transducers are placed on both sides of the ceiling in positions of the load induction and the system connection. Horizontal displacement measurements on both sides of the top and the bottom of the connection evaluate the rotational behavior of the system connection. In addition, an optical measurement on the surface of the ceiling in the area of the system connection is performed in all tests.

Figure 7.

Test setup of the 3-point bending test for wall–ceiling connections made of CLT (a) Front view (b) Side view.

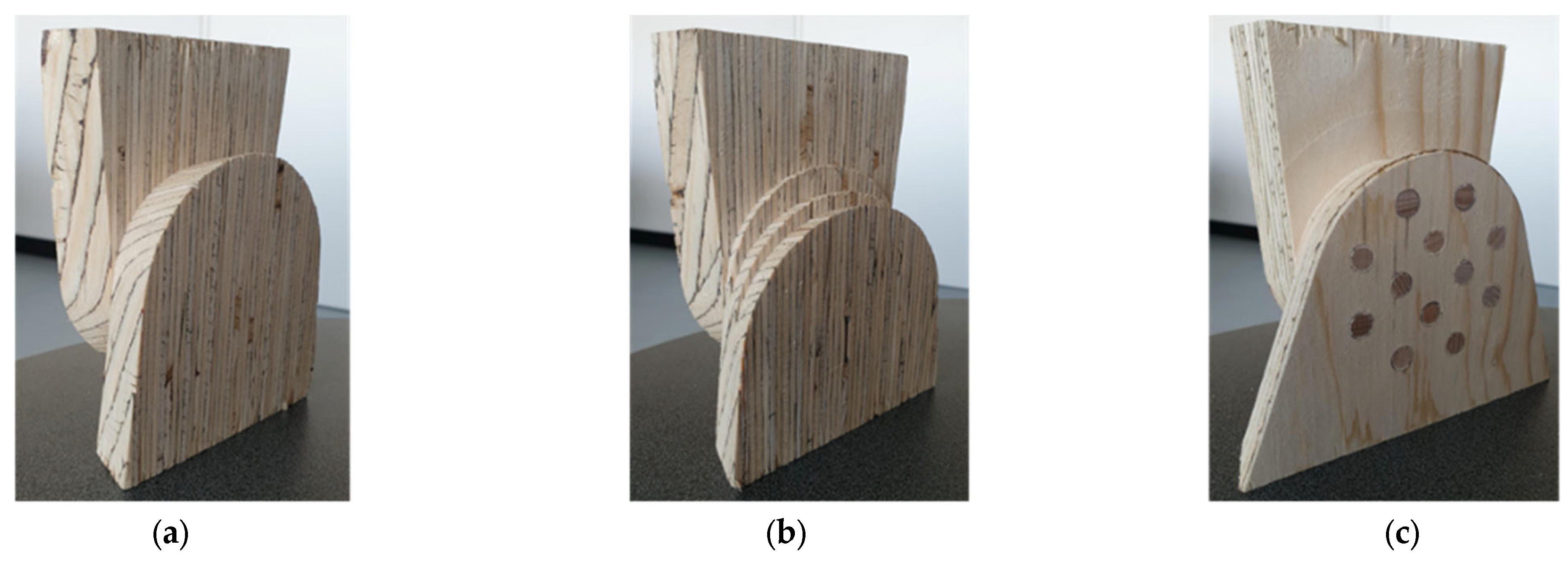

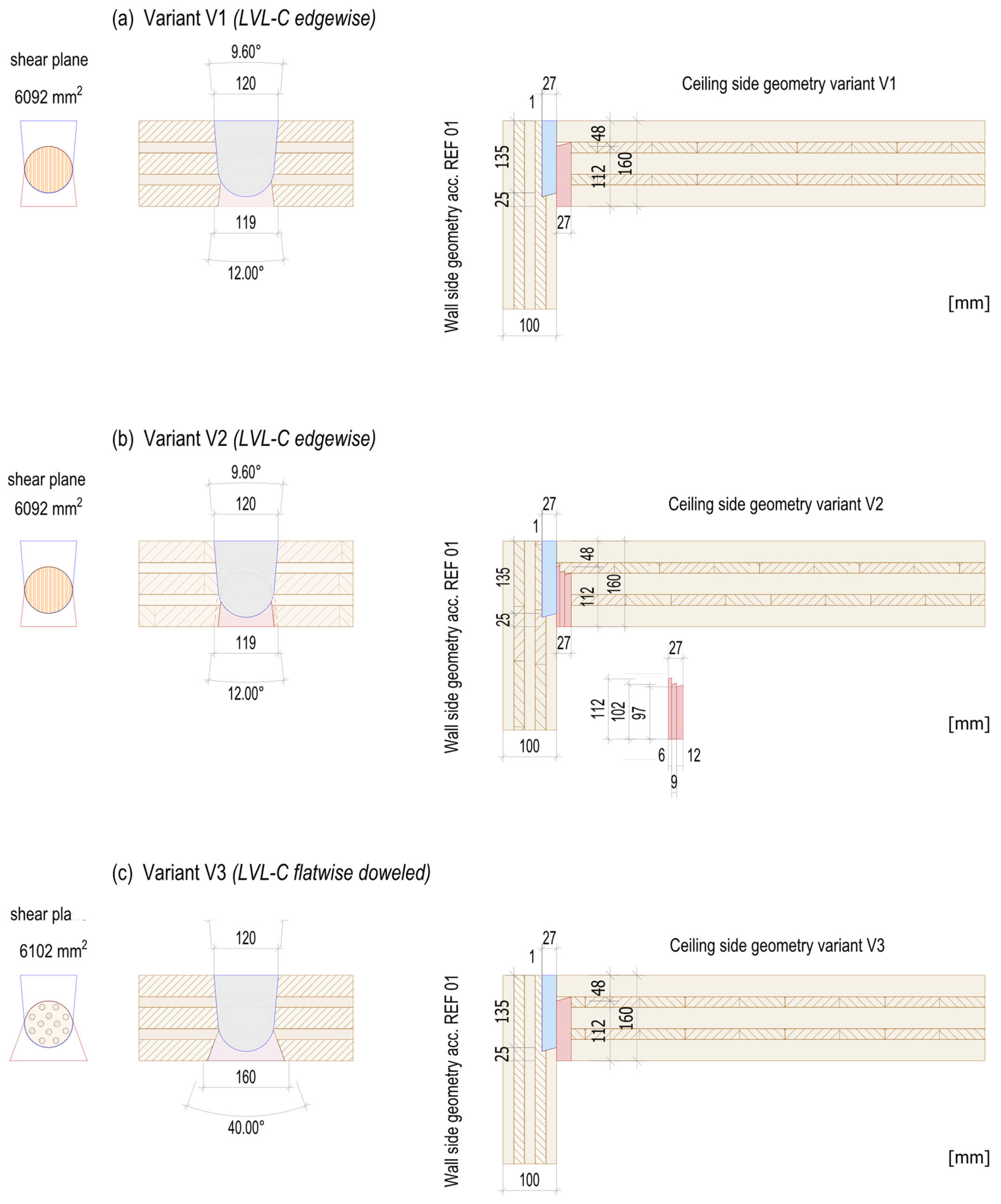

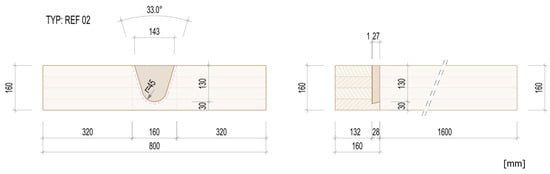

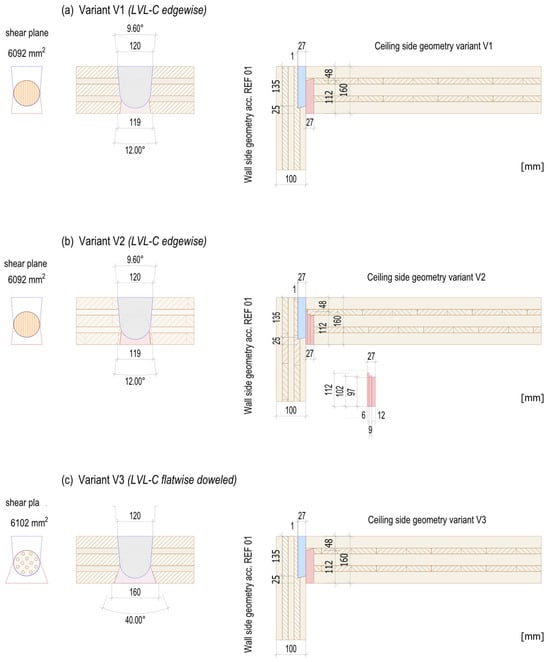

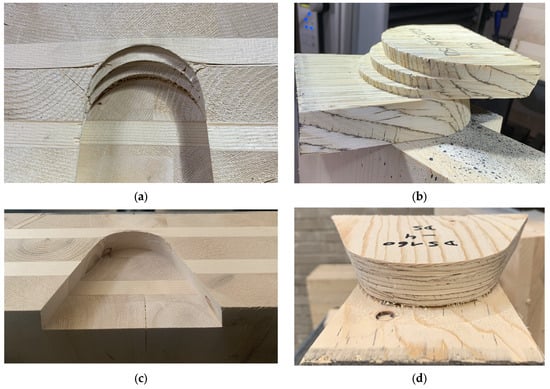

The “double dovetail” system connector for wall–ceiling connections made of CLT can be designed in three variants, shown in Figure 8.

Figure 8.

(a) Variant V1 (b) Variant V2 (c) Variant V3 of the wood–wood system connector.

The main fiber direction is always oriented in the insertion direction for both veneer arrangements. The alignment of the LVL can be seen in the system connector variants in Figure 8.

Variant V1: The system connector is based on the requirements set out in Z-9.1-649 [1] and includes flanks inclined up to 6° on both sides.

Variant V2: By stepping the tenon base, a noticeable increase in load-bearing capacity is achieved, especially with thin floor slabs. V1 and V2 are manufactured in Edgewise veneer arrangement and from one piece.

Variant V3: Manufactured from one piece or from two parts glued together. The veneers are oriented in a flatwise arrangement. The shear surface is reinforced by means of glued-in beech dowels across the coupling element. This veneer arrangement is particularly favorable with regard to the dimensional stability of the system connector. Furthermore, the individual production of the dovetail tenons allows a material-saving combination of two different tenon geometries.

The development of the reference geometry of the timber system connection is based on REF 01 of the bar combinations 120 × 160 mm tests and is initially determined for the wall-side tenon WS of the system connector. The height of the ceiling-side tenon of the system connector must be adjusted in compliance with a notch ratio of α = 0.5 accordingly [1,10] and an undamaged cover lamella. However, the notch taper should be designed with a similar opening angle γ as for the wall-side tenon. The timber system connector Variant 01 (V1) is defined according to these criteria. Spruce LVL-32C [13] with the veneer arrangement in Edgewise design is used as the material for the system connector. In the shear area, the design-relevant ceiling-side tenon is 120 mm wide and 112 mm high. Optimization potential is attainable by increasing the tenon width as well as by reducing the tenon height.

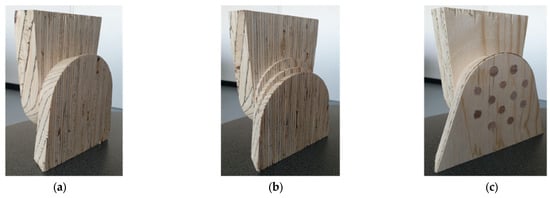

In the following, two further variants will be investigated. Variant 02 (V2) with a stepped tenon base on the ceiling side (veneers in Edgewise design) and Variant 03 (V3) with an extended notch taper angle. By extending the mortise and tenon angle in Variant 03, the direction of the funneling in the wood system connection must be rotated by 90° due to the increased load transfer via the flank sides. This means the arrangement of the veneers is Flatwise. Furthermore, longitudinal dowelling of the shear surface of the two dovetail segments by means of 12 beech dowels is required. Several test series (see Figure 9) with four tests each are carried out for the three variants. The laboratory tests were performed at the Technical Testing and Research Institute (TVFA) of the University of Innsbruck.

Figure 9.

Test series (a) Variant V1 (b) Variant V2 (c) Variant V3 of the wood–wood system connector for wall–ceiling connections made of CLT.

