Characteristics of Plane Gate Vibration and Holding Force in Closing Process by Experiments

Abstract

1. Introduction

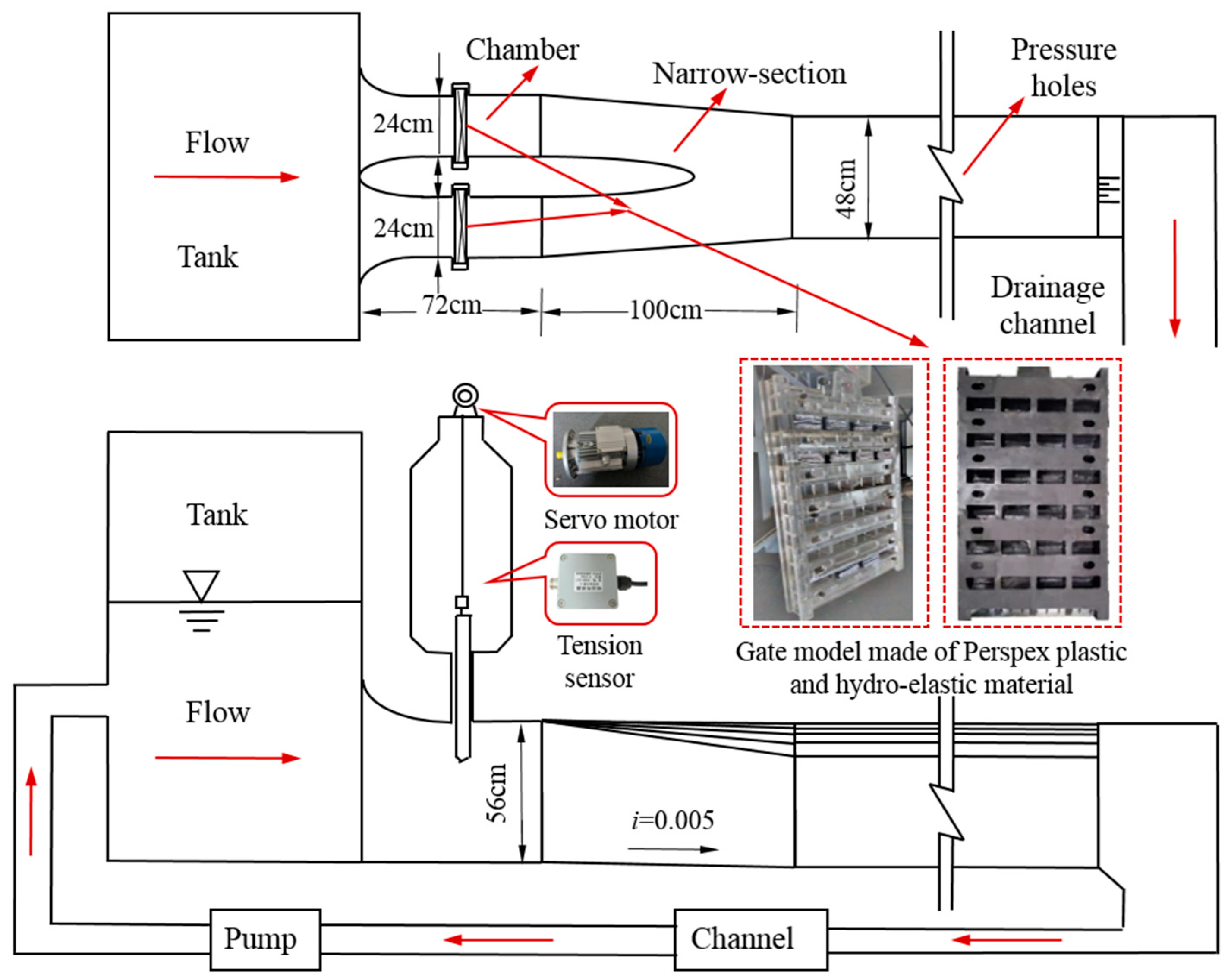

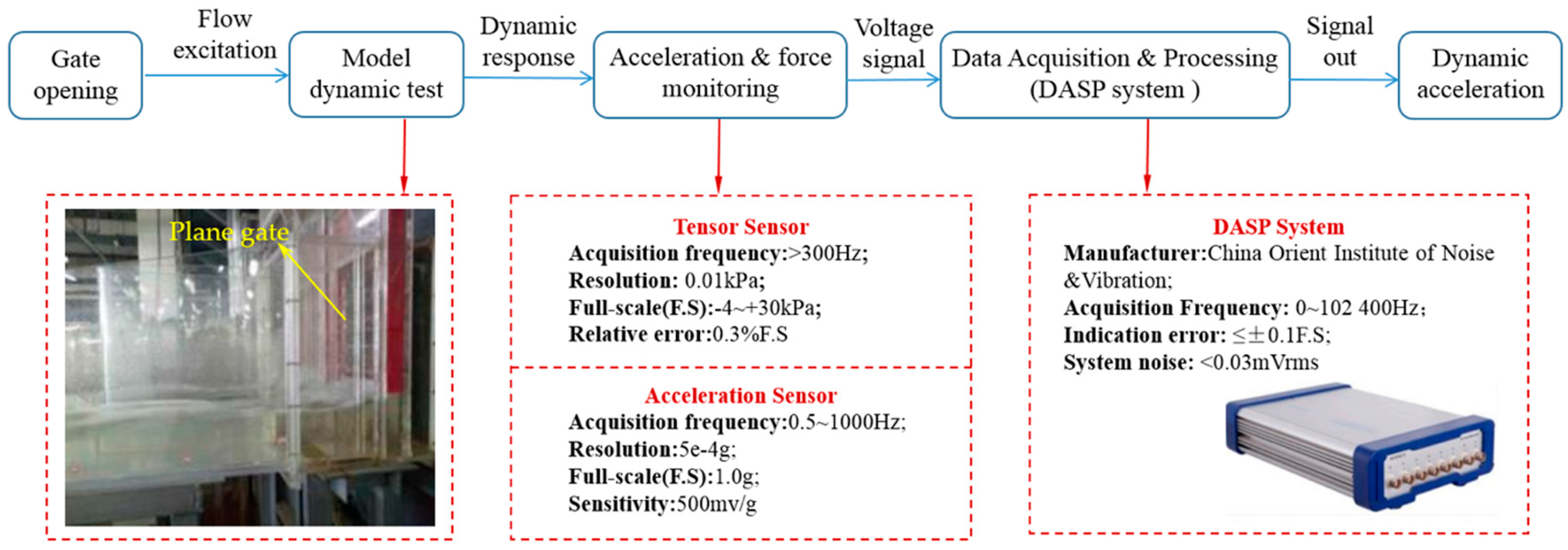

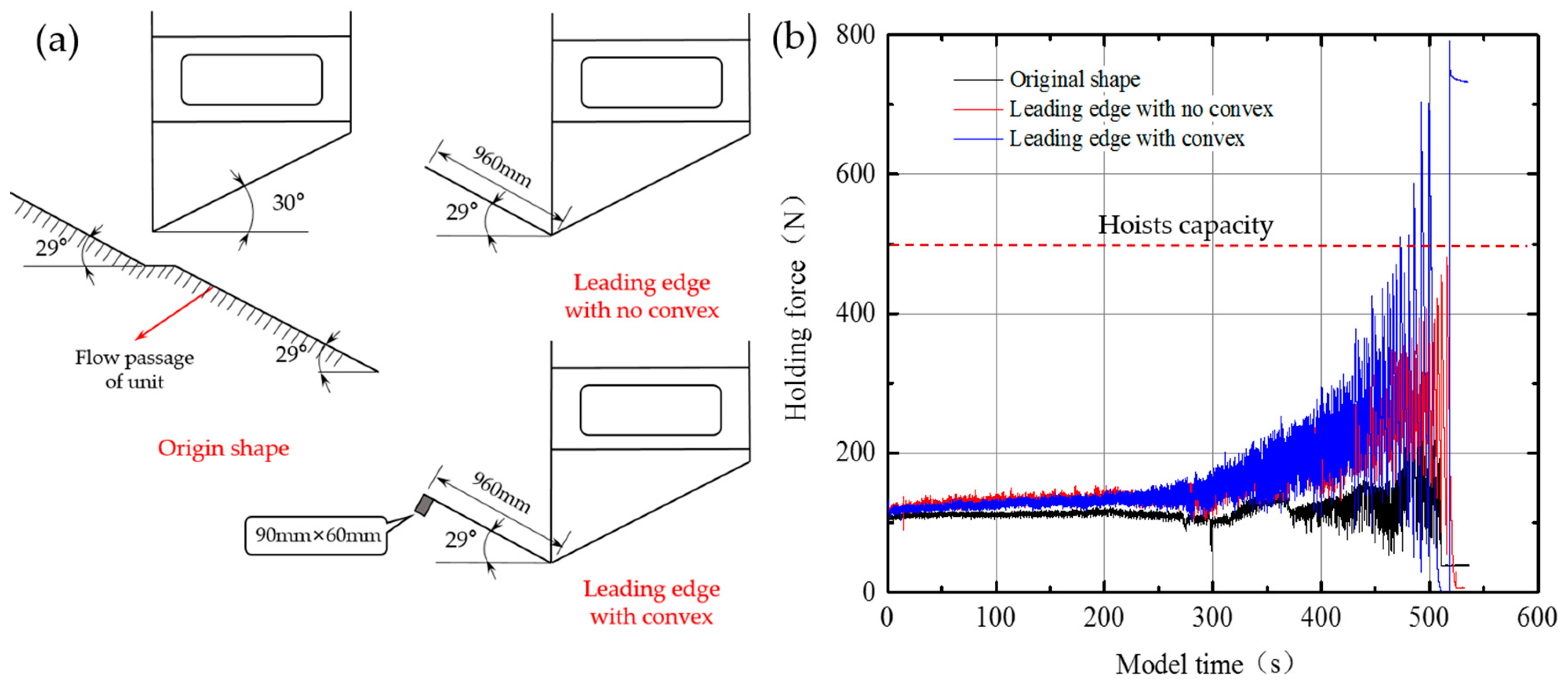

2. Physical Model Test

3. Results and Discussion

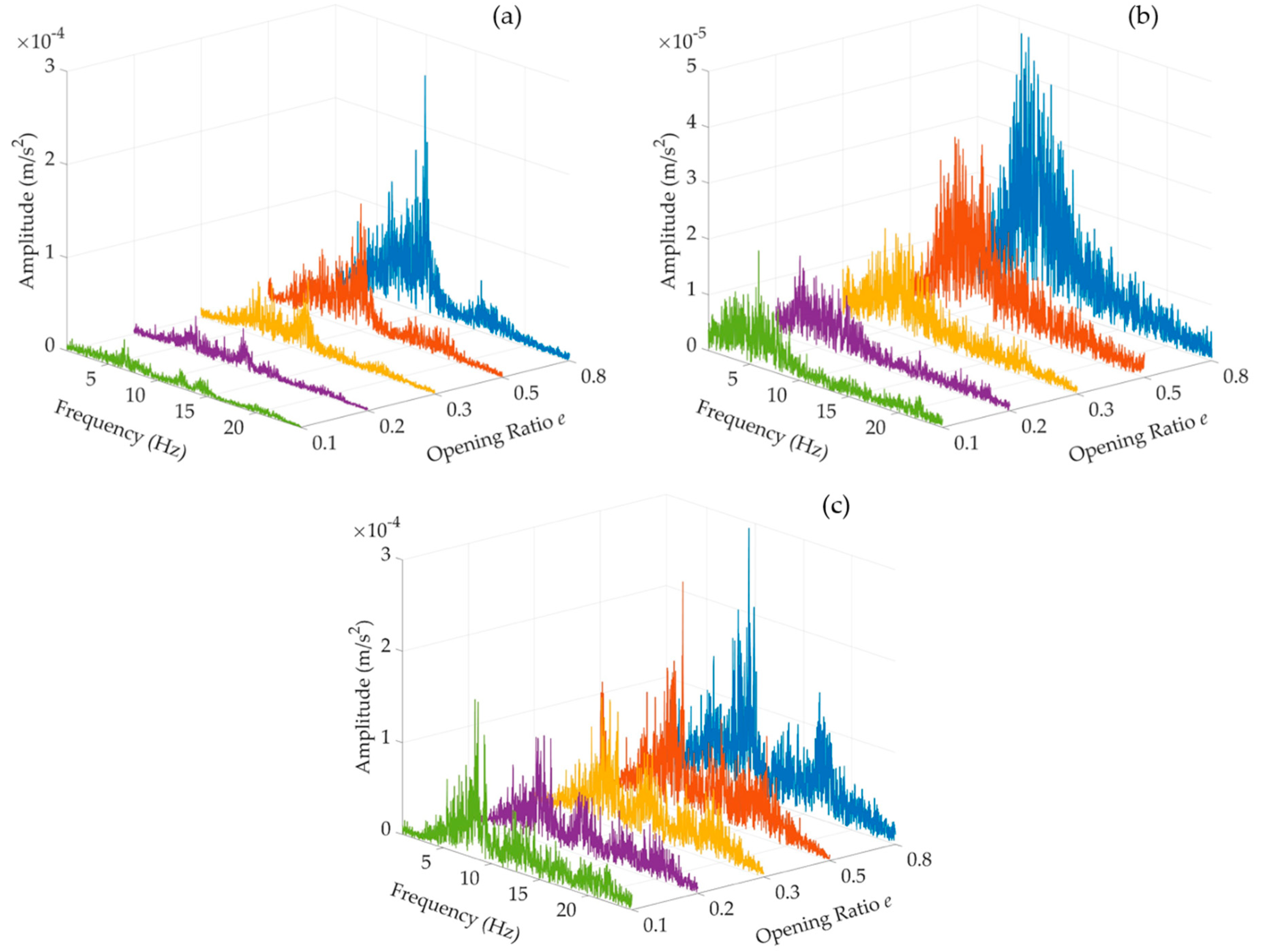

3.1. Characteristics of Vibration

3.1.1. Vibration in Fixed Gate Opening

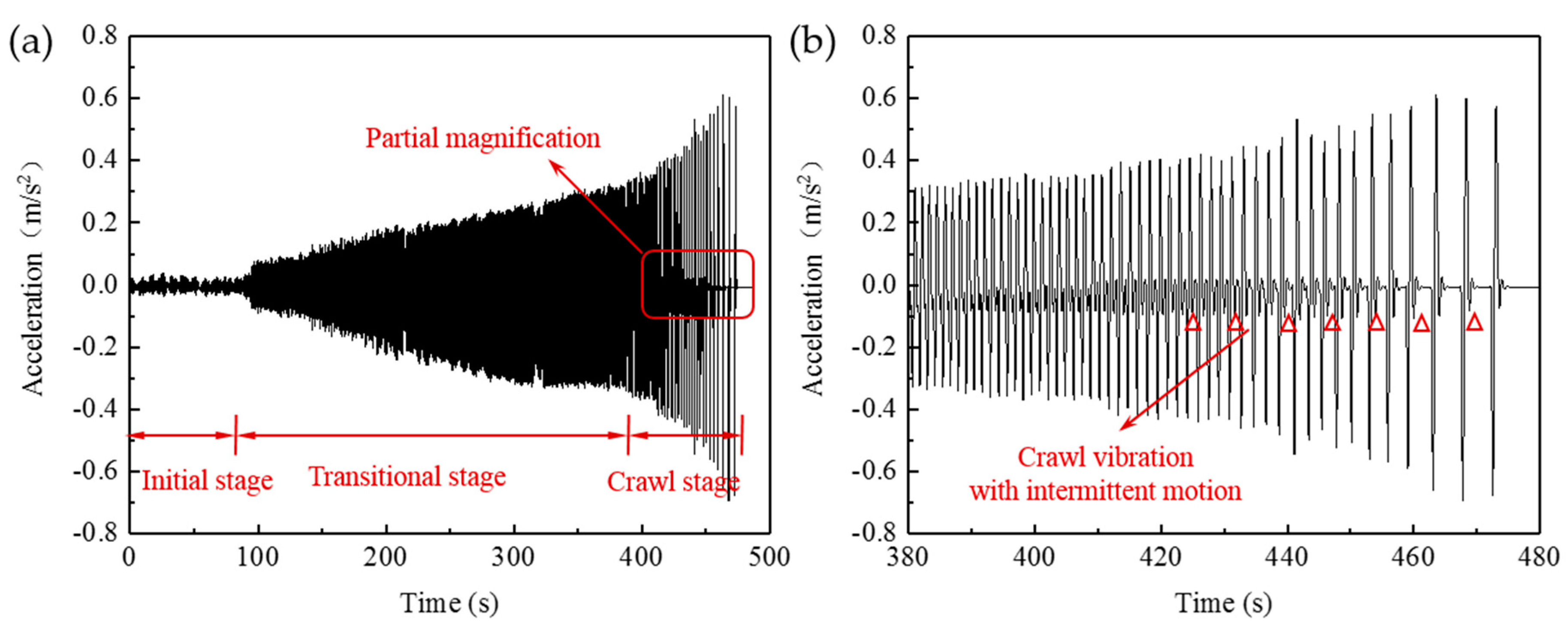

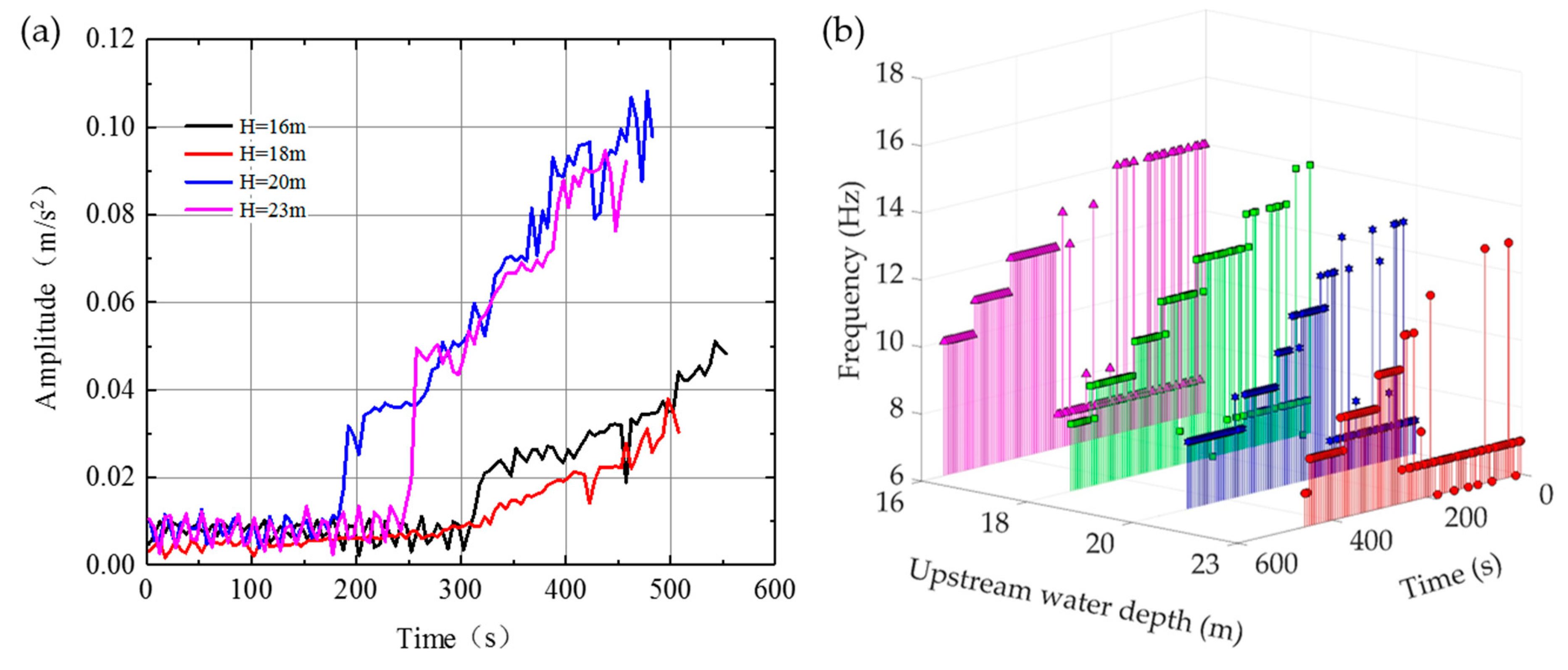

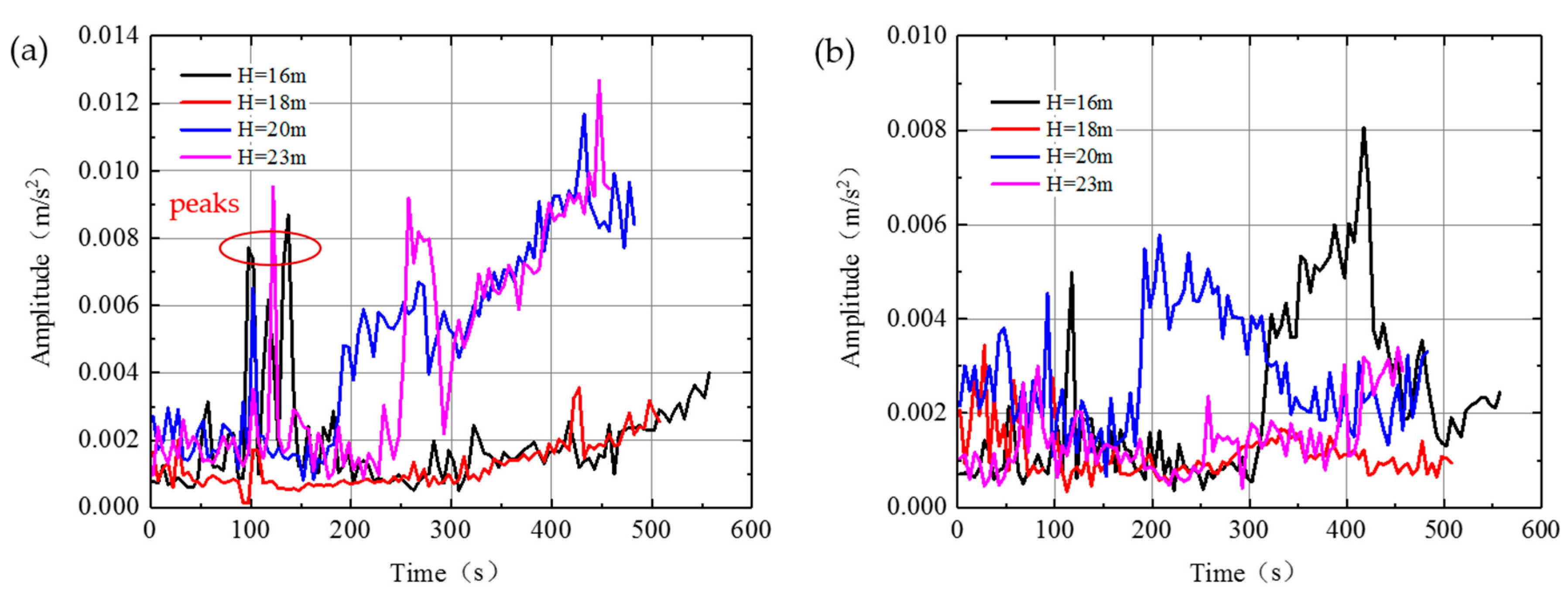

