Abstract

Dairy industries have a high environmental impact, with very high energy and water consumption and polluting effluents. To increase the sustainability of these industries it is urgent to implement technologies for wastewater treatment allowing water recycling and energy savings. In this study, dairy wastewater was processed by ultrafiltration and nanofiltration or ultrafiltration and reverse osmosis (UF/RO) and retentates from the second membrane separation processes were assessed for bioenergy production. Lactose-fermenting yeasts were tested in direct conversion of the retentates (lactose-rich streams) into bioethanol. Two Kluyveromyces strains efficiently fermented all the lactose, with ethanol yields higher than 90% (>0.47 g/g yield). Under severe oxygen-limiting conditions, the K. marxianus PYCC 3286 strain reached 70 g/L of ethanol, which is compatible with energy-efficient distillation processes. In turn, the RO permeate is suitable for recycling into the cleaning process. The proposed integrated process, using UF/RO membrane technology, could allow water recycling (RO permeate) and bioenergy production (from RO retentate) for a more sustainable dairy industry.

1. Introduction

According to the EU, agricultural markets outlook report for 2017–2030, the world milk production will surpass one billion tons/year by 2030. Moreover, strong growth of the dairy processing industry is foreseen, as consumption of cheese and processed dairy products is expected to rise [1]. Consequently, huge amounts of dairy effluent streams need to be handled, typically carrying out polluting charges of 0.4 to 8.0 g/L BOD5 [2].

The dairy industry can use as much as 60 L of water per kg of processed milk, most of the water being consumed in the clean-in-place stages [3]. Dairy wastewaters mainly contain salts, lactose, proteins, and lipids, and water recycling is mandatory to increase dairies sustainability.

The most promising treatment technologies for water recycling are based on membrane separation processes. Nanofiltration (NF) and reverse osmosis (RO) are pressure driven membrane separation processes currently employed to remove organic components from wastewaters, producing, as permeate, purified water to be recycled in the cleaning process [3,4]. The nanofiltration membranes contain pores that act like a sieve, allowing the selective passage of components depending on their shape and molecular size. On the one hand, because of their efficiency for the removal of organic compounds, relatively low-pressure requirements, and selective separation of salts, nanofiltration membranes are increasingly employed in wastewater treatment [5]. On the other hand, membranes used in reverse osmosis are not porous and can be considered as “water-swollen gels”, allowing the diffusion of water and vestiges of inorganic ions towards the low-pressure side, while retaining most molecules and ions (e.g., chloride). Indeed, reverse osmosis is one of the most economically advantageous processes used for water purification and recovery of valuable compounds in several types of industrial waste streams [6,7].

The major components of dairy effluents are protein and lactose. Proteins from whey are often recovered through ultrafiltration (UF) processes and sold as food supplements (whey protein powder) [8] or microparticulated and incorporated into dairy products to improve texture. Membrane separation technologies might be further applied for treatment of dairy wastewaters to reduce polluting discharge or to recycle water according to local law regulations. It has been reported that the water recovered from whey, by using a combined ultrafiltration and reverse osmosis system, exhibits a cleaning efficiency similar to that of fresh potable water, without affecting the quality or safety of the manufactured product [9]. The use of UF prior to NF or RO, not only allows protein recovery but also reduces membrane fouling during the NF and RO processes. In addition, the possibility of using the NF or RO retentates as a substrate for the production of bioenergy carriers, such as biogas and bioethanol, will boost the economic competitiveness of the industrial process.

Saccharomyces cerevisiae is widely used for the industrial production of bioethanol. Wild-type strains are not able to ferment lactose because they lack lactose transporters or beta-galactosidase, however, they are able to ferment d-glucose and d-galactose, the sugars resulting from lactose hydrolysis. On the one hand, the inclusion of a previous acid hydrolysis step can lead to the formation of fermentation inhibitors; on the other hand, an enzymatic hydrolysis step will increase process costs. The use of recombinant S. cerevisiae strains, engineered for lactose fermentation by expressing heterologous lactose permease or beta-galactosidase genes, is a possible alternative [10,11], but the use of genetically modified organisms in the food sector raises particular concerns.

Another option is to use natural lactose-fermenting yeasts belonging to the genus Kluyveromyces, namely K. lactis and K. marxianus, already used in some fermented dairy products. Unlike S. cerevisiae, these are Crabtree-negative yeasts, meaning that under full aerobic conditions respiration is predominant [12]. Conversely, under oxygen-limiting conditions fermentation is preferred with ethanol as the main product. K. marxianus can grow over a broader range of temperatures than K. lactis, tolerating temperatures as high as 45 °C [13]. Their GRAS (generally regarded as safe) status, together with thermotolerance and high growth and fermentation yields, constitute desirable traits for industrial applications. These yeasts have been used to convert lactose from cheese whey into yeast biomass (animal feed additive), bio-ingredients (e.g., oligonucleotides, used as flavor enhancers), and enzymes, namely beta-galactosidase for lactose-free milk [14,15].

The European Project “SUSMILK Re-design of the dairy industry for sustainable milk processing” (FP7-613589) is aimed at developing a sustainable dairy industry. In the framework of this project, wastewaters were processed by UF, to obtain microparticulated whey protein concentrates (UF retentates), followed by NF or RO to generate permeates to be recycled into the cleaning process, and retentates with high lactose content (>100 g/L), here assessed for the production of bioethanol. The performance of ten Kluyveromyces strains was evaluated, at high-cell density, without supplementation, in order to identify efficient yeasts for industrial bioethanol production from concentrated lactose-rich streams. Two strains were selected exhibiting fermentation performances superior to those of the K. marxianus CBS 397 strain, thus far regarded as one of the most efficient lactose-fermenting yeasts for industrial lactose-fermenting processes.

