Abstract

A high temperature is produced in the process of precision milling of titanium alloy, and the cutting temperature can be effectively reduced by placing a micro-texture on the tool surface. In order to study the milling temperature of micro-textured ball-end milling cutter in milling titanium alloy under the combined action of a blunt radius with different edges and a micro-texture with different parameters, a new method based on micro-element theory and the generation and transmission of cutting heat has been established. At the same time, the influence of different radii of blunt edges on the milling temperature is simulated by the finite element method and experimentally verified to explore the influence of different radii of a blunt edge and micro-texture parameters on the milling temperature. Taking the milling temperature as the evaluation index, the optimum parameters of micro-circular pit texture are as follows: the diameter of micro-circular pit is 40 micron, pit spacing is 225 micron, distance from cutting edge is 100 microns, and radius of the blunt edge is 60 microns.

1. Introduction

Titanium alloys are widely used in various fields because of their high strength, corrosion resistance, and heat resistance properties. However, at the same time, owing to the characteristics of titanium alloy, such as small deformation coefficient, high specific strength, good toughness, and so on, it is easy to produce a high temperature when milling titanium alloy, and the cutting force per unit area is large and the tool wear is serious. Especially in precision milling applications (i.e., a very small amount of material is removed), overly high milling temperatures are the main cause of tool wear and the poor surface quality of workpieces. In the actual production process, the blunt radius of the cutting edge has a significant effect on the force thermal characteristics in the cutting process. Especially in precision cutting, the cutting work is mainly completed by the cutting edge of the cutting tool, which is the first part to contact the workpiece. Changing the shape of the cutting edge has directly influenced the cutter-workpiece contact state and modifies the length of the cutter-workpiece contact state across three heat source regions, resulting in changes in the generation and transmission of cutting heat. Therefore, the blunt radius of the cutting edge has an important influence on the cutting temperature in the cutting process. Tian Xingqiang and Nie Huawei [1] take the blunt radius of the cutting edge of a titanium alloy Ti6Al4V end milling cutter as the research object. The experimental results show that the milling temperature initially decreases, and then tends to smooth with an increasing cutting-edge radius. Mohamed N.A. Nasr [2] has studied the turning process of austenitic stainless steel AISI 316L with different cutting radii of a cemented carbide cutter; the authors report that the cutting temperature increases with the increase of the blunt circle radius in the range of 0.02–0.1 mm. Zheng Weijuan et al. [3] use the Advantedge 3D software to simulate the milling process of 45 steel with different cutting radii of a blunt circle radius end milling cutter. The curves of the cutting radii are increased from 0.02 mm to 0.08 mm; the authors report that the milling temperature initially decreases, and then increases with the increase of the cutting-edge radius. The lowest milling temperature occurs when the cutting-edge radius is 0.06 mm. Yang Weidong and others [4] used abaqus to simulate the process of cutting 45 steel with a cemented carbide blade with a blunt edge. The authors report that increasing the radius in the range of 0–0.02 mm presented a decreasing cutting temperature. However, in the cutting-edge radius range of 0.02–0.1 mm, the cutting temperature gradually increases as the radius increases. In order to study the effects of the cutting edge on the hard cutting performance of the tools, Tao Liang [5] and others have used the Advantedge finite element simulation software to simulate hardened bearing steel with five kinds of tools with different blunt radii. The research has found that the high temperature area of the cutting tools increases with the increase of the blunt radius, and the highest cutting temperature is located near the cutting edge. According to a large number of studies, when cutting titanium alloy and other difficult-to-machine materials, placing a micro-pit texture on the surface of the tool can improve the processing quality of the workpiece and prolong the service life of the tool. The micro-pit texture plays a role in grinding and anti-wear in the process, so that the cutting force and cutting temperature are reduced. The diameter, spacing, distance from the cutting edge, depth, and other parameters related to the pits have different effects on the cutting force and temperature. The reasonable selection of the parameters for the micro-texture is of great significance for improving the machining quality and cutting performance of the tool. Wang Liang [6] made use of a laser marking machine to produce different micro-textures on the rake face of cemented carbide tools. The cutting experiments show that a micro-texture has the effect of improving cutting performance, reducing cutting force, and reducing cutting temperature. Zhang Yongbo [7] uses the Advantedge software to simulate the turning process of cemented carbide cutting tools with a groove texture. The authors report that the insertion of a groove texture significantly reduces the cutting temperature. With the increase of the texture spacing, the cutting temperature increases slowly; with the increase of the groove width, the cutting temperature initially decreases, and then increases. Cai Xiao [8], in order to study the influence of micro-texture on cutting force and cutting temperature, prepared micro-texture tools by the laser processing method. Through comparative tests, it is concluded that micro-texture tools can effectively reduce the cutting force and cutting temperature compared with non-texture tools. Chen Hongfeng and Lian Yunsong [9] have studied the influence of micro-texture on cutting performance of trapezoidal groove surface with different texture parameters by finite element simulation. The results show that reasonable texture parameters can effectively improve the friction between cutting tool and chip and promote heat dissipation, thus achieving the effect of reducing the cutting force and cutting temperature. Yu Zhanjiang and Cai Qianqian [10] have carried out high-speed cutting experiments on SUS304 stainless steel using micro-texture tools and non-texture tools. The cutting performance of micro-texture tools has been studied. The research found that the micro-groove texture and the pit texture can effectively reduce the friction coefficient of the tool surface, thus reducing the cutting force and the cutting temperature; a micro-pit texture can obviously improve the surface quality. Zhang Na and Yang [11] have established many different types of micro-texture hard alloy models and conducted three-dimensional friction simulation tests of different types of surface micro-texture cemented carbide and titanium alloy by finite element simulation software. The results show that the groove texture can increase the heat dissipation area and significantly reduce the friction temperature, and the diamond pit texture can control the temperature increase during the friction process.

