Abstract

In the world of cultural heritage, a wide range of artefacts and buildings are made of wood and, therefore, are subjected to moisture-induced stress and strain cycles, owing to environmental fluctuations. Simultaneous action of moisture and mechanical loads lead to a mechanosorptive effect on wood. Therefore, an increase in time-dependent creep, due to mechanical loads, is observed. The assessment of these complex phenomena entails the use of advance and interdisciplinary approaches. Consequently, this article reviews experimental and mathematical methods to study these degradation mechanisms in wooden artefacts and timber elements in heritage buildings. The paper presents the results of a six-step descriptive literature review, providing an overall picture of the ongoing research. Experimental techniques need to be improved so that they are in line with the conservation principles. The combination of experiments and simulations is a reliable predictive approach for better assessing the potential risk damages due to temperature, humidity cycles, and mechanical loads in complex structures. Thus, advanced numerical simulations and mathematical modelling include climate data and experimental measurements. This work also provides an overview of research performed on different categories of cultural heritage characterised by multi-layer structures. The mechanical response to wood–moisture relation is affected by the level of complexity of these structures. Finally, the use of realistic models is limited by knowledge about the material properties and the behaviour of complex structures over time. In addition, research gaps, limitations, and possible future research directions are also provided. This review may represent a starting point for future research on the thermo-hygro-mechanical behaviour of wood heritage.

1. Introduction

Wood is an anisotropic and hygroscopic material which has played a crucial role in the evolution of civilisation [1]. The long-term preservation of this material is an important issue in the field of cultural heritage (CH) where it has long been used as a building material and for handcrafted wooden objects. In recent years it has also been enlightened in modern building construction as a strong, lightweight, and sustainable material that can lead the decarbonisation of built environments [2,3,4,5,6,7]. Despite those attractive properties, due to its nature and chemical components, wood is most sensitive to biological degradation and environmental climate-induced decay, which might affect the wood’s physical and mechanical properties. These properties, at a macroscopic level, are determined by wood’s microstructural architecture features.

The biological degradation degree of wood may vary according to several aspects, namely: (1) wood species, i.e., variations in decay resistance [8]; (2) moisture content, i.e., wet or dry wood [9]; (3) climate conditions, i.e., certain microclimates are more favourable to biological growth [10]; types of environments [11]. Among the heritage materials, biodegradation is one of the most common and well-studied types of decay [12,13,14,15,16,17]. Biological deterioration mechanisms affect wood physically, e.g., they affect mechanical properties, density, and others, as well as chemically, e.g., brown rots and white rots, while also compromising the micro-structure of the elements [18].

As a hygroscopic material, wood exchanges moisture with the surrounding air. This exchange is driven by temperature and relative humidity gradients, and it is determined by the current amount of water, i.e., free water and bond water. This exchange of moisture is defined as a sorption or desorption process, according to the increase or decrease in the relative humidity, respectively. They take place until reaching an equilibrium, which is known as the equilibrium moisture content (EMC). The latter is defined as the moisture content level that wood will attain in an atmosphere at which neither further drying nor wetting would take place. Below the so-called fibre saturation point (FSP), moisture content variation causes reductions and increases in the dimensions of wood, as well as changes in its mechanical properties. These changes in dimensions are defined as swelling and shrinkage, respectively, when wood gains and loses moisture. Qin and Liu, [19] discuss the definition of FSP and the effects of the instability of dimensions and the stress of material when moisture content dries below this limit. As an anisotropic material, wood exhibits different properties depending on the anatomical direction in which they are measured. The three main anatomical directions are shown in Figure 1a. Due to the fibrous structure, the amount of swelling and shrinkage is also affected by this strong anisotropy.

Figure 1.

(a) The three anatomical directions of wood: radial (R), perpendicular to the growth rings; tangential (Tg), tangential to the growth rings; longitudinal (L), parallel to the fibre grain. (b) Drying shrinkage and distortions of wood are affected by annual growth rings: (1) the cupping of a flatsawn board; (2) quartersawn board retains its shape; (3) the diamonding of a square section; (4) the oval wrap of a round piece.

Uncontrolled drying of cultural heritage under the FSP may lead to harmful and large dimensional changes, particularly when moisture gradients occur [20,21]. Indeed, surface layers rapidly reach FSP when the air’s relative humidity (RH) decreases and tends to shrink. The moisture transport in the core layers does not occur instantaneously, so the inner part has not begun to shrink at that stage. This non-uniform situation restrains outer swelling and shrinkage, producing tension stresses within the surface layers of the material. Tension stresses on the surface are balanced by compression stresses in the core layers. As drying goes on, tensioned and compressed areas are inverted [22]. When a material is stressed, it might distort or strain, i.e., it is mathematically expressed as the ratio of the dimensional change of the material to its original dimension, as described above. These stresses and strains are named, moisture-induced stresses and strains [23]. When the stress–strain cycle reaches the yield point, i.e., the amount of stress exceeds the elastic deformation of the material, wood can deform to failure stress levels. This value is strongly affected by different moisture content, as well as by the different anatomical directions [24].

Temperature (T) can also affect wood preservation and induce stresses and strains. Extreme fluctuation may cause direct and indirect effects on the hygroscopic material. Indeed, changes in temperatures directly influence moisture content, even without relative humidity changes, possibly drying out fibres [21]. Their variation can also involve variations in relative humidity; thus, high temperature indirectly causes mechanical stress–strain cycles, as described previously [22,23,24]. Although the water vapour transport in wood is lower than the heat one, low temperatures may further reduce water vapour diffusion, ensuing the shortening of the amplitude of moisture content fluctuations [21]. The first mechanism (i.e., moisture transport) may be a process of hours or days; on the contrary, heat transport through a material takes around minutes or hours. For this reason, scholars assume the response of wood to air temperature variation instantaneously, avoiding thermal gradient within the material [25]. An additional positive effect of low temperatures concerns the increase in time allowed for the response of wood to relative humidity changes. Therefore, the allowable amplitude of the moisture variations increases [26]. Temperature influences the rate of chemical reactions; thus, at moderate RH and low temperature, the wood cellulose results are stable.

In real-case studies, this situation is even more complex in objects and structures that are made up of multiple layers, which are characterised by different mechanical properties and ensuing responses to environmental changes. Moreover, moisture-induced effects could become severe whether or not further load occurs. Thus, a straightforward analysis of a material’s climate-induced deformation mechanisms entails studies on heat and moisture transport, as well as on thermo-hygro-mechanical behaviour. For a better understanding of transport physical phenomena, especially when coupled with mechanical models, it is important to use numerical techniques, mathematical modelling, and software [27]. In this regard, experimental tools play a key role, as they allow the input parameters of mathematical models to be obtained, as well as quantitative assessment and validation the thermo-hygro-mechanical behaviour of models’ validation.

All these studies reveal how the use of wood as cultural heritage, as well as building materials, is of great importance. The analysed literature shows the importance of moisture-induced damage. As the literature review described previously, this issue is covered by some reviews in the literature. However, they are more focused on wooden structures and elements [27,28]. In the field of cultural heritage, the existing review is limited to panel paintings [25,29]. Despite that, a great number of papers exist on moisture-induced stresses in other types of cultural heritage that need to be reviewed in order to provide an overall picture of the ongoing research. Experts from different fields may benefit from this review. By identifying research gaps, limitations, and possible future research directions, this work also spots new possible areas of collaboration among them.

2. Research Aims

The main aim of this paper is to provide an overview of experimental and mathematical methods employed, in the field of cultural heritage, to study moisture-induced stress and strain in wood objects and wood buildings. The paper investigates the possibility of combining different techniques, as well as mathematical modelling and numerical simulations. This approach allows for the obtaining of useful parameters and realistic models to study and preserve this valuable heritage material. Moreover, it is a useful tool to perform real-time and long-term monitoring, essential to the conservation and preservation of wooden artefacts and buildings. Furthermore, the present work reviews field studies in an attempt to show how complex structures influence the mechanical behaviour of wood, leading to harmful climate-induced damages. In this regard, employing and combining different techniques helps to avoid irreversible damage.

The methodology of this descriptive literature review is presented in Section 3. Section 4 briefly goes through the basic principles of heat and mass transfer, as well as the thermo-hygro-mechanical behaviour of wood, to drive the reader into the topic with the proper equipment and knowledge. Understanding heat and moisture transport in wood is essential to predict climate-induced damages that affect the mechanical behaviour of wood. For the same reason, in Section 5, complex wooden structures of cultural heritage are addressed. The equations presented in Section 4 underlay the mathematical models and numerical simulations described in Section 6 to predict unrecoverable degradation processes in cultural heritage. In the same section, experimental methods, by means of which moisture-induced mechanical effects are thoroughly understood and analysed, are also presented. In Section 7, moisture-induced stress and strain in several types of artefacts are reviewed. The focus is on four categories: paintings, musical instruments, furniture, and buildings. In Section 8, discussions and conclusions are presented. In the same section, the limitation and novelty of this review are also discussed. Finally, Section 9 provides insight into possible future applications of the techniques and identifies areas for further investigation.