2. Materials and Methods

2.1. Source and Characterization of Nanofiltration (NF) and Reverse Osmosis (RO) Permeates and Retentates

Cheese whey was obtained from Queizuar (Queixerías Bama, A Coruña, Spain), processed by cross flow ultrafiltration (Membralox® EP 1940), at permeate rates of 5000 to 10,000 L/day, and the generated permeates further processed by cross flow nanofiltration (DOWTM Filmtec NF 3840/30) or reverse osmosis (DOWTM Filmtec RO 3838/30) by Universidad de Santiago de Compostela, Aula de Productos Lácteos, Spain. The filtration conditions for both NF and RO were the following: feed rate, 8000 L/h; permeate flow rate, 5800 L/h; and transmembrane pressure, 25 to 33 bar. NF and RO retentates were sterilized in autoclave (15 min at 121 °C), centrifuged (12,857× g at 4 °C for 20 min) to remove precipitated components and stored at 4 °C. The NF and RO permeates and processed retentates were analyzed for pH and ionic, carbohydrate, and protein characterization.

Physicochemical analysis of permeates and processed retentates were carried out by the Mineral Science and Technology Unit of LNEG (S. Mamede de Infesta, Porto, Portugal). The pH was determined by potentiometry. Cations, lithium, sodium, potassium, magnesium, calcium, iron, manganese, copper, and zinc were determined by flame atomic absorption spectroscopy; ammonium by potentiometry; cadmium and lead by plasma optical emission spectroscopy (ICP-OES); and mercury by inductively coupled plasma mass spectrometry (ICP-MS). Anions, fluoride, chloride, nitrate, phosphate, and sulfate were quantified by ionic chromatography; nitrite by visible molecular absorption spectrometry; and bicarbonate by volumetric titration.

Carbohydrates were quantified in a high-performance liquid chromatography (HPLC) system Waters Alliance 2695 Separation Module (Waters Corporation, Milford, MA, USA), equipped with a Waters 2414 Refractive Index Detector and a Waters 486 Tunable Absorbance Detector (210 nm). An Aminex HPX-87H column (Bio-Rad Laboratories, Hercules, CA, USA) was used to separate the compounds at 60 °C with 5 mM sulfuric acid as mobile phase at a flow rate of 0.5 mL/min. Protein content of processed retentates was determined by Pierce™ BCA Protein Assay kit.

2.2. Yeast Strains and Fermentation Assays

The Kluyveromyces strains (Table 1) were obtained from the Portuguese Yeast Culture Collection (PYCC), Caparica, Portugal. Strains were routinely maintained in rich YPD medium (20 g/L peptone, 10 g/L yeast extract, and 20 g/L d-glucose).

Table 1.

List of Kluyveromyces strains used in this study.

The fermentation process was performed in shake flasks (volume ratio medium/flask 1/5), with cotton plugs (for mild oxygen-limiting conditions) or rubber plugs with piercing needles with 0.22 μm pore size cellulose acetate filter, for pressure release (for severe oxygen-limiting conditions), in an orbital shaker (Agitorb 200, Aralab) at 30 °C and 150× rpm. The Kluyveromyces strains were grown for approximately 24 h in YPD medium. Cells were harvested by centrifugation (10,414× g at 4 °C for 10 min), washed twice with cold sterile water and used to inoculate 20 mL sterile NF or RO retentates, at an initial biomass of 4 to 5 g cell dry weight per liter (gCDW/L). The fermentation assays were performed in triplicate.

The fermentation process was monitored by periodic sampling. Cell growth was monitored by optical density (OD) measurements at 600 nm in a DU® 800 Spectrophotometer Beckman Coulter and by determination of cell dry weight (CDW), after 24 h drying at 100 °C. For the analysis of substrate consumption and product formation, samples were centrifuged (16,100× g) for 5 min at 4 °C and supernatants were stored at −20 °C. Thawed supernatants were diluted (1/20) with 5 mM sulfuric acid, incubated for 15 min at 60 °C and 15 min at room temperature. Precipitated proteins were removed by centrifugation (16,100× g for 10 min at 4 °C) and the resulting supernatants were filtered through a 0.22 μm pore size nylon filter and analyzed by HPLC as described in the previous section.

3. Results and Discussion

3.1. Chemical Composition of Nanofiltration and Reverse Osmosis Permeates and Retentates from Dairy Wastewater

The processing of industrial water streams through nanofiltration (NF) or reverse osmosis (RO) has been contemplated towards recycling of water and chemicals or disposal according to regulations. Wastewater from the dairy industry is usually a diluted version of milk, dairy products, or by-products (e.g., whey), having lactose concentrations equal or inferior to 50 g/L. Processing wastewater from the dairy industry through membrane technology contributes to the selective recovery of chemicals. UF can retain the majority of proteins, while NF or RO can concentrate the remaining organic chemicals, with lactose as the major component. This work is based on processing dairy wastewaters through UF, to recover the majority of the proteins in the retentate, followed by UF permeate processing through NF or RO. The permeates and retentates obtained from the NF or RO processing were analyzed, targeting specific applications, permeates for water recycling into the cleaning process and retentates for the production of bioethanol. With this purpose, processing of wastewater through UF/NF or UF/RO was designed to obtain a lactose concentration of 120 to 150 g/L in the retentates, in order to reach, by yeast fermentation, ethanol titers higher than 50 g/L, which is compatible with energy-efficient distillation processes [16].

3.1.1. Composition of NF and RO Permeates and Comparison with Drinking Water Regulation

The permeates from the NF or RO processing were analyzed in relation to pH, conductivity, total dissolved solids, anions, cations, and vestigial elements (Table 2) against the following current recommendations and regulations for drinking water: Guidelines for drinking-water quality [17], EU Directive 98/83/EC on the quality of water intended for human consumption [18], Regulation on ground water and drinking water [19] and Water quality standards of drinking water [20] (Table S1 in Supplementary Materials). As expected, NF revealed lower salt rejection than RO, leading to higher total dissolved solids and conductivity in the permeate (3.86 vs. 0.19 g/L and 6440 vs. 317 μS/cm, respectively). The conductivity limit defined by the EU Directive 98/83/EC for drinking water is 2500 μS/cm and the total dissolved solids are generally recommended to be below 0.5 to 0.6 g/L, both limits only met by RO permeate. Both of the NF and RO permeates are acidic (pH of 5.85 and 5.39, respectively) exhibiting pH values outside the limits normally suggested (6.5 < pH < 8.5). Nevertheless, pH adjustments can easily be performed if necessary.

