Abstract

Topology Optimisation is a broad concept deemed to encapsulate different processes for computationally determining structural materials optimal layouts. Among such techniques, Discrete Optimisation has a consistent record in Civil and Structural Engineering. In contrast, the Optimisation of Continua recently emerged as a critical asset for fostering the employment of Additive Manufacturing, as one can observe in several other industrial fields. With the purpose of filling the need for a systematic review both on the Topology Optimisation recent applications in structural steel design and on its emerging advances that can be brought from other industrial fields, this article critically analyses scientific publications from the year 2015 to 2020. Over six hundred documents, including Research, Review and Conference articles, added to Research Projects and Patents, attained from different sources were found significant after eligibility verifications and therefore, herein depicted. The discussion focused on Topology Optimisation recent approaches, methods, and fields of application and deepened the analysis of structural steel design and design for Additive Manufacturing. Significant findings can be found in summarising the state-of-the-art in profuse tables, identifying the recent developments and research trends, as well as discussing the path for disseminating Topology Optimisation in steel construction.

1. Introduction

1.1. The Origins of Topology Optimisation

Notwithstanding historical perspectives, as discussed in [1,2], which root Structural Optimisation and Topology Optimisation (TO) at the very beginning of the classical theory of elasticity, it is usually well accepted that TO had its de facto surgency under the name of Optimal Layout Theory and denoted the ability to optimise not only the structural elements shape and size but also its layout. That dates back to successful attempts made by Prager [3,4] and Rozvany [5,6,7,8] from the early 1970s to late 1980s, to generalise the 1904s Michell theory for weight optimisation of thin bars (Figure 1a) [9,10], which is based on the Maxwell theorem for frames [11].

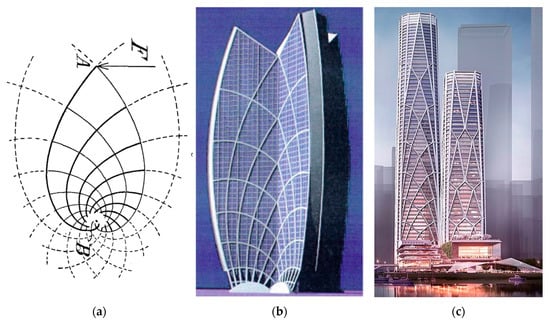

Figure 1.

(a) Original Michell’s minimum frame [9], (b) structural design by Zalewski and Zabłocki [105], and (c) CITIC financial centre in Shenzhen by SOM [105].

Almost simultaneously, Pedersen pioneered the optimal layout design for trusses [12]. In addition, Olhoff [13] managed to optimise Kirchoff equations solutions for finding the plates optimal thickness, leading to ribbed solutions of good value for the aerospace industry. Further developments were endeavoured by Rozvany and Olhoff, among others [14,15,16].

After these early developments and proven accomplishments in aerospace structures design, TO experienced rapid growth at the beginning of the 1990s as it became easily distinguishable from Shape or Size Optimisation concepts. The latter already well-disseminated the design practice required near-optimal initial topologies and would yield no better than intuitive final layouts, unlike TO [17,18].

Such revolutionary abilities justify the TO massification in several engineering disciplines throughout the product design and manufacture. The automotive industry soon followed the aerospace and applications widened to medical devices and personalised medicine, defence, electronics, several kinds of consumer goods and mechanical engineering endeavours, new materials design, and even arts and architecture. Civil and structural engineering may be latecomers after an auspicious start with truss optimisation investigations [12,19], but also show an accelerating trend in the TO application. Currently, the fourth industrial revolution and its reliance on Additive Manufacturing (AM) processes, on the opposition to standard subtractive processes, face significant challenges, as more advanced, scalable, and user-friendly design methods are required to unleash its incredible potential. TO is undoubtedly an adequate answer for such an enterprise. Its systematic use may overcome the knowledge barriers still moving many practitioners away from AM, as better described by Pradel et al. [20].

1.2. Topology Optimisation Modern Age

Formerly described developments were only made possible by the advances on the homogenisation method, by Bendsøe and Kikuchi in 1988 [21,22] and Suzuki and Kikuchi [23]. In simple terms, the homogenisation method is deemed to solve a material distribution problem, as previously formulated by Kohn and Strang [24,25,26,27], considering either only two states: The presence or the absence of the structural material. A more profound explanation and interesting example can be found in Bendsøe and Rozvany books [28,29].

The homogenisation method, along with Svanberg’s Method of Moving Asymptotes (MMA) [30], became the basis of most of the following applications, developments, and TO commercial software. However, in 1993, Xie and Steven [31] proposed the so-called Evolutionary Structural Optimisation (ESO) procedure as a possibility for simplifying TO computations by mimicking natural evolutionary processes in Finite Element Analyses (FEA). This led to significant criticism from many other researchers after some shortcomings were identified [32,33,34,35].

As the discussion proceeded on the ESO method, justifications were debated, and enhancements have been proposed [36,37,38,39,40]. However, the results of evolutionary methods continue to drive some intense discussions in Academia [41].

Fundamental studies on methods and approaches continued with the work by Duysinx and Bendsøe [42] on the continua TO under stress constraints, as well as in related numerical issues [32,43]. After these fundamental works, TO had a significant growth as a discipline, and the distinction between its two significant sub-fields, the Discrete Optimisation and the Optimisation of Continua became less evident. While the first of those two concepts is deemed to optimise a finite number of known elements and is preferred in several practical applications [44], the second unrestrictedly optimises topology within a solid.

Meanwhile, applications-focused research flourished, with optimisation early works being published in materials design [45], compliant mechanisms [46,47], electronics [48], connections positioning and design [49], buckling phenomena and truss design [50,51] [52], and alternative approaches for the ribbed plate problem [53].

The new millennium brought significant progress in TO algorithms but also in modelling and freely or cheaply accessible software, such as Sigmund’s MATLAB code [54,55] or the Karamba plug-in for the Grasshopper environment [56].

Discrete Optimisation had some essential developments, both with algorithms development [57] and practical applications [58,59]. The former depicts an interesting option for Discrete Optimisation in the automotive industry and a good “how-to” example. However, significant numerical problems can arise when node positioning is also considered an optimisable parameter [60].

Within the Optimisation of Continua, many valuable works could be highlighted. Yet, one cannot omit important developments in filters [61,62], projection methods [63,64], computational methods [65,66,67], as well as in the controversy evolutionary approach for continua [68]. Furthermore, practical methods, such as Coelho et al.’s useful model with global and local levels of intervention [69], as well as applications in form-finding [70], stiffened plates [71], and TO under load position uncertainty [72], proved the suitability of TO methods for industrial execution. In fact, all the former offer solutions and examples for managing essential aspects of the TO application to structural steel design.

Concomitantly, automotive research centres developed several in-house tools and approaches to introduce TO in industrial Computer-Aided Engineering (CAE). Some examples can be found by Nishigaki et al. [73], Shin et al. [74], Fredricson et al. [44], Aeri and Morrish [75], and Yao et al. [76].

For the TO applications to leverage AM, several notorious works were published from 2010 on. Brackett et al. [77] is an excellent starting point, as it addresses the TO mature approaches, including Solid Isotropic Microstructure (or Material) with Penalisation (SIMP) and Evolutionary Structural Optimisation (ESO), suitable for practical applications. However, much has evolved in the next 10 years, including the consolidation of other approaches, algorithms, and workflows. Therefore, Leary et al. [78] and Nguyen and Vignat [79] worked on design methods offering a good understanding of the theme.

Likewise, insights on AM technologies, as provided in [80,81] are much recommended for fully understanding the role of TO in the fourth industrial revolution.

1.3. Topology Optimisation in Civil and Structural Engineering

Within civil and structural engineering, significant TO applications can be found in several sub-fields. While Discrete Optimisation of truss-like structures is, probably, the most straightforward application—and, indeed, has some early and interesting applications such as the Structural Topology and Shape Annealing (STSA) approach to transmission towers by Shea and Smith [82], the Mixed-Integer Non-Linear Programming (MINLP) approach to industrial steel buildings structural cost optimisation complying with Eurocode 3 (EC3) by Kranvanja and Zula [83], the method for trusses optimisation by Torii et al. [84] or the employment of genetic algorithms by He and Wang [85]—there are some works on the TO of structural systems under seismic loads. Such could be regarded as a surprise, since the seismic design is undoubtedly more complex and demanding compared with static loading common cases but may be explained by the resourcefulness of TO addressing complex issues which, otherwise, would hardly be efficiently solved with analytical means. Among the aforementioned works, one can highlight the steel frames optimisation by Memari and Madhkhan [86], more recent studies of space structures under seismic loads with evolutionary approaches [87,88], a comparison of different soft computing algorithms by Liu and Li, taking infrastructures lifelines as the study object [89], as well as Sarkisian et al.’s well-known mastery for innovative solutions, materialised in the use of TO for meeting significant seismic, aesthetical, budgetary, and regulatory demands for a specific building [90].

