Abstract

Energy efficiency is one of the important indicators for the evaluation of green buildings, and it is also related to the sustainable development of the building industry and energy conservation. Using agricultural waste in concrete to produce biomass recycled aggregates can effectively utilize agricultural solid waste to develop new wall materials with economic and energy-efficient properties. In this study, industrial wastes such as ground, granulated blast-furnace slag (GGBS) and fly ash (FA) were used to replace cement as cementitious material and coconut shell (CC) as lightweight coarse aggregate (LWA) in lightweight concrete. The lightweight coconut shell aggregate concrete with a density of less than 1950 kg/m3 was used as structural concrete. The thermal conductivity of synthesized biomass recycled aggregate concrete (SBRAC) was about 0.47 W/mK, which is 217% and 19% lower than that of natural aggregate concrete (NAC) and crushed coconut shell aggregate concrete (CCSAC), respectively. With the same volume, the costs of SBRAC and CCSAC are 25.1% and 4.9% lower than that of NAC, respectively.

1. Introduction

Concrete, as the most widely used man-made building material in the world, is widely used in public buildings such as streets, gymnasiums, and civil buildings [1]. Concrete buildings consume a lot of energy in the process of construction and service periods, so, the use of energy-saving raw materials in construction to improve the energy efficiency of buildings is one of the key research directions for energy saving in concrete structures. More energy-efficient buildings can reduce the consumption of fossil fuels, thereby reducing the amount of greenhouse gases such as carbon dioxide emitted into the atmosphere. This is undoubtedly conducive to the realization of the goal of “carbon peak, carbon neutrality” in the context of global environmental protection [2,3,4]. The study of Mahlia [5] shows that an insulation material that can effectively reduce the construction cost and provide acceptable comfort to the occupants is very popular because it has the dual benefits of huge energy saving and cost saving and effectively reduces environmental emissions caused by the use of electricity. Considered to be one of the most promising sectors in the industrial sector, it is crucial to reduce heat loss in buildings by improving their thermal insulation properties, as this can lead to building energy savings and reduce greenhouse gas emissions, thereby reaching the sustainable development of the industry.

In addition, the use of industrial and agricultural waste in concrete construction will be an additional advantage. Solid waste accounts for more than 60% of the total global waste, of which the annual output of coconut exceeds 60 million t [6] and the output of coconut shell exceeds 9 million t. These agricultural solid wastes are not used, occupy a large amount of high-quality arable land, and cause water pollution and air pollution. Many researchers have conducted much work on the reuse of coconut shell waste, such as the use of coconut shell aggregates, coconut shell ash, etc. to develop sustainable building materials [7,8,9,10]. Using solid waste to replace natural aggregate can not only consume a large amount of solid waste but also reduce the mining of natural stone, protect the environment, and effectively reduce energy consumption. Ramesh [11] found that the compressive strength of concrete made of coconut shell and coconut shell ash instead of coarse aggregate and cement was satisfactory. It can effectively improve the thermal conductivity of concrete. Compared with natural aggregate concrete, its thermal conductivity is reduced by more than 60%. In addition, Ikponmwosa reported that, compared with traditional concrete structures, coconut shell coarse aggregate concrete can effectively reduce the apparent density of concrete, so it can be used as light concrete in many special fields. In addition, Ikponmwosa [12] found that the use of coconut shells to partially replace natural coarse aggregates can still be applied to building load-bearing members after being added to concrete. Compared with ordinary concrete, when the replacement rate of coconut shell coarse aggregate reaches 40%, the thermal conductivity of coconut shell coarse aggregate concrete decreases by more than 40% [13].

As a composite material, cement is still one of the indispensable materials in its production process [14]. Carbon dioxide (CO2), which is emitted in large quantities during cement production, is one of the main causes of global warming. Liu [15] introduced binders for concrete other than cement, which can produce a polymerization effect through the reaction between alkaline liquids and raw materials rich in silica and alumina, commonly referred to as “Geopolymers”. The use of geopolymer technology not only greatly reduces CO2 emissions from the cement industry but also effectively utilizes industrial solid wastes such as fly ash and blast furnace slag [16,17,18]. The components, such as alumina and calcium oxide, contained in blast furnace slag can undergo the depolymerization and repolymerization of sub-bonds in an alkaline environment to form calcium silicate hydrate and calcium aluminate hydrate gel with cementation. Experiments show that low-calcium fly ash is more suitable as a raw material for polymerization because the presence of a large amount of calcium may interfere with the polymerization process and eventually change the microscopic morphology of the polymer [19]. Islam [20] reported that when the ratio of calcium silicate to sodium hydroxide was 1.5:2.5, the geopolymer concrete under the cementitious material system of fly ash and granulated blast furnace slag (0.8:0.2) obtained a better compressive strength. Chowdhury [21] studied the effect of granulated blast furnace slag on the anti-carbonation performance of geopolymer concrete and found that the finer particle size of granulated blast furnace slag and higher concentration of sodium hydroxide can make the geopolymer concrete obtain better performance in carbonization resistance. The studies of Ustaoglu and Khan [22,23,24] showed that the use of industrial by-products to prepare geopolymer concrete can effectively reduce CO2 emissions from concrete compared to cement concrete and has a better carbon reduction potential.

