Abstract

The oscillating phenomenon of the weld pool has a direct physical correspondence with its penetration state, which has broad application prospects in the monitoring of weld penetration states. This article studied the characteristics of the oscillating phenomenon of the weld pool in short-circuiting gas metal arc welding (S-GMAW) with different penetration states based on a welding high-speed photography system. The results show that the form of the liquid bridge electric explosion impact on the weld pool is “surface impact” in S-GMAW. The oscillation frequency of the weld pool decreases as the size of the weld pool increases. Compared with the partially penetrated weld pool, the boundary conditions of the fully penetrated weld pool had different boundary conditions, resulting in higher oscillation amplitude and lower oscillation frequency. In S-GMAW, no difference in welding voltage signal, caused by the difference in amplitude of the weld pool oscillation with different penetration states, was observed.

1. Introduction

In the automatic welding process, the penetration state of the weld is the main factor that affects the quality of the welded joint. A large number of studies have shown that the oscillation phenomenon of the weld pool reflects the penetration state of the weld [1,2]. Therefore, research on the oscillation phenomenon of the weld pool in the S-GMAW is of great significance for the automated weld quality. A large number of scholars have conducted research on the characteristics of the oscillation phenomenon of the weld pool, most of which are based on the gas tungsten arc weld (GTAW) [3,4,5]. Reference [6] shows that the oscillation phenomenon of the weld pool in GTAW has stable frequency characteristics, and the weld pool has two oscillation modes: one is the axisymmetric vibration of the geometric center of the weld, and the other is asymmetric vibration. Reference [7] found that the change of the weld pool penetration state could cause a sudden change in the oscillation mode, and the natural oscillation frequency of the weld pool has a direct physical relationship with the weld pool volume.

The research on the oscillation phenomenon of the weld pool in the GMAW process is still relatively rare, while research on the GTAW has gradually matured. Reference [8] studied the oscillation phenomenon of the P-GMAW weld pool, based on welding high-speed photography equipment. The standing wave oscillation mode of the GTAW weld pool was not found in pulse gas metal arc welding (P-GMAW). At present, there is still a lot of controversy in the research on the oscillation phenomenon of the weld pool in S-GMAW. Reference [9] pointed out that, although the droplet transition phenomenon of S-GMAW triggers the oscillation of the weld pool, it leads to a significant increase in the aspect ratio of the weld pool and also interferes with the oscillation phenomenon. Due to the randomness of the impact of electric explosions, the oscillation phenomenon of the weld pool does not have a stable frequency characteristic. However, Reference [10] proved that the oscillation phenomenon of the weld pool in the S-GMAW process has specific natural oscillation frequency characteristics.

The oscillating phenomenon of the GMAW weld pool contains enough information to infer the penetration state of the weld. Therefore, the research on the oscillating phenomenon of the S-GMAW weld pool is particularly important to realize the fine control of the S-GMAW welding process.

2. Materials and Methods

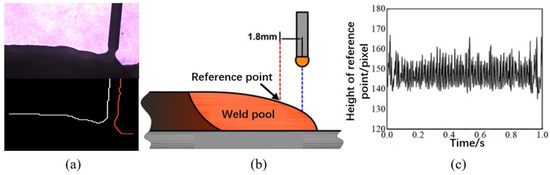

The dynamic phenomenon of the side of the weld pool was recorded by a welding high-speed photography system in this study, and a reference point on the weld pool surface was defined to measure the height of the reference point. The oscillation signal of the weld pool could be extracted by continuously measuring the height of the upper surface of the weld pool in the side-view of the high-speed photography, with the help of the image-processing software, as shown in Figure 1. The sampling frequency of the high-speed photography system used in this paper is 10,000 Hz, and the frequency characteristics of the molten pool oscillation signal extracted, based on the high-speed photography images, will not be lost.

Figure 1.

The process of extracting the oscillation signal of the weld pool: (a) the high-speed photography and the contour of the upper surface of the molten pool; (b) The position of the reference point; (c) The oscillation signal of weld pool in S-GMAW.

