Abstract

Construction of earth fill dams offers a cost-effective solution for various purposes. However, their susceptibility to internal soil erosion, known as piping, poses a significant risk of structural failure and resultant loss of life and property. Soil stabilization emerges as a practical technique to fortify these dams against such threats. This study investigated the impact of lime on the internal erosion properties of clay soils, focusing on CH and ML soil types. Specimens of different lime content were prepared and remolded at 95% relative compaction and optimum moisture content. Hole Erosion tests at varying lime concentrations and curing durations were adapted to conduct the investigation. This investigation aims to optimize lime content and curing time for cohesive soil stabilization against internal erosion. Findings revealed that 2% and 5% of quicklime, by dry weight of the soil, effectively stabilized CH and ML soils, respectively, against internal erosion, with a two-day curing period proving optimal. Furthermore, the addition of lime significantly enhanced erosion rate index and critical shear strength in clay soil, underscoring its efficacy in soil stabilization efforts.

1. Introduction

Internal erosion is defined as the erosion of soil particles due to water flowing through the soil [1,2]. It occurs when the seepage forces of water are larger than the resistance forces of soil, thus forcing the soil particles to start moving due to the water flow. These seepage forces cause erosion in both natural soil deposits and hydraulic and embankment-fill structures. Additionally, erosion does not occur uniformly through a structure; however, it increases in places with a concentration of seepage and water velocity [3]. Various modifications happen in the soil through the erosion process that led to alterations in the void ratio, hydraulic conductivity, and shear strength of the soil. Many factors affect the erosion of the soil. Factors include soil water content; unit weight; plasticity index; void ratio; soil swell; and percent passing sieve #200, soil pH, and clay minerals [4]. Other studies [5,6] showed that internal soil erosion is affected by soil type, water and material properties, and soil–piping resistance relationships. Generally, these factors resemble the physical and mineral composition of the soil [4].

Various types of internal erosion are recognized in hydraulic structures, such as piping, suffusion, blowout (heave, uplift), Suffusion, and backward erosion [5,6,7]. Piping involves the formation of a continuous tunnel, and as a result, water will flow between the upstream and downstream of the earth structure. This eases the erosion of the surrounding soil. The heave resulted in an imbalance of seepage uplift force and buoyant weight of soil particles, causing the lifting of soil particles. Suffusion erosion occurs when the small particles are transmitted and pass through the pores of the larger cohesionless granular soils. Backward erosion takes place when soil particles are separated from each other by seepage forces, causing them to move backward from downstream to upstream [7].

The main factors that affect the erosion phenomenon can be listed as the erodibility of soil, water velocity inside the soil mass, and the geometry of the earth-structure. Therefore, erodibility can be defined as the relationship between water velocity and the corresponding erosion rate experienced by the soil. However, there is a problem with the definition as water velocity is a vector quantity and varies along the flow, and it is theoretically zero at the soil–water intercede. Therefore, the best definition of erodibility can be designated as the relationship between the erosion rate (Ż) and the shear stress (τ), and it is noticed that there is a direct relationship between the erosion rate, shear stress, and the type of soil [4]. Briaud [4] stated that grain size controls the coarse-grained soil erosion and plasticity controls the fine soil erosion. Sherard et al. [8] showed that soil piping resistance is higher in well-compacted high-plasticity clays more than well-graded coarse sand and sand gravel mixture [9]. Another study by Ke and Takahashi [9] demonstrated that non-cohesive gap-graded soil erodes more because of the reduction in the strength and efficiency of shearing resistant forces due to the absence of some grain sizes.

Other physical soil factors affecting the erodibility of the soil are soil laying at the site, the degree of compaction, and the homogeneity of the soil [10]. Khoshghalb et al. [11] investigated the low-compaction level on the internal erosion behavior of the soil. The study revealed that at low compaction level the soil does not necessarily erode more if the suitable water content is used. Skempton and Brogon [12] and Tomlison and Vaid [13] introduced new factors affecting the erosion of the soil such as water flow velocity, flow direction, hydraulic gradient, and possible chemical reactions in the soil. Furthermore, soil erodibility is affected by other factors such as the unit weight of soil, water content, void ratio, plasticity index, soil swell, pH of soil, clay minerals, and percent of soil passing sieve #200. Moreover, soil erosion depends on the physical and mineral composition of soil [12].

Studies by Luthi [14] and Banu and Attom [5,6] revealed that approximately 30–50% of embankment failures and are caused by the internal erosion of the soil. These percentages are considered a very high percentage and indicated that the majority of the earth fill dams and embankments are failed due to internal erosion. Therefore, the need to stabilize the soil against internal erosion is a vital step to prevent the catastrophic consequences of hydraulic embankment structure failure and save lives and properties.

Several materials and techniques have been used in soil stabilization such as cement stabilization [15,16], lime stabilization [5,6,17], bituminous stabilization [18,19], electrical stabilization [20,21], grouting [22,23], fly ash stabilization [24,25], burned sludge stabilization [26,27,28], sisal fiber stabilization [29,30], polypropylene stabilization [31,32], and compaction [33]. These materials and techniques were used to increase the shear strength properties, as well as to reduce settlement, compressibility, and expansion of the soils. However, few studies were found in the literature about soil stabilization against internal erosion. A recent study by Rodríguez and Cardoso [34] used bio-cementation through enzymatically induced carbonate precipitation treatment to prevent soil erosion. The study concluded that the use of such material will prevent the scour erosion. On the other hand, researchers have recently developed several tests to evaluate soil internal erosion such as the Pinhole Test [8], Jet Erosion Test [35,36], Hole Erosion Test, and Slot Erosion Test [37]. The development of these tests allowed for the investigation of the internal erosion phenomena in more depth and to understand the behavior of failure mechanism throughout the failure process. In addition, interested researchers can use these tests to study the effect of different materials on the internal erosion and to stabilize both cohesive and non-cohesive soils against internal erosion.

