Abstract

In the liquid composite molding process, a binder is used to fix the preform. In this study, the influence of a non-reactive epoxy binder was investigated. To allow the measurement of permeability, the preform specimen was produced under three preforming conditions: neat fabric preform, binder-treated fabric preform without heat treatment, and binder-treated fabric preform with heat treatment. The in-plane directional permeability, K1 (having maximum flow velocity), and K2 (having minimum flow velocity) of the binder-treated fabric preform decreased approximately 80% compared to the neat fabric preform. The permeability in the out-of-plane direction decreased approximately 80% in the binder-treated fabric preform without heat treatment and about 98% in the binder-treated fabric preform with heat treatment. This decrease occurred because the treated binder on the fiber hindered resin impregnation. The effect of the binder on the friction coefficient of carbon fabric was also investigated. The friction coefficient was high when the binder was on the friction surface and increased 40–200% at 110 °C, compared to 25 °C.

1. Introduction

As the demand for composite materials with high strength and light weight increases, composite manufacturing processes are being investigated to reduce production costs. Among these processes, liquid composite molding (LCM), including resin transfer molding (RTM) or structural reaction injection molding (S-RIM), is advantageous for manufacturing complex-shaped products. These inexpensive processes can be used without an autoclave process [1,2,3,4]. In LCM, the fiber is preformed in the mold prior to injecting resin. The fiber preform process using a binder is recommended, because fiber layers should be bonded to each other to fix the desired shape. There are many kinds of binders. Depending on the materials used, they can be classified into thermoset and thermoplastic binders and may be powder or liquid-type binders. As the amount of binder used in LCM increases, it can easily fix a preform of a complex shape owing to the high adhesion between the fibers. However, there are several associated issues preventing the large amount of binder use, including changes in the shear properties and the friction coefficient of the fiber preform, as well as the poor permeability. Consequently, optimization studies attempting to identify an efficient preform process by analyzing the effects of binders are needed [5,6,7].

Many studies on the use of binders in the fiber preform process for LCM have been conducted [8,9,10,11]. Tanoglu et al. investigated the effect of a thermoplastic polyester binder on the glass transition temperature and mechanical properties of S2-glass-fibre reinforced epoxy composites through a T-peel test, a double cantilever beam (DGB) test, and a short beam shear (SBS) test [8]. Estrada et al. examined the influence of binder materials, known as tackifiers, on the characteristics of fiberglass preforms according to the different concentrations of the tackifiers [9]. Tanoglu and Seyhan manufactured electrical-glass/polyester composite panels using a preform tailored to various concentrations of the thermoplastic binder and analyzed their compressive mechanical behavior and failure modes [10]. Brody and Gillespie Jr studied the characteristics of two types of preform binder—reactive thermosets and non-reactive thermoplastic—in glass/vinyl ester composites. In their study, the interplay adhesion of woven glass plies and inter-laminar shear strength of woven-glass-reinforced vinylester composites was achieved depending on the type, amount, and processing of the binder [11]. Asareh et al. investigated the change in the ultimate strength of 800 Tex HTS-coated carbon fibers through double lap shear under different activation temperatures and activation techniques, including an electric oven, hot plate, microwave, and CO2 laser [12]. There have been many studies on the effect of binders on the mechanical properties of processed composite materials, and some have shown that binders could affect the permeability of preform in LCM [6,9,13,14]. Recent studies have focused on the change in permeability depending on the chemical state of the binder to minimize the binder effect during LCM [15,16]. Among the process parameters, the permeability of the fiber preform is an important factor in LCM that determines the total process time, thereby affecting the cost of production. The measuring method of the permeability of fiber preform was introduced by Adams et al. [17], Weitzenböck et al. [18,19], and Fauster et al. [20] using optical radial flow in a porous medium in the in-plane direction. For the out-of-plane directional permeability, Endruweit et al. [21] and Francucci et al. [22] used a method applying the saturated permeability. In addition, in the measurement of permeability, it is necessary to test with the same fluid, because the results may change depending on the type of test fluid used [23]. In this study, using equipment capable of measuring permeability, changes in the permeability of a twill-woven carbon fabric with a non-reactive epoxy binder treatment was investigated in the LCM process. In addition, the changes in the coefficient of friction between fabrics and between fabric and the metallic mold were observed via friction tests. These tests demonstrated another important effect of binder on the friction coefficient, using a parameter for predicting fiber wrinkles in the LCM process. By analyzing both kinds of process parameters, it was possible to determine the characteristic changes in reinforcements in LCM as a function of the binder usage during the preforming process.