The welding power is the German EWM PHYNIX 5000 power, and the current polarity is direct-current electrode-positive (DCEP). The distance between the tip and workpiece (CTWD) is 15 mm, and the welding gun is perpendicular to the welding seam for welding. In this paper, the groove of the plane butt joints is “I” type. In order to effectively remove the oxide film on the surface of the base metal, an angle grinder and acetone are used to treat the welding seam and the range of 30 mm nearby before welding. Q235 low-carbon steel and ER50-6 carbon steel welding wire were selected for the base metal and welding wire, respectively. The thickness of the base metal is 2 mm and 4 mm, and the welding wire diameter is 1.2 mm. The welding shielding gas is 72%Ar + 28%CO2 mixed gas, the gas flow is 20 L/min, and the voltage is 20 V. The specific process parameters are shown in Table 1.

Table 1.

The welding parameters used in this article.

3. Results and Discussion

3.1. The Welding Pool Oscillation Process

Multiple consecutive high-speed photographic images during one droplet transition period of the conventional short-circuit transition process is selected to observe the oscillation process of the weld pool, as shown in Figure 2a. Figure 2b is the oscillation signal of the reference point B on the surface of the weld pool. The position of the wave crest is shown by the arrow in Figure 2a.

Figure 2.

(a) The oscillation process of partially penetrated S-GMAW weld pool (wire feeding speed is 3 m/min, plate thickness is 4 mm); (b) The oscillation signal at reference point of partially penetrated S-GMAW weld pool.

As shown in Figure 2a, due to the impact of the electric explosion, the liquid metal of the weld pool under the welding wire forms a surface wave under pressure and transmits to the surrounding, and the surface wave at the back of the welding wire moves to the rear edge, which did not pass the reference point, as shown by Arrow 1 at 28.5 ms in Figure 2a. Since the forward-moving surface wave is hindered by the front wall of the weld pool, it has a higher peak, which is defined as the main wave in this paper. The main wave causes a drastic height change at the reference point, as shown by Arrow 2 at 30.7 ms in Figure 2a. The two wave crests merge into one wave crest during the backward movement, as shown by the blue arrow at 32.9ms in Figure 2a. The amplitude of the secondary wave, formed after the main wave passes through, gradually decreases under the action of oscillation damping, as shown by the blue arrow at 44.2 ms in Figure 2a. Usually, when the main wave crest propagates towards the trailing edge of the weld pool, another liquid traveling wave will be triggered at the next droplet transition. The continuous superposition and attenuation of these traveling waves constitute the undulating liquid level of the weld pool.

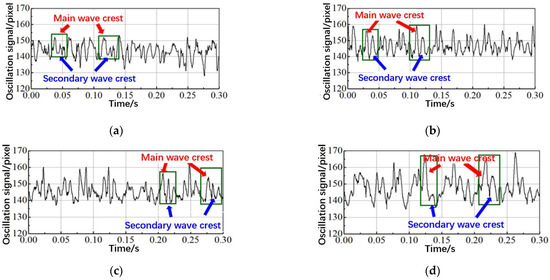

Figure 3 shows the oscillation signal of the partially penetrated weld pool with different wire feeding speeds (2.4 m/min, 2.7 m/min, 3.0 m/min, 3.3 m/min). It can be found that the oscillation amplitude increases with the increase of the wire feeding speed in the S-GMAW process. The heat input and amount of metal transition acting on the weld pool is low with low wire feeding speed, which results in the weld pool with smaller volume and less deformation, as shown in Figure 4a. With the increase of wire feeding speed, the melting amount of welding wire increases per unit time, which results in more deposition of molten metal and increase of the weld pool size; the amount of metal pushed away by the impact of electric explosion increases, and the deformation of weld pool and the amplitude of weld pool also increase, as shown in Figure 4b.

Figure 3.

The oscillating signal at the reference point on the surface of the molten pool of the S-GMAW process with different wire feeding speeds. (a) 2.4 m/min; (b) 2.7 m/min; (c) 3.0 m/min; (d) 3.3 m/min.

Figure 4.