To sum up, the blunt radius of the cutting edge and the micro-texture parameters are important in improving the machinability of titanium alloys and reducing cutting temperatures. However, there are few studies on the combined influence of these two factors on the cutting of titanium alloys. Therefore, studies are urgently needed to investigate the influence of cutting-edge form and texture parameters on the processing properties of titanium alloys. In this work, a novel milling temperature model is proposed, which relies on the method of micro-element approximations and refers to the generation and conduction law of cutting heat. The proposed model is established for titanium alloy milling processes using ball end milling cutters under the action of an action of blunt edge and analyze its influence mechanism. The influencing mechanisms of different blunt radius and texture parameters on milling temperatures are analyzed. Furthermore, different blunt radius and micro-texture parameters are used to simulate and test the titanium alloy milling process; the influence of different blunt radius and micro-texture parameters on milling temperatures is also analyzed. According to the simulation and experimental results for each set of parameters, the optimal combination of the blunt radius of the cutting edge and texture parameters is obtained.

2. Establishment of Milling Temperature Model

2.1. Analysis of Milling Heat Source of Ball-End Milling Cutter

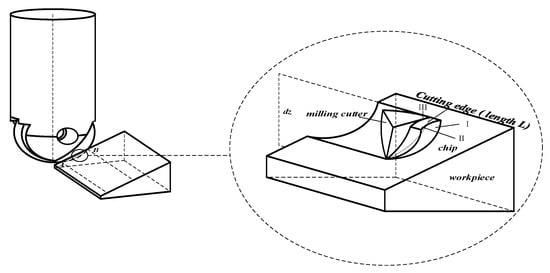

A simplified diagram of the heat source model for ball-end milling cutter is illustrated in Figure 1. According to the structure of the ball-end milling cutter and milling principle, when calculating the cutter temperature, the ball-end milling cutter can be decomposed into numerous uniform micro units along the axial direction, and the cutting of each micro unit can be simplified as oblique cutting. The milling heat for this kind of cutter is mainly generated in three areas. The first heat source area is the shear surface, where the heat is generated by the deformation work done to overcome the plastic deformation of the metal. The second heat source area is the rake face, where the heat is generated by the friction between the chip and the rake face. The third heat source area is the rear, where the heat is generated by the friction between the rear and the workpiece. When calculating the temperature field of the workpiece, the surface heat sources of the three deformation zones are equivalent to the line heat sources at the cutting edge. The ball end milling cutter can be discretized into a collection of uniform micro-elements along the axis, and the cutting process of each micro element can be simplified as oblique cutting. The discrete micro-element line heat sources are dz in height, dL in length, and β1 in helix angle of the milling cutter, in the following:

Figure 1.

Simplification of a heat source model for ball-end milling cutters.

During the milling process of ball-end milling cutter with micro-texture, the contact state between the cutter and the workpiece is constantly changing, and the heat flux density is non-uniform distribution. During the cutting process, the length of spiral heat source changes continuously, which is a process from zero to the longest and from the longest to zero. Therefore, the heat transfer process of the micro-textured ball-end milling cutter can be simplified as an intermittent heating process of the periodicity on the workpiece processing surface by the spiral heat source with variable length, non-uniform heat flux density, and constant change [12]. As the helix angle of the ball-end milling cutter with micro-texture used in this paper is zero, it is not necessary to consider the influence of helix angle on the variation of linear heat source. In order to simplify the analysis, the ball-end milling cutter is divided into numerous uniform micro-elements along the cutting edge and the cutting process of each micro-element is simplified to a right-angle cutting form.