2. Experimental

2.1. Materials

Twill-balanced woven carbon fabric with T300(3K) was supplied by Toray Corporation. HUNTSMAN’s Araldite LT3366 was used as an epoxy binder, which is a non-reactive powder type, for fixing the fibers through cold stamping after melting at an appropriately high temperature. The epoxy binder has a softening point above 110 °C and a glass transition temperature of 75–85 °C. To measure the permeability, silicone oil (KF-96-350cs) from ShinEtsu Corporation, which has a viscosity range (340cp at room temperature) similar to that of the epoxy widely used in resin transfer molding (RTM), was used.

2.2. Preforming Process

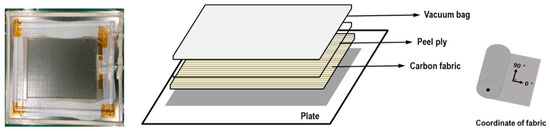

Binder-treated fabric was manufactured using an epoxy binder applied uniformly (5 ± 1 g/m2) to one side of Toray’s twill-woven carbon fabric roll. For the preforming process to prepare the preform specimen, the carbon fabrics were laminated 8-ply (Figure 1) in the same direction and compressed using a vacuum bag, and, if required, heat treatment was performed for 30 min. at 110 °C in a convection oven. For investigating the effects of the binder, three types of preform specimens were fabricated: neat fabric preform, binder-treated fabric preform without heat treatment (preforming at room temperature), and binder-treated fabric preform with heat treatment (preforming at 110 °C). Every case was fabricated with the same size (300 mm × 300 mm), and in the measurement of permeability the fiber volume fraction of the preform was determined by fixing the thickness using the upper and lower jigs before the test fluid injection (Figure 2). The fiber volume fraction was calculated except for the binder volume fraction because it was negligibly small (<3%) compared to the amount of fiber (Table 1).

Figure 1.

Preforming process for the carbon fabric preform using vacuum bagging.

Figure 2.

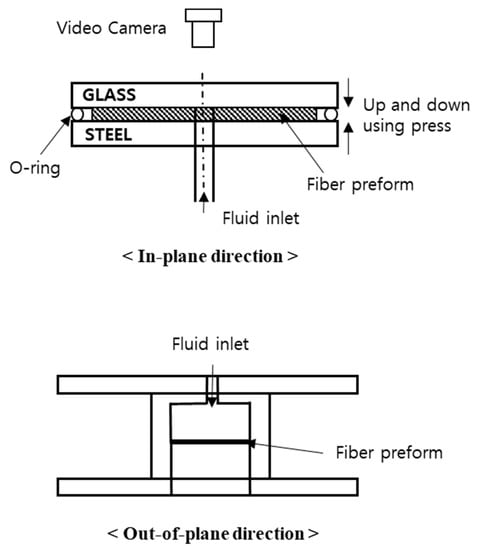

Schematic of the permeability measurement system.

Table 1.

Binder content in the fabric preform specimen in each fiber volume fraction.

2.3. Permeability Measurement

2.3.1. In-Plane Direction

The permeability for two-dimensional flow was calculated using polar coordinates expression of Darcy’s law as follows:

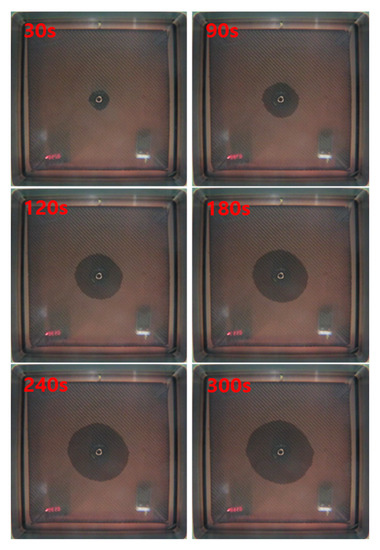

The expression was used to obtain the unsaturated permeability by observing the flow front over time, where the injection pressure was constant. In the above expression, is the volume-averaged fluid velocity, is the unsaturated permeability, and and represent the viscosity of the fluid and the pressure gradient, respectively. Figure 3 shows the change in the flow front of the resin over time. Using the method suggested by Adams et al. [17] and assuming that the flow front is elliptical, the permeability was obtained through curve fitting using the least squares method. With the measurement system shown in Figure 2, the test for each case was conducted 5 times and the average value is shown.