Based on the above situation, the use of agricultural solid waste, coconut shells, to develop a biomass recycled coarse aggregate to replace natural aggregates in concrete production can not only improve the utilization rate of agricultural solid waste but also create more economic and environmental benefits. The focus of this study is to compare the thermal conductivity, engineering performance, and economic evaluation of coconut shell lightweight aggregate geopolymer concrete. It shows the difference in thermal conductivity compared with foam concrete and sintered bricks.

2. Materials and Methods

2.1. Materials

2.1.1. Cementitious Materials

The binders used in the test are fly ash (FA) and ground, granulated blast-furnace slag (GGBS). The properties conform to the Chinese national standard GB/T 1596-2005. Both FA and GGBS were produced by the Qingdao Iron and Steel Company, and the main performance indicators are shown in Table 1. The alkali activator solution used in this study was a mixture of Na2SiO3 solution and NaOH, with a mass ratio of 2.5:1. The molarity of NaOH solution was 8. The composition of the Na2SiO3 solution was as follows: 12.4% Na2O, 30.1% SiO2, and 57.5% water.

Table 1.

The technical indicators of FA and GGBS.

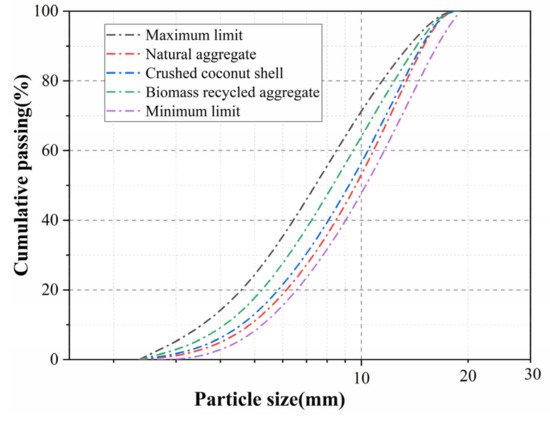

2.1.2. Crushed Coconut Shell

Under normal circumstances, the aggregate with a particle size exceeding 4.75 mm is called coarse aggregate. The thickness of natural coconut shell is generally in the range of 4.7–7 mm. The specification stipulates that the thickness of coarse aggregate for concrete is less than 0.4 times of the average particle size. It belongs to a flat partial, so the particles with a particle size larger than 13.2 mm are screened out. The diameter distribution interval of the crushed coconut shell particles after sieving treatment is shown in Figure 1, which conforms to the Chinese national standard GBT 14685-2011. Physical indicators such as the apparent density of the crushed coconut shell after treatment are shown in Table 2.

Figure 1.

Particle size distribution curve of coarse aggregate.

Table 2.

Physical index of crushed coconut shell.