The conceptual design of tall buildings gathered practitioners and researchers attention (as depicted in Figure 1b), leading to a more practical design process optimisation [91] or algorithms focused research [92]. Nevertheless, the systematic employment of TO for the conceptual design of tall buildings is particularly evident in the Skidmore, Owings, and Merill experience. As reported by Baker with other SOM engineers and academics [93,94,95,96,97], such solutions were developed for impactful projects and competitions (Figure 1c).

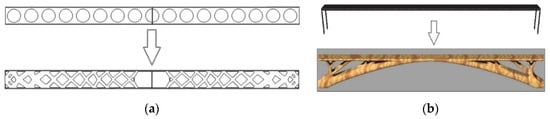

Steel sections and the connections design are two other sub-fields where TO has had an impact. Regarding the former, the Tsavdaridis group (Figure 2a) and Lagaros et al. research on steel beams with web openings [98], Yao et al.’s creative employment of evolutionary algorithms for pre-tensioned cable structures design [99], and Leng’s book chapter on cold-formed steel members [100] must be referred. Regarding the latter, it is important to stress out the contributions by Oinonen et al. [101] and Elsabbagh [102] on the bolted steel connections geometric optimisation and stiffeners optimisation, respectively.

Figure 2.

(a) From cellular to topology optimised beam [106] (reproduced under the Creative Commons Attribution 4.0 International License, http://creativecommons.org/licenses/by/4.0/ accessed on 25 February 2021) and (b) bridge topology optimisation from problem statement to optimal solution [104].

The bridge design, on the other hand, has had lesser attention from the TO point of view. Nevertheless, Zhang et al.’s work on bridge design accounting for construction constraints with ESO algorithms [103] and Xie et al.’s Bi-Directional Evolutionary Structural Optimisation (BESO) algorithms application to the bridge conceptual design (Figure 2b) [104] must be mentioned.

Beyond steel design but still within structural engineering, concrete TO has had some landmarks, including Lee et al.’s work on frame nodes [107], Briseghella et al.’s fresh look into the classical concrete shell supported bridge design [108], Gaynor et al.’s approach to TO for enhancing strut-and-tie models [109], and the use of TO by Chaves and Cunha [110] in the Carbon Fibre Reinforced Polymers (CFRP) reinforcement design for concrete slabs. Other civil engineering sub-fields for TO include the building’s thermal behaviour design [111].

1.4. Seminal Works and Systematic Reviews

Most of the former developments are well documented, explained, and exemplified in extensive and, mostly, user-friendly books. That is the case of Haftka and Gurdal’s Elements of Structural Optimisation [112] with several editions, the profusely cited Bendsøe and Sigmund’s “Topology Optimisation-Theory, Methods, and Applications” [113] and, more recently, with Arora, Rozvany, and Lewinski books [114,115] and Lewinski et al.’s book [105]. More specific works addressing computational methods [116] or buckling [117] in TO have also recently been made available.

Eschenauer and Olhoff [1] presented an extensive systematic review, encompassing the TO evolution from early structural optimisation to the fundamentals of TO, formulated in Michell structures [9], until the last century’s late developments. There, microstructure and macrostructure approaches have been described within a product design context, paving the way for the concepts and approaches developed in the new millennium. The latter include numerical methods such as SIMP, enclosed into the density approaches, and ESO, whose retrospective analysis can be found in another useful Review Article by Rozvany [35]. Moreover, such article is equally crucial for understanding the controversy around ESO (and BESO, its bi-directional development), with several authors referring to it as Sequential Element Rejections and Admissions (SERA) for not employing evolutionary processes nor yielding necessarily an optimal solution.

Before that, Hassani and Hinton [118,119] had summarised the basic concepts and criteria for the emerging TO.

Yet, the history of TO Review Articles is mostly made of sectorial perspectives. Among the first, one can find Fredricson’s [120] revision to TO in the automotive industry, focusing on the applications rather than on approaches or methods. Contrariwise, methods-driven reviews have been more frequent, and include assessments about ESO discrete approach developments [121] on Level-Set Methods (LSM or LS) [18]. Broader critical investigations of the former, added to the remaining density approaches, such as Rational Approximation of Material Properties (RAMP), Topological Derivatives (or the Bubble-Method), and Phase-Field Approach, as well as Lagrangian approaches [122,123] are also available.

Optimisation methods in AM have been a theme for a profusion of Review Articles along the last decade. While some assess manufacturing technologies and how optimisation methods can be accounted for in the process [124,125,126,127,128], others analysed the suitability of TO approaches for given AM endeavours, such as construction in Buchanan and Gardner [129], aerospace structures in Plocher and Panesar [130] or the automotive industry in Sehmi et al. [131]. Moreover, optimisation approaches impact the AM customised healthcare, environmental impact, supply chain efficiency, life-cycle analysis, hazards and energy consumption, which is part of Huang et al.’s review [132].

The same decade also brought landmark review articles on particular topics, including TO applications in vibration problems [133], fluid problems [134], and materials design [135]. However, recent reviews on TO-assisted structural engineering are the most meaningful for this article’s scope. Those include Kingman et al.’s [136] review on TO employment for perforated steel beams design and tall buildings conceptualisation, a review on buckling by Ferrari and Sigmund [137], Elhegazy’s [138] perspective on how TO is a critical part of Value Engineering (VE) and how it benefits the design and life of multi-story buildings, as well as a review by Li and Tsavdaridis on topology optimised and additively manufactured joints for steel structures [139].

Recent reviews on the use of metaheuristic algorithms in civil engineering, by Yang et al. [140] and Bekdaş et al. [141], do not neglect the genetic algorithms of TOs for bridges, roofs, frames, and trusses design.

1.5. Potential for Topology Optimisation and Additive Manufacturing in Construction

The asymmetry in size between the TO related literature in civil and structural engineering and many other fields made clear by the former brief historical overview, suggests that TO applications in construction are far from meeting its potential. Such a fact can only come as a surprise, given the sector size, with a yearly output of USD 10,800,000,000,000 as of 2017 [142], a tradition in analytical structural optimisation and an urgent need for weight reduction along with stiffness and resistance enhancement, as tools for leveraging the continuous race towards higher buildings, greater spans in bridges and roofs, more economic efficiency, and more ambitious sustainability goals.

Steel construction, deploying 450,000,000 to 815,000,000 tonnes [2,143,144] of structural steel per year worldwide pre-COVID-19 era, and with a market size over USD 100,000,000,000 in 2019 [145], is involved in a global effort to meet decarbonisation and energy efficiency goals, including the Paris Agreement pledge, European Green Deal objectives, and further commitments, such as the UN-backed carbon neutrality by 2050, to which most EU countries abide [146,147]. The path for achieving this is narrow and relies mostly upon employing less steel in constructions, while manufacturing a higher-end product, to more stringent sustainability demands. As a result, AM and, therefore, TO will be indispensable.

Apart from some slight oscillations due to technical details, it is commonly accepted that steelmaking consumes over 560 kg of Coal Equivalent [148] and produces an average of 1.85 carbon dioxide tonnes per tonne of structural steel [147]. Thus, reported weight reductions of 18% to 75% in steel connections [139,149,150,151], by employing TO, are expected to have a critical impact in steel construction goals.

Within steel design, connections detailing is one activity where the potential to optimise Topology is more significant. Connections usually account between 12% and 25% of most of the steel structure’s total weight and its conceptual design has a tremendous impact on its weight and efficiency, making it especially prone to TO.