Figure 3.

Observation of the resin flow front over time (V. F.: 50%, neat fabric preform).

2.3.2. Out-of-Plane Direction

In the general RTM process, the permeability in the out-of-plane direction was calculated using the saturated permeability equation as follows:

where is the saturated permeability, is the flow rate (m3/s), A is the cross-sectional area of the porous medium, and L and represent the length of the porous medium and the pressure difference, respectively. was calculated by measuring the difference between the inlet pressure and the outlet pressure after waiting for the saturation of resin flow—that is, the flow rate became constant. With the measurement system shown in Figure 2, the test for each case was conducted 5 times.

2.4. Friction Coefficient Test

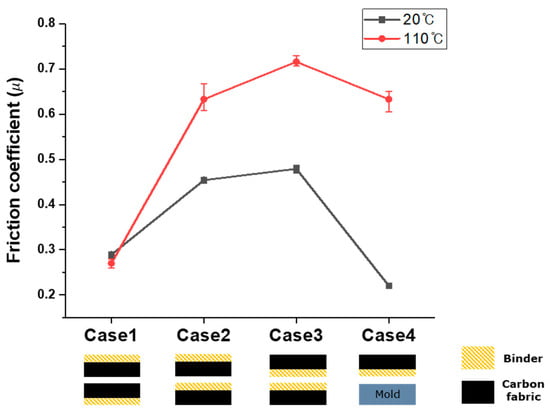

In this study, the friction coefficient between the fabric and mold surface, as well as the fabric to fabric friction coefficient, was measured as a function of the presence of the binder and the temperature conditions. The kinetic friction coefficient was measured using an FP-2260, which can control the movement speed of specimen, supplied by the Thwing-Albert Corporation, with a 20 mm/s sliding speed and a 0.5 kg weight (Figure 4). Because the fabric used in this study had an epoxy binder on one side only, the test cases were set up as shown in Figure 5. In Figure 5, cases 1–3 were intended to examine the change in the coefficient of friction between fabrics according to the conditions of the binder treatment, and case 4 was intended to show the same change between the fabric and the metallic mold.

Figure 4.

Equipment for measuring the friction coefficient.

Figure 5.

Test cases of the coefficient of friction of carbon fabric.

3. Results and Discussion

3.1. Permeability in the in-Plane Direction

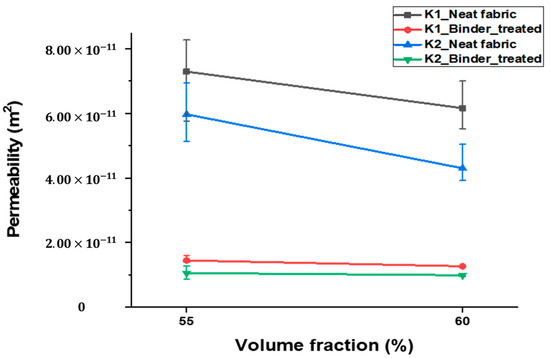

Figure 6 shows the permeability in the in-plane direction for each fiber volume fraction. The tests were conducted on two cases with fiber volume fractions of 55% and 60%. The permeability of the fiber in the 90° direction (having a maximum flow velocity) is K1, and the permeability of the fiber in the 0° direction (having a minimum flow velocity) is represented by K2. In each measurement, the neat fabric preform and binder-treated fabric preform with a heat treatment during the preforming process were used to investigate the effect of the binder on the in-plane permeability. The average value of each test is indicated, and the error bar shows the maximum and minimum of the sample. As shown in Figure 6 and Table 2, the permeability of the binder-treated fabric preform decreased in every case, regardless of in-plane direction (K1, K2) and the fiber volume fraction. It can be inferred that the treated binder hindered the impregnation of resin in the preform, decreasing the permeability by approximately 80% for K1 and 82% for K2, at a 55% fiber volume fraction, and 80% for K1 and 77% for K2, at a 60% fiber volume fraction. In spite of the consideration of the amount of porosity reduction due to the binder content noted in Table 1, the permeability in the in-plane direction of the binder-treated fabric preform significantly decreased, which means that the binder treatment changed the permeability characteristics of the fabric preform itself. In addition, the permeability of the fiber tended to decrease as the fiber volume fraction increased in both the K1 and K2 directions, regardless of the binder treatment, and especially for neat fabric, which exhibited a larger decrease (K1: −16%, K2: −28%) than that of the binder-treated fabric. It is assumed that the permeability of the binder-treated preform, which had already been reduced due to the effect of the binder, was less affected by the decrease in the fiber volume fraction than that of the neat fabric preform.