During the milling process of a ball-end milling cutter, because the cutting edge is a circular arc, the cutting depth at different positions of the cutting edge exhibits a state of constant change from zero to the maximum value. From the classical cutting force formula, it can be seen that the change of the cutting depth causes slight changes in the main cutting force, which can be ignored. Therefore, each cutting element can be integrated and the influence of the cutting edge form on the cutting temperature can be obtained.

2.2. Average Temperature: The Shear Surface

Most of the heat generated on the shear surface passes to the chip and part to the workpiece. The heat generated q1 per unit time per unit area on the shear surface is as follows:

where is the shear force, is the shear velocity along the shear plane, and is the shear angle.

The average temperature of the three surface heat sources is solved (sheer plane, rake face, rear). First, the average temperature of the shear plane is solved. It is assumed that the surface of the semi-infinite object has a moving surface heat source with a width of 2lm and an infinite length. If the heat per unit area per unit time is q, the average temperature in the surface heat source can be expressed as follows:

where c0 is the specific heat of the object (J/(kg·K)), ρ0 is the object density (kg/m3), v is the moving speed of the surface heat source (m/s), k0 is the thermal conductivity of the object [W/(m·K)], lm is the half (m) of the surface heat source width, and θ is the initial temperature of the object (°C).

(1) The average temperature of the chip-side shear surface.

For the chip, the heat source produced by shearing is a continuous fixed heat source. According to the equation of heat balance, the average temperature of the shear zone is as follows:

where R1 is the ratio of heat to chip in the first deformation region, c1 is the specific heat capacity of temperature , ρ1 is the density of the workpiece material, and θ0 is the initial temperature of the workpiece.

(2) The average temperature of the workpiece-side shear surface.

The average temperature of the shear surface on the workpiece can be calculated according to the temperature field of the moving surface heat source. The average temperature of the workpiece-side shear plane is obtained as follows:

where k1 is the thermal conductivity of the workpiece material at the temperature , and is the thermal conductivity coefficient of the workpiece material at temperature .

Equation (4) is equal to Equation (5). According to the chip shear deformation, the relative slip εslip is as follows:

where γrake is the rake angle of the micro-element cutting of the ball-end milling cutter.

Given and , the ratio R1 of the heat transfer from the shear surface to chip is as follows:

where ac is the actual cutting depth.

2.3. Average Temperature: The Contact Area of the Rake Cutter Surface

The friction heat source per unit time per unit area of the rake knife face is q2:

where Ff is the friction force on the rake face; vc is the chip flow velocity, ; lf micro-rake is the contact length between the chip and the rake face in the micro-element cutting of the ball-end milling cutter; and uf is the friction work done when cutting off the chip per unit volume, .

(1) The average temperature of the rake face calculated from the chip’s perspective.

The friction heat source is a moving heat source for the chip, and the chip is viewed as semi-infinite. Also, according to Jaeger’s solution [13], the average temperature of the rake face is obtained as follows:

where R2 is the percentage of the friction heat of the chip, α2 is the temperature coefficient of the workpiece material when the temperature is the average of and , and c2ρ2 is the volumetric heat capacity when the temperature of the workpiece material is the average of and .

(2) The average temperature of the rake face calculated from the tool’s perspective.

The friction heat source is a continuous fixed heat source on the tool’s rake face. The heat source is located using a semi-infinite principle, regarding the tool as 1/4 infinite gross (2D cutting) or 1/8 infinite gross (3D cutting). The average temperature of the rake face is obtained as follows:

where R2 is the percentage of the friction heat of the chip, is the initial temperature of the tool, k3 is the thermal conductivity of the cutting tool when the temperature is the average of and , and is the area coefficient related to the aspect ratio of the surface heat source.

Equation (9) is equal to Equation (10). Hence, the percentage R2 of friction heat transfer to the chip can be expressed as follows:

where uf is the friction work done when the unit volume chip is removed.

2.4. Average Temperature: The Contact Area of the Rear Cutter Surface

According to the literature, the average temperature of the rear surface contact area can be calculated [14]. The calorific value per unit time and per unit area of the friction heat source on the rear face is q3:

where Ffa is the rear face friction force (N), V is the cutting speed (m/min), and lf micro-rear is the contact length between the cutter and the back face in micro-element cutting of a ball-end milling cutter.

(1) The average temperature of the rear face calculated from the workpiece’s perspective.

The friction heat source is a moving surface heat source for the workpiece, and the workpiece is regarded as semi-infinite. The moving surface heat source theory is applied to obtain the average temperature of the rear face as follows:

where R3 is the ratio of the heat generated in the contact area (between rear face and workpiece) that flows into the workpiece, k4 is the thermal conductivity coefficient [W/(m·k)] when the temperature of the workpiece material is the average value of and θ0, and α3 is the thermal conductivity coefficient when the temperature of the workpiece material is the average value of and .

