Large Gradient Micro-Structure Topography Measurement with Multi-Angle Stitching Digital Holographic Microscope

Abstract

1. Introduction

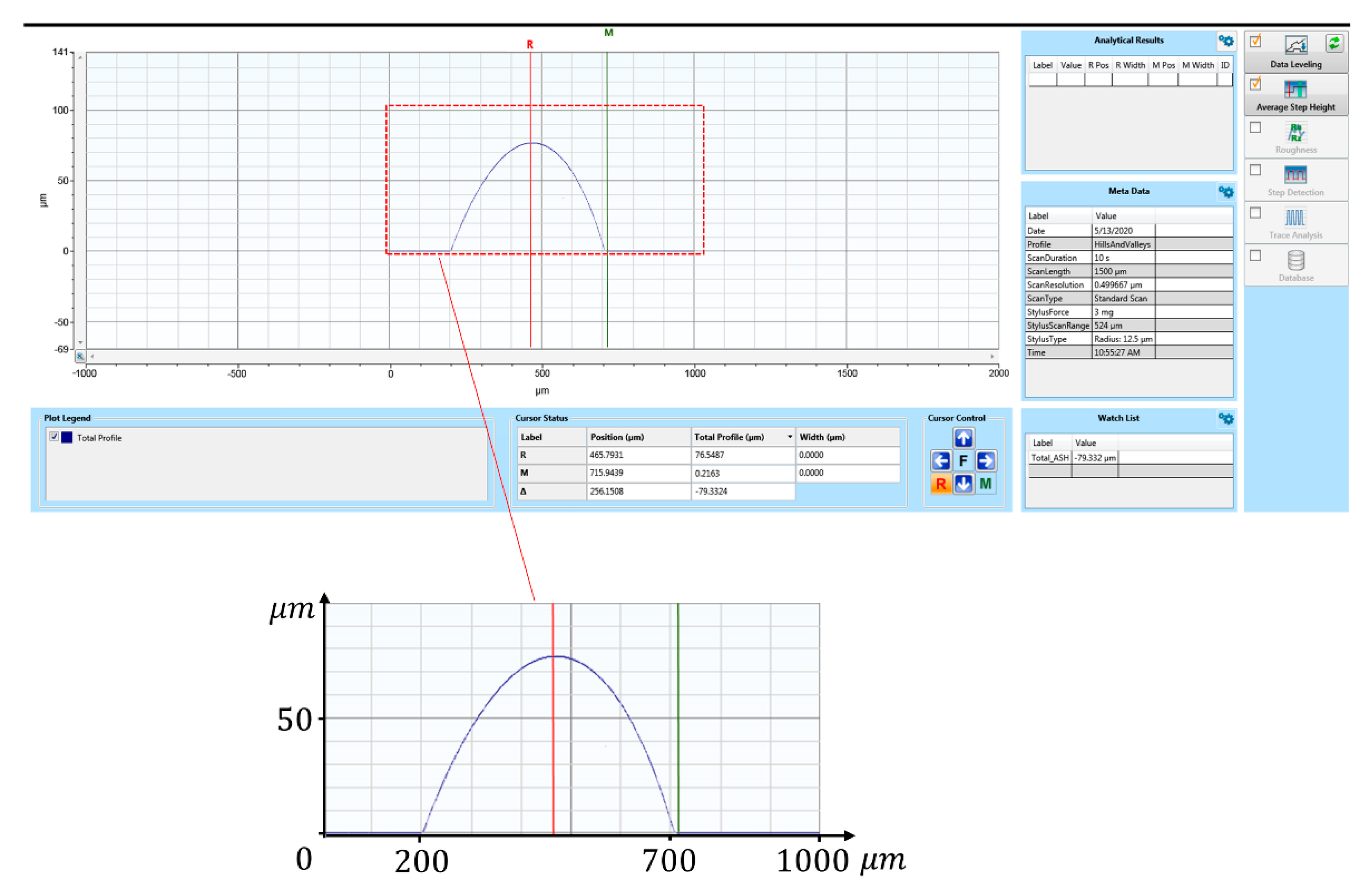

2. Measurement Procedure

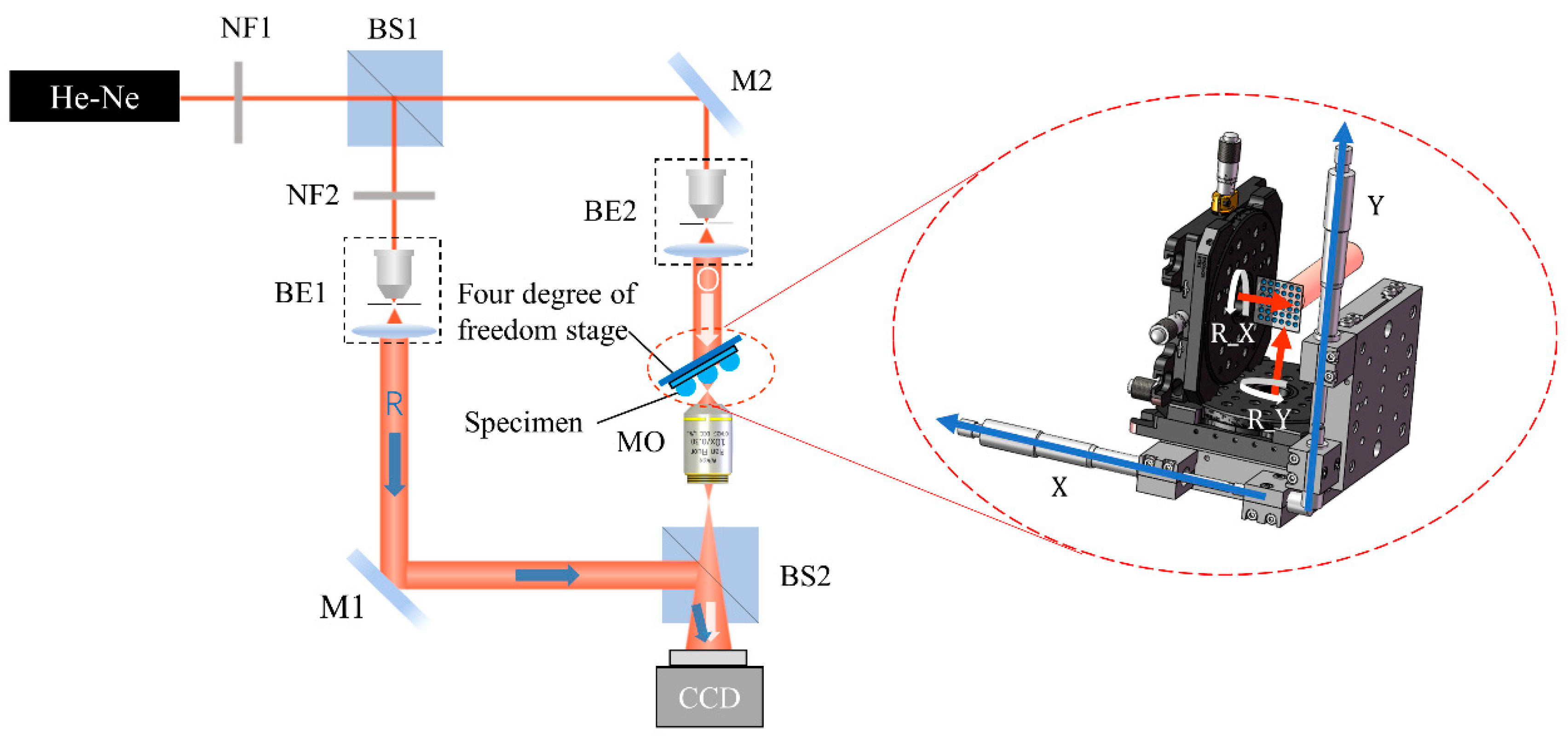

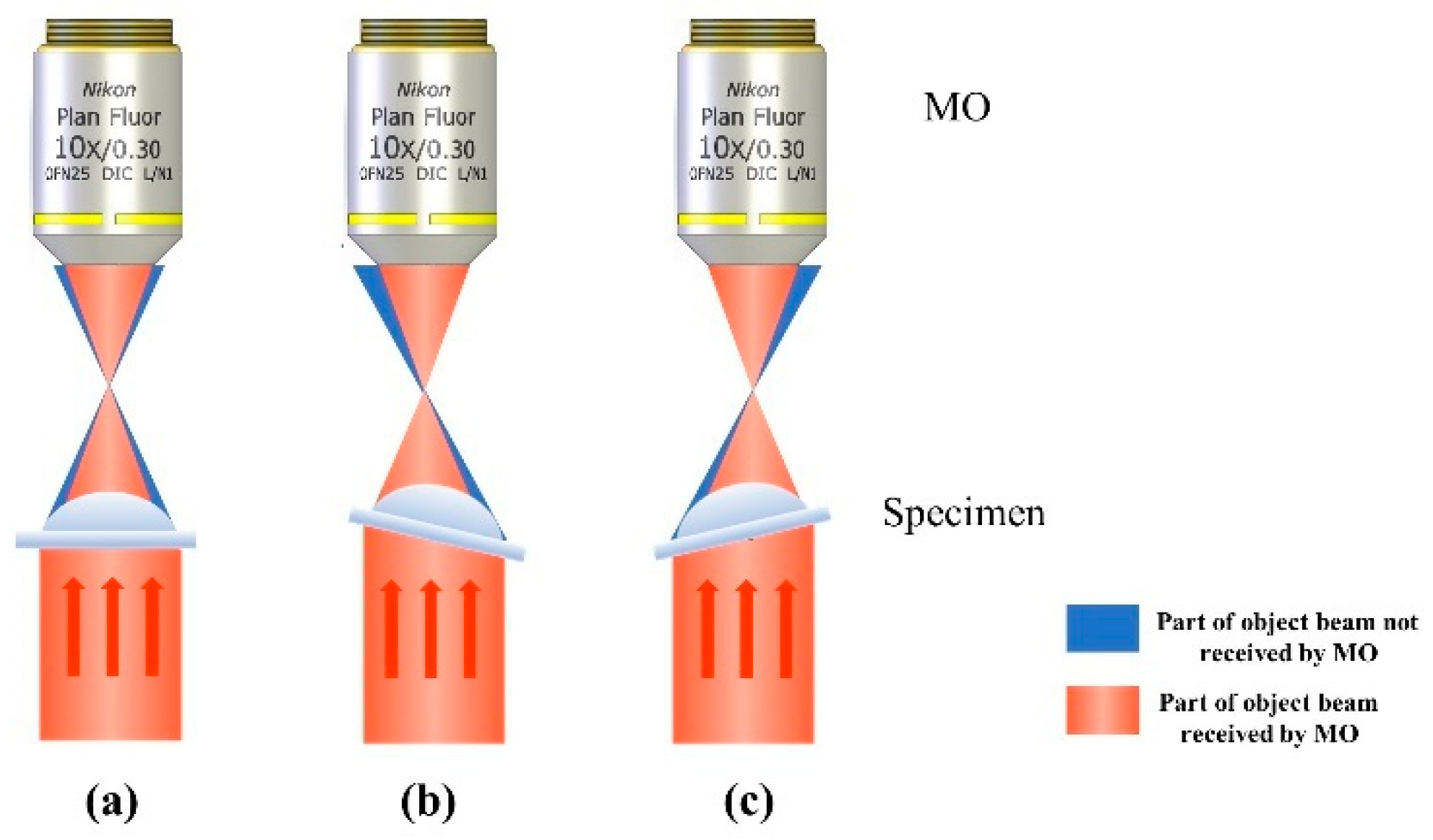

