Abstract

The development of inexpensive and highly robust nanocatalysts (NCs) to boost electrochemical hydrogen evolution reaction (HER) strengthens the implementation of several emerging sustainable-energy technologies. Herein, we proposed a novel nano-architecture consisting of a hierarchical structured Ni@Pd nanocatalyst with Pt-clusters decoration on the surface (denoted by Ni@Pd-Pt) for HER application in acidic (0.5 M H2SO4) and alkaline (0.1 M KOH) mediums. The Ni@Pd-Pt NC is fabricated on a carbon black support via a “self-aligned” heterogeneous nucleation-crystal growth mechanism with 2 wt.% Pt-content. As-prepared Ni@Pd-Pt NC outperforms the standard Pt/C (30 wt.% Pt) catalyst in HER and delivers high-rate catalytic performance with an ultra-low overpotential (11.5 mV) at the cathodic current density of 10 mA∙cm−2 in alkaline medium, which is 161.5 mV and 14.5 mV less compared to Ni@Pd (173 mV) and standard Pt/C (26 mV) catalysts, respectively. Moreover, Ni@Pd-Pt NC achieves an exactly similar Tafel slope (42 mV∙dec−1) to standard Pt/C, which is 114 mV∙dec−1 lesser when compared to Ni@Pd NC. Besides, Ni@Pd-Pt NC exhibits an overpotential value of 37 mV at the current density of 10 mA cm−2 in acidic medium, which is competitive to standard Pt/C catalyst. By utilizing physical characterizations and electrochemical analysis, we demonstrated that such an aggressive HER activity is dominated by the increased selectivity during HER due to the reduced competition between intermediate products on the non-homogeneous NC surface. This phenomenon can be rationalized by electron localization owing to the electronegative difference (χPt > χPd > χNi) and strong lattice mismatch at the Ni@Pd heterogeneous binary interfaces. We believe that the obtained results will significantly provide a facile design strategy to develop next-generation heterogenous NCs for HER and related green-energy applications

1. Introduction

Hydrogen has been investigated as a potential candidate for the implementation of green-energy technologies, however, sustainable hydrogen production is the key prerequisite to this end [1,2]. It is a well-known fact that hydrogen does not exist freely in nature but is largely available in compounds such as water and hydrocarbons, therefore, efficient generation of hydrogen is imperative for use in various applications. Recently, great efforts have been devoted to the sustainable generation of hydrogen from electrochemical water splitting. Hydrogen evolution reaction (HER) plays a major role in electrochemical water splitting [3]. However, the HER incurs a very high overpotential and requires an omnipotent nanocatalyst (NC) to lower down the overpotential and to trigger the HER kinetics. Thus far, carbon-supported platinum (Pt/C) is the state-of the-art electrocatalyst that boosts the HER kinetics by virtue of its excellent activity, high turnover frequency, relatively low overpotential and high current density [4,5]. Since the widespread application of Pt is limited by its high material cost and scarcity, minimization of Pt-loading or even the discovery of alternatives to Pt-based catalysts are key steps for industry efficient hydrogen production [6].

By keeping the aforementioned issues in view, enormous efforts are devoted towards designing alternative catalysts with earth abundance, cost-effective and superior activity over the past several decades including transition metal oxides [7,8], sulfides [9,10], carbides [11,12], nitrides [13,14], borides [15,16], phosphides [17,18] and metal-free catalyst [19,20], which can overcome the economical limitations and stability issues. Additionally, some noble metals (e.g., Pd, Ru) are also used to trigger the HER kinetics. According to a volcano plot, Pd is supposed to be a possible alternative of Pt towards the HER because the adsorption energy of Pd is nearly similar to that of Pt, therefore, it can be a potential HER catalyst [21,22]. Moreover, Pd has high hydrogen (H2) adsorption energy immediately next to Pt and thus can absorb a considerably large amount of H2 from both the gas phase and electrolytes. In addition, Pd is nearly five times more economical as compared to that of Pt. While Pd-based catalysts have the potential to replace Pt in HER, a narrow gap in HER catalytic activity still exists as compared to that of Pt-based catalysts. Numerous alternative strategies such as alloying Pd with late-transition metals [23], morphology and composition control [24], coupling with optimized support materials [25], tuning the particle size and so on have been directed to fill this gap. However, none of them has outperformed Pt-based catalysts in HER.

Based on the aforementioned arguments and in line with recent developments, in the present study, we synthesized a ternary NC comprising hierarchical Ni@Pd NC with Pt-clusters decoration on the surface via a “self-aligned” heterogeneous nucleation-crystal growth mechanism on carbon black support (namely Ni@Pd-Pt). Our previous studies demonstrated that Pt-clusters decoration effectively shelters the catalyst surface from oxidation and creates intense active sites for HER facilitation [26,27,28,29,30,31]. In such a unique structure, Pt-clusters are decorated on the Ni@Pd surface and at the heteroatomic interfaces of Ni-to-Pd; where the ligand effect (due to difference in electronegativity of adjacent atoms) and lattice strain (due to lattice mismatch) plays a key role at the heterogenous interfaces and relocate electrons to the NC surface, hence, the formation of catalytic active sites takes place, which boosts the HER kinetics. Besides, neighboring Pd reaction sites share the intermediate steps during HER, therefore, boost the activity of Ni@Pd-Pt in HER. Hence, the Ni@Pd-Pt NC delivers a lower overpotential of 11.5 mV at the cathodic current density of 10mA cm−2. This overpotential is 15 and 2.2-times less compared to Ni@Pd NC (173 mV) and Pt/C (26 mV) catalysts, respectively. Additionally, ternary Ni@Pd-Pt NC offers a similar Tafel slope of 42 mV dec−1 to that of standard Pt/C. Moreover, As-prepared Ni@Pd-Pt NC demonstrates significantly enhanced HER performance compared to Ni@Pd NC in an acidic medium with an overpotential of 37 mV. This overpotential value is the same as a standard Pt/C catalyst.

2. Experimental

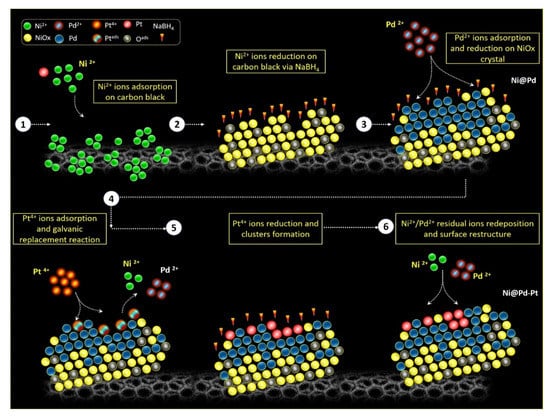

2.1. Synthesis of Ni@Pd-Pt Nanocatalyst

Ni@Pd-Pt NC was fabricated on a carbon black support (Vulcan XC-72R) by using a “self-aligned” heterogeneous nucleation-crystal growth mechanism. (Scheme 1) [29]. Initially, 1.02 g of a solution containing 0.1 M of Ni-precursor (i.e., nickel (II) chloride hexahydrate (NiCl2·6H2O, Showa Chemical Co. Ltd., Okayama, Japan)) was mixed with 400 mg of carbon black (5.0 wt.%) and stirred at 400 rpm for 3.5 h. This solution accommodates 0.102 mmoles (6 mg) of Ni2+ ions with a metal to carbon support ratio of 0.3 (i.e., Ni is 30 wt.% of carbon support). Subsequently, in the 2nd step, 5 mL of fresh D.I. water solution consisting of 0.03 g of NaBH4 (99%, Sigma-Aldrich Co., Saint Louis, MO, USA) was instantly mixed into the solution (i.e., Ni2+ adsorbed carbon black) and continuously impregnated at 400 rpm for 10 s. Further, 1.02 g of palladium (Pd) precursor (with Pd/Ni molar ratio 1:1) solution consisting of 0.102 mmoles of Pd2+ ions (i.e., 0.1 M) was subsequently added in the 3rd step. The palladium (II) chloride (i.e., PdCl2, 99%, Sigma-Aldrich Co.) was mixed in 1.0 M HCl solution to prepare Pd precursor solution. Hence, Ni@Pd NC was prepared.