(2) The average temperature of the rear face calculated from the tool’s perspective.

The friction heat source is a fixed continuous heat source for the rear face. The heat source is located using a semi-infinite principle, regarding the tool with the 1/4 infinite principle (two-dimensional cutting) or 1/8 infinite principle (three-dimensional cutting). According to the heat source formula of the static continuous action surface, the average temperature of the tool rear face is as follows:

where k5 is the thermal conductivity when the temperature of the tool material is the average of and .

Given Equations (13) and (14) are equal, R3 can be defined as follows:

From Equations (10) and (14), it can be seen the average cutting temperature of the tool is as follows:

Substituting Equations (8) and (12) into Equation (16) results in the following:

2.5. Milling Temperature Model

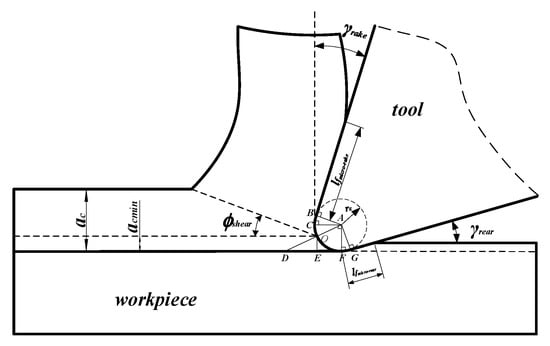

When the form of the cutting-edge changes from a sharp edge to a blunt edge, the chip contact state near the cutting-edge changes. As shown in Figure 2, the cutting edge of the tool is divided into two parts at the diversion point O under a blunt edge cutting. The parts above point O mainly have friction with the chips, so the edge cuts into the rake face of the tool, and the tool-chip contact length is . The part below the point O mainly has friction with the workpiece. The lOF is cut into the rear face of the tool, and the tool–workpiece contact length becomes . According to the arc length formulae,

where acmin is the limit cutting thickness and γrear is the rear angle of the cutter.

Figure 2.

Milling temperature model under a blunt edge.

Considering the influence of the blunt cutting edge on the cutting performance of the tool, the percentages of the frictional heat transfer from the rake face to the chip and the proportion of heat generated by the contact area (between the rake face and the workpiece) that flows into the tool can be computed. More specifically, under the action of the radius of the blunt cutting edge, these two heat transfers can be obtained from Equations (10) and (14), respectively,

The analysis shows that, with the increase of rε, the values of lOF and lOCB increase. Consequently, and increase, and decreases. Therefore, as the radius of the blunt edge increases, the milling temperature for each cutting micro-element decreases. When the radius of the cutting edge gradually increases, the composition of the cutting force at the cutting-edge changes, the extrusion and friction effects at the cutting-edge increase, and the proportion of cutting heat transferred to the cutting tool increases. As this proceeds, the heating effect caused by the increasing radius of the cutting edge exceeds the cooling effect, so the temperature of the cutting tool increases with the continuous increase of the radius of the cutting edge.

3. Simulation Experiment of Titanium Alloy Milling Process by Ball-End Milling Cutter with Micro-Texture

3.1. Establishment of Material Model and Friction Model

The material of the micro-texture ball-end milling cutter is cemented carbide, and its parameters can be directly given from the material library of the software. The workpiece material is Ti6Al4V, and some basic material properties of titanium alloy are shown in Table 1. In order to ensure the accuracy of the finite element simulation results, the Johnson–Cook constitutive equation is adopted in this simulation; the material parameters of the Johnson–Cook model of Ti6Al4V are shown in Table 1. A, B, n, m, and C are all structural constants of the model; E is Young’s modulus; μ is Poisson’s ratio; and ε0 is the reference strain rate.

Table 1.

Titanium alloy Johnson–Cook material model parameters.

The tool–chip contact area is divided into the tool–chip close contact area and the tool–chip non-close contact area; the simulation friction models used in the two kinds of areas are different. In the cutting simulation of μσn and σs, the magnitude of these two values are mainly judged through comparative analysis, as shown in Equation (22).

where τf is the friction shear stress of the tool, μ is the friction coefficient of the tool–chip contact area, σs is the maximum shear stress of titanium alloy, and σn is the normal stress of titanium alloy.

