Featured Application

This work suggests a stabilization technique for improving the engineering properties of problematic soils (i.e., very high plastic clays of low strength and high deformability) based on the combined effect of sand, lime, and polypropylene fibers. The proposed stabilization technique proved to be very effective, largely increasing the unconfined compressive strength and ductility of clay soils.

Abstract

Improving the mechanical properties of low-strength soils (e.g., high plasticity clays) is one of the main branches of geotechnical engineering. The adoption of stabilization techniques for ensuring that structures will be founded on an adequately strong soil base is a common practice. Stabilization techniques for clay soils may include inert materials (cohesionless soils), chemical substances (cement, lime, or industrial additives), or the use of randomly distributed fibers. While all of these additives are added to low-strength soils by mixing, the question remains whether an optimal combination of stabilization techniques can be achieved for maximizing soil strength. Besides, each one of these additives contributes to an increase in soil strength in a different manner (soil replacement, chemical bonding of soil particles, and soil reinforcement respectively), while, according to the literature, each technique has its limitations. The latter refers to a limited effect on strength improvement and a maximum possible percentage, beyond which an additive has an adverse effect on strength; it also refers to other factors, such as brittleness failure, material availability, overall cost, and environment-related issues. Hence, in the present study, the efficiency of improving the basic geotechnical properties of a very high plasticity clay (liquid limit ωl = 86%) with a coupled effect between dune sand, lime, and polypropylene (PP) fibers has been investigated. The samples prepared by combining the three aforementioned soil improvement techniques were compared in terms of plasticity, compaction characteristics, unconfined compressive strength (UCS), and California Bearing Ratio (CBR) index. The experimental results show that the combination of these additives may lead to a considerable improvement in the strength and ductility of soils, even with a small amount of lime additive. Also, it was observed that 20% of sand, 3.4% of lime and 0.9% of fibers (by wt%) offers the best performance in terms of strength improvement for the clay tested (i.e., 12.75 times improvement compared to the untreated clay).

1. Introduction

In recent years, Algeria has started a significant program of repair and construction of pavements, in line with the economic dynamics the country is experiencing. Often, these projects are materialized in areas with problematic soils. One of these soils is the clay of Sidi-Hadjeres in the M’sila region. This clay is characterized mainly by high sensitivity to moisture changes; this is a major problem, since the climate in this specific region of Algeria is arid, with hot and dry summers and cold and rainy winters. When such clay is subjected to wet-dry cycles (due to weather or human activities), structures (such as roads) experience serious damages due to excessive or differential settlements, as well as due to the catastrophic action of heave.

Randomly distributed fibers are frequently used in ground improvement in light of their benefits (availability, simplicity of mixing with soils, and their contribution to reducing weak planes) [1,2,3,4]. Although fiber-reinforced clays exhibited higher stiffness and ductility than raw clay due to their increased energy absorption potential [5], polypropylene and basalt fibers when used alone have a limited effect on strength improvement [6], while Yadav et al. [7] observed an adverse effect of waste fibers (rubber) on the peak strength of soils; Yadav et al. also highlighted that with increasing fiber content, the ductility increases, while the swelling pressure decreases.

In practice, the engineering properties of cohesive soils can be improved by incorporating non-expansive soils [8] or using chemicals, such as cement, lime, or other industrial additives, to neutralize the deformable character of the clay. Non-expansive soils contribute to a reduction in the deformability of clay minerals by reducing their plasticity, but their effect on strength is rather limited. For example, in the study of Amri et al. [8], when clayey soil was mixed with dune sand (with 40% replacement), the UCS increased by 30% (from 161 to 209 kPa), while the plasticity index decreased by 18% (from 41% to 23%).

On the other hand, the improvement in strength with lime (chemical stabilization) is more remarkable; in this respect, Hussain and Dhar [9,10] indicated that the strength of clay tripled with the addition of 5% of lime, while the ductility decreased. However, despite the improvement in strength, lime-stabilized clays were characterized by brittle failure causing cracks in pavement layers [11]. The mechanism of strength development for lime-stabilized clay can be explained by the calcium ions (Ca+2) resulting from the lime (quick lime (CaO) or hydrated lime (Ca(OH)2) reacting with the silica and alumina of clay to form stronger bonds of calcium aluminate hydrates (CAH) and calcium silicate hydrates (CSH) related to the soil particles. These processes are commonly defined in the literature by cation exchanges, agglomeration, and flocculation phenomena [12].