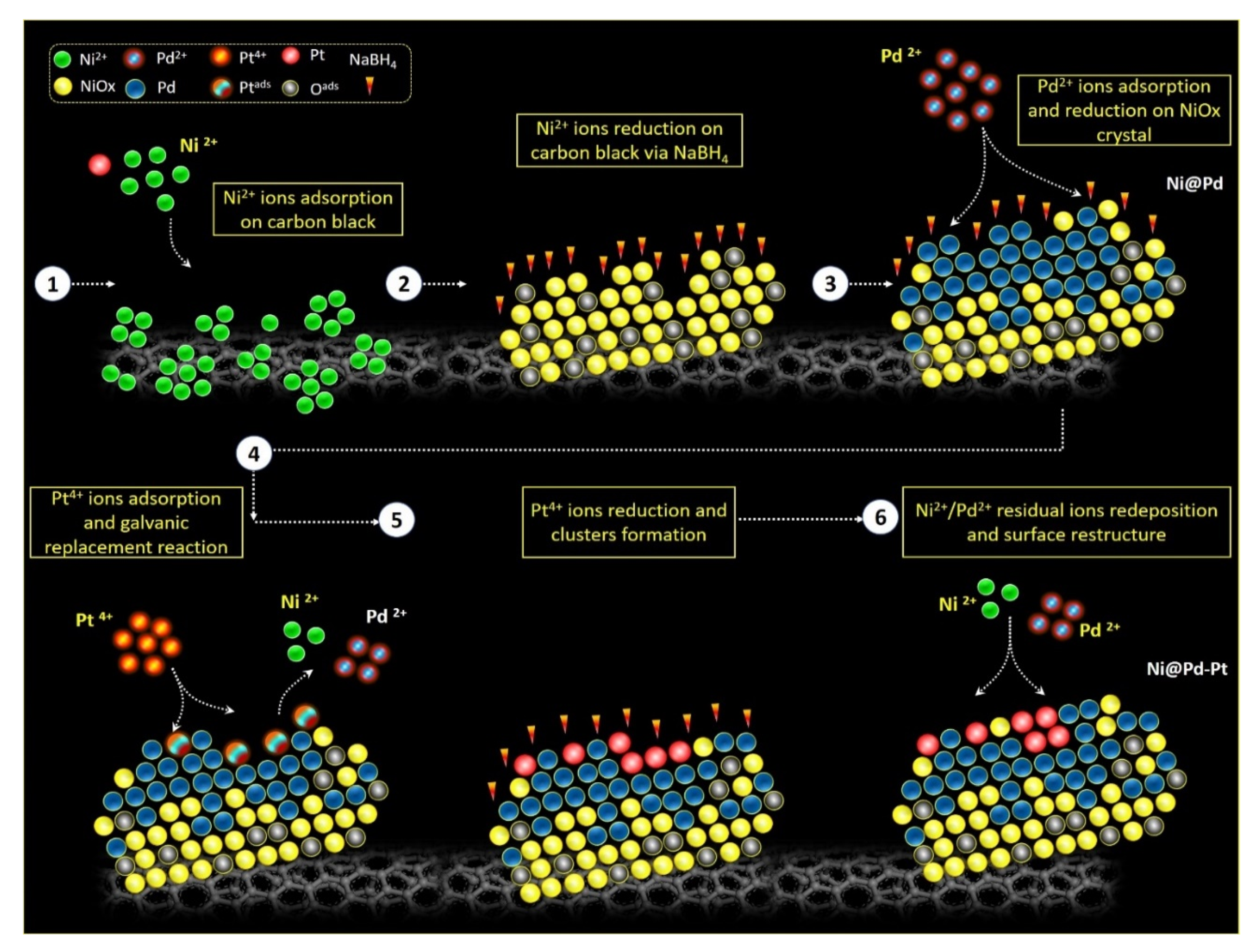

Scheme 1.

Schematic depiction of the synthesis procedure for Ni@Pd (steps 1–3) and Ni@Pd-Pt nanocatalysts.

After 10 min, a suitable amount of Pt precursor (H2PtCl6·6H2O; 99%, Sigma-Aldrich Co.) solution in D.I. water was added into Ni@Pd (step 4) and subsequently reduced within 10 s by the reducing agent (NaBH4) in step 5. As obtained products were cleaned many times with acetone/ethanol/D.I. water, centrifuged, and finally put in oven at 60 °C for drying. The Pt/C and Pd/C control samples were prepared by mixing Pt (Pd) metal ions in carbon black at 25 °C for 6 h followed by reducing via reduction agent. In the present work, the Pt (Pd)/carbon black ratio was 30 wt.%.

2.2. Physical Characterizations of Ni@Pd-Pt Nanocatalyst

The physical properties of Ni@Pd-Pt and the control samples (i.e., Pd/C, Pt/C and Ni@Pd) were obtained by microscopic and X-ray spectroscopic techniques. The aberration-corrected scanning transmission electron microscopy (AC-STEM) images were obtained from the Industrial Technology Research Institute (ITRI), Taiwan. X-ray photoelectron spectroscopy (XPS) of Ni@Pd-Pt and control samples was executed at beamlines BL-24A1 of the National Synchrotron Radiation Research Center (NSRRC), Taiwan. For investigating the phases and structure of as-prepared catalysts, X-ray diffraction (XRD) analysis was been done. The XRD spectra were obtained at incident X-ray of wavelength 1.033 Å (12 KeV) at the NSRRC, Taiwan. To obtain good quality spectra, each experiment was repeated two-times and subsequently averaged for a fair comparison. The inductively coupled plasma-optical emission spectrometer (ICP-OES; Jarrell-Ash, Markham, ON, Canada, ICAP 9000) was utilized to determine the exact composition of experimental NCs.

3. Electrochemical Analysis

The electrochemical HER experiment was carried out by using an electrochemical cell (CH Instruments, Austin, TX, USA, Model 600B, CHI 600B) consisting of three electrodes. A glassy carbon electrode was used as a working electrode in the electrochemical cell. The Ag/AgCl (the voltage was calibrated by 0.204 V, in alignment with that of Reversible hydrogen electrode (RHE)) and Hg/HgCl2 (the voltage was calibrated by 0.242 V, in alignment with that of RHE) electrodes were used as reference electrodes for acidic and alkaline mediums, respectively. For the counter electrode, the graphite rod was utilized for avoiding any Pt contamination during the experiment. The slurry for conducting the HER measurements was prepared by adding 5 mg of catalyst powder in 50 μL of 5% Nafion 117 solution and 1 mL of isopropanol (IPA). This mixture was sonicated for 30 min before the experiment for better uniformity of catalyst slurry. For the HER experiment, 20.0 μL of as-prepared catalyst slurry was drop cast and air-dried on a glassy carbon rotating disk electrode (RDE) with an area of 0.196 cm2. The HER activity was calculated by linear sweep voltammetry (LSV) carried out within the potential range from −0.20 and 0.20 V at a sweeping rate of 2 mV s−1, and a rotation rate of 1600 rpm in N2 saturated 0.1 M KOH electrolyte. The stable and clean surface of the electrode is achieved by sweeping the electrode many times between 0.00 and 1.24 V in N2 saturated 0.1 KOH electrolyte before each test. An iR correction was used for compensating the potential loss due to the external resistance of the electrochemical system.

