Abstract

Modification of epitaxial graphene on silicon carbide (EG/SiC) was explored by ion implantation using 10 keV nitrogen ions. Fragments of monolayer graphene along with nanostructures were observed following nitrogen ion implantation. At the initial fluence, sp3 defects appeared in EG; higher fluences resulted in vacancy defects as well as in an increased defect density. The increased fluence created a decrease in the intensity of the prominent peak of SiC as well as of the overall relative Raman intensity. The X-ray photoelectron spectroscopy (XPS) showed a reduction of the peak intensity of graphitic carbon and silicon carbide as a result of ion implantation. The dopant concentration and level of defects could be controlled both in EG and SiC by the fluence. This provided an opportunity to explore EG/SiC as a platform using ion implantation to control defects, and to be applied for fabricating sensitive sensors and nanoelectronics devices with high performance.

1. Introduction

Graphene is well known as a two-dimensional material with several remarkable properties like high electrical conductivity, high flexibility, low electric noise and high mechanical strength [1]. The lack of bandgap limits its application potential. Graphene based digital devices cannot be “switched-off” due to a constant flow of electrons. Switching is a necessity in electronic devices such as switches and transistors. Efforts are made to control the bandgap in growth and post processing, but it is a big challenge.

Modification of surfaces functionalizes graphene and has demonstrated a band gap [2], which makes possible its usage in digital electronics, nanoelectronics, spintronics, magnetronics and much more. The structural changes also alter its optical, electrical, mechanical and magnetic properties, thus offers its applicability for biosensors, gas sensors, optoelectronic devices, solar cells, detectors, batteries, pressure sensors, etc. The structure of graphene has been altered using various methods such as chemical doping, covalent functionalization and electron/ion beam irradiation [3,4,5].

The ion beam technology is a high precision and high reproducibility process. Structural modifications introduced using ion irradiation are much more effective due to the reason that there is an efficient transfer of energy from energetic incident ions to the atoms of graphene. Impurity doping can be done by ion irradiation (both by insertion of atoms from primary ion beam or via backscattered atoms from the substrate) and various atoms, molecules or ions can be explored. This range of options is not offered by any other technology. Both dopant and defects introduction in the material at the same time up to a desired depth can be also tailored.

The low energy ion implantation has been shown to modify the different types of graphene, such as produced by mechanical exfoliation, chemical vapor deposition (CVD) and sublimation epitaxy (epitaxial graphene) process. Experimental and theoretical studies showed an array of nanodots and nanowires on graphene on SiO2 using 30 keV Ga ion irradiation [6]. The structural modification in mechanically exfoliated multilayer graphene on SiO2 substrate caused an increase in defects with the increase in dwell time of ion irradiation, along with an increase in the compressive strain using focused ion beam (FIB) with Ga ions [7]. It was also shown that multilayered graphene is p-type doped due to defects thereby resulting in increasing the work function [7]. Modified single layer CVD graphene showed metal–insulator transition at larger doses of Ga ion irradiation using FIB [8]. There was a change of work function of graphene with an increase in defect density with increasing Ga irradiation dose [8]. Argon ion irradiation in the energy range of 0–200 eV with time of 0–10 s was applied on few layers of graphene. The study optimized beam energy and irradiation time to remove surface contaminants and to flatten the surface damage [9]. Nanopores were formed (size of two nanometers) following the treatment of exfoliated graphene on SiO2 with hydrogen plasma etching [10]. Single layers of graphene nanopatterning were obtained by using helium ions and nanostructures and nanoribbons appeared at a dose of 2.0 × 1016 ions/cm2 [11]. Nanopores were also obtained in exfoliated graphene using 35 keV Ga ion irradiation [12].

Different types of ions create different levels of defects. Xu et al. used B, N and F ion irradiation on CVD grown monolayer graphene at 35 eV and 20 eV energy between 1 × 1014 ions/cm2 to 6 × 1015 ions/cm2 fluence [13]. Willke and co-workers observed that 25 eV N ion implantation at 5 × 1014 ions/cm2 fluence resulted in doping of epitaxial graphene (EG) with N concentration of around 1% [14]. Ion implantation on EG with 25 eV B and N ions showed an increase in resistance and a change in magnetoresistance from positive to negative [15]. Defect differences appeared at 200 keV N and Ar ion irradiation of epitaxial graphene, along with a decrease in corrugation [16]. Previously we showed that ion beam implantation (30 keV) and ion beam irradiation (100 MeV) using silver ions acts as a tool to increase sensing capacity of EG on SiC [17,18].

Earlier studies explored defect generation in graphene and SiC independently [19,20,21,22]. Only some studies are about defect generation in both graphene and SiC. The substrate plays a crucial role in defect generation in EG on SiC, which shows the importance to study defect generation in both EG and SiC as defect generation in both graphene and SiC enhances their applicability in various interdisciplinary areas [6]. This study presents the effects of ion implantation using N ions on structural properties of EG and SiC. The EG/SiC was irradiated with 10 keV N+ ions at 1 × 1012 ions/cm2 to 1 × 1014 ions/cm2 fluences. This range of energy of incident ions create defects both in graphene and SiC while other energy ranges (eV and MeV) influence either graphene or the SiC substrate. Further, doping of graphene with N is advantageous as it results in n-type doping of graphene due to the reason that C and N have comparable atomic radii and chemical bond lengths, which causes substitution of C atom by N atom [23]. Theory revealed that different N dopant configurations result in affecting the local density of states and local charge distribution, and thus changes of the electronic and sensing properties of graphene [24]. The N doping is a way to have n-type graphene material, and is an excellent platform for Li batteries, fuel cells, supercapacitors. This plays a critical role for developing graphene-based nanoelectronics and optronics. Although chemical methods also produce n-type graphene, but they have many disadvantages comparatively to ion implantation like lack of precise control on the concentration of the dopant, contamination and inferred secondary impurities and site selectivity. The ion implantation has revolutionized the semiconductor technology to have a significant economic and societal impact. Integration of ion implantation with EG/SiC will be a further and major step-up into technological progress. Ion implantation of graphene with trivalent and pentavalent impurities presents huge prospect for industrial scale, non-chemistry reliant functionalization and processing of 2D materials.