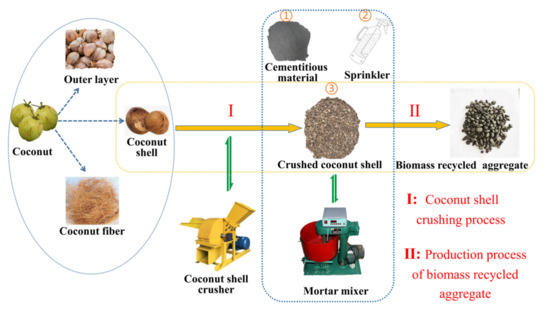

2.1.3. Synthesized Biomass Recycled Aggregates

The use of processed crushed coconut shells to make synthesized biomass recycled aggregates is an innovative attempt in this study. Before the test, the crushed coconut shell was soaked in water until it was saturated with water to ensure the volume stability of the coconut shell aggregate. In the test, continuous stirring with a mortar mixer, adding dry powder (GGBS:FA = 8:2) composite cementitious material, and adding mixed alkali solution were alternately performed. In order to ensure that the mixing solution was fully mixed with the gelling material, a sprayer was used to spray the alkaline solution. The results showed that the cement slurry can be better attached to the surface of the crushed coconut shell when the solution-to-binder ratio is about 0.25, and, finally, a synthesized recycled aggregate with a thickness of about 1.5 mm is formed. The treatment process is shown in Figure 2. The cementitious material system used in the synthesized biomass regenerated aggregate (SBRAC) is shown in Table 3. The treated aggregates were left standing for 24 h for hardening and shaping and then transferred to an environment with a temperature of 20 °C and a humidity of 95% for 30 days of curing. The particle size distribution of the synthesized biomass recycled coarse aggregate is shown in Figure 1, which conforms to the Chinese national standard GBT 14685. Figure 3 shows the processing process of the synthesized biomass regenerated aggregate and the state of the aggregate after hardening and molding, and Table 4 shows the apparent densities of different raw materials.

Figure 2.

Production process of synthesized biomass recycled aggregate.

Table 3.

The cementitious material system of synthetic biomass recycled aggregate (per cubic meter of synthesized biomass recycled aggregate).

Figure 3.

(a) Hardening and molding process of recycled coarse aggregate of synthesized biomass. (b) Synthesized biomass regenerated coarse aggregate.

Table 4.

Apparent density of different raw materials (kg/m3).

2.2. Mix Proportions

Three groups of concrete mixing methods were designed in the test, as shown in Table 5. Except for the difference in the types of recycled aggregates, the types and proportions of other concrete components remained unchanged. The purpose of the experimental study was to find out the differences in the effects of different types of concrete coarse aggregates on the engineering properties of concrete. The dosage of concrete mixing solution was determined according to the minimum slump of 160 mm specified in the Chinese national standard GBT 50080-2016.

Table 5.

Mix proportions of concretes.

2.3. Testing Methods

2.3.1. Thermal Conductivity

A heat flux meter (THB 110) manufactured by Lindsays was used to measure the heat flux of a 50 mm thick plate sample, and the heat flux was converted to the thermal conductivity of the concrete by Equation (1).

where ΔQ is the heat flow through the flat wall (W); ΔS is the area of concrete slab (m2); Δδ is the thickness of concrete slab (m); Δt is the temperature difference between the two sides of the concrete slab, (K); and λ is thermal conductivity. The smaller the value, the less heat passing through the material per unit thickness and the better the thermal insulation.

2.3.2. Self-Shrinkage of Concrete

According to the Chinese national standard GBT 50082, the self-shrinkage test of concrete specimens with the size of 100 × 100 × 515 mm was studied. The self-shrinkage performance of concrete is expressed by the self-shrinkage rate, as shown in Equation (2).

where Li is the self-shrinkage value of concrete specimen (mm); L is the length of the concrete specimen (mm).

2.3.3. Compressive Strength

According to the relevant regulations of Chinese national standard GBT 50081, the strengths of the 150 mm cube concrete specimen at the ages of 3 days, 7 days and 28 days were taken as the compressive strength values of concrete. After solidification, the concrete specimens were transferred to an environment of 20 ± 2 °C and 90 ± 5% relative humidity for curing.