Clayey soils are the core materials used in earth fill embankments and pond projects. Such projects are mainly used for water retention and water diversion in addition to other hydraulic purposes. Since the main and common reasons behind failure of earth fill embankment is piping and internal erosion, it is essential to stabilize the clay against this phenomenon using a well-known and efficient stabilizer.

Lime is used in stabilizing soils against swelling and to improve the mechanical properties of weak soils [5,6]. Lime stabilizes the soil due to the soil–lime reaction that generates long-term cementitious pozzolanic bonding. This reaction takes place when the calcium in the lime reacts with the aluminates and silicates in the clay, resulting in a stable and stronger soil. However, using of lime at a large scale and long term has also been investigated. Most of the investigations revealed that lime could improve the chemical and biological properties of soils, and that the long term use of lime will increase the soil chemical properties [38]. Another study showed that liming acid soils will keep the pH value suitable to grow crops [39]. Additionally, the effect of freezing and thawing on soil stabilized with lime has been studied. The study revealed that the strength of highly plastic clay at 28 days curing time increased by 15 times and 3 times for low-plastic soil but decreased by about 10–15% after three freeze–thaw cycles [40]. The microstructure was also influenced by the addition of lime and resulted in decreasing the pores [41]. Recently, many researchers investigated the use of lime and lime mixed with different materials to stabilize the clay soil and improve its’ mechanical properties [41,42,43,44].

This research aims to assess the effectiveness of lime as a stabilizing agent against internal erosion in clay soils and to advance the understanding of internal erosion behavior. Two types of clayey soils, namely, CH and ML, were selected and mixed with Quick Lime at varying percentages by dry weight of the clay. The Hole Erosion Test (HET) was employed to evaluate the internal erosion indices of the soils. The findings of this study are expected to contribute practical insights towards constructing safer dams and more efficient earth fill embankments while mitigating the risks associated with soil internal erosion failure. Additionally, this research will pave the way for exploring the utilization of alternative stabilization materials, such as solid wastes and other environmentally hazardous substances, in civil engineering practices.

2. Methodology

In this research, the HET was employed to investigate the use of Quick Lime as a stabilizing agent against internal erosion of clay soils. The effectiveness of the HET as a screening tool for evaluating the internal erosion indices of embankment dam was assured by Reclamations’ Dam Safety Office, of which has assigned a research team headed by Farrar et al. [45]. Furthermore, the simplicity of the HET was underlined as the main advantage, along with the low cost of the test [37]. Throughout the literature review, it was observed that most of the investigations have used the HET in their studies.

HET simulates water flow under piping erosion conditions similar to that which occurs in earth fill dams in nature. Wan and Fell [37] developed this test that introduced new Erosion Rate Index (IHET) values that provide an indication of the soil’s susceptibility to erosion. The value of IHET varies from less than 2 to more than 6. The erosion decreases as the IHET value increases, as shown in Table 1 [37].

Table 1.

Qualitative terms for representative IHET [37].

3. Materials and Testing Program

Two types of clay soils were selected, and the initial physical properties such as specific gravity, compaction parameters, Atterberg’s limits, maximum dry unit weight, and optimum moisture content were determined in accordance with ASTM standard procedures. The initial physical properties are shown in Table 2.

Table 2.

Physical properties of the used soils.

In this research, an adequate number of specimens from the two soils were prepared in the hole erosion test cylindrical mold with 10 cm diameter and 10.16 cm height. The soil was passed through sieve no. 40 and then the two types of soil were mixed with different lime content by dry weight of the soil at five different percentages, namely, 1%, 2%, 3%, 4%, and 5%. Six identical samples were prepared and tested for each lime content at three different curing times (24 h, 48 h, and seven days). Two identical samples were tested, and the average value of the results was taken. Two samples from each soil with zero lime content were prepared and tested as reference samples. All specimens were prepared in the standard mold at 95% relative compaction and optimum water content conditions. A 6 mm diameter hole was drilled throughout the longitudinal direction of the samples to simulate a concentrated leak pipe of 10.16 cm in length. Figure 1 shows a prepared specimen with the 6 mm drilled hole at the center of the specimen.

Figure 1.

Prepared sample with the 6 mm drilled hole.

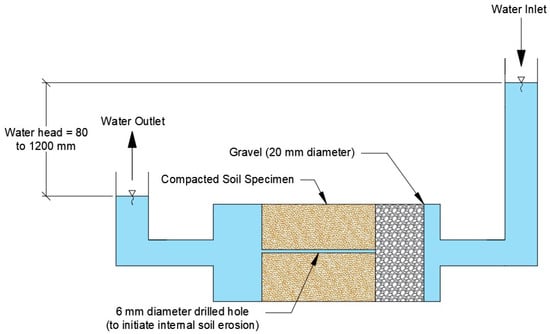

The HET was employed to evaluate the erosion rate of the compacted samples at each percentage for the two types of soils. In this test, the sample was placed between two different heads of water: inlet (upper-stream) and outlet (downstream). The water was allowed to flow throughout the hole with a difference in head between inlet and outlet of a value in the range of 500 to 1200 mm. The head value was chosen within this range to initiate erosion. The chosen head between the inlet and outlet remained constant throughout the test but might be changed after a minimum of 45 min of running test time if no failure in the sample takes place. The hydraulic gradient, the flow rate at any time, and the diameter of the hole at the end of the test were measured. Figure 2 shows the schematic diagram of the Hole Erosion Test.