More recently, there has been an increased interest in using more than one of these additives for soil stabilization simultaneously to reduce the limitation of each one when used alone. In this respect, Goufi et al. [13] used dune sand along with lime to stabilize a very expansive clay, reporting that the plasticity of clay decreased significantly when these additives were associated. Further, the same authors reported a significant improvement in strength and indicated that the clay treated with both lime and sand exhibits a brittle failure. Similarly, Boz et al. [6], used 6 mm-long polypropylene (PP) fibers and lime simultaneously to enhance the strength of kaolin (liquid limit ωl = 52% and plasticity index PI = 26%). Relatively, when kaolin was mixed with 1% polypropylene fibers (no lime added), the peak UCS increased after 28 days of curing from 97 to 150 kPa, while the UCS reached 400 kPa when 9% of lime was added to the previous kaolin-fiber mixture (again after 28 days of curing). Also, the authors reported that fibers created some gaps and that the fibers were insufficiently adhered with soil particles in the first case (no lime); however, for clays stabilized simultaneously with lime and fibers, a more rigid soil structure were obtained.

2. Research Significance

From examining the literature, it can be observed that most experimental studies on the topic of fiber reinforced soils have been conducted on granular or low plasticity, fine-grained soils [14,15,16,17]. However, the fiber-sand contact mechanism differs greatly from the respective fiber-clay mechanism. The first is purely frictional, while in the second, in addition to friction, the contact mechanism involves adhesion, thus the latter is stronger for high plasticity clays, although the mechanism has not yet been fully understood [14]. Furthermore, previous works indicate a rather limited effect of sand addition on the strength of clay. However, the presence of lime significantly improves the strength but decreases the ductility of clay [11,13].

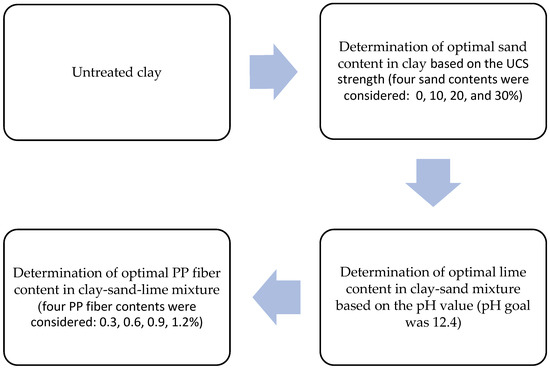

The present study aims to investigate the potential beneficial effect of the use of PP fibers along with lime and sand to enhance the engineering properties of a typical problematic soil and, in particular, to remove the restrictions associated with the use of a single additive (the limited increase in strength and the drop of ductility for the case of sand and lime, respectively). The experimental procedure presented herein consists of the following successive steps: optimizing the sand content based on the UCS test results, determining lime demand for the clay-sand mixtures based on the pH value, increasing the fiber content progressively in the mixture from 0 to 1.2 wt% (at 0.3% intervals) to quantify its effect on the fundamental geotechnical properties of clay.

3. Materials and Methods

3.1. Materials

The clay used in the present study was collected from the Sidi-Hadjeres region in M’sila, Algeria. The physical and mechanical properties of this soil are shown in Table 1, whilst its chemical composition is described in Table 2. This soil is a montmorillonite clay, which according to USCS classification system, it is classified as high plastic clay; further, it is characterized by very high swelling potential according to the different criteria used to identify expansive soils [18,19,20].

Table 1.

Properties of clay used.

Table 2.

Chemical composition of clay.

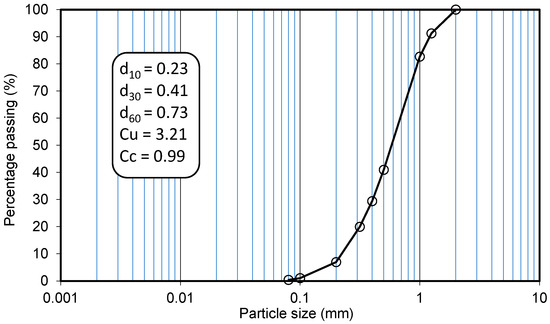

Siliceous dune sand collected from Oued-Souf, Algeria, with a specific density of 2.65 and sand equivalent of 86% was used as inert stabilizer. As per USCS classification, it is considered to be a clean, poorly-graded sand (SP), (See Figure 1).

Figure 1.

Particle size distribution curve of the sand used.