2. Materials and Methods

Substrates of 4H–SiC (0001) was used for the growth of EG. The graphene was grown inside an inductively heated furnace by thermal decomposition of SiC substate at 2000 °C having an argon pressure at 1 atm [25]. Nitrogen ion (N+) implantation was carried out at Inter University Accelerator Center (IUAC), New Delhi, India employing 30 kV tabletop accelerator. N+ ions with 10 keV energy were used for ion implantation at varying fluences between 1 × 1012 ions/cm2 to 1 × 1014 ions/cm2. Stopping and range of ions in matter (SRIM) software was exploited for calculating various parameters like projected range of ions and different types of energy losses [26].

The atomic force microscopy (AFM) by Veeco instruments with 3100 dimensions was done in the tapping mode on both as grown and ion-implanted samples. Raman-AFM WITEC model alpha 300 instrument with excitation laser of 532 nm was used for measuring Raman spectra. An axis Ultra DLD instrument having monochromatic Al (Kα) radiation (hv = 1486.6 eV) was used for doing the XPS measurements. The base pressure in analysis chamber was <1.5 × 10−7 Pa when the XPS spectra were recorded. The C 1s, Si 2p and O 1s core level spectra obtained from XPS further were deconvoluted using Casa XPS software package [27].

3. Results

3.1. AFM

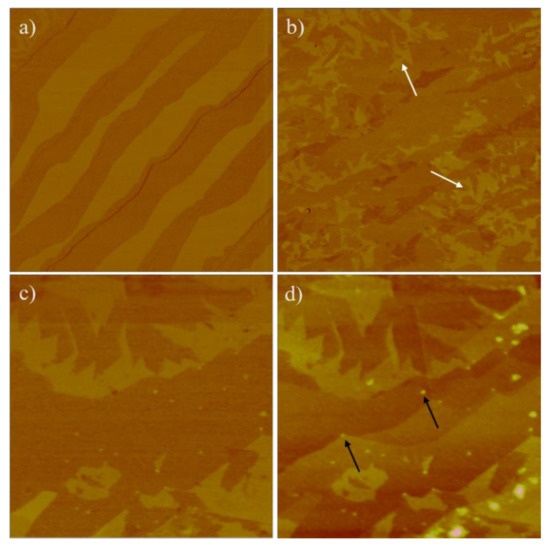

The pristine and nitrogen ion-implanted EG at 1 × 1014 ions/cm2 fluence is shown in Figure 1a,b which are Atomic Force Microscopy (AFM) phase images obtained at scan areas of 10 µm × 10 µm. The pristine graphene is dominantly covered with monolayer graphene (ML) and bilayer (BL) graphene (darker areas) as depicted in Figure 1a. The thickness of graphene was obtained using optical reflectance mapping. Figure 1b shows changes in the surface morphology following ion implantation which resulted in fragmentation of the ML graphene shown by white arrows. Figure 1c is the phase image and Fig 1d is height image of the sample implanted at the highest fluence (1 × 1014 ions/cm2) showing presence of dot like structures (shown with black arrows) referred as “nanostructures”. Their diameters are estimated from software Nanoscope III (V5.3) (Digital Instruments/Vecco Metrology group, Plainview, NY, USA) to be between 40–70 nm and the heights of around 0.8–1.2 nm.

Figure 1.

Atomic force microscopy (AFM) phase images of (a) pristine and (b) N+ ion-implanted epitaxial graphene (EG) on SiC at 1 × 1014 ions/cm2 fluence over a scan area of 10 µm × 10 µm with white arrows showing fragmentation of Monolayer (ML) graphene; (c) phase and (d) height image of N+ ion-implanted EG on SiC at 1 × 1014 ions/cm2 fluence over scan area 2 µm × 2 µm with black arrows showing presence of nanostructures.

At the elastic impact of the energetic ions on the atoms of the material, i.e., in case of nuclear energy loss, the atoms of the material are dislocated from their initial sites in the lattice when the transmitted energy is higher than the displacement threshold energy. The minimum energy required for displacing a single C atom in graphene is 22.2 eV [28]. The minimum lattice displacement energy for the C atom is 20 eV and the Si atom is 35 eV in SiC [29]. In this case, the energy of the incident energetic ions (nitrogen ions) is much more than the energy required for displacing C atoms in graphene and Si and C atoms in the SiC lattice. This resulted in creation of C and Si Frenkel defects. Further, if the surface binding energy required by the atom to bind to the solid surface is lower than the incident energy of the ions, then the atom can be sputtered. In SiC, the surface binding energy was reported to be 7.4 eV for C and 4.7 eV for Si [30].

As the transferred energy is greater than the surface binding energy and the displacement threshold energy of Si and C atoms, it likely results in both displacement and sputtering of target atoms. We estimated the electronic energy loss (Se) and the nuclear energy loss (Sn) by the SRIM software for N+ ion implantation in EG on SiC, and the results are tabulated in Table 1. It was found that in N+ ion implantation, Sn dominates as compared to Se.

Table 1.

Electronic and nuclear energy loss, longitudinal straggling and lateral straggling calculated from stopping and range of ions in matter (SRIM) simulations.