Figure 6.

Change in the permeability in the in-plane direction according to the binder treatment.

Table 2.

The permeability of the fabric preform in the in-plane direction.

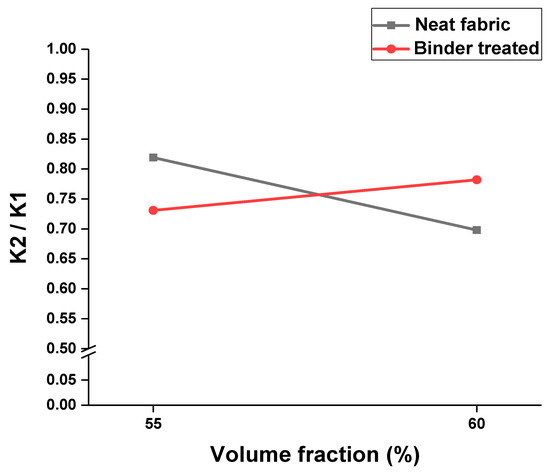

Figure 7 shows the K2/K1 values according to the fiber volume fraction. The K2/K1 value is a factor that can be obtained by dividing the permeability in the 0° direction (having a minimum flow velocity) of K2 into the permeability in the 90° direction (having a maximum flow velocity) of K1. As the shape of flow front of the resin is closer to circular, or isotropic, the factor approaches 1. The fabric preform exhibited a K2/K1 ratio of between 0.7 and 0.82.

Figure 7.

The value of K2/K1 according to the binder treatment.

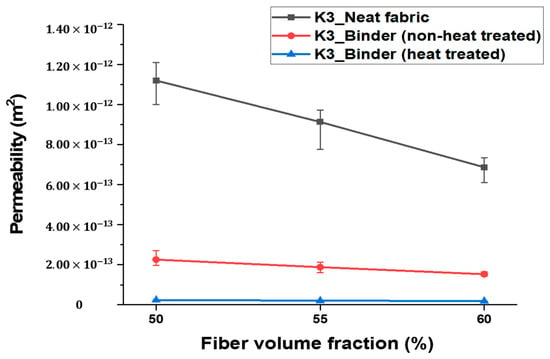

3.2. Permeability in the out-of-Plane Direction

In the LCM process, the permeability along the out-of-plane direction (z-axis) is also important when the resin is first injected into the fiber surface because of the flow media or the gap between the mold and then impregnated in the vertical direction of the surface. Consequently, the permeability in the out-of-plane direction was measured using the equation in Section 2.3.2, and the results are shown in Figure 8 and Table 3 according to the three types of fiber volume fractions: 50%, 55%, and 60%. To investigate the effect of the binder treatment, neat fabric preform and two types of binder-treated fabric preform (without heat treatment and with heat treatment during the preforming process) were prepared. As with the tendency of change in the permeability in the in-plane direction, all three cases showed a tendency to decrease the permeability of the preform in the out-of-plane direction when the fiber volume fraction increased. In addition, the binder-treated preforms exhibited a lower permeability than that of the neat fabric preforms. When the fiber volume fraction was 50%, 55%, and 60%, the permeability of the binder-treated preform without heat treatment exhibited a 78–79% reduction, and the binder-treated preform with heat treatment exhibited a 97–98% reduction compared to the permeability of the neat fabric preform. These results indicate that the binder treatment hindered the impregnation of resin in the out-of-plane direction. In particular, the permeability of the binder-treated fabric preform with heat treatment during the preforming process decreased more than that of the binder-treated fabric preform without heat treatment because the binder was softened during the heat treatment and permeated between the fibers under the 1 atm pressure applied by a vacuum bag. This phenomenon can greatly affect the reduction in the permeability of the fiber preform. To support this argument, micro observations of the binder in the preform is discussed in Section 3.3 below.