Table 2.

Comparison of the nanofiltration (NF) and reverse osmosis (RO) permeates’ properties and composition against current recommendations and regulations for drinking water.

Among the most hazardous inorganic chemicals are the anions fluoride and nitrate/nitrite. Fluoride and nitrate/nitrite levels in both NF and RO permeate are within the limits defined by the different regulations for drinking-water quality. Chloride and sulfate have recommended limits defined only due to aesthetic (odor and taste) effects (<200–250 mg/L and <250–500 mg/L, respectively). While chloride in RO permeate (78.5 mg/L) is within the limits defined, in the NF permeate the level of this anion is well above (more than seven-fold) the acceptable limits. In contrast, both of the NF and RO permeates clearly meet the recommended sulfate limits. The limits for phosphates and bicarbonate are not defined since the concentrations commonly found in water are not of heath or aesthetic concerns.

Among the cations with limits generally recommended are sodium, ammonium, manganese, and iron. The levels of manganese and iron are below the detection limit, and therefore below the limits suggested. In turn, whereas sodium and ammonium levels in NF permeate (725 and 121 mg/L, respectively) are well above the limits recommended (200 and 0.5–1.5 mg/L, respectively), the levels of these cations in the RO permeate are low (18.7 and 0.1 mg/L, respectively) and compatible with drinking water standards. Vestigial elements (cadmium, lead, and mercury) are all below the detection limits in the NF and RO permeates.

In summary, the levels of several inorganic chemicals (chloride, sodium, and ammonium), pH, total dissolved solids, and conductivity in the NF permeate are not according to the recommendations and regulations for drinking-water quality. In turn, the RO permeate from dairy wastewater meets the criteria of drinking water standards, except for pH, and therefore can be recycled for cleaning processes in the dairy.

3.1.2. Composition of the NF and RO Retentates

The pH of the processed NF and RO retentates (5.34 and 5.73, respectively) falls within the appropriate range for yeast metabolism (5.0 to 6.0), as defined in standard media for yeast cultivation (Table 3, Table S2 in Supplementary Materials).

Table 3.

Comparison of the processed NF and RO retentates’ properties and composition against reference defined media for yeast cultivation.

These RO and NF retentates contained, as main organic components, lactose (129–145 g/L), citric acid (15–18 g/L), proteins (14–18 g/L) and minor concentrations (<2 g/L) of galactose and lactic acid (Table 3). The lactose concentration in the retentates (129–145 g/L) is according to the requirements defined to obtain ethanol concentrations through biological conversion higher than 50 g/L, if ethanol yield is higher than 0.38 g/g (i.e., above 75% of the theoretical maximum).

When compared to the reference defined media for yeast cultivation, namely yeast nitrogen base (YNB, Difco™) or other mineral media [21,22] (Table S2), both of the NF and RO retentates contained the most relevant inorganic ions, although at different concentrations (Table 3). Generally, the level of inorganic ions in media is adjusted to the concentration of the carbon source. For example, YNB is designed for 5 g/L of carbon source, whereas “Verduyn” and “Delft” media are for 10 and 22 g/L, respectively. Accordingly, the total amount of inorganic ions in these media range from 7 to 23 g/L. The NF and RO retentates have a total of 13 to 16 g/L of inorganic ions, which is in the range of those found in standard yeast media. Because the fermentation process is to be performed at high cell density, and thus with minimal cell growth, the salts present in the NF and RO retentates should be enough to support fermentation, as long as all the necessary elements for yeast metabolism are present.

While both retentates had a surplus of chloride, sodium, potassium, and calcium, the concentration of ammonium and sulfate were approximately 10 times lower than the standard yeast media. Bicarbonate and fluoride present in retentates (respectively approximately 3300 mg/L and 130 to 373 mg/L) are not common components of these media.

The main differences in ionic composition between the NF and RO retentates were higher levels of fluoride and sodium in the NF retentate, and higher levels of chloride and potassium in the RO retentate. Sodium and fluoride are known toxic compounds for most yeast species and sodium fluoride is a common inhibitory compound for yeast metabolism at 50 mM (2 g/L) [23,24]. Moreover, potassium has been described as preferential to sodium for yeast metabolism [25]. In fact, it was reported that lactose hydrolysis by K. marxianus was faster in the presence of K+ than Na+ [26]. Accordingly, the RO retentate should be more advantageous as a fermentative substrate than the NF retentate because it had a higher potassium/sodium ratio (Table 3).

3.2. Screening of Kluyveromyces Strains for NF or RO Retentate Fermentation

To study the ability of Kluyveromyces strains to directly use NF and RO retentates as a substrate for ethanol production (without supplementation), the following ten lactose-fermenting strains were selected from a yeast culture collection (PYCC): five K. marxianus strains and five K. lactis strains (Table 1). The K. marxianus CBS 397 (PYCC 3884) strain was expressly included in this screening for benchmarking, as this strain has been often described as one of the best lactose-fermenting yeasts, both in terms of ethanol production rate and maximum ethanol titer [27,28,29,30].

All strains were pre-grown on a YPD medium to generate yeast biomass, which was used to inoculate the NF and RO retentates at high cell density (4.2 ± 0.6 gCDW/L). The fermentation was performed under mild oxygen-limiting conditions (see Material and Methods for details). Fermentation processes at high cell density are faster, also favoring production of ethanol over yeast biomass and other by-products [31,32]. This is a common industrial setup in sugarcane ethanol production in Brazil, where high cell density fermentation is achieved through yeast recycling [33]. Moreover, it is generally accepted that yeast cell viability is lower under anaerobic conditions [34], and, in particular, K. lactis is unable to grow under strict anaerobiosis, although it can ferment and grow under oxygen-limiting conditions, e.g., below 1% air saturation [35].