3.1.2. Vibration in Closing Process

3.1.3. Comparison of Vibration in Two Operation Modes

3.2. Characteristics of Holding Force

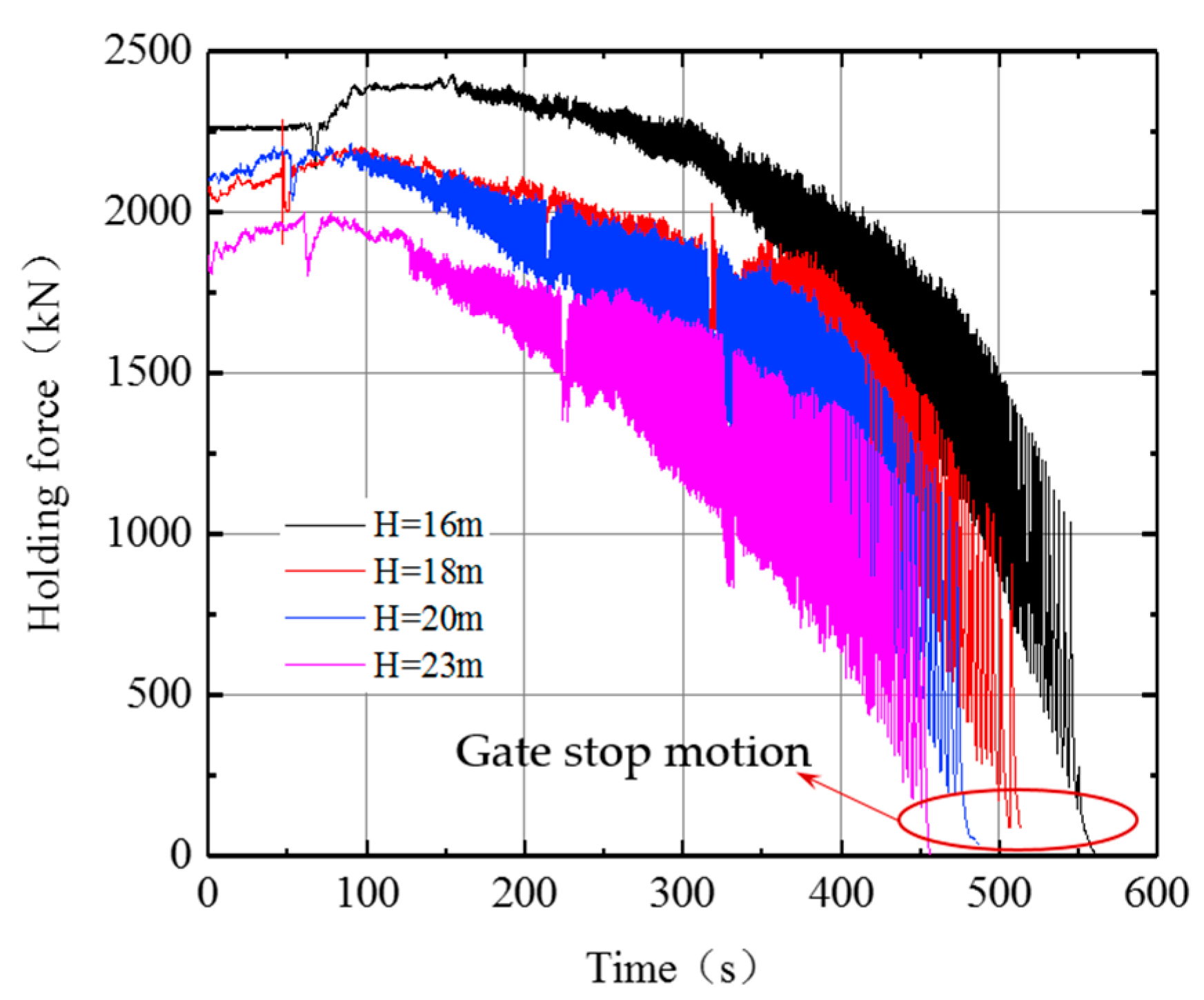

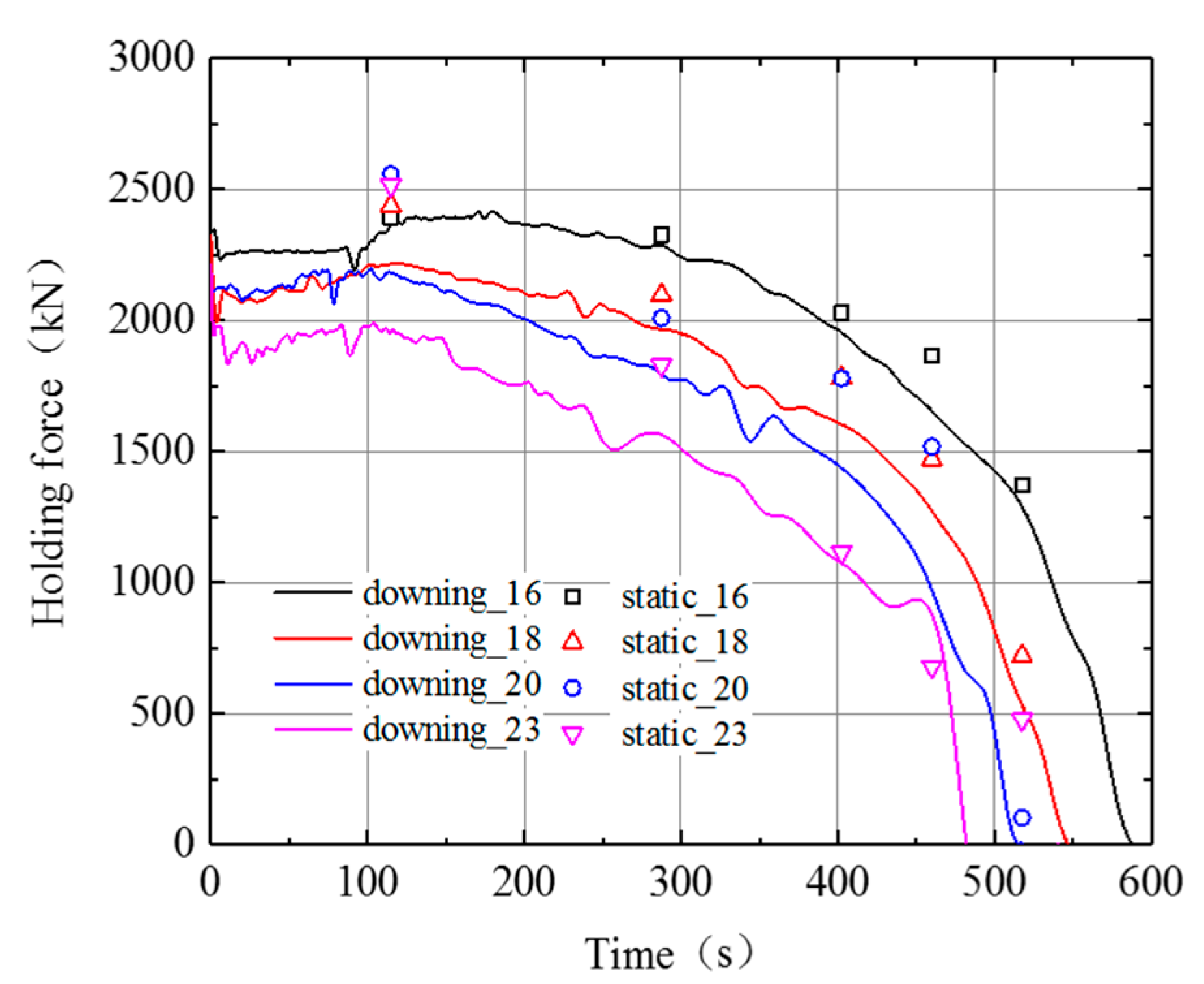

3.2.1. Holding Force in Two Operation Modes

3.2.2. Comparison of Holding Force in Two Operation Modes

3.2.3. Crawl Vibration in Closing Process

3.3. Correlation between Gate Vibration and Holding Force

3.3.1. Correlation in Fixed Gate Opening

3.3.2. Correlation in Closing Process