3. Results and Discussion

3.1. Bar-Shaped Investigations for Load Bearing Optimization of RDJ

3.1.1. Bar-Shaped Investigations—Load-Bearing Part of the Tenon Base and Flanks

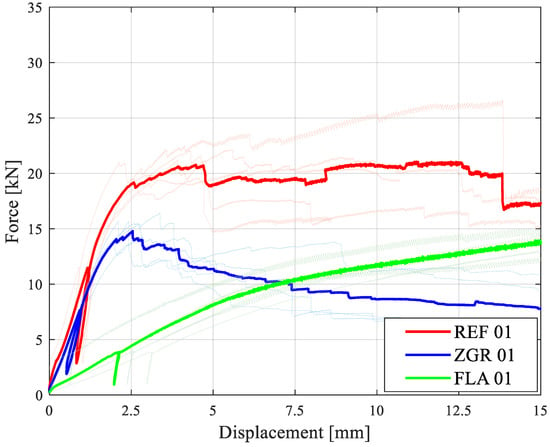

- Equal-height GLT beam combination of 120 × 160 mm with a 10° opening angle

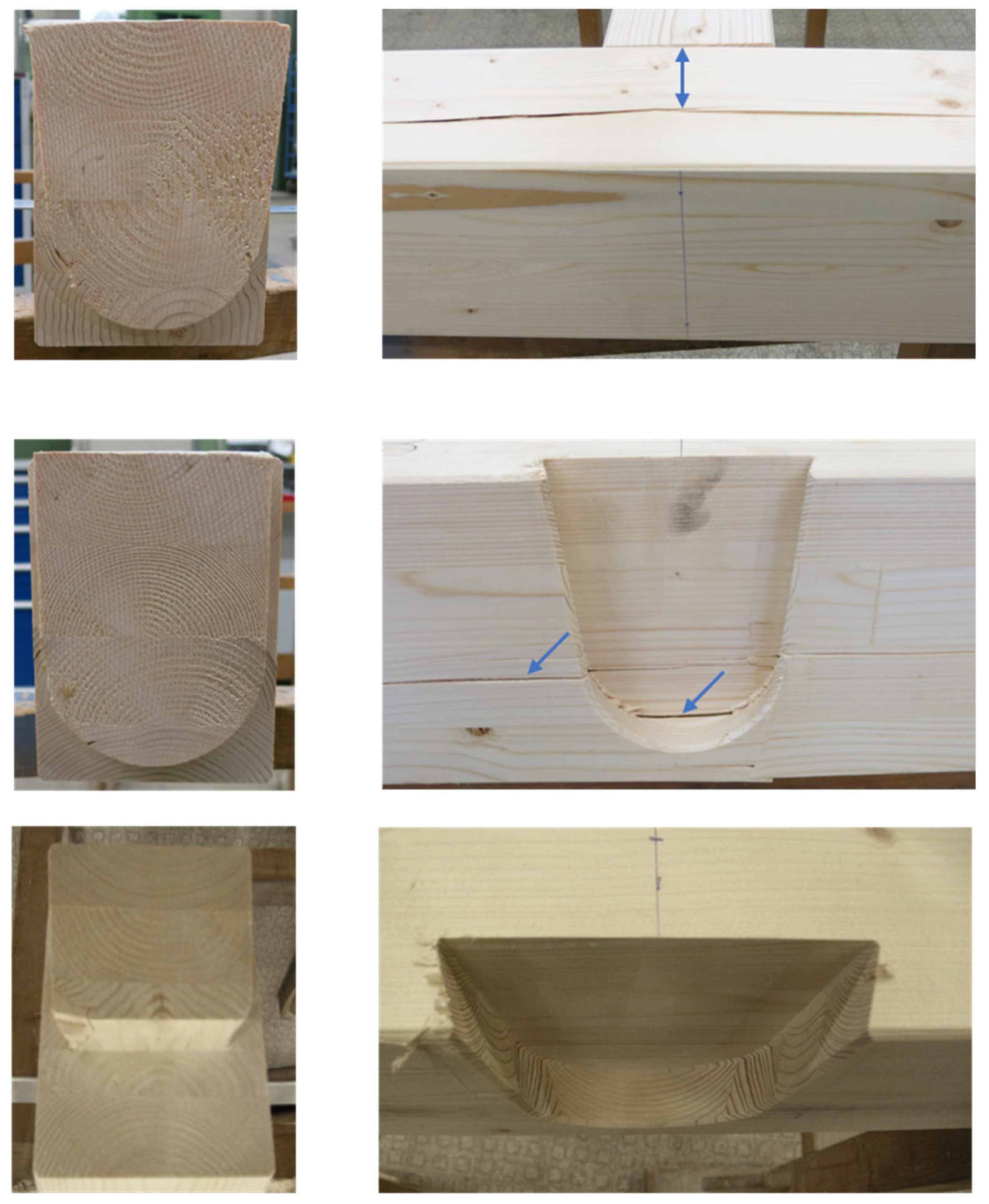

When evaluating the GLT girder combinations series REF 01, ZGR 01, FLA 01, it can be seen that the failure modes of the reference form REF 01 as well as the basic tenon form ZGR 01 are almost identical. In both cases, a transverse tension failure of the main girder occurs, see Figure 10. The effective depth teff in the test runs is approximately 0.75∙bHT. This value is significantly lower than the uniform calculation value of teff = 100 mm for transverse connection failure (mode 1) for single-sided dovetail connections specified in Z-9.1-649 [1]. Since teff is a significant factor in the calculation formula for the load-bearing capacity of the transverse connection, it can be determined that the calculated characteristic load-bearing capacity for mode 1 according to [1] is not achieved in the test runs of series ZGR 01, which takes the shrinkage of the flanks into account, if the pre-timber height hVH = 0.15 hHT is given. The REF 01 series reaches the calculated value during the test, but only due to the existing flank load components. These are not taken into account in the calculation formula of the Z-9.1-649 [1] approval. Lower pre-timber heights hVH = 0.05 hHT (REF 03 series under 3.1.2) lead to lower connection depths teff and thus to larger deviations of the bearing capacity of the tapping base from the calculated value for mode 1 according to [1].

Figure 10.

Damage patterns and cracks for series with 120 mm × 160 mm beam combinations—REF 01 (top), ZGR 01 (middle) and FLA 01 (bottom).

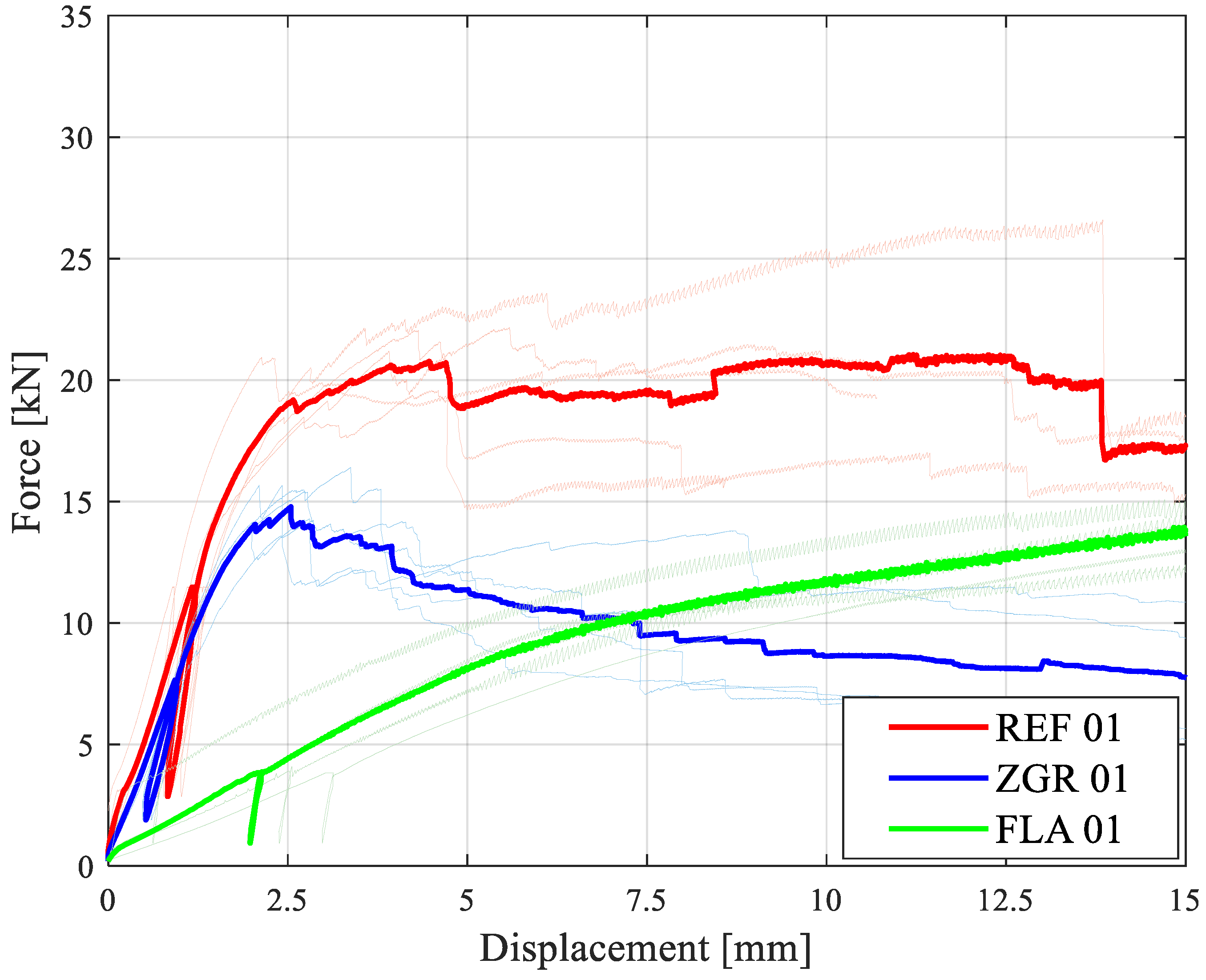

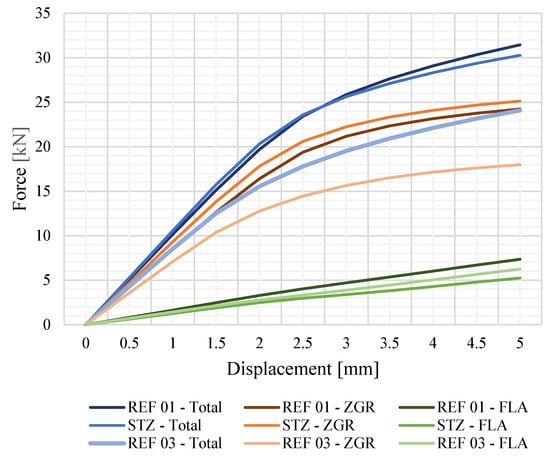

To determine the separately investigated load-bearing components of the tapping base and the flanks, their stiffness is determined by means of series ZGR 01 and FLA 01. These are then related to the total stiffness of the reference form series REF 01. In the course of the investigation of REF 01, it is found that the stiff tenon base is initially the main force transmission path of the joint. With increasing changes in the stiffness ratios, due to incipient damage in the tenon base, rearrangement processes occur towards the flanks. The residual load-bearing capacity of the wood connection, which is approximately 75% of the ultimate load, is ensured by the flanks. Since the force transmission via the flanks has little stiffness, noticeable deformations occur after failure of the bearing capacity of the tenon base. This effect is clearly visible in series FLA 01, since the trunnion does not rest on the bottom of the tenon hole. That means, the bottom of the main beam remains undamaged, see Figure 10, and the stiffness of the connection is represented only by that of the flanks. For series FLA 01 the stiffness is therefore very low. All load-deformation mean value curves for 120 mm × 160 mm beam combinations are shown in Figure 11. Their loads and stiffnesses are listed in Table 2.

Figure 11.

Load-deformation mean value curves (thick colored lines, listed in legend) of the related single tests (thin colored lines) for 120 mm × 160 mm beam combinations.

Table 2.

Evaluation of the tests—loads and stiffnesses according to EN 14358 [21].