3. Literature Review

3.1. Methodology

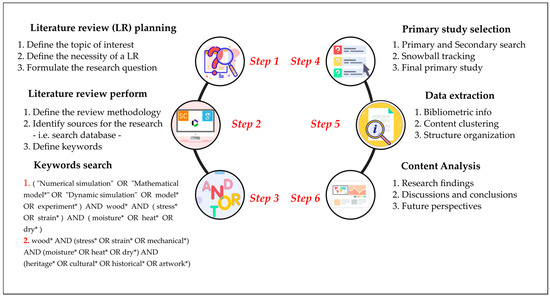

This research followed a descriptive Literature Review (LR) through the steps shown in Figure 2. Once the scope was cleared, the following research question was formulated: “What experimental and mathematical methods are employed in the field of cultural heritage to study moisture induced stress and strain in wood objects and wood buildings?”. Then, the necessity of a LR was clarified. These three achieved goals, i.e., define the topic, define the necessity of a LR, and formulate the research question, are part of step 1, which is entitled Literature review (LR) planning. To address the LR objectives, a total of six steps were followed.

Figure 2.

The six-step literature review methodology is followed to perform a descriptive literature review: step 1 is literature review planning, step 2 is literature review perform, step 3 is keywords search, step 4 is primary study selection, step 5 is data extraction, and step 6 is content analysis. Asterisk (*) in step 3 is used to finding words that start with the same letters, e.g., experiment* finds either experiments or experimental.

Literature review perform (Step 2): To avoid bias in the results due to the author’s experience, a clear methodology was defined. The material was obtained by searching keywords in three electronic databases: Scopus, Web of Science Core Collection, and Google Scholar. The selected keywords, with relative Boolean logic operators, were reported in step 3 in Figure 2. Their choice was driven by the attempt to obtain a thorough and complete overview, which started from a large number of papers not limited to the investigated field.

Primary study selection: The primary studies are those skimmed through in step 4. Their selection comprised three sub-steps: (i) the primary and (ii) the secondary searches, as well as (iii) the snowball tracking. The literature obtained after steps 2 and 3 was evaluated by reading the title, abstract, and conclusions (i). Then, a further step of evaluation was performed by reading the full text (ii). The number of selected studies was enhanced by using their bibliographies, i.e., snowball tracking [30]. The main inclusion criterion was relevance to the research question. At the end of that step, the set of final primary studies was obtained.

Data extraction: The data relating to each primary study was extracted and synthesised. Collected data was organized in an Excel worksheet to provide some bibliometric information, including the title, authors, first author’s country, author’s keywords, and publication details (i.e., year of publication and type of publication). Finally, the content of the document has been carefully analysed and clustered by topic; thus, a skeleton structure of the paper was organized. The classification and processing of the data extracted allowed us to answer the research question and conduct qualitative and descriptive analyses.

Content analysis: After the classification and summary of the research findings, in this step, they were reported in a critical and analytical way. Within the discussions and conclusions sections, we present results we discussed, highlighting advantages and drawbacks of experimental methods and mathematical modelling. As a final step of the content analysis, the paper analysed gaps and conceived possible future research directions.

3.2. Bibliometric Analysis

Bibliometric information extracted from retrieved documents is analysed. A graphical representation of this information is also provided. A first step of analysis consisted of scrutinising the author’s keywords. Due to the huge number of keywords, a word-cloud visualisation provides a quick understanding of their content (Figure 3). The bigger the word, the more it appears in research papers as keywords. This type of analysis helped with understanding the main research interests in the field and shaping the structure of the paper.

Figure 3.

The word-cloud map, which shows keywords used in our references, according to their weight. The bigger the word, the more it appears in research papers as keywords.

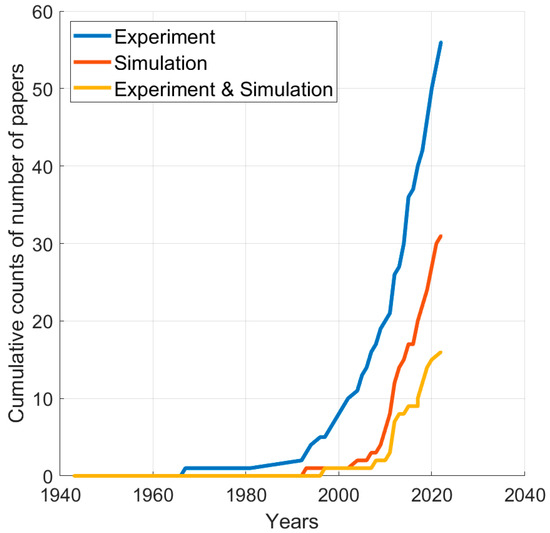

Figure 4 shows an increasing trend in the number of articles on this topic, with a sensitive growth from 2000 onwards. From that year, indeed, a nearly exponential increase is also observed in the cumulative curves in Figure 5. The steeper rise of the curve is observed for those papers which employed simulation and mathematical modelling as methods for the analysis (entitled “Simulation” in Figure 5), as well as their combined analyses with experimental methods (entitled “Experiment & Simulation” in Figure 5).

Figure 4.

Number of articles per year from 1943 to 2022.

Figure 5.

The cumulative sum of the number of articles per year for the same period. It shows three different curves representing different topics of the papers: Experiment, Simulation, as well as Experiment and Simulation.

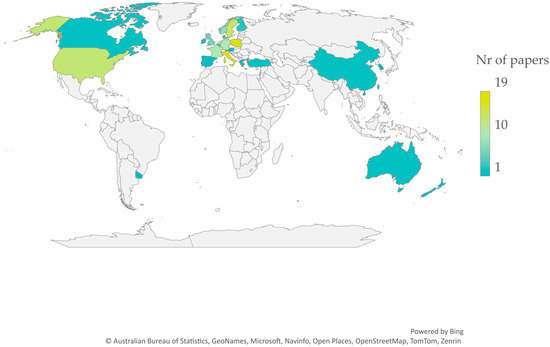

The geographical distribution of the articles, by country, was shown in Figure 6. To produce that map, the affiliation of the main author was analysed. The largest percentage of the studies was conducted in Italy (13%), Poland (11%), Sweden (9%), and the United States (9%). They are followed by France (7%), Germany (7%), the Netherlands (7%), and Norway (6%).

Figure 6.

Distribution of the retrieved studies by country. The different colours reflect the percentage of the studies conducted in each country. Developed by using [31].

4. Theory of Heat and Mass Transfer and Thermo-Hygro-Mechanical Behaviour of Wood

The Equations described in this section are essential for predicting the coupled heat and moisture transport in wood, as well as the induced stress and strain, as will be described in Section 6.2. The unit and nomenclature are reported in Nomenclature section.

4.1. Heat and Moisture Transfer

When wood is exposed to ambient air, heat and moisture are absorbed and transported inside the structure. The most common approach to describe this transport inside wood is to use Fourier’s law (Equation (1)) and Fick’s second law (Equation (2)), respectively, for heat and moisture:

where θ [°C ] is the temperature, t is the time, is the thermal conductivity, is the specific heat capacity, and [ is the density. In Equation (2), u [%] is the moisture content and D is the diffusion coefficient. The spatial operator () defines the Cartesian coordinate system xyz, which coincides with the orthotropic direction R, Tg, and L. The moisture transport model below the FSP combine the transport of water vapour through the pores () and bound water () in the cell walls, as well as their coupling through sorption. This more complex moisture transport system is better described by a multi-Fickian model in Equations (3) and (4) [32]:

where [] is the sorption rate. The sign of indicates the change phase: For a positive value, water is absorbed from the vapour phase to the bound phase. At low relative humidity, the sorption to bound water is fast, and the moisture transport in wood is governed by the water vapour diffusion (Equation (2)). At higher relative humidity, e.g., RH > 75%, the sorption rate decreases, and as demonstrated by Wadsö [33], it is governed by a non-Fickian behaviour [34]. In the study, six different species of wood were studied, and a non-Fickian behaviour was observed in the range of 75 to 84% of the sorption curves [35,36].