1.6. Metrics for Research Output in Topology Optimisation

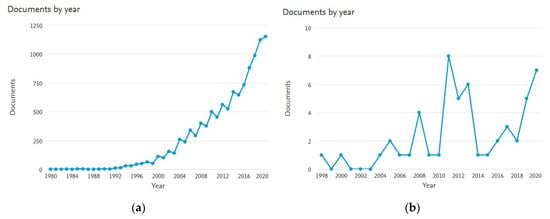

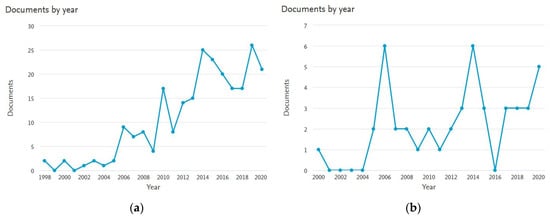

Performing a data analysis with the Scopus search tool (www.scopus.com) on 28 November 2020, it has been possible to observe that Topology Optimisation has been referred in scientific literature since the early 1980s, but not until the new millennium has the related scientific output been consistently increasing (Figure 3a). This fact can be related to the well-known recent computing power increase and massification, on which TO has a strong dependence. Furthermore, the ascendant trend has increased over the last 5 years, up to almost 1200 documents per year in 2020, during which more scientific and engineering disciplines have reportedly started employing TO more systematically. An interesting etymological approach lies in noticing an early word choice for Topological Optimisation over Topology Optimisation which, however, was not able to be employed in more than 10% of the analysed documents, over the recent years (Figure 4).

Figure 3.

Scopus search data analysis for (a) Topology Optimisation and (b) Topology Optimisation AND Civil Engineering, in Title, Keywords or Abstract in Research, Review, and Conference articles, on 28 November 2020.

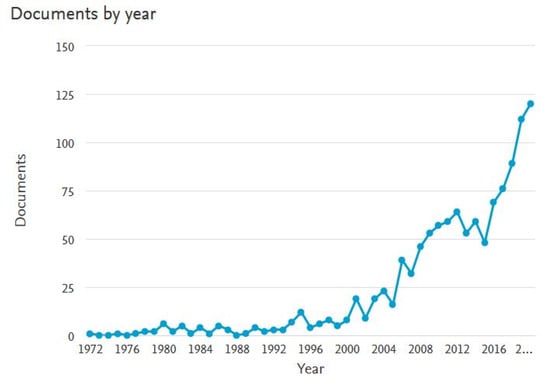

Figure 4.

Scopus search data analysis for Topological Optimisation in Title, Keywords or Abstract in Research, Review, and Conference articles, on 28 November 2020.

A different perspective is attained analysing the coexistence of TO and Civil Engineering (Figure 3b), Structures (Figure 5a), and Steel and Connections or Joints (Figure 5b) in articles title, keywords or abstract. Among these three, TO and Structures is the most common, even if under 2.5% of the total TO articles, and with a steady increasing trend. However, many Mechanical and Industrial Engineering documents use the keyword Structures. Furthermore, TO and Civil Engineering have been practically not coincident until 2010 and, from there, yield a rather inconstant volume of documents not exceeding 10 per year. A similar conclusion can be drawn for the use of TO and Steel Connections (or Joints), except for the fact that its modern employment seems to have started in 2005 and that it has not peaked above six documents per year. This suggests that the current TO massification as an advanced engineering design method has not yet been brought to Civil and Structural Engineering comprehensively.

Figure 5.

Scopus search data analysis for (a) Topology Optimisation AND Structures and (b) Topology Optimisation AND Steel AND Connections OR Joints, in Title, Keywords or Abstract in Research, Review, and Conference articles, on 28 November 2020.

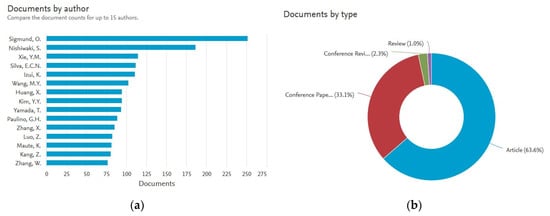

Figure 6a as well as Figure 7a,b offer a brief insight on the field leading players. As a result, we observe Sigmund, Nishiwaki, and Xie leading the list of most prolific authors. At the same time, the Dalian University of Technology, Danmarks Tekniske Universitet (DTU) and State Key Laboratory of Structural Analysis for Industrial Equipment are the most productive research centres. The National Natural Science Foundation of China is the primary funding agent for the research on this topic. It is well ahead of the US National Science Foundation and not matched by the remaining entities.

Figure 6.

Scopus search data analysis for Topology Optimisation in Title, Keywords or Abstract in Research, Review, and Conference articles without date or discipline constraints, on 28 November 2020, organised by (a) author and (b) document type.

Figure 7.

Scopus search data analysis for Topology Optimisation in Title, Keywords or Abstract in Research, Review, and Conference articles without date or discipline constraints, on 28 November 2020, organised by (a) research institution and (b) funding entity.

As depicted in Figure 6b, Research Articles account for almost two-thirds of the analysed documents, with Conference Articles making one-third and leaving Conference Reviews and Journal Review Articles with 2.3% and 1.0% of the literature volume, respectively. This suggests a need for systematic reviews on the topic so that the literature is consolidated as a whole and sectorial reviews help each research discipline adapt and incorporate recent advances in TO, which is being developed in other disciplines.

1.7. Scope of This Document

This work has been developed to systematise recent advances in the Topology Optimisation for structural steel design. It is focused on the 2015–2020 period, apart from this Introductory Section. It is organised with a dual approach, deemed to depict the relatively modest TO applications in the field in recent years, as well as to systematise significant developments in adjoining fields, which may be inspirational for structural steel design. As a result, it is not expected to collide with any recent Systematic Reviews on TO in other disciplines, while filling the void for a Revision focused on TO recent developments for structural steel design. Therefore, it is aimed to provide a valuable resource and encourage engineers and researchers to embrace TO in a more systematic and sustained manner for structural steel design.

The document structure includes a Methods Section after this Introduction, which will be followed by six sections depicting the literature investigation results, organised in TO fields, approaches, methods, criteria and software, TO in structural steel design, recent advances in other fields with potential for application in structural steel design, TO for AM, and future trends. Afterwards, the most important observations are discussed, and a brief on the attained conclusions is provided.

2. Methods

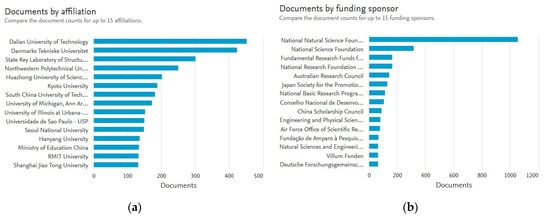

The literature research on Topology Optimisation was conducted between late November and early December 2020, encompassing Identification, Screening, Sorting, Eligibility Assessment, Information Extraction, Qualitative Synthesis, and Discussion Stages, as better depicted and systematised in Figure 8. While attending to this scientific field’s case-specificity, compliance with well-established guidelines for systematic reviews, such as in [152] was pursued. Inspiration was found in other recent Review Articles, such as in [153,154,155,156].

Figure 8.

Search and systematic review methodology.

Scientific literature has been searched with significant broadness. All published and peer-review items were considered, including Journal Research Articles, Conference Proceedings, Review Articles, Peer-reviewed Book Chapters, and Approved Master and Doctoral Theses. On the other hand, Technical Books, which are not necessarily peer-reviewed, were considered only for framing the research topic in the Introductory Section. Many notable books’ unavoidability supports such a decision for defining Topology Optimisation, including Bendsøe and Sigmund’s “Topology Optimisation: Theory, Methods, and Applications” [113] with 7301 citations according to Google Scholar as of 28 November 2020.

For a more in-depth insight into the current research, industry developments, and future trends, EU-funded research projects as well as European, US, and worldwide patents were also investigated.

The temporal scope for literature search has been set for the most recent 5 years (2015–2020), yet considering the Topology Optimisation novelty as a discipline (illustrated in Figure 3a), previous and very significant research items were investigated and considered for conceiving an explanatory Introduction.

An encompassing fabric of data sources was put together for this endeavour. Thus, Journal Articles and Conference Proceedings were redundantly searched in Mendeley Desktop, Scopus Online, Springer Online, Taylor and Francis Online, and Willey online search engines. Moreover, most active research groups repositories were also investigated, including the DTU TopOpt group, Loughborough University, and the University of Leeds. Several universities Theses repositories were searched. However, literature findings through reading articles was not negligible and added to the former. Patents were found in Google Patents, Espacenet, and USPTO search engines. Research Projects were found in the European Commission projects database, and books were searched using the ProQuest online tool. Table 1 quantifies the search dimensions.

Table 1.

Search dimensions.

A group of three basic keywords and 12 keyword strings were systematically used in all databases. The former included “Topology optimization”, “Design for Additive Manufacturing” and “Topological optimization”, while the latter are “Topology optimization” AND “Additive Manufacturing”, “Topology optimization” AND “Steel Design”, “Topology optimization” AND “Steel Detailing”, “Topology optimization” AND “Steel Structures”, “Topology optimization” AND “Structural Engineering”, “Topology optimization” AND “Connections”, “Topology optimization” AND “Construction”, “Topology optimization” AND “Joints”, “Topology optimization” AND “Review”, “Topology optimization” AND “Civil Engineering”, “Topology optimization” AND “Multiple Loading”, “Topology optimization” AND “Robustness”. These keywords and strings have been selected to match the articles’ Title, Keywords or Abstract, where such option is explicitly available, as it is the case of the Scopus search tool.