Schematic diagram of the influence of the wire feed speed on the pool oscillation: (a) Low wire feed speed with small volume of welding pool and weak external impact; (b) High wire feed speed with large volume of welding pool and strong external impact.

Due to the existence of oscillation damping, the oscillation amplitude of the weld pool would gradually decrease during one droplet transition period, as shown in the peak amplitude of the oscillation after the main wave in the green box in Figure 3. Lv Xiaoqing et al. [11] indicated that, when the main wave of the weld pool propagates in the fluid for a distance x, the relationship between the oscillation amplitude A and the energy decay factor α is shown in Equation (1):

where, A0 is the initial oscillation amplitude of the weld pool and α is the energy attenuation factor, which is related to the viscosity of the weld pool fluid.

Behroozi F et al. [12] derived the relationship between the energy attenuation factor α and the viscosity η of the weld pool fluid, based on the principle of energy conservation in fluid mechanics, as shown in Equation (2):

where, ρ is the density of the liquid metal in the weld pool, σ is the surface tension of the liquid metal, g is the acceleration of gravity, λ is the wavelength, η is the viscosity, and η = 4.3 mPa·s.

The study of Leng et al. showed that the wavelength λ of the oscillating wave generated by the impact of a droplet is equal to the diameter of the droplet [13]. The transmission speed of surface traveling waves v mainly depends on the surface tension and density of the weld pool [13], as shown in Equation (3):

where, the surface tension (σ) of the fluid of Q235 steel is 1.0 N·m−1, the energy attenuation factor (α) obtained by Equation (2) is 0.05, and the surface wave velocity obtained by Equation (3) is 0.77 m/s. Then, the relationship among the weld pool oscillation amplitude (A), the initial oscillation amplitude (A0), and time is shown in Equation (4):

It should be noted that the residual oscillation phenomenon in the weld pool can also affect the decay process of the oscillation amplitude, but this effect is difficult to measure and analyze based on existing methods. It can be seen from Equations (2)–(4) that the attenuation process of the main wave of the weld pool mainly depended on the density and surface tension of the weld pool metal, but the initial oscillation amplitude (A0) of the main wave is related to the size of the weld pool and the magnitude of the impact from the electric explosion.

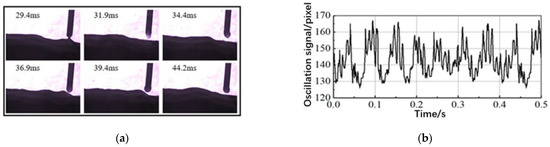

Although reference [6] have shown that the weld pool has different oscillation modes with different penetration states in GTAW, few studies have analyzed the differences in the oscillation phenomenon of the S-GMAW weld pool in different penetration states. Figure 5 shows the oscillation process and oscillation signal of the full penetration weld pool in the S-GMAW process, the wire feeding speed and the plate thickness of which is 3 m/min and 2 mm, respectively. It can be found from Figure 5a that the weld pool in the fully penetrated state also forms oscillating waves under the impact of the electric explosion, similar to the partially penetrated state.

Figure 5.

(a) The oscillation process of fully penetrated S-GMAW weld pool (wire feeding speed is 3 m/min, plate thickness is 2 mm); (b) The oscillation signal at reference point of fully penetrated S-GMAW weld pool.

It can be found that the weld pool of the short-circuit transition process in the full penetration and non-penetration states forms the main wave under the impact of the electric explosion, and moves to the tail of the molten pool, due to the damping caused by the viscosity of the molten pool metal. As shown in Figure 5b, the oscillation amplitude of the fully penetrated molten pool is higher than that of the non-penetrated molten pool. At the same time, the oscillation signal shows a large amplitude. The low-frequency oscillatory waves carry multiple high-frequency oscillatory waves with small amplitudes.