4.2. Thermo-Hygro-Mechanical Behaviour

The thermo-hygro-mechanical behaviour of wood during drying is described by scholars by means of the total strain. Equation (5) is worked out by Svensson [37] and Mårtesson and Svensson [38]:

In Equation (5), [-] is the total strain, which combines different contributions: the thermal strain , the elastic strain , the free swelling and shrinkage strain called hygro-expansion, the viscoelastic (creep) strain and the mechanosorptive . In the field of cultural heritage, an adjustment could be made to Equation (5). The thermal strain () is usually omitted since its contribution, in comparison to other terms, is exceedingly small. Deformations due to moisture content changes are, indeed, bigger than the expansion or contraction resulting from temperature variations [19,39]. Free moisture-induced swelling and shrinkage occur during drying free of stress; thus, is directly proportional to the hygro-expansion coefficient ( and the rate of changes in moisture content ). The viscoelastic (creep) strain (), at the mean indoor temperature (≈20 °C), might be neglected due to its small contribution [26,39]. The elastic strain is modelled by Hooke’s law, , where is the stress and E is the elastic modulus. It represents the recoverable material behaviour, and it could be influenced by moisture content. The mechanosorptive effect is, here, represented by [19]. Simplifying this complex effect, it is the result of the simultaneous action of moisture content changes and a mechanical load. Thus, an increase in the time-dependent creep, owing to mechanical loads, is observed. This phenomenon is well-explained by Mårtensson [40], as well as Navi and Stefanie [41], at different scales of observation. It might lead to permanent deformations.

5. Wood Cultural Heritage

In this section, an overview of the existing types of wooden works of art is presented. The focus is on the environmental fluctuations, which may affect indoor and outdoor cultural heritage building elements and artefacts. The mechanical response to wood–moisture relations is affected by the level of complexity of assembly, particularly in composite structures.

The term wood cultural heritage refers to all wooden man-made products and architectural heritage buildings. Their intrinsic cultural and historical value make their preservation a mandatory issue. They might be housed in a new or old building that may constitute a cultural heritage itself. Figure 7 shows examples of valuable wooden heritage, such as paintings, musical instruments, and buildings.

Figure 7.

Examples of wooden cultural heritage: (a) a panel painting entitled “Ritratto di Ludovico Bolognini” by Maestro della Pala dei Muratori—attr.- Bologna, Pinacoteca Nazionale; (b) a historical wooden violin, anonymous; (c) a wooden cabin made by Jan van Mekeren, stored in Rijksmuseum—Picture taken from the Rijksmuseum website Rijksmuseum, hét museum van Nederland; (d) wooden building in Tønsberg, entitled “Fadum storehouse”.

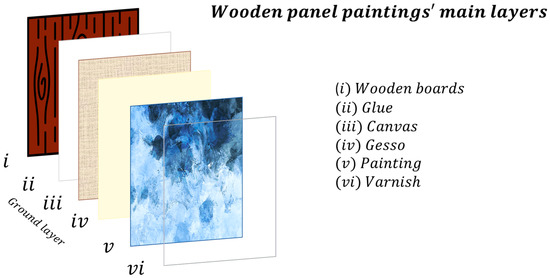

5.1. Paintings

Paintings on wooden panels are made of different humidity-sensitive layers; thus, damages owing to moisture changes might regard each of them (Figure 7a). A wide range of literature on the dimensional response of wooden panel painting to environmental changes exists [25,42,43,44]. As far as it is known, painting on wooden panels comprehends different layers whose thickness and composition may vary according to the geographical area and historic period. More generally, they consist of six main layers, with a layout shown in Figure 8: (i) the wooden panel, i.e., boards glued together, (ii) an animal glue layer as a primer for (iii) canvas, (iv) a gesso preparation—a mixture of animal glue and gypsum or ground chalk—to promote the smoothness and adhesion of the subsequent (v) painting layer, and the last film, which is usually covered with (vi) a layer of varnish to protect the painting from further damage [44]. Moreover, dimensional changes to one specific layer could affect adjacent ones. The application of ground layers on wood boards, for example, may result in the cupping of wood panels [45,46]. The different responses to humidity changes of gesso and wood may also lead to fractures in the paint layer. For this reason, while studying these types of damages, it is important to know the painting’s wooden structure, as well as the mechanical properties and the characteristic response of each film to heat and water diffusion [47].

Figure 8.

Schematic overview of the main layers of a wooden panel painting. The number system is referred to as the one in the text. (ii), (iii), and (iv) are part of the ground layer of the painting.

5.2. Musical Instruments

Musical instruments are valuable and fragile wooden objects which require efforts to be preserved while ensuring their original function (Figure 7b). To achieve this issue during the past century, maintenance treatments were applied. For this reason, it is possible to find them on the objects and restoration material, whose ageing and inappropriate environmental conditions could intensify the instruments’ degradation [48]. These restoration materials mainly derive from cleaning and consolidant treatments [49,50]. These artefacts consist of multiple wooden layers glued together and, sometimes, finished with a varnish layer. Varnish is applied to the outer layer of instruments to protect them from external agents. Often, they are applied in several steps, forming a multi-layered coating system. According to their compositions, they act as moisture barriers, influencing sorption and the ensuing effect on the dimensional stability of wood [51]. Musical instruments could be made with different wood species characterised by different mechanical properties and behaviours [52,53]. These valuable artefacts might be strongly affected by heat and moisture content variation, mechanical stresses, and their combination over time.

5.3. Furniture

Wooden furniture describes highly decorated surfaces whose interaction with the indoor surrounding environment may lead to cracking and warping until the loss of material occurs (Figure 7c). They commonly consist of decorative layers on a wood support, joined together by animal glue. These valuable layers are crafted by different decorative techniques, such as marquetry and veneer, using different species of wood or materials, such as ivory, and resulting in ornamental patterns such as flowers or parqueterie. They are often finished by lacquering [54,55]. Due to the hygroscopic nature of these materials and the variety of objects belonging to this category, the study of the mechanical response to environmental changes could be complex. High mechanical stresses may occur when wood swelling and shrinkage are restricted by glue layers. Today, limited literature exists on how the relative humidity cycle may affect wood until the failure of the material [56,57,58].

5.4. Buildings

Heritage wooden buildings and building components are amongst the ancient oeuvres made by mankind (Figure 7d). They are complex and heterogeneous architectures characterised by a hierarchical organisation. Buildings or some building components, structural or non-structural, have been built with wood for millennia. Different building techniques have been employed during human history, and they have been influenced by climate conditions and the availability of forest resources. It is possible to distinguish three types of timber building components: the post and beam structures, the timber-frame structure, and the log structure. However, there are changes within the main category, including the shape of the logs [59]. The weakest part of these structures are the joints, which ensure the union between different elements, as well as provide the force transmission and load transfer between them. Hence, in historical buildings, partially or completely destroyed joints can threaten the stiffness and the load bearing capacity of the whole structure. The type of connections and mechanism may be characterised by a great variability due to the improvement in joining techniques over the centuries [60,61]. Humidity variation and long-term loading are among the main causes of damages for these types of building components and structures. Their combination is also a harmful threat to their durability, giving rise to the so-called mechanosorptive effect.

6. Experimental Methods, Mathematical Modelling and Numerical Simulations Applied on Cultural Heritage

The successful study of the thermo-hygro-mechanical response of wooden objects requires knowledge about the full response of the material to environmental cycles. As this response is not constant over time, a continuous analysis of wood behaviour is essential for identifying risk periods. In cultural heritage, a critical aspect is to avoid further damage. In this context, non-destructive technique (NDT) and advanced mathematical modelling are very often employed [62]. Furthermore, there are useful approaches that combine different methods and techniques to capture all the factors that affect the thermo-hygro-mechanical behaviour, such as moisture content, wood density, and growth ring orientation, among others [26,63]. Nonetheless, this section overviews experimental and theoretical techniques by focusing on measuring moisture-induced stress and dimensional changes in wooden artefacts, as well as by avoiding the description of complementary techniques, which aim at measuring influencing parameters, such as moisture content, by using a vacuum microbalance.

6.1. Experimental Methods and Techniques

The preservation and conservation of the world of cultural heritage demand the application of non-invasive and reversible techniques. With the development of science and technology, a wide range of techniques has been applied and adapted to the study of artwork [64]. Indeed, several techniques were originally developed for other field applications, whereby no particular attention was paid to the preservation of the analysed sample.

Another limitation is represented by the application of sensor-based analyses to valuable and decorated objects. These techniques require a medium to couple sensors to the wooden surface. The coupling mediums are often highly adhesive glues with low impedance to ensure proper measurement and support sensors’ weight. The use of strong adhesives is not in line with conservation principles since they are not reversible and induce further damage in wooden artefacts while being removed. For this reason, some studies have been conducted to find suitable adhesive materials [65,66]. The selection of the adhesive method must take into account the duration of the measurements. Some binders employed are volatile, so they have been used in short-term applications [67]. The challenge that these applications bring makes it easier to use dummy samples, which mimic real artefacts. They reproduce a simplified geometry of the real artefacts, which have the same dimensions and are made of the same types of wood and layers, as in the case of a panel painting.

The following sensors will be briefly addressed in terms of basic principles’ pieces of knowledge and applications to cultural heritage, namely strain gauges, deformometric kit (DK), digital image correlation (DIC), photogrammetry, and the laser scanner technique.

