Abstract

Using waste engine oil (WEO) to partially replace petroleum-based asphalt binders offers a promising solution to mitigate the environmental impact of waste WEO while reducing the dependence on non-renewable asphalt resources. To enhance the comprehensive properties of a modified asphalt containing 6 wt% WEO, an organic rectorite (OREC) with various contents was introduced to the modified asphalt system. The effect of OREC on the structure, storage stability, rheological properties, and self-healing property of WEO-modified asphalt were evaluated using a Fourier transform infrared spectrometer, softening point instrument, and rheometer. The results demonstrated that that no chemical reaction occurs between OREC and WEO-modified asphalt. The addition of OREC can enhance the storage stability and high-temperature stability while marginally decreasing the low-temperature cracking resistance and self-healing properties of WEO-modified asphalt. When the content of OREC increases to 2 wt%, the 48 h softening point difference value of the OREC + WEO composite-modified asphalt drops to 1.8 °C, and this composite-modified asphalt exhibits superior high-temperature rutting resistance, low-temperature cracking resistance, and self-healing property compared to the corresponding base asphalt. In summary, the addition of OREC can effectively offset the adverse effects of WEO on the properties of base asphalt.

1. Introduction

The utilization of solid waste materials in road materials and structures is an effective and environmentally responsible approach to achieving sustainable development in road engineering. One such waste material is waste engine oil (WEO), which is generated annually in large quantities, reaching approximately 40 million tons from motor vehicle services alone, according to reports [1]. In order to effectively recycle and utilize WEO while avoiding environmental pollution caused by incineration, dumping, and landfilling, there is growing interest in exploring its application in asphalt pavements [2,3,4,5,6,7]. WEO contains a significant amount of aromatic solvents, paraffinic oils, and polyolefin oils, among other low-molecular-weight components [8]. The presence of aromatic components in WEO can increase the content of lightweight fractions in the asphalt matrix [9], thereby softening the asphalt [10,11,12]. Previous studies have primarily focused on using WEO as an asphalt rejuvenator, as it can compensate for the loss of lightweight components in aged asphalt and help restore its performance [2,13,14]. However, researchers have also turned their attention to utilizing WEO as an asphalt modifier or substitute, given its similar functional groups and molecular structure to asphalt [8,15]. This approach presents a promising avenue for addressing environmental concerns related to the disposal of waste engine oil while simultaneously seeking sustainable solutions in road construction and maintenance. Research findings indicate that WEO can enhance the asphalt’s low-temperature crack resistance, self-healing property, and aging resistance, but it significantly affects the high-temperature rutting resistance of the asphalt [1,8,9,16]. This significant reduction in high-temperature rutting resistance severely limits the practical application of WEO-modified asphalt in road engineering [16]. Moreover, higher WEO content can reduce the storage stability of the corresponding WEO-modified asphalt, impacting its construction and workability. Hence, finding a balance or improving the overall performance of WEO-modified asphalt is crucial for determining its potential for engineering applications.

Layered silicates, known as naturally occurring nanoscale clays, have emerged as a valuable additive for enhancing the high-temperature rutting resistance and aging resistance of asphalt [17,18,19]. In particular, these silicates have shown promising results in improving the storage stability of polymer-modified asphalt. The unique structure of layered silicates allows them to disperse uniformly within the asphalt matrix, forming a stable network that enhances the overall performance of the asphalt mixture [20,21]. Among the most commonly used layered silicates are montmorillonite (MMT) and its organically modified derivatives [22,23,24]. Ke et al. [20] employed organically modified montmorillonite (OMMT) to enhance the storage stability, high-temperature stability, and aging resistance of SEBS-modified asphalt. The research findings showed that the addition of 3 wt% OMMT reduced the 48-h softening point difference of SEBS-modified asphalt from 8.5 °C to 1.1 °C, significantly improving the storage stability of SEBS-modified asphalt. This improvement was attributed to OMMT’s ability to promote the uniform dispersion of SEBS in the asphalt matrix. Other relevant research has confirmed that OMMT can enhance the storage stability of polymer-modified asphalts, such as those modified with waste packaging polyethylene and polyurethane thermoplastic elastomers, compensating for the reduced high-temperature stability caused by the polymers, albeit at the cost of decreased low-temperature crack resistance [19,25]. Cheng et al. [26] found that MMT can inhibit the evaporation of lightweight components in asphalt, thus reducing the impact of aging time on the self-healing performance of SBS-modified asphalt. There have also been reports on the use of OMMT to improve the properties of WEO-modified asphalt [1]. Similar to its effects on other types of polymer-modified asphalt [27,28], OMMT can enhance the high-temperature stability of WEO-modified asphalt while reducing its low-temperature crack resistance. However, through proper formulation design, OMMT can elevate the high-temperature stability, fatigue performance, and self-healing property of WEO-modified asphalt to levels exceeding those of the corresponding base asphalt. The literature review above confirms the vast potential of MMT and its organic modified derivatives in balancing or enhancing the overall performance of polymer-modified asphalt.