The projected range for N+ ion implantation is 10.4 nm along with a longitudinal straggling of 3 nm. This shows that most of the damages are generated due to the ion implantation are settled not in the graphene layer, but into the SiC substrate. In this work, defects in graphene are recognized as direct and indirect defects. Direct defects are referred to as defects that arise by the direct impact of the incident ions with C atoms of graphene. Indirect defects are the defects that are created by the impact of the substrate atoms on the C atom of graphene. During the process of collision of incident ions with the substrate atoms, the substrate atoms are sputtered. The sputtered substrate atoms further undergo collision with the C atom of graphene and remove the C atom from the graphene lattice. This process of defect generation in graphene is referred to as indirect defects [6]. It was reported previously that sputtered C atoms undergo agglomeration into small clusters due to their high structural fluidity during the process of ion irradiation [31,32]. Direct and indirect defects cause agglomeration of sputtered atoms which presumably resulted in the formation of nanostructures that are observed in this study on ion-implanted EG/SiC in Figure 1c,d. The Monte Carlo simulation of defect generation upon 0.1 to 1000 keV energy range in ML graphene supported by SiO2 substrate showed that C Frenkel pairs are primary defect than Si Frenkel pairs [6]. Defect generation in 0.25–50 keV ion-implanted SiC using molecular dynamics simulation reported that most defects are carbon vacancies and carbon interstitials with small fraction of antisite defects (atoms of different type exchanged position) [29]. It was proposed that the substrate plays a major role in enhancing the sputtering yield [6] when C sputtering yield was presented to be higher in graphene supported by SiO2 substrate than in suspended graphene. Sputtering following ion implantation breaks graphitic carbon bonds and causes graphene fragmentation as observed in Figure 1b. AFM results showed that ion implantation provides a single step process for nano-pattering of EG/SiC in controlled manner which can be further used for developing optoelectronic, electronic and magnetronic devices of high performance.

3.2. Raman Spectroscopy

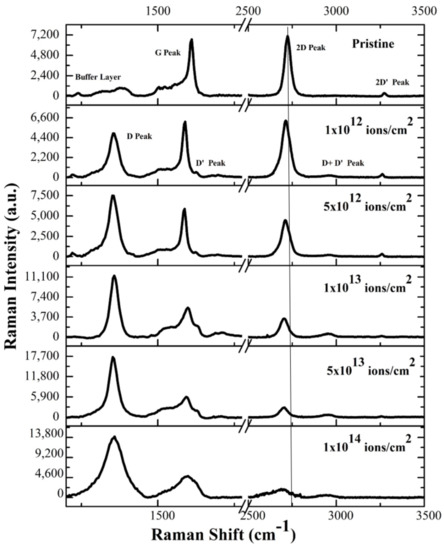

Raman spectroscopy provides structural fingerprints of the molecules in a material and is a nondestructive method. Figure 2 presents spectra obtained from Raman spectroscopy of pristine and 10 keV N+ ion-implanted EG at varying fluences. The Raman spectra of graphene are characterized by the G peak located around ~1580 cm−1 and a 2D peak present at 2730 cm−1 wavenumbers. The G peak is the only first order peak and is a result of bond stretching both by aromatic ring atoms and chain atoms [33]. The 2D peak indicates defect free graphene and is related to a two phonons process. D peak which occurs at ~1350 cm−1 wavenumber is related to defects in graphene and is not observed for pristine graphene [34]. Additionally, the presence of D+D′ at 2950 cm−1 and D′ at 1620 cm−1, also demonstrate defects in EG [35].

Figure 2.

Raman spectra of pristine and N+ ion-implanted EG on SiC obtained at different fluences.

Figure 2 shows the absence of the D peak in pristine graphene, thus showing as grown graphene is of high quality. Figure 2 shows the presence of the D peak in all ion-implanted samples. The D′ peak is clearly visible up to 5 × 1013 ions/cm2 fluence, however, at the highest fluence (1 × 1014 ions/cm2) the D′ peak is not visible as it merged with the G peak. The D+D′ peak appeared in all ion-implanted samples, reflecting a significant amount of defects [35]. The intensity ratio of D peak and G peak is represented as I(D)/I(G) and the intensity ratio of 2D peak and G peak is represented as I(2D)/I(G). They were calculated using Figure 2 for all ion-implanted samples. Defects are generated following ion implantation which resulted in the decrease in I(2D)/I(G) and an increase I(D)/I(G) which was also evident from a previous study [36]. Figure 2 also shows the fluence dependent rise in the intensity of D peak and fall in the intensity of the 2D peak. This signifying increase in defects with the increase in fluence. This is similar to a previous study following ion implantation on graphene sheets. The graphene sheets were prepared by the direct liquid exfoliation of graphite layers which then were deposited on a Si–substrate [37]. There is an increment in the full width half maxima (FWHM) of the 2D peak with increasing fluence.

In graphene, the sp3 defects dominate when I(2D)/I(G) > 1 and I(D)/I(G) < 1, while domination by vacancy defects is observed when I(2D)/I(G) < 1 and I(D)/I(G) > 1 [38]. Another study reported domination of sp3 defects when I(D)/I(D′) is in the range of 7 to 13, and domination of vacancy defects when I(D)/I(D′) is in the range of 3.5 to 7 [35]. The authors referred to sp3 defects as “hopping defects”. These defects distort the bonds between the carbon atoms, retaining the general sp2 configuration, while vacancy defects arise due to missing of atoms from its lattice site. At a fluence of 1 × 1012 ions/cm2, sp3 defects dominate as I(2D)/I(G) > 1, I(D)/I(G) < 1 and I(D)/I(D′) is higher than 7 and at a fluence 5 × 1012 ions/cm2 and higher, vacancy defects dominate as I(2D)/I(G) < 1 and I(D)/I(G) > 1, and I(D)/I(D′) is in the range of 3.5 to 7.