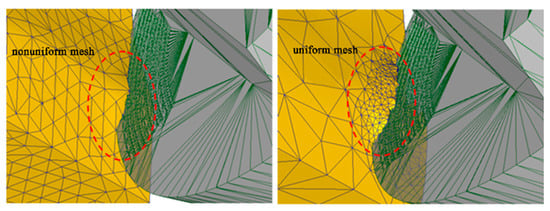

3.2. Simulation Boundary Conditions and Mesh Generation

To further study the influence of the radius of the blunt edge on the cutting performance of titanium alloy, the finite element software deform was used to simulate and analyze the influence rule. The finite element models of cutting tools and workpieces used in the simulation are the same as those mentioned above. The software transmits the calculation data through the grid, so the grid quality seriously affects the accuracy of simulation results. During the simulation process, the mesh will be distorted continuously. Using the adaptive mesh division method in deform to re-divide the distorted mesh can effectively ensure the simulation accuracy. A tetrahedral mesh is used for the mesh division of the workpiece and the cutter, with the number of cutter meshes set at 70,000 and the number of workpiece meshes set at 35,000. The whole workpiece is divided by using a grid with a minimum grid size of 0.1 mm and a mesh grid size ratio of 1:4, and a thinning pane with a size of 0.05 mm is added near the cutting edge of the cutter and at the part of the workpiece surface in contact with the cutting edge. In this way, the simulation results can be more accurate without reducing the simulation efficiency. The partitioned mesh is shown in Figure 3.

Figure 3.

Adaptive mesh generation.

To make the simulation process consistent with the actual machining process, it is necessary to add boundary conditions to the workpiece and the tool. To ensure the fixed position of the workpiece in the machining process, the three directional nodes of X, Y, and Z where the workpiece surface does not come into contact with the cutter are respectively restrained. At the same time, set the shear friction coefficient between the cutter and the workpiece to be 0.6 and the heat transfer coefficient to be 45. Finally, the cutting tool and the workpiece are set with an initial temperature and a heat transfer surface, the initial temperature is set to be 20 degrees at room temperature, and the heat transfer surface is the two cutting edge surfaces of the cutting tool and the upper surface of the workpiece.

3.3. Simulation Scheme Design

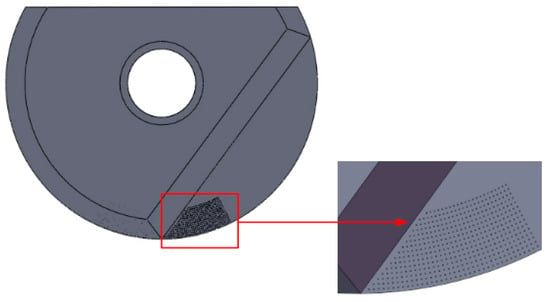

In this work, the cutting parameters used for the simulation experiments are as follows: cutting speed vc = 120 m/min; feed per tooth fz = 0.08 mm; cutting width ae = 0.5 mm; and cutting thickness ap = 0.3 mm. These values have been reported in the literature to provide the best cutting performance of titanium alloy [15]. Taking an example that is 30 μm in diameter, 125 μm in pitch, and 90 μm in distance from the edge, the distribution of the micro-texture is shown in Figure 4. On the basis of the above parameters, a four-factor five-level table design is established, as shown in Table 2. The influence of the micro-circular pit texture on the milling temperature of the ball-end milling cutter is analyzed through orthogonal experiments.

Figure 4.

Distribution form of the micro-texture.

Table 2.

Four factors and five levels table of the simulation parameters.

3.4. Analysis of Milling Temperature Simulation Results

The range analysis method is used to process the average milling temperature of the simulation test of titanium alloy milling using the micro-texture ball-end milling cutter with a blunt edge. The relevant data are shown in Table 3. From the magnitude of the extreme difference of the four factors in the table, it can be determined that the influence order of the texture parameters for each micro-circular pit and the radius parameters of the blunt edge on average milling temperature is as follows: radius of blunt edge > distance from cutting edge > distance between micro-circular pits > diameter of micro-texture parameters. That is, the radius of blunt circle has the greatest influence on the average milling temperature, while the diameter of micro-circular pit has the least influence.

Table 3.

Range analysis table of the milling temperature simulation data.

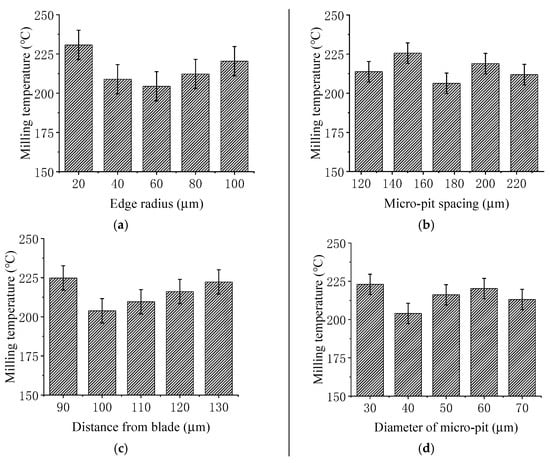

The analysis of the data is shown in Figure 5 and the analysis of variance is shown in Table 4. According to the F value in the table, it can be seen that the order of significance level is as follows: edge radius > distance from blade > diameter of micro-pit > micro-pit spacing.