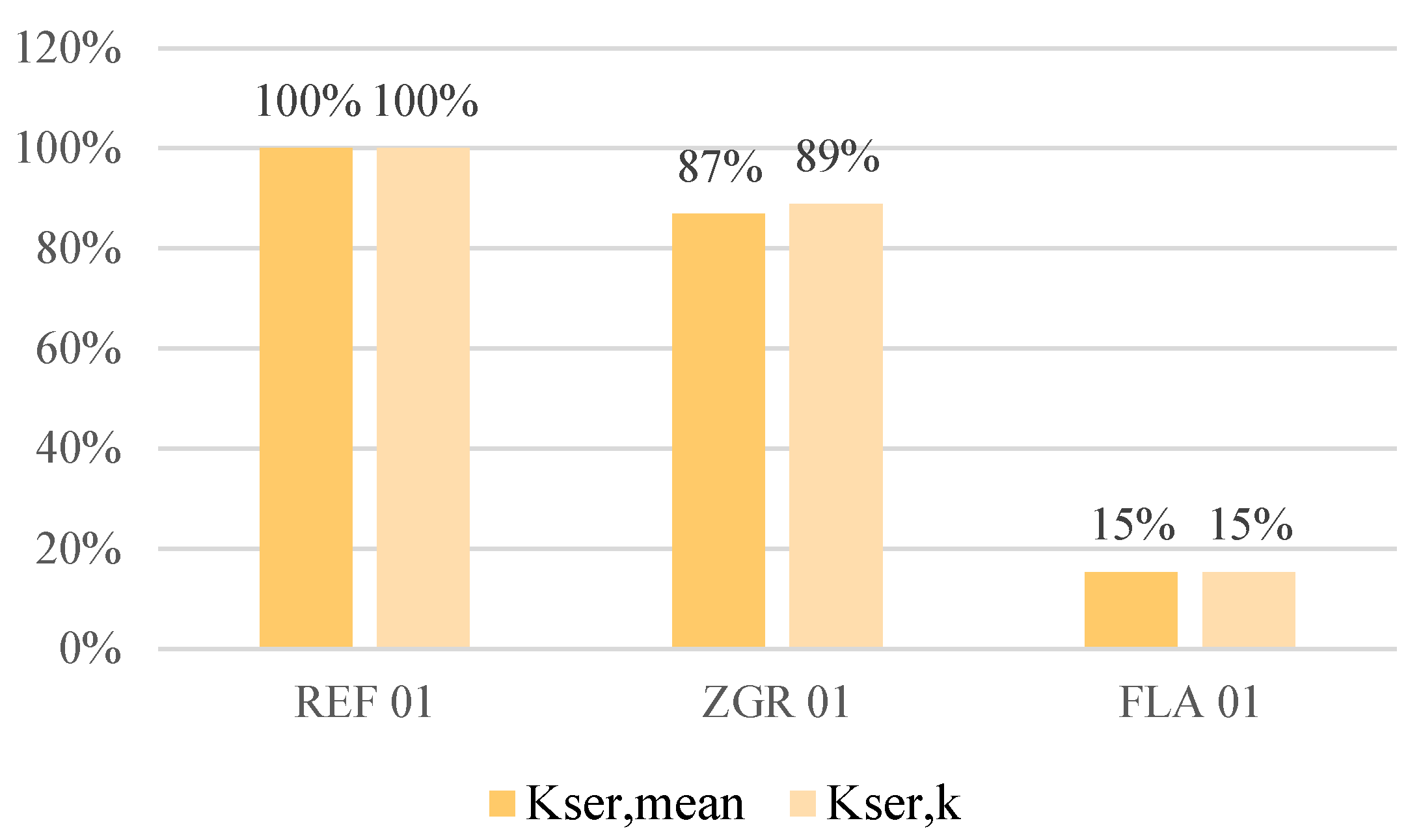

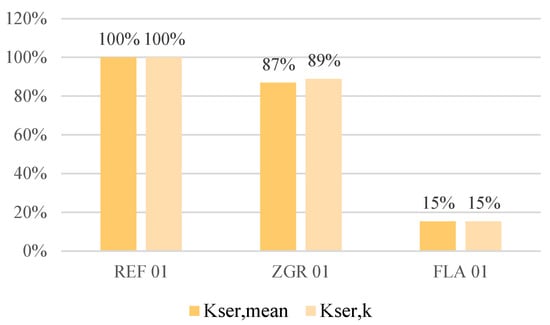

The investigations of the stiffness on GLT girder combinations with cross sections of 120 × 160 mm show that the participation of the load transfer over the flanks, which contributes to series REF 01, amounts to 15% (see Figure 12). As already mentioned, in common calculation models the flank load transfer part is not considered. However, at low pre-timber heights, redistribution processes from the bottom of the journal to the flanks already occur at small load steps. The flanks guarantee a residual load-bearing capacity of almost 75%, which is important for the robustness of the connection and the structure as a whole. The characteristic load of the reference geometry REF 01 achieved in the test, corresponds exactly to the calculated value according to [1]. However, the value of the pure tenon base form ZGR 01 is lower. In the case of beam combinations of the same height, the calculated value according to [1] is only achieved in the present test runs if the flank load-bearing component is taken into account.

Figure 12.

Weighted stiffnesses of Series 01 (graphs).

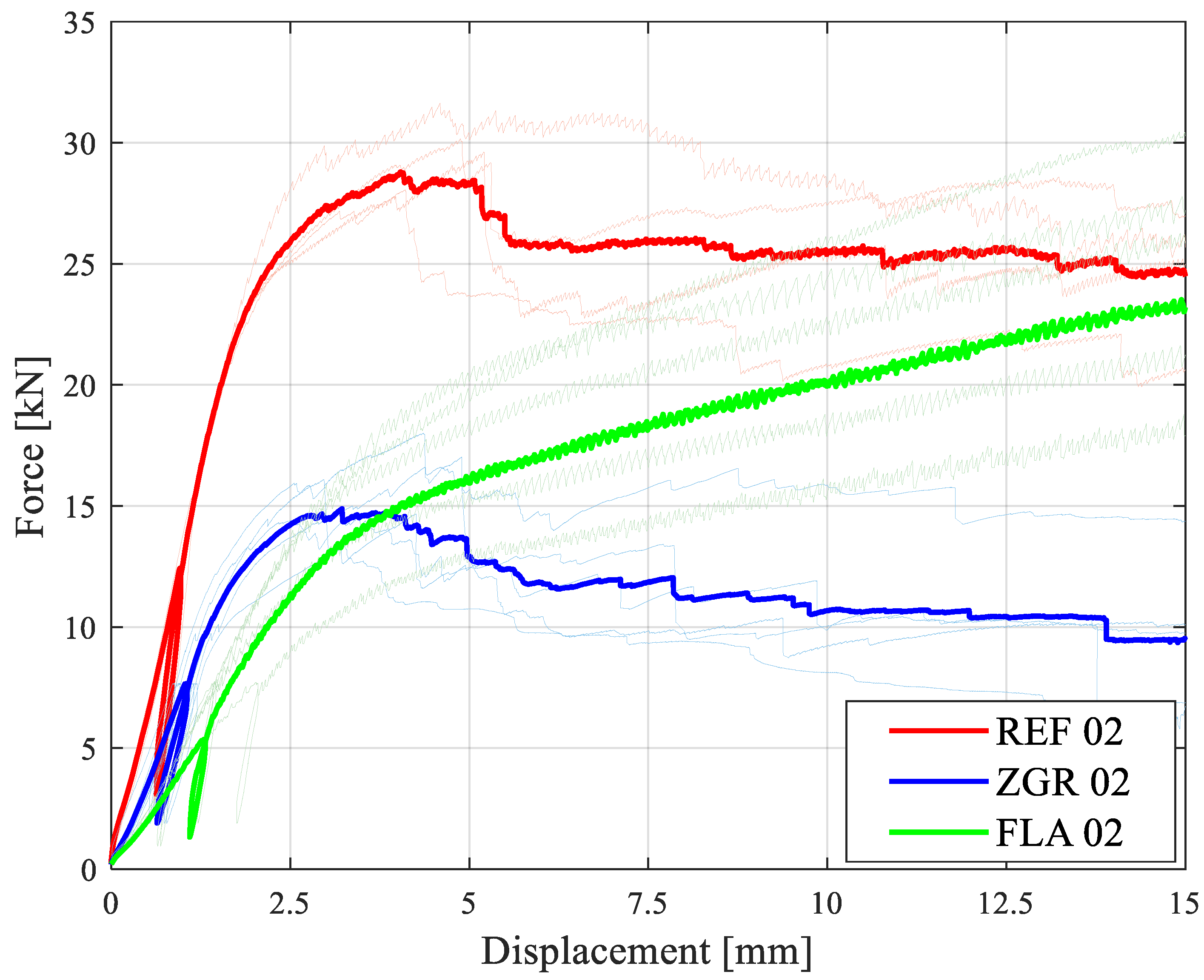

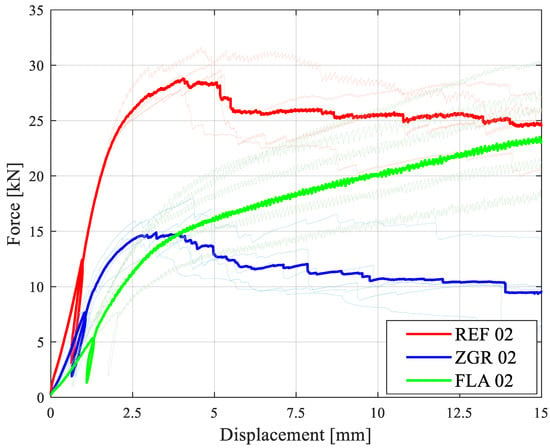

- Equal-height GLT girder combination of 160 × 160 mm with an opening angle of 33°

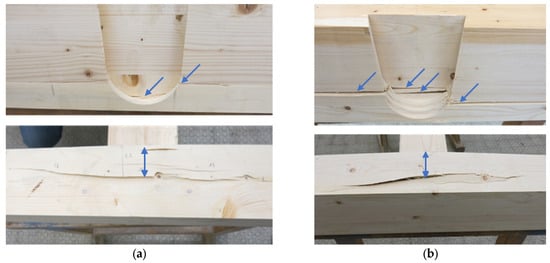

In order to demonstrate the optimization potential for shapes with a larger notch taper angle γ, GLT beam combinations series REF 02, ZGR 02, FLA 02 were investigated in the same way as in the previous series. The failure mode of the reference geometry REF 02 now differs from the corresponding basic tenon shape ZGR 02 by a multi-step force application due to the load-bearing components of the flanks. This leads to a higher total resultant force transmission, which is shown by a greater effective depth teff of the reference shape compared to the basic tenon shape. The FLA 02 series flank form is again tested without the tenon base. The load achieved with the FLA 02 series is higher than with the FLA 01 due to the wider flank angle. This is also visible in the damage patterns of the main beam (see Figure 13).

Figure 13.

Damage patterns and cracks for series with 160 mm × 160 mm beam combinations—REF 02 (top), ZGR 02 (middle) and FLA 02 (bottom).

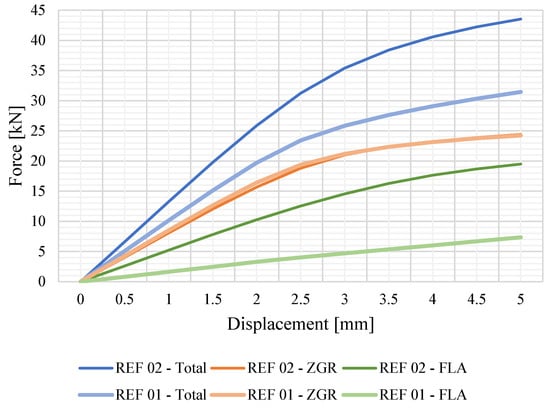

The basic tenon form, ZGR 02, shows exactly the same values as the corresponding basic tenon form, ZGR 01. Its calculated load-bearing capacity can also be estimated on the safe side by using the calculation formula for mode 1 in [1]. The significant increase in the load-carrying capacity of the reference form REF 02 compared to REF 01, therefore results exclusively from the higher flank load-bearing component because of the wider notch taper angle. The ductile behavior of the connection and the robustness of the structure as a whole can also be guaranteed by widening the notch taper angle γ. The increase in load-bearing capacity before failure and the residual load-bearing capacity at failure of the connection depend exclusively on the flank load-bearing component and thus on the inclination of the flanks. The potential of this load increase for the REF 02 series is 66%, compared to the ultimate load of the basic tenon form ZGR 02, which is relevant for the design. After failure of the tenon base, approximately 90% of the ultimate load at an opening angle of 33° is available as residual load-bearing capacity through the flanks in the case of large deformations. Taking the flank load-bearing components into account in the calculation formulas would lead to a significant increase in the ultimate load potential of the timber connection at large opening angles. Due to the early onset of redistribution effects with beam combinations of the same height, these could also be included in the ultimate load calculation—assuming appropriate milling accuracy and limitation to NKL 1. The flank load-bearing components certainly ensure the robustness of the structure as a result of their considerable residual load-bearing capacity. All load-deformation mean value curves for 160 mm × 160 mm beam combinations are shown in Figure 14. Their loads and stiffnesses are listed in Table 3.

Figure 14.

Load–deformation mean value curves (thick colored lines, listed in legend) of the related single tests (thin colored lines) for 160 mm × 160 mm beam combinations.

Table 3.

Evaluation of the tests—loads and stiffnesses according to EN 14358 [21].