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Darbre, G.R.; Smet, C.A.M.D.; Kraemer, C. Natural frequencies measured from ambient vibration response of the arch dam of Mauvoisin. Earthq. Eng. Struct. D. 2015, 29, 577–586. [Google Scholar] [CrossRef]

- Wójcicki, Z.; Kostecki, S.; Grosel, J. Operational Modal Analysis of Weir on Odra River in Poland. Procedia Eng. 2016, 153, 874–881. [Google Scholar] [CrossRef][Green Version]

- Peng, Y.; Zhang, J.; Xu, W.-L.; Rubinato, M. Experimental Optimization of Gate-Opening Modes to Minimize Near-Field Vibrations in Hydropower Stations. Water 2018, 10, 1435. [Google Scholar] [CrossRef]

- Lian, J.; Zheng, Y.; Liang, C.; Ma, B. Analysis for the Vibration Mechanism of the Spillway Guide Wall Considering the Associated-Forced Coupled Vibration. Appl. Sci. 2019, 9, 2572. [Google Scholar] [CrossRef]

- Hardwick, J.D. Flow-induced vibration of vertical-lift gate. J. Hydraul. Div. ASCE. 1974, 1005, 631–644. [Google Scholar]

- Jongeling, T.H.G. Flow-induced self-excited in-flow vibrations of gate plates. J. Fluids Struct. 1988, 2, 541–566. [Google Scholar] [CrossRef]