The screening criteria for removal included duplicate items, the mismatch between title and content, corrupted files, and the impossibility of accessing the document. Discarded items under the Sorting stage criteria comprised documents whose content do not adhere to any of the sub-themes previously defined as meaningful for this article scope, and better described in Section 3 to Section 8. The eligibility assessment was focused on the document content, excluding items without a particular relevance, without critical information, with any perceived methodological shortcoming or possible strong bias due to funding.

An effort has been endeavoured for performing inclusive research, avoiding the exclusion of less proficiently written articles and language bias. However, some articles written in Chinese and Japanese, for which machine translation was not successful, could not be included.

3. Topology Optimisation—One Concept, Various Fields

3.1. The Mathematical Concept of Topology

Topology, described as General Topology and Algebraic Topology under the Mathematics Subject Classification, studies objects’ properties which are subjected to continuous deformations [157,158,159]. Hence, a topological space (or domain), commonly referred to as a topology, maintains its properties, including dimension, compactness, and connectedness if undergone such deformations. Invariance within topological domains accrues in reversibility under continuous deformations or homomorphism, making this abstract concept crucial for the Topology Optimisation’s founding principles, as formulated by Maxwell and Michell.

3.2. Structural Optimisation and Topological Optimisation in the Context of Structural Steel Design

Structural Optimisation and Topological Optimisation concepts have been used with increasingly unrestrained freedom, even in Academia. Thus, it may be helpful to mention that the most rooted nomenclature employs Structural Optimisation as an umbrella for Topology Optimisation, on the one hand, and Shape and Size Optimisation, on the other hand [44,160]. In the context of Structural Steel Design, while seldomly, the use of Structural Topology Optimisation (STO) has been reported [139], referring to TO in this specific field.

Conceptually, Shape and/or Size Optimisation is easy to define, considering its scope, limited to variables as cross-sectional properties, member types and geometry, and rigidly constrained by predefined configurations. In simple terms, Topology cannot be changed and, therefore, this concept is deemed to improve an existing design, in which it very much depends on closeness to optimal.

Topology Optimisation, also named Layout Optimisation by some pioneers, bears the capacity for topological modification. In other words, it is unrestricted in its ability to create voids or add material in the design domain and act upon the structure’s connectivity. That said, it is relatively straightforward that TO contains and exceeds the Shape and Size Optimisation and therefore, fulfils all the possible Structural Optimisation scopes.

It should be highlighted that TO is not constrained to materially homogenous volumes. It may be employed as heterogeneous, including composite or microstructurally designed materials, but also in grid-like “ground structures”, made of one-dimensional elements.

In practical terms, differences are significant not so much between concepts, but mostly between applications and engineering fields. Concerning structural steel design, the Size, Shape, and Topology Optimisation can be graded into an intervention freedom continuous scale. The practical constraints and one-dimensional members design may limit optimisation to size and shape, even if the possibility for adding or suppressing members in a predefined configuration is available. The optimisation of continua, either in small volumes as joints or macro elements, as a building or bridge geometrical envelope, find a most suitable tool in TO.

3.3. Discrete Optimisation and Optimisation of Continua in the Context of Structural Steel Design

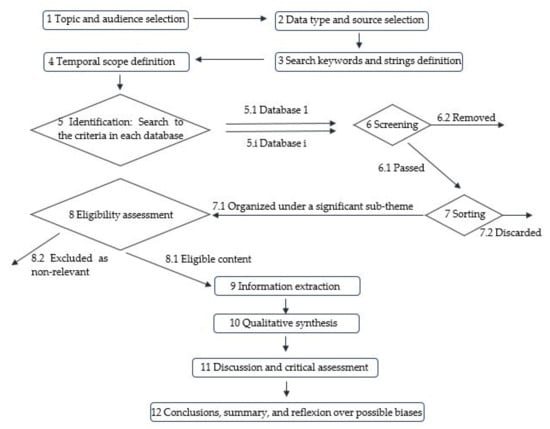

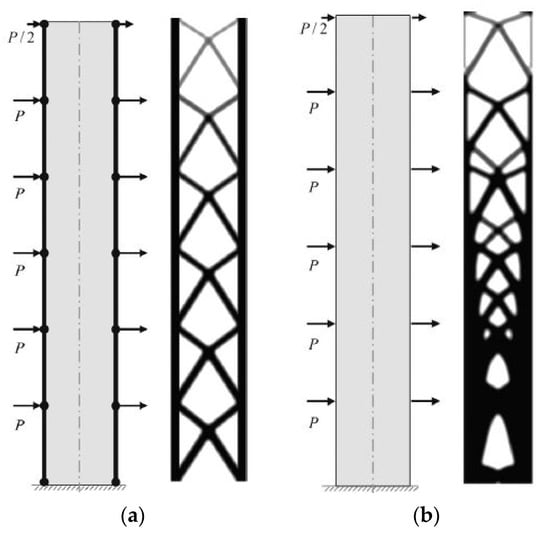

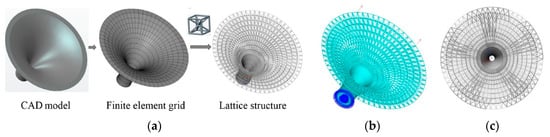

Topology Optimisation applications can be divided into Discrete Optimisation and Optimisation of Continua, based on the Topology considered for the optimisation problem (Figure 9).

Figure 9.

Example of (a) problem statement and discrete optimisation [94] and (b) problem statement (left) and optimisation of continua (right) [94].

The optimisation of discrete structures has a history of its own. It has been present in structural engineering from its early days, even if with a different scope, and this reason justifies why some researchers find the roots of TO in the classical theory of elasticity. As suggested by its name, Discrete Optimisation is directed to discrete structures. Its objectives lie in finding the optimal number, location, shape, size, and connectivity for structural elements and nodes coordinates. Therefore, one can understand that most early Discrete Optimisation applications have been limited to Shape and Size Optimisation, rather than TO, due to significant limitations on the optimisable variables’ domain. For the very same reason, Discrete Optimisation has been used under the names of Truss Topology Optimisation (TTO) or Topology Optimisation of Skeletal Structures (TOSS) and its early applications to finding optimal layouts led to the name Layout Optimisation, regarded by many as a former name for TO.

However, the Discrete Optimisation scope exceeds one-dimensional members. In fact, since the advances by Prager and Rozvany, which used grid-like structures, TO has grown as a merger of techniques and approaches, deemed to find optimal solutions for specific cases. Continuum structures can be modelled as ground structures—complex systems of one-dimensional elements—and therefore, be subjected to Discrete Optimisation.

A major issue of Discrete Optimisation can be attributed to considering nodes coordinates in or out of the optimisation domain. If coordinates are not possible to optimise, solutions can easily result in a plethora of thin, one-dimensional structural element. Conversely, if the nodes positions vary, node superposition will likely occur, leading to significant computational problems.

The Optimisation of Continua is usually applied to solids, shells, or design envelopes (which, in fact, are solids) and is deemed to optimise the design space external boundaries shape, as well as the internal boundaries shape. The latter refers to the newly created boundaries between the material and void.

4. Approaches, Methods, Criteria, and Software in Topology Optimisation

4.1. Approaches and Optimisation Methods

4.1.1. On the Nomenclature Complexity

An unexpected layer of complexity in TO lies in the terminology. Approaches, methods, methodologies, models, techniques, and algorithms, etc. are used in conflicting ways by an expanding and very diverse research and practice community.

In this article, a choice has been made to refer to the comprehensive strategies for solving a well-defined TO problem as “methods”. Such an option adheres to some of the most respected leaders and book-writers in disciplines, such as Bendsøe, Rozvany, and Sigmund, to name a few, with some occasional exceptions. In this manner, the well-known SIMP, RAMP or ESO are considered methods, while others are grouped by similarity. That is the case of OMP and NOM, both nested under the “Homogenisation” methods family. Such an option is, evidently, arguable.

Other options resided in considering six approaches, in which the defining criterion was the ability to group methods by its functional similarity. Thus, Density-Based, Level-Set, Topological Derivatives, Phase-Field, Heuristic and Hybrid approaches were accounted. As a result, other approach classifications, such as Material/Geometrical or Lagrangian/Eulerian, could not be simultaneously considered.