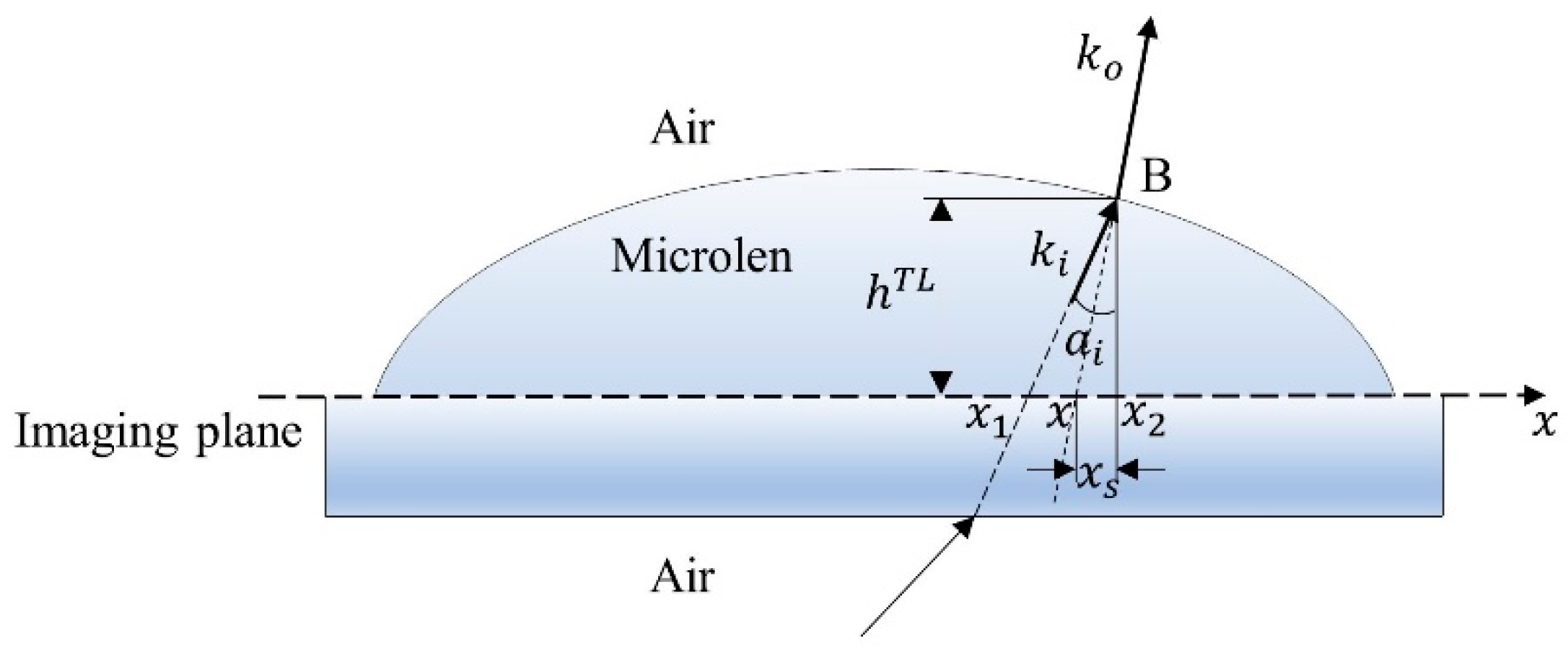

2.1. Experimental Setup

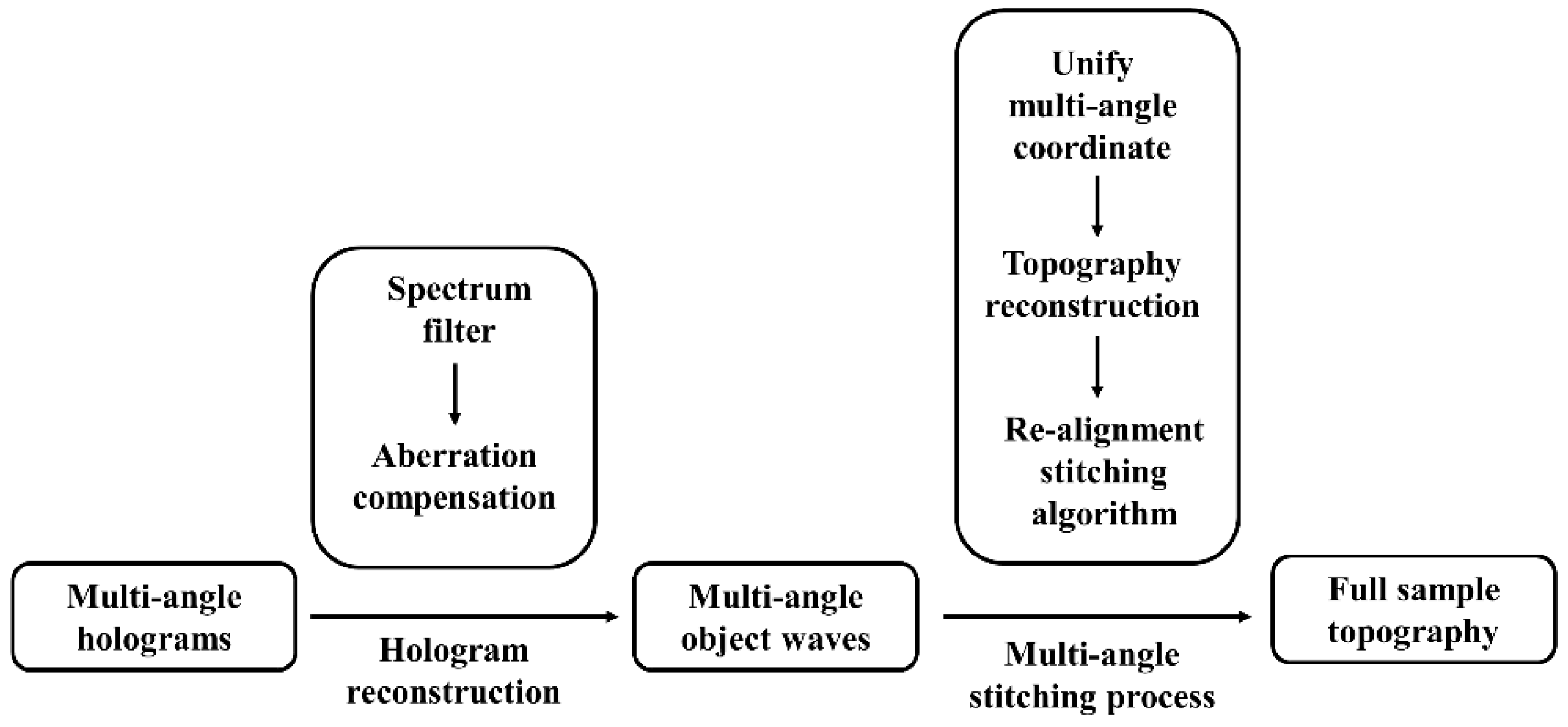

2.2. Data Processing Procedure

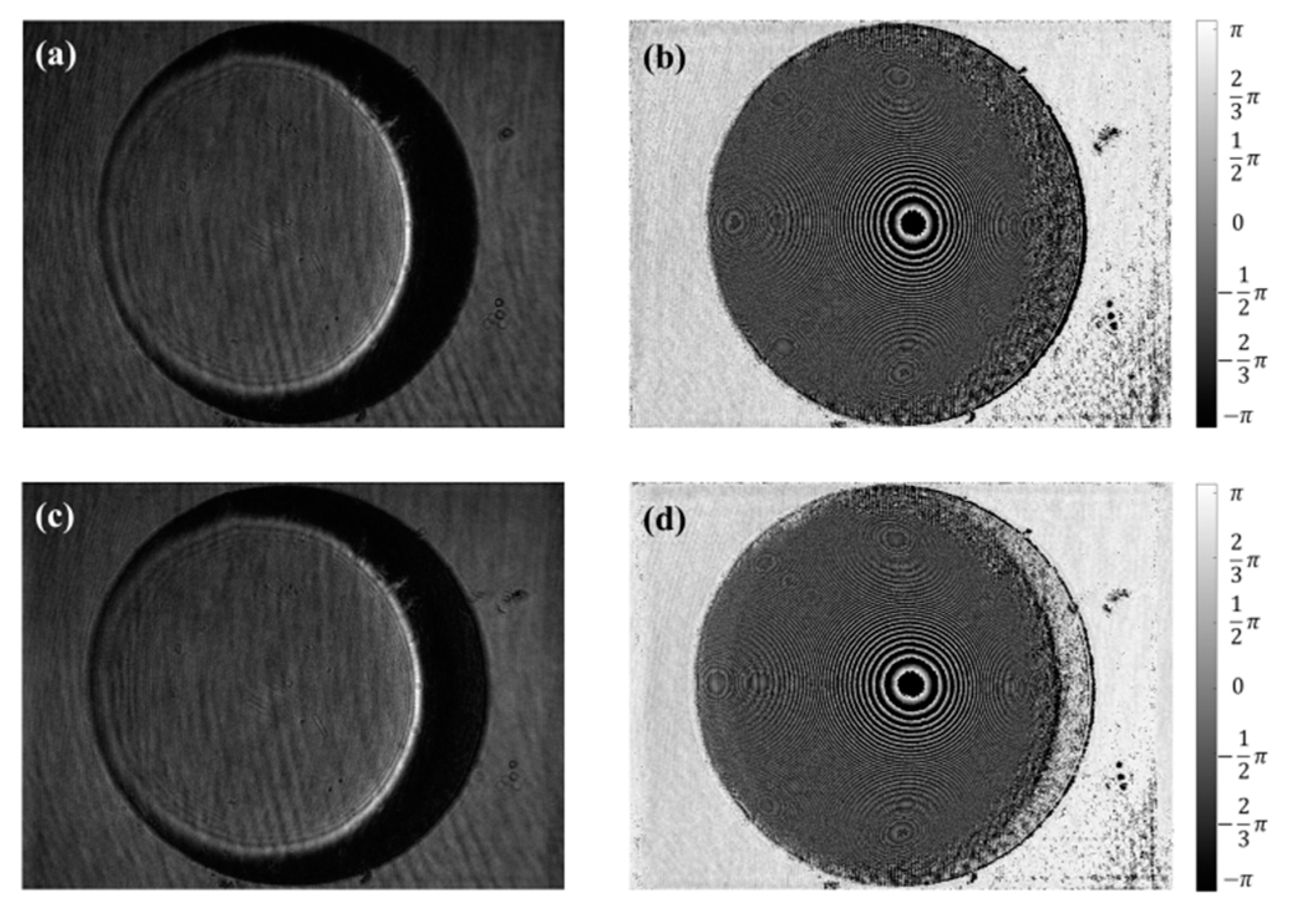

2.2.1. Hologram Reconstruction

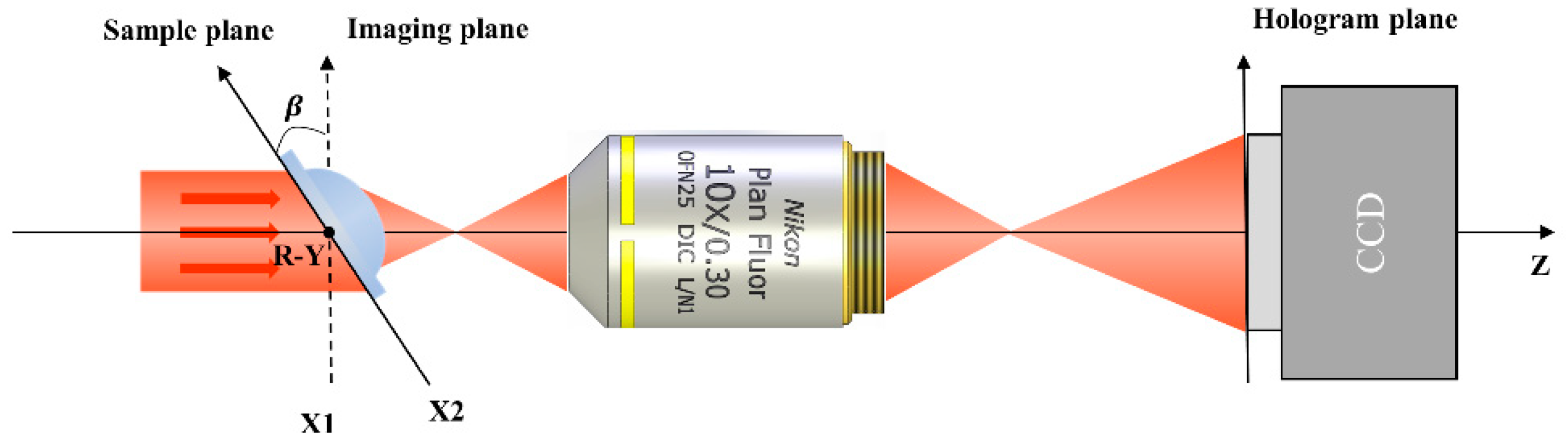

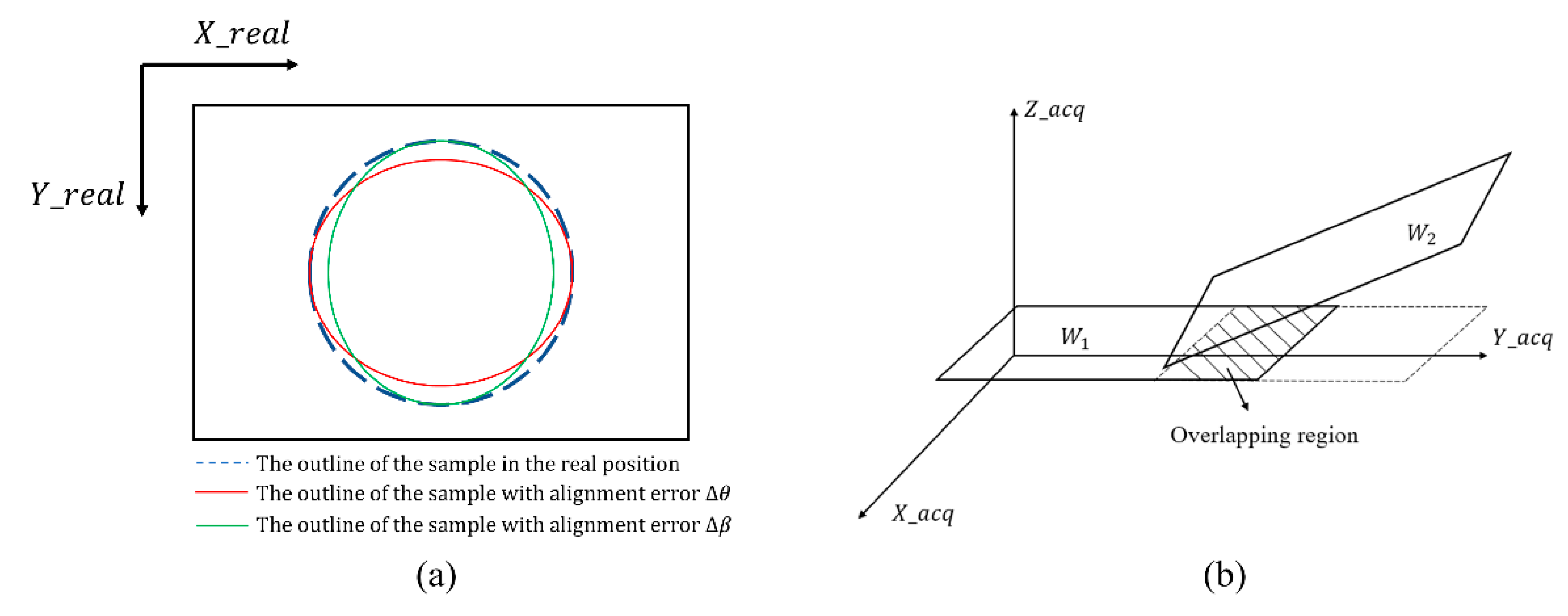