Quick lime provided from Lime-Saida factory in Algeria was used as a treatment agent. Its physical and chemical properties are given in Table 3.

Table 3.

Properties of clay used.

PP fibers (locally available) were used as reinforcement elements. The technical characteristics of these fibers are given in Table 4 (the values were obtained from technical data sheets).

Table 4.

Characteristics of PP fibers used.

3.2. Methods

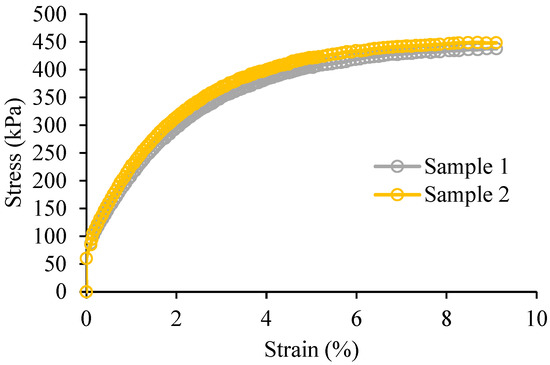

Fiber-reinforced soil samples can be prepared in the laboratory in both dry and wet states and placed by pouring or pluviation [21]. However, the latter is more appropriate for cohesionless dry soils [3]. For producing samples, oven-dried and crushed clay was first mixed with sand in the desired proportion. Then, PP fibers were gradually added to the mixture. The mixture was rigorously mixed until homogeneity, thereby reducing the dispersion of results. Repeatability tests have been conducted on clay-fiber mixes for different fiber concentrations to control the effectiveness of the mixing procedures adopted. For example, the typical responses of fiber-reinforced samples with a fiber concentration of 0.6% are shown in Figure 2, which indicates similar behavior in terms of curvature and UCS (the relative variation of UCS between the two tests was less than 3%).

Figure 2.

Repeatability tests for fiber-reinforced clays (0.6% PP fiber content).

3.3. Standards Used

The maximum dry density (MDD), and the optimum moisture content (OMC) were determined for raw clay, clay-sand, and fiber-reinforced clay (with and without lime) as per the ASTM D698 (2012) standard [22]. Plasticity characteristics (liquid limit, plasticity limit, plasticity index) were evaluated as per the ASTM D4318 standard [23]. UCS tests were performed according to the ASTM D2166 [24] standard on cylindrical specimens (5 cm in diameter and 10 cm in height).

4. Results

4.1. Optimizing Sand and Lime Contents

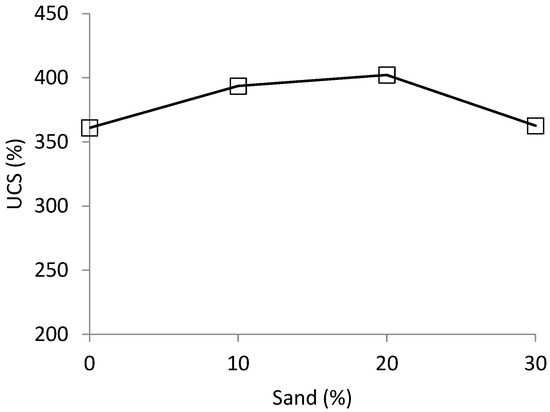

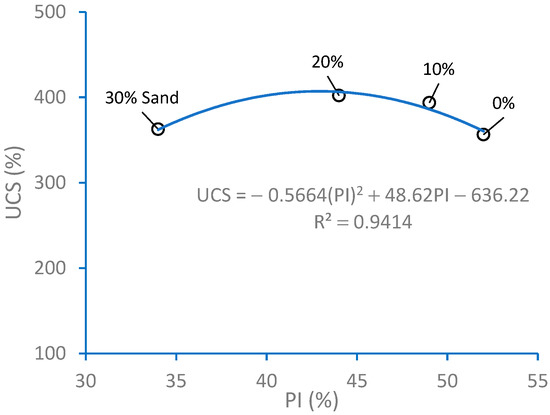

To optimize additives content for clay improvement, the procedure followed in this investigation is shown in Figure 3. Accordingly, the first step was optimizing the sand content based on the peak UCS strength. Four sand contents were used (0, 10, 20, and 30%) while the results of the UCS are shown in Figure 4. As shown, the optimal sand content was 20%, where the strength of raw clay was increased from 361 kPa to 402 kPa. This behavior may be explained by the fact to that the sand contributes to the rigidity of the mixture, but further addition reduces the beneficial action of cohesion of clay on the UCS; as shown in Table 5, the plasticity index has a larger fall beyond the optimal point. These findings indicate a limited effect of sand on improving the strength of clay soils and confirm that increasing the strength of clay soil by reducing its plasticity is an insufficient practice that is valid only for soils with sand contents up to 20% (additional quantities of sand has an adverse effect on strength). This is also shown in the UCS–PI chart in Figure 5, where R2 = 0.94. Rationally thinking, this loss in strength due to the reduction of cohesion (and thus, the reduction in bonding between soil particles) can be replaced by chemical (lime) or mechanical (PP fibers) strengthening.