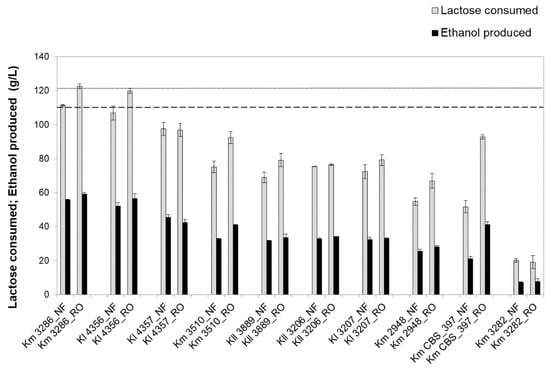

Under the conditions applied, the fermentation of the NF and RO retentates with all the Kluyveromyces strains resulted in ethanol as the major product, with lactose/ethanol conversion yields between 67% and 93% of the theoretical maximum (Table 4). The lower ethanol yield was apparently linked to higher acetate yield. In turn, cell biomass did not significantly change during the process for all the strains. The fermentation performance of each strain in the NF or RO retentates was similar, except for the K. marxianus PYCC 3510 and K. marxianus PYCC 3884 (CBS 397) strains, which fermented more efficiently in the RO retentate than in the NF retentate (Figure 1 and Table 4).

Table 4.

Fermentation parameters in the NF and RO retentates under mild oxygen-limiting conditions. Average values of three independent experiments with corresponding standard deviation.

Figure 1.

Lactose consumed (gray bars) and ethanol produced (black bars) at 16 h fermentation in the NF and RO media. Km, K. marxianus PYCC strain; Kl, K. lactis PYCC strain; Kll, K. lactis var. lactis PYCC strain; dash line, average initial lactose concentration in the assays in NF retentate; and dot line, average initial lactose concentration in the assays in RO retentate. Error bars represent standard deviation from the average value of three independent experiments.

The K. marxianus PYCC 3286 and K. lactis PYCC 4356 strains stood out as the best fermentative strains, showing lactose and ethanol conversion yields higher than 87% of the theoretical maximum, with total lactose conversion within 16 h (Table 4), performing significantly better than the others, including the benchmarking strain K. marxianus CBS 397. In both retentates, the K. marxianus PYCC 3282 strain displayed the poorest lactose fermentation capacity, with only 20% of the lactose consumed after 46 h and with the lowest ethanol yield (67% of the theoretical maximum) (Table 4).

Lactic acid was exhaust from the NF and RO retentates in less than 46 h. As far as citric acid was concerned, the K. lactis PYCC 3889, PYCC 3206, and PYCC 3207 strains, as well as the K. marxianus PYCC 3282 strain consumed 55% to 75% of the initial amount. Interestingly, the K. lactis PYCC 4357, K. marxianus PYCC 3286, K. marxianus PYCC 3510, and K. marxianus PYCC 3884 strains produced 3 to 5 g/L citric acid. Acetic acid, glycerol (Table 4), and minor amounts (<1 g/L) of malic acid, succinic acid, and sorbitol were other end products, in addition to ethanol. Generally, the K. marxianus strains produced higher amounts of acetic acid (2 to 8 g/L) than the K. lactis strains (<1 g/L). The only exception was the K. lactis PYCC 4357 strain, for which the produced level of acetic acid fell in the range typically observed for the K. marxianus strains, i.e., approximately 2 g/L at the time of maximum ethanol (Table 4) and 3.5 g/L at 46 h. The K. marxianus PYCC 3884 (CBS 397) strain produced the highest amounts of acetic acid, as high as 8.3 g/L in the NF retentate (Table 4).

Glycerol was produced, in variable amounts, by all strains. High concentrations of glycerol, 2.3 to 3.0 g/L at the time of maximum ethanol (Table 4) and approximately 4 g/L at 46 h, were produced by the K. lactis PYCC 3889 and the K. lactis PYCC 3206 strains, whereas the K. marxianus strains, and the K. lactis PYCC 4356, and K. lactis PYCC 3207 strains produced less than 2 g/L (Table 4), even after 46 h.

Among all the ten strains examined, herein, we were intrigued by the poor fermentation features displayed by the K. marxianus PYCC 3282 (CBS 608) strain. In fact, other researchers had reported that this strain displays lactose consumption profiles similar to those of the K. marxianus CBS 397 strain, in rich medium with 20 g/L lactose, both strains being considered as good lactose consumers [36,37]. In our screening, which was performed in lactose-rich substrates (>100 g/L), the two strains showed dissimilar fermentative behaviors. The K. marxianus PYCC 3282 strain had the poorest performance, consuming only 20% of initial lactose (approximatley 33 g/L), whereas the K. marxianus CBS 397 strain was able to exhaust lactose and achieve ethanol titers up to 48 g/L in the RO retentate (Table 4). The discrepancy between our results and the literature could result from diverse tolerance to ethanol or high sugar concentration (osmotolerance). In a similar rich medium, we found that the lactose consumption rate by the K. marxianus PYCC 3282 strain was severely impaired when the lactose concentration was increased. At approximately 20 g/L lactose, the sugar was virtually exhausted (93% consumption) in the first 5 h of fermentation (initial 2.7 gCDW/L), while at approximately 40 g/L lactose, no sugar consumption was observed in the same 5 h period (Figure S1 in Supplementary Materials). In addition, lactose fermentation was also negatively affected by ethanol, as only 56% lactose was consumed when the medium was supplemented with approximately 20 g/L ethanol (Figure S1 in Supplementary Materials). In contrast, the K. marxianus CBS 397 strain was fairly insensitive to lactose concentration and ethanol. These results point to a combined effect of low tolerance of the K. marxianus PYCC 3282 strain to high concentrations of both sugar and ethanol.