4. Results and Discussion

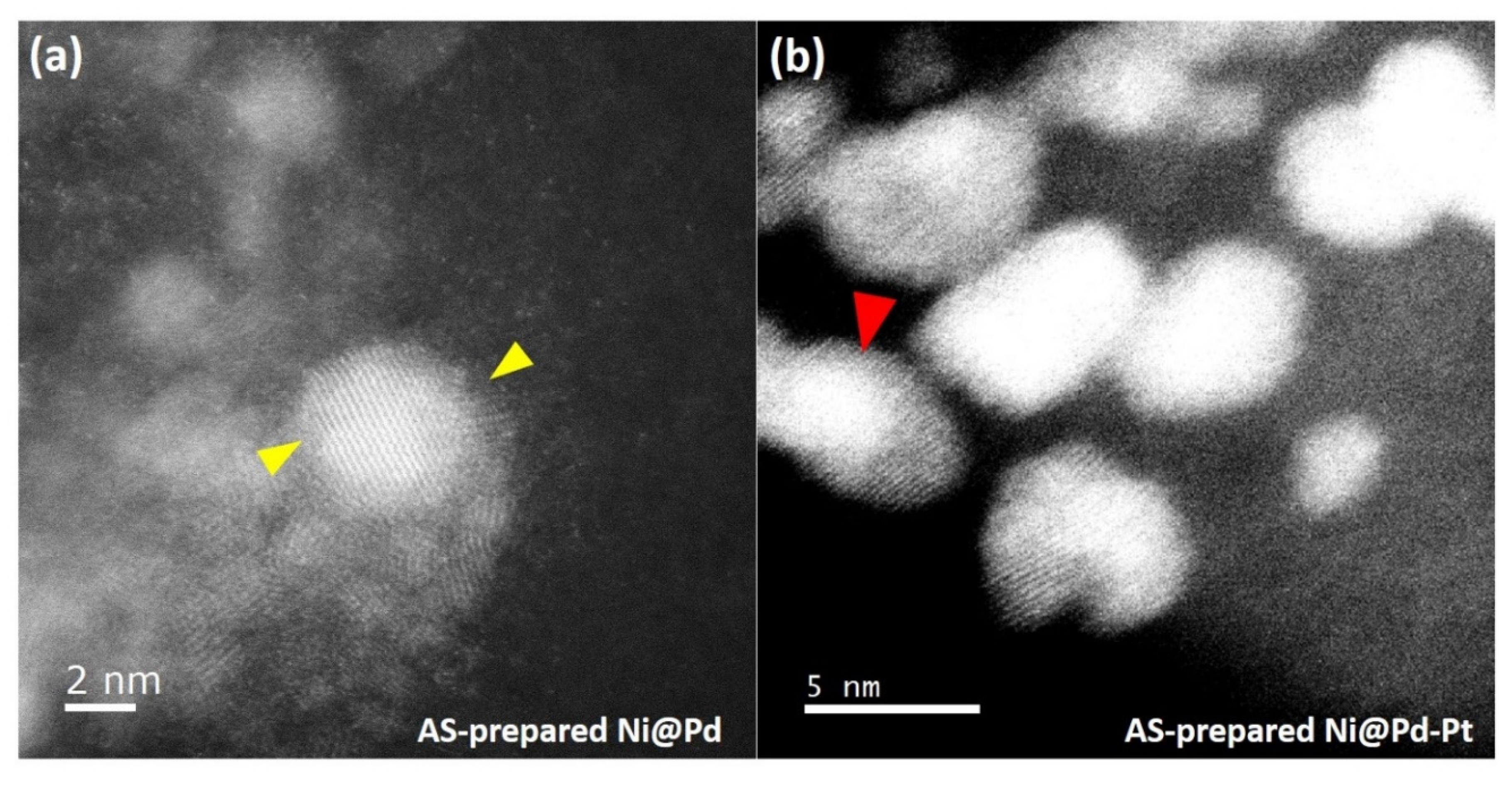

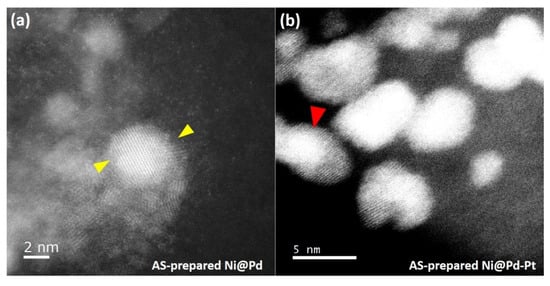

Aberration-corrected scanning transmission electron microscopy (AC-STEM) was utilized for revealing the surface morphology and crystal structure of experimental NCs. Figure 1 represents the comparative STEM images of Ni@Pd and Ni@Pd-Pt NCs. Accordingly, Ni@Pd (Figure 1a) nanoparticles exhibit a hierarchical structure, where long-range ordered atomic arrangements are observed on the surface due to capping of Pd-atoms over disorders Ni-atoms underneath. Such a characteristic confirms the formation of the hierarchical structure of Ni@Pd NC with a high density of surface defects (yellow arrows denote surface defects in Figure 1a), in which Pd-atoms are stacked over Ni-atoms. For the Ni@Pd-Pt catalyst, sub-nanometer to nanometer-scaled decorated Pt-clusters (indicated by the red arrow in Figure 1b) were observed on the Ni@Pd surface exhibiting the highest Z contrast in the HAADF-STEM image. Meanwhile, due to its highest Z number (Z = 78) in the ternary system they could be determined as Pt.

Figure 1.

Aberration-corrected scanning transmission electron microscopy (AC-STEM) images of as-prepared (a) Ni@Pd and (b) Ni@Pd-Pt nanocatalysts (NCs).