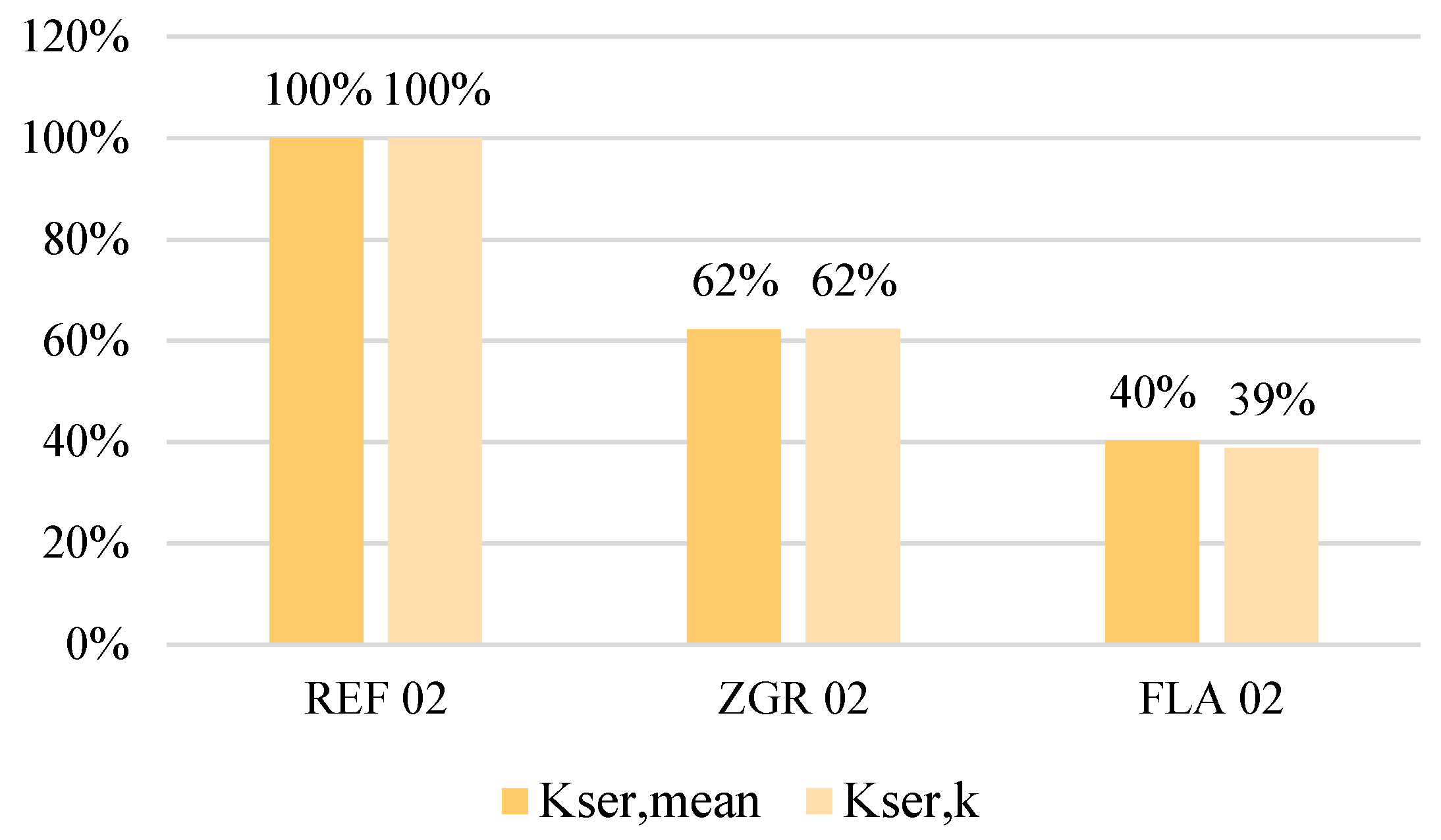

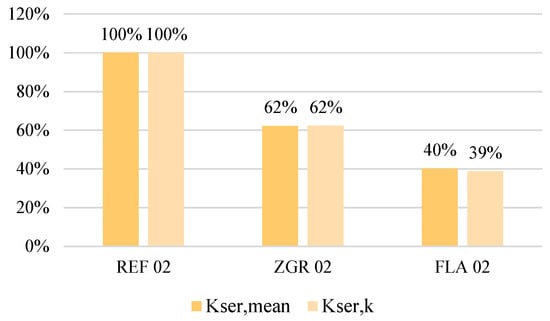

The contribution of the flanks to the force transmission can be illustrated by comparing the stiffness of the results on GLT girder combinations with cross sections of 160 × 160 mm of the REF 02, ZGR 02 and FLA 02 series. This results in a load participation of the flanks of 40%, which contributes to the reference form REF 02 (see Figure 15).

Figure 15.

Weighted stiffnesses of Series 02 (graphs).

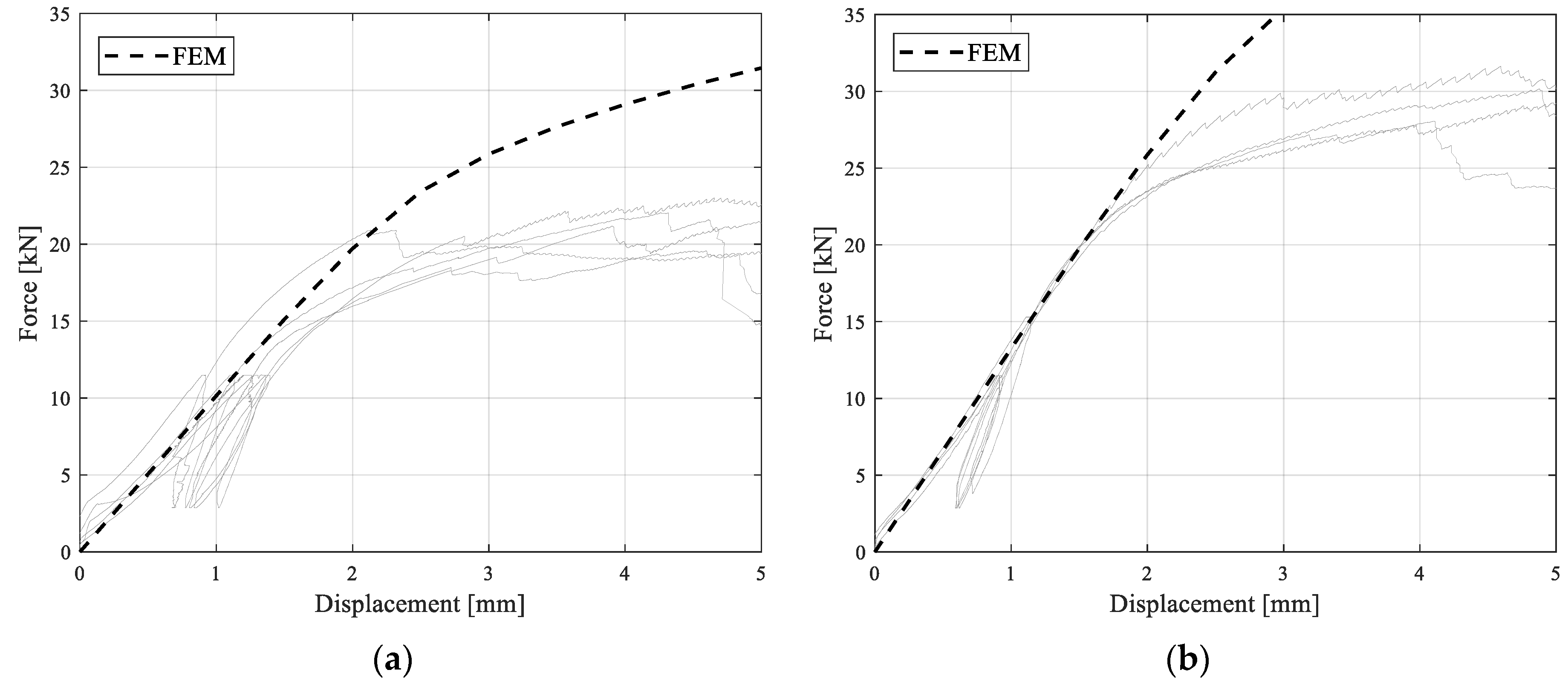

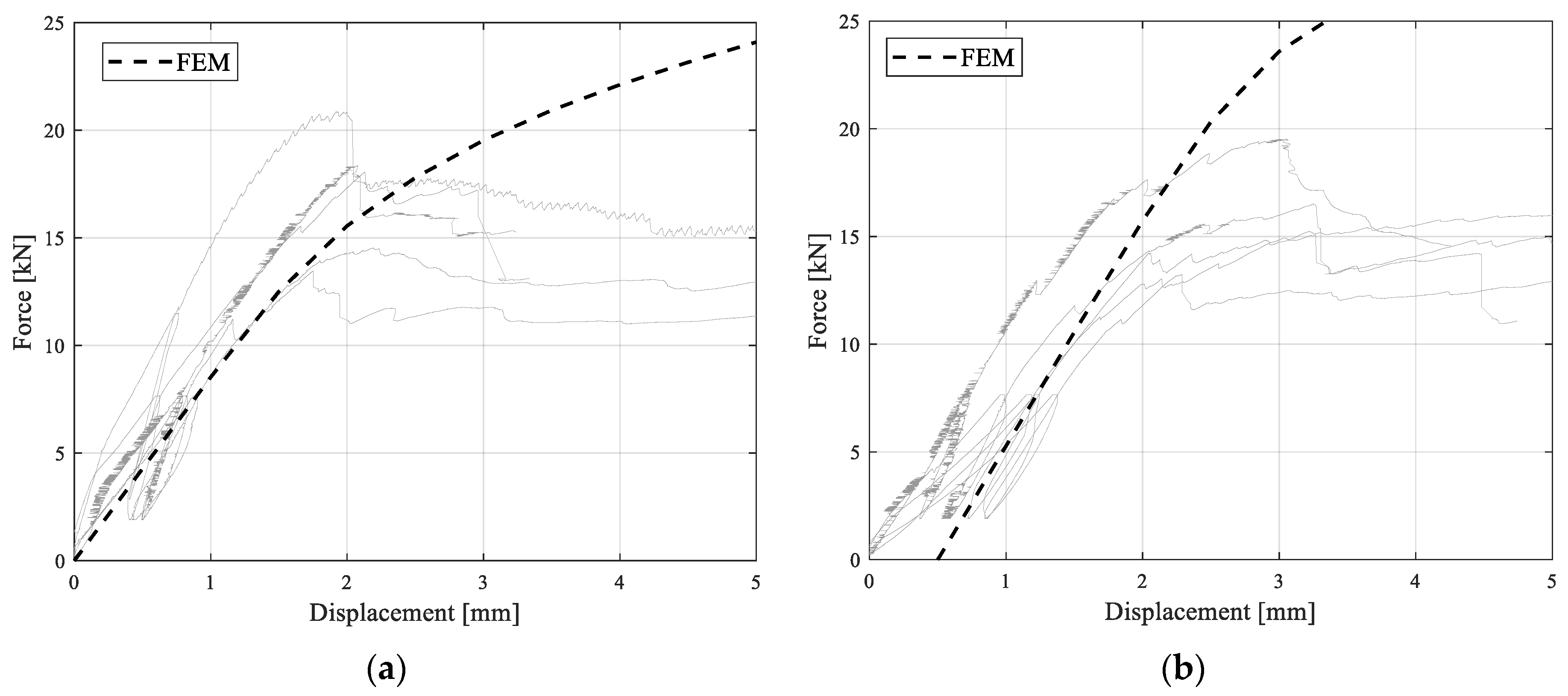

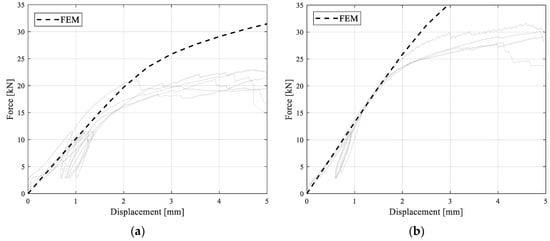

- FEM—Validation

Stiffness values for solid spruce wood C24 according to EN 338 [17] and yield stresses according to Sandhaas and van de Kuilen [18] are applied for the bilinear material model with Hill yield criterion and isotropic hardening in the course of the simulations (Table 1). All results of the test runs of the reference geometries REF 01 and REF 02 can thus be validated in numbers (see Figure 16).

Figure 16.

FEM—Validation of the test runs (thin solid lines) (a) REF 01 (b) REF 02.

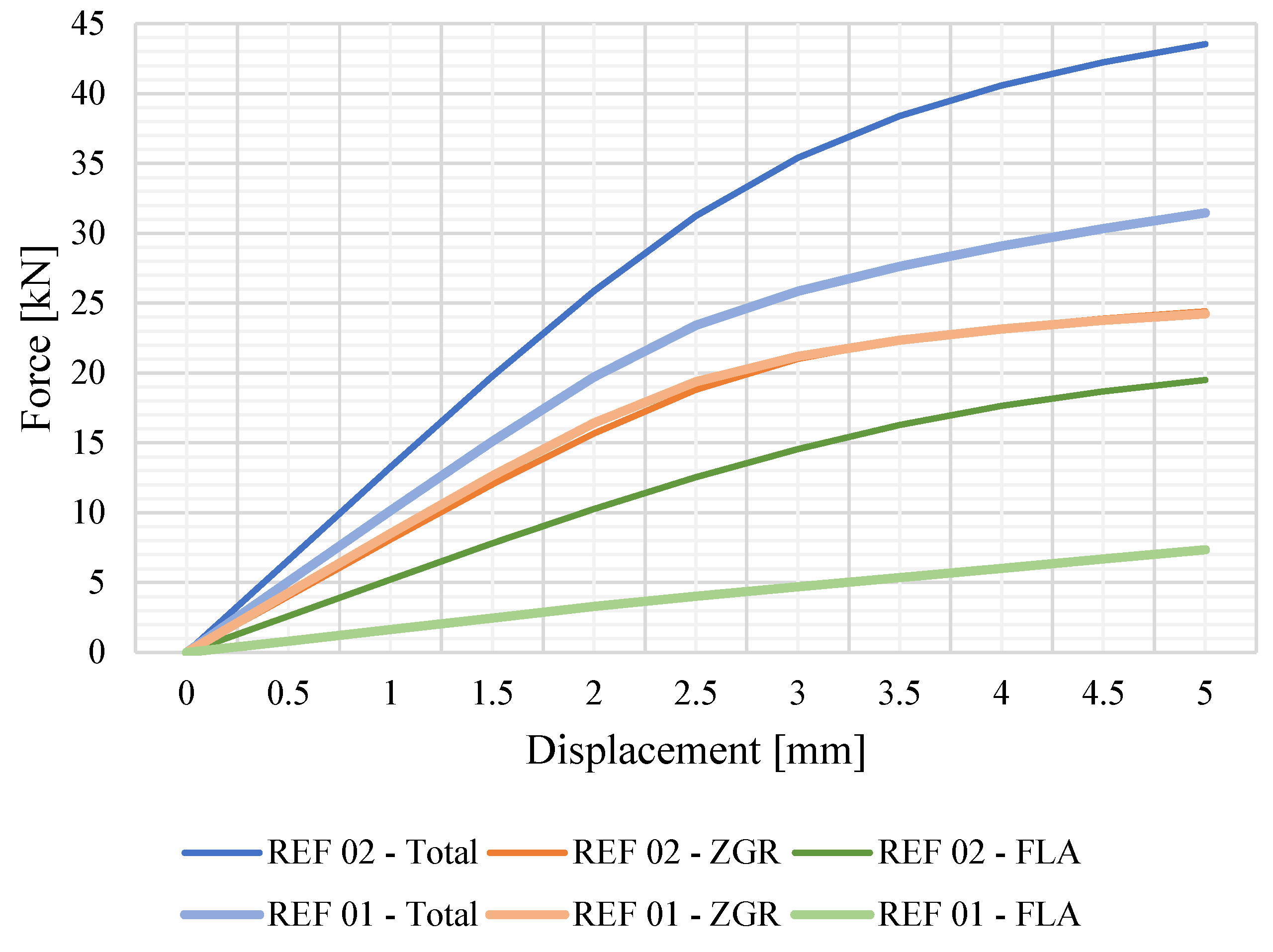

The flank load components can be confirmed in FE simulations of the two reference geometries REF 01 and REF 02 (Table 4). The same applies to the fact that both tenon bases show identical load-bearing behavior in the FE simulations (cf. series ZGR 01 and ZGR 02). This confirms that improved load bearing and stiffness properties in the tests result exclusively from increased properties of the flanks (see Figure 17).