2.2.2. Multi-Angle Stitching Process

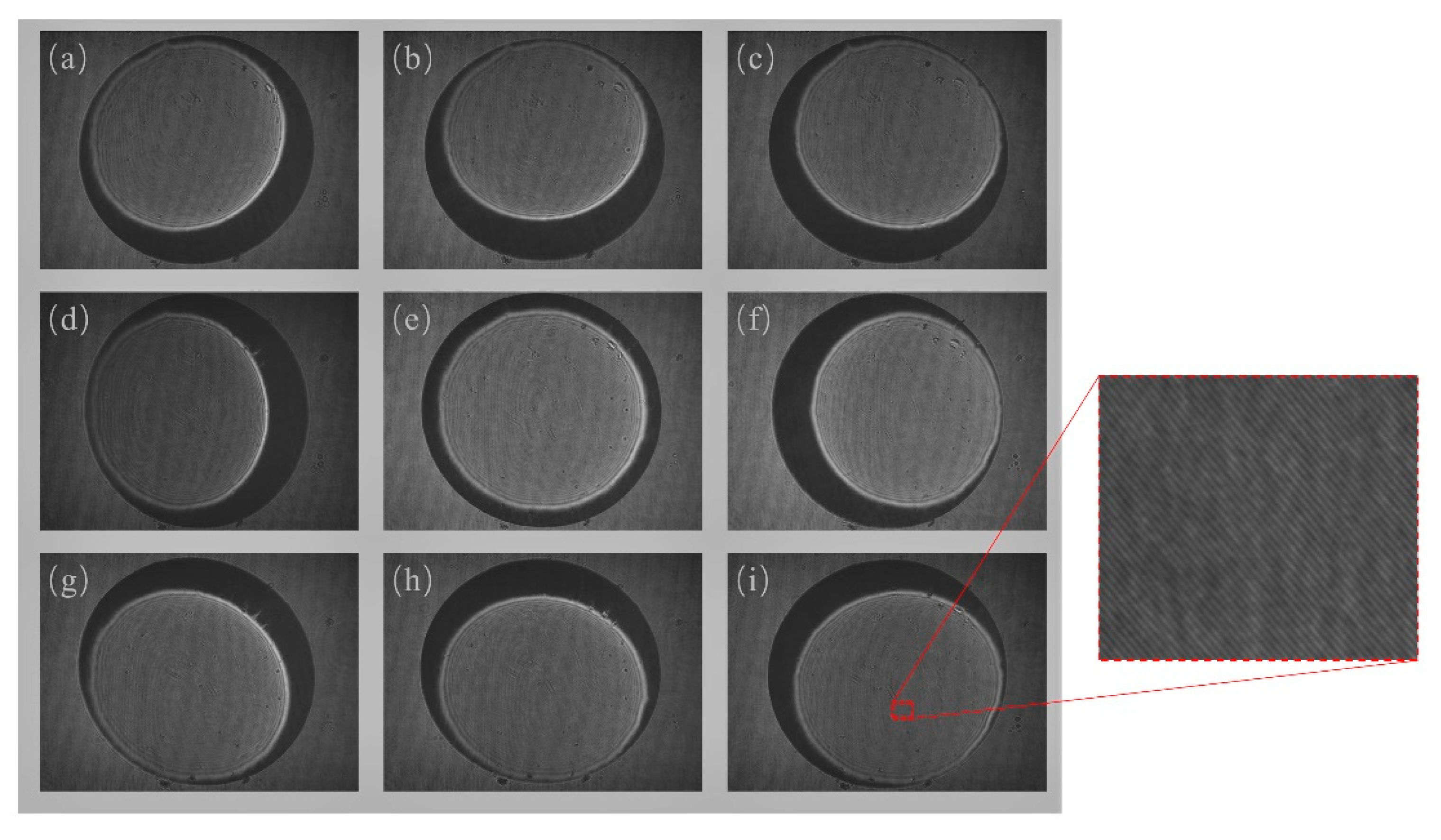

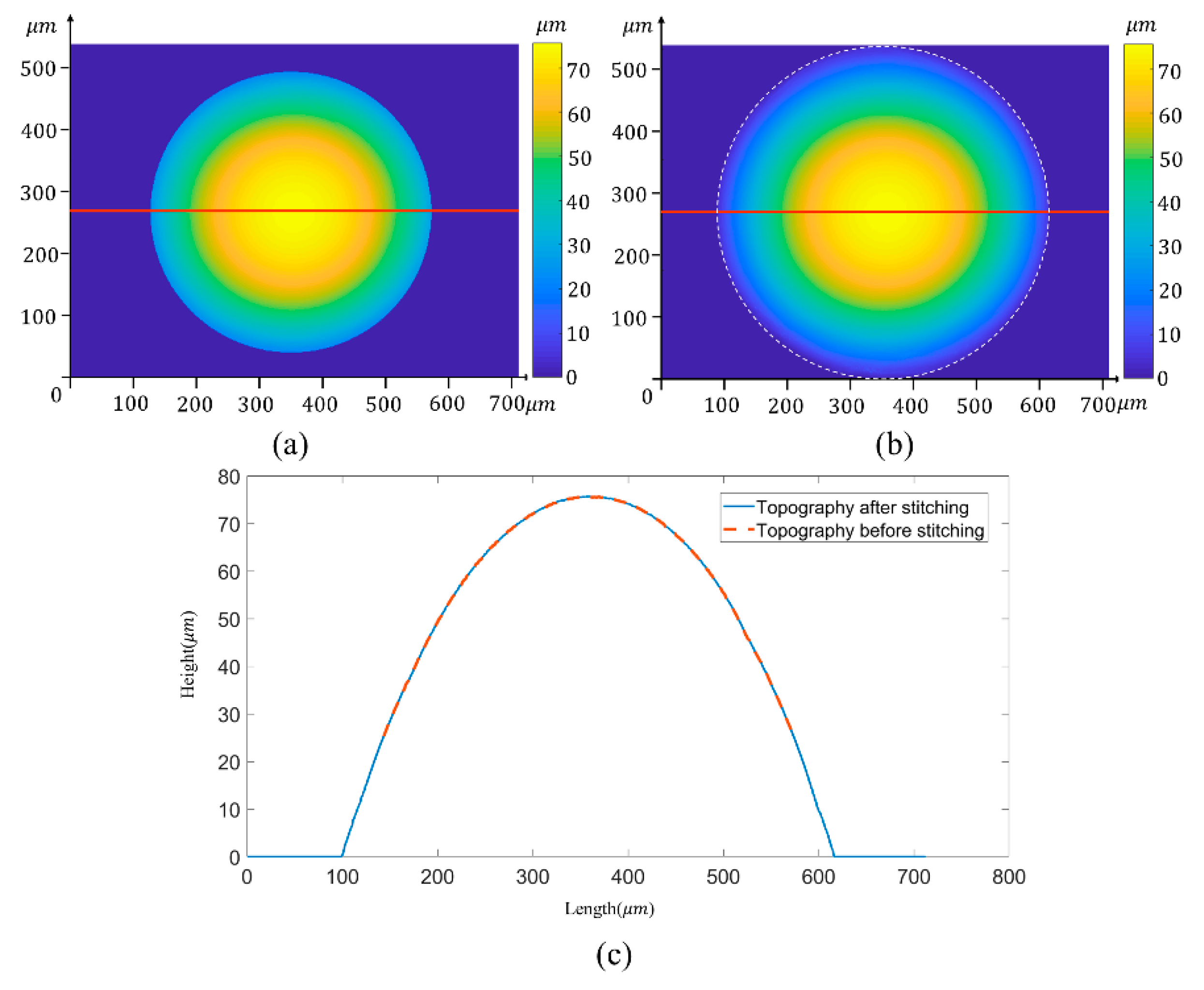

3. Experimental Results

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Steiner, H.; Hortschitz, W.; Kainz, A.; Stifter, M.; Jachimowicz, A.; Schalko, J.; Keplinger, F.; Kohl, F. MOEMS