Figure 2.

Schematic diagram of the Hole Erosion Test.

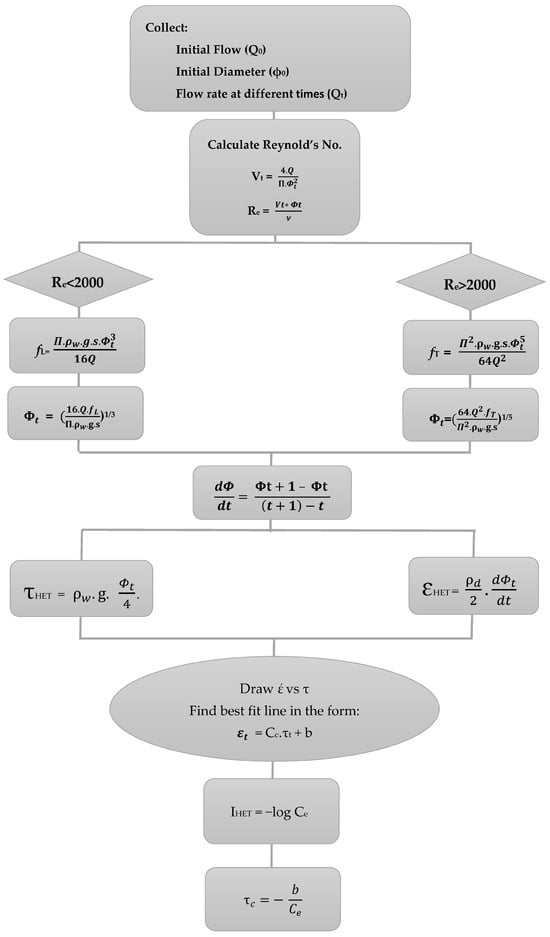

The diameter of hole at any time throughout the test can be determined using the recorded data. Additionally, the erosion rate per unit surface area and wall shear stress along the hole was calculated at any time of the test. The IHET and the critical shear stress (τc) values were determined from the above measured and calculated parameters. Figure 3 shows the steps of calculating the erosion rate index and the critical shear stress; all symbols are defined in Table 3.

Figure 3.

Diagram explaining the steps to calculate the IHET and τc.

Table 3.

Symbols of Figure 3.

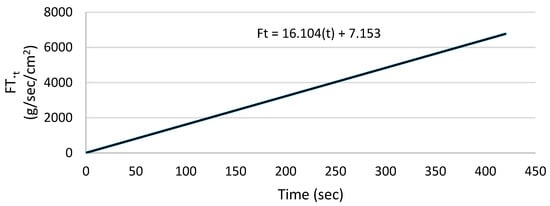

Figure 4 shows the friction factor (FT.t) versus time. The relationship was linear. The friction factors throughout the test timing were determined from the linear equation shown in Figure 5.

Figure 4.

Friction factors versus test time.

Figure 5.

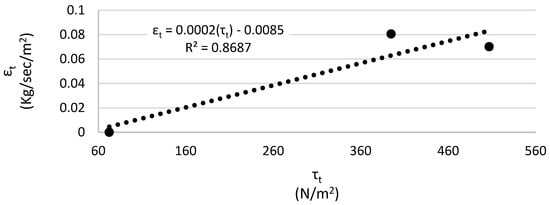

Rate of erosion per unit area (ɛo) versus the shear stress (τt) at different test timings.

To obtain the diameter at any time, Figure 4 was used. At a specific time, FT can be obtained, and the corresponding Q will already be measured during the test. All other variables were constant and known throughout the test. By applying Equation (1), the diameter at any time can be calculated.

is the diameter at time t.

To obtain the erosion rate index IHET and the critical shear τc, the best fit line between the points relating the rate of erosion per unit area (ɛo) and the shear stress (τt) at different test timings was drawn. Additionally, the equation of the best-fit line was obtained. The results are shown in Figure 5.

4. Results and Discussion

4.1. Effect of Adding Lime on Soil Erosion Parameters

Two types of clay soils: Soil #1 (CH) and Soil #2 (ML), with different percentages of lime, were tested. Soil 1 was mixed with 0.5%, 1.0%, 1.5%, and 2.0% of lime. Soil #2 was mixed with 1.0%, 2.0%, 3.0%, 4.0%, and 5.0% of lime. The percentage of added lime was defined by the dry weight of the soil.

For Soil #1, a sample containing 5% lime was tested after 1 day, and no erosion was noticed after 2 h of continuous water flow. The flow rate of the water path was almost constant throughout the test time, and the final diameter exhibited no change from the initial diameter. Hence, it was excluded from calculations, and the percentages for Soil #1 were reduced to be in the range between 0.5% and 2.0% at 0.5% increments. Moreover, both the 1.5% sample and 2.0% sample were stable when tested after 24 h of curing time; therefore, no further testing at 48 h and 7 days was conducted.