The problem resulting from the possibility of employing different Optimality Criteria (OC) for one given method and possibly using the same Optimality Criterion for different methods could only be solved by creating a diverse group for OC.

However, other problems arise from using different names for the same method or for different authors’ applications of the same method. For example, one can consider the ESO method, also referred to as SERA by researchers who were not involved in its original proposition, regarding their views on the method shortcomings. Likewise, the Bubble Method is referred under different names, and recent developments in Level-Set Methods and Topological Derivatives have not yielded universally accepted names for its methods, due to several increments from many researchers and applications to many different problems.

Contrariwise, several well-known methods have remarkable resemblances which could be better regarded as different applications of a single method. That can be found in the extended ESO family, in applying Genetic Algorithms (GA) and Swarm Methods, and in the different options for solving the Hamilton-Jacobi Equation in Level-Set Methods by only a handful of examples. An option was taken to leave all the methods that have some expression in the surveyed literature, regardless of its similitude, and group methods that differ only in using well-known algorithms, such as GA or Swarms.

4.1.2. Framing New Developments into the Body of Knowledge

It was never easy to organise TO in approaches, methods, or sub-fields, as one can observe from the notorious Review Articles’ classification discrepancies, such as in [1,35,119,122] or [131]. However, recent research adds complexity in this issue due to so many outputs on particular, yet transversal, issues.

At the current status of accelerated progress and interrelatedness in TO methods and algorithms, it is quite challenging to frame newly published research into categories, so that its value and applicability for one certain problem is evident. For such an end, one can find utility in Table 2, where general approaches and methods were organised to the formerly depicted criteria, and the recent relevant research was inserted. If researchers and practitioners, especially the newly arrived in this field, find it helpful to navigate through the literature and understand the potentially useful contributions, this table will accomplish its purpose.

Table 2.

Topology optimisation (TO) approaches, methods, and recent developments.

Recent research is generally less focused on fundamental and theoretical issues and more attentive to computational issues, application details, and case-specificity. There is also a trend to employ and mix concepts from different methods. For these reasons, framing recent research into approaches and methods is increasingly difficult and potentially erroneous.

One other interesting issue concerns SIMP methods. While such a theme dominated the research output for a long time, new publications devoted to it are relatively decreasing (mostly compared to the escalating numbers of TO related papers). Moreover, many research and industrial endeavours still employ SIMP, even if depicting and discussing it ceased to be considered pivotal.

Among the newer approaches, Level-Set Methods appear to be in accelerated development. This can be explained by the migration of density-based, and especially SIMP, researchers and practitioners to an approach with so many standard features.

On the other hand, Phase-Field Approaches are yet to gain momentum and Topological Derivatives, even if with a significant history, have not much recent research output. The latter, however, continues to provide a background for many developments and comparisons in mainstream methods.

With the Heuristics group, it is quite interesting to observe that the last two decades of profuse output in ESO and BESO methods seem to decrease, while Genetic Algorithms are sharply on the rise.

The working-set approach by Verbart and Stolpe [314] has not been included in the previous table due to its versatility, allowing an easy adaptation to several methods and optimality criteria.

Recent developments, such as the Deformable Simplicial Complex (DSC) Method [315] and the Virtual Scalar Field Method (VSFM), which allows considering a connectivity constraint as a thermal effect [316], show interesting features which substantiate mentioning it in this review. However, it is not yet the time to insert it in the Table 2 classification, as further developments will tell whether specific categories are justified.

Analogously, other methods, such as the Moving Morphable Components (MMC) have been proposed in the past [317,318], as alternatives to the more established aforementioned ones, but its applications beyond these authors’ works remain not very profuse. However, promising contributes are regularly obtained by employing it, such as the Virtual Component Skeleton (VCS) method by Wang et al. [319], for controlling topologically optimised boundary smoothness, which deserves to be referred.

For the Discrete Optimisation of trusses, the article by Zhang et al. [320] is fundamental for understanding the Ground Structure Method (GSM), as well as its Voronoi and quadrilateral methods of discretisation.

Recent conclusions on the Equivalent Static Loads Method (ESLM) [321] offered clarity to previously reported findings and highlighted the caution needed for analysing the potential of the methods.

For an interesting discussion on preconditioning, its impact upon computing efficiency, and an example on Preconditioned Conjugate Gradients (PCG), the reader is referred to the work by Kaveh et al. [322].

4.1.3. Heuristics as a Source of Controversy

The use of optimisation methods whose solution is not necessarily optimal, referred to as Heuristics, has been in the centre of discussion on the TO theory, since the first so-called Evolutionary methods were proposed. Without entering a discussion already well depicted in [35,121,122,123], criticism is mostly due to the reported incapacity of evolutionary methods for attaining convergent optimal solutions, to failing to achieve acceptable solutions in some cases, and to the difficulty in generalising the method for real structures constraints.

It is quite interesting that some other researchers highlight the employment of Heuristics in filters and other techniques deemed to avoid local optima, which are used well beyond the evolutionary methods.

As expected, many of those claims have been rebutted, discussed, but also admitted and led to many of the current developments.

As a result, the current discussion on TO methods in Academia is still centred on the SIMP/BESO antagonism, as well as in the new developments in Level-Set, Topological Derivatives, and Phase-Field Methods, while practical applications are mostly employing SIMP methods.

Considering that Meta-Heuristics (high-level procedures for combining or selecting heuristic methods for one given problem solving or adequate approximation) and Artificial Intelligence (AI) based methods are rapidly spreading within civil and structural engineering [323,324], due attention will be given to the Heuristics approaches in structural steel design in this article. However, the current imbalance must be highlighted.

4.2. Optimality Criteria

Considering the impracticability in proving that an attained solution is mathematically correct when thousands of variables are involved, the Optimality Criteria (OC) had to be set. For such an end, several precursory intuitive criteria were used, such as the Fully Stressed Design (FSD) and the Simultaneous Failure Mode Design (SFMD) until the so-called rigorous criteria were adopted. The latter epithet is usually given to any criterion complying with Kunh-Tucker optimality conditions.

Table 3 systematises the most common OC, which is applied to the prevalent Density-Based Approach methods.

Table 3.

Frequently used optimality criteria methods.

4.3. Practical Methodologies

Unsurprisingly, the literature devoted to TO is profuse in depicting theoretical approaches and methods, as well as in validating it with well-known or trivial cases, but much scarcer in providing comprehensive and holistic methodologies (which contain practical aspects) for implementing a TO strategy into the Engineering design. This is related not only to researchers’ tendency to publish their work and industrial practitioners and developers not doing so, but also to the fact that TO is still in a stage of developing and stabilising methods before a universal application by non-experts. Moreover, Topology Optimisation is still much more complex than the regular structural analysis and design in most engineering fields, requiring a significant time, studying and computational resources that limit the number of large-scale projects currently being developed.

One further issue lies in TO objectives. While academic developments must seek assurance of optimisation to the theoretical extrema, industrial applications are usually comfortable with optimisation to a certain pre-defined threshold and value reliability, predictability, reproducibility and, frequently, computing efficiency above all. However, avoiding local extrema is a common goal.

Nevertheless, some examples were found in a recently published literature, which can be referred to as interesting examples for conceiving case-specific methodologies for the systematic application of TO in structural steel design. Table 4 summarises those findings.

Table 4.

Methodologies or strategies for practical TO implementation in engineering design.

4.4. Computer Programmes

The availability of computational resources is paramount for ensuring TO applications beyond the research community, which has the ability to produce their software. That is undoubtedly the case of Structural Steel Design researchers and professionals, to whom software development may not be the primer priority.

Fortunately, both the commercial software and code provided by researchers and developers are available. However, while the former frequently comes as a “black-box” and can even be challenging to be aware of the employed approaches and methods, the latter may lack user-friendliness, require pre- and post-processing, lack graphical interfaces, and not provide an adequate tool for applications more complex than trivial examples.

Considering the relevance of computer programmes for developing TO strategies, a review of the currently available and reportedly more used commercial software and computer programmes is summarised in Table 5.

Table 5.

TO commercial software and computer programmes.

A remark shall be made concerning the Advantages and Disadvantages columns. Not only does the information rely on the consulted literature and commercial software technical detailing, but it also compares very different programmes. Commercial software is fundamentally different from free codes. Therefore, the advantages and disadvantages are essentially focused on each programme’s nature and much less on its quality. Regarding the latter, we remain neutral and only reported (mostly) successful applications depicted in the published literature.