transducer with a non-linear transfer characteristic for static displacement measurement applications on the example of an inclination sensor. Sens. Actuators A Phys. 2017, 263, 727–732. [Google Scholar] [CrossRef]

- Chourasia, R.K.; Prasad, S.; Singh, V. A novel Bragg fiber waveguide based narrow band inline optical filter. Optik 2018, 169, 269–276. [Google Scholar] [CrossRef]

- Carter, S.G.; Birkedal, V.; Wang, C.S.; Coldren, L.A.; Maslov, A.V.; Citrin, D.S.; Sherwin, M.S. Quantum Coherence in an Optical Modulator. Science 2005, 310, 4. [Google Scholar] [CrossRef] [PubMed]

- Haffner, C.; Heni, W.; Fedoryshyn, Y.; Niegemann, J.; Melikyan, A.; Elder, D.L.; Baeuerle, B.; Salamin, Y.; Josten, A.; Koch, U.; et al. All-plasmonic Mach–Zehnder modulator enabling optical high-speed communication at the microscale. Nat. Photon 2015, 9, 525–528. [Google Scholar] [CrossRef]

- Li, K.; Yöntem, A.Ö.; Deng, Y.; Shrestha, P.; Chu, D.; Zhou, J.; Yao, J. Full resolution auto-stereoscopic mobile display based on large scale uniform switchable liquid crystal micro-lens array. Opt. Express 2017, 25, 9654. [Google Scholar] [CrossRef] [PubMed]