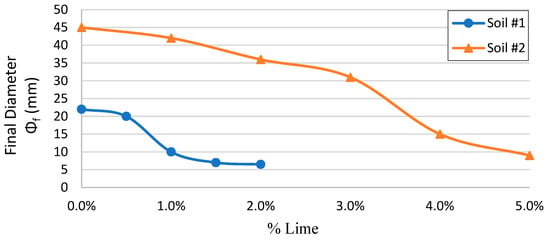

4.1.1. Effect of Adding Lime on the Diameter of the Hole

To visualize the effect of adding lime on the final diameter of the water path, the relationship between the final diameters of the water path versus the lime percentage on both soil types was plotted and is shown in Figure 6. As shown in Figure 5, the relation between the percentage lime added and the final diameter of the water path was inversely related. An increase in the lime percentage added to the soil would achieve a reduction in the final diameter of the water path and be closer to the initial diameter. Figure 6 implies that 2% of lime by dry weight of Soil #1 reduced the change in diameter by 97%. This behavior was also noticed when 5% lime was added to Soil #2. For Soil #1, the diameter at 0% lime was 22 mm in comparison of 6.5 mm at 2.0% lime. Similarly, in Soil #2, the diameter was equal to 45 mm at 0% lime, while at 5%, the diameter was 9 mm.

Figure 6.

Relationship between final diameter of water path and percent lime at 24 h curing time for Soil #1 and Soil #2.

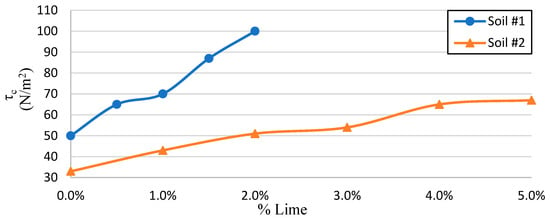

4.1.2. Effect of Adding Lime on Critical Shear Stress

Critical shear stress (τc) was plotted against percentage of lime added to both soils, as shown in Figure 7. It is noticed that an increase in lime percentage would lead to an increase in the critical shear stress of the soil. For Soil #1 at 2% lime, the critical shear stress reached 100 N/m2 at 24 h of curing time. This was a 50% increase in critical shear stress at the stabilizing lime percentage of 2% compared to 50 N/m2 critical shear stress at 0% lime.

Figure 7.

Relationship between critical shear (τc) and percent lime at 24 h curing time for Soil #1 and Soil #2.

Similarly, with a greater percentage, a 203% increase in critical shear stress was achieved for Soil #2 with the addition of 5% lime by dry weight of soil. The critical shear stress increased from 33 N/m2 at 0% lime to 100 N/m2 at 5% lime addition and 48 h curing time.

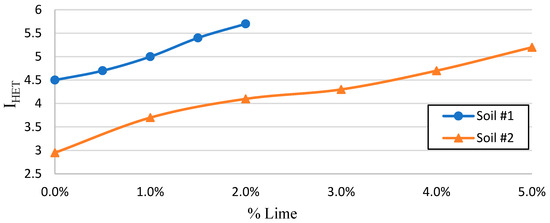

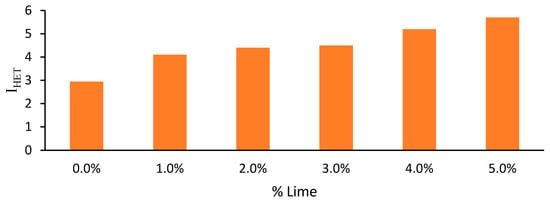

4.1.3. Effect of Adding Lime on IHET

The main output of the HET analysis is to determine the IHET. IHET is used to classify the soil based on its resistance to erosion. Wan and Fell [37] classified soil based on the value of the IHET as per Table 1. IHET value ranges from less than 2 (very rapid erodibility) to more than 6 (extremely slow erodibility). Figure 8 below shows the relationship between lime percentage added and IHET value at 24 h curing time. It is obvious, for both soils, that an increase in lime percentage led to an increase in IHET value and hence an increase in the stability of the soil.

Figure 8.

Relationship between IHET and percent lime at 24 h curing time for Soil #1 and Soil #2.

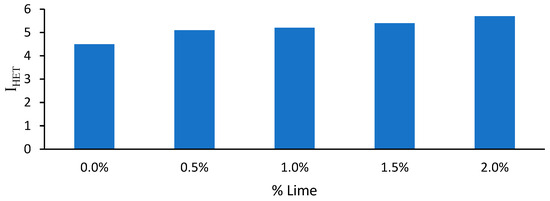

Figure 9 shows the overall IHET value increase for Soil #1. The IHET, with 0% lime, was 4.5, which is classified as moderately slow erodible soil as per Wan and Fell [37]. With the addition of 2% lime by dry weight of the soil, the IHET value increased to 5.7 at 24 h of curing time. The new value of the IHET of 5.7 classifies Soil #1 as a very slow erodible soil.

Figure 9.

Overall increase in IHET values versus lime percentage for Soil #1.

Similarly, Figure 10 shows the overall IHET value increase for Soil #2. The IHET of Soil #2, with 0% lime, was 2.9, which is classified as very rapidly erodible soil. With the addition of 5% lime by dry weight of soil, the IHET value increased to 5.7 at 7 days curing time. The new value of the IHET of 5.7 classifies Soil #2 as a very slow erodible soil.

Figure 10.

Overall increase in IHET values versus lime percentage for Soil #2.