3. Results

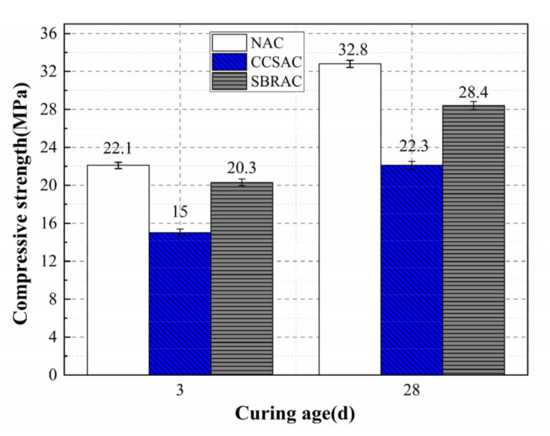

3.1. Compressive Strength and Density

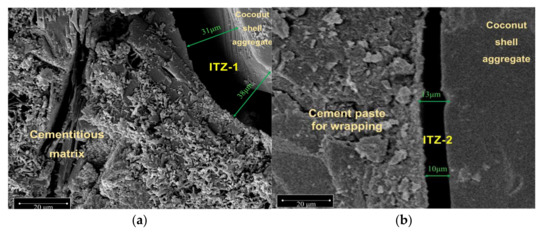

The compressive strength values of concrete with different coarse aggregates are shown in Figure 4. In 3 days, the compressive strength values of CCSAC and SBRAC reached 67.9% and 91.9% of the compressive strength of NAC, respectively; as the curing age reached 28 days, the concrete was 28 days old, and the compressive strength values of CCSAC and SBRAC reached 67.9% and 86.6% of the compressive strength of NAC, respectively. The transition area between the aggregate and the cement paste, that is, the so-called interface transition zone (ITZ), is one of the important indicators affecting the performance of concrete. The CCS has a high water absorption rate, and when it is directly added to the concrete, a micro “puddle” will be formed around the CCSA, making the thickness of the ITZ between the concrete cement material matrix and the crushed coconut shell more than 30 mm, as shown in Figure 5a. This phenomenon can be the main cause of deterioration inside the concrete, thereby greatly affecting the properties of the concrete [25,26,27]. The synthesized aggregate treated with cement slurry has no volatilization of moisture in the aggregate and good volume stability. After long-term curing, an “internal curing effect” [28,29], which favors the performance of the aggregate, reduces the thickness of the ITZ between the coconut shell aggregate and the outer cement slurry, as shown in Figure 5b.

Figure 4.

Compressive strength of concretes.

Figure 5.

(a) The ITZ between the cementitious matrix and coconut shell in CCSAC at age of 28 days. (b) The ITZ between the cement paste for wrapping and coconut shell in SBRAC at age of 28 days.

At the age of 3 days, the SBRAC only had a few aggregate failures on the compressive failure surface. The strength of the cement slurry matrix in the concrete was weak and failed first. At the age of 28 days, there were many aggregate failures and a situation where the SBRA broke due to shear failure. The reason for this phenomenon may be due to the increase in the strength of the cement paste matrix in the concrete [30].

The density values of concrete are shown in Table 6. The results show that the use of CCSA and SBRA to replace NA can effectively reduce the density of concrete. The density values of CCSAC and SBRAC are 1820 kg/m3 and 1945 kg/m3, respectively, which are lower than the 1950 kg/m3 specified for light aggregate concrete.

Table 6.

Apparent density of coarse aggregates.

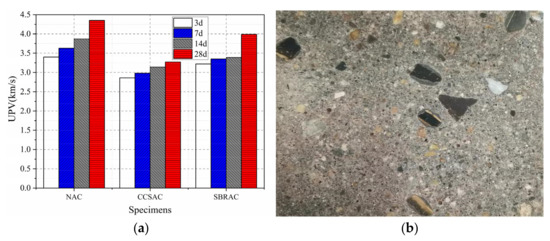

3.2. Ultrasonic Pulse Velocity Test

The UPV test method can be used to qualitatively evaluate the uniformity of the concrete structure. At the same time, it can be used to find the positions and depths of defects such as cracks in the concrete. The UPV test values of each group of concrete test blocks are shown in Figure 6. The test results show that the UPV value will gradually increase with the increase of concrete curing age. Karakurt [31,32] and other studies have shown that, with the increase of concrete curing age, the pores and cracks in the concrete gradually decrease, and the concrete density gradually increases, so that the UPV value increases. This trend is consistent with the change trend of the concrete compressive strength value. As shown in Figure 6b, compared with CCSAC, the UPV value of SBRAC is significantly improved, which may be due to the effective improvement of the interfacial transition zone (ITZ) formed by SBRA in the concrete, thereby improving the uniformity inside the concrete. At the same time, according to the experience of Karakurt [31], both RAC and SBRAC are considered excellent-quality concrete because the UPV value is higher than 4 km/s, while CCSAC is average-quality concrete because its UPV value is lower than 3.5 km/s.

Figure 6.

(a) Ultrasonic pulse velocity of Concretes (UPV) (b) Section of SBRAC.