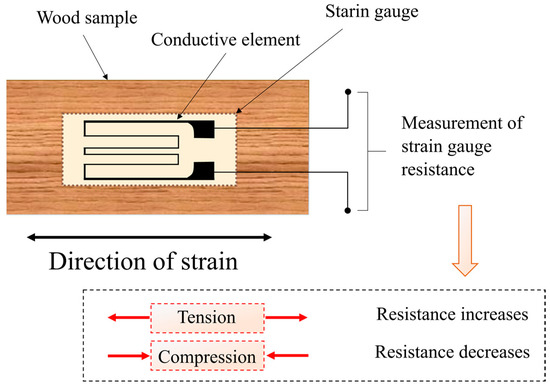

Strain gauges (Figure 9) are sensor-based techniques able to measure strain experienced by a wooden object when subjected to temperature and relative humidity fluctuations. These sensors are defined by Dulie-Barton et al. [64] as point measurement or point–strain measurement techniques. When the sensor, glued on the wood surface, is subjected to tensile or compressive mechanical forces, it changes its length and cross-section, i.e., width x thickness [68,69]. According to Equation (6), these changes result in changes in electrical resistance:

where, [] is the electrical resistivity, L [] is the length, and A [] is the cross-section area of the strain gauge. The use of this analytical method has been reported on wooden dummy panel paintings [45,46], as well as complex objects such as wooden cabinets [70]. In the latter, the sensors are installed on a duplicate of the original and valuable object. Point–strain measurements also have the disadvantage of providing the strain in the gauge direction. Wood is an anisotropic material, so the strain measurements with one sensor are non-representative. For this reason, multiple sensors are used [70].

Figure 9.

Schematic diagram of a strain gauge mounted on a wood sample. Wood tension and compression result in a change in electrical resistance. Red arrows corresponds to the direction of the tension and compression forces.

In this type of application, strain gauges are assembled in groups, assessing the strategic position on the artefact according to the aspects to be captured, e.g., the response of the joints. To obtain a whole description of the hygro-mechanical response of the object, strain gauges should be combined with other sensors that are able to detect environment parameters and moisture content. This approach allows for the performance of real-time monitoring analysis. Anaf et al. [46] apply this technique to study the influence of a new heating system in a church. They use a so-called ‘wood sensor’, a strain gauge glued on a 16th century oak block, sacrificed from a beam of a historic house, to assess the environmental condition and the level of risk for the wooden church interior.

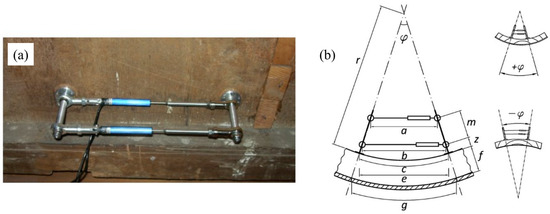

A deformometric kit (DK) is usually used to directly monitor dimensional changes. Additionally, two parallel transducers measure the relative movement and distance of two columns fixed on the rear of a panel, i.e., the no-decorate part (Figure 10a). When the object is subjected to moisture-induced dimensional changes, the two columns change their distance following the movement; thus, when cupping deformations occur, they rotate, resulting in a change of the angle of their axis. By processing data, it is possible to obtain useful parameters, such as the cupping angle or the radius of curvature (Figure 10b). A thorough explanation, integrated with explicative images, is provided by Uzielli et al. [71]. The DK is suitable for describing panel behaviour, its deformations, i.e., both in-plane and out-of-plane, and their evolution over time. As in Dupre et al. [63], it is possible to directly monitor local strain and the cupping angle with a high accuracy. Further, the author combined the DK’s techniques with two stereo-image acquisition, complementary techniques that allow a whole analysis of the painting, i.e., front and rear of the panel, to be obtained. Differently from the strain gauge, this method was applied by the same authors on another in-situ analysis [72,73]. They also used the DK for laboratory analysis using a replica [74].

Figure 10.

(a) A deformometric kit (DK) fixed on the rear of a panel painting; (b) schematic diagram of DK. Reproduced with permission from Ref. [71]. Copyright © 2012 Elsevier Masson SAS. All rights reserved.

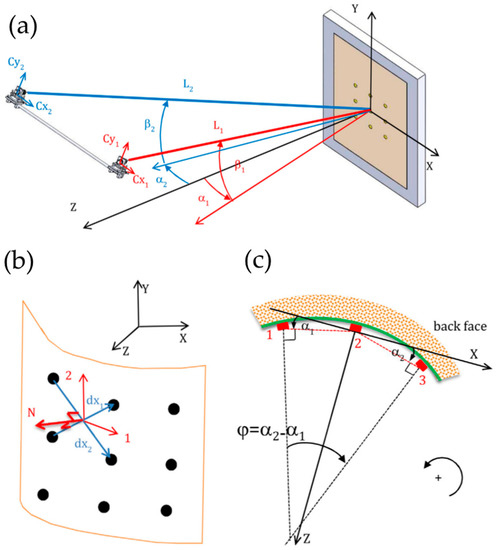

A widely used technique is the digital image correlation (DIC). Deformations can be measured by comparing successive digital images, in the grey scale, by digital cameras; by dedicated correlation algorithms, it is possible to compare images, before and after applying stress to an artefact, and calculate the displacement and surface strain fields [75]. Applying this technique to 3D objects, such as wooden statues, could be more difficult. For this reason, in the field of cultural heritage, it is usually used for detecting strain field across near-to-planar surfaces. An advanced set-up allows a complete assessment of the moisture-induced deformation of the whole objects to be obtained. As shown in Dupre et al. [63], employing two cameras (stereovision) is possible to obtain 3-D coordinates (i.e., x, y, and z), by triangulation [76], to study out-of-plain displacement (e.g., cupping). Dupre et al. [63] point out that this technique has limitations; the overriding occurs in the rear of the panel which, due to its brown coating, results in a uniform optical appearance. The ensuing low contrast makes the correlation of images uncertain and, thus, a stereo-mark tracking technique [77] is preferred. It consists of tracking the displacement of markers at the surface of the objects. This procedure also makes triangulation, to obtain the three spatial directions, easier. Techniques described by Dupre et al. [63] are shown in Figure 11.

Figure 11.

(a) A stereoscopic device, consists of two cameras, to obtain 3D coordinates by triangulation; (b) calculation of the strain field by the normal to the surface calculated in the initial state and deformed state; (c) the calculation of cupping and local strain by calculation of cupping angles considering three aligned marks. Reproduced with permission from Ref. [63]. Copyright © 2020 Elsevier Masson SAS. All rights reserved.

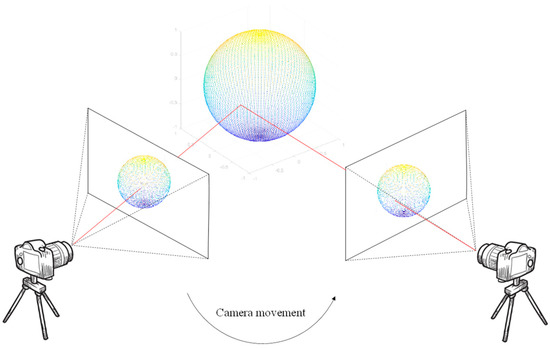

Other digital-image techniques, such as photogrammetry (Figure 12), allow for a better measurement of three-dimensional deformations. The digital photogrammetry technique is usually applied to the virtual reconstruction of cultural heritage and aerial mapping investigation [78]. Recent studies in the field combine this technique with computer vision tools, rekindling interest in this type of technique [79]. The basic principle consists of extracting a ‘cloud’ of three-dimensional data from two-dimensional photographic images taken from different angles by different cameras. Then, the images are processed by dedicated software, and the 3D coordinates are obtained. The main limitation of photogrammetry is the accuracy of the model, which primarily depends on the distance between the object and the camera, as well as the camera’s resolution. On the other hand, this technique allows for the measurement of deformations and distortions of wood on a large scale, such as the inspection of timber members [80,81]. It is also applied to small wooden objects, even if it is, sometimes, difficult to implement in a museum environment [63]. Konopka et al. [82] applied this technique to investigate instruments’ displacements due to climate variations.

Figure 12.

The basic principle of photogrammetry: a ‘cloud’ of three-dimensional data is extracted from at least 2 two-dimensional images, taken from different angles by different cameras. To obtain spatial coordinates of different points, dedicated software is employed.