Rectorite (REC), as a nanoscale layered silicate, possesses a similar interlayer structure to MMT but with a layer spacing more than twice that of MMT, and it also has a higher aspect ratio than MMT [29]. This unique structure and larger layer spacing make Rectorite an attractive material for various applications, including the modification of asphalt. Zhang et al. [17] selected three types of quaternary ammonium salts, namely, dodecyl trimethyl ammonium chloride (1231), lauryl dimethyl benzyl ammonium chloride (1227), and stearyl trimethyl ammonium chloride (1831), as organic modifiers to prepare organic rectorite (OREC) and modified asphalt. The researchers conducted a series of experiments, including hydrophilicity tests, X-ray diffraction (XRD), Fourier transform infrared spectroscopy (FTIR), and scanning electron microscopy (SEM), to investigate the macroscopic and microscopic properties of the modified asphalt. These studies laid the foundation for further research on the application of OREC-modified asphalt, providing valuable insights into the performance and properties of this novel asphalt modification approach. According to the research by Jia et al. [30,31], asphalt modified with organic rectorite (OREC) exhibits excellent storage stability, with a more pronounced improvement in high-temperature stability compared to OMMT. Moreover, its adverse effects on the low-temperature crack resistance of asphalt are less significant than those observed with OMMT. Based on these findings, it can be predicted that REC and its organically modified derivatives also have the potential to enhance the overall performance of WEO-modified asphalt, primarily in terms of storage stability and high-temperature performance, thereby facilitating the efficient utilization [32,33,34,35,36] of WEO in asphalt pavements. However, as of now, there is still a lack of research on the performance of OREC + WEO composite-modified asphalt.

Based on the aforementioned considerations, this study aims to replace a portion of asphalt with waste engine oil (WEO) to avoid the adverse environmental impacts of discarded engine oil. The research focuses on investigating the chemical structure, storage stability, high- and low-temperature rheological properties, and self-healing property of OREC + WEO composite-modified asphalt at different OREC content levels. The primary focus is to explore the impact of OREC on the properties of WEO-modified asphalt and recommend the appropriate dosage of OREC in WEO-modified asphalt.

2. Experimental Section

2.1. Experimental Raw Materials

This study employed a comprehensive range of materials, including waste engine oil (WEO), organic rectorite (OREC), and SK 70# base asphalt, each with distinctive technical properties. The OREC was prepared from a natural rectorite and an octadecyl dimethyl benzyl ammonium chloride, and the preparation process has been detailed in reference [17]. These materials were carefully selected to explore their potential applications in sustainable road engineering, as detailed in Table 1, Table 2 and Table 3.

Table 1.

Technical properties of waste engine oil.

Table 2.

Technical properties of organic rectorite.

Table 3.

Technical properties of asphalt.

2.2. OREC + WEO Composite-Modified Asphalt

The preparation of the OREC + WEO composite-modified asphalt involved a meticulous and well-controlled procedure, ensuring the effective integration of the waste engine oil (WEO) and organic rectorite (OREC) into the asphalt matrix. The process was conducted using a state-of-the-art asphalt high-speed shearing machine, which provided optimal conditions for achieving a homogeneous and stable mix. To begin, the base asphalt was carefully heated to reach a flowing state, precisely at 165 °C. At this critical temperature, the stirring speed of the machine was set at 2000 rpm to ensure efficient mixing. Gradually, 6% of the waste engine oil (WEO) was methodically introduced into the heated asphalt, and the stirring process continued for a duration of 15 min. This step was crucial in achieving proper dispersion and homogenization of the WEO within the asphalt.

Subsequently, the organic rectorite (OREC) was incorporated into the system at specific mass fractions, including 0.5%, 1%, 1.5%, and 2% based on base asphalt binder [1,19]. The addition of OREC was conducted with precision, ensuring a slow and gradual introduction into the asphalt. The stirring process persisted for an additional 30 min, maintaining the same temperature and stirring speed. This carefully controlled blending phase allowed for the full interaction and bonding between the OREC and WEO with the asphalt, leading to the formation of the desired OREC + WEO composite-modified asphalt.

2.3. Testing Methods

The chemical structure of the modified agent and asphalt samples was determined using a Nicolet 6700 Fourier transform infrared spectrometer (FTIR) with a testing range of 4000–650 cm−1 and a resolution of 4 cm−1. The storage stability of the composite-modified asphalt was measured according to the “Test Methods of Highway Engineering Asphalt and Asphalt Mixture” (JTG E20-2011 [37]) using the polymer-modified asphalt exudation test method. Three replicates were used in this test. The high-temperature performance of the asphalt samples was assessed using a TA dynamic shear rheometer (DSR) with a temperature scanning mode at 58 °C, 64 °C, 70 °C, and 76 °C, and a scanning frequency of 10 rad/s. Meanwhile, the low-temperature performance of the asphalt samples was measured using a Cannon bending beam rheometer (BBR) at −18 °C. The “Fatigue-Intermittent-Fatigue” test for the asphalt samples was conducted using the same DSR instrument with a time scanning mode at 25 °C and 10 Hz loading frequency. The loading was controlled at 12% strain with an intermittent time of 300 s. It is generally believed that fatigue damage occurs in asphalt when the complex shear modulus decreased by 50–60%, so the loading was stopped when the complex shear modulus decreased by 50% and 60%, respectively. The self-healing property of the asphalt samples was evaluated using the healing index (HI) formula (as shown in Equation (1)), which provided a quantitative assessment of the material’s ability to self-repair. The comprehensive testing methods applied in this research allowed for a thorough analysis of the modified asphalt’s performance under various conditions, contributing to a better understanding of its potential application in sustainable road engineering.

In the equation, G0 represents the initial complex shear modulus, Gh represents the initial complex shear modulus after the healing (intermittent) period, t1 represents the time required for the initial complex shear modulus to decrease by 50% (or 60%) before the healing period, and t2 represents the time required for the initial complex shear modulus to decrease by 50% (or 60%) after the healing period.