- Naudascher, E. Flow-induced loading and vibration of gates. Proc. Int. Symp. Hydraul. High Dams 1988, 1–18. [Google Scholar]

- Thang, N.D.; Naudascher, E. Self-excited vibrations of vertical-lift gate. J. Hydraul. Res. 1986, 24, 391–404. [Google Scholar] [CrossRef]

- Thang, N.D. Gate Vibrations due to Unstable Flow Separation. J. Hydraul. Eng. 1990, 116, 342–361. [Google Scholar] [CrossRef]

- Ishii, N.; Knisely, C.W. Flow-induced vibration of shell-type long-span gates. J. Fluids Struct. 1992, 6, 681–703. [Google Scholar] [CrossRef]

- Ishii, N.; Knisely, C.W.; Nakata, A. Coupled-Mode Vibration of Gates with Simultaneous Over-and Underflow. J. Fluids Struct. 1994, 8, 455–469. [Google Scholar] [CrossRef]

- Ogihara, K.; Ueda, S. The Conditions of Self-Excited Vibration Occurring in Radial Gates. Water Power Conf. 1999, 1–10. [Google Scholar] [CrossRef]

- Chowdhury, M.R.; Hall, R.L. Dynamic Performance Evaluation of Gate Vibration. J. Struct. Eng. 1999, 125, 445–452. [Google Scholar] [CrossRef]