3.2. Analysis of Frequency Characteristics of Welding Pool Oscillation

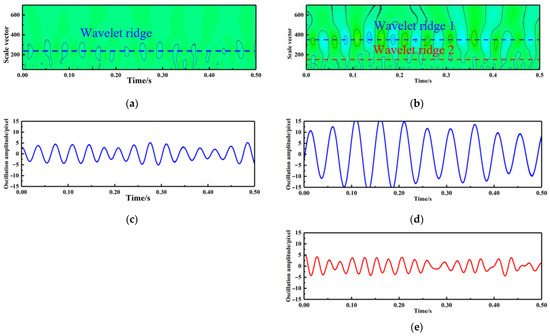

The free oscillation process of the weld pool could be interrupted by the droplet transition process, which will greatly disturb the continuity of the oscillation signal. In order to analyze the frequency characteristics of the weld pool oscillation signal of S-GMAW, continuous wavelet transform is used to extract discontinuous frequency features of the oscillation process. Figure 6 is the wavelet quantity diagram of the weld pool oscillation signal under different penetration states, and the corresponding oscillation signal component at the scale vector with stable frequency characteristics. Equation (5) is the conversion relationship between scale vector (α) and the corresponding stable frequency characteristics (f):

where, the sampling frequency of high-speed photography (fs) is 10 kHz, (α) is the scale vector, and fα is the frequency of the wavelet basis function selected. The frequency of the wavelet basis function used in this paper is 0.796.

Figure 6.

Wavelet Quantity Diagrams and Corresponding Oscillating Signal Components of Melt− Pool Oscillations: (a) The wavelet quantity diagram of Figure 2b; (b) The wavelet quantity diagram of Figure 5b; (c) The corresponding oscillating signal components at the wavelet ridges of (a); (d) The corresponding oscillating signal components at wavelet ridges 1 of (b); (e) The corresponding oscillating signal components at wavelet ridges 2 of (b).

It can be found from Figure 6a that a stable continuous wavelet ridge line appears in the wavelet quantity diagram of the oscillation signal of the partially penetrated weld pool, which indicates that the oscillation process has only one frequency characteristic. The corresponding oscillating signal components at the wavelet ridges are shown in Figure 6c, and the oscillation frequency is 26.5 Hz. As for the fully penetrated weld pool, the wavelet quantity diagram has two stable continuous wavelet ridges, indicating that the oscillation signal has two frequency characteristics, 20 Hz and 53 Hz, respectively. The component diagrams of the oscillating signal corresponding to the two frequencies are shown in Figure 6d and Figure 6e, respectively.