On the basis of their fermentation performance in the NF and RO retentates, the K. marxianus PYCC 3286 and K. lactis PYCC 4356 strains were selected for further studies, still using the K. marxianus CBS 397 strain for benchmarking.

3.3. Influence of Different Oxygen-Limiting Conditions in NF or RO Rententate Fermentation Performance

The implementation of industrial fermentations of retentates from dairy wastewater processing through membrane technology requires the evaluation of oxygen availability on the fermentation performance. Taking into account that industrial fermentation processes are preferentially performed under anaerobic or severe oxygen-limiting conditions to avoid extra costs on aeration, and knowing that the Kluyveromyces spp. metabolism is significantly reduced under strict anaerobiosis, two different oxygen-limiting conditions (named mild and severe) were tested in the fermentation of NF and RO retentates (see Materials and Methods for details).

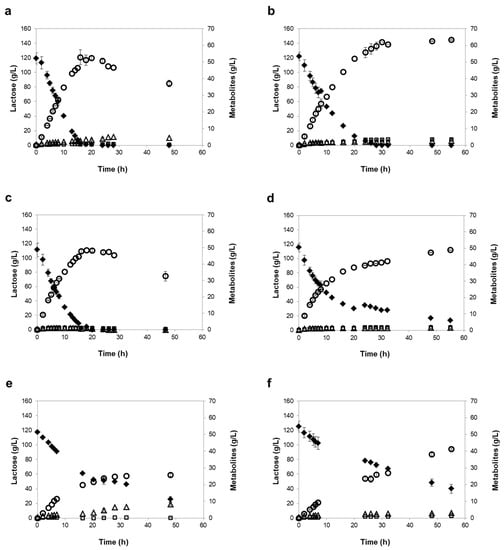

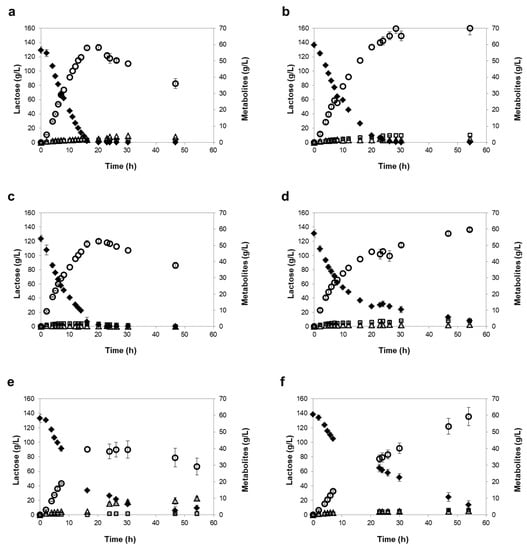

The two strains selected, K. marxianus PYCC 3286 and K. lactis PYCC 4356, revealed a linear lactose consumption and ethanol production during the first 8 h of fermentation (Figure 2 and Figure 3), with higher rates under mild than under severe oxygen-limiting conditions (Table 5). Consequently, the time required to achieve maximum ethanol titers was 16 to 20 h under mild oxygen-limiting conditions and 29 to 55 h under severe oxygen-limiting conditions. The rates of lactose consumption and ethanol production were up to 25% higher in the RO retentates, which may result from the different salt composition between the two retentates. As expected, the two strains fermented slower under severe oxygen-limiting conditions, but reached higher final ethanol concentrations, because ethanol cannot be used in the absence of oxygen (Table 5). In contrast, under mild oxygen-limiting conditions, the level of ethanol decreased after lactose was exhausted (Figure 2 and Figure 3).

Figure 2.

Fermentation profiles of the K. marxianus PYCC 3286 strain (a,b), the K. lactis PYCC 4356 strain (c,d), and the K. marxianus CBS 397 strain (e,f), in NF media, in mild oxygen-limiting conditions (left panels) and severe oxygen-limiting conditions (right panels). Lactose (♦), ethanol (◯), glycerol (□), and acetic acid (△). Error bars represent standard deviation from the average value of three independent experiments.

Figure 3.

Fermentation profiles of the K. marxianus PYCC 3286 strain (a,b), the K. lactis PYCC 4356 strain (c,d) and the K. marxianus CBS 397 strain (e,f), in the RO media, in mild oxygen-limiting conditions (left panels) and severe oxygen-limiting conditions (right panels). Lactose (♦), ethanol (◯), glycerol (□), and acetic acid (△). Error bars represent standard deviation from the average value of three independent experiments.

Table 5.

Fermentation parameters under mild oxygen-limiting conditions versus severe oxygen-limiting conditions in the NF and RO retentates. Average values of three independent experiments with corresponding standard deviation.

Under mild oxygen-limiting conditions, the K. marxianus PYCC 3286 and K. lactis PYCC 4356 strains behaved similarly. Moreover, under severe oxygen limitation, the initial lactose consumption rates were identical (Table 5), however, the K. marxianus PYCC 3286 strain consumed lactose at a fairly constant rate until exhaustion, while the consumption rate notably decreased for the K. lactis PYCC 4356 strain after the first 20 h (Figure 2 and Figure 3), this strain requiring over 55 h of fermentation to consume lactose completely.