Cancado et al., based on the intensity ratio between D peak and G peak, classified graphene defect generation into two stages, stage I and stage II. In Stage I, there is a rise in the I(D)/I(G) ratio, but in stage II there is a fall in the I(D)/I(G) ratio. The stage II is also marked by a broadening of FWHM of D and 2D peaks [36]. The two stages are discussed in detail by Kaushik et al. for ion implantation using Ag− ion in epitaxial graphene [17]. Figure 2 shows an increase of the FWHM of the 2D peak in N+ ion-implanted EG at varying fluences. At fluence of 1 × 1014 ions/cm2, there is a significant broadening of FWHM of D and 2D peaks. This marks a clear indication of the onset of stage II [36]. Luchesse et al. simulated phenomenological model and gave the relation between I(D)/I(G) and the average distance between defects represented as LD as shown below [39].

where rA = 3.1 nm and rS = 1 nm are the radii of the activated area and the structurally disordered area. Details of activated and disordered area are mentioned further by Kaushik et al. [17]. The constant CA = 4.2 which depends on the laser excitation energy (in this work it is 2.33 eV) and the maximum possible value of I(D)/I(G). The I(D)/I(G) were estimated from the results obtained by Raman spectroscopy (Figure 2) and LD was calculated in graphene using the above equation. The Equation (2) below shows the relation between LD and defect density represented as nD.

nD = 1014/ π LD2

The nD was estimated using Equation (2). Table 2 tabulates the values of I(D)/I(G), LD and nD at different fluences in the ion-implanted samples of EG/SiC.

Table 2.

Intensity ratios of D and G peaks (I(D)/I(G)), mean distance between defects in graphene (LD) and defect density (nD) in N+ ion-implanted EG/SiC.

Table 2 shows the rise in the defect density with the increase of fluence. Figure 2 shows that the 2D peak is positioned at ~2730 cm−1 in the pristine sample. Besides reduction in the 2D peak intensity with the increasing fluence, we also observed a red shift of the 2D peak (Figure 2) in the ion-implanted samples. The 2D peak is fitted with a Lorentzian curve and we observed that the 2D peak centered at 2730 cm−1 in the pristine sample shifted to 2680 cm−1 in the highest implanted fluence. This red shift of the 2D peak is because of relaxation of compressive strain following ion implantation as pristine EG is initially under compressive strain. Earlier studies showed that following electron beam implantation a red shift in the 2D peak is due to tensile strain or due to relaxation of compressive strain [40].

The structural modifications in the 4H–SiC substrate was explored using Raman spectroscopy. Defects in graphene appear due to a combination of direct collision of the incident ions with graphene atoms and due to the impact of indirect collision of the substrate atoms [6]. Thus, it is essential to investigate defects generated in SiC as well. Two prominent peaks in SiC Raman spectra are FTO (2/4) at 776 cm−1 and LO at 965 cm−1 [41]. Figure 3a shows the presence of these prominent SiC peaks in the Raman spectra. Figure 3a indicates a decrement in the intensity of FTO (2/4) and LO with the rise in fluence, which is similar to that reported earlier in ion irradiated SiC [42]. C sub lattices has displacement energy of 20 eV and Si has of 35 eV in the SiC lattice. Since the transmitted energy in this study is higher than the threshold energy required for C and Si atom, the displacement of Si and C atoms from its lattice site occurs and which causes breaking of the SiC bonds. This results in a reduction of the intensity of the FTO (2/4) peak along with the LO peak, which can be observed in Figure 3. At the highest fluence (1 × 1014 ions/cm2), a shift and narrowing of the FTO (2/4) peak along with the LO peak is observed (Figure 3a). This is in agreement with a previous study, which reported that this could be due to the fact that point defects trap the free carriers. The LO phonon loses the plasmonic coupling as a result of defects causing a shift in the LO peak [43]. Figure 3b illustrates newly formed Raman bands in the range around ~500–550 cm−1 at the highest fluence. This is due to the formation of Si–Si bonds in the samples implanted at a fluence 1 × 1014 ions/cm2 [44]. In addition to that there also occur less intense bands in the region of 650–800 cm−1 in the Raman spectra of the sample with the highest fluence. This could be due to the formation of a new vibrational modes of Si–C following the ion implantation. Sorieul and co-workers reported that defects generated in SiC by ion irradiation result in breakdown of Raman selection rules, which leads to generation of Si–Si and C–C and new Si–C vibrational modes [44]. Further, Figure 3b shows a bump in the region 815–950 cm−1 which is due to the superposition of three transverse optical phonons which are 2TO (X), 2TO (W) and 2TO (L) of silicon [45].

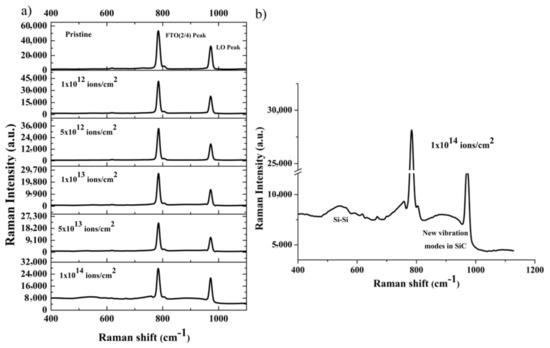

Figure 3.

(a) Raman spectra showing changes in the prominent SiC peaks at varying fluences in N+ ion-implanted samples; (b) Raman spectra of the sample implanted at fluence 1 × 1014 ions/cm2.