- Anami, K.; Ishii, N.; Knisely, C.W.; Tsuji, T.; Oku, T.; Sato, S. Friction-Maintained Dynamic Stability. In Vibration Problems ICOVP 2011. Springer Proc. Phys. 2011, 779–785. [Google Scholar] [CrossRef]

- Kolkman, P.A.; Vrijer, A. Vertical Gate Vibrations by Galloping or By Fluid Inertia. J. Hydraul. Res. 1987, 25, 418–423. [Google Scholar] [CrossRef]

- Markovic, J.; Drobir, H. A high head gate innovation numerical and experiment analysis of hydrodynamic forces. Math. Model. Civ. Eng. 2010, 2, 27–34. [Google Scholar]

- Erdbrink, C.D.; Krzhizhanovskaya, V.V.; Sloot, P. Reducing cross-flow vibrations of underflow gates: Experiments and numerical studies. J. Fluids Struct. 2014, 50, 25–48. [Google Scholar] [CrossRef]

- Lee, S.O.; Seong, H.; Kang, J.W. Flow-induced vibration of a radial gate at various opening heights. Eng. Appl. Comput. Fluid Mech. 2018, 12, 567–583. [Google Scholar] [CrossRef]

- Demirel, E.; Aral, M.M. A Design for Vortex Suppression Downstream of a Submerged Gate. Water 2020, 12, 750. [Google Scholar] [CrossRef]

- Gao, Z.; Yan, G.; Liu, P.; Chen, F.; Lv, F. Study on Flow-Induced Vibration Characteristics of Hydraulic Hoist of large-Span up welling Radial Steel Gate. Appl. Mech. Mater. 2011, 117, 241–246. [Google Scholar]

- Ng, F.C.; Abas, A.; Abustan, I.; Rozainy, Z.M.R.; Abdullah, M.; Jamaludin, A.b.; Kon, S.M. Fluid/structure interaction study on the variation of radial gate’s gap height in dam. IOP Conf. Ser. Mater. Sci. Eng. 2018, 370, 012063. [Google Scholar] [CrossRef]

- Shen, C.; Wang, W.; He, S.; Xu, Y. Numerical and Experimental Comparative Study on the Flow-Induced Vibration of a Plane Gate. Water 2018, 10, 1551. [Google Scholar] [CrossRef]

- Cai, Y.F.; Han, Y.F. Research on the Radial Gate Fluid-Structure Coupling of Hydraulic Steel Gate. Appl. Mech. Mater. 2015, 733, 468–471. [Google Scholar] [CrossRef]

- Lian, J.J.; Chen, L.; Liang, C.; Liu, F. Presentation and Verification of an Optimal Operating Scheme Aiming at Reducing the Ground Vibration Induced by High Dam Flood Discharge. Int. J. Environ. Res. Public Health 2020, 17, 377. [Google Scholar] [CrossRef] [PubMed]

- Lian, J.J.; Chen, L.; Ma, B.; Liang, C. Analysis of the Cause and Mechanism of Hydraulic Gate Vibration during Flood Discharging from the Perspective of Structural Dynamics. Appl. Sci. 2020, 10, 629. [Google Scholar] [CrossRef]

- Yang, M.; Lian, J.J.; Lin, J.Y. Excitation mechanism of flow induced plane gate vibration. J. Hydrodyn. 1997, 4, 437–449. (In Chinese) [Google Scholar]

- Billeter, P.; Staubli, T. Flow-induced multiple-mode vibrations of gates with submerged discharge. J. Fluids Struct. 2000, 14, 323–338. [Google Scholar] [CrossRef]

- Yan, G.H.; Chen, J.F. Prototype observation and study on flow induced vibration of curved gate in surface hole of spillway dam. J. Hydroelectr. Eng. 2012, 2, 142–147. (In Chinese) [Google Scholar]

- Yang, T.; He, S.; Shen, C.; Yang, Q. Fluid-induced Vibrations Test of Hydraulic Plane Gate for Different Conditions. Int. Conf. Sens. 2016, 1083–1089. [Google Scholar] [CrossRef]

- Ministry of Water Resources of the People’s Republic of China. Specification for Design of Steel Gate in Hydraulic and Hydroelectric Engineering (NB 35055—2015); China Water & Power Press: Beijing, China, 2015; pp. 52–54. (In Chinese)

- Liang, C.; Zhang, J.L.; Lian, J.J.; Liu, F. Research on slip-stick vibration of emergency gate induced by high dam flood discharge. J. Hydraul. Eng. 2018, 49, 1503–1511, 1522. (In Chinese) [Google Scholar]

- Ji, S.K.; Zhou, L. Vibration analysis of sluice gate closure process for diversion of Yellow River. Water Conserv. Hydropower Technol. 2001, 12, 64–66. (In Chinese) [Google Scholar]

- Li, G.Q.; Yang, J.W.; Yang, B.; Li, B. Analysis of prototype observation results of lifting and closing force of sluice gate in spillway tunnel of tianqiao hydropower station. Water Conserv. Hydropower Technol. 2005, 10, 4–7. (In Chinese) [Google Scholar]

- Ma, C.; Sheng, C.; Lian, J.; Ma, B.; Liu, F. Failure analysis of a leaf gate jammed in closing process. Eng. Fail. Anal. 2020, 110, 104391. [Google Scholar] [CrossRef]

- Novak, G.; Mlateralčnik, J.; Bombač, M.; Vošnjak, S. Hydrodynamic forces during the operation of a model radial gate. J. Appl. Water Eng. Res. 2016, 51, 70–77. [Google Scholar] [CrossRef]