Figure 8.

Change in the permeability in the out-of-plane direction according to the binder treatment.

Table 3.

Permeability of the fabric preform in the out-of-plane direction.

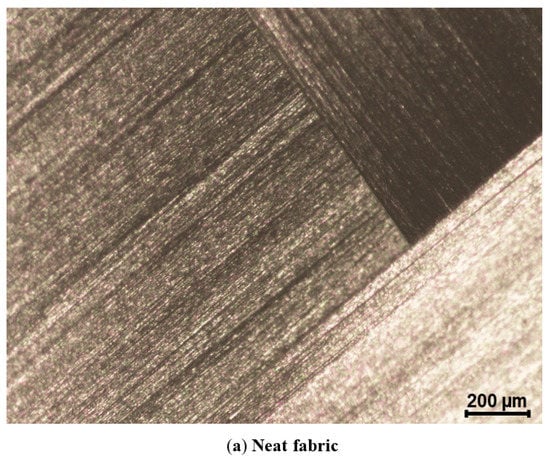

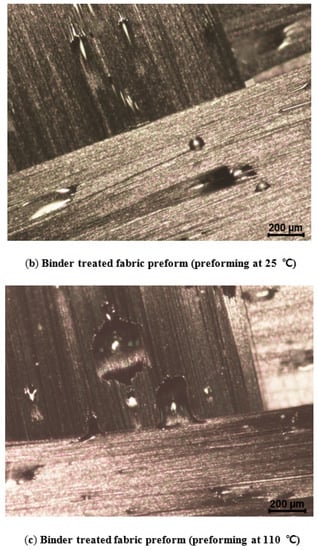

3.3. Microstructure Observations

To observe the shape of the binder in the preform, an ECLIPSE LV 150N optical microscope was used. Unlike the smooth surface of the neat fabric preform (Figure 9a), the original size of the powder binders lightly attached to the fiber surface was observed on the binder-treated preform without heat treatment during the preforming process (Figure 9b). In contrast, the preform that underwent heat treatment during the preforming process exhibited binders pressed in the in-plane direction and that adhered to the fiber in a flat shape (Figure 9c). The binder processed with a temperature above the glass transition temperature was flattened while being applied by a vacuum bag of 1 atm, and some of these binders permeated between the fibers and had a flat shape in the fiber in-plane direction to reduce the out-of-plane directional space where the fluid can flow. In the two types of binder-treated fabric preform (Figure 9b,c), the impregnation of the test fluid was disturbed by the binder occupying space to pass, resulting in a decrease in the permeability of the preform, especially in the heat-treated preform (Figure 9c), where the binders having a flat shape in the fiber in-plane direction led to a significant decrease (>97%) in the out-of-plane directional permeability.

Figure 9.

Micro observations of different types of preform.

3.4. Friction Coefficient Results

The results of the measurement of the kinetic friction coefficient are shown in Figure 10 and Table 4. The measurements were taken at room temperature (25 °C) and a binder treatment temperature of 110 °C. The friction coefficient of the surface with the binder was higher than that of the neat fabric; in the cases that the binder was on the friction surface (Cases 2 and 3), the friction coefficient at 110 °C was increased by 40% and 50% compared to the friction coefficient at room temperature (25 °C), respectively. Given that there was no change in the friction coefficient as a function of temperature in Case 1, which had no binder on the friction surface, the friction surface of cases 2 and 3 was changed due to the effect of temperature changes in the binder. Because the epoxy binder used in this study has a glass transition temperature of 75–85 °C at 110 °C, above the glass transition temperature, the binder was in a viscous state, which increased the energy loss at the friction surface due to viscous dissipation. In addition, the adhesion force at the friction surface also increased owing to the viscous binder, and consequently the friction coefficient of the surface with the binder increased. Similarly, in case 4, which shows the friction coefficient between the binder-treated fabric and the metallic mold, the friction coefficient at 110 °C was nearly three times higher than the friction coefficient at room temperature.

Figure 10.

The change in friction coefficient of the carbon fabric as a function of temperature.

Table 4.