Table 4 and Table 5 summarize the results obtained in Figure 7, Figure 8 and Figure 9 as the final results for Soil #1 and Soil #2, respectively. The tables present the erosion parameters including τc, IHET, and Φf, noting that the initial diameter (Φ0) was 6 mm.

Table 4.

Erosion parameters of Soil #1.

Table 5.

Erosion parameters of Soil #2.

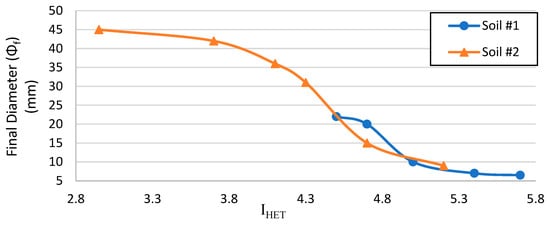

Figure 11 shows the relationship between the final diameter of the water path and the IHET in both soils. This shows that the larger the IHET, the lower the final diameter of the water path in the soil sample and the less erodible the soil.

Figure 11.

Relationship between final diameter of water path and the erosion rate index (IHET) at 24 h curing time for Soil #1 and Soil #2.

Table 6 and Table 7 summarize the change in erosion parameters such as final diameter of water path (Φf), τc, and the IHET for Soil #1 and Soil #2, respectively. A description of the erodibility of soil is given based on the IHET value in the last column of the same tables.

Table 6.

Erosion rate parameters for Soil #1.

Table 7.

Erosion rate parameters for Soil #2.

The findings from Table 6 and Table 7 indicate that the addition of 2% lime by dry weight effectively stabilized Soil #1 against internal erosion. This conclusion is supported by the obtained IHET of 5.7, which classifies the soil as very slow erosion. Furthermore, the HET conducted on a soil sample treated with 2% lime showed insignificant change in diameter or flow over a two-hour period, indicating sustained stability.

Similarly, for Soil #2, a 5% lime addition by dry weight proved sufficient for internal erosion stabilization. The resultant IHET of 5.7 underscores the soil’s classification as very slow erosion. Additionally, the HET carried out on the 5% lime-treated soil demonstrated consistent diameter and flow characteristics over a continuous four-hour period, reaffirming the soil’s enduring stability.

4.2. Effect of Lime Percentage and Curing Time on Soil Erosion Parameters

Careful consideration of curing time is essential in engineering projects involving materials, particularly those subject to chemical interactions when mixed. This period is crucial for enhancing the strength and stability of the materials utilized. In this study, Quick Lime served as a stabilizing agent for two types of clayey soils, known to achieve near-complete curing within the initial 48 h.

The testing of samples, incorporating varying percentages of lime, occurred at three distinct curing intervals: 24 h, 48 h, and 7 days. Subsequent sections will delve into the analysis of how curing time impacts erosion parameters. Moreover, the combined influence of increased lime percentage and extended curing duration will be examined.

The erosion parameters under scrutiny include the diameter of the Φf, τc, and IHET. These variables will be examined concerning both lime percentage and curing time to gain deeper insights into their interplay.

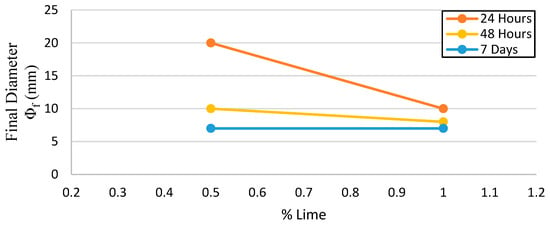

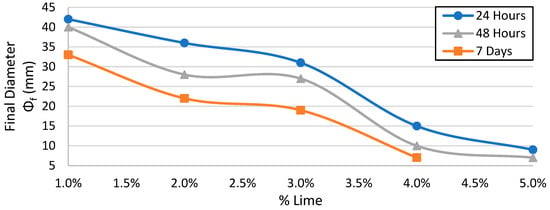

4.2.1. Effect of Lime Percentage and Curing Time on Diameter of the Water Path

Figure 12 and Figure 13 below show the relationship between the final diameter of the water path versus the percentage of lime added at three different curing times (24 h, 48 h, and 7 days) for both Soil #1 and Soil #2. The diameter curve for both soils at 7 days is the lowest among the three curing curves. This indicates that the change in final diameter becomes lower with the increase in curing time.

Figure 12.

Effect on increase in lime percentage and curing time on the final diameter of the water path (Φf) for Soil #1.

Figure 13.

Effect on increase in lime percentage and curing time on the final diameter of the water path (Φf) for Soil #2.

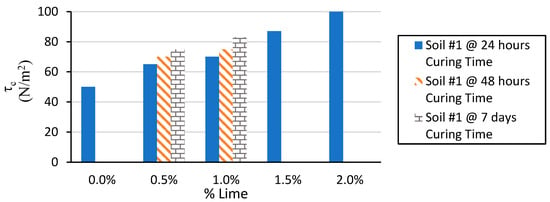

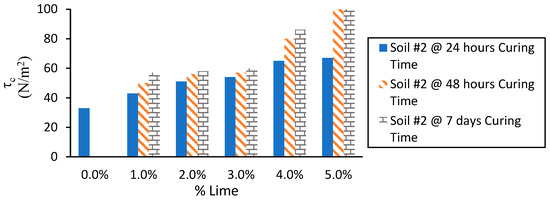

4.2.2. Effect of Lime Percentage and Curing Time on Critical Shear Stress

Figure 14 and Figure 15 present the relationship between the critical shear stress and the percentage of lime added at three different curing times (24 h, 48 h, and 7 days) for both soils, Soil #1 and Soil #2, respectively. The critical shear stress for both soils at 7 days was the highest among the three curing bars at each lime percentage. However, the increase in the percentages as shown in the figures implies that the lime gained most of its strength at 24 h curing time.