Figure 3.

Flow chart of the procedure followed to optimize additives used.

Figure 4.

Effect of sand addition on UCS.

Table 5.

Plasticity characteristics for clay-sand mixes.

Figure 5.

Correlation between UCS and Plasticity index.

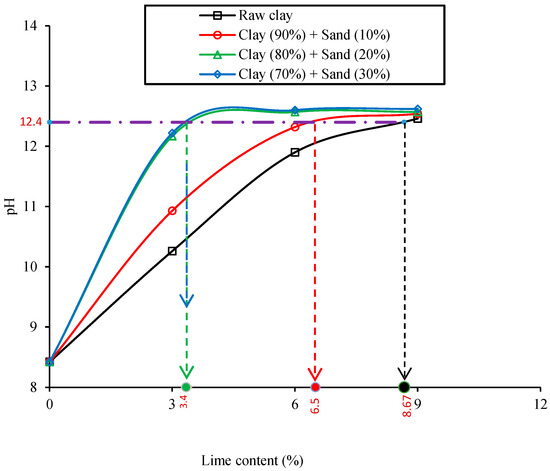

The second step was to determine the quantity of the alkali activator necessary to ensure the pozzolanic reactivity between clay minerals and Ca(OH)2 that was considered to be the lime fixation point; further addition of lime does not bring more changes in plasticity, as reported in the literature [12]. The lime demand was determined according to the Eads–Grim test [25]. Accordingly, the quantity of lime required to complete pozzolanic hydration products is that which elevated the pH value to 12.4. As shown in Figure 6, the results indicate that the lime demand for raw clay is equal to 8.4%, while when the clay is mixed with 10% and 20% sand, the lime demand decreases to 6.5% and 3.4%, respectively. However, lime demand remained unchanged for further increases in sand content. Thus, this finding corroborates that 20% sand is the optimal quantity that should be added to this specific clay.

Figure 6.

Determining lime demand.

4.2. Effect of Fibers on Compaction Characteristics

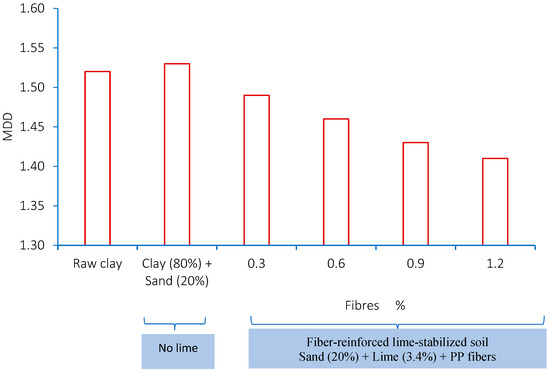

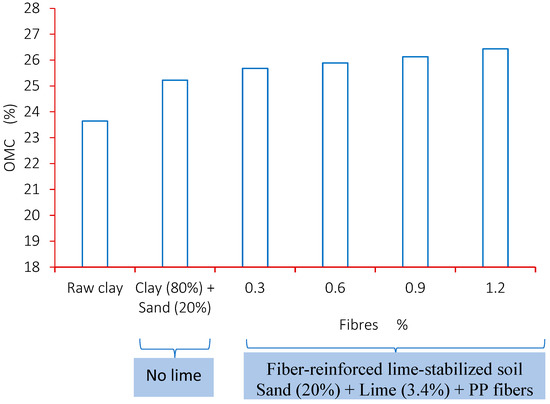

Figure 7 and Figure 8 show the variation of compaction characteristics for raw clay, lime-stabilized soil (unreinforced clay-sand mixture), and lime-stabilized-fiber-reinforced clay mixes with different fiber contents. As indicated, the MDD (Maximum Dry Density) of lime-treated-clay-sand mix decreases as the fiber content increases, which shows a proportionality between fiber content and MDD (all samples were compacted at identical compaction energies following the ASTM D698 [22] standard. For example, when adding 1.2% of fibers to the control mix, the MDD decreases by 7% in comparison to the unreinforced clay. The decrease in MDD for the reinforced samples is partially attributed to the difference in unit weight between fibers and soil. It is also attributed to the difficulty to achieve the same MDD in a reinforced (and thus, stronger) soil with the same compaction energy. However, the gain in strength provided by fiber addition compensates the reduction in density; MDD could be increased to a desired and feasible level by increasing the compaction energy.