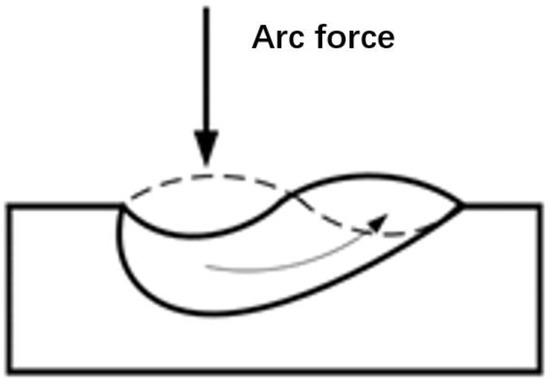

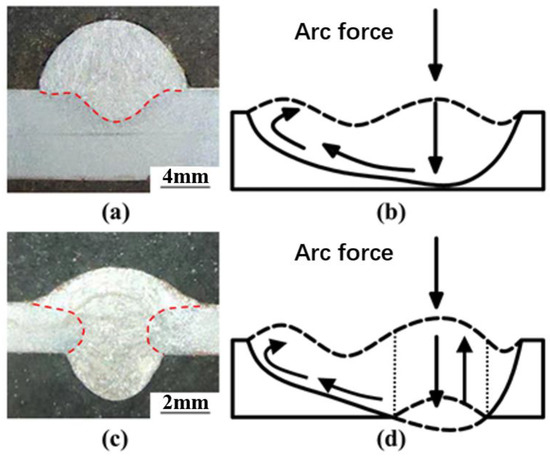

Under mobile welding conditions, the GTAW weld pool is prolonged in the length direction, causing asymmetrical back and forth “sloshing” on the free surface of the weld pool [14], as shown in Figure 7. The oscillation phenomenon in the GMAW welding process was similar to that of the GTAW. The front part of the weld pool in the S-GMAW welding process was subjected to the “surface impact” from the electric explosion, and the whole weld pool oscillated in a swaying mode. The difference in weld pool oscillation modes and boundary conditions between the partially penetrated and fully penetrated weld pool is shown in Figure 8. Figure 8a,c are the cross-sections of the incomplete penetration weld and the full penetration weld, respectively, Figure 8b,d are the corresponding oscillation mode, respectively. In a fully penetrated weld pool, where the front of the weld pool bottom is fully penetrated, the oscillation phenomenon is similar to that of a partially penetrated weld pool. However, the freedom of oscillation in a fully penetrated weld pool increases, and the liquid above the penetration point can move vertically. This results in a greater amplitude for the oscillations, making the fully penetrated weld pool more susceptible to high-amplitude oscillations. This phenomenon also appears in the oscillation phenomenon of the GTAW weld pool [6,14].

Figure 7.

The weld pool oscillation mode [11].

Figure 8.

(a) Partial penetration weld cross section; (b) Partial penetration weld pool oscillation mode; (c) Full penetration weld cross section; (d) Full penetration weld pool oscillation mode.

The above research results show that the oscillation mode of the GMAW short-circuit transition weld pool can be analogous to the oscillation mode of the GTAW weld pool. Shi Y analyzed the relationship between the oscillation frequency and the size of the GTAW weld pool [14], as shown in Equation (6):

where, h is the depth of the weld pool, and the relationship between wavelength (λ) and wavenumber (K) is K = 2π/λ.

The wavenumber (K) of the partially penetrated weld pool can be solved by the First Kind Bessel function equation (Jm) [14], as shown in Equation (7):

In Equation (6), Rpool is the equivalent radius of weld pool.

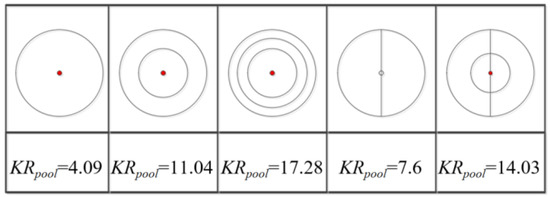

The solution of under different oscillation modes of the weld pool is shown in Figure 9 [15].

Figure 9.

Solutions of Bessel Functions with different oscillation modes [15].

According to Figure 2 and Figure 5, the oscillation mode corresponding to the partially penetrated weld pool in S-GMAW is shown on the right side of Figure 8, KRpool = 14.03, and Equation (6) can be evolved into Equation (8):

where, B is the equivalent diameter of weld pool, B = (W × L)0.5, W is the pool width, and L is the pool length.

It can be found from Figure 2 and Figure 5 that there is no significant difference between the oscillation modes of the weld pool with different penetration states. Xiao [6] proved that the weld pools oscillation phenomenon with different penetration state were similar when the ratio of the equivalent diameter of the bottom to the top is less than 0.5 in a fully penetrated weld pool. In S-GMAW, the ratio between the bottom diameter and the top surface of the full penetration part is less than 0.5, so, Equation (7) can be used to describe the frequency characteristics of both the fully and partially penetrated weld pool oscillation phenomenons.

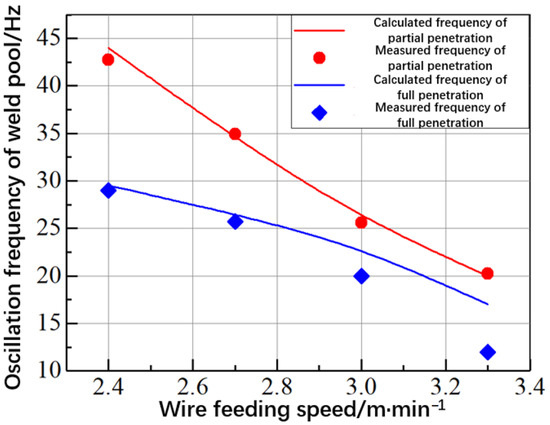

In order to verify the accuracy of Equation (7), the base plates with 2 mm and 4 mm are used to prepare the welds with fully and partially penetrated states. The calculated oscillation frequency is compared with the actual measured oscillation frequency of the weld pool, as shown in Figure 10.