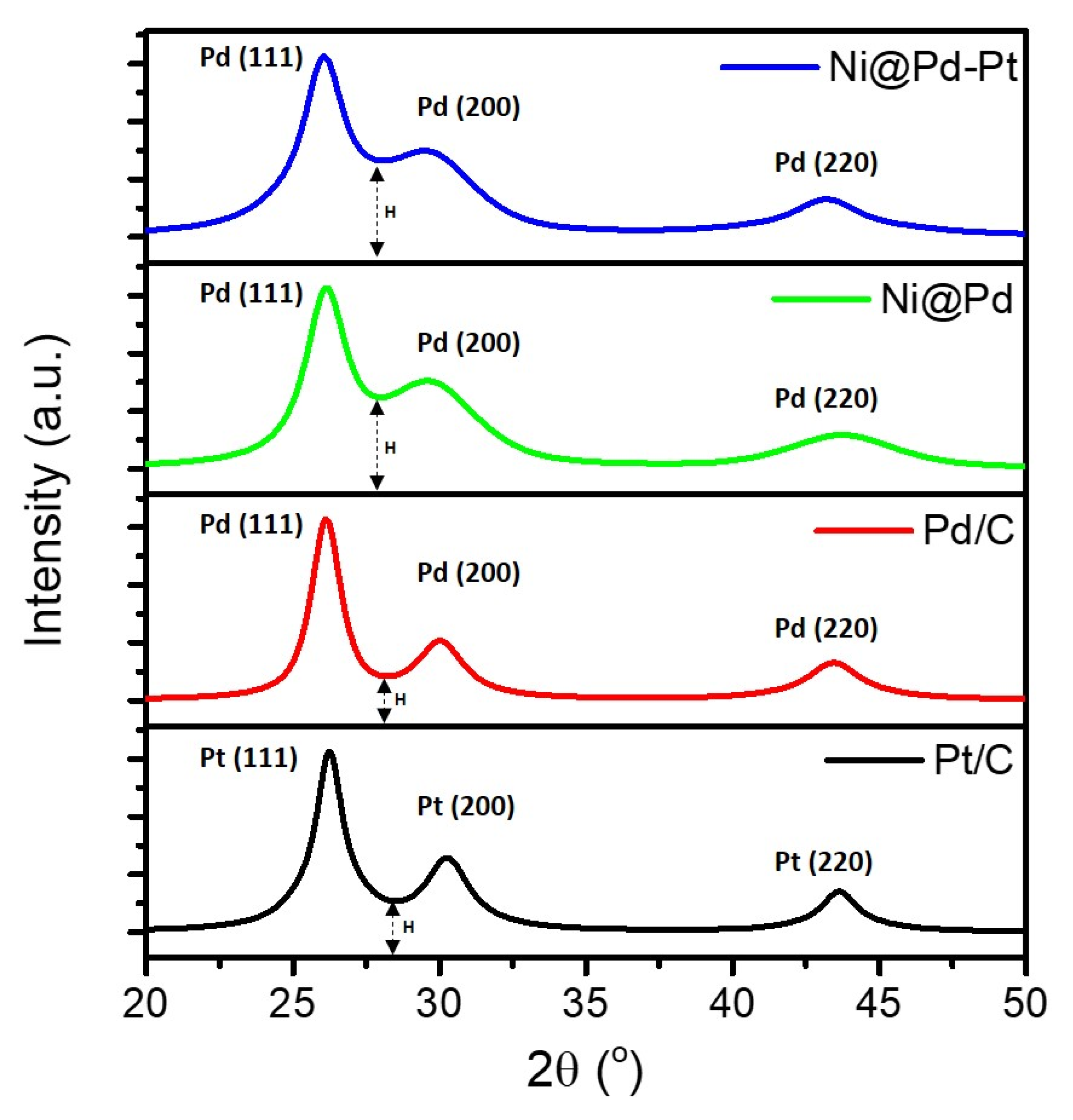

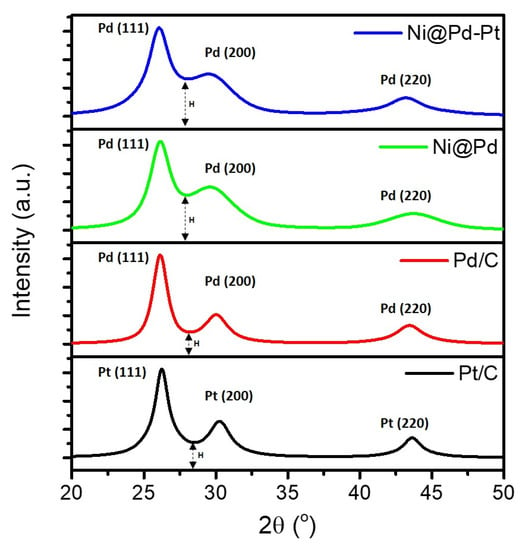

Further structural information of the experimental NCs under investigation was obtained via XRD analysis. Figure 2 depicts the XRD spectra of Ni@Pd-Pd NC compared with control samples (Ni@Pd, Pd/C and Pt/C). Accordingly, Pt/C exhibits characteristic diffraction signals at 26.25°, 30.36° and 43.64° corresponding to (111), (200) and (220) planes of fcc crystal lattice structure. Similar fcc Pt/Pd peaks were observed for Pd/C, Ni@Pd, and Ni@Pd-Pt NCs. Herein, it is worth noting that the closely packed Pt/Pd (111) planes of experimental NCs did not change significantly. However, distinct variations in open planes (i.e., Pt/Pd (200) and (220)) have been observed for Ni@Pd and Ni@Pd-Pt NCs. As shown in Figure 2, (200) and (220) planes of Pd/C are negatively shifted (i.e., towards a lower angle), which indicates its larger lattice constant compared to Pt/C in open planes. This phenomenon is due to the oxide formation in open planes due to NaBH4 assisted rapid crystal growth. For Ni@Pd NC, the closely packed (111) plane demonstrates similar features as that of Pd/C, however, compared to Pd/C, the (200) and (220) planes of Ni@Pd NC are significantly broadened and shifted to lower (larger lattice constant) and higher (lower lattice constant) angles, respectively. These characteristics indicate the co-existence of an expansive and compressive strain in the different planes. Moreover, Ni@Pd NC possesses higher background intensity (H) compared to Pd/C. The high background scattering is due to the presence of surface defects on Ni@Pd surface, which is consistent with former STEM analysis. Besides, the XRD pattern of Ni@Pd-Pt NC uncovers the effects of Pt-decoration on Ni@Pd surface. The Ni@Pd-Pt NC explores similar features in the closely packed (111) plane as that of Ni@Pd. However, compared to Ni@Pd, the broadened and narrowed (200) and (220) plane, respectively, indicates that Pt-clusters are mainly deposited on the open planes of Ni@Pd NC.

Figure 2.

X-ray diffraction (XRD) patterns of Ni@Pd-Pt NC compared with Ni@Pd, Pd/C and Pt/C.