Table 4.

FE—Comparison of stiffnesses with test series.

Figure 17.

FEM—Comparison of the load-bearing behavior of reference shapes REF 01 and REF 02.

3.1.2. Bar-Shaped Investigations—Stepped Tenon Base

Girder combinations with low pre-timber heights hVH at the main girder fail by exceeding the transverse tension strength. The main reason is that there is too little transverse tension volume available due to insufficient connection depth teff below the fillet of the main girder. Moreover, the combination of a low transverse tension strength of the wood and load introductions with a low pre-timber height, lead to premature transverse tension failure resulting from defects in the wood.

The total dimensions of the pre-timber of the main beam is composed of:

hVH = (hHT − hNT) + (hNT − hZ)

As already mentioned, the unfavorable case of load distribution occurs with beam combinations of the same height, as frequently applied in practice. Z-9.1-649 [1] does not limit this dimension parameter and allows teff = 100 mm in any case in the transverse tension check for mode 1 failure (transverse connection—failure of the main girder side).

In order to investigate the bearing behavior in such a case, a test series of 120 × 160 mm GLT-girder combinations with minimum pre-timber heights and permissible geometry parameters was developed according to [1]. The REF 03 series was thus tested in five tests and on the same test setup as in the previous investigations with respect to mode 1 failure according to [1]. Furthermore, a series is developed following the measure of a “double dovetail tenon” set by Tannert in [3]. Step-shaping the depth of the tenon forms a three-row shape of the stepped tenon base, starting from the fillet of the tenon. The individual levels of the steps are optimized in terms of their widths and heights so that the uppermost step has the maximum width and can thus take the most load. The aim here is to distribute the load application over several levels. This results in a more favorable distribution of the transverse tension stresses in the area of the fillet of the mortise of the load-bearing side and a delayed failure of the main girder. By introducing part of the forces at the higher level (uppermost step), a greater connection depth teff is achieved and thus a greater transverse tension volume is attained. As a result, even imperfections in the wood have hardly any influence on the load transfer.

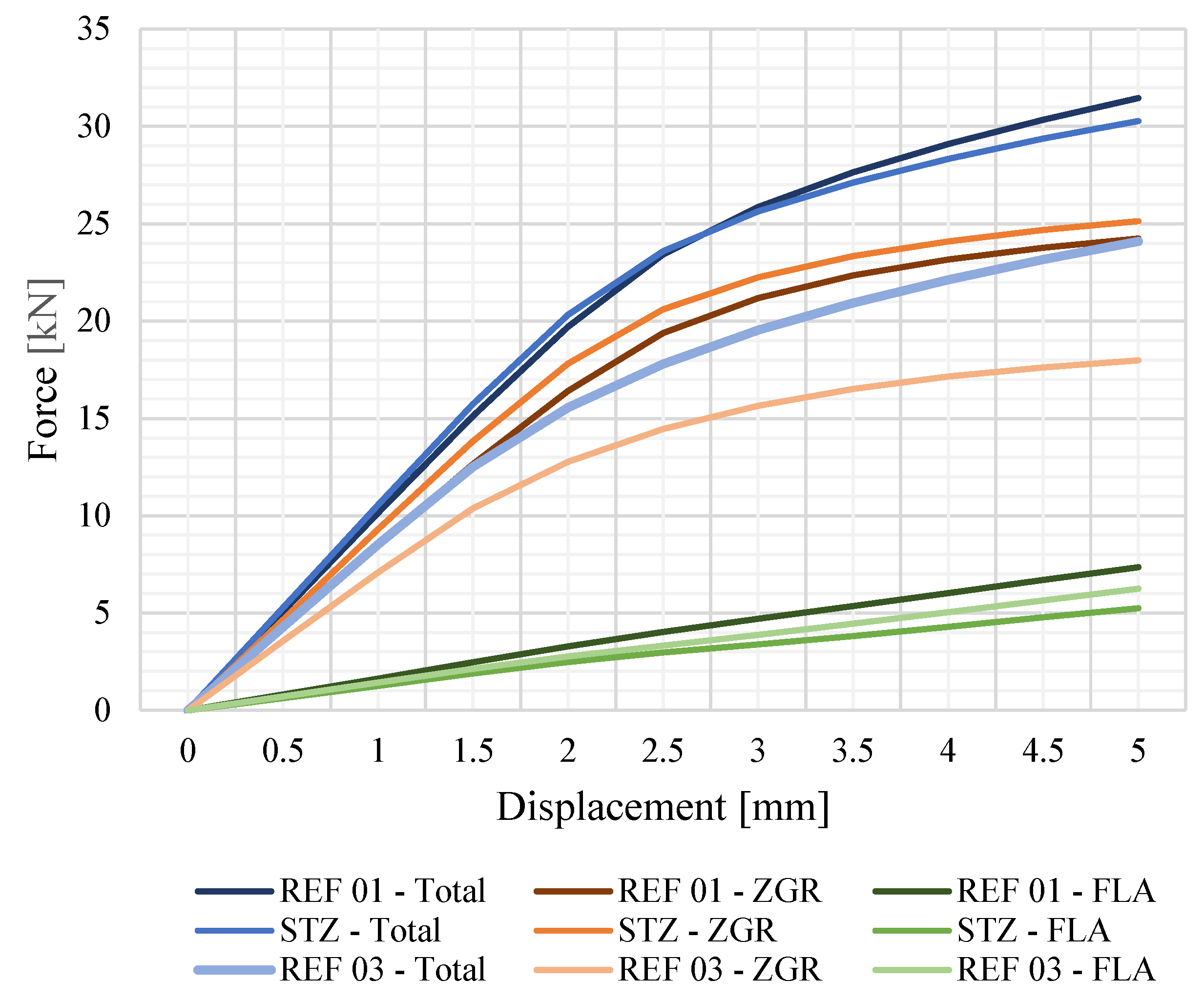

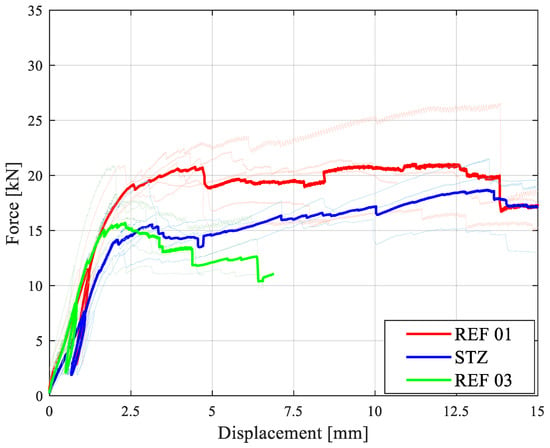

Due to the stepping of the tenon base, the connection depth teff of series STZ increases by approximately 50% (see Figure 18). The loads of the mean value curve of series STZ can almost reach those of the reference geometry REF 01 at 15 mm deformation (see Figure 19). Therefore, REF 01 is taken into account in all comparisons.

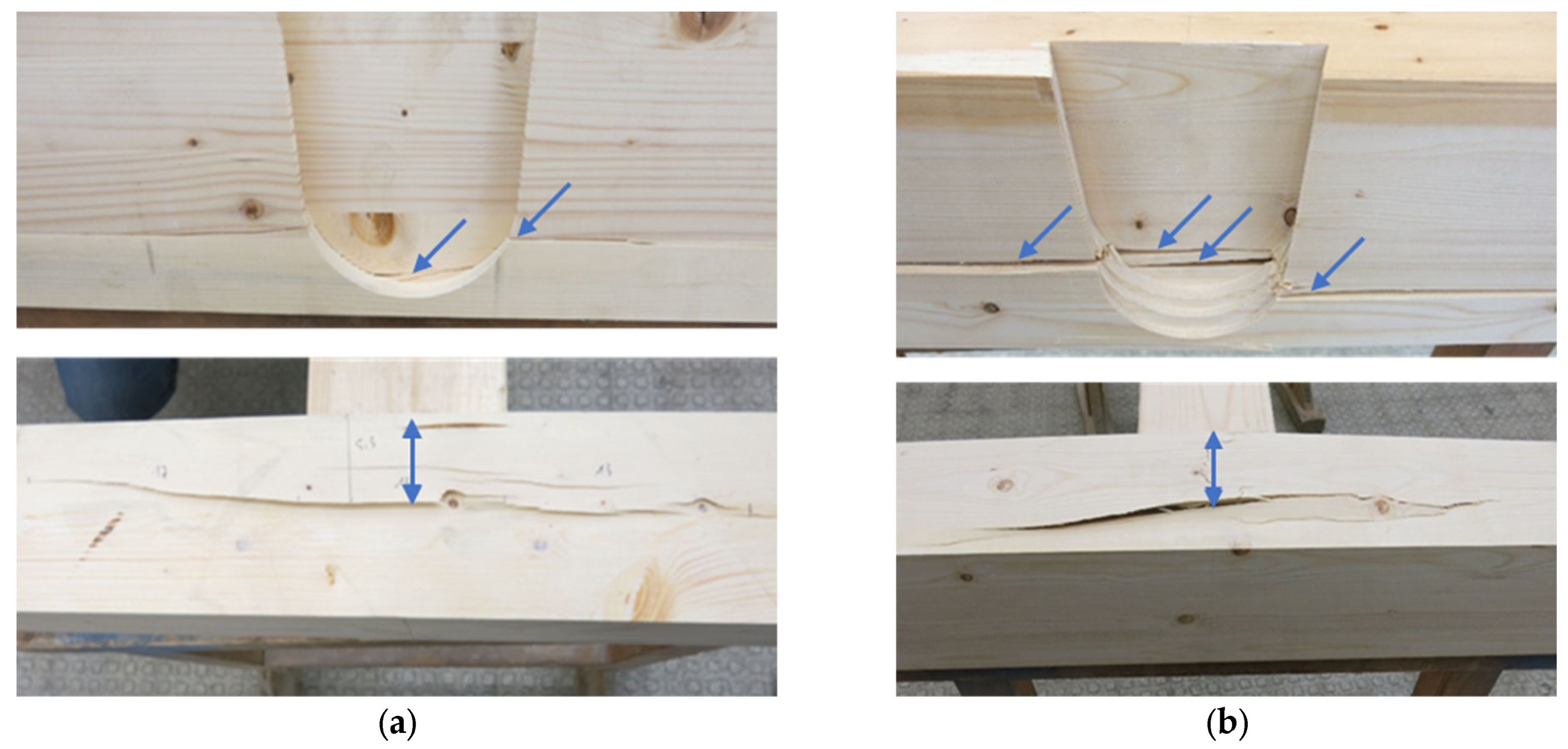

Figure 18.

Damage patterns and cracks for (a) REF 03 series (b) STZ series.

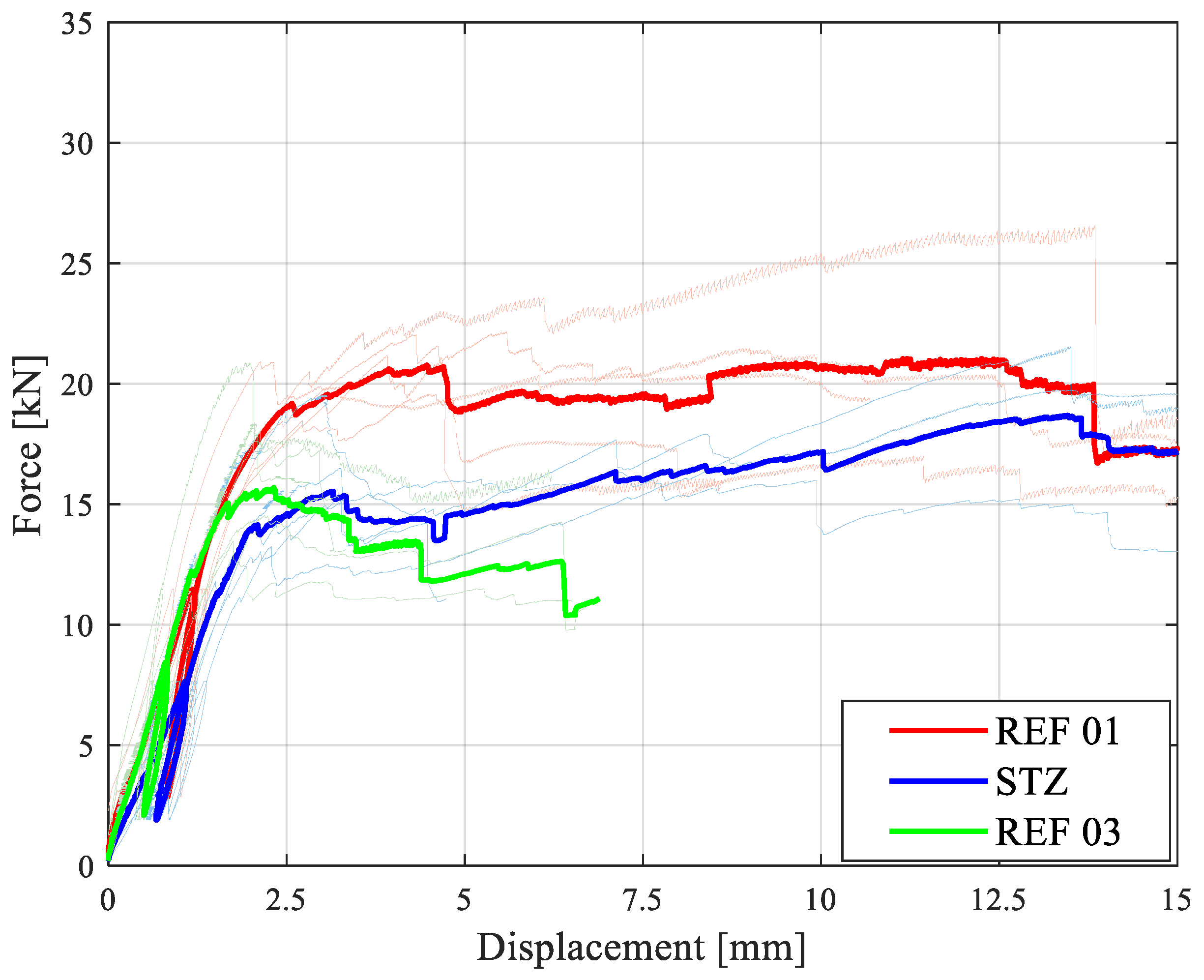

Figure 19.