3. Results and Discussion

3.1. Chemical Structure

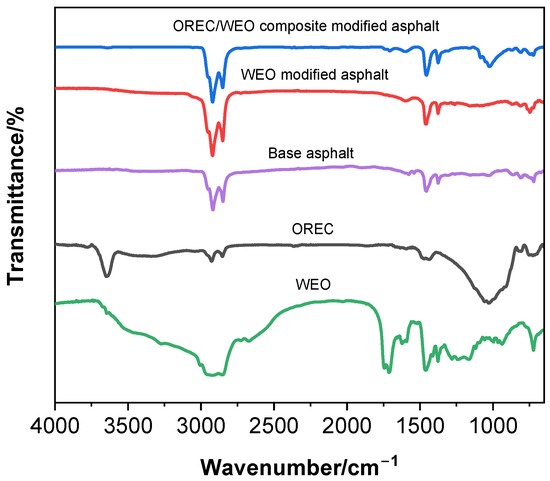

Figure 1 shows the infrared spectra of OREC, WEO-modified asphalt, and OREC + WEO composite-modified asphalt. From the graph, it can be observed that OREC and all asphalt samples exhibit characteristic peaks related to C–H stretching vibrations at 2932 cm−1 and 2850 cm−1, as well as C–H bending vibrations at 1456 cm−1 and 1371 cm−1. For OREC, the peaks observed at 3646 cm−1, 1027 cm−1, 816 cm−1, and 730 cm−1 can be attributed to the stretching vibrations of Al–OH, Si–O–Si, the vibrations of Al–OH, and the bending of Si–O–Al in the structure, respectively [38,39]. After incorporating OREC, weak absorption peaks related to the stretching of Al–OH (3646 cm−1) and strong absorption peaks related to the stretching of Si–O–Si (1027 cm−1) were observed in the spectrum of the OREC + WEO composite-modified asphalt. Furthermore, in comparison to WEO-modified asphalt, the composite-modified asphalt of OREC + WEO exhibited an additional absorption peak (1027 cm−1) in the spectrum, which corresponds to the presence of OREC. This observation suggests that the coexistence of OREC and WEO-modified asphalt occurs through a purely physical interaction, indicating that the coexistence of OREC and WEO-modified asphalt is purely physical coexistence.

Figure 1.

FT-IR spectra of WEO, OREC, base asphalt, WEO-modified asphalt, and 2% OREC+ 6% WEO composite-modified asphalt.

3.2. Storage Stability

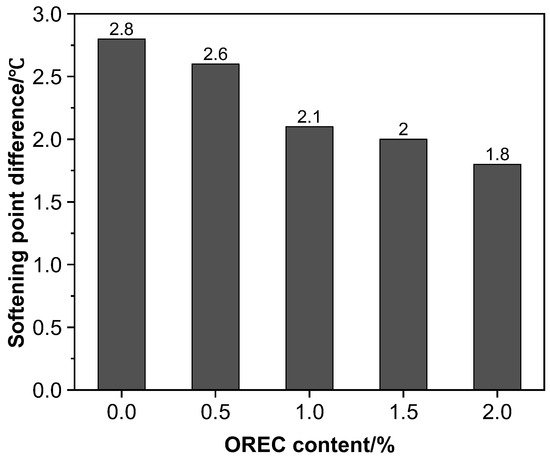

Figure 2 presents the test results of the 48-h softening point difference (SPD) for OREC + WEO composite-modified asphalt at different OREC content levels. From the graph, it is evident that the SPD value for WEO-modified asphalt is 2.8 °C. In comparison, the SPD value of OREC + WEO-modified asphalt decreases, and this reduction is particularly prominent at a 1% OREC dosage, with the SPD value experiencing a significant drop. Beyond the 1% dosage, the SPD decrease tends to stabilize. When the OREC content reaches 2%, the corresponding SPD value for the asphalt sample is 1.8 °C, which is 1.0 °C lower than the asphalt without OREC. These results demonstrate that the addition of OREC improves the storage stability of WEO-modified asphalt. Due to certain differences in solubility and density between WEO and asphalt, WEO-modified asphalt tends to exhibit some exudation issues at high temperatures. Previous reports have indicated that under high shear conditions, nanoscale layered silicates can form a well-dispersed structure in the asphalt matrix, hindering the free movement of all components in the asphalt [18,19]. Therefore, in this study, the OREC used as a nanoscale layered silicate can impede the movement of WEO components in the asphalt matrix, thus enhancing the system’s storage stability.

Figure 2.

Effect of the OREC contents on the storage stability of the WEO-modified asphalt.

The “Technical Specifications for Highway Asphalt Pavement Construction” (JTG F40-2004 [40]) stipulates that the SPD value for SBS polymer-modified asphalt should not exceed 2.5 °C to ensure good storage stability of the modified asphalt. From Figure 2, it can be observed that when the OREC content exceeds 0.5%, the corresponding SPD value for OREC + WEO composite-modified asphalt is below 2.5 °C. Based on these technical requirements, this study selected OREC content ranging from 1% to 2% for further research on the composite-modified asphalt.