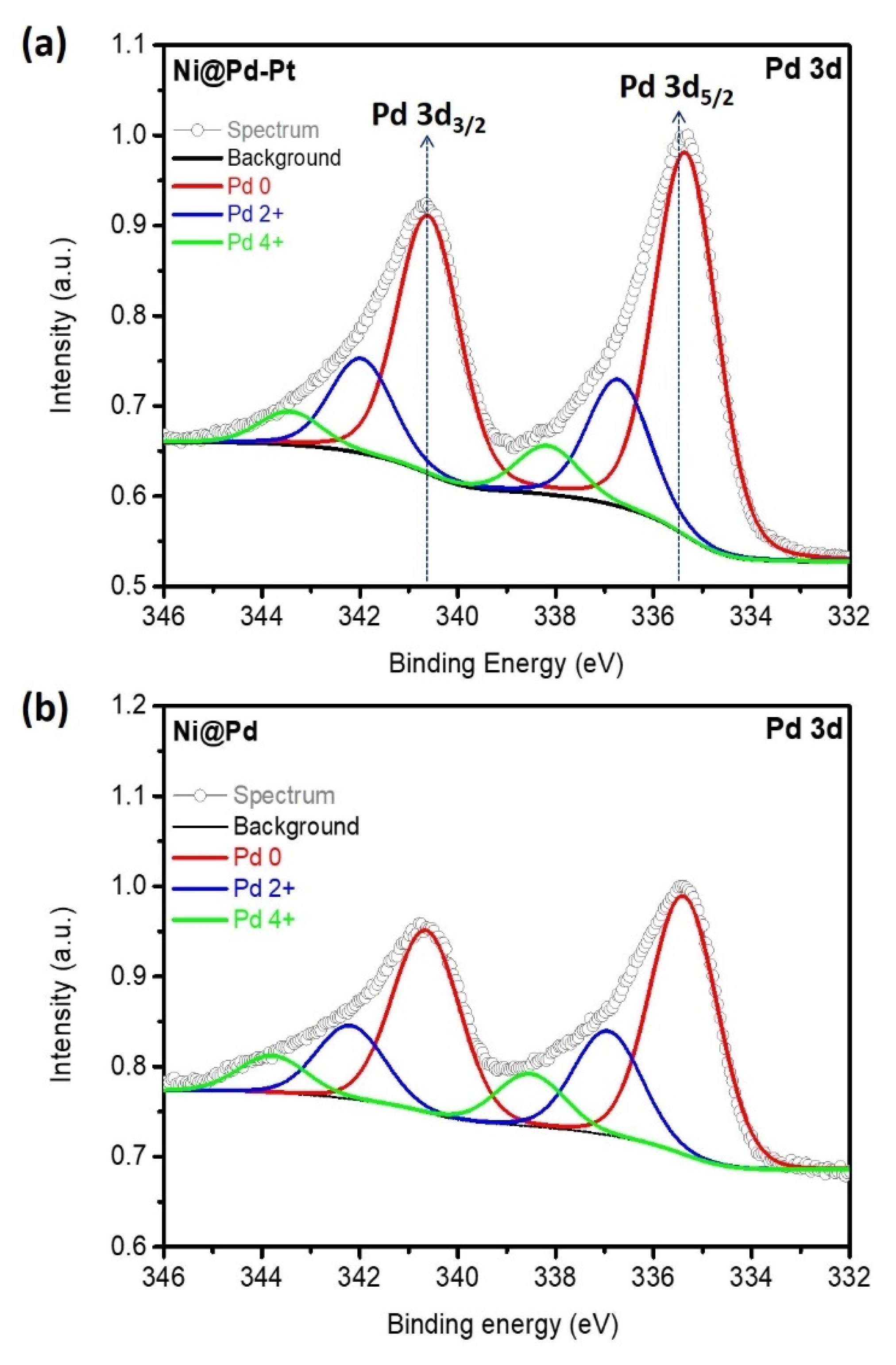

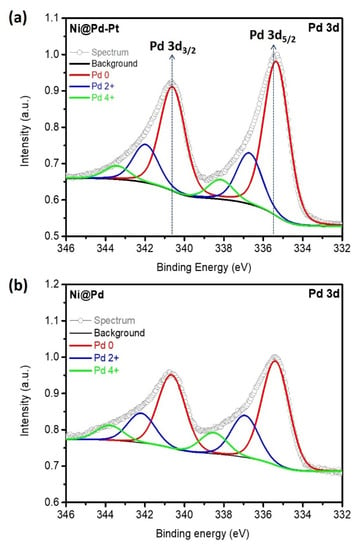

The X-ray photoelectron spectroscopy (XPS) is utilized at Pd-3d orbitals to get further evidence about change in the electronic structure of Ni@Pd NC after Pt-clusters decoration. For acquiring the XPS spectra, the X-ray with a −2.6 nm probing depth and 485 eV excitation energy was used. The fitted XPS spectra of experimental NCs in the Pd-3d region has been represented in Figure 3. In a Pd3d spectrum, the doublet peaks centered around 336.0 eV and 341.0 eV, respectively, are characteristic current (photoemission) responses from Pd 3d5/2 and Pd 3d3/2 orbitals. These peaks were simulated and deconvoluted to analyze the emission signals from various oxidation states of “Pd”; the obtained parameters are summarized in Table 1. Accordingly, the higher ratio of Pd (0) comparative to Ni@Pd confirms that Pt-clusters protect the Pd-atoms from surface oxidation in Ni@Pd-Pt NC. Moreover, the intensity of signals (i.e., emission peaks) in XPS spectrum is directly proportional to the target atom’s electron density. Hence, the higher intensity for Ni@Pd-Pt NC indicates its higher index of 3d electrons in Pd atoms, which proves electron relocation from Ni-to-Pd atoms and further to Pt-atoms. Besides, the reduced binding energy (BE) of Ni@Pd-Pt NC also confirms the electronegativity gap and lattice strain drove electron relocation from Ni atoms to Pd atoms. XPS spectra of Ni@Pd-Pt NC at the Pt-4f orbital and Ni@Pd NC at the Ni-2p orbital have been depicted in Figures S1 and S2, respectively.

Figure 3.

X-ray photoelectron spectroscopy of (a) Ni@Pd-Pt and (b) Ni@Pd NCs at Pd-3d orbitals.

Table 1.

The elemental oxidation states, composition ratios and binding energies of Ni@Pd-Pt compared with Ni@Pd NC.