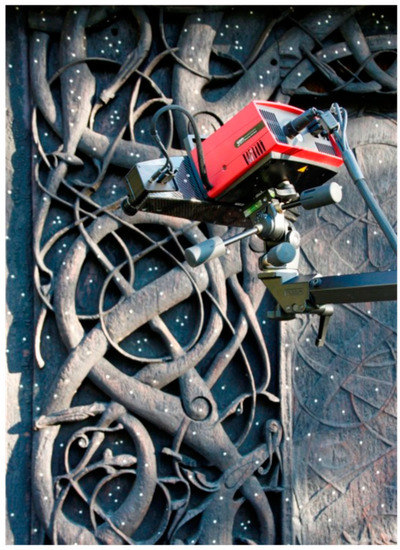

In the same context, which is often used when applying photogrammetry, is the laser scanner technique (Figure 13) [83,84]. A laser light is projected on the artefacts and a detector collects the reflected signal from the surface. Usually, the detector is an image sensor, such as a digital camera, equipped with charge coupled device (CCD) sensors. Similar to photogrammetry, this technique is, most often, used in other contexts, i.e., 3D digitalisation of cultural heritage [83]. Relatively recently, it has been applied in structural health monitoring for assessing the displacements of big structures. In Lee et al. [85], they assessed the displacement of a wooden building structure. The same technique is also applied by Bratasz and Kozłowski [86] to monitor dimensional changes on a valuable polychrome altarpiece. Specifically, they analysed three elements characterised by different thicknesses, as well as their responses to temperature and relative humidity changes. By knowing the distance between the sensor and the detector, they detected when the object changes its position and the ensuing distance from the sensor.

Figure 13.

A 3D documentation of the Urnes stave church using a laser scanner. The picture is taken from https://www.niku.no/ (Accessed on 20 March 2023) Copyright © Niku 2009.

Outside of the overviewed experimental techniques, other methods are applied in a few studies in the literature, most of which are applied with limitations, as they are not classified within the non-destructive techniques (NDT). However, they might provide useful information about the heat and moisture deformations. As an example, the work of Fioravanti et al. [87] applied a dead load test to study the mechanosorptive behaviour of an historical violin. The test is not usually applied to valuable wooden artefacts [88]. The violin was subjected to a load under varying climate conditions. To avoid damaging the artefacts, a reduced load was applied on the sound table, i.e., less than the forces of normal tuning. Part of this paper’s results will be discussed in Section 7.2.

6.2. Mathematical Modelling and Numerical Simulations

Mathematical modelling and numerical simulations are useful tools for understanding the degradation and deterioration processes of materials. Relatively recently, they have been used in the conservation of cultural heritage [89]. A validation is needed in model-based methods by means of comparing the numerical results against the experimental results. Furthermore, these results allow the input parameters of mathematical models to be obtained and boundary conditions, e.g., geometry, outdoor and/or indoor climate, surface resistance to water vapour diffusion and/or water absorption, among others, to be defined.

Among relevant studies in the field, the most studied parameters are summarised in Table 1. The presented parameters are employed as input variables in mathematical models and used to verify numerical simulations. They strongly depend on wooden directions and the moisture content in wood. For that reason, experiments summarised in the table have been conducted under controlled climate conditions and changing environmental parameters, i.e., temperature and relative humidity. Practically, input parameters are essential for solving differential equations, which describe the physical and mechanical behaviours of wood at different boundary conditions. To solve these equations, the finite element method (FEM) is employed, as analytical solutions are impossible; it is mostly used in the analysis of wood for different applications [90,91,92,93]. FEM analysis is a useful tool for predicting future and past heat and moisture movement, as well as the response of hygro-mechanical behaviour in wooden artefacts and buildings. Thus, by subdividing complex mathematical models into their individual elements, it is possible to solve mathematical equations governing physical and mechanical problems in complex geometry and nonlinear behaviour materials, such as wooden heritage objects.

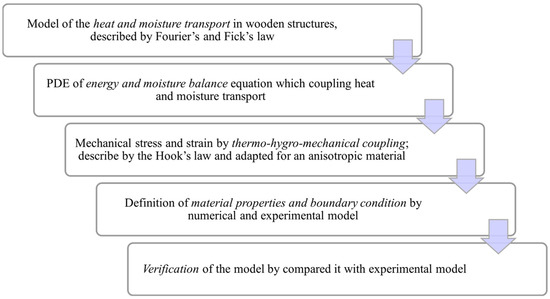

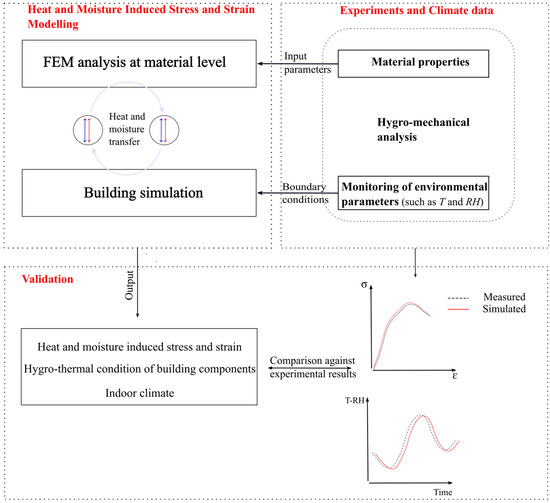

A multiphysical approach allows for the capture of the thermo-hygro-mechanical response of wood, the analysis of induced stress and strain, and, possibly, the propagation of cracks [93]. Simplifying the mentioned approach, the followed steps are summarised and presented in Figure 14. The detailed equations are presented in Konopka et al. [94], Jakieła, Bratasz, and Kozłowski [26], Schellen and Schijndel [95], as well as Schellen and Schijndel [96].

Figure 14.

Outline of the steps of a multiphysics model to simulate heat and moisture transport, as well as induced mechanical stresses, summarised based on the description made by Konopka et al. [94], Jakieła et al. [26], Schellen and Schijndel [95], as well as Schellen and Schijndel [96].

Most advanced models are developed by finite element software. Among others, the most used in the field are COMSOL and Abaqus; while the former is a multiphysics program able to combine the hygro-mechanical model and the heat and moisture transport model, the latter needs specific subroutines to achieve the same objective [95,97,98,99,100].

As pointed out in Schellen and van Schijndel [96], COMSOL may be a promising tool to simulate moisture-induced stress and strain in wooden artefacts. The presented model was adapted from Jakiela et al. [26], whose results also allow for the validation of the model in the software and, as already mentioned, the calculation of essential input, such as the moisture diffusion coefficient. The more detailed the model, the more computational resources and parameters are required. Therefore, model assumptions and, usually, simplification are imposed. So far, it has been pointed out, from the literature in the field, that a three-dimensional model of the deformation due to climate variation is complicated; hence, one and two-dimensional models are preferred. However, three-dimensional models can also be found in the literature [94,101,102].

This simplification is possible, as dimensional changes in the longitudinal directions are, usually, negligible compared to those in radial and tangential ones. Then, simplified analyses are conducted on complex cultural heritage—from multi-layer panel-based paintings and cabinets to statues and timber structures [97,103,104,105]. Moreover, in most cases, important elements, such as glue layers and types of joints, are analysed as separate issues elsewhere [106,107]. To further reduce numerical efforts, other studies do not consider some details; for example, some disregard veneer and different types of wood in cabinets [82,97].

Despite the simplifications, numerical models are useful tools for supporting restoration and conservation strategies [108]. For movable artefacts stored in indoor environments, an alternative approach is discussed. It combines the building simulation and the finite element analysis at the material level. Some scholars have demonstrated that this approach allows for the prediction of the historical indoor microclimate to which an artefact has been adapted and, thus, developed more reliable prediction about moisture-induced stress and strain [109]. This simulation model predicts indoor climate based on external conditions, and it is validated with data obtained from on-site measurements.

In Huijbregts et al. [97], the authors use a HAMBase model (heat, air, and moisture model for building and system evaluation) combined with a FEM software to assess the risk of mechanical degradation of a wooden cabinet after a new heating system was installed. When the artefacts are housed in a historic building, a heating, ventilation, and air conditioning (HVAC) system is usually installed to avoid uneven temperature and relative humidity fluctuations; this environment is often influenced by the outdoor environment [110,111,112]. Through the described approach, which combines the building simulation and the moisture transport at the material level, it is possible to directly simulate the impact of the HVAC system on the moisture-related mechanical stress [95]. The physical model and the mathematical development of an HAM model are outside the scope of the paper. A whole description is reported in de Wit [113].

7. Hygro-Mechanical Response of Wooden Cultural Heritage

In the world of cultural heritage, a wide range of artefacts are made of wood and, therefore, subjected to moisture-induced dimensional changes [15]. In this section, the studies conducted in this field, focusing on moisture-induced stress and strain in several types of artefacts, are reviewed. Although wood–moisture relations are the same, different structures, materials, and interactions can influence these mechanisms. More details about their structures and weaknesses related to changes in climate parameters are reported in Section 5.1.

7.1. Paintings

Wood experiences induced stress and strain when subjected to restrained swelling and shrinkage. This might occur when the panel is fixed in a rigid frame and undergoes an ensuing external force that may lead to the destruction of the artefact [15,63]. The panel may also experience mechanical stresses when a gradient of moisture between the inner and outer parts of the object occurs. Dimensional distortion, such as cupping under humidity variation, might be increased due to the presence of layers characterised by different hygroscopicity. Some of them may function as barrier vapour layers, while for others, instead, the barrier effect is negligible, e.g., the varnish and gesso layers, respectively [47,114].