3.3. High-Temperature Rheological Properties

3.3.1. Complex Modulus

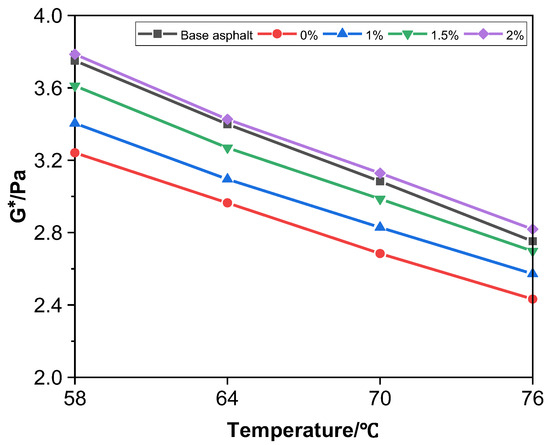

Figure 3 displays the test results of the complex modulus (G*) for base asphalt and OREC + WEO composite-modified asphalt at different OREC content levels. From the graph, it can be observed that as the temperature increases in the high-temperature range from 58 °C to 76 °C, the G* values of all asphalt samples gradually decrease, indicating that heating reduces the stiffness of the asphalt. At the same temperature, the WEO-modified asphalt without OREC consistently exhibits lower G* values than the base asphalt, suggesting that WEO softens the asphalt, leading to lower stiffness of WEO-modified asphalt compared to the corresponding base asphalt at high temperatures. With an increase in OREC content, the G* values of OREC + WEO composite-modified asphalt gradually increase, indicating that the introduction of OREC enhances the stiffness of WEO-modified asphalt. This is related to the fact that OREC itself possesses relatively high stiffness as a nanoclay and also hinders the movement of various components in the asphalt system. However, compared to the base asphalt, the modified asphalt with OREC content not exceeding 1.5% consistently exhibits lower G* values at high temperatures, thus showing lower high-temperature stiffness. When OREC content reaches 2%, the corresponding composite-modified asphalt demonstrates higher stiffness than the base asphalt. These results indicate that OREC, when added in an amount exceeding 1.5%, can fully compensate for the loss of high-temperature stiffness in WEO-modified asphalt compared to the base asphalt.

Figure 3.

Test results of G* values of base asphalt and WEO/OREC-modified asphalt.

3.3.2. Phase Angle

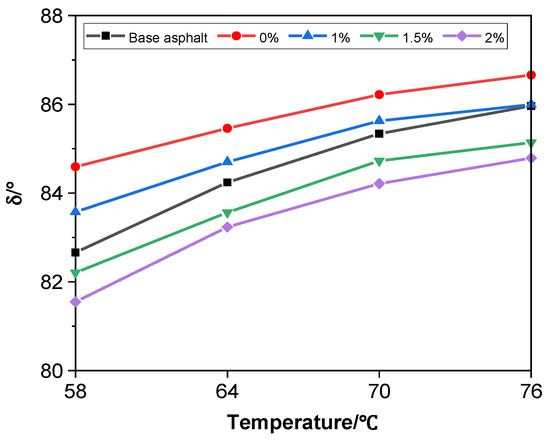

Figure 4 shows the test results of the phase angle (δ) for base asphalt and OREC + WEO composite-modified asphalt at different OREC content levels. From the graph, it can be observed that during the temperature increase, the δ values of the asphalt samples all show an upward trend, indicating that temperature rise promotes the transition of asphalt from elasticity to viscosity. Compared to the base asphalt, WEO-modified asphalt exhibits higher δ values in the temperature range of 58 °C to 76 °C, indicating lower elasticity and higher viscosity at high temperatures. WEO contains a considerable amount of aromatic components, which increases the content of light components in the asphalt [8,15]. The increase in light component content contributes to the asphalt exhibiting lower viscosity properties. Furthermore, from the graph, it can be seen that with an increase in OREC content, the δ values of OREC + WEO composite-modified asphalt gradually decrease, indicating that the addition of OREC helps reduce the viscosity of WEO-modified asphalt. For OREC content at 1% in the composite-modified asphalt, its δ value is still higher than that of the base asphalt. However, when the OREC content exceeds 1%, the δ value of the composite-modified asphalt decreases below that of the base asphalt. This implies that adding 1.5% or more of OREC is necessary to restore the elasticity of WEO-modified asphalt to a level above that of the base asphalt.

Figure 4.

Test results of δ values of base asphalt and WEO/OREC-modified asphalt.