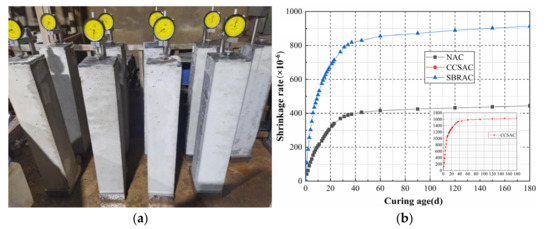

3.3. Self-Shrinkage Rate of Concretes

The self-shrinkage values of concrete with different types of coarse aggregates are shown in Figure 7. Compared with the crushed coconut shell aggregate concrete, the autogenous shrinkage of the synthesized biomass recycled aggregate concrete is effectively reduced. As shown in Table 7, the moisture inside the crushed coconut shell aggregate decreased significantly with the increase of the age of the concrete, and the internal moisture content decreased from 19.8% to 14.8% at the age of 28 days of the concrete, while the decrease rate reached 25.3%. The continuous loss of water may be the main reason for the large shrinkage of crushed coconut shell aggregate concrete. On the contrary, the moisture content of the synthesized biomass recycled aggregate wrapped with the attached cement paste is only about 3% at the age of 28 d. This is due to the attached mortar shell structure on the surface of the synthesized biomass regenerated aggregate, which can effectively maintain the volume stability of the coconut shell aggregate.

Figure 7.

Self−shrinkage rate of concretes. (a) The specimens of concrete self-shrinkage; (b) Self-shrinkage rate of concretes.

Table 7.

Water content of synthesized biomass recycled aggregates.

Compared with natural aggregate concrete, the self-shrinkage rate of synthesized biomass recycled aggregate concrete is relatively high, generally around 800 × 10−6, which is higher than 400 × 10−6 of NAC, which may hinder the synthesized biomass recycled aggregate. This is one of the potential pitfalls of applications in concrete.

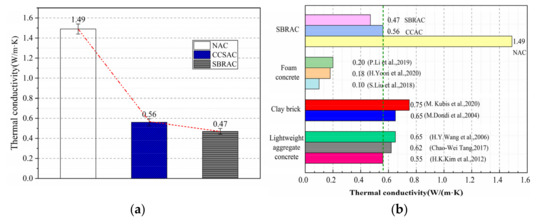

3.4. Thermal Conductivity of Concrete

Concrete structures used in residential buildings must not only ensure the safety of the structure but also take into account energy conservation. The use of concrete with low thermal conductivity during building construction is undoubtedly beneficial to building energy conservation. The thermal conductivity values of concrete are shown in Figure 8. Due to the different thermal conductivity of different materials, as shown in Figure 8a, the thermal conductivity of natural aggregate concrete is up to 1.49 W/mK. Secondly, the thermal conductivity of crushed coconut shell aggregate concrete is the lowest value of 0.56 W/mK. This is because crushed coconut shell is a porous biomass material, and it has a lower thermal conductivity value than natural aggregate. The thermal conductivity of SBRAC is 0.47 W/mK, which is because the cement slurry shell attached to the surface of the SBRA effectively converts the pores on the surface of the coconut shell into closed pores, thereby effectively reducing the thermal conductivity of SBRA.

Figure 8.

(a) Thermal conductivity of different types of concrete. (b) Comparison of thermal conductivity of different wall insulation materials.

Thermal conductivities of commonly used energy-saving materials are shown in Figure 8b. The thermal conductivity of lightweight aggregate concrete is generally in the range of 0.5–0.65 W/mK [23,33,34]. The thermal conductivity of clay bricks is generally 0.65–0.75 W/mK [35,36,37]. The thermal conductivity of foam concrete is generally in the 0.1–0.2 W/mK range [38,39]. The thermal conductivity of synthesized biomass recycled coarse aggregate concrete is lower than that of clay brick masonry structures and light aggregate concrete, which means that synthesized biomass recycled coarse aggregate concrete has a greater potential for building energy saving.

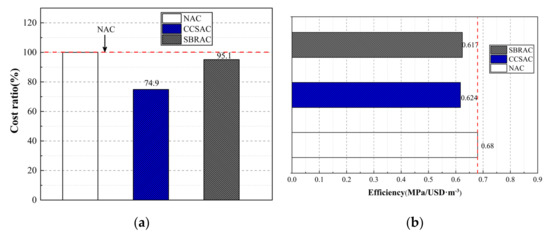

3.5. Economic Evaluation and Strength–Economic efficiency

The prices of raw materials for concrete are shown in Table 8, where the prices of various raw materials were collected from December 2021 in Hainan Province, China. Combined with the mix ratios of each series of concrete, the unilateral cost of concrete is calculated as shown in Table 9. Among them, as shown in Figure 9a, compared with NAC, the unilateral cost of concrete of CCSAC and SBRAC is reduced by 25.1% and 4.9%, respectively, which has an advantage in unilateral concrete cost.

Table 8.

Prices of raw materials for concrete (USD/t).

Table 9.

Cost of one cubic meter of concrete (USD/m3).

Figure 9.

(a) Cost ratio of concretes. (b) Compressive strength−economic efficiency.