Figure 14.

Effect on increase in lime percentage and curing time on critical shear stress (τc) for Soil #1.

Figure 15.

Effect on increase in lime percentage and curing time on critical shear stress (τc) for Soil #2.

An increase in lime percentage will continue increasing the critical shear stress. However, if lime is added further than the lime fixation point, the soil will be stabilized, while the extra lime will work on increasing the soil strength. That is why at higher lime percentages, the critical shear stress value exhibited a larger jump between different curing times, as shown in the bar charts below.

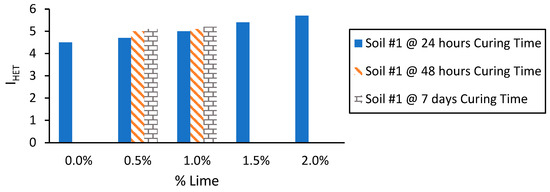

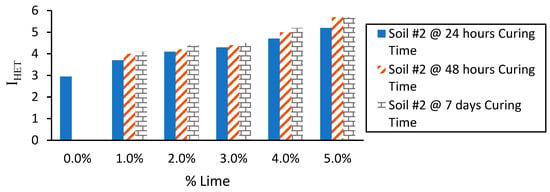

4.2.3. Effect of Lime Percentage and Curing Time on Erosion Rate Index (IHET)

Figure 16 and Figure 17 present the relationship between the Erosion Rate Index and the percentage of lime added at three different curing times (24 h, 48 h, and 7 days) for Soil #1 and Soil #2, respectively. The IHET for both soils at 7 days was the highest amongst the three curing bars at every lime percentage. This indicated that the IHET of the soil increased as the curing time increased.

Figure 16.

Effect on increase in lime percentage and curing time on IHET for Soil #1.

Figure 17.

Effect on increase in lime percentage and curing time on IHET for Soil #2.

Moreover, with a higher lime percentage, the escalation in the IHET diminished. This can be attributed to two primary reasons. Firstly, lime fixation was attained, implying that a further rise in lime content will not enhance soil stability against internal erosion; instead, it will bolster the soil’s strength. Secondly, quick lime typically undergoes full curing at 48 h, and extending the curing period beyond this duration will not yield a significant effect.

4.3. Effect of Soil Type and Gradation of the Soil on the Percentage of Lime Needed to Stabilize the Soil against Internal Erosion

As noted in Section 4.1 previously, Soil #1 is categorized as CH soil, while Soil #2 falls under the ML soil classification according to the Unified Soil Classification System. CH soil is characterized by its clayey nature with low plasticity and a high clay content, evident from the grain size distribution presented in Table 2, which indicates that Soil #1 contains 65% clay. In contrast, Soil #2, designated as ML soil, is described as low-plastic silt with only 17% clay content. This discrepancy elucidates why Soil #1 required only 2% lime of dry mass of soil for stabilization, whereas Soil #2 necessitated 5% lime. The lime primarily reacts with the clayey constituents within the soil, accounting for the disparity in required percentages. Consequently, the soil type and the proportion of clayey material therein significantly influence the amount of lime needed to mitigate internal erosion.

5. Conclusions

This study investigated the potential use of lime to stabilize cohesive soil against internal erosion. The objective was achieved by conducting multiple Hole Erosion tests on two types of clayey soils classified as CH soil and one as ML soil. Various lime percentages were added to each soil, and the effect on the erosion parameters such as Φf, τc, and IHET was studied. The results were analyzed to optimize the lime content and curing time to stabilize each type of cohesive soil against internal erosion. Based on the test results, the following conclusion may be drawn out:

- An increase in lime percentage will significantly increase the critical shear stress and the IHET. This implies that the addition of lime to the clay soils will increase their resistivity to the internal erosion and further stabilize the soil against piping.

- The test results showed that Quick Lime gained most of its strength at 2 days curing time to stabilize the soil against internal erosion.

- It was noticed that lime is more effective with CH soil than with ML soil containing sand. Only 2.0% of lime with a curing time of 48 h will stabilize CH soil, while ML soil with sand needed 5.0% of lime at 48 h to stabilize the soil. This is because the lime mainly reacted with clayey particles to produce a stabilized soil,

- An increase in lime percentage will exhibit a significant reduction on the final diameter of the water path of the samples for both clayey soil types. Just 2% of lime by dry weight of the soil will control the diameter size of the water path for CH soil and 5% for ML soil.

Author Contributions

Conceptualization, R.A. and M.A.; methodology, R.A., M.A. and M.Y.; software, R.A., M.A. and M.E.-E.; validation, M.A. and M.E.-E.; formal analysis, R.A., M.A., M.E.-E. and M.Y.; investigation, R.A., M.A., M.E.-E. and M.Y.; resources, M.A.; data curation, R.A., M.A., M.E.-E. and M.Y.; writing—R.A., M.A. and M.Y.; writing—review and editing, R.A., M.A., M.E.-E. and M.Y.; visualization, M.A. and M.E.-E.; supervision, M.A., M.E.-E. and M.Y.; project administration, M.A., M.E.-E. and M.Y.; funding acquisition, M.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research was financially supported by the American University of Sharjah (AUS) through the Faculty Research Grant program (FRG17-R-25) and Open Access Program (OAP).