Figure 10.

Calculation and measured frequency of weld pool oscillating phenomenon in S-GMAW.

It can be found from Figure 10 that the actual oscillation frequency of the weld pool with different penetration states under different wire feeding speeds is close to the calculated result of Equation (7).

However, the deviation between the measured value and the calculated value of the full penetration weld pool is significantly higher than that of the partial penetration weld pool. When the wire feeding speed is 3.3 m/min, the deviation is significant. The increase in wire feeding speed caused the width of the full penetration part at the bottom of the weld pool to increase, and the free oscillation area expanded, which, in turn, affected the oscillation process of the weld pool, resulting in deviations.

3.3. Effect of Weld Pool Oscillation on the Welding Voltage Signal

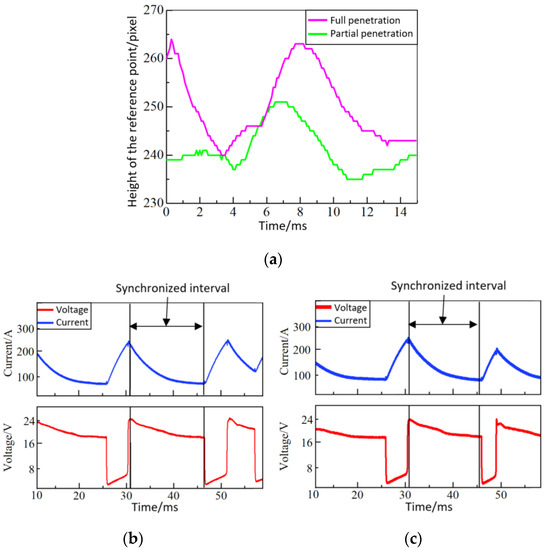

The oscillation phenomenon of the weld pool causes the fluctuation of the distance between the welding wire and the weld pool surface, which, in turn, changes the arc length. The voltage signal of the GTAW process can reflect the dynamic change process of the arc length caused by the oscillation of the weld pool in real time; then, it can realize the sensing of the penetration state of the weld [1]. For the S-GMAW welding process, the droplet transfer process complexes the relationship between arc length and voltage in the welding process. The previous article has proved that the change of the weld pool penetration state could change the oscillation mode and amplitude of the weld pool [8]. Therefore, the internal relationship between the oscillation phenomenon of the weld pool and the arc stage voltage of the welding process is the base of the research on the sensing method of the penetration state of the weld pool in S-GMAW. Figure 11 shows the weld pool surface height change process and the synchronous electrical signal in both full and partial penetration states. Although the oscillation amplitude of the full penetration weld pool is twice that of the partial penetration state, both the synchronous voltage signals were similar, as shown in Figure 11b,c.

Figure 11.

The height change process of the reference point on the weld pool surface and the synchronized welding electrical signal: (a) The height change process of the reference point on the weld pool surface with different penetration state; (b) The synchronized welding electrical signal of fully penetrated weld pool; (c) The synchronized welding electrical signal of partially penetrated weld pool.

The electric explosion of the S-GMAW welding process increased the density of metal vapor in the arc space and increased the conductivity of the arc column area, weakening the influence of the molten pool oscillation phenomenon on the arc voltage. The large amplitude of current change in the arc phase further concealed the voltage fluctuations caused by the oscillation phenomenon of the weld pool. Therefore, the voltage signal in the arc phase of the S-GMAW welding process cannot respond to the oscillation process of the weld pool.

4. Conclusions

This study investigates the characteristics of weld pool oscillation in traveling S-GMAW. On the basis of the experimental results obtained, the following conclusions can be drawn:

(1) The oscillation amplitude of the full penetration weld pool is significantly higher than that of the partial penetration weld pool with the same parameter;

(2) In S-GMAW (Superimposed Gas Metal Arc Welding), the weld pool experiences a “surface impact”, due to electric explosion. The oscillations of the weld pool exhibit stable frequency characteristics that decrease as the volume of the weld pool increases, regardless of whether it is fully or partially penetrated;

(3) No significant difference can be found in welding voltage signal between full penetration state and partial penetration state in S-GMAW.