In both of the under mild and under severe oxygen-limiting conditions, the K. marxianus CBS 397 strain displayed lower lactose consumption and ethanol production rates than the other two strains, especially in the NF retentates, requiring 30 to 48 h to achieve maximum ethanol titers under mild oxygen-limiting conditions and more than 55 h under severe oxygen-limiting conditions (Table 5). In the NF retentate, under mild oxygen-limiting conditions, the strain was unable to exhaust lactose (30% of lactose remains in the medium at 120 h fermentation). It is important to note that the ethanol yield and productivity values determined in our study for the reference strain K. marxianus CBS 397 are similar to those reported by other researchers for fermentations with this strain in synthetic medium with 200 g/L lactose and 0.2 vvm aeration (0.43 g/g and 2.12 g/L/h, respectively) [38], and in concentrated whey powder (0.44 g/g and 1.3 g/L/h, respectively) [27]. Comparable parameters were also reported for fermentation of cheese whey, despite the lower lactose content (50 to 59 g/L) [28,39]. The ethanol productivity determined for the K. marxianus PYCC 3286 and K. lactis PYCC 4356 strains under mild oxygen-limiting conditions (approximately 4 g/L/h) also compares favorably with the productivity achieved with an evolved recombinant S. cerevisiae strain (0.46 g/L/h), which is able to ferment concentrated cheese whey (150 g/L lactose) [40].

It was apparent that the K. lactis strain performed unsatisfactorily under severe oxygen-limiting conditions, confirming the known requisite of K. lactis strains for oxygen, probably related to impaired sterol import and lack of the Rox1p-mediated system that is essential for the response to low oxygen levels in S. cerevisiae [41,42]. Importantly, the performance of the K. marxianus PYCC 3286 strain was fairly independent of the levels of oxygen examined. This is an attractive trait of the K. marxianus PYCC 3286 strain, since the fermentation under severe oxygen restriction has the advantage of achieving higher final ethanol titers, as ethanol cannot be utilized via respiration, and of minimizing the need for aeration supply under industrial settings. Furthermore, this trait allows fermentations at high cell density, which may bring cost benefits to the process, especially if cell recycling can be considered. The excellent tolerance of the K. marxianus PYCC 3286 strain to ethanol has been recently noted by other authors who showed that this strain can tolerate up to 79 g/L of ethanol [43]. Moreover, a high beta-galactosidase specific activity was also reported for this strain (3207 IU/g DW) [44]. It is conceivable that the combination of high ethanol tolerance and high beta-galactosidase activity are decisive features for the superior fermentative behavior displayed by the K. marxianus PYCC 3286 strain in the NF and RO retentates, both under mild and severe oxygen-limiting conditions. Additionally, the fact that K. marxianus PYCC 3286 can tolerate temperatures as high as 42 °C and high salinity (16% NaCl (w/v) (CBS database (http://www.westerdijkinstitute.nl/Collections/BioloMICS.aspx) allows for a wider range of operational conditions to be tested.

4. Conclusions

This work aimed to evaluate the possibility of implementing an integrated process allowing water recycling and bioenergy production from dairy wastewater. The processing of dairy wastewater through sequential crossflow UF/RO allowed the selective recovery of proteins in the UF step, while contributing to reduced fouling in the subsequent RO step. In turn, the RO processing led to a permeate that complied with legislation for water recycling and a RO retentate able to be efficiently converted into bioethanol, with lactose concentrations of approx. 150 g/L. The K. marxianus PYCC 3286 strain was selected as the best performing strain for the RO retentate fermentation under severe oxygen-limiting conditions, reaching 70 g/L (8.9% v/v) of ethanol, with a corresponding yield of 0.49 g/g (>95% of the maximum theoretical) and a volumetric productivity of 3.67 g/L/h.

The implementation of this integrated process under industrial settings demands further process intensification studies using this yeast strain (e.g., cell recycling), particularly in combination with long membrane technology operations to assess fouling constraints and cleaning requirements. The processing of different dairy wastewaters (e.g., those containing low lactose concentrations) may also represent new challenges for membrane operations and for yeast performance, however, this work represents an important step towards the implementation of the circular economy concept in the dairy industry.

Supplementary Materials

Supplementary materials can be found at https://www.mdpi.com/2076-2607/7/11/545/s1.

Author Contributions

Conceptualization, C.F.; methodology, M.J.L, C.F. and H.S.; investigation, M.J.L.; resources, B.R.; writing—original draft preparation, M.J.L., H.S. and C.F.; writing—review and editing, M.J.L., S.M., B.R., H.S. and C.F.; supervision, C.F. and H.S.; project administration, C.F. and S.M.; funding acquisition, C.F. and H.S.

Funding

This research was funded by: the European Commission in the framework of EU Project SUSMILK (FP7-613589); the Fundação para a Ciência e a Tecnologia (FCT), Portugal (postdoctoral fellowship SFRH/BPD/102803/2014 to M.J.L.); and the Project LISBOA-01-0145-FEDER-007660 (Microbiologia Molecular, Estrutural e Celular) funded by FEDER funds through COMPETE2020-Programa Operacional Competitividade e Internacionalização (POCI) and by national funds through FCT.

Acknowledgments

We thank Queizuar for providing dairy wastewaters and Alfonso Perez at the Universidad de Santiago de Compostela, Aula de Productos Lácteos, Spain, for providing UF/NF and UF/RO permeates and retentates. We thank Maria Adelaide Ferreira, responsible for analysis of retentates and permeates, from the Mineral Science and Technology Unit, LNEG. We also thank Margarida Monteiro (LNEG) for technical assistance with microbiology work, Paula Chicau and Cristina Leitão (ITQB) and Maria do Céu Penedo (LNEG) for the HPLC analyses.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study, in the collection, analyses, or interpretation of data in the writing of the manuscript, or in the decision to publish the results.

References

- European Commission. U AGRICULTURAL OUTLOOK for the Agricultural Markets and Income 2017–2030. Technical Report. 2017. Available online: https://ec.europa.eu/info/sites/info/files/food-farming-fisheries/farming/documents/agricultural-outlook-2017-30_en.pdf (accessed on 8 October 2019).