Figure 5.

Influence of micro-texture parameters and blunt edge parameters on the milling temperature. (a) Influence of the cutting edge radius on the milling temperature. (b) Influence of the distance from the edge on the milling temperature. (c) Influence of the micro-pit spacing on the milling temperature. (d) Influence of the micro-pit diameter on the milling temperature.

Table 4.

Variance analysis of simulation data.

Figure 5 shows the relationships between the micro-texture parameters and the blunt radius on the average milling temperature. As shown in Figure 5a, as the radius of the blunt cutting-edge increases, the average milling temperature decreases rapidly first, and then increases slowly. As shown in Figure 5b, as the distance from the cutting-edge increases, the average milling temperature initially decreases, and then increases. As shown in Figure 5c, the average milling temperature increases at first and then decreases; this pattern repeats as the micro–pit spacing further increases. As shown in Figure 5d, the average milling temperature decreases initially; this is followed by increasing and then decreasing average milling temperature values as the diameter of the micro-round pits increase. Therefore, when the average milling temperature is taken as the evaluation index, the optimal parameters of the micro-texture are as follows: the diameter of the micro-circular pit is 40 μm, the pitch of the micro-circular pit is 175 μm, the distance from cutting edge is 100 μm, and the blunt radius of the cutting edge is 60 μm.

4. Experimental Verification

4.1. Preparation and Experimental Device of Micro-Round Pit Textured Ball-End Milling Cutter

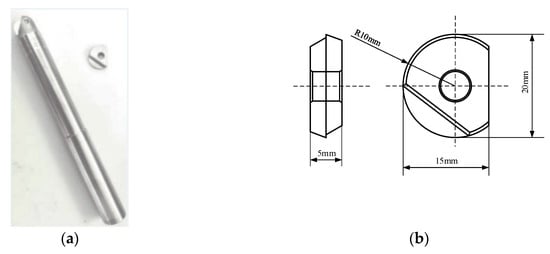

For verifying the accuracy of the above simulation results and conducting further relevant milling experiments, a BNM-200 ball-end milling cutter is used as the cutting tool and YG8 is used as the cutting tool material. The size of the cutting tool and the cutting blade are shown in Figure 6. Micro-round pit textures with different parameters are prepared on the rake face of the ball-end milling cutter using a fiber laser. The fiber laser is shown in Figure 7.

Figure 6.

Tool and tool size diagram. (a) Tool and tool bar diagram; (b) Tool size diagram.

Figure 7.

Fiber laser.

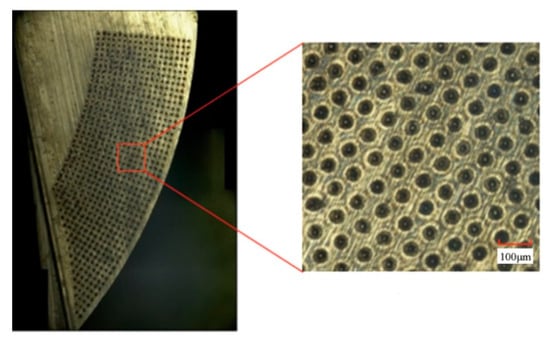

The fiber laser produced by Beijing Zhengtianhengye numerical control technology company limited is used to machine the micro-texture on the front face of the cutter. The equipment model is ZT-Q-50. After the micro-round pit texture is prepared on the front face of the cutter using an optical fiber laser, the texture area needs to be post-treated. Firstly, the texture area is polished by sandpaper; then, the ultrasonic cleaning device SL3-120B type manufactured by Shanghai Sheyan instrument company limited company is used to clean the residue inside the pits. The cleaning solution is an acetone solution. The micro-texture morphology finally prepared after the treatment is shown in Figure 8.

Figure 8.

Texture profile of micro-circular pits.