3.3.3. Rutting Factor

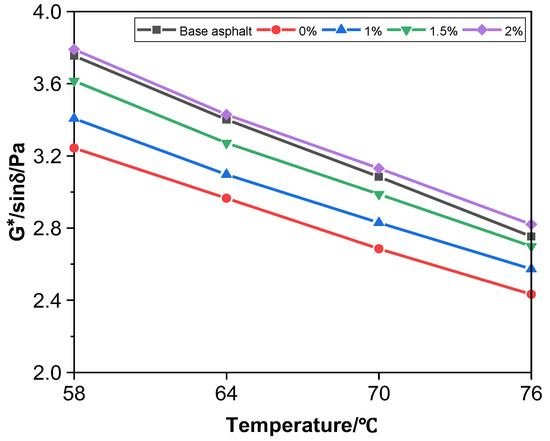

Figure 5 presents the test results of the rutting factor (G*/sinδ) for base asphalt and OREC + WEO composite-modified asphalt at different OREC content levels. From the graph, it can be observed that as the temperature increases, the G*/sinδ values of the asphalt samples all show a decreasing trend. Clearly, temperature rise has an adverse effect on the rutting resistance performance of the asphalt. WEO-modified asphalt exhibits significantly lower G*/sinδ values in the temperature range of 58 °C to 76 °C compared to the base asphalt, indicating poorer high-temperature rutting resistance. In contrast, OREC + WEO composite-modified asphalt has higher G*/sinδ values compared to WEO-modified asphalt, and this difference becomes more pronounced with an increase in OREC content. These results indicate that adding OREC improves the high-temperature rutting resistance performance of WEO-modified asphalt. Only when the OREC content reaches 2%, the G*/sinδ value of OREC + WEO composite-modified asphalt exceeds that of the base asphalt, thereby showing superior high-temperature rutting resistance compared to the base asphalt. Therefore, from the perspective of rutting resistance performance, it is recommended to add 2% of OREC to prepare OREC + WEO composite-modified asphalt.

Figure 5.

Test results of G*/sinδ values of base asphalt and WEO/OREC-modified asphalt.

3.4. Low-Temperature Rheological Properties

3.4.1. Creep Stiffness

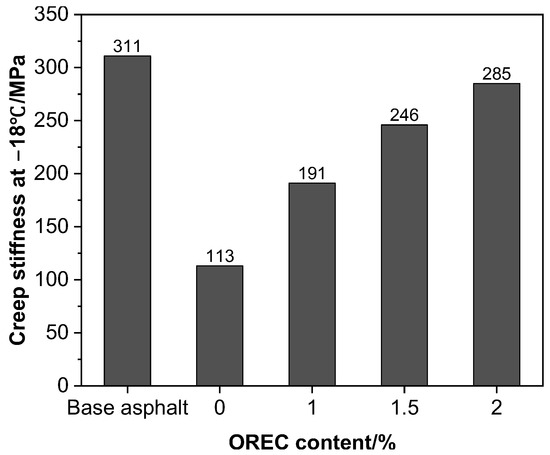

Figure 6 shows the test results of the creep stiffness (S) for base asphalt and OREC + WEO composite-modified asphalt at different OREC content levels. From the graph, it can be observed that the base asphalt has the highest S value at −18 °C. In comparison, WEO-modified asphalt exhibits a 63.7% reduction in S value, indicating that the addition of WEO significantly reduces the stiffness of the base asphalt at low temperatures, enhancing its low-temperature flexibility, and thereby improving the low-temperature cracking resistance performance of the base asphalt. This is attributed to the increase in the proportion of light components in the asphalt due to the presence of WEO. As the OREC content increases from 0% to 2%, the S value of OREC + WEO composite-modified asphalt gradually increases, indicating that the introduction of OREC increases the low-temperature stiffness of WEO-modified asphalt, thus reducing its low-temperature cracking resistance performance. When the OREC content reaches 2%, the corresponding composite-modified asphalt has an S value of 285 MPa, which is only 8.4% lower than the base asphalt. This means that the composite-modified asphalt with 2% OREC content does not show a significant difference in low-temperature cracking resistance performance compared to the base asphalt. Based on the increasing trend of S values in the graph, it can be inferred that as the OREC content continues to increase, the low-temperature stiffness of the corresponding composite-modified asphalt may exceed that of the base asphalt.

Figure 6.

Test results of G*/sinδ values of base asphalt and WEO/OREC-modified asphalt.

3.4.2. Creep Rate

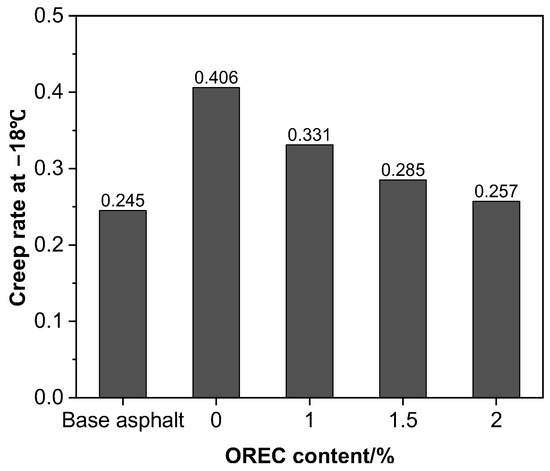

Figure 7 presents the test results of the creep rate for base asphalt and OREC + WEO composite-modified asphalt at different OREC content levels to further assess the impact of OREC on the low-temperature performance of WEO-modified asphalt. From the graph, it can be observed that compared to the base asphalt, WEO-modified asphalt exhibits a 65.7% increase in creep rate at −18 °C. This indicates that WEO-modified asphalt has greater stress relaxation ability at low temperatures, resulting in better low-temperature cracking resistance performance compared to the base asphalt. With the addition of OREC, the creep rate of OREC + WEO composite-modified asphalt gradually decreases. As the OREC content increases from 0% to 2%, the creep rate of the modified asphalt decreases from 0.406 to 0.257, a reduction of 36.7%. This result suggests that adding OREC reduces the stress relaxation ability of WEO-modified asphalt, thus adversely affecting its low-temperature cracking resistance performance. Additionally, from the graph, it can be seen that when the OREC content reaches 2%, the corresponding composite-modified asphalt has a creep rate only 4.9% higher than the base asphalt. This result further confirms that the low-temperature cracking resistance performance between the composite-modified asphalt with 2% OREC content and the base asphalt does not show a significant difference. Based on the decreasing trend of the creep rate shown in the graph, it can be predicted that as the OREC content continues to increase, the low-temperature cracking resistance performance of the composite-modified asphalt may decrease below that of the base asphalt, which is consistent with the analysis results of the S value. Therefore, from the perspective of low-temperature cracking resistance performance, it is recommended to use an OREC content which does not exceed 2%.