5. Topology Optimisation in Structural Design of Steel Elements and Joints

5.1. Steel Elements Design

Structural design has been pushed into Topology Optimisation for several reasons. Not only does the technology availability in much user-friendlier tools [388] play a critical role in facilitating the centuries-old task of optimising structural design, but also external pressures drove structural engineers into TO. Such pressures have been found both upstream, with an architectural demand for shapes that can only be optimised with extreme computational resources [389,390] and downstream, with the need for design processes able to foster Additive Manufacturing [391].

The former reasoning also explains why structural steel design has shown a particular prospect for successful TO applications [392]. The range of the applications includes Shape and Size Optimisation for steel members, as well as Topology Optimisation for the whole structural envelope. Furthermore, and unlike most of the other engineering disciplines, structural steel engineering still finds a preferred tool in Discrete Optimisation, over the Optimisation of Continua, for several problems with the macro-structures conceptual design.

Among the members design, perforated beams and shear walls are particularly prone to TO. The former has been studied in depth by Tsavdaridis’ group at the University of Leeds [346], and the latter had a recent development in Bagherinejad [360], using commercial software. In both cases, a preliminary design with circular holes has been shown to evolve to a lattice-like geometry, with significant material subtraction in well-known less stressed areas. In a larger scale, floor diaphragm members have also been studied by Fischer et al. [393], to understand the optimisation possibilities under in-plane loading.

Still, within the sectional optimisation domain, the Free Material Optimisation (FMO) method extension [394] provided a critical tool for plates, shells, and member’s parts design, and an impressive Academia-Industry joint effort allowed developing the Sectional Optimisation Method (SOM), which enabled the design of optimised aluminium members, accounting for fabrication constraints, standards regulations, and local instability phenomena [341].

Concerning structural systems and trusses optimisation, recent improvements include multi-objective optimisation techniques [395], Differential Evolution Algorithms [267], quantile regression for fostering the use of (discontinuous) I-beam cross-sections as design variables [396], and developments with the Interior Point method for non-linear and non-convex truss optimisation problems [397]. However, one of the most impressive developments can be found by Larsen et al. [398], a near-optimal truss design based on the homogenisation-based continuum TO. Practical applications of truss optimisation to bracing the systems design have some interesting contemporary examples in [399,400,401,402,403].

Therefore, high-rise buildings are an ideal ground for employing truss optimisation methods [106]. Specific issues of tall buildings have been addressed by recent TO studies, including the development of a genetic algorithm-based method for optimising outrigger systems [404], using swarm optimisers [279], considering linearised buckling in the TO process [405], developing a method for optimising bracing systems under adaptive multimodal load patterns [406,407], and conceiving structural systems for tall buildings based on the Optimisation of Continua using Reissner–Mindlin (or Mindlin–Reissner) shell elements [407].

Loading is, undeniably, a major challenge for TO in buildings structural systems, especially when multiple actions, combinations, and modes are considered and more so when the structure-load interaction is strong and influences the latter intensity. That is the case of seismic loading, in which specific, and usually extensive, code prescriptions apply. Subjected to such constraints, research in Topology Optimisation of seismically loaded structures is still exiguous. Nevertheless, the works of Kaveh’s group on shear walls [408] and on different ductility steel Moment Resisting Frames (MRF) [409] can be highlighted as well as Qiao et al.’s [410] braces optimisation to the non-linear dynamic analyses of earthquakes time-histories.

A similar complexity can be found in fixed offshore structures for oil and gas or wind energy production. Even though such structural systems usually have a simple and intelligible conceptual design, wave and extreme loading require rather complex engineering [411]. For those reasons, recent developments in the conceptual design optimisation of jackets [412], including geotechnical aspects [413,414] and fatigue design [415] are very significant. Likewise, the method by Cicconi et al. [416] for multicriteria optimisation of modular steel towers is expected to have an impact on the industry.

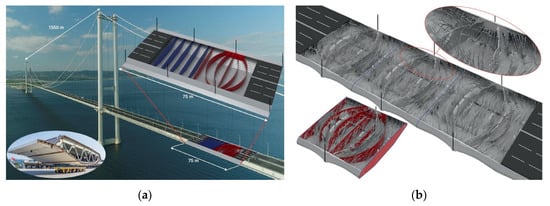

Long-span structures have also been an object of study in TO, even if the research output is scarce in quantity. Within this subject, one can mention the Topology Optimisation of domes through a Colliding Bodies Optimisation (CBO) method by Kaveh [417] and the general space-frame steel roof optimisation method with Genetic Algorithms by Kociecki and Adeli [265]. Concerning bridge engineering, the spotlight is in the DTU TO group steel girder optimisation for super-long suspended spans, employing computational morphogenesis [418] (Figure 10).

Figure 10.

Super-long suspended spans optimisation with computational morphogenesis. (a) Case-study initial (blue) and interpreted (red) design [418] and (b) computational morphogenesis result [418]; (reproduced under the Creative Commons Attribution 4.0 International License, http://creativecommons.org/licenses/by/4.0/ accessed on 25 February 2021).

Other significant advances, which may have an impact on structural steel design optimisation, include Christensen’s work on TO under extensive and non-linear deformations [165] and Kristiansen et al.’s [419] studies on contact pressure and friction.

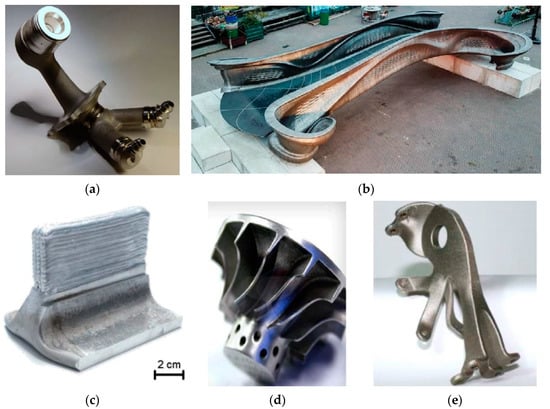

As steel design and detailing is deeply affected by fabrication and erection procedures, which usually constrain engineering options in a more extensive manner compared to construction with other common materials, a further investigation into recent research papers devoted to considering such aspects into TO is due. For such an end, and regardless of a deeper review on Additive Manufacturing for TO in Section 7, one shall refer to recent reviews [420,421], and keynote [422] on employing welding robotics in the so-called Wire and Arc Additive Manufacturing (WAAM) of topology optimised steel members and connections. However, the most common methods of creating steel in AM use powder as a feedstock and laser or electron beams as binding mechanisms [423]. Even if high-quality surfaces and accurate geometries are achievable with such means [424], steel properties are TO variables with broader uncertainty, due to its complex and repeated heating and cooling cycles [425]. Control, inspection, and testing will have an increasingly paramount role in enabling steel fabrication processes reliant on Topology Optimisation [129] and will add to the well-known hindrances of cost, aversion to change, and lack of technical knowledge [426].

5.2. Joints Detailing

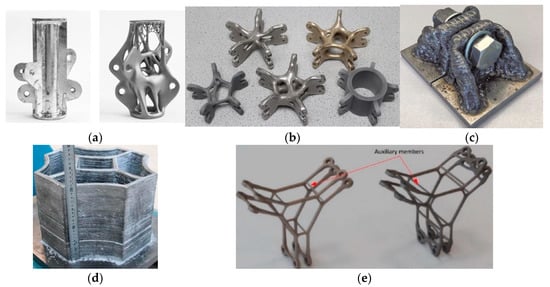

In the current state-of-the-art steel connections (or joints, since both names are interchangeably used in structural engineering), TO is built of many mechanical engineering originated research endeavours and some developments made in the context of structural engineering research projects. Within the latter domain, innovative connections have been prototyped, breaking barriers of conventional manufacture constraints and delivering outstanding weight reduction [139]. Moreover, joints compactness, as regularly achieved by such designs, is critical for structural steel detailing, which is usually heavily constrained by space limitations.

Some recent examples of topologically optimised and additively manufactured joints can be found in Figure 11. Herein, new concepts and interesting solutions for space structures can be found [422], yet the significant predominance of applications for lattice, reticulated, and generally tensegrity structures is evident. Such shortcoming is mostly due to the limited quantity of load combinations which can reasonably be considered for the optimisation process. Should multi-axial bending and shear add to the tension and compression stresses, the TO procedure would escalate several levels of complexity and yield less intuitive results, in which validation would become a critical issue [427]. In fact, experimental testing of these joint details under a multitude of load cases is an inevitable step towards the broader employment of TO in steel joints detailing [139,427].

Figure 11.