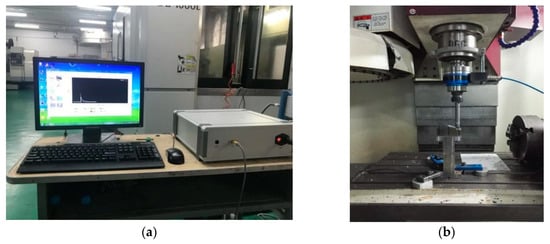

In this experiment, the VDL-1000E type three-axis vertical milling machine produced by Dalian machine tool group company limited is used for the milling process. The material of the workpiece to be processed is Ti6Al4V, with a hardness of 36 HRC, heat transfer coefficient of 7.995 W/(m·k), Poisson’s ratio of 0.41, yield strength of 825 MPa, and elastic modulus of 110 GPa. In the milling process, the linear velocity of the tool tip remains zero to prevent the tool tip from abrasion and ensure the machining quality. Hence, a table workpiece with an inclination angle of 15 degrees needs to be used. The temperature measurement adopts a E12-3-K-U type thermocouple, and the model is IESC type data acquisition system are used for temperature data collection. The schematic diagram of the experimental device is shown in Figure 9.

Figure 9.

Experimental setup diagram. (a) Milling temperature acquisition system. (b) Workpiece clamping diagram.

4.2. Analysis of Influence Law of Milling Temperature

The average milling temperature values under the combined effects of different micro-texture parameters and different cutting edge blunt radius parameters obtained through orthogonal experiments are shown in Table 5. It can be determined that the influence order of the texture and edge radius parameters on the average milling temperature is as follows: blunt edge radius > distance from cutting edge > distance between micro pits > diameter of micro pits. That is, the radius of the blunt circle has the greatest influence on the average milling temperature, while the diameter of the micro-circular pit has the least influence.

Table 5.

The range analysis of milling temperature experimental data.

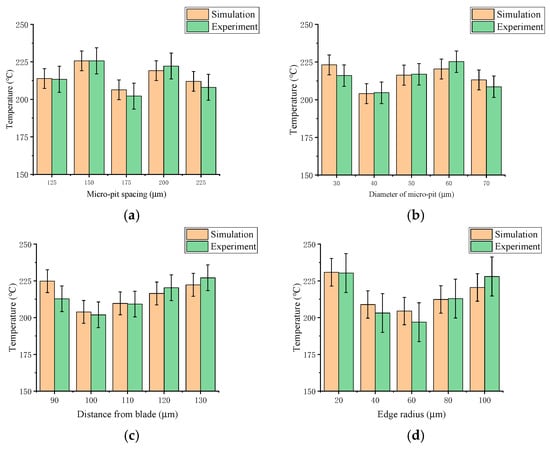

The analysis of the data is shown in Figure 10 shows and the analysis of variance is shown in Table 6. According to the F value in the table, it can be seen that the order of significance level is as follows: edge radius > distance from blade > micro-pit spacing > diameter of micro-pit.

Figure 10.

Relationship between the micro-circular pit texture and the blunt edge parameters on the average milling temperature. (a) Influence of the micro-pit spacing on the milling temperature. (b) Influence of the micro-pit diameter on the milling temperature. (c) Influence of the distance from the edge on the milling temperature. (d) Influence of the blunt radius of and the cutting edge on the milling temperature.

Table 6.

Variance analysis of experimental data.

Figure 10 shows the simulation and experimental comparison of micro-circular pit texture parameters and cutting-edge parameters against average milling temperature. It can be seen from the above that the influence rules of various parameters on milling temperature in simulation and experimental results are basically the same, which shows that the changes of cutting edge and micro-texture parameters do affect the change rules of milling temperature. The deviation between simulation results and experimental results is mainly because of the vibration of machine tool in the experiment and the error in non-linear solution in simulation calculation. As shown in Figure 10a, the average milling temperature increases first and then decreases with the increase of micro-pit spacing. The spacing of micro-pits continues to increase, and the average milling temperature increases first and then decreases again. As shown in Figure 10b, the average milling temperature decreases first, then increases, and then decreases with the increase of the diameter of the micro-round pit. As shown in Figure 10c, as the distance from the cutting-edge increases, the average milling temperature decreases first and then increases. As shown in Figure 10d, with the increase of the cutting-edge radius, the average cutting temperature decreases first and then increases.

As can be seen from Figure 10, when the average cutting temperature is taken as the evaluation index, the optimal parameters are as follows: the diameter of the micro-circular pits is 40 μm, the spacing between the micro-circular pits is 175 μm, the distance from the cutting edge is 100 μm, and the radius of blunt cutting edge is 60 μm.