Figure 7.

Maximum dry density (MDD) for different mixes.

Figure 8.

Optimum moisture content for different mixes.

It can also be observed that the MDD of the unreinforced clay-sand mix is slightly higher than the respective one of the raw clay. The replacement of a percentage of clay with sand modifies the soil structure and, as a result, the compactibility is improved, creating a denser medium.

Another observation is that the PP fibers did not induce a significant effect on the OMC due to their hydrophobic nature, whereas a substantial increase in OMC was observed due to the presence of lime in the mix. The latter consumes an additional quantity of water for humidification and chemical reactions.

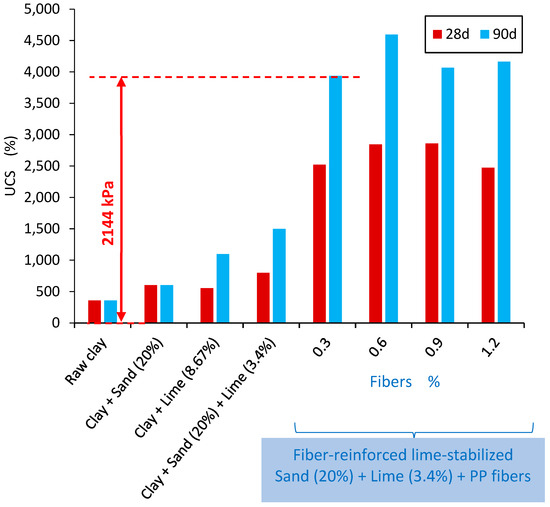

4.3. Effect of Fiber Content on UCS

The effect of fiber content on UCS is shown in Figure 9. Four fiber contents were considered: 0.3, 0.6, 0.9, and 1.2% (by wt%). Soil specimens were compacted at their respective optimum characteristics. Samples of untreated clay (unreinforced, non-stabilized) were compared against clay-sand mixtures (80% of clay and 20% of sand). The UCS tests were performed after 28 and 90 days of curing in laboratory conditions (24 ± 2 °C, 50 ± 2% RH). The results show that the UCS can significantly be increased when using sand, lime and fibers together in the proper proportions.

Figure 9.

Effect of different additives on UCS.

The UCS increased from 361 to 402 kPa for the clay samples treated with sand after 28 days of curing, indicating an improvement of just 11.7%. For the samples containing 20% sand, 3.34% lime and PP fibers, the strength increased to 800, 2523, 2842, 2860, and 2474 kPa for 0, 0.3, 0.6, 0.9, and 1.2% fiber contents, respectively. From the 28 to 90 days of curing, the strength continued to rise to even higher levels (see Figure 9); for example, for mixtures with a fiber content of 0.6%, the UCS was as high as 4593 kPa (12.76 times higher than that of the raw clay). There is no doubt that this remarkable increase in strength is attributed to the combined effect of the three different additives (lime, sand, and fibers) in the proper proportions.

The PP fibers in combination with the cementitious compounds formed by lime will cause a substantially increase in strength. The existence of fibers limits the relative displacements between the different ingredients, thus, improving interlocking, density and stiffness [17,26]. Furthermore, when a soil-fiber mass is loaded, the fibers with their tensile capacity receive part of the interparticle forces, creating a pseudo-cohesion which improves the interfacial mechanism [3].