- Britz, T.J.; Van Sckalkwyk, C.; Hung, Y.T. Treatment of dairy processing wastewater. In Handbook of Industrial and Hazardous Waste Treatment, 2nd ed.; Marcel Dekker Inc.: New York, NY, USA, 2004; pp. 616–646. [Google Scholar]

- Rad, S.J.; Lewis, M.J. Water utilisation, energy utilisation and waste water management in the dairy industry: A review. Int. J. Dairy Technol. 2014, 67, 1–20. [Google Scholar] [CrossRef]

- Dresch, M.; Daufin, G.; Chaufer, B. Membrane processes for the recovery of dairy cleaning-in-place solutions. Lait 1999, 79, 245–259. [Google Scholar] [CrossRef]

- Shahmansouri, A.; Bellona, C. Nanofiltration technology in water treatment and reuse: Applications and costs. Water Sci. Technol. 2015, 71, 309–319. [Google Scholar] [CrossRef] [PubMed]

- Beaton, N.B. Ultrafiltration and reverse osmosis in the dairy industry-an introduction to sanitary considerations. J. Food Prot. 1979, 42, 584–590. [Google Scholar] [CrossRef]

- Park, H.-G.; Kwon, Y.-N. Long-term stability of low-pressure reverse osmosis (RO) membrane operation—A pilot scale study. Water 2018, 10, 93. [Google Scholar] [CrossRef]

- Early, R. Dairy products and milk-based food ingredients. In Natural Food Additives, Ingredients and Flavourings; Baines, D., Seal, R., Eds.; Woodhead Publishing Limited: Sawston, UK, 2012; pp. 417–445. [Google Scholar] [CrossRef]

- Meneses, Y.E.; Flores, R.A. Feasibility, safety, and economic implications of whey-recovered water in cleaning-in-place systems: A case study on water conservation for the dairy industry. J. Dairy Sci. 2016, 99, 3396–3407. [Google Scholar] [CrossRef]

- Domingues, L.; Guimarães, P.M.R.; Oliveira, C. Metabolic engineering of Saccharomyces cerevisiae for lactose/whey fermentation. Bioeng. Bugs 2010, 1, 164–171. [Google Scholar] [CrossRef]

- Guimarães, P.M.R.; Teixeira, J.A.; Domingues, L. Fermentation of lactose to bio-ethanol by yeasts as part of integrated solutions for the valorisation of cheese whey. Biotechnol. Adv. 2010, 28, 375–384. [Google Scholar] [CrossRef]

- Hagman, A.; Säll, T.; Compagno, C.; Piskur, J. Yeast “Make-accumulate-consume” life strategy evolved as a multi-atep process that predates the whole genome duplication. PLoS ONE 2013, 8, e68734. [Google Scholar] [CrossRef]

- Castro, R.C.A.; Roberto, I.C. Selection of a thermotolerant Kluyveromyces marxianus strain with potential application for cellulosic ethanol production by simultaneous saccharification and fermentation. Appl. Biochem. Biotechnol. 2014, 172, 1553–1564. [Google Scholar] [CrossRef]

- Belém, M.A.F.; Lee, B.H. Production of bioingredients from Kluyveromyces marxianus grown on whey: An alternative. Crit. Rev. Food Sci. Nutr. 1998, 38, 565–598. [Google Scholar] [CrossRef] [PubMed]

- Radecka, D.; Mukherjee, V.; Mateo, R.Q.; Stojiljkovic, M.; Foulquié-Moreno, M.R.; Thevelein, J.M. Looking beyond Saccharomyces: The potential of non-conventional yeast species for desirable traits in bioethanol fermentation. FEMS Yeast Res. 2015, 15. [Google Scholar] [CrossRef]

- Galbe, M.; Sassner, P.; Wingren, A.; Zacchi, G. Process engineering economics of bioethanol production. Adv. Biochem. Eng. Biotechnol. 2007, 108, 303–327. [Google Scholar] [CrossRef] [PubMed]

- World Health Organization (WHO). Guidelines for Drinking-Water Quality. Technical Report. 2017. Available online: https://apps.who.int/iris/bitstream/handle/10665/254637/9789241549950-eng.pdf?sequence=1 (accessed on 8 October 2019).

- European Commission (EC). Council Directive 98/83/EC of 3 November 1998 on the Quality of Water Intended for Human Consumption. Technical Report. 1998. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:31998L0083&from=EN (accessed on 8 October 2019).

- United States Environmental Protection Agency (EPA). Ground Water and Drinking Water-National Primary Drinking Water Regulations; Technical Report; 2017. Available online: https://www.epa.gov/ground-water-and-drinking-water/national-primary-drinking-water-regulations#Inorganic (accessed on 8 October 2019).

- Japan Water Works Association (JWWA). JSupply of Drinking Water with Clean and Safe-Water Quality Standards of Drinking Water. Technical Report. 2007. Available online: http://www.jwwa.or.jp/english/water_en/water-e07.html (accessed on 8 October 2019).

- Jensen, N.B.; Strucko, T.; Kildegaard, K.R.; David, F.; Maury, J.; Mortensen, U.H.; Forster, J.; Nielsen, J.; Borodina, I. EasyClone: Method for iterative chromosomal integration of multiple genes in Saccharomyces cerevisiae. FEMS Yeast Res. 2014, 14, 238–248. [Google Scholar] [CrossRef]

- Verduyn, C.; Postma, E.; Scheffers, W.A.; Van Dijken, J.P. Effect of benzoic acid on metabolic fluxes in yeasts: A continuous-culture study on the regulation of respiration and alcoholic fermentation. Yeast 1992, 8, 501–517. [Google Scholar] [CrossRef]

- Li, S.; Smith, K.D.; Davis, J.H.; Gordon, P.B.; Breaker, R.R.; Strobel, S.A. Eukaryotic resistance to fluoride toxicity mediated by a widespread family of fluoride export proteins. Proc. Natl. Acad. Sci. USA 2013, 110, 19018–19023. [Google Scholar] [CrossRef]

- Murguia, J.R.; Belles, J.M.; Serrano, R. The yeast HAL2 nucleotidase is an in vivo target of salt toxicity. J. Biol. Chem. 1996, 271, 29029–29033. [Google Scholar] [CrossRef]