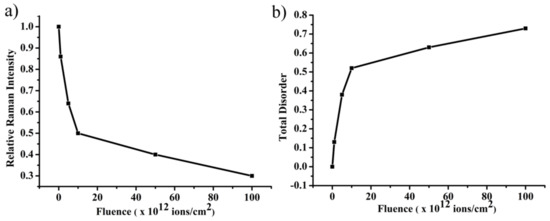

The relative Raman intensity which is denoted as RRI is the ratio between the average intensity of the first order Raman modes in the ion-implanted sample and that of the pristine sample [46]. Figure 4a shows a decrease in RRI from its maximum value of 1 in the non-implanted sample to the value of 0.30 in the sample implanted at fluence of 1 × 1014 ions/cm2. Increased amount of defects with increasing fluence is the reason behind the reduction in the value of RRI, which is in agreement with a previous study [46]. The total disorder, which quantifies the damage of the crystallinity of materials is defined as 1-Anorm. The Anorm is the ratio between the total area under the principal first order Raman band in the implanted material and the area under the principal first order Raman band of the crystalline material [47]. The ranges used for estimating the area under principal first order bands (FTO (2/4) and LO) are ~760 cm−1–800 cm−1 and 955 cm−1–990 cm−1. Following ion implantation total area under principal first order bands of implanted sample reduces which results in rise in total disorder in implanted samples. The rise in the value of the total disorder with increasing the fluence signifies the decreased crystallinity of the material with increasing fluence [47]. Figure 4b shows the change in the total disorder at varying fluences following the ion implantation, with increment in the value of the total disorder to 0.73 in the highest fluence implanted sample (1 × 1014 ions/cm2). Raman results suggest that one can introduce different levels of defects into both EG and SiC by just tuning the fluence which forms a platform for developing high performance supercapacitors, sensors, etc. as defects in controlled manner enhance storage capacity and sensing capacity of EG/SiC.

Figure 4.

Variation in (a) relative Raman intensity, (b) total disorder following 10 keV N+ ion implantation.

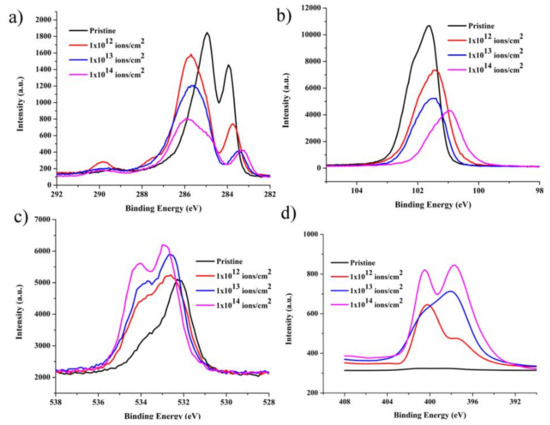

3.3. XPS

Figure 5a shows the C 1s spectra of as grown EG/SiC and implanted EG/SiC at 1 × 1012, 1 × 1013 and 1 × 1014 ions/cm2 fluences obtained from XPS at takeoff angle of 90°. The C 1s spectra of EG/SiC are characterized by a graphitic carbon (C=C) peak around 284.8 eV and a silicon carbide (Si–C) peak around ~283.8 eV. Additionally, due to the graphitization process, a minor contribution around 289.0 eV is due to the formation of O-C=O bonds [48] in the pristine sample. Following N+ ion implantation, C 1s spectra show a reduction of the intensity of both graphitic carbon (C=C) and silicon carbide peak (Si–C) than the pristine sample. This is indicative of irradiation-induced damages scaling with an increasing fluence, as revealed by the fact that the overall C 1s and Si 2p spectra intensity decreases when going from 1 × 1012 to 1 × 1014 ions/cm2.

Figure 5.

(a) C 1s; (b) Si 2p; (c) O 1s and (d) N 1s spectra obtained from XPS of pristine and N+ ion-implanted EG on SiC samples.

There was a broadening of the C1s spectra in the region between 284.5 eV to 287.5 eV in all ion-implanted samples, Figure 5a It may have been due to the presence of the C=N bond at 285.7 eV following the nitrogen ion implantation in graphene [49]. Figure 5d shows the corresponding N 1s spectra which reveal two components at 397.9 eV and 400.3 eV, that can be assigned to pyridinic and quaternary type N-functionalities, respectively [49,50]. The overall N 1s intensity increased with increasing ion fluence which was indicative of an effective N implantation.

Figure 5b shows Si 2p spectra with the SiC peak at ~101.6 eV in as grown EG/SiC sample in agreement with earlier study [51]. The Si 2p spectra of N+ ion-implanted samples reveal a decreased intensity of the SiC peak with increasing fluence, in agreement with Raman results (Figure 3). In addition, Si 2p spectra shift towards a lower binding energy approaching BE values which is characteristic of pure Si. [52]. These changes can be interpreted as resulting from breakdown of the Si–C bonds and an increased generation of homonuclear bonds of the sp3 C–C and Si–Si type (Figure 5b).

Figure 5c presents the O 1s spectra which clearly depict a fluence dependent rise in the O 1s peak intensity. There appears two peaks at ~532.1 and 533.2 eV in the O 1s spectra obtained after deconvolution of the O 1s spectra (data not shown) in the as grown EG/SiC sample, peaks are attributed to C=O and C–OH peak, respectively [53]. The high binding energy component increases by the ion implantation which is indicative of C–OH formation. The XPS showed that dopant concentration can be precisely controlled by controlling the fluence which provides a simple method for developing nitrogenated graphene at varying concentrations and enhances the applicability of EG/SiC in nanoelectronics.

4. Conclusions

There was a structural modification of monolayer/bilayer graphene and the SiC substrate using 10 keV N ion implantation. This works shows that at this energy both dopant and defects can be introduced simultaneously in graphene and SiC, while other studies have investigated defect generation in either graphene or SiC. The AFM investigation show a fragmentation of the single and bilayer graphene accompanied by a formation of nanostructures. The ion implantation caused breaking of graphitic carbon bonds which results in the fragmentation of monolayer and bilayer graphene at many places. There was an agglomeration of sputtered carbon atoms into small clusters due to their high structural fluidity which results in formation of nanostructures. The corresponding Raman spectra showed an increase in the D peak intensity up to the fluence of 5 × 1013 ions/cm2 and a decrease in the D peak intensity at 1 × 1014 ions/cm2 fluence. Stage I type of defects dominated up to 5 × 1013 ions/cm2 fluence while stage-II defects were present at the highest fluence. There were sp3 defects at 1 × 1012 ions/cm2 fluence and vacancy defects at the higher fluences, as well as an increase in defect density with increase in the fluence. With increasing fluence there was a fall in intensity of the prominent peaks of SiC along with an increase in the value of the total disorder and a decrease in the value of the relative Raman intensity. This was interpreted as the SiC interface with graphene is affected by the N ion bombardment and should be considered when there is device processing. The XPS reveals C=N formation and a fluence dependent decrease in the SiC peak intensity from the Si 2p XPS spectra. A rise in O1s spectra with increase in fluence was observed due to an increase of C=O and C-O-H bond intensity with increasing fluence. Altogether, this work illustrates the possibility that nitrogen doping and different levels of defects may be introduced in both graphene and SiC by N ion implantation on EG/SiC, which implies process control as well as consideration of careful selection of the process conditions for modifying graphene and SiC or both.