Examples of topologically optimised and additively manufactured metallic connections for civil engineering structures. Left to right and top to down: (a) Non-TO and TO joint specimens by ARUP [355]; (b) several joints designed in the University of Leeds [139]; (c) wire and arc additive manufacturing (WAAM) printed bolted joint in the Technical University of Darmstadt [422] (reproduced under the Creative Commons Attribution-NonCommercial-NoDerivs License); (d) WAAM printed node in the Technical University of Darmstadt [422] (reproduced under the Creative Commons Attribution-NonCommercial-NoDerivs License); (e) joint specimens topologically optimized with the bi-directional evolutionary structural optimisation (BESO) method for axial loads and bending in the RMIT University [427].

A further step towards the application of TO in joints design can be envisaged in Wang et al.’s comprehensive method for optimizing and fabricating joints in three-like structures [428]. As such, the nature-inspired structural concept is particularly prone to TO, in which a solution for optimising and manufacturing its joints is paramount. Other interesting developments in the TO of joints among tubular elements can be found in the work by Kanyilmaz and Berto [429,430]. Concerning the optimisation of spherical nodes in space frames, the work by Hassani et al. [364] is particularly relevant for providing a holistic guideline, including fabrication concerns, practical issues with Grasshopper modelling, as well as results post-processing and interpretation. Likewise, the work by Alberdi et al. [431] on the connections topology optimisation in Moment Resisting Frames (MRF) is deemed to assist structural designers in the task of managing the recursive task of designing frames and its joints.

Nevertheless, several and significant factors still hinder joints TO. Some of the most apparent problems lie in the materials properties uncertainty and fabrication cost. With a strong relation to AM techniques [139], those can only be solved by sensible technology developments, financial investments in the industrial capacity, and workforce know-how, as well as a stronger standards framework.

Problems with the optimisation process have an outstanding issue in the incapacity of some algorithms for accounting non-linearity [422]. This is critical in several connection types, including the bolted ones, where plasticity plays a major role. However, significant advances have been made in the modelling of bolted connections, holes, bolt-hole contact, and friction in the context of TO [432,433,434,435].

Furthermore, a very significant research published in the context of mechanical engineering systems is general enough to have a profound impact also on steel joints detailing. That is undoubtedly the case of the technique for creating idealized bolts with the topological derivative approach proposed by Rakotondrainibe et al. [247] in a Renault associated research. Other examples can be found in the synthesis method for mechanisms proposed by Kang et al. [436] with a possible application to the pinned and sliding joints in structures.

5.3. Buckling and Local Instability Phenomena

Member buckling phenomena has been addressed in Discrete Optimisation for a long time. However, within the Optimisation of Continua, multiple global and local, real and fictional, buckling modes hampered progress after precursory works undertaken in Instituto Superior Técnico [437]. Some notorious problems have been found in the appearance of buckling associated with low-density regions, high local stresses, which add to the repetition of modes, convergence problems, and the need for an extensive computational capacity for dealing with so many modes [137,388,438].

Recent advances already allow accounting for buckling in TO endeavours in a computationally feasible manner [438,439,440,441,442], mitigating some of the aforementioned problems. Though, those methods rely on linearized buckling, which is generally regarded as an inadequate simplification for many engineering problems [137,443,444] and therefore, face significant opposition from many researchers. Adding to such a discussion, a recent research paper using non-linear pre-buckling analyses in the context of microstructural design [445] found that under certain loading conditions, linear and non-linear buckling analyses yield similar results. Considering the knowledge gathered by structural engineers in linear and non-linear buckling over time, it is expected that such a conclusion may be proven valid for several other cases.

On the other hand, advances have been made in the last few years on the non-linear buckling of topologically optimized continua [446,447]. Such remarkable achievements employ non-incremental analyses and recursive design.

Despite the mentioned problems, under which buckling phenomena can only be regarded as a mostly unsolved problem in the TO of continua, some practical applications found simpler or more sophisticated strategies for modelling instabilities in optimisation methods. That is the case of Tsavdaridis’ work on local instability in optimised aluminium cross-sections [341].

Regarding Discrete Optimisation, methods for considering buckling also evolved. Among a recent contribution, one can highlight the work by Weldeyesus and Tugilimana on trusses [397,448], Xu et al. suggested a practical approach for TO in tensegrity structures [449,450], as well as the research by Zhao et al. [451] on methods for mitigating member instability in reticulated structures.

5.4. Structural Design Codes Compliance

Bridging research and practice in structural engineering faces some hindrances beyond the simple transfer of knowledge. Unlike many other fields, where product design is strongly bounded with Research and Development, since testing, compliance, and certification will follow pilot production, the design of building and bridge structures must comply with an extensive set of rules, codes of practice, and standards beforehand. Those documents are typically reviewed in a pluriannual basis and not necessarily include the most recent research, since a broad and heterogeneous community of practitioners is not expected to radically change the design methods frequently.

As a result, many calculation approaches based on non-constant members or employing advanced sectional analyses, even if practical and validated, may take long until explicitly defined in structural standards [452]. This is certainly the case for widely adopting TO in civil and structural engineering and, also, a reason underlying the scarce number of recent publications in TO to specific standards prescriptions.

Within the recent literature pertaining to optimisation programmes, exceptions to the former can be found in Tsavdaridis’ optimisation of aluminium cross-sections [341], as well as in works of the Discrete Optimisation of trussed structures, including truss design to Eurocode 3 (EN1993-1-1 or, simply, EC3) with Differential Evolution Algorithms [267] and bracing systems optimisation with GA to the AISC-LRFD American standard [402,453].

5.5. Multiple Loading and Robustness

Significant obstacles still limit the broader employment of TO in structural design. One of the most important is the susceptibility of optimisation results to loading patterns. Albeit, recent advances onto robust solutions, which show endurance to loading scenarios multiplicity [454] and extreme degrees of TO in structural design usually result in members that efficiently withstand a finite number of loading patterns used in the design, but may be inefficient for other loading patterns, even resulting in less intuitive and less visually appealing topologies. In fact, real structural design optimisation problems are deemed to fulfil the requirements of multiple objective functions [455,456,457,458].

Under these circumstances, the TO use for structural engineering is impaired by three reasons: First, loading patterns can be very profuse, up to hundreds or thousands in complex structures. This is not necessarily a research problem, but a practical one since common computational methods are still not suited for delivering TO results for many loading patterns in a reasonable time.

The second problem is related to the absence of accidental and unconventional loading patterns in regular structural design. Without it, the redundancy of structural members may become negligible and an unexpected collapse under non-conventional loading may occur.

The last, and possibly most severe, set of problems is related to the current methods for TO under multiple alternating loads. Notwithstanding some recent advances, current methods still face the inconvenience of non-unique solutions [459] and local extrema, as well as the difficult to account for loads with very different scales of intensity [458].

Multiple-loading and multi-objective optimisations have been handled with a plethora of methods. Both deterministic or physically accurate, and uncertainty-based methods, including notorious fuzzy approaches, have been used [458]. Arguably, the Kreisselmeier–Steinhauser function (KS) stood out in the past decades, mostly in aeronautical engineering studies.

Among recent advances, one can highlight the efforts to account for uncertainties in the loading intensity and position with the method by Wang and Gao [460], and the compliance-function-shape-oriented approach by Csébfalvi [461] and precursory work [462], the generalized material interpolation scheme by Chan et al. [463], as well as the RBTO approach by Nishino and Kato [464].

Previously, Li et al. proposed one more option for multi-objective TO, employing the Normalized Exponential Weighted Criterion (NEWC) and the Fuzzy Multiple-Attribute Group Decision-Making (FMAGDM) theory [458]. Likewise, Yi and Sui introduced the use of the Transplanting Independent Continuous and Mapping Ideas into Materials with the Penalisation (TIMP) method for the TO of plate structures under multiple loading [465]. Its interesting feature lies in adding one more penalty function to a SIMP-like method.

One very different advance can be found in the approach by Tang et al. [466] to the wind loading complexity through integrating Computational Fluid Dynamics (CFD) models into a BESO method for TO.

Much of this research is related to contemporary multiple loading. The problem of non-simultaneous multiple loading implies significant computational efforts to extend the analysis scope, integrate TO results, and deal with very significant practical issues.

Works on dealing with alternating loads can be found early in the TO literature, including the 1970s Prager work [467], but hardly can be considered solutions for the complexity of the currently analysed problem. Recent works with alternating loads include Alkalla et al.’s Revolutionary Superposition Layout (RSL) method [468], as well as Lógó and Pintér contributions, [459,467]. Furthermore, Tsavdaridis et al. managed to use a method to examine and overly stress paths and compose comprehensive layouts, optimized for several sets of loads [341], [469].