- Blomberg, A.; Adler, L. Tolerance of fungi to NaCl. Mycol. Ser. 1993, 10, 209–232. [Google Scholar]

- Rajakala, P.; Karthigai Selvi, P. The effect of pH, temperature and alkali metal ions on the hydrolsis of whey lactose catalysed by β -galactosidase from Kluyveromyces marxianus. Int. J. Dairy Sci. 2006, 1, 167–172. [Google Scholar] [CrossRef][Green Version]

- Díez-Antolínez, R.; Hijosa-Valsero, M.; Paniagua-García, A.I.; Garita-Cambronero, J.; Gómez, X. Yeast screening and cell immobilization on inert supports for ethanol production from cheese whey permeate with high lactose loads. PLoS ONE 2018, 13, e0210002. [Google Scholar] [CrossRef]

- Gabardo, S.; Rech, R.; Rosa, C.A.; Ayub, M.A.Z. Dynamics of ethanol production from whey and whey permeate by immobilized strains of Kluyveromyces marxianus in batch and continuous bioreactors. Renew. Energy 2014, 69, 89–96. [Google Scholar] [CrossRef]

- Janssens, J.H.; Burris, N.; Woodward, A.; Bailey, R.B. Lipid-enhanced ethanol production by Kluyveromyces fragilis. Appl. Environ. Microbiol. 1983, 45, 598–602. [Google Scholar] [PubMed]

- Mahmoud, M.M.; Kosikowski, F.V. Alcohol and single cell protein production by Kluyveromyces in concentrated whey permeates with reduced ash. J. Dairy Sci. 1982, 65, 2082–2087. [Google Scholar] [CrossRef]

- Vijaikishore, P.; Karanth, N.G. Glycerol production by fermentation. Appl. Biochem. Biotechnol. 1984, 9, 243–253. [Google Scholar] [CrossRef]

- Silveira, W.B.; Passos, F.J.V.; Mantovani, H.C.; Passos, F.M.L. Ethanol production from cheese whey permeate by Kluyveromyces marxianus UFV-3: A flux analysis of oxido-reductive metabolism as a function of lactose concentration and oxygen levels. Enzym. Microb. Technol. 2005, 36, 930–936. [Google Scholar] [CrossRef]

- Basso, L.C.; De Amorim, H.V.; De Oliveira, A.J.; Lopes, M.L. Yeast selection for fuel ethanol production in Brazil. FEMS Yeast Res. 2008, 8, 1155–1163. [Google Scholar] [CrossRef]

- Liu, C.-G.; Hao, X.-M.; Lin, Y.-H.; Bai, F.-W. Redox potential driven aeration during very-high-gravity ethanol fermentation by using flocculating yeast. Sci. Rep. 2016, 6, 25763. [Google Scholar] [CrossRef]

- González Siso, M.I.; Cerdán, E.M. Kluyveromyces lactis: A suitable yeast model to study cellular defense mechanisms against hypoxia-induced oxidative stress. Oxidative Med. Cell. Longev. 2012, 2012, 14. [Google Scholar] [CrossRef]

- Lane, M.M.; Burke, N.; Karreman, R.; Wolfe, K.H.; O’Byrne, C.P.; Morrissey, J.P. Physiological and metabolic diversity in the yeast Kluyveromyces marxianus. Antonie Van Leeuwenhoek 2011, 100, 507–519. [Google Scholar] [CrossRef]

- Varela, J.A.; Montini, N.; Scully, D.; Van der Ploeg, R.; Oreb, M.; Boles, E.; Hirota, J.; Akada, R.; Hoshida, H.; Morrissey, J.P. Polymorphisms in the LAC12 gene explain lactose utilisation variability in Kluyveromyces marxianus strains. FEMS Yeast Res. 2017, 17. [Google Scholar] [CrossRef]

- Ryu, Y.; Jang, H.; Lee, H. Enhancement of ethanol tolerance of lactose assimilating yeast strain by protoplast fusion. J. Microbiol. Biotechnol. 1991, 1, 151–156. [Google Scholar]

- Sansonetti, S.; Curcio, S.; Calabrò, V.; Iorio, G. Bio-ethanol production by fermentation of ricotta cheese whey as an effective alternative non-vegetable source. Biomass Bioenergy 2009, 33, 1687–1692. [Google Scholar] [CrossRef]

- Guimarães, P.M.R.; François, J.; Parrou, J.L.; Teixeira, J.A.; Domingues, L. Adaptive evolution of a lactose-consuming Saccharomyces cerevisiae recombinant. Appl. Environ. Microbiol. 2008, 74, 1748. [Google Scholar] [CrossRef] [PubMed]

- Fang, Z.-A.; Wang, G.-H.; Chen, A.-L.; Li, Y.-F.; Liu, J.-P.; Li, Y.-Y.; Bolotin-Fukuhara, M.; Bao, W.-G. Gene responses to oxygen availability in Kluyveromyces lactis: An insight on the evolution of the oxygen-responding system in yeast. PLoS ONE 2009, 4, e7561. [Google Scholar] [CrossRef] [PubMed]

- Snoek, I.S.; Steensma, H.Y. Why does Kluyveromyces lactis not grow under anaerobic conditions? Comparison of essential anaerobic genes of Saccharomyces cerevisiae with the Kluyveromyces lactis genome. FEMS Yeast Res. 2006, 6, 393–403. [Google Scholar] [CrossRef] [PubMed]

- Madeira-Jr, J.V.; Gombert, A.K. Towards high-temperature fuel ethanol production using Kluyveromyces marxianus: On the search for plug-in strains for the Brazilian sugarcane-based biorefinery. Biomass Bioenergy 2018, 119, 217–228. [Google Scholar] [CrossRef]

- Rollini, M.; Trinetta, V.; Musatti, A.; Manzoni, M. Influence of substrate on β-galactosidase production by Kluyveromyces strains. Ann. Microbiol. 2008, 58, 705. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).