Author Contributions

Conceptualization, P.D.K., G.R.Y. and M.S.; formal analysis, P.D.K.; investigation, P.D.K. and G.B.V.S.L.; resources, P.D.K., G.R.Y., G.G., R.Y. and M.S.; visualization, P.D.K.; writing—original draft, P.D.K.; writing—review & editing, P.D.K., G.R.Y., G.B.V.S.L., G.G., R.Y. and M.S.; funding acquisition, P.D.K. and M.S. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by research grant from Swedish Research Council (project 2016-06014). P.D. Kaushik acknowledges support from the Åforsk Research Grant (19-675). G.G. acknowledges financial support from VR grant 2018-03957 and Vinnova grant 2019-04882. R.Y. acknowledges financial support via VR grant 2018-04962.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Geim, A.K.; Novoselov, K.S. The rise of graphene. Nat. Mater. 2007, 6, 183–191. [Google Scholar] [CrossRef] [PubMed]

- Dvorak, M.; Oswald, W.; Wu, Z. Bandgap Opening by Patterning Graphene. Sci. Rep. 2013, 3. [Google Scholar] [CrossRef] [PubMed]

- Dabrowski, P.; Rogala, M.; Wlasny, I.; Klusek, Z.; Kopciuszyński, M.; Jalochowski, M.; Strupiński, W.; Baranowski, J. Nitrogen doped epitaxial graphene on 4H-SiC(0001)—Experimental and theoretical study. Carbon 2015, 94, 214–223. [Google Scholar] [CrossRef]

- Thiele, C.; Felten, A.; Echtermeyer, T.; Ferrari, A.C.; Casiraghi, C.; Löhneysen, H.V.; Krupke, R. Electron-beam-induced direct etching of graphene. Carbon 2013, 64, 84–91. [Google Scholar] [CrossRef]

- Daukiya, L.; Mattioli, C.; Aubel, D.; Hajjar-Garreau, S.; Vonau, F.; Denys, E.; Reiter, G.; Fransson, J.; Perrin, E.; Bocquet, M.-L.; et al. Covalent Functionalization by Cycloaddition Reactions of Pristine Defect-Free Graphene. ACS Nano 2017, 11, 627–634. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.; Zhao, H.; Yan, D.; Pei, J. Investigation on gallium ions impacting monolayer graphene. AIP Adv. 2015, 5, 067171. [Google Scholar] [CrossRef]

- Wang, Q.; Shao, Y.; Ge, D.; Yang, Q.; Ren, N. Surface modification of multilayer graphene using Ga ion irradiation. J. Appl. Phys. 2015, 117, 165303. [Google Scholar] [CrossRef]

- Wang, Q.; Dong, J.; Bai, B.; Xie, G. Investigating change of properties in gallium ion irradiation patterned single-layer graphene. Phys. Lett. A 2016, 380, 3514–3519. [Google Scholar] [CrossRef]

- Kwon, K.C.; Son, P.K.; Kim, S.Y. Ion beam irradiation of few-layer graphene and its application to liquid crystal cells. Carbon 2014, 67, 352–359. [Google Scholar] [CrossRef]

- Xie, G.; Yang, R.; Chen, P.; Zhang, J.; Tian, X.; Wu, S.; Zhao, J.; Cheng, M.; Yang, W.; Wang, D.; et al. A General Route Towards Defect and Pore Engineering in Graphene. Small 2014, 10, 2280–2284. [Google Scholar] [CrossRef] [PubMed]

- Naitou, Y.; Iijima, T.; Ogawa, S. Direct nano-patterning of graphene with helium ion beams. Appl. Phys. Lett. 2015, 106, 033103. [Google Scholar] [CrossRef]

- Morin, A.; Lucot, D.; Ouerghi, A.; Patriarche, G.; Bourhis, E.; Madouri, A.; Ulysse, C.; Pelta, J.; Auvray, L.; Jede, R.; et al. FIB carving of nanopores into suspended graphene films. Microelectron. Eng. 2012, 97, 311–316. [Google Scholar] [CrossRef]

- Xu, Y.; Zhang, K.; Brusewitz, C.; Wu, X.; Hofsass, H.C. Investigation of the effect of low energy ion beam irradiation on mono-layer graphene. AIP Adv. 2013, 3, 72120. [Google Scholar] [CrossRef]

- Willke, P.; Amani, J.A.; Thakur, S.; Weikert, S.; Druga, T.; Maiti, K.; Hofsäss, H.; Wenderoth, M. Short-range ordering of ion-implanted nitrogen atoms in SiC-graphene. Appl. Phys. Lett. 2014, 105, 111605. [Google Scholar] [CrossRef]

- Willke, P.; Amani, J.A.; Sinterhauf, A.; Thakur, S.; Kotzott, T.; Druga, T.; Weikert, S.; Maiti, K.; Hofsäss, H.; Wenderoth, M. Doping of Graphene by Low-Energy Ion Beam Implantation: Structural, Electronic, and Transport Properties. Nano Lett. 2015, 15, 5110–5115. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.-H.; Qin, X.-F.; Wang, F.-X.; Fu, G.; Wang, X.-L. Raman and morphology visualization in epitaxial graphene on 4H-SiC by Nitrogen or Argon ion irradiation. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Int. Mater. Atoms 2015, 365, 260–263. [Google Scholar] [CrossRef]