Figure 7.

Test results of creep rate values of base asphalt and WEO/OREC-modified asphalt.

3.5. Self-Healing Property

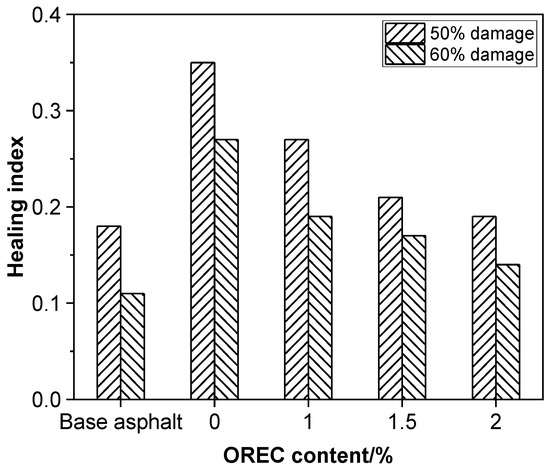

Figure 8 shows the test results of the healing index (HI) for base asphalt and OREC + WEO composite-modified asphalt at different OREC content levels. From the graph, it can be observed that as the damage level increases from 50% to 60%, the HI values of all asphalt samples decrease, indicating that higher fatigue damage is detrimental to the recovery of asphalt mechanical properties. At the same damage level, the base asphalt consistently exhibits the lowest HI value, while WEO-modified asphalt has the highest HI value, indicating that WEO-modified asphalt has the best self-healing ability, and the base asphalt has the poorest self-healing property. WEO contains a higher proportion of light components, which can increase the fluidity of the asphalt and enhance its repair ability (i.e., self-healing property). However, with the increase in OREC content, the corresponding composite-modified asphalt’s HI value gradually decreases, indicating that adding OREC reduces the asphalt’s self-healing ability. This is because OREC, as a nanoclay, forms a dispersed structure in the asphalt, reducing the mobility of asphalt molecules and thereby negatively affecting the asphalt’s fluidity. Nevertheless, even with 2% OREC content, the OREC + WEO composite-modified asphalt still exhibits HI values 5.6% and 27.2% higher than the base asphalt at 50% and 60% damage levels, respectively. This indicates that the composite-modified asphalt with 2% OREC content has a higher healing property than the base asphalt.

Figure 8.

Test results of healing index of base asphalt and WEO/OREC-modified asphalt.

4. Conclusions

The OREC + WEO composite-modified asphalt was prepared by adding four different OREC content levels to the WEO-modified asphalt. A series of tests were conducted to investigate the impact of OREC on the chemical structure, storage stability, rheological properties, and self-healing property of the composite-modified asphalt. The main conclusions are as follows:

- (1)

- Compared to WEO-modified asphalt, OREC + WEO composite-modified asphalt did not show any new peaks related to chemical reactions, indicating that OREC and WEO-modified asphalt are only physically mixed. Therefore, the influence of OREC on the macroscopic properties of WEO-modified asphalt mainly manifests in the physical form.

- (2)

- Adding OREC improves the storage stability of WEO-modified asphalt. Compared to WEO-modified asphalt, the 48-h softening point difference of the composite-modified asphalt with 2% OREC content decreased from 2.8 °C to 1.8 °C, meeting the requirements of “Technical Specifications for Highway Asphalt Pavement Construction” for polymer-modified asphalt storage stability (≤2.5 °C).

- (3)

- Adding OREC can enhance the stiffness, elasticity, and resistance to rutting of WEO-modified asphalt at high temperatures, but it has a negative impact on low-temperature crack resistance and the self-healing property. However, only when the OREC content reaches 2% does the corresponding composite-modified asphalt exhibit better high- and low-temperature performance and self-healing property than the base asphalt. Therefore, the introduction of OREC can fully compensate for the performance loss caused by WEO in asphalt, and the OREC content is recommended to be 2%.

- (4)

- The findings of this research shed light on the potential benefits of using an organic rectorite as an additive in waste engine oil-modified asphalt and could be valuable for paving material engineers and researchers seeking sustainable and high-performance asphalt solutions. However, it is essential to further evaluate the impact of OREC on the aging resistance of WEO-modified asphalt, and we note that further research and field tests may be required in order to validate the practical application and long-term performance of this modified asphalt mixture. Additionally, it is essential to compare the effects of OREC with other types of nanoclays on the performance of WEO-modified asphalt.