5. Conclusions

This paper mainly studies the influence of different cutting edge blunt radii and different micro-texture parameters on the milling temperature. The milling temperature is taken as the evaluation standard to establish the optimal combination parameters of the micro-pit texture and the blunt radius. It is found that the milling temperature first decreases and then increases with the increase of radius rε. Under the action of a blunt cutting edge, when the milling temperature is taken as the evaluation index, the optimal parameters of the micro-texture and the blunt edge are as follows: the diameter of the micro-circular pit is 40 μm, the spacing between the micro-circular pits is 175 μm, the distance from the cutting edge is 100 μm, and the radius of the blunt cutting edge is 60 μm. In addition, through conducting the simulation analysis and experimental verification of the milling process under the action of the blunt edge, the following four conclusions are drawn. First, when the texture parameters increase, the ability of the micro-round pit texture to capture chips is enhanced, which reduces the heat carried away by chips. However, as the micro-texture also has the function of anti-wear and friction reduction, the average milling temperature initially decreases and then increases when the radius of the blunt edge increases. Second, when the distance from the cutting edge increases, the average milling temperature initially decreases; subsequently, the temperature increases and then decreases. Third, when the spacing between micro-pits increases, the average milling temperature initially increases and then decreases. Fourth, when the diameter of micro-circular pits increases, the average milling temperature initially decreases; subsequently, the temperature increases and then decreases.

Author Contributions

Conceptualization, S.Y. and X.L.; Data Curation, S.S.; Methodology, S.Y. and S.S.; Software, P.H.; Project Administration, S.Y.; Supervision, X.L.; Writing-Original, S.S.; Writing-Review, S.Y.; Data Analysis, S.S. and P.H. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by [The National Natural Science Foundation of China] grant number [51875144]. And the APC was funded by [The National Natural Science Foundation of China and Construction of scientific research collaborative innovation platform-Advanced manufacturing intelligent technology].

Conflicts of Interest

The authors declare no conflict of interest.

References

- Tian, X.; Nie, H. Study on Blunt Radius of Milling Cutter Edge to Milling Ti6Al14V Temperature. Enterp. Technol. Dev. 2016, 12, 92–93. [Google Scholar]

- Nasr, M.N.A.; Ng, E.G.; Elbestawi, M.A. Modelling the effects of tool-edge radius on residual stresses when orthogonal cutting AISI 316L. Int. J. Mach. Tools Manuf. 2007, 47, 401–411. [Google Scholar] [CrossRef]

- Zheng, W.; Huang, B.; Zhao, X.; Zhou, Y. Finite Element Analysis on Influence of Rounded Cutting Edge Radius of Milling Cutter to Cutting Property. Coal Mine Mach. 2014, 10, 125–127. [Google Scholar]

- Yang, W.; Jia, P.; Zhang, Z.; Chen, S.; Huang, J. Research on Simulation and Experiments of the Blunt Radius of Carbide Tool. J. New Ind. 2015, 8, 44–50. [Google Scholar]

- Tao, L.; Pan, K.; Ji, B. Effects of Edge Radius on Tool’s Hard Machining Characteristics. Mach. Electron. 2019, 11, 7–9. [Google Scholar]

- Liang, W. Experimental Study on Cutting Titanium Alloy with Surface Textured Tool. Master’s Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2012. [Google Scholar]

- Zhang, Y.; Zhang, M. Simulation Study on Cutting Performance of Surface Textured Tool Based on AdvantEdge. Light Ind. Mach. 2019, 37, 78–82. [Google Scholar]

- Xiao, C. The Optimal Design of Microtextured Turning Tools and Study on Their Cutting Performance. Master’s Thesis, Southeast University, Nanjing, China, 2018. [Google Scholar]

- Chen, H.; Lian, Y.; Mu, C. Designing and Cutting Performance Research of Surface Micro-textured Tools Based on Finite Element. Tool Eng. 2018, 4, 13–20. [Google Scholar]

- Yu, Z.; Cai, Q.; Wang, X.; Xu, J.; Yu, H. Preparation of Micro-textured Turning Tools and High Speed Micro Turning Test of SUS304 Steel. China Surf. Eng. 2016, 29, 1–7. [Google Scholar]

- Zhang, N.; Yang, F.; Liu, X.; Liu, G.; Sun, S. 3D Simulation Analysis of Friction Process between Textured Cemented Carbide and Titanium Alloy. Tool Eng. 2019, 79–83. [Google Scholar]

- Bi, Y.; Fang, Q.; Dong, H.; Ke, Y. Research on 3D Numerical Simulation and Experiment of Cutting Temperature for High Speed Milling of Aerospace Aluminum Alloy. J. Mech. Eng. 2010, 7, 160–165. [Google Scholar] [CrossRef]

- Vanda, M.L.; Reginaldo, T. Coelho an inverse method to estimate the moving heat source in machining process. Appl. Therm. Eng. 2012, 45, 64–78. [Google Scholar]

- Wang, S.; Man, Z.; Fang, Y. Study on Cutting Heat of Flank of Metal Cutting Tool. Manuf. Technol. Mach. Tool 2011, 1, 92–96. [Google Scholar]

- Wei, X.; Hou, Z. Experimental Study on Cutting Force in Turning Process. J. Hebei Univ. Eng. 2017, 3, 97–100. [Google Scholar]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).