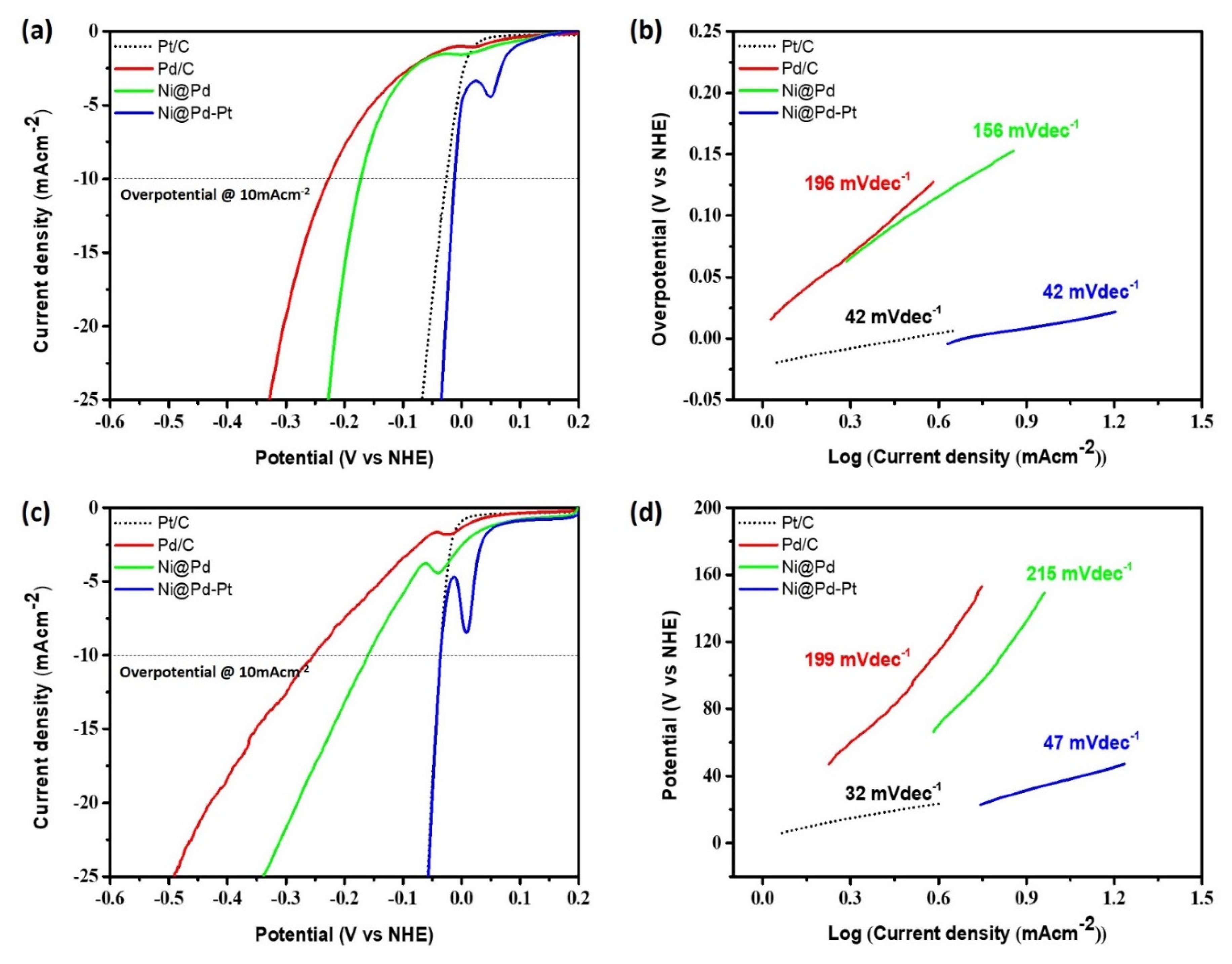

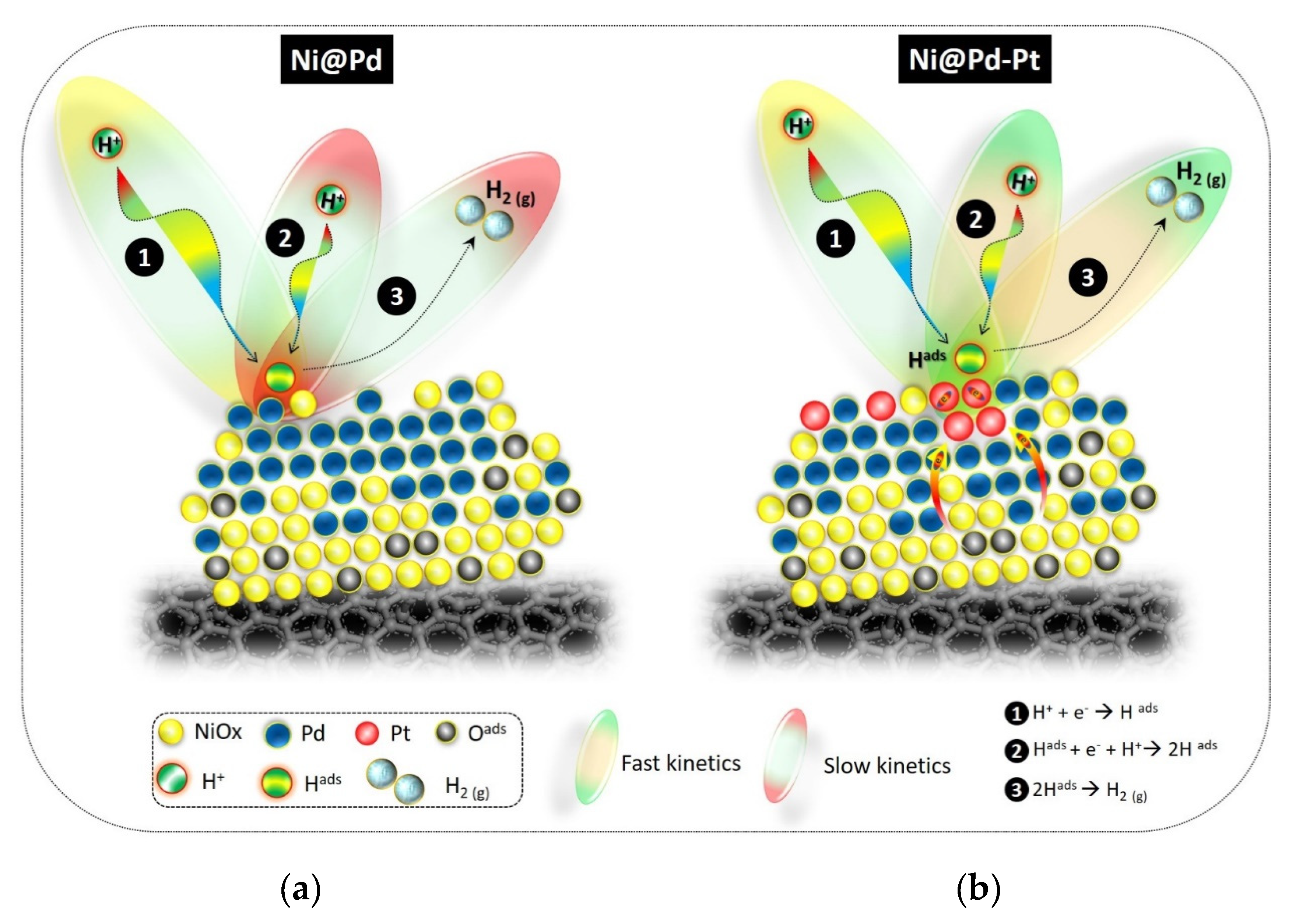

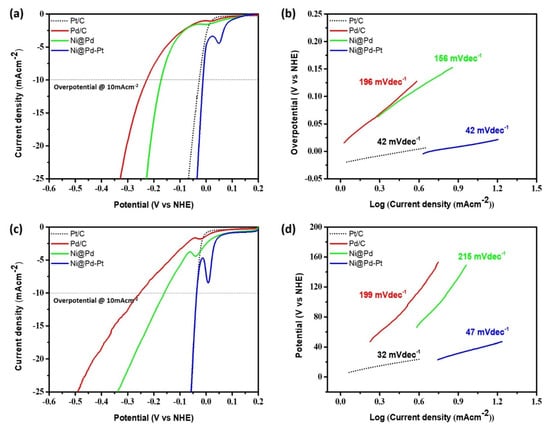

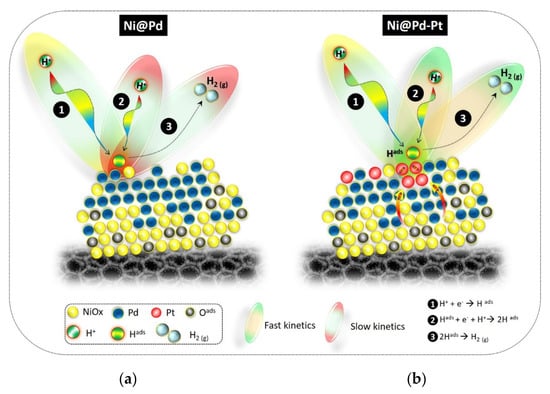

It is a well-known fact that the electronic structure of the catalysts has a major effect on their electrochemical HER performance. Accordingly, superior HER performance is expected from Ni@Pd-Pt NC as compared to Ni@Pd. The HER activities of Ni@Pd-Pt and control samples were investigated by using a linear sweep voltammetry (LSV) technique (Figure 4a,c). The LSV curves were obtained at a rotation rate of 1600 rpm, 2 mV s−1 scan rate and an applied potential window of −0.20 and 0.20 V at room temperature. The N2 saturated 0.1 M KOH (for alkaline medium) and 0.5 M H2SO4 (for acidic medium) electrolytes were used for LSV measurement. As-obtained HER parameters in both alkaline and acidic mediums have been summarized in Table 2. The overpotential is supposed to be the minimum potential needed to start the HER at the surface of catalyst at any cathodic current density. It is evident from Figure 4a that Ni@Pd-Pt NC outperforms all other NCs under investigation in an alkaline medium. The Ni@Pd-Pt NC exhibits significantly reduced overpotential of 11.5 mV, which is 161.5 mV lesser than that compared to Ni@Pd at the cathodic current density of 10 mA cm−2 in an alkaline medium. Of most importance, Ni@Pd-Pt NC surpasses the HER performance of standard Pt/C catalyst (30 wt.% Pt) and exhibits relatively less overpotential in an alkaline medium (14.5 mV). On the other hand, Ni@Pd-Pt NC also demonstrates competitive HER performance as that of standard Pt/C catalyst in acidic medium. The Ni@Pd-Pt NC achieves a low overpotential of 37 mV in an acidic medium, which is similar to Pt/C and 121 mV lower as compared to Ni@Pd NC (Figure 4c). Such an enhanced HER activity of Ni@Pd-Pt NC compared to Ni@Pd and Pt/C catalysts is due to the fact of unique charge relocation on the NC surface and high lattice strain. Moreover, an even closer inspection of LSV curves gives a clear insight into the surface chemical identities of Ni@Pd and Ni@Pd-Pt nanocatalysts. Accordingly, the intense peaks observed before 0 mV at the cathodic current density of 4.5 mA cm−2 and 8 mA cm−2 in alkaline and acidic medium, respectively, reflects the presence of PdPt and NiPd alloys on the Ni@Pd-Pt surface. The HER mechanism proceeds through a series of reactions in both the alkaline and acidic mediums. As shown in Scheme 2, in the acidic medium, adsorbed hydrogen ions (i.e., Hads) were formed on reactive sites of the catalyst surface in the first (discharge) step (commonly known as the Volmer reaction (1)), which was followed by an electrochemical desorption step (known as the Heyrovsky reaction (2)) and a recombination step (i.e., the Tafel reaction) (3).

Figure 4.

(a) The linear sweep voltammetry (LSV) and related (b) Tafel plots of experimental NCs under investigation in alkaline medium (0.1 M KOH). (c) LSV curves and related (d) Tafel plots of experimental NCs under investigation in acidic medium (0.5 M H2SO4). All the LSV curves were measured in 0.1 M KOH electrolyte solution at a scan rate of 2 mV s−1.

Table 2.

The hydrogen evolution reaction (HER) parameters of experimental NCs under investigation in alkaline and acidic medium.

Scheme 2.

Schematic representation for the dominating factors and pathways in HER for (a) Ni@Pd and (b) Ni@Pd-Pt nanocatalysts in acidic medium. In this scheme, reaction steps refer to a (1) discharge step followed by an (2) electrochemical desorption step and (3) recombination step.

Besides the alkaline medium, HER proceeds via a different pathway based in an acidic medium. In an alkaline medium, because H+ is not available from the electrolyte, the HER initiates from the dissociation of water (H2O) molecules to give protons (i.e., H+), which follows both the Volmer step (4) and the Heyrovsky step (5) of alkaline HER. Meanwhile, the Tafel step is similar to that in the acidic medium. The overall HER process in an alkaline medium is depicted in Equation (6).