- Takahashi, H.; Kureyama, N.; Chikayama, M.; Yamada, K. Flatbed-Type Three-Dimensional Display System as a Tool for Cooperation Working. In Proceedings of the 2008 3rd International Conference on Innovative Computing Information and Control, Dalian, China, 18–20 June 2008; p. 57. [Google Scholar]

- Seymour, J.P.; Wu, F.; Wise, K.D.; Yoon, E. State-of-the-art MEMS and microsystem tools for brain research. Microsyst. Nanoeng. 2017, 3, 16066. [Google Scholar] [CrossRef] [PubMed]

- Sheikhaleh, A.; Jafari, K.; Abedi, K. Design and Analysis of a Novel MOEMS Gyroscope Using an Electrostatic Comb-Drive Actuator and an Optical Sensing System. IEEE Sens. J. 2019, 19, 144–150. [Google Scholar] [CrossRef]

- Charrière, F.; Kühn, J.; Colomb, T.; Montfort, F.; Cuche, E.; Emery, Y.; Weible, K.; Marquet, P.; Depeursinge, C. Characterization of microlenses by digital holographic microscopy. Appl. Opt. 2006, 45, 829. [Google Scholar] [CrossRef] [PubMed]

- Kemper, B.; Bauwens, A.; Vollmer, A.; Ketelhut, S.; Langehanenberg, P. Label-free quantitative cell division monitoring of endothelial cells by digital holographic microscopy. J. Biomed. Opt. 2010, 15, 6. [Google Scholar] [CrossRef] [PubMed]

- Liżewski, K.; Kozacki, T.; Kostencka, J. Digital holographic microscope for measurement of high gradient deep topography object based on superresolution concept. Opt. Lett. 2013, 38, 1878. [Google Scholar] [CrossRef] [PubMed]

- Józwik, M.; Kozacki, T.; Liżewski, K.; Kostencka, J. Digital holography with multidirectional illumination by LCoS SLM for topography measurement of high gradient reflective microstructures. Appl. Opt. 2015, 54, 2283. [Google Scholar] [CrossRef] [PubMed]

- Kozacki, T.; Liżewski, K.; Kostencka, J. Absolute shape measurement of high NA focusing microobjects in digital holographic microscope with arbitrary spherical wave illumination. Opt. Express 2014, 22, 16991. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.K. Principles and techniques of digital holographic microscopy. SPIE Rev. 2010, 018005. [Google Scholar] [CrossRef]

- Colomb, T.; Kühn, J.; Charrière, F.; Depeursinge, C.; Marquet, P.; Aspert, N. Total aberrations compensation in digital holographic microscopy with a reference conjugated hologram. Opt. Express 2006, 14, 4300. [Google Scholar] [CrossRef] [PubMed]

- Matsushima, K. Formulation of the rotational transformation of wave fields and their application to digital holography. Appl. Opt. 2008, 47, D110. [Google Scholar] [CrossRef] [PubMed]

- De Nicola, S.; Finizio, A.; Pierattini, G.; Ferraro, P.; Alfieri, D. Angular spectrum method with correction of anamorphism for numerical reconstruction of digital holograms on tilted planes. Opt. Express 2005, 13, 9935. [Google Scholar] [CrossRef] [PubMed]

- Kozacki, T.; Liżewski, K.; Kostencka, J. Holographic method for topography measurement of highly tilted and high numerical aperture micro structures. Opt. Laser Technol. 2013, 49, 38–46. [Google Scholar] [CrossRef]

- Kühn, J.; Colomb, T.; Montfort, F.; Charrière, F.; Emery, Y.; Cuche, E.; Marquet, P.; Depeursinge, C. Real-time dual-wavelength digital holographic microscopy with a single hologram acquisition. Opt. Express 2007, 15, 7231. [Google Scholar] [CrossRef] [PubMed]

- Lee, B.; Jang, C.; Kim, D.; Lee, B. Single Grating Reflective Digital Holography with Double Field of View. IEEE Trans. Ind. Inf. 2019, 15, 6155–6161. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, C.; He, Y.; Tang, Y.; Xie, Z.; Zhao, L.; Hu, S. Large Gradient Micro-Structure Topography Measurement with Multi-Angle Stitching Digital Holographic Microscope. Appl. Sci. 2020, 10, 6110. https://doi.org/10.3390/app10176110

Jin C, He Y, Tang Y, Xie Z, Zhao L, Hu S. Large Gradient Micro-Structure Topography Measurement with Multi-Angle Stitching Digital Holographic Microscope. Applied Sciences. 2020; 10(17):6110. https://doi.org/10.3390/app10176110

Chicago/Turabian StyleJin, Chuan, Yu He, Yan Tang, Zhongye Xie, Lixin Zhao, and Song Hu. 2020. "Large Gradient Micro-Structure Topography Measurement with Multi-Angle Stitching Digital Holographic Microscope" Applied Sciences 10, no. 17: 6110. https://doi.org/10.3390/app10176110

APA StyleJin, C., He, Y., Tang, Y., Xie, Z., Zhao, L., & Hu, S. (2020). Large Gradient Micro-Structure Topography Measurement with Multi-Angle Stitching Digital Holographic Microscope. Applied Sciences, 10(17), 6110. https://doi.org/10.3390/app10176110