Data Availability Statement

Data are available from the corresponding author upon reasonable request.

Acknowledgments

The authors would like to acknowledge the support and contributions of the American University of Sharjah (AUS), their Civil Engineering Department staff, and the Open Access Program (OAP) during this research. This paper represents the opinions of the authors and does not represent the opinions or position of the American University of Sharjah.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Lachouette, D.; Golay, F.; Bonelli, S. One-dimensional modeling of piping flow erosion. Comptes Rendus Mécanique 2008, 336, 731–736. [Google Scholar] [CrossRef]

- Bezzazi, M.; Khamlichi, A.; Vera, M.P.; Rubio, M.D.C.; Olegario, C.L. A Simplified Analytical Modeling of the Hole Erosion Test. Am. J. Eng. Appl. Sci. 2010, 3, 765–768. [Google Scholar] [CrossRef]

- Flores-Berrones, R.; Lopez-Acosta, N.P. Internal Erosion Due to Water Flow through Earth Dams and Earth Structures; InTech: London, UK, 2011. [Google Scholar]

- Briaud, J.-L. Case histories in soil and rock erosion: Woodrow wilson bridge, brazos river meander, nor-mandy cliffs, and new orleans levees. J. Geotech. Geoenviron. Eng. 2008, 134, 1425–1447. [Google Scholar] [CrossRef]

- Banu, S.A.; Attom, M.F. Effect of Curing Time on Lime-Stabilized Sandy Soil against Internal Erosion. Geosciences 2023, 13, 102. [Google Scholar] [CrossRef]

- Banu, S.; Attom, M. Internal Erosion Stabilization of Cohesionless Soil Using Lime. Water 2023, 15, 1992. [Google Scholar] [CrossRef]

- Fell, R.; Wan, C.F.; Cyganiewicz, J.; Foster, M. Time for development of internal erosion and piping in embankment dams. J. Geotech. Geoenviron. Eng. 2003, 129, 307–314. [Google Scholar] [CrossRef]

- Sherard, J.L.; Dunnigan, L.P.; Decker, R.S.; Steele, E.F. Pinhole test for identifying dispersive soils. J. Geotech. Eng. Div. 1976, 102, 69–85. [Google Scholar] [CrossRef]

- Ke, L.; Takahashi, A. Influence of internal erosion on deformation and strength of gap-graded non-cohesive soil. In Proceedings of the Sixth International Conference on Scour and Erosion, Paris, France, 27–31 August 2012; pp. 847–854. [Google Scholar]

- Flores-Berrones, R.; Ramírez-Reynaga, M.; Macari, E.J. Internal erosion and rehabilitation of an earth-rock dam. J. Geotech. Geoenviron. Eng. 2011, 137, 150–160. [Google Scholar] [CrossRef]

- Khoshghalb, A.; Nobarinia, M.; Stockton, J.G.; Kalateh, F. On the effect of compaction on the progression of concentrated leaks in cohesive soils. Acta Geotech. 2020, 16, 1635–1645. [Google Scholar] [CrossRef]

- Skempton, A.W.; Brogan, J.M. Experiments on piping in sandy gravels. Geotechnique 1994, 44, 449–460. [Google Scholar] [CrossRef]

- Tomlinson, S.S.; Vaid, Y.P. Seepage forces and confining pressure effects on piping erosion. Can. Geotech. J. 2000, 37, 1–13. [Google Scholar] [CrossRef]

- Lüthi, M. A Modified Hole Erosion Test (het-p) to Study Erosion Characteristics of Soil; University of British Columbia: Vancouver, BC, USA, 2011. [Google Scholar]

- Archibong, G.A.; Sunday, E.U.; Akudike, J.C.; Okeke, O.C.; Amadi, C. A review of the principles and methods of soil stabilization. Int. J. Adv. Acad. Res. Sci. 2020, 6, 2488–9849. [Google Scholar]

- Firoozi, A.A.; Olgun, C.G.; Firoozi, A.A.; Baghini, M.S. Fundamentals of soil stabilization. Int. J. Geo-Eng. 2017, 8, 1–16. [Google Scholar] [CrossRef]

- Negi, A.S.; Faizan, M.; Siddharth, D.P.; Singh, R. Soil stabilization using lime. Int. J. Innov. Res. Sci. Eng. Technol. 2013, 2, 448–453. [Google Scholar]

- Andavan, S.; Kumar, B.M. Case study on soil stabilization by using bitumen emulsions–A review. Mater. Today Proc. 2020, 22, 1200–1202. [Google Scholar] [CrossRef]

- Matthew, A.G.; Paul, A.S. Soil stabilization using Bitumen emulsion and cement combination as additive. J. Earth Sci. Eng. 2018, 8, 66–74. [Google Scholar]

- Afrin, H. A review on different types soil stabilization techniques. Int. J. Transp. Eng. Technol. 2017, 3, 19–24. [Google Scholar] [CrossRef]

- Nayem, N.H. Enhancement of Soil Characteristics Using Different Stabilization Techniques. Environ. Eng. 2023, 8, 71–79. [Google Scholar]