Among the most studied layers is the gesso, as it might increase both the permanent deformation in a wooden panel, as well as the vulnerability of the painting layer to cracking [45,115,116,117]. The applied layer creates a restraint on the surface of the panel and, thus, a higher strain as a response to environmental variations compared with untreated specimens [46]. Furthermore, as it is considered one of the most vulnerable layers, it has hence been used as a reference to determine allowable environmental fluctuations.

Other factors may also influence the magnitude of induced damages and, thus, the level of risk to which the wooden object is subjected. The study of these induced damages over time should be conducted while also taking into account the board thickness, the amplitude of RH variations, and the frequency of fluctuations. The latter is defined by Anaf and Schalm [118] as the duration of the fluctuations. As numerically demonstrated by Rachwał et al. [104], the analysed artists’ material weakly responds to daily fluctuations, so lower-frequency fluctuations are needed. The authors found that, for a panel thickness of 40 mm, the necessary period to observe a response is 90 days. This result is in line with the work of Arends et al. [119] that shows how daily fluctuations only result in larger expansions in a thin board. At a fixed fluctuation frequency and panel thickness, the behaviour of the deformation depends on the amplitude of RH.

Table 1.

Studied parameters employed as input variables in mathematical models and used to verify numerical simulations. The found studies heterogeneously represent the wooden heritage objects and elements analysed in Section 5.

Table 1.

Studied parameters employed as input variables in mathematical models and used to verify numerical simulations. The found studies heterogeneously represent the wooden heritage objects and elements analysed in Section 5.

| Ref. | Year | Studied Parameters | Tests and Procedures | Studied Object | Wood Specie | Use in the Model | |||

|---|---|---|---|---|---|---|---|---|---|

| Parameter | Unit | ||||||||

| [120] | 2022 | Tension strength, ʃ | Tension test: Universal Testing Machine | Between 10 and 40% of ultimate stress as state in [121] | Different coatings assembly on historical panel painting and cupboard (furniture) | − | Input for numerical simulations of hygro-mechanical behaviour of coated wooden artwork | ||

| Strain, ɛ | − | ||||||||

| Young’s modulus, E | |||||||||

| Density of water vapour flow rate, g | Dry and wet cup tests | As described in EN ISO 12572 [122] and EN ISO 7783 [123] | |||||||

| Water vapour resistance, Z | |||||||||

| Water vapour permeance, W | |||||||||

| Water vapour permeability, δ | |||||||||

| Temperature, θ Relative Humidity, φ | °C - | Climate chamber, to control RH and kept constant T | |||||||

| [26] | 2008 | Equilibrium moisture content, EMC | % | Moisture adsorption/desorption isotherms | Sartorius vacuum microbalance | Massive wooden cylinder, simulating a wooden sculpture | Lime wood (Tilia sp.) | Input parameters to model moisture transport in wood subjected to climatic fluctuations e.g., in [97] | Results use in [95] to verify the developed model |

| Moisture diffusion coefficient, D | permeance cup procedure | A modified ASTM E 96–80 [124] | |||||||

| Yield point Strength Young’s modulus, E | Stress, MPa and strain, % MPa | Extensometer | ISO Standard 3346 [125] | ||||||

| [70] | 2018 | Total strain, ɛ Displacement, u Temperature, θ Relative Humidity, φ Moisture Content, MC | % mm °C - % | Strain gauges Linear variable displacement transducer (LVDT) In a climate chamber at varying of temperature and relative humidity EN 16682 [126] | Replica of historical cabinet door panels | Oak (Quercus sp.) | Experimental results used to compare FEM simulation results in [93] | ||

| [97] | 2015 | Temperature, θ Relative Humidity, φ Specific Humidity, SH | - | On-site measure campaign—indoor and outdoor, inside the cabinet climate chamber | Wooden cabinet | Oak (Quercus sp.)—sides and doors Veneer layer: Kingwood Tulip wood Rosewood Ebony Olive wood Holly | Validate simulated HAMbase model Validate heat and moisture transfer model | ||

| [104] | 2012 | Equilibrium moisture content, EMC Moisture diffusion coefficient, D Surface emission coefficient, h Dimensional changes → Strain, ɛ | % µm − | Moisture adsorption/desorption isotherms Cup test Displacement transducer | Vacuum microbalance ASTM E 9680 [124] Use a formula to obtain strain | Wood supports of panel painting | Lime wood (Tilia sp.) | Input parameter in the model Results use to validate dimensional response of wood (strains) in [109] | |

| [74] | 2006 | Cupping Force Cupping Deformations Temperature, θ Relative Humidity, φ | °C - | Monitoring cross beam (MCB) apparatus—a system of three LVDT RH cycles in climate chamber | Replica of a panel painting | White poplar (Populus alba L.) | Input parameters for descriptive models to predict the board’s mechanical behaviour | ||

| [82] | 2018 | Deformation, Z Temperature, θ Relative Humidity, φ | °C - | Tensioned string RH cycles in climate chamber | Measured by photogrammetric methods | Replicas of a clavichord | Spruce (Picea sp.) Beech (Fagus sp.) Oak (Quercus spc) | Validation of the numerical simulation for the short-term behaviour | |

| [127] | 2018 | —longitudinal Moisture content, MC | Pa % | Bending test − | Heritage building elements—carpentry corner joints (replica) | Pine wood (Pinus sp.) | Input parameters in the simulation | ||

| [114] | 2008 | Moisture diffusion coefficient, D Surface emission coefficient, S Permeability, P—of coatings Moisture content, MC | % | Sorption test in a climate chamber | Replica of panel paintings, including varnish layers | Spruce (Picea sp.) | Use parameters as input in simulation model, e.g., in [128] | ||

| [129] | 2022 | Total force Cupping deflection Temperature, θ Relative Humidity, φ | N Mm °C - | Miniature load cells Displacement transducers T and RH sensors | Panel painting | White poplar (Populus alba L.) | Calibration of Finite Element Method (FEM) | ||

7.2. Musical Instruments

Climate parameters variations induced dimensional changes and deformations in wooden musical instruments, which is characterised by inhomogeneity when a varnish is adopted. Thermal and moisture deformation might induce undesired stress–strain cycles, leading to significant deformation above the elastic level [130,131].

In many but, by far, not all cases, in the literature to study thermo-hygro-mechanical behaviour, it was considered to be environmental fluctuation that occurred both during conservation, when the objects is in a display case, and during a concert. It has long been known that, during a performance, these types of wooden oeuvres are subjected both to mechanical load and moisture variation. Indeed, tuning the instrument exerts a pressure, which causes a sustained load, resulting in local plastic deformation [132].

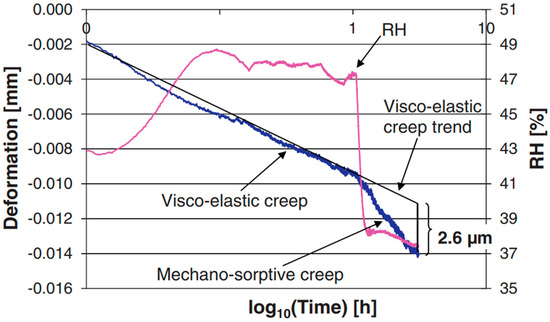

As shown in Fioravanti et al. [87] when relative humidity decreases, the creep effect is intensified due to the mechanosorptive behaviour of wood (Figure 15). In the same study, the authors highlight how the load, applied by playing the bow, is negligible compared with the one applied by tuning. The player influences only the violin temperature without compromising the moisture transfer mechanism, i.e., mass variations due to hygro-thermal changes [133]. The highest level of risk for different types of instruments was detected in the soundboard. This is probably due to the deformation induced by the string tension [87,101,108,131].

Figure 15.

The mechanosortpive effect: when relative humidity (pink line) decreases, the creep effect (blue line) is intensified. Reproduced with permission from Ref. [87]. Copyright © 2013 Elsevier Masson SAS. All rights reserved.

It is worth mentioning that moisture changes may also affect the tone of musical instruments, as well as the sound quality. This issue is the subject of thorough scientific investigation as one of the main conservation purposes to be attempted [134,135].

7.3. Furniture

Wooden cabinets are valuable type of furniture made with high-quality types of wood with relatively small defects, such as knots, and thin annual rings that could influence the mechanical response of the material. Cabinet boards, usually made of oak, are assembled and, sometimes, restrained by cleated ends by means of joints, such as animal glue and tongue-and-grove joints. Then, a veneer decorative layer might be glued in a restrained shrinkage area as a joint. Moreover, the applied decoration, as veneer, may consist of a different type of wood, whose thickness may influence shrinkage behaviour [70].