Friction coefficient of the carbon fabric as a function of temperature.

4. Conclusions

The effect of a non-reactive epoxy binder generally used to fix the preform of the product in the LCM process was investigated. First, the permeability of the preform in the in-plane and out-of-plane directions were measured respectively using the unsaturated and saturated permeability equation according to the binder treatment. All the cases of fabric preform exhibited the highest permeability in the 90° direction (K1) and the lowest permeability in the 0° direction (k2), and both K1 and K2 decreased by about 80% with binder treatment at fiber volume fractions of 55% and 60%. The permeability in the out-of-plane direction also decreased with the binder treatment. In this case, the permeability in the out-of-plane direction of the binder-treated fabric preform (without heat treatment during the preforming process) decreased by approximately 80% compared to the neat fabric preform, and the binder-treated fabric preform (with heat treatment during the preforming process) decreased by approximately 98%. The reduction in permeability was significant even considering the reduction in the porosity of the preform arising from the presence of the binder. Thus, in agreement with the measurement results of permeability, this reduction was due to the fact that the binder changed the permeability characteristics of the preform. In particular, the binder was flattened and impregnated within the fibers during the preforming process including heat treatment, as was observed through micro-optical observation, and this binder significantly hindered the flow in the out-of-plane direction, resulting in a 98% reduction in the permeability. This decrease in permeability lowered the impregnation rate of the resin, which was closely related to the rate of production in the LCM process, resulting in a higher production cost. Additionally, the change in the kinetic friction coefficient used as a variable in forming simulations for wrinkle prediction in the LCM process was investigated according to the binder treatment. The friction coefficient was high when the binder was on the friction surface, and the binder became viscous at 110 °C, resulting in an increase in the friction coefficient by 40–200% compared to room temperature (25 °C). Therefore, based on the results of this study, changes in the characteristics of carbon fabric used as a reinforcement for composite materials can be predicted when a binder is used in the LCM process.

Author Contributions

H.M.Y. carried out the experimental design of this study and wrote the original draft. J.W.L. also carried out experimental design of this study. J.S.K. organized experimental data. M.K.U. supervised this study. All authors read and approved the final manuscript.

Funding

This work was funded by the Development of a Skin Spar Integrated Wingtip Composite Structure for a Single Aisle Aircraft using High Temperature Resin Infusion Process (20005403), Development of Mass Production Technology for Trunk Lid based on Hybrid Wet Compression Molding (10083584), Civil-Military Technology Cooperation Program (No.15-CA-MA-13-MKE) and the Technology Innovation Program (No.10053841) funded by the Ministry of Trade, Industry & Energy (MOTIE, Korea).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Kang, M.K.; Lee, W.I.; Hahn, H.T. Analysis of vacuum bag resin transfer molding process. Compos. Part A Appl. Sci. Manuf. 2001, 32, 1553–1560. [Google Scholar] [CrossRef]

- Trochu, F.; Ruiz, E.; Achim, V.; Soukane, S. Advanced numerical simulation of liquid composite molding for process analysis and optimization. Compos. Part A Appl. Sci. Manuf. 2006, 37, 890–902. [Google Scholar] [CrossRef]

- Kim, R.W.; Kim, C.M.; Hwang, K.H.; Kim, S.R. Embedded Based Real-Time Monitoring in the High-Pressure Resin Transfer Molding Process for CFRP. Appl. Sci. 2019, 9, 1795. [Google Scholar] [CrossRef]

- Yoo, H.M.; Kwon, D.J.; Park, J.M.; Yum, S.H.; Lee, W.I. Mechanical properties of norbornene-based silane treated glass fiber reinforced polydicyclopentadiene composites manufactured by the S-RIM process. e-Polymers 2017, 17, 159–166. [Google Scholar] [CrossRef]

- Ogale, V.; Alagirusamy, R. Textile Preforms for Advanced Composites. IJFTR 2004, 29, 366–375. [Google Scholar]

- Shih, C.H.; Lee, L.J. Tackification of textile fiber preforms in resin transfer molding. J. Compos. Mater. 2001, 35, 1954–1981. [Google Scholar] [CrossRef]

- Carley, E.P.; Dockum, J.F., Jr.; Schell, P.L. Preforming for liquid composite molding. SAE Trans. 1990, 99, 344–361. [Google Scholar]