- Kaushik, P.D.; Rodner, M.; Lakshmi, G.B.V.S.; Ivanov, I.G.; Greczynski, G.; Palisaitis, J.; Eriksson, J.; Solanki, P.R.; Aziz, A.; Siddiqui, A.M.; et al. Surface functionalization of epitaxial graphene using ion implantation for sensing and optical applications. Carbon 2020, 157, 169–184. [Google Scholar] [CrossRef]

- Kaushik, P.D.; Ivanov, I.G.; Lin, P.-C.; Kaur, G.; Eriksson, J.; Lakshmi, G.; Avasthi, D.; Gupta, V.; Aziz, A.; Siddiqui, A.M.; et al. Surface functionalization of epitaxial graphene on SiC by ion irradiation for gas sensing application. Appl. Surf. Sci. 2017, 403, 707–716. [Google Scholar] [CrossRef]

- Compagnini, G.; Giannazzo, F.; Sonde, S.; Raineri, V.; Rimini, E. Ion irradiation and defect formation in single layer graphene. Carbon 2009, 47, 3201–3207. [Google Scholar] [CrossRef]

- Ochedowski, O.; Bussmann, B.K.; D’Etat, B.B.; Lebius, H.; Schleberger, M. Manipulation of the graphene surface potential by ion irradiation. Appl. Phys. Lett. 2013, 102, 153103. [Google Scholar] [CrossRef]

- Sorieul, S.; Costantini, J.-M.; Gosmain, L.; Calas, G.; Grob, J.-J.; Thomé, L. Study of damage in ion-irradiated α-SiC by optical spectroscopy. J. Phys. Condens. Matter 2006, 18, 8493–8502. [Google Scholar] [CrossRef] [PubMed]

- Kaushik, P.D.; Aziz, A.; Siddiqui, A.M.; Lakshmi, G.; Syväjärvi, M.; Yakimova, R.; Yazdi, G.R. Structural and optical modification in 4H-SiC following 30 keV silver ion irradiation. (International Conference on Inventive Research in Material Science and Technology, Hotel Arcadia, Coimbatore, Tamil Nadu, India, 23–24 March 2018). AIP Conf. Proc. 2018, 1966, 020035. [Google Scholar] [CrossRef]

- Granzier-Nakajima, T.; Fujisawa, K.; Anil, V.; Terrones, M.; Yeh, Y.-T. Controlling Nitrogen Doping in Graphene with Atomic Precision: Synthesis and Characterization. Nanomater 2019, 9, 425. [Google Scholar] [CrossRef] [PubMed]

- Lee, W.J.; Lim, J.; Kim, S.O. Carbon Nanomaterials: Nitrogen Dopants in Carbon Nanomaterials: Defects or a New Opportunity? (Small Methods 1-2/2017). Small Methods 2017, 1. [Google Scholar] [CrossRef]

- Yazdi, G.; Vasiliauskas, R.; Iakimov, T.; Zakharov, A.; Syväjärvi, M.; Yakimova, R. Growth of large area monolayer graphene on 3C-SiC and a comparison with other SiC polytypes. Carbon 2013, 57, 477–484. [Google Scholar] [CrossRef]

- Ziegler, J.F.; Ziegler, M.D.; Biersack, J.P. SRIM—The stopping and range of ions in matter. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2010, 268, 1818–1823. [Google Scholar] [CrossRef]

- Walton, J.; Wincott, P.; Fairley, N.; Carrick, A. Peak Fitting with CasaXPS: A Casa Pocket Book; Accolyte Science: Knutsford, UK, 2010. [Google Scholar]

- Lehtinen, O.; Kotakoski, J.; Krasheninnikov, A.V.; Tolvanen, A.; Nordlund, K.; Keinonen, J. Effects of ion bombardment on a two-dimensional target: Atomistic simulations of graphene irradiation. Phys. Rev. B 2010, 81, 153401. [Google Scholar] [CrossRef]

- Devanathan, R.; Weber, W.J.; Gao, F. Atomic scale simulation of defect production in irradiated 3C-SiC. J. Appl. Phys. 2001, 90, 2303–2309. [Google Scholar] [CrossRef]

- Chang, J.; Cho, J.-Y.; Gil, C.-S.; Lee, W.-J. A Simple method to calculate the displacement damage cross section of silicon carbide. Nucl. Eng. Technol. 2014, 46, 475–480. [Google Scholar] [CrossRef]

- Saito, Y.; Yoshikawa, T.; Inagaki, M.; Tomita, M.; Hayashi, T. Growth and structure of graphitic tubules and polyhedral particles in arc-discharge. Chem. Phys. Lett. 1993, 204, 277–282. [Google Scholar] [CrossRef]

- Dutta, N.; Mohanty, S.; Buzarbaruah, N. Modification on graphite due to helium ion irradiation. Phys. Lett. A 2016, 380, 2525–2530. [Google Scholar] [CrossRef]

- Malard, L.M.; Pimenta, M.A.; Dresselhaus, G.; Dresselhaus, M.S. Raman spectroscopy in graphene. Phys. Rep. 2009, 473, 51–87. [Google Scholar] [CrossRef]

- Beams, R.; Cançado, L.G.; Novotny, L. Raman characterization of defects and dopants in graphene. J. Phys. Condens. Matter 2015, 27, 83002. [Google Scholar] [CrossRef] [PubMed]

- Eckmann, A.; Felten, A.; Mishchenko, A.; Britnell, L.; Krupke, R.; Novoselov, K.S.; Casiraghi, C. Probing the Nature of Defects in Graphene by Raman Spectroscopy. Nano Lett. 2012, 12, 3925–3930. [Google Scholar] [CrossRef] [PubMed]