Author Contributions

Conceptualization, H.Q.; methodology, H.Q. and T.C.; software, H.Q.; validation, H.Q. and T.C.; formal analysis, H.Q.; investigation, H.Q.; resources, H.Q.; data curation, H.Q.; writing—original draft preparation, H.Q.; writing—review and editing, H.Q.; visualization, H.Q.; supervision, S.X.; project administration, S.X.; funding acquisition, S.X. All authors have read and agreed to the published version of the manuscript.

Funding

This work was funded by the National Natural Science Foundation of China (Funding number: 51675269).

Institutional Review Board Statement

The study did not require ethical approval.

Data Availability Statement

The data could be obtained from the corresponding author.

Acknowledgments

The authors sincerely acknowledge the financial supports by the National Natural Science Foundation of China (Grant No. 51675269).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Xiao, Y.H.; Ouden, G.D. Weld pool oscillation during GTA welding of mild steel. Weld. J. 1993, 8, 111–118. [Google Scholar]

- Kotecki, D.J. Mechanism of ripple formation during welding solidification. Weld. J. 1972, 51, 386–391. [Google Scholar]

- Renwick, R.J. Experimental Investigation of GTA Weld Pool Oscillations. Weld. J. 1983, 62, 25–30. [Google Scholar]

- Maruo, H.; Hirata, Y. Natural frequency and oscillation modes of weld pools. 1st Report: Weld pool oscillation in full penetration welding of thin plate. Weld. Int. 1993, 7, 614–619. [Google Scholar] [CrossRef]

- Jianbin, J.U.; Suga, Y.; Ogawa, K. Penetration Control by Monitoring Molten Pool Oscillation in TIG Arc Welding. Mater. Sci. 2002, 18, 362–366. [Google Scholar]

- Xiao, Y.H. Sensing of weld pool penetration during GTA welding. Weld. J. 1994, 34, 155–164. [Google Scholar]

- Wu, S.J. Observation and Analysis of Three-Dimensional Weld Pool Oscillation Dynamic phenomenons: A sensor was used to observe weld pool oscillation in three dimensions, and then the 3D data was used to analyze the oscillation phenomenons. Weld. J. 2017, 96, 143–153. [Google Scholar]

- Yudodibroto, M.; Hermans, M. Observations on Droplet and Arc Behaviour during Pulsed GMAW. Weld. World 2009, 53, 171–180. [Google Scholar] [CrossRef]

- Yoo, C.D. An Experimental Study on Sensitvity and Signal Characteristics of Welds Pool Oscillation. Trans. Jpn. Weld. Soc. 1993, 24, 54–62. [Google Scholar]

- Hermans, M.J.M.; Ouden, G.D. Process phenomenon and stability in short circuit gas metal arc welding. Weld. J. 1999, 78, 137–141. [Google Scholar]

- Lv, X.; Zhang, P.; Li, H. Analysis of weld pool vibration characteristics in pulsed metal inert welding. Trans. China Weld. Inst. 2017, 38, 1–4. [Google Scholar]

- Behroozi, F. Fluid viscosity and the attenuation of surface waves: A derivation based on conservation of energy. Eur. J. Phys. 2004, 25, 115. [Google Scholar] [CrossRef]

- Leng, J.L. Splash formation by spherical drops. J. Fluid Mech. 2001, 427, 73–105. [Google Scholar] [CrossRef]

- Shi, Y.; Zhang, G.; Ma, X.J.; Gu, Y.F.; Huang, J.K.; Fan, D. Laser-Vision-Based Measurement and Analysis of Weld Pool Oscillation Frequency in GTAW-P. Weld. J. 2015, 94, 176–187. [Google Scholar]

- Sen, M.; Mukherjee, M.; Singh, S.K. Effect of Double-Pulsed Gas Metal Arc Welding (DP-GMAW) Process Variables on Microstructural Constituents and Hardness of Low Carbon Steel Weld Deposits. J. Manuf. Process. 2017, 31, 424–439. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).