- Tanoglu, M.; Robert, S.; Heider, D.; McKnight, S.H.; Brachos, V.; Gillespie, J.W., Jr. Effects of thermoplastic preforming binder on the properties of S2-glass fabric reinforced epoxy composites. Int. J. Adhes. Adhes. 2001, 21, 187–195. [Google Scholar] [CrossRef]

- Estrada, G.; Vieux-Pernon, C.; Advani, S.G. Experimental characterization of the influence of tackifier material on preform permeability. J. Compos. Mater. 2002, 36, 2297–2310. [Google Scholar] [CrossRef]

- Tanoğlu, M.; Seyhan, A.T. Compressive mechanical behaviour of E-glass/polyester composite laminates tailored with a thermoplastic preforming binder. Mater. Sci. Eng. A 2003, 363, 335–344. [Google Scholar] [CrossRef][Green Version]

- Brody, J.C.; Gillespie, J.W., Jr. Reactive and non-reactive binders in glass/vinyl ester composites. Polym. Compos. 2005, 26, 377–387. [Google Scholar] [CrossRef]

- Asareh, M.; Mills, A.R.; Denis, D.C. Investigation of preform manufacturing techniques using novel binder coated carbon fibre tows. In Proceedings of the 13th European Conference on Composite Materials, Stockholm, Sweden, 2–5 June 2008. [Google Scholar]

- Rohatgi, V.; Lee, L.J. Moldability of tackified fiber preforms in liquid composite molding. J. Compos. Mater. 1997, 31, 720–744. [Google Scholar] [CrossRef]

- Sommerlot, S.; Luchini, T.; Loos, A. The effects of a low areal weight inter-layer tackifier on saturated permeability of carbon fabrics. In Proceedings of the American Society for Composites: Thirty-First Technical Conference, Williamsburg, VA, USA, 19–22 September 2016.

- Lionetto, F.; Moscatello, A.; Maffezzoli, A. Effect of binder powders added to carbon fiber reinforcements on the chemoreology of an epoxy resin for composites. Compos. Part B Eng. 2017, 112, 243–250. [Google Scholar] [CrossRef]

- Schmidt, S.; Mahrholz, T.; Kühn, A.; Wierach, P. Powder binders used for the manufacturing of wind turbine rotor blades. Part 1. Characterization of resin-binder interaction and preform properties. Polym. Compos. 2018, 39, 708–717. [Google Scholar] [CrossRef]

- Adams, K.L.; Russel, W.B.; Rebenfeld, L. Radial penetration of a viscous liquid into a planar anisotropic porous medium. Int. J. Multiph. Flow 1988, 14, 203–215. [Google Scholar] [CrossRef]

- Weitzenböck, J.R.; Shenoi, R.A.; Wilson, P.A. Radial flow permeability measurement. Part A: Theory. Compos. Part A Appl. Sci. Manuf. 1999, 30, 781–796. [Google Scholar]

- Weitzenböck, J.R.; Shenoi, R.A.; Wilson, P.A. Radial flow permeability measurement. Part B: Application. Compos. Part A Appl. Sci. Manuf. 1999, 3, 797–813. [Google Scholar]

- Fauster, E.; Berg, D.C.; Abliz, D.; Grössing, H.; Meiners, D.; Ziegmann, G.; Schledjewski, R. Image processing and data evaluation algorithms for reproducible optical in-plane permeability characterization by radial flow experiments. J. Compos. Mater. 2019, 53, 45–63. [Google Scholar] [CrossRef]

- Endruweit, A.; Luthy, T.; Ermanni, P. Investigation of the influence of textile compression on the out-of-plane permeability of a bidirectional glass fiber fabric. Polym. Compos. 2002, 23, 538–554. [Google Scholar] [CrossRef]

- Francucci, G.; Rodríguez, E.S.; Vázquez, A. Study of saturated and unsaturated permeability in natural fiber fabrics. Compos. Part A Appl. Sci. Manuf. 2010, 41, 16–21. [Google Scholar] [CrossRef]

- Tonejc, M.; Ebner, C.; Fauster, E.; Schledjewski, R. Influence of test fluids on the permeability of epoxy powder bindered non-crimp fabrics. Adv. Manuf. Polym. Compos. Sci. 2019, 5, 128–139. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).