Moreover, Tafel slope analysis was employed to assess the HER performance of nanocatalysts, which provides key information about the reaction pathways of HER. To further get insight into the HER mechanism, the Tafel plots (linear portion only) were simulated by using the following Tafel equation:

where : the Tafel slope, : the current density, : the exchange current density.

A smaller Tafel slope indicates a faster hydrogen generation rate (i.e., increased HER kinetics). The Tafel slopes of experimental NCs are plotted in Figure 4b,d for alkaline and acidic mediums, respectively, and summarized in Table 2. Accordingly, Ni@Pd-Pt NC exhibits the lowest Tafel slope of 42 mV dec−1 in an alkaline medium, which is exactly the same as that of standard Pt/C. Whereas in an acidic medium Ni@Pd-Pt NC achieves a competitive low Tafel slope of 47 mV dec−1, which is very close to standard Pt/C catalyst (32 mV dec−1). Generally, if the Tafel slope is between 40 and 120 mV dec−1, then the Heyrovsky reaction is the rate-determinative step (RDS). In this case, the electrochemical desorption step severely hampers the overall reaction process [32]. Accordingly, in the present study, HER followed the Heyrovsky reaction. Furthermore, the stability test results of Ni@Pd-Pt NC in both alkaline and acidic mediums have been added in Figure S3.

Cyclic voltammetry (CV) technique (depicted in Figure S4) provides further structure-performance-correlation. The CV curves were obtained in an alkaline (0.1 M KOH) electrolyte (N2-saturated) with 2 mV/s sweeping rate at room temperature. As depicted in Figure S3, Pd/C and Ni@Pd NCs exhibit a smeared peak profile at lower potentials (<0.4 V vs RHE.), which is attributed to the diffusion of H+ ions in the Pd crystal, resulting in a higher overpotential compared to Ni@Pd-Pt NC, hence, comparatively suppressed HER activity. In the case of Ni@Pd-Pt NC, sharp and narrow current responses for H+ desorption and adsorption (i.e., peaks H/H*) are observed, which confirms the presence of sub-nanometer scaled Pt-clusters on the Ni@Pd surface, resulting in low resistance and enhanced Faradaic process. This leads to improved HER kinetics compared to Pd/C and Ni@Pd NCs.

5. Conclusions

In this work, Pt-clusters decorated Ni@Pd hierarchically structured ternary metallic nanocatalyst were prepared on carbon black support by using “self-aligned” heterogeneous nucleation-crystal growth mechanism. As-obtained Ni@Pd-Pt NC efficiently catalyzes the HER with an ultra-low overpotential of 11.5 mV at the 10 mA cm−2 cathodic current density in alkaline medium, which is 14.5 mV less compared to standard Pt-C catalyst. Of special relevance, the overpotential of Ni@Pd NC is suppressed by 161.5 mV by decorating ~2.0 wt.% of Pt. Moreover, Ni@Pd-Pt NC achieves the Tafel slope value of 42 mV dec−1, which is the same as that of a standard Pt/C catalyst. The as-prepared Ni@Pd-Pt NC also exhibits outstanding performance in the acidic medium. In brief, the obtained results outline an efficient strategy for the development of next-generation HER catalysts with ultra-low content of Pt.

Supplementary Materials

The following are available online at https://www.mdpi.com/2076-3417/10/15/5155/s1, Figure S1: The XPS spectra at Pt-4f orbital of Ni@Pd-Pt NC, Figure S2: The XPS spectra at Ni-2p orbital of Ni@Pd NC, Figure S3: Stability test results of Ni@Pd-Pt NC, Figure S4: Cyclic voltammograms of experimental NCs, Table S1: ICP-OES determined composition ratios of experimental NCs, and Table S2: Benchmark Table for HER activity of Pt-based NCs.

Author Contributions

Data curation, S.-P.W.; formal analysis, D.B., S.L. and C.Y.; funding acquisition, P.-C.C.; project administration, P.-C.C.; resources, P.-C.C.; supervision, K.-W.W.; validation, D.B.; writing—original draft, D.B.; writing—review and editing, P.-C.C. All authors have read and agreed to the published version of the manuscript.

Funding

We acknowledge the funding support of the Ministry of Science and Technology, Taiwan (MOST 106-2112-M-007-016-MY3, MOST 107-2221-E-027-009-MY2, MOST 108-3116-F-007-001, MOST 107-3017-F-006-003, and MOST 109-3116-F-007-001).

Acknowledgments

The authors thank T.-Y. Chen and the staff of the National Synchrotron Radiation Research Center (NSRRC), Hsinchu, Taiwan (BL-01C1, BL-01C2, BL-07, and BL-17C) and Spring-8, Japan (BL-12B2) for helping in various synchrotron-based spectroscopies and diffraction analysis. Additionally, the authors acknowledge the Precision Research and Analysis Center at NTUT and financial supports from the Ministry of Education for the funding of “Center for Neuromodulation Medical Electronics Systems” from the featured areas research center program within the framework of the higher education sprout project.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Nocera, D.G. The Artificial Leaf. Acc. Chem. Res. 2012, 45, 767–776. [Google Scholar] [CrossRef] [PubMed]

- Walter, M.G.; Warren, E.L.; McKone, J.R.; Boettcher, S.W.; Mi, Q.; Santori, E.A.; Lewis, N.S. Solar Water Splitting Cells. Chem. Rev. 2010, 110, 6446–6473. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Zhang, X.; Jiang, W.; Zhang, Y.; Huang, L.; Chen, Y.; Yang, Y.; Li, L.; Hu, J. In situ transformation of Cu2O@MnO2 to Cu@Mn(OH)2 nanosheet-on-nanowire arrays for efficient hydrogen evolution. Nano Res. 2018, 11, 1798–1809. [Google Scholar] [CrossRef]

- Zheng, Y.; Jiao, Y.; Zhu, Y.; Li, L.H.; Han, Y.; Chen, Y.; Du, A.; Jaroniec, M.; Qiao, S.Z. Hydrogen evolution by a metal-free electrocatalyst. Nat. Commun. 2014, 5, 3783. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.; Zhang, W.; Zhang, F.; Zhang, Z.; Tang, B.; Li, J.; Wang, X. Theoretical Expectation and Experimental Implementation of In Situ Al-Doped CoS2 Nanowires on Dealloying-Derived Nanoporous Intermetallic Substrate as an Efficient Electrocatalyst for Boosting Hydrogen Production. ACS Catal. 2019, 9, 1489–1502. [Google Scholar] [CrossRef]

- Zou, X.; Zhang, Y. Noble metal-free hydrogen evolution catalysts for water splitting. Chem. Soc. Rev. 2015, 44, 5148–5180. [Google Scholar] [CrossRef]

- Zhao, Z.; Liu, H.; Gao, W.; Xue, W.; Liu, Z.; Huang, J.; Pan, X.; Huang, Y. Surface-Engineered PtNi-O Nanostructure with Record-High Performance for Electrocatalytic Hydrogen Evolution Reaction. J. Am. Chem. Soc. 2018, 140, 9046–9050. [Google Scholar] [CrossRef]

- Yin, H.; Zhao, S.; Zhao, K.; Muqsit, A.; Tang, H.; Chang, L.; Zhao, H.; Gao, Y.; Tang, Z. Ultrathin platinum nanowires grown on single-layered nickel hydroxide with high hydrogen evolution activity. Nat. Commun. 2015, 6, 6430. [Google Scholar] [CrossRef]

- Hou, Y.; Pang, H.; Zhang, L.; Li, B.; Xin, J.; Li, K.; Ma, H.; Wang, X.; Tan, L. Highly dispersive bimetallic sulfides afforded by crystalline polyoxometalate-based coordination polymer precursors for efficient hydrogen evolution reaction. J. Power Sour. 2020, 446, 227319. [Google Scholar] [CrossRef]

- Lee, C.-H.; Lee, S.; Kang, G.-S.; Lee, Y.-K.; Park, G.G.; Lee, D.C.; Joh, H.-I. Insight into the superior activity of bridging sulfur-rich amorphous molybdenum sulfide for electrochemical hydrogen evolution reaction. Appl. Catal. B Environ. 2019, 258, 117995. [Google Scholar] [CrossRef]