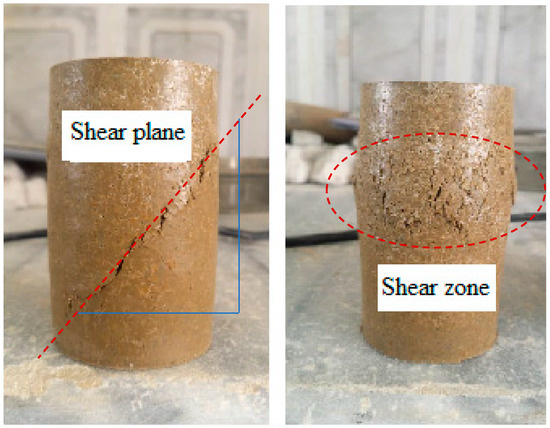

Figure 10 shows the failure mode of two soil samples that were stressed in the unconfined compression test apparatus, differing only in that the one is unreinforced, while the other had been reinforced with fibers. As shown, a shear plane inclined at an angle of approximately 45° is visible in the case of the unreinforced clay, whereas a shear zone exists in the case of the reinforced clay specimen. The latter is due to the bridging effect exerted by fibers, restricting the relative displacement between the two parts of the sample. In addition, deformation evolved slowly in the reinforced samples, thus declaring a more ductile behavior in comparison with plain clay.

Figure 10.

Failure mode of two soil samples differing only in reinforcement: unreinforced clay (left), clay reinforced with PP fibers (right).

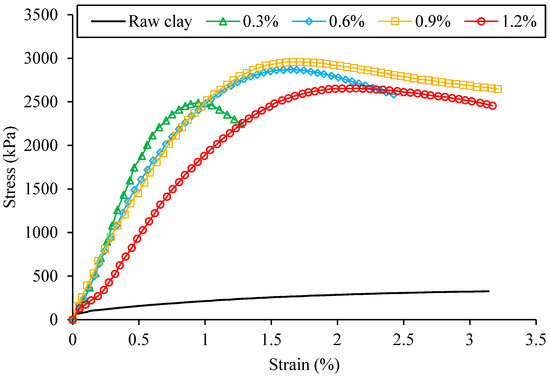

Figure 11 shows the stress-strain curves for the samples treated with sand, lime, and PP fibers (the latter at different percentages). For comparative purposes, the stress-strain curve for the untreated clay is also plotted on the same figure. As it can be seen, the effect of these additives is appreciable in terms of peak stress, strain at failure, and initial slope.

Figure 11.

Effect of fiber content on stress-strain curves (20% sand, 3.4% lime).

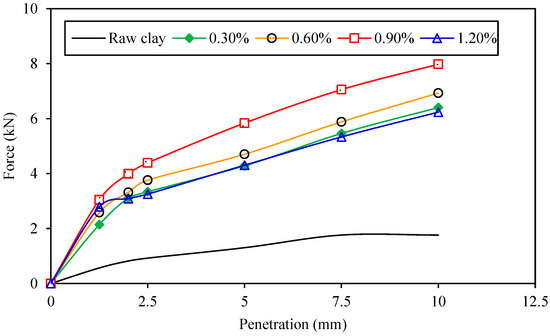

4.4. CBR Test Results

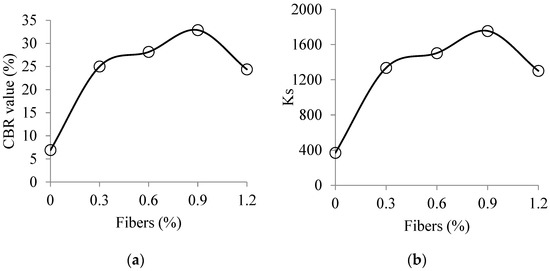

The CBR (California Bearing Ratio) test is a penetration test meant for the evaluation of the subgrade strength of roads and pavements. The relationship between the load created by a standard circular plunger with a 50 mm diameter (the CBR test apparatus) and the penetration depth of the plunger for both the reinforced and unreinforced samples are plotted in Figure 12. As can be seen, the load-penetration depth response is largely affected by the addition of fibers. The fiber-reinforced samples are more resistant to punching shear efforts, as compared to the unreinforced samples. The variation of the unsoaked CBR value for the samples reinforced with different percentages of fibers is shown in Figure 13a. It is evident from the curves that the CBR value has significantly been improved. For instance, the CBR value increased from 6.9 to 32.9 when 0.9% of fibers were added to the clay (i.e., a 377% improvement). The secant modulus (Ks) was also calculated from the stress-penetration depth curve for the various CBR tests. The variation of Ks with increasing fiber content is shown in Figure 13b. Similar to the CBR ratio, a significant improvement in Ks is observed by fiber addition.

Figure 12.

Load-penetration CBR curves for different fiber concentrations.

Figure 13.

Effect of fiber addition on CBR value (a) and Secant modulus (b).