Load-deformation mean value curves (thick colored lines, listed in legend) of the related single tests (thin colored lines) for 120 mm × 160 mm beam combinations.

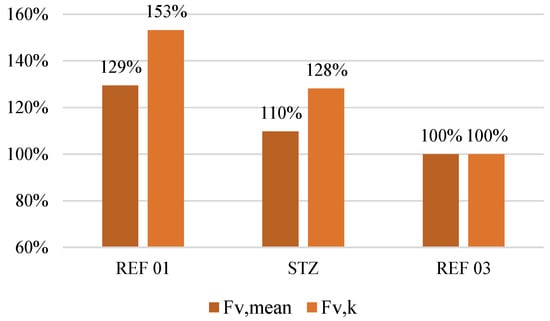

The high spread of the ultimate loads in the REF 03 series with minimum pre-timber height is striking, which is due to the effects of local defects and thus premature failure. The tests of this reference geometry spread with respect to the ultimate loads Fv,k at a covariance COV of 18% (see Table 5). The minimum initiation height from the beginning of the fillet of the mortise to the lower edge of the girder is only capable of ensuring a connection depth teff of 50 mm. The widely spreading values are due to local defects, which lead to different transverse tension crack propagation. This results in premature failure below the tenon base of the load-bearing main girder without redistribution possibilities. In contrast, the stepped tenon base geometry of the STZ series exhibits a high dispersion in terms of its stiffness. This is due to the form closure on several levels and the associated tolerances, i.e., until the closing of the multi-stage overall system. However, the load transfer to the multiple levels results in a significant increase in the ultimate load, which has a positive effect on the characteristic calculation value Fv,k in particular (see Figure 20). The initial stiffness values Kser spread with a covariance (COV) of up to 32% (see Table 5). However, if deformations of up to 15 mm are allowed, the connection force-locks at all step levels. The mean load curve of the STZ series thus approaches that of the reference form REF 01 at 15 mm deformation.

Table 5.

Evaluation of the tests—loads and stiffnesses according to EN 14358 [21].

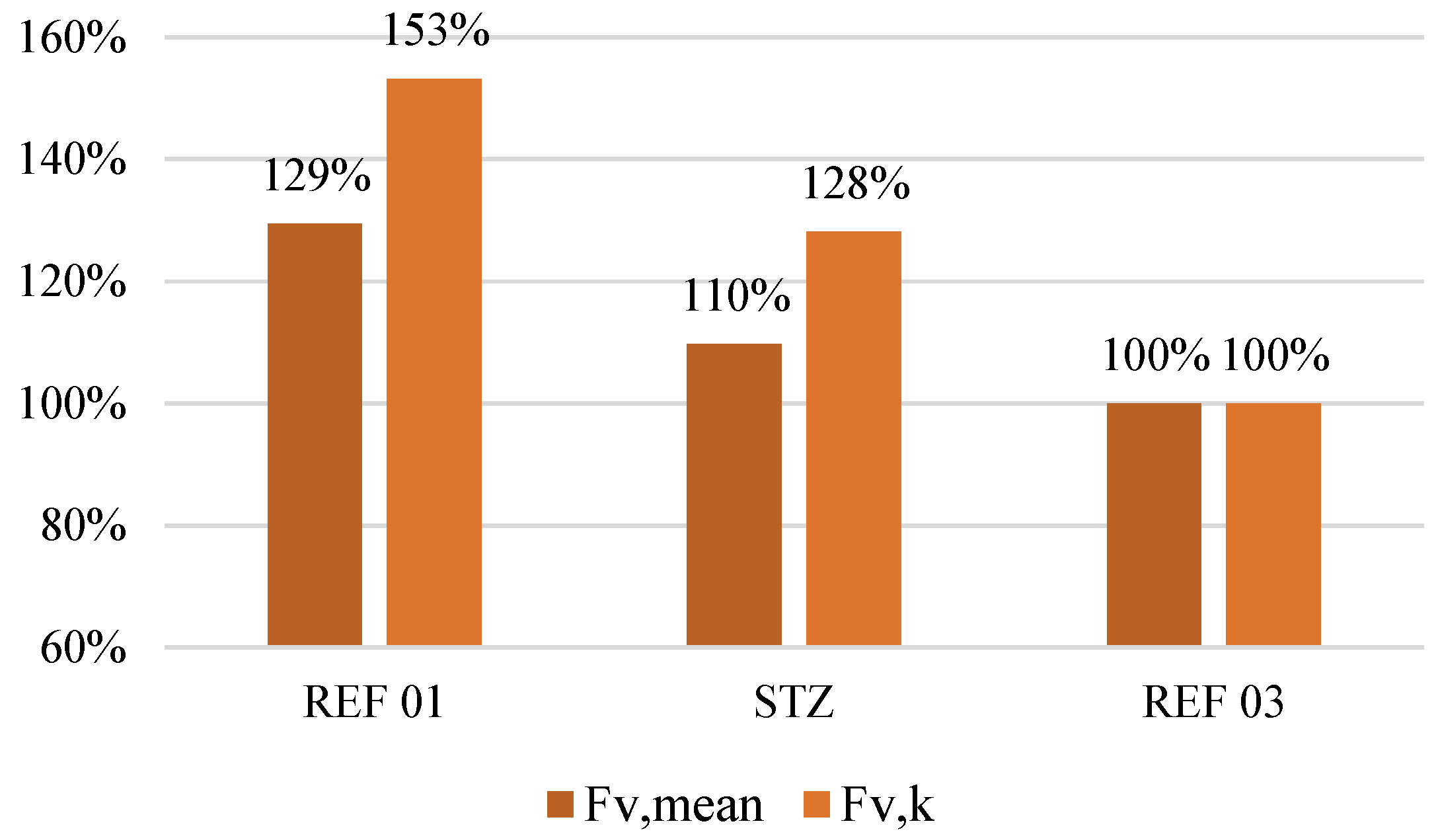

Figure 20.

Weighted strengths of Series 03 (graphs).

By stepping the tenon base, a height distribution of the load application can be achieved, which is also reflected in the fracture patterns. Failure is thus not determined by a defect in the transverse tension volume. Ultimately, all test specimens reach a similar ultimate load level after deforming to a higher or lesser degree. The individual levels of the stepped tenon base communicate with each other, so that in the event of an individual level yielding, the load can be redistributed to other, intact levels.

In the reference form REF 03, the entire force is applied via the single “step” located far below, with a low connection depth teff. As a result, only a small transverse tension volume of the main girder is activated in the transverse connection. If the load introduction is distributed over several levels according to the geometry of the STZ series, an overall higher force introduction is achieved. In this way, approximately 75% of the width of the 120 × 160 mm main beam bHT can be activated as the resisting connection depth teff. The stepped tenon base is designed so that the step with the lowest connection depth also introduces the lowest load component. The two higher steps introduce higher load components with greater effective connection depths. This means that the widest step at the top transfers more than half of the resultant force to the load-bearing main beam.

- FEM—Validation

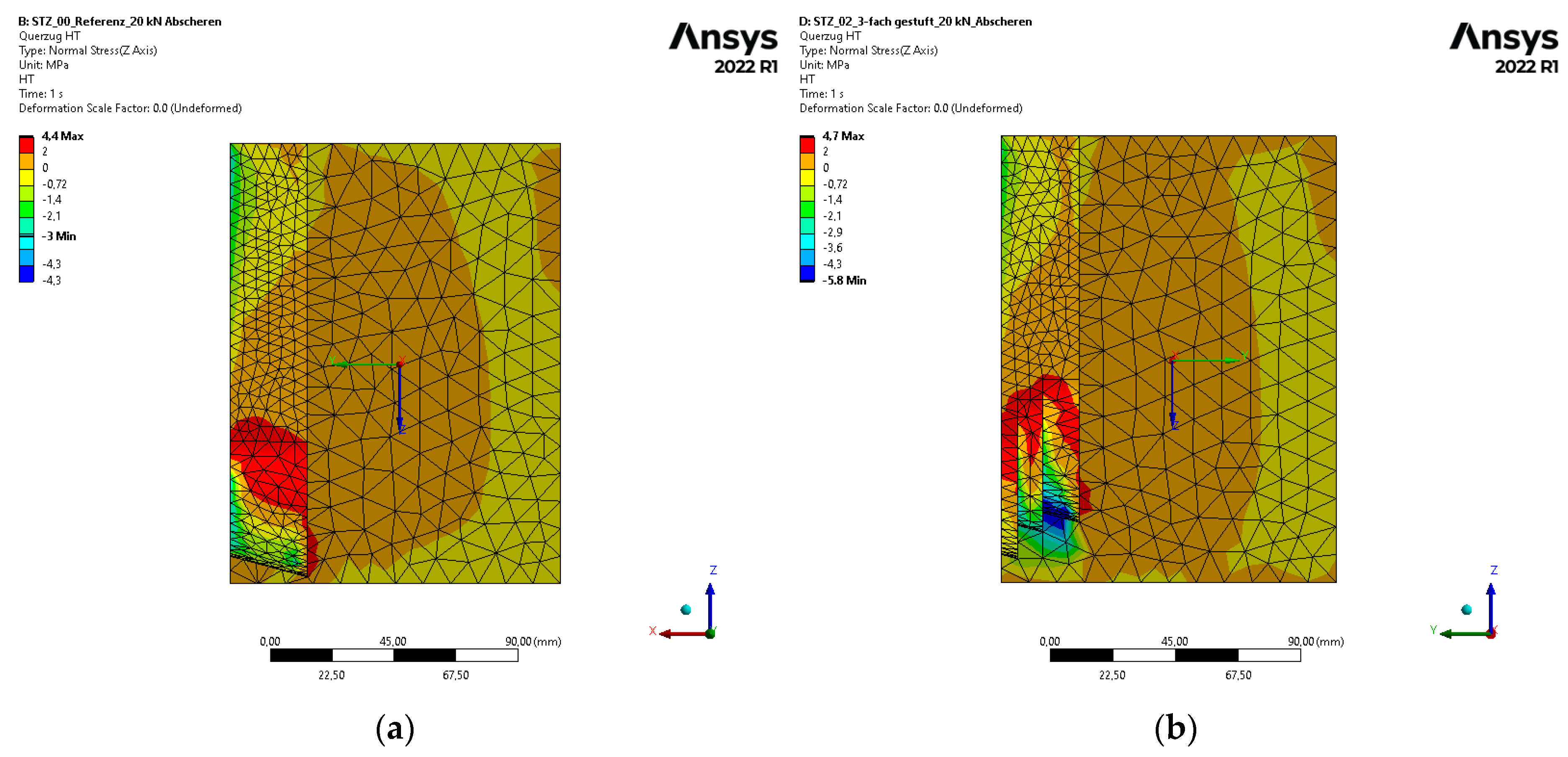

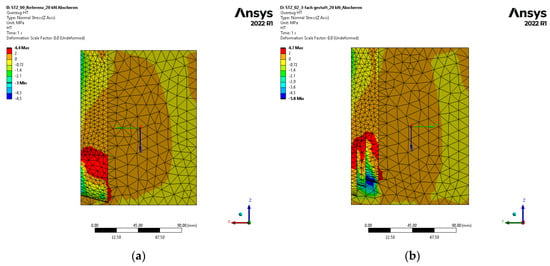

The positive effect of the stepping can also be seen in the course of numerical simulations (see Figure 21).

Figure 21.

FEM—Transverse tension and compression stresses (z-direction) in the hole of the main girder (a) Reference REF 03 section (b) Step shape STZ section.

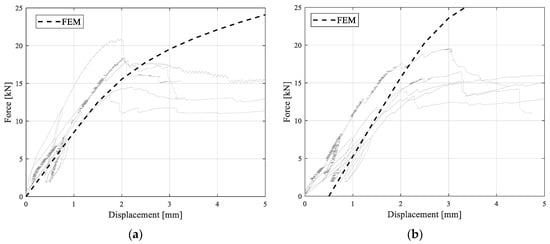

Stiffness values for solid spruce wood C24 according to EN 338 [17] and yield stresses according to Sandhaas and van de Kuilen [18] are applied for the bilinear material model with Hill yield criterion and isotropic hardening in the course of the simulations (Table 1). All results of the test runs of the reference geometry REF 03, as well as the stepped tenon base geometry STZ, can thus be validated in numbers (see Figure 22).