The ratio of concrete at 28 d of compressive strength to unit cost is shown in Figure 9b. Compared with natural aggregate concrete (NAC), crushed coconut shell aggregate concrete (CCSAC). and synthesized biomass recycled aggregate concrete (SBRAC), the compressive strength–cost efficiency reached 0.624 MPa/USD·m−3 and 0.617 MPa/USD·m−3, respectively, which were close to 0.68 MPa/USD·m−3 of NAC. This indicates that the SBRA made from crushed coconut shell has a better cost advantage performance, and the compressive strength–cost efficiency values are comparable to that of NAC, which has great potential for application.

4. Conclusions

The purpose of this study was to study the preparation of SBRA from agricultural by-product coconut shell and to evaluate the mechanical properties, thermal conductivity, and economic performance of SBRAC. Based on the above research results, the following conclusions can be drawn:

1. When the water-to-binder ratio is about 0.25, the cement slurry can better adhere to the surface of the crushed coconut shell and finally form the SBRA, whose shape tends to be oval, and the aggregate gradation is good. The SBRAC prepared by mixing crushed coconut shell and cement slurry has good volume stability. The 3 days and 28 days compressive strength values of SBRAC reach 91.9% and 86.6% of NAC, respectively.

2. Compared with CCSAC, the attached mortar shell structure on the surface of SBRA effectively maintains the volume stability of coconut shell aggregate and reduces the self-shrinkage of concrete. However, compared with natural aggregate concrete, the self-shrinkage rate of synthesized biomass recycled aggregate concrete (NAC) is relatively high, generally around 800 × 10−6, which is higher than 400 × 10−6, that of NAC.

3. SBRA can effectively reduce the thermal conductivity of concrete, and the thermal conductivity of SBRAC is lower than that of wall materials such as ordinary concrete and clay bricks, which means that SBRAC has a greater potential for building energy savings.

4. Under the same volume, the cost of CCSAC and ABRAC reached 74.9% and 95.2% of that of RAC, respectively; and, at the age of 28 days, the compressive strength–cost ratio of CCSAC and ABRAC reached 93% and 92% of NAC, respectively, which indicates a cost-friendly concrete.

5. The use of SBRA to completely replace NA did not cause the significant attenuation of concrete performance, but the shrinkage performance and cost of SBRAC still have potential for further optimization, and how to effectively reduce the cost of use and improve the shrinkage performance are key factors in the application of SBRAC.

Author Contributions

Investigation, methodology, formal analysis, data course, and writing—original draft preparation, H.L.; project administration, conception, and funding acquisition, Q.L.; writing—review and editing and software, H.Q.; resources, visualization, X.X.; validation, Q.W.; writing—review and visualization, S.N. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China, grant number 52078261.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors gratefully acknowledge the financial support of Project Numbers 52078261 from the National Natural Science Foundation of China, Development and Application of Biomass Artificial Reef (20220035).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Biernacki, J.J.; Bullard, J.W.; Sant, G.; Brown, K.; Glasser, F.P.; Jones, S.; Ley, T.; Livingston, R.; Nicoleau, L.; Olek, J.; et al. Cements in the 21st century: Challenges, perspectives, and opportunities. J. Am. Ceram. Soc. 2017, 100, 2746–2773. [Google Scholar] [CrossRef] [PubMed]

- Ding, S.; Zhang, M.; Song, Y. Exploring China’s carbon emissions peak for different carbon tax scenarios. Energy Policy 2019, 129, 1245–1252. [Google Scholar] [CrossRef]

- Ma, M.; Ma, X.; Cai, W.; Cai, W. Low carbon roadmap of residential building sector in China: Historical mitigation and prospective peak. Appl. Energy 2020, 273, 115247. [Google Scholar] [CrossRef]

- Fang, K.; Tang, Y.; Zhang, Q.; Song, J.; Wen, Q.; Sun, H.; Ji, C.; Xu, A. Will China peak its energy-related carbon emissions by 2030? Lessons from 30 Chinese provinces. Appl. Energy 2019, 255, 113852. [Google Scholar] [CrossRef]

- Mahlia, T.M.I.; Taufiq, B.N.; Ismail; Masjuki, H.H. Correlation between thermal conductivity and the thickness of selected insulation materials for building wall. Energy Build. 2007, 39, 182–187. [Google Scholar] [CrossRef]