- Saravanan, R.; Murthi, P.; Poongodi, K.; Raju, A. A study on the effect of waste plastic strips in the stabilization of clay soil. IOP Conf. Ser. Mater. Sci. Eng. 2020, 981, 032062. [Google Scholar] [CrossRef]

- Kumari, D.; Xiang, W.-N. Review on biologically based grout material to prevent soil liquefaction for ground improvement. Int. J. Geotech. Eng. 2019, 13, 48–53. [Google Scholar] [CrossRef]

- Bhuvaneshwari, S.; Robinson, R.G.; Gandhi, S.R. Stabilization of expansive soils using fly ash. Fly Ash India 2005, 8, 1–10. [Google Scholar]

- Amiralian, S.; Chegenizadeh, A.; Nikraz, H. A review on the lime and fly ash application in soil stabilization. Int. J. Biol. Ecol. Environ. Sci. 2012, 1, 124–126. [Google Scholar]

- Al-Sharif, M.M.; Attom, M. The use of burned sludge as a new soil stabilizing agent. Environ. Pipeline Eng. 2000, 2000, 378–388. [Google Scholar]

- Attom, M.; Mortula, M.M.; Munjed, A. Shear strength stabilization using burned sludge ash. Int. J. Adv. Mech. Civ. Int. J. Adv. Mech. Civ. Eng. 2017, 4, 42–45. [Google Scholar]

- Ai-sharif, M.M.; Attom, M. A geoenvironmental application of burned wastewater sludge ash in soil stabilization. Environ. Earth Sci. 2014, 71, 2453–2463. [Google Scholar] [CrossRef]

- Patil, S.C.; Mathada, D.V.S.; Bharamagoud, B. Comparative study on black cotton soil stabilization by using lime and sisal fiber. Int. J. Innov. Res. Sci. Technol. 2018, 5, 109–115. [Google Scholar]

- Zafar, T.; Ansari, M.A.; Husain, A. Soil stabilization by reinforcing natural and synthetic fibers–A state of the art review. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Amena, S.; Chakeri, D. A study on the effects of plastic waste strips and lime on strength characteristics of expansive soil. Adv. Civ. Eng. 2022, 2022, 6952525. [Google Scholar] [CrossRef]

- Radwan, M.K.H.; Lee, F.W.; Woon, Y.B.; Yew, M.K.; Mo, K.H.; Wai, S.H. A study of the strength performance of peat soil: A modified cement-based stabilization agent using fly ash and polypropylene fiber. Polymers 2021, 13, 4059. [Google Scholar] [CrossRef] [PubMed]

- Hemanth, T.R.S.S.; Sharma, V. Strength and compaction behavior of copper slag stabilized soil. Mater Today Proc. 2023, 93, 505–509. [Google Scholar] [CrossRef]

- Rodríguez, R.F.; Cardoso, R. Study of biocementation treatment to prevent erosion by concentrated water flow in a small-scale sand slope. Transp. Geotech. 2022, 37, 100873. [Google Scholar] [CrossRef]

- Hanson, G.J. Development of a jet index to characterize erosion resistance of soils in earthen spillways. Trans. ASAE 1991, 34, 2015–2020. [Google Scholar] [CrossRef]

- Moore, W.L.; Masch, F.D., Jr. Experiments on the scour resistance of cohesive sediments. J. Geophys. Res. 1962, 67, 1437–1446. [Google Scholar] [CrossRef]

- Wan, C.F.; Fell, R. Investigation of rate of erosion of soils in embankment dams. J. Geotech. Geoenvironmental Eng. 2004, 130, 373–380. [Google Scholar] [CrossRef]

- Ameyu, T. A Review on the Potential Effect of Lime on Soil Properties and Crop Productivity Improvements. J. Environ. Earth Sci. 2019, 2, 17–23. [Google Scholar] [CrossRef]

- Álvarez, E.; Viadé, A.; Fernández, M.L. Effect of liming with different sized limestone on the forms of aluminium in a Galician soil (NW Spain). Geoderma 2009, 152, 1–8. [Google Scholar] [CrossRef]

- Yıldız, M.; Soğancı, A.S. Effect of freezing and thawing on strength and permeability of lime-stabilized clays. Sci. Iran. Trans. A Civ. Eng. 2012, 19, 1013–1017. [Google Scholar] [CrossRef]

- Nan, J.; Chang, D.; Liu, J.; Chen, H.; Lee, J.-S.; Kim, S.Y. Investigation on the microstructural characteristics of lime-stabilized soil after freeze–thaw cycles. Transp. Geotech. 2024, 44, 101175. [Google Scholar] [CrossRef]

- Dharini, V.; Balamaheswari, M.; Presentia, A.N. Enhancing the strength of expansive clayey soil using lime as soil stabilizing agent along with sodium silicate as grouting chemical. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Adnan, M.; Kumar, S.; Garg, N.; Gupta, K.K.; Das, S.K. Soil stabilization using waste “Bagasse ash and lime”: A review. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Sundary, D.; Munirwan, R.P.; Al-Huda, N.; Sungkar, M.; Jaya, R.P. Shear strength performance of dredged sediment soil stabilized with lime. Phys. Chem. Earth Parts A/B/C 2022, 128, 103299. [Google Scholar] [CrossRef]

- Farrar, J.A.; Torres, R.L.; Erdogan, Z. Bureau of reclamation erosion testing for evaluation of piping and internal erosion of dams. In Geotechnics of Soil Erosion; American Society of Civil Engineers: Reston, VA, USA, 2007; pp. 1–10. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).