Figure 22.

FEM- Validation of the test runs (thin solid lines) (a) REF 03 (b) STZ.

Due to the delayed closure of the entire system in the tests with the stepped tenon base shape STZ, the FE curve had to be shifted by 0.5 mm.

The mean value curves of the test results of the REF 01 and STZ series show equally high ultimate loads (see Figure 19), although those of the stepped tenon base form are only reached at deformations of 15 mm. In the FE model, these series show the same initial stiffnesses Kser (see Figure 23). The initial stiffness Kser is overestimated in the FE model for the STZ series, since the problem of closing the individual steps resulting from a lack of fitting accuracy is not covered by the model.

Figure 23.

FEM—Comparison of the load-bearing behavior of reference shapes REF 01 and REF 03 with stepped tenon base shape STZ.

Reference form REF 03 shows the lowest initial stiffness, Kser, in the FE model (see Figure 23). The ultimate loads in the tests of the REF 03 series, shown in Figure 19, are all reached within deformations of 5 mm. Furthermore tests of REF 03 show a higher initial stiffness, Kser,mean, as in the FE model because of a positive “outlier” in the tests (see Table 6).

Table 6.

FEM—comparison of stiffnesses with test series.

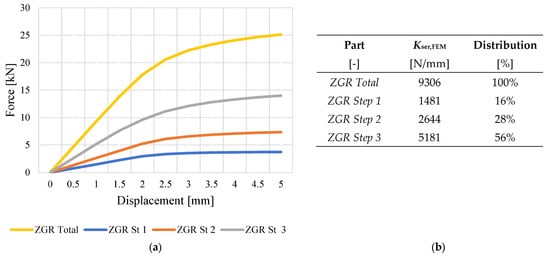

The individual steps of the tenon base attract different load proportions (see Figure 24). The widest, step 3 at the top, absorbs more than half of the load share of the entire tenon base. In general, the FE model for the STZ geometry shows a distribution of the load-bearing components between the tenon base and the flanks of approximately 88% to 12% (total value Kser,FEM of STZ in Table 6). This distribution thus, corresponds to that of the reference shape REF 01 (see Figure 23).

Figure 24.

(a) Load-bearing components of the steps (graphs) (b) Tabular listing.

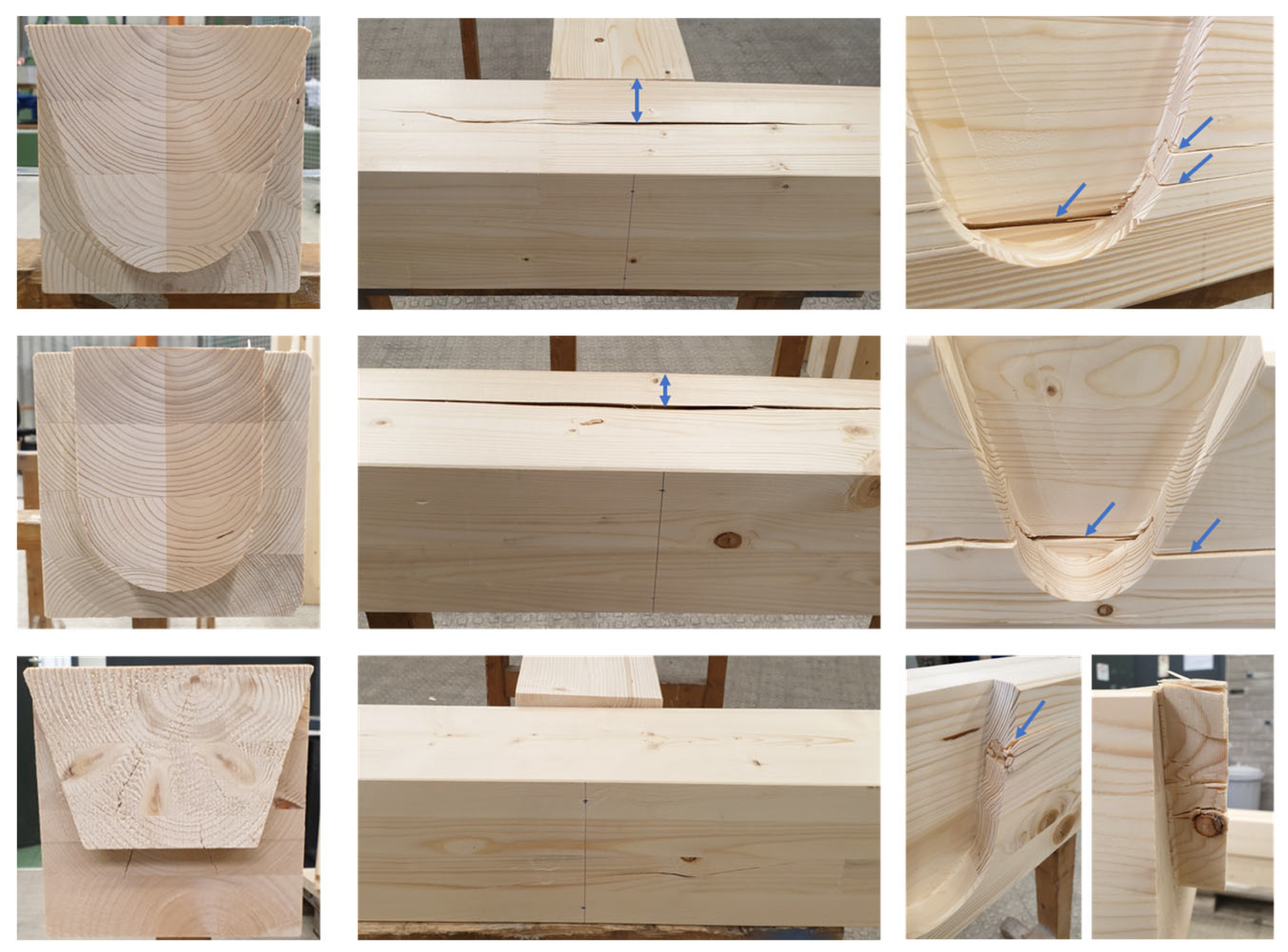

3.2. Coupling Element for CLT Wall–ceiling Connections—Double Dovetail

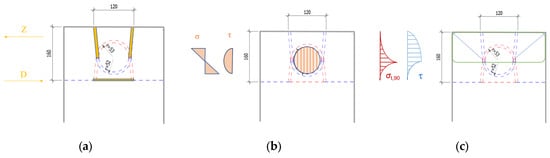

In principle, the failure modes shown in Figure 25 are possible:

- Mode 1: Failure of the cover lamella of the CLT wall element (transverse tension, or transverse compression).

- Mode 2: Failure of the LVL system connector (combined shear, bending tension failure)

- Mode 3: Failure of the cover lamella of the CLT ceiling element (transverse tension with rolling shear).

Figure 25.

Failure modes of the system connection. (a) Cover lamella wall side (b) System connector (c) Cover lamella ceiling side.

Figure 25.

Failure modes of the system connection. (a) Cover lamella wall side (b) System connector (c) Cover lamella ceiling side.

In the present studies of the variants of the wall–ceiling connection, the failure is due to the notching of the cover lamella from the CLT (mode 3) or shearing of the system connector (mode 2). Calculation models for notched CLT-elements are described in Serrano et al. [22], Serrano and Danielsson [23] and Malagic et al. [24]. Values of tests conducted with the “double dovetail tenon” on CLT 5 s 160 mm elements, indicate much higher load-bearing capacities of the rounded dovetail joint geometry as for the fully notched CLT-elements with width bz and height hz. Test values for fully notched bar-shaped CLT 5 s 160 mm cross sections can be found in Friberg [25]. The load bearing capacities of mode 3 of the system connector can therefore be best compared with fully notched elements with comparable heights (hz-r). The reasoning is that the load transmission starts from the beginning of the rounding of the rounded dovetail joint down to the tenon base contrary to notched elements, as all the load transmission has been transferred to the same level support. Shear strength values for edgewise and flatwise veneer arrangements of Kerto© LVL-Q (see [19]) can be used for the calculation of mode 2 load bearing capacities. The reason being that nearly the same strength value was reached in shear tests of the connector with flatwise and edgewise arranged dowels. Failure on the wall side (mode 1) is not decisive for any of the variants due to the low support torsion that occurs. The eccentricity limit center is also maintained by means of a stiff bearing with regard to torsion of the wall element.

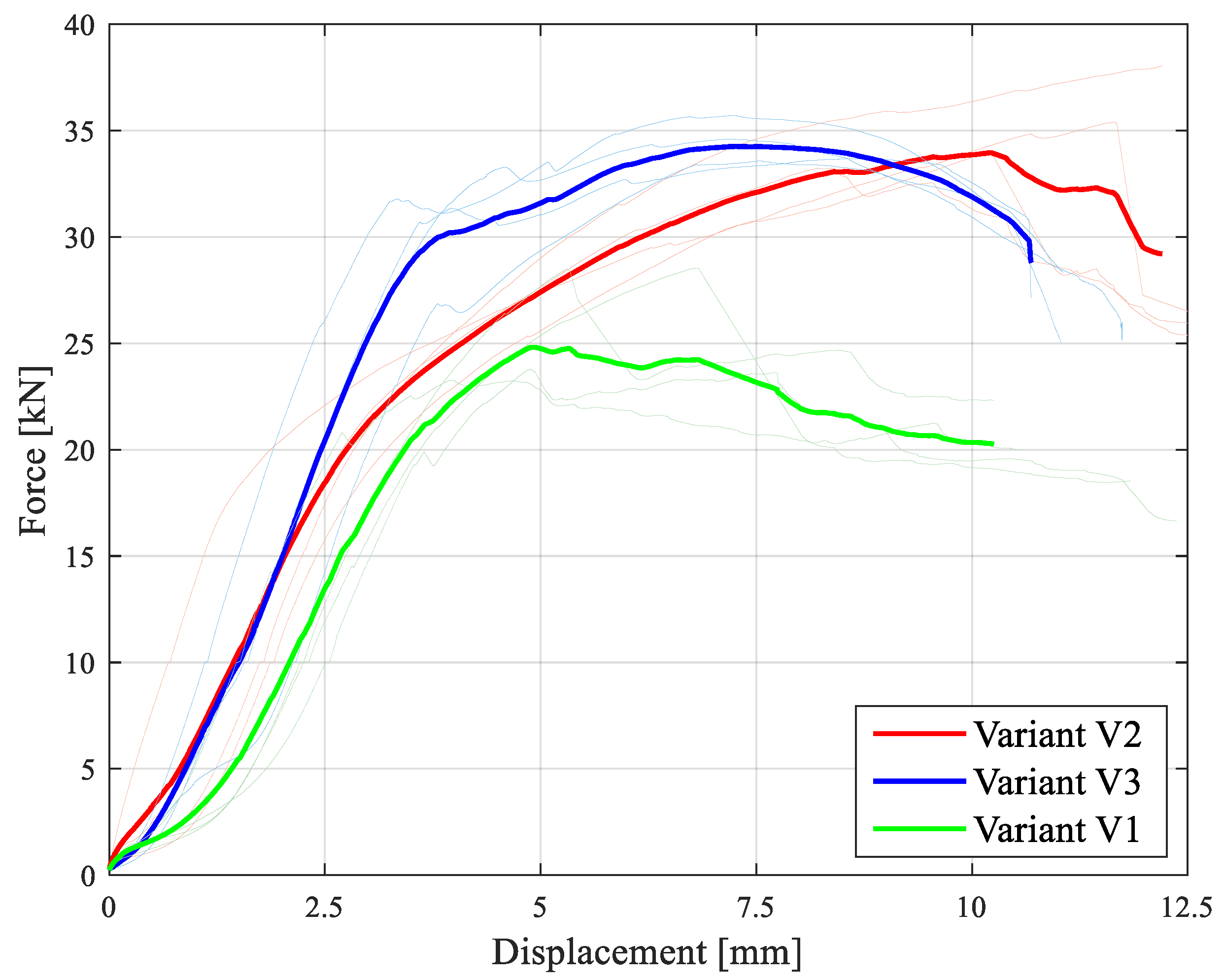

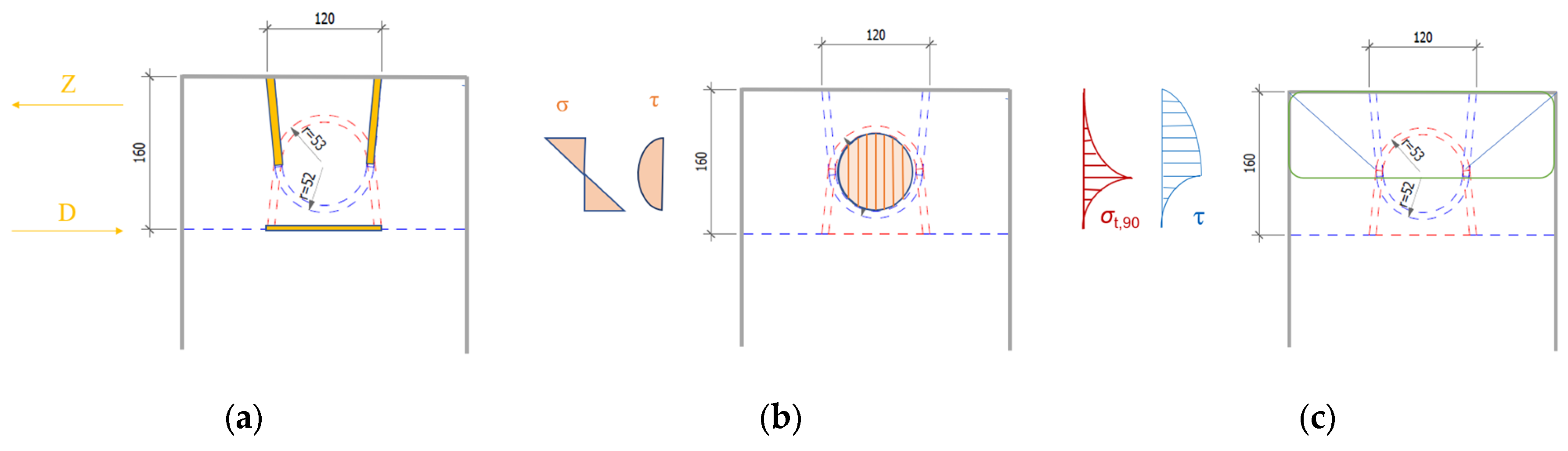

In the course of optimization measures, which have the objective of delaying the failure on the ceiling side, a significant load increase is achieved for V2 and V3 compared to V1. The connection is optimized in such a way that the failure of the cover lamella of the CLT ceiling element is delayed in V2 by stepping the tenon base on the ceiling side, or it even occurs on the side of the system connector in V3. V2 and V3 fail at the same load level, which corresponds to an optimization of these two failure modes.