5. Conclusions

This research aimed to improve the geotechnical properties of very high plasticity clay using three agents: sand, lime and PP fibers. The outcomes of this research can be summarized as follows:

- Sand as an additive reduces the plasticity of clay, but its effect on strength is limited (i.e., 10% improvement), while sand content should be limited to 20 wt% (for the clay tested), since further increases in sand content reduces the UCS strength. In addition, the use of sand reduces the demand in lime from 8.7% to 3.4% (i.e., 155% decrease).

- Adding PP fibers to lime-stabilized-clay-sand mixtures, results in a slight decrease in the MDD, due to the relative difference in density between fibers and soil; it is also difficult to achieve the same level of densification in the reinforced soil with the same compaction energy. In terms of OMC, it is observed that PP fibers have an insignificant effect; any such change observed was due to the presence of lime. The latter consumes water for its pozzolanic reactions.

- Using sand, lime, and PP fibers simultaneously significantly improves the UCS strength. For 0.6% of fiber addition, the UCS strength reached 2864 and 4593 kPa after 28 and 90 days of curing respectively (please compare with the 361 kPa of the untreated clay, which is 7.9 and 12.7 times lower respectively).

- An analogous improvement was observed in the CBR value and secant modulus for 0.9% of fiber addition in the lime-stabilized-clay-sand mixtures. Further addition of fibers results in a decrease of the CBR value.

The above findings clearly show that, the simultaneous use of sand, lime, and PP fibers is very advantageous in improving the engineering properties of very high plastic clays. In addition to that, using these additives together reduces the lime demand and corrects some other technical limitations commonly appear when using each one additive separately (brittleness, limited effect on strength).

Author Contributions

Conceptualization, A.M. and L.P.; methodology, A.M. and L.P.; validation, A.M. and L.P.; formal analysis, A.M. and L.P.; investigation, A.E.G.; resources, A.E.G.; data curation, A.M. and A.E.G.; writing—original draft preparation, A.M. and L.P.; writing—review and editing, A.M. and L.P.; visualization, A.M.; supervision, A.M. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data are available on request from the corresponding Author.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Botero, E.; Ossa, A.; Sherwell, G.; Ovando-Shelley, E. Stress-Strain Behavior of a Silty Soil Reinforced with Polyethylene Terephthalate (PET). Geotext. Geomembr. 2015, 43, 363–369. [Google Scholar] [CrossRef]

- Meddah, A.; Sahli, M.; Safer, S. Etude de l’effet de La Rugosité Des Renforcements Sur Le Comportement Des Massifs En Terre Armée. In Proceedings of the Journées d’étude de Génie Civil, M’Sila, Algeria, 25–26 November 2015; pp. 54–59. [Google Scholar]

- Meddah, A.; Merzoug, K. Feasibility of Using Rubber Waste Fibers as Reinforcements for Sandy Soils. Innov. Infrastruct. Solut. 2017, 2, 5. [Google Scholar] [CrossRef]

- Meddah, A.; Sahli, M. Pullout Behavior of Steel Reinforcements Used for Mechanically Stabilised Structures. Min. Sci. 2021, 28, 47–58. [Google Scholar] [CrossRef]

- Dhar, S.; Hussain, M. The Strength Behaviour of Lime-Stabilised Plastic Fibre-Reinforced Clayey Soil. Road Mater. Pavement Des. 2018, 20, 1757–1778. [Google Scholar] [CrossRef]

- Boz, A.; Sezer, A.; Özdemir, T.; Hızal, G.E.; Azdeniz Dolmacı, Ö. Mechanical Properties of Lime-Treated Clay Reinforced with Different Types of Randomly Distributed Fibers. Arab. J. Geosci. 2018, 11, 1–14. [Google Scholar] [CrossRef]

- Yadav, J.S.; Tiwari, S.K. Effect of Waste Rubber Fi Bres on the Geotechnical Properties of Clay Stabilized with Cement. Appl. Clay Sci. 2017, 149, 97–110. [Google Scholar] [CrossRef]

- Amri, S.; Akchiche, M.; Bennabi, A.; Hamzaoui, R. Geotechnical and Mineralogical Properties of Treated Clayey Soil with Dune Sand. J. Afr. Earth Sci. 2019, 152, 140–150. [Google Scholar] [CrossRef]

- Hussain, M.; Dhar, S. Influence of Lime and Fiber on Strength and Consolidation Characteristics of Expansive Soil. In Proceedings of the Geotechnics for Transportation Infrastructure, Singapore, 13 June 2019; Sundaram, R., Shahu, J.T., Havanagi, V., Eds.; Springer: Singapore, 2019; pp. 505–515. [Google Scholar]