- Cançado, L.G.; Jorio, A.; Ferreira, E.; Stavale, F.; Achete, C.A.; Capaz, R.B.; Moutinho, M.; Lombardo, A.; Kulmala, T.S.; Ferrari, A.C. Quantifying Defects in Graphene via Raman Spectroscopy at Different Excitation Energies. Nano Lett. 2011, 11, 3190–3196. [Google Scholar] [CrossRef] [PubMed]

- Mishra, M.; Alwarappan, S.; Kanjilal, D.; Mohanty, T. The Effect of Low Energy Nitrogen Ion Implantation on Graphene Nanosheets. Electron. Mater. Lett. 2018, 14, 488–498. [Google Scholar] [CrossRef]

- Zandiatashbar, A.; Lee, G.-H.; An, S.J.; Lee, S.; Mathew, N.; Terrones, M.; Hayashi, T.; Picu, R.; Hone, J.; Koratkar, N. Effect of defects on the intrinsic strength and stiffness of graphene. Nat. Commun. 2014, 5, 3186. [Google Scholar] [CrossRef] [PubMed]

- Lucchese, M.; Stavale, F.; Ferreira, E.; Vilani, C.; Moutinho, M.; Capaz, R.B.; Achete, C.; Jorio, A. Quantifying ion-induced defects and Raman relaxation length in graphene. Carbon 2010, 48, 1592–1597. [Google Scholar] [CrossRef]

- Murakami, K.; Kadowaki, T.; Fujita, J.-I. Damage and strain in single-layer graphene induced by very-low-energy electron-beam irradiation. Appl. Phys. Lett. 2013, 102, 43111. [Google Scholar] [CrossRef]

- Tsukamoto, T.; Hirai, M.; Kusaka, M.; Iwami, M.; Ozawa, T.; Nagamura, T.; Nakata, T. Annealing effect on surfaces of 4H(6H)SiC(0001)Si face. Appl. Surf. Sci. 1997, 113, 467–471. [Google Scholar] [CrossRef]

- Kaushik, P.D.; Aziz, A.; Siddiqui, A.M.; Greczynski, G.; Jafari, M.J.; Lakshmi, G.; Avasthi, D.; Syväjärvi, M.; Yazdi, G.R. Modifications in structural, optical and electrical properties of epitaxial graphene on SiC due to 100 MeV silver ion irradiation. Mater. Sci. Semicond. Process. 2018, 74, 122–128. [Google Scholar] [CrossRef]

- Piluso, N.; Camarda, M.; Anzalone, R.; La Via, F. Micro-Raman Characterization of 4H-SiC Stacking Faults. Mater. Sci. Forum 2014, 778, 378–381. [Google Scholar] [CrossRef]

- Sorieul, S.; Costantini, J.; Gosmain, L.; Thomé, L.; Grob, J.J. Raman Spectroscopy Study of Heavy-Ion-Irradiated Alpha-SiC. J. Phys. Condens. Matter. 2006, 18, 5235. [Google Scholar] [CrossRef]

- Iatsunskyi, I.; Nowaczyk, G.; Jurga, S.; Fedorenko, V.; Pavlenko, M.; Smyntyna, V. One and two-phonon Raman scattering from nanostructured silicon. Optik 2015, 126, 1650–1655. [Google Scholar] [CrossRef]

- Héliou, R.; Brebner, J.; Roorda, S. Optical and structural properties of 6H–SiC implanted with silicon as a function of implantation dose and temperature. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. Atoms 2001, 175, 268–273. [Google Scholar] [CrossRef]

- Menzel, R.; Gärtner, K.; Wesch, W.; Hobert, H. Damage production in semiconductor materials by a focused Ga+ ion beam. J. Appl. Phys. 2000, 88, 5658–5661. [Google Scholar] [CrossRef]

- Singh, B.; Murad, L.; Laffir, F.; Dickinson, C.; Dempsey, E. Pt based nanocomposites (mono/bi/tri-metallic) decorated using different carbon supports for methanol electro-oxidation in acidic and basic media. Nanoscale 2011, 3, 3334–3349. [Google Scholar] [CrossRef] [PubMed]

- Guo, M.; Li, D.; Zhao, M.; Zhang, Y.; Geng, D.; Lushington, A.; Sun, X. Nitrogen ion implanted graphene as thrombo-protective safer and cytoprotective alternative for biomedical applications. Carbon 2013, 61, 321–328. [Google Scholar] [CrossRef]

- Jiang, Z.-J.; Jiang, Z. Interaction Induced High Catalytic Activities of CoO Nanoparticles Grown on Nitrogen-Doped Hollow Graphene Microspheres for Oxygen Reduction and Evolution Reactions. Sci. Rep. 2016, 6, 27081. [Google Scholar] [CrossRef] [PubMed]

- Riedl, C.; Coletti, C.; Starke, U. Structural and electronic properties of epitaxial graphene on SiC(0 0 0 1): A review of growth, characterization, transfer doping and hydrogen intercalation. J. Phys. D Appl. Phys. 2010, 43, 374009. [Google Scholar] [CrossRef]

- Bashouti, M.Y.; Sardashti, K.; Ristein, J.; Christiansen, S. Early stages of oxide growth in H-terminated silicon nanowires: Determination of kinetic behavior and activation energy. Phys. Chem. Chem. Phys. 2012, 14, 11877. [Google Scholar] [CrossRef] [PubMed]

- Oh, Y.J.; Yoo, J.; Kim, Y.I.; Yoon, J.K.; Na Yoon, H.; Kim, J.-H.; Bin Park, S. Oxygen functional groups and electrochemical capacitive behavior of incompletely reduced graphene oxides as a thin-film electrode of supercapacitor. Electrochim. Acta 2014, 116, 118–128. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).