The difference in shrinkage, according to the anatomical direction and the curvature of the growth rings, affects the wooden board’s deformations [136]. Thereby, quartersawn boards, i.e., when the annual rings are perpendicular to the board, tend to deform less often. As shown in Luimes et al. [70], when the board is not perfectly quartersawn, the object is subjected to some deformations (Figure 1b). Although a panel of a wooden cabinet is similar to a panel of a painting, i.e., wooden boards glued together, the more complex structures of the first may increase moisture-induced stress and strains.

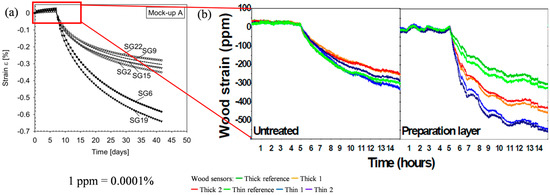

Comparing the study of (i) Luimes et al. [70] with the one of (ii) Anaf et al. [46], as shown in Figure 16, it is worth it to note how the wooden structure that mimicked a cabinet (i) (Figure 16a) experienced a higher strain than the one that mimicked a panel painting (ii) (Figure 16b). The two specimens had similar dimensions, i.e., (i) 633 × 545 × 15 mm and (ii) 45 × 100 × 3/6 mm, and they experienced the same drop of relative humidity (ca. a RH step of 40%). The shapes of the curves, which describe the time evolution of the strain experienced by the wood panel, are comparable. Despite the smaller thickness of (ii), it experienced a smaller mechanical strain. This is probably due to the restrained structure in (i) and the type of frequency fluctuations. High-frequency fluctuations, i.e., day–night fluctuations, do not allow for a full response of the panel to the RH changes. Strain values of (ii) increased when a preparation layer was applied on the surface (Figure 16b).

Figure 16.

(a) Strain experienced by a wooden structure mimicked a cabinet (i), and (b) strain experienced by a wooden structure mimicked a panel painting (ii), owing to a drop of relative humidity. In (a), different curves are referred to with different strain gauges on the same mock-up. Strain gauges (SG) 2, 9, 2, and 15 are fixed on the front and rear of the panel near the cleated end. SG 6 and 19 are fixed to the half-length of the panel. In (b), thick refers to two samples with a thickness of 6 mm; thin, instead, refers to samples with a thickness of 3 mm. The red square shows the total length of the y axis of (b) compared to (a). From Luimes et al. (2018) [70] and Anaf et al. (2020) [46].

7.4. Historical Buildings

Heritage wooden buildings and building components might be exposed to outdoor environments, and thus, they are not protected against precipitation, solar radiation, and wind. Most authors, such as Fragiacomo et al. [100], do not take into account those parameters to avoid an overly complex analysis, instead supposing the case of a sheltering situation.

In that case, the most harmful threat for heritage buildings’ durability is humidity. As explained in Section 1, relative humidity variation induces internal stresses and distortions due to restrained swelling and shrinkage. Hence, buildings and structural elements may lose their integrity, as well as experience changes in mechanical properties [137]. Most swelling and shrinkage events occur in the directions perpendicular to the grains, namely radial and tangential. As described by Rantamanus [138], the moisture-induced stresses are more evident in those directions. The same author also explained that the smallest cross-sections are more sensitive to moisture cycling than larger ones, and the surface protective coating represents an effective protection for those cycles. Those assumptions are demonstrated by the work of Fragiacomo et al. [100]. As pointed out in their study, in addition to the size of the cross-section and the presence of a coating, the type of climate is also an influencing factor for wooden components exposed to an outdoor environment. Indeed, the higher induced stresses have been detected in climate zones with the highest values of annual relative humidity variations.

Joining parts play a key role in the force and load transmission; thus, moisture-induced stresses in those areas may compromise the performance of the whole structure. In agreement with the type of joint, forces and stresses are differently distributed. Moisture content changes in this connection part may increase the stresses perpendicular to the grain [139]. As shown in Pestka et al. [140,141] higher moisture content corresponds to higher values and larger areas of stress, when compared to a dried sample. The effect of moisture might consider a further load to be added to the external mechanical load, so their simultaneous effects induce additional deformations and accelerate the reduction in strength with time.

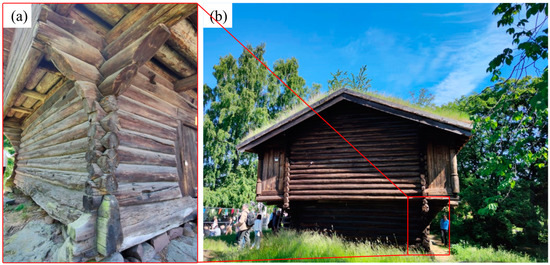

Although some works in the literature are not directly referred to as cultural heritage, they might help with the understanding of wooden timber behaviour in the same conditions, i.e., being subjected to natural climate variations while sustaining loads [28,137,142,143,144]. Research in that direction might be a useful tool to study the mechanosorptive behaviour of wood in building components and structures [142], firstly, due to the lack of these investigations in the heritage field and, also, because useless samples allow for the performance of experiments which may compromise the heritage integrity [143]. For example, Larsen and Ormarsson [144] studied the mechanosorptive strains and stress distribution by cutting a timber log, which is the unit element of important heritage buildings. An example is the Heierstad loft, a log house in Tønsberg in Norway, shown in Figure 17a [12]; a detailed view of the logs is shown in Figure 17b. The carried-out results from the descripted studies are essential information needed in the assessment of timber structures [145]. As highlighted by Cavalli and Togni [146], the assessment of heritage and timber structures needs continuous monitoring and the use of non-destructive techniques.

Figure 17.

(a) Carpentry corner joint of the logs; (b) a heritage log house building in Tønsberg, Norway—Heierstad loft.

8. Discussions and Conclusions

8.1. Limitation and Novelty of the Study

In this review, the authors summarised and discussed the available studies focusing on moisture-induced stress and strain in wooden cultural heritage artefacts and buildings that exist in literature. This provided key insights for critical thinking about this subject. Indeed, this review contributes to the current knowledge base by showing the literature studied in a different perspective. This work shows how different types of cultural heritage have common characteristics, and the study across its categories (e.g., painting, violins, and furniture, among many others) may encourage interdisciplinary scientific investigations. Nonetheless, a clear and systematic division within different categories may help to extract and collect parameters that are useful for modelling analyses. Moreover, the review presents real case studies and numerical approaches, summarising the followed methodologies in a clear and simplified way. This could make the interaction between experts from different fields of expertise smoother.

Although it provides added value to the existing literature, the present work has some limitations. Some of them are linked to the choices made by the authors, as well as to the focus that has been chosen for the article. Mathematical modelling and numerical simulations, for example, are described as approaches although, analytically and methodologically, they do not provide detailed information on their computational aspects. Focusing on the description of the experimental studies, the present literature does not take into account complementary techniques which allow the study of important parameters, such as the moisture content. This choice was made in the belief that providing too many details on complementary aspects could cause the main subject to lose focus. Some topics that would have been relevant to the study were not covered, as they were too broad to be integrated with the present work. Given their importance, they have been outlined as possible future lines of research. Among them, one example is the effect that climate change can have on moisture-induced stress and deformation in old wood.

8.2. Discussions on the Reviewed Studies

A summary of the advantages and disadvantages in the application of methods and techniques, analysed and discussed in this section and Section 6.1, is provided in Table 2. This was made to provide a clear understanding of the more in-depth analysis of the research findings, which will be presented later on. Based on the values presented in this table, it is clear that, in order to meet the conservation needs of the artefacts, there could be some limitations. The accuracy and resolution of the obtained images are among the most common problems in this regard.

Table 2.

Summary of the main advantages and disadvantages of the analysed techniques.

Experimental methods and mathematical simulations are tools which might help to define restoration and conservation procedures [108,147]. The combination of them is a powerful approach to analysing complex and unique works of art and prevent new or further degradations. This approach provides wide knowledge about the full response of wooden heritage to environmental cycles.

Monitoring valuable artefacts and buildings requires the use of non-destructive techniques (NDT). However, results obtained by NDT can be affected by moisture content, compromising the validity of obtained data [148]. This aspect does not make the use of NDT useless, but it requires the consideration of the moisture content during the analyses in order to correlate it with the obtained results [149]. The degree of influence of MC on non-destructive tests also varies, accordingly, with the wood species [150].

The main limitation of experimental methods is the application of point–strain measurements due to their need to bond the sensor to the work of art. The strong adhesive needed for high-quality measurements risks damaging vulnerable wooden surfaces. This drawback warranted the use of dummy samples, which mimic real artefacts. Alternatively, more conservative-friendly adhesives have been tested. Their use is still limited to short-term applications. For this reason, no-contact techniques, such as image-based ones, are sometimes preferred, but they are less accurate. Point–strain measurements, as recalled by their name, provide punctual information about the monitored surface. For anisotropic materials, such as wood, these collected data are non-representative of the whole object or building element; thus, an array of multiple sensors is employed.