- Dhar, S.; Hussain, M. The Strength and Microstructural Behavior of Lime Stabilized Subgrade Soil in Road Construction. Int. J. Geotech. Eng. 2019, 15, 471–483. [Google Scholar] [CrossRef]

- Abdi, M.R.; Ghalandarzadeh, A.; Shafiei Chafi, L. An Investigation into the Effects of Lime on Compressive and Shear Strength Characteristics of Fiber-Reinforced Clays. J. Rock Mech. Geotech. Eng. 2021, 13, 885–898. [Google Scholar] [CrossRef]

- Bell, F. Lime Stabilization of Clay Minerals and Soils. Eng. Geol. 1996, 42, 223–237. [Google Scholar] [CrossRef]

- Goufi, A.E.; Harichane, K.; Harichane, Z.; Ghrici, M.; Driss, A.A.E. Improvement of the Geotechnical Properties of a Clay–Sand Mixture Treated with Lime. Innov. Infrastruct. Solut. 2022, 7, 1–14. [Google Scholar] [CrossRef]

- Esmaeilpourshirvani, N.; Taghavighalesari, A. Transportation Geotechnics Improvement of the Engineering Behavior of Sand-Clay Mixtures Using Kenaf Fiber Reinforcement. Transp. Geotech. 2019, 19, 1–8. [Google Scholar] [CrossRef]

- Hamza, M.; Aziz, M.; Xiang, W.; Waqas, M.; Zhihong, Y.; Ali, M.; Dilawar, M.; Mohammed, A.; Ali, F.; Ullah, R.; et al. Strengthening of High Plastic Clays by Geotextile Reinforcement. Arab. J. Geosci. 2022, 15, 1–16. [Google Scholar] [CrossRef]

- Kulanthaivel, P.; Selvakumar, S.; Soundara, B.; Kayalvizhi, V.S.; Bhuvaneshwari, S. Combined Effect of Nano-Silica and Randomly Distributed Fibers on the Strength Behavior of Clay Soil. Nanotechnol. Environ. Eng. 2022, 7, 23–34. [Google Scholar] [CrossRef]

- Meddah, A.; Saadallah, S.; Nakache, M. Effects of Fibrous Rubberized Waste on the Geotechnical Properties of Clayey Soil. In Proceedings of the 1st International Conference on Innovative Academic Studies, Konya, Turkey, 10–13 September 2022. [Google Scholar]

- Seed, H.B.; Woodward, R.J.; Lundgren, R. Prediction of Swelling Potential for Compacted Clays. J. Soil Mech. Found. Div. 1962, 88, 53–87. [Google Scholar] [CrossRef]

- Dakshanamurthy, V.; Raman, V. A Simple Method of Identifying an Expansive Soil. Soils Found. 1973, 13, 97–104. [Google Scholar] [CrossRef]

- Ranganatham, B.V.; Satyanarayana, B. A Rational Method of Predicting Swelling Potential for Compacted Expansive Clays. In Proceedings of the Soil Mechanics and Foundation Engineering, Montreal, QC, Canada, 8–15 September 1965; pp. 92–96. [Google Scholar]

- Ibraim, E.; Diambra, A.; Russell, A.R.; Muir Wood, D. Assessment of Laboratory Sample Preparation for Fibre Reinforced Sands. Geotext. Geomembr. 2012, 34, 69–79. [Google Scholar] [CrossRef]

- ASTMD-698; Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Standard Effort (12,400 Ft-Lbf/Ft3 (600 KN-m/M3)). American Society for Testing and Materials: West Conshohocken, PA, USA, 2012.

- ASTMD4318-17; Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. ASTM Int.: West Conshohocken, PA, USA, 2017.

- ASTM-D2166; Standard Test Method for Unconfined Compressive Strength of Cohesive Soil. American Society for Testing and Materials: West Conshohocken, PA, USA, 2006.

- ASTMD6276-19; Standard Test Method for Using PH to Estimate the Soil-Lime Proportion Requirement for Soil Stabilization. American Society for Testing and Materials: West Conshohocken, PA, USA, 2019.

- Syed, M.; GuhaRay, A.; Goel, D. Strength Characterisation of Fiber Reinforced Expansive Subgrade Soil Stabilized with Alkali Activated Binder. Road Mater. Pavement Des. 2022, 23, 1037–1060. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).