Author Contributions

Conceptualization and investigation, M.J. and D.W.; methodology and resources, X.L.; software and validation, D.Y. and X.L.; formal analysis and data curation, S.Y.; writing—original draft preparation, D.Y.; writing—review and editing, M.J.; visualization and supervision, A.C.F. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Guangxi Transportation Science and Technology Demonstration Project (Grant number 2023-0002).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Access to any other materials can be requested by writing to the corresponding authors.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Lu, Z.; Qiu, R.; Zhang, B.; Wang, L. The synergistic effect of waste engine oil and organic mont morillonite on properties of bitumen: Conventional, high-temperature rheological, and self-healing. Constr. Build. Mater. 2023, 364, 129946. [Google Scholar] [CrossRef]

- Yan, S.; Dong, Q.; Chen, X.; Zhou, C.; Dong, S.; Gu, X. Application of waste oil in asphalt rejuvenation and modification: A comprehensive review. Constr. Build. Mater. 2022, 340, 127784. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, H.; Liu, X.; Apostolidis, P.; Erkens, S.; Skarpas, A.; Leng, Z.; Airey, G. Micromechanics-based viscoelasticity predictions of crumb rubber modified bitumen considering polymer network effects. Transp. Res. Rec. 2022, 2676, 73–88. [Google Scholar] [CrossRef]

- Gao, Y.; Zhang, Y.; Yang, Y.; Zhang, J.; Gu, F. Molecular dynamics investigation of interfacial adhesion between oxidised bitumen and mineral surfaces. Appl. Surf. Sci. 2019, 479, 449–462. [Google Scholar] [CrossRef]

- Li, H.; Ling, X.; Zhao, J.; Li, W.; Chen, Z. Interlayer temperature analysis of asphalt pavement based on grey correlation degree. J. Munic. Technol. 2022, 40, 55–61. [Google Scholar]

- Sha, A.; Liu, Z.; Jiang, W.; Qi, L.; Hu, L.; Jiao, W.; Barbieri, D.M. Advances and development trends in eco-friendly pavements. J. Road Eng. 2021, 1, 1–42. [Google Scholar] [CrossRef]

- Sudarsanan, N.; Kim, Y.R. A critical review of the fatigue life prediction of asphalt mixtures and pavements. J. Traffic Transp. Eng. Engl. Ed. 2022, 9, 808–835. [Google Scholar] [CrossRef]

- Liu, S.; Peng, A.; Wu, J.; Zhou, S.B. Waste engine oil influences on chemical and rheological properties of different asphalt binders. Constr. Build. Mater. 2018, 191, 1210–1220. [Google Scholar] [CrossRef]

- Liu, S.; Peng, A.; Zhou, S.; Wu, J.; Xuan, W.; Liu, W. Evaluation of the ageing behaviour of waste engine oil-modified asphalt binders. Constr. Build. Mater. 2019, 223, 394–408. [Google Scholar] [CrossRef]

- Wang, D.; Baliello, A.; Poulikakos, L.; Vasconcelos, K.; Kakar, M.R.; Giancontieri, G.; Pasquini, E.; Porot, L.; Tušar, M.; Riccardi, C. Rheological properties of asphalt binder modified with waste polyethylene: An interlaboratory research from the RILEM TC WMR. Resour. Conserv. Recycl. 2022, 186, 106564. [Google Scholar] [CrossRef]

- Ma, J.; Nivitha, M.R.; Hesp, S.A.; Krishnan, J.M. Validation of empirical changes to asphalt specifications based on phase angle and relaxation properties using data from a northern Ontario, Canada pavement trial. Constr. Build. Mater. 2023, 363, 129776. [Google Scholar] [CrossRef]

- Yan, S.; Zhou, C.; Zhang, J.; Li, G. Molecular dynamics simulation on the rejuvenation effects of waste cooking oil on aged asphalt binder. J. Traffic Transp. Eng. Engl. Ed. 2022, 9, 795–807. [Google Scholar] [CrossRef]

- Qurashi, I.A.; Swamy, A.K. Viscoelastic properties of recycled asphalt binder containing waste engine oil. J. Clean. Prod. 2018, 182, 992–1000. [Google Scholar] [CrossRef]

- Hoon Moon, K.; Cannone Falchetto, A.; Wang, D.; Wistuba, M.P.; Tebaldi, G. Low-temperature performance of recycled asphalt mixtures under static and oscillatory loading. Road Mater. Pavement Des. 2017, 18, 297–314. [Google Scholar] [CrossRef]

- Qiu, Y.; Ding, H.; Rahman, A.; Wang, W. Damage characteristics of waste engine oil bottom rejuvenated asphalt binder in the non-linear range and its microstructure. Constr. Build. Mater. 2018, 174, 202–209. [Google Scholar] [CrossRef]

- Cui, Y.N.; Du, C.X.; Guo, L.D. Study on rheological properties of waste oil recycled asphalt. J. Funct. Mater. 2022, 53, 10116–10121+29. [Google Scholar]

- Zhang, Z.; Jia, M.; Jiao, W.; Qi, B.; Liu, H. Physical properties and microstructures of organic rectorites and their modified asphalts. Constr. Build. Mater. 2018, 171, 33–43. [Google Scholar] [CrossRef]

- Lu, H.; Ye, F.; Yuan, J.; Yin, W. Properties comparison and mechanism analysis of naphthenic oil/SBS and nano-MMT/SBS modified asphalt. Constr. Build. Mater. 2018, 187, 1147–1157. [Google Scholar] [CrossRef]

- Jia, M.; Zhang, Z.; Liu, H.; Peng, B.; Zhang, H.; Lv, W.; Zhang, Q.; Mao, Z. The synergistic effect of organic montmorillonite and thermoplastic polyurethane on properties of asphalt binder. Constr. Build. Mater. 2019, 229, 116867. [Google Scholar] [CrossRef]

- Ke, Y.; Cao, J.; Xu, S.; Bian, C.; Zhang, C.; Jia, X. Storage stability and anti-aging performance of SEBS/ organ-montmorillonite modified asphalt. Constr. Build. Mater. 2022, 341, 127875. [Google Scholar] [CrossRef]