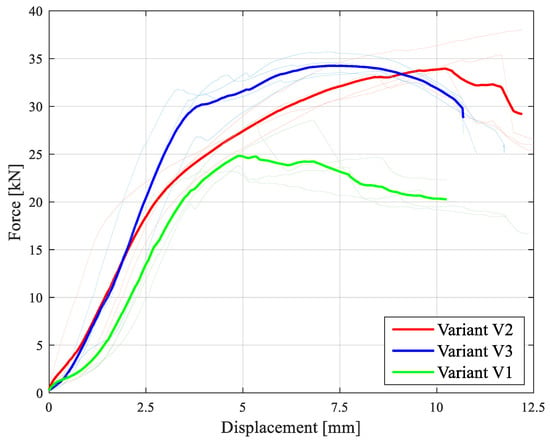

The variants investigated are characterized by a ductile failure of the connection, whereby variant V2 and V3 do not fail up to a 10 mm displacement (see Figure 26). In variant V2, this is due to a deeper force transmission introduced over several levels, which leads to a delay in failure of the CLT on the ceiling side as compared to variant V1. In variant V3, the connector fails on shear, whereby the doweling by means of 12 ϕ10 grooved beech dowels ensures the necessary ductility with a flatwise arrangement of the veneers. Damage patterns of Variant V2 and Variant V3 are shown in Figure 27.

Figure 26.

Load-deformation mean value curves (thick colored lines, listed in legend) of the related single tests (thin colored lines) of wall–ceiling connections with wood–wood system connectors Variant V1, Variant V2 and Variant V3.

Figure 27.

Damage patterns for (a) Variant 2—ceiling hole decisive (b) Variant 2—connector (c) Variant 3—slab hole (d) Variant 3—connector decisive.

The V2 and V3 variants are optimized geometries with the same load-bearing capacity level at different failure modes for the present combination of the same-height connection of a CLT 160 5 s ceiling element to a CLT 100 5 s wall element by means of a pure wood–wood connection, which is ensured by system connectors of the wood-based material Kerto©Q.

In the tests, variants V2 and V3 show a load-bearing capacity that is 50% higher than that of variant V1. Their initial stiffness values Kser are also 4% and 15% higher than those of variant V1. All values are listed in Table 7. The ultimate loads and stiffnesses achieved allow CLT floor elements b = 1.25 m to be connected to CLT wall elements by means of two or three connectors and a center distance of the coupling elements of 600 mm or 400 mm, depending on the live loads to be applied, in purely static terms up to a span of 5.0 m in building construction at service class 1 (NKL1).

Table 7.

Load capacities and initial stiffnesses of the three variants of the wood system connection.

4. Conclusions

In the case of equal-height connections of dovetail joints with a low pre-timber height, the widening of the notch taper angle leads to significantly improved load-bearing behavior. This applies to both bar-type connections and the new wood–wood system connection for CLT wall–ceiling connections. The values of tests conducted with the “double dovetail tenon” on CLT-elements also indicate much higher load-bearing capacities of the rounded dovetail joint geometry as for the fully notched CLT-elements.

The available investigations have shown that a robust and secure wood–wood connection is ensured by the dovetail geometry together with its inherent flank inclination. The more the flanks are inclined, the higher is their load-bearing capacity before failure. That also applies to the residual load-bearing capacity of the connection after failure. This always remains the same for any material combination, irrespective of time. Similar properties are produced by stepping the tenon base of a dovetail joint. This activates a larger volume of the load-bearing component during force application. It reduces the influence of local flaws and thus delays the failure of the connection. The abovementioned optimization measures have a very great influence on component connections at the same height, which also makes them suitable for floor elements that are connected to wall elements by means of the system connector. The load-bearing capacity of wall–ceiling connections made of CLT could be increased by 50% by such geometric optimization. The wood–wood system connection consisting purely of wood-based materials is thus a structural alternative to mechanical system connectors for ceiling loads and spans relevant in building construction. It meets the specifications of load-bearing structures with regard to ductility and robustness, even in the connection area.

Preliminary numerical moisture simulations of the system connection also indicate promising results. With Edgewise veneer arrangement, the coupling element swells and shrinks mainly transverse to the insertion direction. With Flatwise veneer arrangement, dimensional stability is provided by wood fiber directions in all three axes: transverse plies transverse to the direction of insertion, beech dowels in the thickness direction, and the main fiber direction in the direction of insertion. System connectors with this veneer arrangement remain dimensionally stable along the flanks. Further investigations on this topic will be part of future research work [26].

5. Patents

The “double dovetail” system connector, with all the variants shown, has also been protected by a patent since July 2023.

Author Contributions

Conceptualization, A.P. and A.K.; methodology, A.P. and A.K.; writing—original draft preparation, A.P.; writing—review and editing, A.K; supervision, A.K.; project administration, A.K.; funding acquisition, A.K. All authors have read and agreed to the published version of the manuscript.

Funding

The work on the wood–wood connections has been funded by the innovation promotion of the country Tirol, Austria (Land Tirol) within the research projects “CNC-manufactured wood–wood connections”, Reference WA-540-02-00606/01-0010 and “wood–wood system connection for multi-storey solid wood construction”, Reference F.42814/9-2022 which were both processed together with the commercial partners Holzbau Lengauer-Stockner (Schwoich, Austria), Holzbau Saurer (Höfen, Austria), and FS1, Fiedler-Stöffler (Innsbruck, Austria).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding authors. The data is not publicly available due to ongoing research.

Acknowledgments

The authors would like to thank the Technical Testing and Research Institute (TVFA) Innsbruck for carrying out the experimental campaign. Special thanks are extended to the partners of the research projects “CNC-manufactured wood–wood connections” and “wood–wood system connection for multi-storey solid wood construction”—Lengauer-Stockner, Saurer and FS1—and the innovation promotion of the country Tirol. The computational results presented here have been achieved (in part) using the LEO HPC infrastructure of the University of Innsbruck.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Z-9.1-649; Schwalbenschwanz-Verbindung in Bauteilen. Deutsches Institut für Bautechnik: Berlin, Germany, 2022.

- CEN/TC 250/SC 5; prEN 1995-1-1 for Formal Enquiry—Eurocode 5: Design of Timber Structures—Part 1-1: General Rules—General Rules and Rules for Buildings. CEN (European Committee for Standardization) CEN: Brussels, Belgium, unpublished.

- Tannert, T. Structural Performance of Rounded Dovetail Connections. Ph.D. Thesis, University of British Columbia, Vancouver, BC, Canada, 2008. [Google Scholar]

- Tannert, T.; Lam, F.; Vallée, T. Structural performance of rounded dovetail connections: Experimental and numerical investigations. Eur. J. Wood Wood Prod. 2011, 69, 471–482. [Google Scholar] [CrossRef][Green Version]

- Tannert, T.; Lam, F. Self-tapping screws as reinforcement for rounded dovetail connections. Struct. Control. Health Monit. Off. J. Int. Assoc. Struct. Control. Monit. Eur. Assoc. Control. Struct. 2009, 16, 374–384. [Google Scholar] [CrossRef]

- Tannert, T. Improved performance of reinforced rounded dovetail joints. Constr. Build. Mater. 2016, 118, 262–267. [Google Scholar] [CrossRef]

- Schickhofer, G. Prüfung und Optimierung von CNC-Gefertigten Schwalbenschwanzzapfverbindungen; Forschungsbericht Holz-Holz-Verbindungen: Graz, Austria, 2014. [Google Scholar]

- Blaß, H.J.; Enders-Comberg, M. Fachwerkträger für den industriellen Holzbau. In Karlsruher Berichte zum Ingenieurholzbau No. 22; KIT Scientific Publishing: Karlsruhe, Germany, 2012. [Google Scholar]

- Braun, M.; Pantscharowitsch, M.; Kromoser, B. Experimental investigations on the load-bearing behaviour of traditional and newly developed step joints for timber structures. Constr. Build. Mater. 2022, 323, 126557. [Google Scholar] [CrossRef]

- ÖNORM EN 1995-1-1; Eurocode 5: Design of Timber Structures—Part 1-1: General—Common Rules and Rules for Buildings (Consolidated Version). CEN (European Committee for Standardization) CEN: Brussels, Belgium, 2019.

- Ehlbeck, J.; Görlacher, R. Tension Perpendicular to the Grain in Joints, STEP 1—C2; Centrum hout: Almere, The Netherlands, 1995. [Google Scholar]

- Gustafsson, P.J. Notched Beams and Holes in Glulam Beams, STEP 1—B5; Centrum hout: Almere, The Netherlands, 1995. [Google Scholar]

- IngenieurHolzbau. de. Finnish Woodworking Industries: Furnierschichtholz-Merkblatt (LVL)—2. Auflage; Studiengemeinschaft Holzleimbau e.V.: Wuppertal, Germany, 2020. [Google Scholar]

- EN 13183-1; Moisture Content of a Piece of Sawn Timber—Part 1: Determination by Oven Dry Method. CEN (European Committee for Standardization) CEN: Brussels, Belgium, 2004.

- EN 26891; Timber structures—Joints Made with Mechanical Fasteners—General Principles for the Determination of Strength Aand Deformation Characteristics. CEN (European Committee for Standardization) CEN: Brussels, Belgium, 1991.

- EN 14080; Timber Structures—Glued Laminated Timber—Requirements. CEN (European Committee for Standardization) CEN: Brussels, Belgium, 2013.

- EN 338; Structural Timber—Strength Classes. CEN (European Committee for Standardization) CEN: Brussels, Belgium, 2016.

- Sandhaas, C.; Van de Kuilen, J.W. Material model for wood. Heron 2013, 58, 171–191. [Google Scholar]

- Z-9.1-847; Bauarten Mit Furnierschichtholz “Kerto-S”, “Kerto-Q” und “Kerto-Qp”. Deutsches Institut für Bautechnik: Berlin, Germany, 2019.

- EN 408; Timber Structures—Structural Timber and Glued Laminated Timber—Determination of Some Physical And Mechanical Properties. CEN (European Committee for Standardization) CEN: Brussels, Belgium, 2012.

- EN 14358; Timber Structures—Calculation and Verification of Characteristic Values. CEN (European Committee for Standardization) CEN: Brussels, Belgium, 2016.

- Serrano, E.; Gustafsson, P.J.; Danielsson, H. Prediction of load-bearing capacity of notched cross laminated timber plates. In International Network on Timber Engineering Research-Meeting 52; Timber Scientific Publishing: Karlsruhe, Germany, 2019. [Google Scholar]

- Serrano, E.; Danielsson, H. Fracture Mechanics Based Design of CLT-plates—Notches at Supports and Half-and-Half Joints. In International Network on Timber Engineering Research-Meeting 53; Timber Scientific Publishing: Karlsruhe, Germany, 2020. [Google Scholar]

- Malagic, A.; Augustin, M.; Silly, G.; Thiel, A.; Schickhofer, G. Load-bearing Capacity and Fracture Behaviour of Notched Cross Laminated Timber Plates. In Proceedings of the International Network on Timber Engineering Research (INTER) Meeting, Online, 19 August 2021; Paper INTER/54-12-5. Timber Scientific Publishing: Karlsruhe, Germany, 2021; pp. 16–19. [Google Scholar]

- Friberg, A. Bärförmåga för KL-trä Med Urtag—Provning och Beräkningsmetoder [Load-Bearing Capacity of CLT with Notches—Testing and Calculation Methods]. Report THID-5526. Bachelor Thesis, Division of Structural Mechanics, Lund University, Lund, Sweden, 2017. (In Swedish). [Google Scholar]

- Pomaroli, A. Holz-Holz Systemverbindung für Wand-Deckenanschlüsse aus Brettsperrholzelementen. Ph.D. Thesis, Universität Innsbruck, Innsbruck, Austria. manuscript under preparation.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).