Deformation and strain measurement techniques, with climate parameter sensors, are used together to take an overall picture of the problem and avoid misleading results. In-depth knowledge of the hygro-mechanical behaviour of wooden heritage requires non-invasive continuous monitoring of materials’ deformation and environmental parameters. This is a limitation in the absence of automated measuring and recording procedures. In the monitoring of artworks in an open environment, a further challenge is represented by connection problems of cables and data logging systems. To deal with this issue, ad hoc and advanced equipment have been developed for monitoring buildings and small artefacts [129,151,152].

The use of NDT does not always allow it to encompass all involved phenomena, and this can lead to an oversimplification of the problem and an overestimation of some parameters, such as moisture [101]. More invasive techniques are then employed and allow for the ensuing capture of important irreversible deformation components, i.e., viscoelasticity and mechanosorption. In the study of musical instruments [130] and building elements [90] these deformations are fundamental for understanding the behaviour of wood. They naturally undergo cyclical moisture content changes and mechanical load during their use. Among the collected studies, the main investigations have been conducted to assess musical instruments. In this context, the work of Fioravanti et al. [87], where dead load tests are employed to study the mechanosorptive effect in a valuable wood violin, is highly relevant. To assess irreversible deformations while avoiding experiments on real artefacts, simulation tools are employed.

Mathematical modelling and numerical simulations, as described in Section 6.2, allow for the study of moisture-induced stress and strain by multiphysics models. During the last decade, these models were developed in advanced FEM software. As demonstrated by Portal et al. [109], a more realistic predictive tool is developed by integrating outdoor and indoor climate data in the model, particularly in historical buildings. It has been shown that combining building dynamic simulation and simulation at the material level allows for a better assessment of actual or potential risks from damages due to environmental changes and mechanical loads.

The reliability of these models depends on many simplifications and assumptions, as well as on materials’ parameters. Parameters which describe material properties and wood are used as input variables to validate the models. After careful assessment, the main studied parameters in the field were summarised in Table 1. The data extracted from several articles have been cross-referenced in order to provide an analysis on the use of these parameters, both as input in the mathematical models and to validate them. Often, the level of detail of some studies does not allow for a clear overview. Although this is outside the scope of many research works, a clear design of how experiments and mathematical models interact is important. For these reasons, in Figure 18, the correlation between experimental methods and numerical modelling is depicted by means of a cognitive scheme.

Figure 18.

The cognitive scheme for the interaction between experimental methods and numerical modelling is depicted.

As highlighted so far, the validation and parameter calculation is often carried out on duplicates of heritage objects. As suggested by some authors, even when experiments on real artefacts are not possible, it is not recommended to take these numbers from the literature to avoid unreliable results [109] The same artefacts or building elements may differ from one another in many characteristics. Therefore, it is also important to characterise the hygro-mechanical behaviour of all elements of an artefact. Instead, to simplify complex models, important layers of wooden heritage are often omitted. In most cases, adhesives and the system of coatings are not investigated, and they are discarded in numerical models. In line with [120,153], an accurate hygro-mechanical analysis should also test and analyse them.

Focusing on studies summarised in this review, it has been shown that the magnitude of induced mechanical stresses is affected by several variables: The thickness and size of the cross-section, the amplitude of RH variation, frequencies of fluctuations, and restrained structures are of most of interest in the literature.

In indoor environments, temperature and relative humidity cycles cause mechanical stress in wooden objects [86]. As pointed out by Rachwal et al. [115], these cycles are more dangerous than damaging events. Forced heating and air-conditioning may exacerbate this phenomenon. This issue covers an important role in the field of cultural heritage, and it is widely studied as it applies to indoor artefacts, particularly panel paintings. On the contrary, due to the many factors involved and the complex analysis, artefacts and buildings in the outdoors are not debated with the same efforts. Concerning wooden historical buildings, studies in the literature are focused on building components and joint parts.

9. Future Perspectives

Conservation of painted wooden objects includes realising their complexity and uniqueness. The attractiveness of the wood heritage, for researchers in different fields, has increased during the last decade. At the same time, the improvement of dedicated equipment and numerical simulation methodologies has further increased, expanding the knowledge about the mechanical response of wooden artefacts to changes in ambient temperature and relative humidity.

Diverse challenges must be overcome to develop preventive conservation strategies and to benefit the conservation community. The study of complex and multi-layered wood objects entails the study of all layers and components of the structures. Sometimes, achieving this aim means a huge amount of work, long-term analyses, and high costs. Therefore, experimental and model simplifications are imposed. This may lead to an oversimplification of complex phenomena, thereby overlooking important irreversible moisture-induced deformations. For example, the mechanosorptive effect in wood artefacts is rarely treated. The study of this effect plays a key role in heritage science, especially for application in historical buildings that are, by their nature, subject to a load and climatic variations, as well as musical instruments, as shown in Section 5.2 [154,155]. More generally, the study of the long-term behaviour of wooden artefacts and buildings needs to consider creep and mechanosorptive phenomena [40,156].

The concept of long-term conservation of wooden cultural heritage is intimately connected with the idea of preserving and protecting them for future generations. Nowadays, wooden heritage preservation is threatened by future climate variations [157]. It is, therefore, essential that future works will continue to investigate the effect that climate change has on this heritage [158]. The ongoing climate change, getting worse in the future, is not only a danger to wood heritage directly exposed to the outdoor environment but also to artefacts in historic buildings [159]. In this context, simulation plays a key role in assessing the impact of climate change on future indoor climates in historic buildings [160]. Future research will need to focus on the effects of climate change on moisture-induced stress and strain in heritage wood by including this aspect in modelling analyses.

In parallel, the accuracy of the simulations should be implemented in several aspects. The use of realistic models is limited by knowledge about the material properties and the behaviour of complex structures over time. This means that future experimental results should investigate further useful parameters to represent the peculiarity of wood behaviour. Additionally, mathematical models’ reliability is affected by experimental and numerical assumptions. Future studies can be conducted to provide more elaborate moisture transfer models under uncontrolled and controlled environments. Further, more physical and mechanical properties should be obtained on glue and adhesive areas, as well as different types of wood often used together. Connections and joint parts, particularly in a wooden building, also need further research and implementation in simulation models.

Although tailored methods and experimental techniques have been developed, the application of image-based techniques to measure moisture-induced displacements requires the implementation of their accuracy. Sensor-based techniques, instead, open new research directions that are focusing on the findings of conservative-friendly adhesives for long-term applications.

In the future, following the defined possible future research directions requires more interdisciplinary collaborations between professional figures. Scientific knowledge supports the optimisation of heritage conservation conditions. More collaborations with industries facilitate the adaptation of techniques from other research fields. An open dialogue with the conservators helps to define conservation needs and answer the questions that come from practical needs. In this direction, research projects already work to reduce the gap between academic studies and conservation practices.

Author Contributions

Conceptualization, G.G. and D.K.; methodology, G.G., G.B.A.C. and D.K.; formal analysis, G.G.; investigation, G.G. and D.K.; resources, G.G., G.B.A.C. and D.K.; writing—original draft preparation, G.G.; writing—review and editing, G.B.A.C. and D.K.; visualization, G.G; supervision, D.K; project administration, D.K; funding acquisition, D.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the European Union’s Framework Program for Research and Innovation (Horizon 2020), grant number 821054 (HYPERION project).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is available on request from the corresponding author.

Acknowledgments

This research was made possible by the International post-degree scholarship (“Borsa di studio di perfezionamento all’estero”) awarded by La Sapienza University of Rome to G.G and the HYPERION project.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript; or in the decision to publish the results.

Nomenclature

The following symbols are used in this manuscript:

| Symbol | Name | Unit |

| temperature | [] | |

| t | time | [] |

| u | moisture content | [] |

| thermal conductivity | [] | |

| specific heat capacity | [] | |

| density | [] | |

| spatial gradient operator | [-] | |

| D | diffusion coefficient | [] |

| water vapour diffusion coefficient | [] | |

| bound water diffusion coefficient | [] | |

| sorption rate | [] | |

| concentration of water in the vapour phase | [] | |

| concentration of water in the bound phase | [] | |

| total strain | [] | |

| thermal strain | [] | |

| elastic strain | [] | |

| free swelling and shrinkage strain | [] | |

| mechanosorptive strain rate | [] | |

| the viscoelastic (creep) strain | [] | |

| E | elastic modulus | [] or [MPa] |

| stress | [] | |

| R | electrical resistance | [] |

| electrical resistivity | [] | |

| L | length | [] |

| A | cross-section area | [] |

| ʃ | tension strength | [] |

| g | density of water vapour flow rate | [] |

| Z | water vapour resistance | [] |

| W | water vapour permeance | [] |

| EMC | equilibrium moisture content | % |

| D | moisture diffusion coefficient | [] |

| δ | water vapour permeability | [] |