- Sha, A.; Jiang, W.; Shan, J.; Wu, W.; Li, Y.; Zhang, S. Pavement structure and materials design for sea-crossing bridges and tunnel: Case study of the Hong Kong–Zhuhai–Macau Bridge. J. Road Eng. 2022, 2, 99–113. [Google Scholar] [CrossRef]

- Zhang, H.; Shi, C.; Han, J.; Yu, J. Effect of organic layered silicates on flame retardancy and aging properties of bitumen. Constr. Build. Mater. 2013, 40, 1151–1155. [Google Scholar] [CrossRef]

- Zhang, Z.P.; Jia, M. Evaluating the effect of organic reagents on short-term aging resistance of the organic rectorite asphalt by multi-indicators. Road Mater. Pavement Des. 2021, 22, 215–229. [Google Scholar] [CrossRef]

- Ren, Z.; Zhu, Y.; Wu, Q.; Zhu, M.; Guo, F.; Yu, H.; Yu, J. Enhanced storage stability of different polymer modified asphalt binders through nano-montmorillonite modification. Nanomaterials 2020, 10, 641. [Google Scholar] [CrossRef]

- Yu, R.; Fang, C.; Liu, P.; Liu, X.; Li, Y. Storage stability and rheological properties of asphalt modified with waste packaging polyethylene and organic montmorillonite. Appl. Clay Sci. 2015, 104, 1–7. [Google Scholar] [CrossRef]

- Cheng, P.; Yang, Z.; Zhang, Z.; Xu, J. Analysis of healing properties and microscopic mechanism of nano montmorillonite/SBS composite modified asphalt under heat aging. Mater. Rev. 2022, 36, 114–119. [Google Scholar]

- Jiang, W.; Yuan, D.; Shan, J.; Ye, W.; Lu, H.; Sha, A. Experimental study of the performance of porous ultra-thin asphalt overlay. Int. J. Pavement Eng. 2022, 23, 2049–2061. [Google Scholar] [CrossRef]

- Li, H.; Wang, J.; Han, X.; Song, X. Study on Application of Extremely Thin Cover of Low Temperature Modified Asphalt. J. Munic. Technol. 2022, 40, 14–16+120. [Google Scholar]

- Huang, Y.; Ma, X.; Liang, G.; Yan, Y.; Wang, S. Adsorption behavior of Cr(VI) on organic-modified rectorite. Chem. Eng. J. 2008, 138, 187–193. [Google Scholar] [CrossRef]

- Jia, M.; Zhang, Z.; Wei, L.; Li, J.; Yuan, D.; Wu, X.; Mao, Z. High- and Low-Temperature Properties of Layered Silicate-Modified Bitumens: View from the Nature of Pristine Layered Silicate. Appl. Sci. 2019, 9, 3563. [Google Scholar] [CrossRef]

- Jia, M.; Sha, A.; Jiang, W.; Li, X.; Jiao, W. Developing a solid–solid phase change heat storage asphalt pavement material and its application as functional filler for cooling asphalt pavement. Energy Build. 2023, 285, 112935. [Google Scholar] [CrossRef]

- Jiang, W.; Li, P.; Sha, A.; Li, Y.; Yuan, D.; Xiao, J.; Xing, C. Research on Pavement Traffic Load State Perception Based on the Piezoelectric Effect. IEEE Trans. Intell. Transp. Syst. 2023, 24, 8264–8278. [Google Scholar] [CrossRef]

- Yuan, D.; Jiang, W.; Sha, A.; Xiao, J.; Wu, W.; Wang, T. Technology method and functional characteristics of road thermoelectric generator system based on Seebeck effect. Appl. Energy 2023, 331, 120459. [Google Scholar] [CrossRef]

- Büchner, J.; Wistuba, M.P.; Remmler, T.; Wang, D. On low temperature binder testing using DSR 4 mm geometry. Mater. Struct. 2019, 52, 113. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, S.; Zhao, Z.; Yan, L.; Wang, C.; Liu, H. HydroBIM—Digital design, intelligent construction, and smart operation. J. Intell. Constr. 2023, 1, 9180014. [Google Scholar] [CrossRef]

- Zhang, P.; Xu, N.; Xiao, P.; Zhao, T.; Gao, F.; Ding, X.; Li, B. Microseismic Source Location Based on Improved Artificial Bee Colony Algorithm: Performance Analysis and Case Study. J. Intell. Constr. 2023. [Google Scholar] [CrossRef]

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. 2011. Available online: https://www.codeofchina.com/standard/JTGE20-2011.html (accessed on 20 August 2023).

- Zhao, Q.; Yin, W.; Long, C.; Jiang, Z.; Jiang, J.; Yang, H. Insights into the adsorption behaviour and mechanism of tetracycline on rectorite mineral: Influence of surface and structure evolution. Appl. Clay Sci. 2022, 229, 106698. [Google Scholar] [CrossRef]

- He, S.; Bai, F.; Liu, S.; Ma, H.; Hu, J.; Chen, L.; Lin, J.; Wei, G.; Du, X. Aging properties of styrene-butadiene rubber nanocomposites filled with carbon black and rectorite. Polym. Test 2017, 64, 92–100. [Google Scholar] [CrossRef]

- JTG F40-2004; Technical Specifications for Construction of Highway Asphalt Pavements. 2004. Available online: http://www.lancarver.com/En/bz_view.asp?id=65 (accessed on 20 August 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).