- Anami, K.; Ishii, N.; Knisely, C.W. Pressure induced by vertical planar and inclined curved weir-plates undergoing streamwise rotational vibration. J. Fluids Struct. 2012, 29, 35–49. [Google Scholar] [CrossRef]

| Projects | Prototype Plane Gate |

|---|---|

| Spillway tunnel | 6 × 14 m2 (width × height) |

| Gate slot | 8.4 × 1.6 m2 (width × thickness) |

| Steel plane gate | 7 × 14.2 × 1.4 m3 (width × height × thickness) |

| Mass | 100 t |

| Operation speed | 1.5 m/min |

| Support type | Sliding block |

| Seal | Downstream seal |

| Gate Bottom edge | Composite type (upstream inclination angle 50° and down inclination angle 30°) |

| Operation requirement | Closing in transient flow and opening in still water |

| Elastic modulus E | 200 GPa |

| Poisson’s ratio μ | 0.3 |

| density ρ | 7.85 × 103 kg/m3 |

| Opening Ratio e | Holding Force (kN) | Standard Deviation | ||||||

|---|---|---|---|---|---|---|---|---|

| 16 m | 18 m | 20 m | 23 m | 16 m | 18 m | 20 m | 23 m | |

| 0.8 | 2391.968 | 2437.359 | 2556.328 | 2513.437 | 0.182 | 0.216 | 0.289 | 0.346 |

| 0.5 | 2324.772 | 2097.109 | 2008.719 | 1828.062 | 0.180 | 0.188 | 0.194 | 0.154 |

| 0.3 | 2027.556 | 1781.109 | 1778.297 | 1114.462 | 0.176 | 0.174 | 0.139 | 0.132 |

| 0.2 | 1864.470 | 1469.297 | 1517.547 | 678.750 | 0.162 | 0.134 | 0.137 | 0.126 |

| 0.1 | 1371.220 | 721.812 | 104.765 | 477.906 | 0.133 | 0.130 | 0.132 | 0.124 |

| Upstream Water | 16 m | 18 m | 20 m | 23 m |

|---|---|---|---|---|

| Gate closed time | 115.3 | 107.6 | 100.3 | 95.78 |

| Initial crawl time | 95.05 | 87.13 | 73.78 | 69.81 |

| Duration of crawl vibration | 20.25 | 20.47 | 26.52 | 25.96 |

| Direction | Water Depth (m) | Gate Opening Ratio e | ||||

|---|---|---|---|---|---|---|

| 0.1 | 0.2 | 0.3 | 0.5 | 0.8 | ||

| Lateral | 16 | –0.257 ** | 0.015 | –0.225 ** | 0.053 ** | –0.043 ** |

| 18 | –0.127 ** | 0.169 ** | 0.142 ** | 0.016 | –0.053 ** | |

| 20 | –0.134 ** | –0.156 ** | –0.256 ** | 0.185 ** | –0.173 ** | |

| 23 | –0.249 ** | –0.177 | –0.088 ** | 0.173 ** | 0.458 ** | |

| Vertical | 16 | –0.472 ** | 0.057 ** | 0.049 ** | 0.085 ** | 0.108 ** |

| 18 | –0.031 ** | 0.228 ** | 0.187 ** | –0.267 ** | 0.053 ** | |

| 20 | –0.189 ** | –0.109 ** | –0.546 ** | –0.095 ** | –0.082 ** | |

| 23 | –0.186 ** | –0.201 ** | 0.093 | –0.166 ** | –0.125 ** | |

| Horizontal | 16 | 0.169 ** | –0.005 | –0.009 | 0.002 | –0.041 ** |

| 18 | –0.027 | –0.054 ** | 0.248 ** | –0.066 ** | –0.014 | |

| 20 | –0.03 ** | 0.001 | –0.123 ** | –0.179 ** | –0.034 ** | |

| 23 | –0.018 | –0.022 * | 0.014 | –0.022 * | –0.225 ** | |

| Water Depth (m) | Initial Stage | Transitional Stage | Crawl Stage | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Lateral | Vertical | Horizontal | Lateral | Vertical | Horizontal | Lateral | Vertical | Horizontal | |

| 16 | 0.045 ** | 0.418 ** | 0.021 | −0.472 ** | 0.946 ** | −0.644 ** | −0.724 ** | 0.737 ** | −0.644 ** |

| 18 | −0.227 ** | 0.761 ** | −0.374 ** | −0.566 ** | 0.955 ** | −0.874 ** | −0.731 ** | 0.723 ** | −0.650 ** |

| 20 | 0.271 ** | 0.285 ** | −0.032 * | −0.555 ** | 0.941 ** | −0.678 ** | −0.720 ** | 0.732 ** | −0.664 ** |

| 23 | −0.138 ** | 0.389 ** | −0.041 ** | −0.667 ** | 0.936 ** | −0.862 ** | −0.720 ** | 0.741 ** | −0.698 ** |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Xu, G.; Li, W.; Liu, F.; Duan, Y. Characteristics of Plane Gate Vibration and Holding Force in Closing Process by Experiments. Appl. Sci. 2020, 10, 6111. https://doi.org/10.3390/app10176111

Wang Y, Xu G, Li W, Liu F, Duan Y. Characteristics of Plane Gate Vibration and Holding Force in Closing Process by Experiments. Applied Sciences. 2020; 10(17):6111. https://doi.org/10.3390/app10176111

Chicago/Turabian StyleWang, Yanzhao, Guobin Xu, Wensheng Li, Fang Liu, and Yu Duan. 2020. "Characteristics of Plane Gate Vibration and Holding Force in Closing Process by Experiments" Applied Sciences 10, no. 17: 6111. https://doi.org/10.3390/app10176111

APA StyleWang, Y., Xu, G., Li, W., Liu, F., & Duan, Y. (2020). Characteristics of Plane Gate Vibration and Holding Force in Closing Process by Experiments. Applied Sciences, 10(17), 6111. https://doi.org/10.3390/app10176111