- Moreno, M.L.; Kuwornu, J.K.M.; Szabo, S. Overview and Constraints of the Coconut Supply Chain in the Philippines. Int. J. Fruit Sci. 2020, 20, S524–S541. [Google Scholar] [CrossRef]

- Bheel, N.; Mahro, S.K.; Adesina, A. Influence of coconut shell ash on workability, mechanical properties, and embodied carbon of concrete. Environ. Sci. Pollut. Res. 2021, 28, 5682–5692. [Google Scholar] [CrossRef]

- Palanisamy, M.; Kolandasamy, P.; Awoyera, P.; Gobinath, R.; Muthusamy, S.; Krishnasamy, T.R.; Viloria, A. Permeability properties of lightweight self-consolidating concrete made with coconut shell aggregate. J. Mater. Res. Technol. 2020, 9, 3547–3557. [Google Scholar] [CrossRef]

- Poonyakan, A.; Rachakornkij, M.; Wecharatana, M.; Smittakorn, W. Potential Use of Plastic Wastes for Low Thermal Conductivity Concrete. Materials 2018, 11, 1938. [Google Scholar] [CrossRef] [Green Version]

- Ismail, Z.Z.; Al-Hashmi, E.A. Use of waste plastic in concrete mixture as aggregate replacement. Waste Manag. 2008, 28, 2041–2047. [Google Scholar] [CrossRef]

- Ramesh Kumar, G.B.; Kesavan, V. Study of structural properties evaluation on coconut fiber ash mixed concrete. Mater. Today Proc. 2020, 22, 811–816. [Google Scholar] [CrossRef]

- Ikponmwosa, E.E.; Ehikhuenmen, S.; Emeshie, J.; Adesina, A. Performance of Coconut Shell Alkali-Activated Concrete: Experimental Investigation and Statistical Modelling. Silicon 2021, 13, 335–340. [Google Scholar] [CrossRef]

- Kanojia, A.; Jain, S.K. Performance of coconut shell as coarse aggregate in concrete. Constr. Build. Mater. 2017, 140, 150–156. [Google Scholar] [CrossRef]

- Mathew, S.P.; Nadir, Y.; Muhammed Arif, M. Experimental study of thermal properties of concrete with partial replacement of coarse aggregate by coconut shell. Mater. Today Proc. 2020, 27, 415–420. [Google Scholar] [CrossRef]

- Aïtci, P. Cements of Yesterday and Today: Concrete of Tomorrow; Elsevier Ltd.: New York, NY, USA, 2000; pp. 1349–1359. [Google Scholar]

- Gülşan, M.E.; Alzeebaree, R.; Rasheed, A.A.; Niş, A.; Kurtoğlu, A.E. Development of fly ash/slag based self-compacting geopolymer concrete using nano-silica and steel fiber. Constr. Build. Mater. 2019, 211, 271–283. [Google Scholar] [CrossRef]

- Liu, H.; Li, Q.; Ni, S.; Wang, L.; Yue, G.; Guo, Y. Effect of nano-silica dispersed at different temperatures on the properties of cement- based materials. J. Build. Eng. 2021, 46, 103750. [Google Scholar] [CrossRef]

- Zhang, P.; Gao, Z.; Wang, J.; Guo, J.; Hu, S.; Ling, Y. Properties of fresh and hardened fly ash/slag based geopolymer concrete: A review. J. Clean. Prod. 2020, 270, 122389. [Google Scholar] [CrossRef]

- Prusty, J.K.; Pradhan, B. Multi-response optimization using Taguchi-Grey relational analysis for composition of fly ash-ground granulated blast furnace slag based geopolymer concrete. Constr. Build. Mater. 2020, 241, 118049. [Google Scholar] [CrossRef]

- Islam, A.; Alengaram, U.J.; Jumaat, M.Z.; Bashar, I.I.; Kabir, S.M.A. Engineering properties and carbon footprint of ground granulated blast-furnace slag-palm oil fuel ash-based structural geopolymer concrete. Constr. Build. Mater. 2015, 101, 503–521. [Google Scholar] [CrossRef]

- Chowdhury, S.; Mohapatra, S.; Gaur, A.; Dwivedi, G.; Soni, A. Study of various properties of geopolymer concrete—A review. Mater. Today Proc. 2021, 46, 5687–5695. [Google Scholar] [CrossRef]

- Ustaoglu, A.; Kurtoglu, K.; Gencel, O.; Kocyigit, F. Impact of a low thermal conductive lightweight concrete in building: Energy and fuel performance evaluation for different climate region. J. Environ. Manag. 2020, 268, 110732. [Google Scholar] [CrossRef] [PubMed]