As the way ahead is likely to be facilitated by the admirable rate of global computational power increase, only a few TO research centres [169] already possess the means for dealing with multiple and alternating loads and load combinations in more-than-trivial problems.

However, structural engineering has deployed solutions for dealing with uncertain loading and enhancing reliability. One solution lies in the current “Capacity Design” philosophy, favoured in Structural Eurocodes for seismic actions [470,471]. Employing it in TO could provide a minimum threshold for providing the versatility to the structural design of elements.

6. Recent Advances in Related Fields with Applicability in Structural Steel Design

Owing to the broadness of Topology and Topology Optimisation concepts, applications are primarily cross-disciplinary within scientific, engineering, and even graphical fields. Thus, neighbouring fields have been thoroughly investigated for recent developments with a perceived or expected potential for usefulness in structural steel design.

Nevertheless, one shall refer to the fact that only a fraction of what lies within the TO umbrella is of value for the theme under scrutiny. Suitability depends mostly on the driven objectives towards optimisation. Therefore, the following synthesis is not deemed to assess TO in other fields, but to identify advances in TO which can be adopted in TO endeavours for structural steel design.

6.1. A Broader Look into the Construction Industry

Newly developed tools for cross-disciplinarity, namely involving architectural design into the structural design efforts for TO [343], will have an impact on structural design. One other interesting investigation analyses incremental loads and structural layouts in TO [472]. Even if it is directed towards incremental concrete bridges, its methods can be useful for dealing with steel structures staged construction and, in a broader sense, assist in TO with multiple loading and evolutive layouts. Furthermore, advances in soil-structure interaction for geotechnical structures optimisation [473] may have an impact on the moving loads’ issue.

6.2. Concrete Structural Design

The recent “Digital Concrete” conference [474] contains strong proofs of concrete design research and practice engagement in TO. While it is undeniable that the current progress is more strongly bounded to concrete Additive Manufacturing, under the name of 3D Concrete Printing (3DCP) [475], Topology Optimisation in concrete structures already advanced far beyond the unreinforced concrete, where AM is already flourishing, paving the way for interesting developments in reinforcement design models.

More than 120 years after the work by Ritter [476] and Mörsch, as well as over 30 years past Schlaich et al.’s notorious contribution [477], the Strut-and-Tie Models (STM) still govern the concrete design with remarkable resemblances to what previous generations of structural engineers mastered. That may well be subject to change as new developments in TO are deemed to reshape our understanding of reinforced concrete design, with contributions by Zhou et al.’s [478], Yang et al.’s [479], Jewett and Carstensen’s [480], and Xia et al.’s [481]. However, the promise of fundamental innovation beyond the aforesaid applications remains restricted to only a few distinct approaches. One of those is Pastore et al.’s [482] risk-factor to replace the Von Mises stress criteria for optimizing heavily constraint structural elements.

Other applications of optimisation in structural concrete design include targeting seismic performance objectives [483,484,485], the optimisation of prestressed concrete members [486], and defining critical concrete structures general topology, from the Optimisation of Continua, as performed by Wu and Wu for bridge pylons [487]. These works will, most certainly, have a contribution also for steel and concrete composite structures.

6.3. Aerospace and Defence Industries

Aerospace engineering, with its utter need for weight reduction and frequently generous funding, has been a source of inspiration for TO breakthrough innovations. Over the years, sensible contributions to critical issues in TO, such as fastener design and dynamic analyses, now used in structural steel design, came from this field [488].

Recent advances in TO from this field include optimisation methodologies for additively manufactured parts with enhanced accuracy to strain and displacement [489], experimental analysis of several topologically optimised micro and macro-structural systems for ribs [490], optimisation to cumulative mechanical and thermal loads [491], and advanced materials design for high-quality AM [492]. All these contributions can have a deep impact on the quality of topologically optimised and additively manufactured alloys, leveraging its rapid application also in the construction industry.

6.4. Automotive Industry

Practical and fabrication-oriented methods are regularly deployed by the automotive industry. Hence, this field has been a continuous source of inspiration for framing TO developments in the track of meaningful advances. Novel methods include Mantovani et al.’s guidelines for integrating AM requirements into TO, as well as for successfully processing and managing the TO results [493]. Similarly relevant are the studies by Van de Ven et al. [494] and Mass and Amir [495] for mitigating the impact of overhangs for AM as design constraints. Limiting or conveniently positioning overhangs is paramount not only for subtracting complexity to the numerical models, but also may prevent failure mechanisms in steel alloys, such as fatigue-related. Such developments are applicable to the most additively manufactured parts, not only in the automotive industry.

Detailed procedures for optimising vehicles parts can be found in Topaç et al.’s [496] reduction of 63% of a mechanical component mass in Kumar and Sharma [497], in Mantovani et al.’s [498] reduction of a steering column support mass in almost 50% in Li and Kim’s approach to topologically optimise a car part with limited information, manufacturability concerns to leverage extrusion and casting processes, as well as a post-processing method for geometry reinterpretation, while achieving almost 40% of weight reduction [499].

6.5. New Materials, Composites, and Polymers Design

Materials design has been taking advantage of TO at a microstructural level and, conversely, promoting its development. As Osanov and Guest [135] formulated it, the fundamental question in architected material design optimisation can be resumed to finding which microstructure will deploy sensible enhancements to macrostructural properties. The answer is complex and involves entrenched unit cell modelling, upscaling, and repetition [184,500,501]. Yet, diverse and frequently remarkable solutions can be attained, from useful elastic properties, including auxetic (NPR) materials (those with a negative Poisson’s ratio), as popularized in Sigmund’s work [502] and currently drawing much attention from the scientific community [503], to extreme thermal properties, optimised fluid permeability, and materials governed by non-linear mechanics for utmost energy absorption.

Within the aforementioned exciting framework, recently published works include modelling methods for designing hierarchical structures employing non-uniform topologically optimised lattices [504], serving as enhanced energy absorbers in sandwich sheets [505] or facilitating manufacturing [506], even with new methods for mitigating non-smooth surfaces, as the Bézier Skeleton Explicit Density (BSED) Representation Algorithm [507]. The microstructural design for avoiding stress peaks has also been recently addressed [508], as uncertainty-resilient design for inter-diffusion interface issues has been brought forward [509], and advances in buckling of microstructures were published by Bluhm et al. [510].

The fabrication of these architected materials with AM techniques is yet another concern. Not seldomly published methods can be incomplete or vague, as Huang et al.’s review pertinently points out, and offers mitigation by congregating some state-of-the-art answers [511].

Even though new materials and, specifically, new material microstructures may still be far from promoting a change in steel alloys, structural steel design can find many important lessons in the formerly cited research. Both the tools and methods created for microstructural optimisation can be employed in the multi-purpose TO, but also solutions developed for a particular material microscale may have an employment in construction macrostructures composed of smaller members. That is also the case of recently developed methods for efficiently handling buckling in polymers optimisation [512], as well as for multimaterial TO (MMTO) [513,514], with its specific problems, as extensive local extrema, and techniques designed to overcome such obstacles. Furthermore, many important advances in TO methods and approaches are being developed within the materials design field, making it especially relevant, also for TO in civil and structural steel design.

At a coarser scale, construction composite materials can also be enhanced under the assistance of TO. That is the case of the types of cement with an enclosure of rubber waste [515] or Carbon Fibre Reinforced Plastics (CFRP) [516].

6.6. Industrial Design, Mechanical Engineering, and Multiphysics Endeavours

One of the most prolific research lines in TO relates to compliant mechanisms design. These flexible structures, which are ubiquitous in most high and low technology consumable products nowadays, have been a perfect ground for TO. Owing to its reliance in parts flexibility rather than hinged joints, these components rigid body design had been complex, frequently erroneous, and very dependent on prototype testing, whereas compliant mechanisms TO bridges most of those shortcomings by efficiently addressing the target flexibility.

Upscaling from small consumables, in electronics for example, larger components such as grippers have been produced using the TO of compliant mechanisms [517]. Furthermore, new methods for addressing the manufacture uncertainty and stress constraints [518] show a new maturity level for compliant mechanisms design, which may lead to its use in more perennial applications and structures.

The mechanical design of diverse components and structures has also faced recent developments in TO related subjects. If, on the one hand, the TO of vibration problems remains largely constrained to small amplitudes [133], on the other hand, techniques are being developed for introducing High-Cycle fatigue as an optimisation criterion [519], [198], and concerns over accidental actions are being addressed within the ship design industry [520].