- Lu, X.F.; Yu, L.; Zhang, J.; Lou, X.W. Ultrafine Dual-Phased Carbide Nanocrystals Confined in Porous Nitrogen-Doped Carbon Dodecahedrons for Efficient Hydrogen Evolution Reaction. Adv. Mater. 2019, 31, 1900699. [Google Scholar] [CrossRef] [PubMed]

- Cui, T.; Dong, J.; Pan, X.; Yu, T.; Fu, Q.; Bao, X. Enhanced hydrogen evolution reaction over molybdenum carbide nanoparticles confined inside single-walled carbon nanotubes. J. Energy Chem. 2019, 28, 123–127. [Google Scholar] [CrossRef]

- Dong, X.; Yan, H.; Jiao, Y.; Guo, D.; Wu, A.; Yang, G.; Shi, X.; Tian, C.; Fu, H. 3D hierarchical V–Ni-based nitride heterostructure as a highly efficient pH-universal electrocatalyst for the hydrogen evolution reaction. J. Mater. Chem. A 2019, 7, 15823–15830. [Google Scholar] [CrossRef]

- Yang, H.; Hu, Y.; Huang, D.; Xiong, T.; Li, M.; Balogun, M.S.; Tong, Y. Efficient hydrogen and oxygen evolution electrocatalysis by cobalt and phosphorus dual-doped vanadium nitride nanowires. Mater. Today Chem. 2019, 11, 1–7. [Google Scholar] [CrossRef]

- Dutta, S.; Han, H.; Je, M.; Choi, H.; Kwon, J.; Park, K.; Indra, A.; Kim, K.M.; Paik, U.; Song, T. Chemical and structural engineering of transition metal boride towards excellent and sustainable hydrogen evolution reaction. Nano Energy 2020, 67, 104245. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, L.-R.; Yao, L.-Y.; Fang, Y.-H.; He, L.; Wei, G.-F.; Liu, Z.-P. Metal boride better than Pt: HCP Pd2B as a superactive hydrogen evolution reaction catalyst. Energy Environ. Sci. 2019, 12, 3099–3105. [Google Scholar] [CrossRef]

- Li, X.; Jiang, L.; Liu, J.; Hua, Q.; Wang, E.; Xie, G. Size-dependent catalytic activity of cobalt phosphides for hydrogen evolution reaction. J. Energy Chem. 2020, 43, 121–128. [Google Scholar] [CrossRef]

- Suliman, M.H.; Adam, A.; Siddiqui, M.N.; Yamani, Z.H.; Qamar, M. Facile synthesis of ultrathin interconnected carbon nanosheets as a robust support for small and uniformly-dispersed iron phosphide for the hydrogen evolution reaction. Carbon 2019, 144, 764–771. [Google Scholar] [CrossRef]

- Rao, C.N.R.; Chhetri, M. Borocarbonitrides as Metal-Free Catalysts for the Hydrogen Evolution Reaction. Adv. Mater. 2019, 31, 1803668. [Google Scholar] [CrossRef]

- Dolganov, A.V.; Muryumin, E.E.; Chernyaeva, O.Y.; Chugunova, E.A.; Mishkin, V.P.; Nishcev, K.N. Fabrication of new metal-free materials for the hydrogen evolution reaction on base of the acridine derivatives immobilized on carbon materials. Mater. Chem. Phys. 2019, 224, 148–155. [Google Scholar] [CrossRef]

- Jaksic, M.M. Hypo–hyper-d-electronic interactive nature of interionic synergism in catalysis and electrocatalysis for hydrogen reactions. Int. J. Hydrogen Energy 2001, 26, 559–578. [Google Scholar] [CrossRef]

- Nørskov, J.K.; Bligaard, T.; Logadottir, A.; Kitchin, J.R.; Chen, J.G.; Pandelov, S.; Stimming, U. Trends in the Exchange Current for Hydrogen Evolution. J. Electrochem. Soc. 2005, 152, J23. [Google Scholar] [CrossRef]

- Bhalothia, D.; Shuan, L.; Wu, Y.-J.; Yan, C.; Wang, K.-W.; Chen, T.-Y. A highly mismatched NiO2-to-Pd hetero-structure as an efficient nanocatalyst for the hydrogen evolution reaction. Sustain. Energy Fuels 2020, 4, 2541–2550. [Google Scholar] [CrossRef]

- Bhalothia, D.; Chen, P.-C.; Yan, C.; Wang, K.-W.; Chen, T.-Y. Heterogeneous NiO2-to-Pd Epitaxial Structure Performs Outstanding Oxygen Reduction Reaction Activity. J. Phys. Chem. C 2020, 124, 2295–2306. [Google Scholar] [CrossRef]

- Begum, H.; Ahmed, M.S.; Lee, D.-W.; Kim, Y.-B. Carbon nanotubes-based PdM bimetallic catalysts through N4-system for efficient ethanol oxidation and hydrogen evolution reaction. Sci. Rep. 2019, 9, 11051. [Google Scholar] [CrossRef]

- Bhalothia, D.; Fan, Y.-J.; Lai, Y.-C.; Yang, Y.-T.; Yang, Y.-W.; Lee, C.-H.; Chen, T.-Y. Conformational Effects of Pt-Shells on Nanostructures and Corresponding Oxygen Reduction Reaction Activity of Au-Cluster-Decorated NiOx@Pt Nanocatalysts. Nanomaterials 2019, 9, 1003. [Google Scholar] [CrossRef]

- Bhalothia, D.; Lin, C.-Y.; Yan, C.; Yang, Y.-T.; Chen, T.-Y. Effects of Pt metal loading on the atomic restructure and oxygen reduction reaction performance of Pt-cluster decorated Cu@Pd electrocatalysts. Sustain. Energy Fuels 2019, 3, 1668–1681. [Google Scholar] [CrossRef]

- Bhalothia, D.; Chou, J.-P.; Yan, C.; Hu, A.; Yang, Y.T.; Chen, T.Y. Programming ORR Activity of Ni/NiOx@Pd Electrocatalysts via Controlling Depth of Surface-Decorated Atomic Pt Clusters. ACS Omega 2018, 3, 8733–8744. [Google Scholar] [CrossRef]

- Bhalothia, D.; Dai, S.; Wang, S.-P.; Yan, C.; Huang, T.-H.; Chen, P.-C.; Hiraoka, N.; Wang, K.-W.; Chen, T.-Y. Sub-nanometer Pt cluster decoration enhances the oxygen reduction reaction performances of NiOx supported Pd nano-islands. Sustain. Energy Fuels 2020, 4, 809–823. [Google Scholar] [CrossRef]

- Bhalothia, D.; Lin, C.-Y.; Yan, C.; Yang, Y.-T.; Chen, T.-Y. H2 Reduction Annealing Induced Phase Transition and Improvements on Redox Durability of Pt Cluster-Decorated Cu@Pd Electrocatalysts in Oxygen Reduction Reaction. ACS Omega 2019, 4, 971–982. [Google Scholar] [CrossRef]

- Bhalothia, D.; Fan, Y.-J.; Huang, T.-H.; Lin, Z.-J.; Yang, Y.-T.; Wang, K.-W.; Chen, T.-Y. Local Structural Disorder Enhances the Oxygen Reduction Reaction Activity of Carbon-Supported Low Pt Loading CoPt Nanocatalysts. J. Phys. Chem. C 2019, 123, 19013–19021. [Google Scholar] [CrossRef]

- Manikandan, A.; Ilango, P.R.; Chen, C.-W.; Wang, Y.-C.; Shih, Y.-C.; Lee, L.; Wang, Z.M.; Ko, H.; Chueh, Y.-L. A superior dye adsorbent towards the hydrogen evolution reaction combining active sites and phase-engineering of (1T/2H) MoS2/α-MoO3 hybrid heterostructured nanoflowers. J. Mater. Chem. A 2018, 6, 15320–15329. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).