- Khan, M.Z.N.; Shaikh, F.U.A.; Hao, Y.; Hao, H. Synthesis of high strength ambient cured geopolymer composite by using low calcium fly ash. Constr. Build. Mater. 2016, 125, 809–820. [Google Scholar] [CrossRef]

- Zhan, B.J.; Xuan, D.X.; Poon, C.S.; Scrivener, K.L. Characterization of interfacial transition zone in concrete prepared with carbonated modeled recycled concrete aggregates. Cem. Concr. Res. 2020, 136, 106175. [Google Scholar] [CrossRef]

- Djerbi, A. Effect of recycled coarse aggregate on the new interfacial transition zone concrete. Constr. Build. Mater. 2018, 190, 1023–1033. [Google Scholar] [CrossRef]

- Gunasekaran, K.; Kumar, P.S.; Lakshmipathy, M. Mechanical and bond properties of coconut shell concrete. Constr. Build. Mater. 2011, 25, 92–98. [Google Scholar] [CrossRef]

- Abate, S.Y.; Song, K.; Song, J.; Lee, B.Y.; Kim, H. Internal curing effect of raw and carbonated recycled aggregate on the properties of high-strength slag-cement mortar. Constr. Build. Mater. 2018, 165, 64–71. [Google Scholar] [CrossRef]

- El-Hawary, M.; Al-Sulily, A. Internal curing of recycled aggregates concrete. J. Clean. Prod. 2020, 275, 122911. [Google Scholar] [CrossRef]

- Hossain, F.M.Z.; Shahjalal, M.; Islam, K.; Tiznobaik, M.; Alam, M.S. Mechanical properties of recycled aggregate concrete containing crumb rubber and polypropylene fiber. Constr. Build. Mater. 2019, 225, 983–996. [Google Scholar] [CrossRef]

- Karakurt, C.; Kurama, H.; Topçu, I.B. Utilization of natural zeolite in aerated concrete production. Cem. Concr. Compos. 2010, 32, 1–8. [Google Scholar] [CrossRef]

- Ghadami, N.; Gheibi, M.; Kian, Z.; Faramarz, M.G.; Naghedi, R.; Eftekhari, M.; Fathollahi-Fard, A.M.; Dulebenets, M.A.; Tian, G. Implementation of solar energy in smart cities using an integration of artificial neural network, photovoltaic system and classical Delphi methods. Sustain. Cities Soc. 2021, 74, 103149. [Google Scholar] [CrossRef]

- Tang, C. Effect of presoaking degree of lightweight aggregate on the properties of lightweight aggregate concrete. Comput. Concr. 2017, 19, 69–78. [Google Scholar] [CrossRef]

- Kim, H.K.; Jeon, J.H.; Lee, H.K. Workability, and mechanical, acoustic and thermal properties of lightweight aggregate concrete with a high volume of entrained air. Constr. Build. Mater. 2012, 29, 193–200. [Google Scholar] [CrossRef]

- Wang, H.Y.; Tsai, K.C. Engineering properties of lightweight aggregate concrete made from dredged silt. Cem. Concr. Compos. 2006, 28, 481–485. [Google Scholar] [CrossRef]

- Alghamdi, A.A.; Alharthi, H.A. Multiscale 3D finite-element modelling of the thermal conductivity of clay brick walls. Constr. Build. Mater. 2017, 157, 101418. [Google Scholar] [CrossRef]

- Kubiś, M.; Pietrak, K.; Cieślikiewicz, Ł.; Furmański, P.; Wasik, M.; Seredyński, M.; Wiśniewski, T.S.; Łapka, P. On the anisotropy of thermal conductivity in ceramic bricks. J. Build. Eng. 2020, 31, 101418. [Google Scholar] [CrossRef]

- Ramamurthy, K.; Nambiar, E.K.; Ranjani, G.I.S. A classification of studies on properties of foam concrete. Cem. Concr. Compos. 2009, 31, 388–396. [Google Scholar] [CrossRef]

- Li, P.; Wu, H.; Liu, Y.; Yang, J.; Fang, Z.; Lin, B. Preparation and optimization of ultra-light and thermal insulative aerogel foam concrete. Constr. Build. Mater. 2019, 205, 529–542. [Google Scholar] [CrossRef]

- Yoon, H.; Lim, T.; Jeong, S.; Yang, K. Thermal transfer and moisture resistances of nano-aerogel-embedded foam concrete. Constr. Build. Mater. 2020, 236, 117575. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).