1. Introduction

Robots are revolutionizing agriculture by addressing labor shortages, automating repetitive and onerous tasks, and enhancing safety and ergonomics. By integrating robots into agricultural systems, we are reshaping the industry and also unlocking transformative potential in precision agriculture to ensure food security, resource management, and environmental sustainability [

1,

2]. Additionally, the challenging conditions of agricultural environments, combined with increasing demands for high-quality production, make robotic technologies a timely and necessary solution [

3,

4,

5]. An indicator of this technological growth and its importance is the global agricultural robotics market, which was valued at approximately USD 14.74 billion in 2024. Also, its value is projected to grow at a compound annual growth rate (CAGR) of 23% from 2025 to 2030 [

6].

In a recent review, advancements in agricultural robots specifically targeting specialty crops were identified [

7]. The findings revealed significant interest in robot solutions for harvesting, along with emerging relevance in tasks such as spraying, pruning, weed control, pollination, transplanting, and fertilizing. These efforts emphasize the importance of robotic technologies and their problem-solving capabilities. Moreover, the review highlighted the importance of collaborative robotics (co-robotics), where robots do not necessarily perform tasks solely, but often in collaboration with humans or other technologies [

7]. Based on the literature, co-robotics is not merely about coexistence, but is characterized by an integration serving a specifically collaborative function [

8]. The integration of such systems leverages the strengths of each platform, facilitating the execution of tasks that exceed the capabilities of either system independently [

9,

10]. Co-robotics has emerged as a promising approach. It strengthens the autonomy and endurance of robots while leveraging the decision-making abilities of humans [

11,

12]. Activities that require high levels of precision and adaptability, as well as considerations such as safety and ergonomics, are key areas of focus for co-robotics [

13,

14].

Within the co-robotics context, we found relevant studies exploring its functionalities. For instance, Fei and Vougioukas [

15] developed a robotic platform to dynamically control worker positioning and travel speed in real time during harvesting operations. Their system uses an algorithm that adjusts these parameters based on inputs such as the distribution of incoming fruit loads and the workers’ fruit-picking rates. The algorithm selects the highest possible speed that still ensures that the fruit-picking percentage remains above a grower-defined minimum threshold. This approach increased harvesting throughput by up to 25%. Another study by Koc and Vatandas [

16] introduced an autonomous robot designed to optimize fruit transportation logistics in agricultural environments. The system was built on the Robot Operating System (ROS) and featured an enhanced hybrid navigation system for precise localization. It integrated high-resolution LiDAR for environmental mapping, an Inertial Measurement Unit (IMU) for motion estimation, and wheel encoders for odometry. The robot was tested across various terrain types to ensure robust performance and validate its effectiveness.

Delving deeper into co-robotics, we found recent studies exploring collaborative systems involving both robots and drones. For instance, a study by Manasherov and Degani [

17] introduced a co-robotic system comprising a ground-based robotic platform and multiple drones for artificial pollination. The platform was equipped with a single sensor to detect flower positions and deployed several drones accordingly. An algorithm assigned each drone a sequence of target flowers and planned safe trajectories to enable effective pollination via aerial deployment. In another study, Mansur et al. [

18] utilized drones to generate navigation maps for agricultural robots operating in row crops, particularly soybeans. This approach demonstrated the potential of integrating drones with ground robots in precision agriculture tasks, such as site-specific application of fertilizers or pesticides using small autonomous machines. Notably, these studies underscore the growing importance of both robots and drones in modern agriculture and, more significantly, the value of their collaboration. While drones are already a well-established technology in the agricultural sector, primarily used for remote sensing [

19], they have recently emerged as effective platforms for spraying applications [

20].

Spraying drones present a promising solution to many challenges associated with conventional manual and machinery-based application methods [

21]. These include reducing human exposure to chemicals [

22], enabling low-volume application [

23], accessing difficult or uneven terrain [

24], and increasing efficiency [

25]. However, despite their advantages, several operational concerns remain, particularly regarding field support requirements. Typically, a field team is needed to set up the drone and, more critically, to prepare the application mixture, which is a labor-intensive, time-consuming, and susceptible-to-error task. Additionally, operators are often required to lift and manually transport the drone to the launch site, further increasing the physical workload and reducing overall efficiency. Trailer-based systems are commercially available to carry spraying components such as water tanks, mixers, chemicals, and pumps to prepare the application mixture. However, these systems do not often carry technologies that would support the final user to dose the chemicals. Moreover, they are generally unsuitable for small farms due to their high cost and scale, making the overall operation less viable. These constraints emphasize the need for more compact, automated, and user-friendly solutions.

Considering the growing importance and adoption of spraying drones and the limited field support typically available for such operations, we propose the integration of a ground-based robotic system designed to enhance the operational efficiency of spraying drones while reducing human labor and error. This integration represents a step toward co-robotics, highlighting the potential for collaboration between robots and drones, as well as the potential collaboration between robots and humans. Therefore, our primary objective was to design and implement a robotic system to support spraying drone operations. Additionally, to enhance the robustness of this work, our secondary objective was to validate the platform by comparing it with traditional manual assessment methods.

To provide a clearer understanding of our approach, the following sections present the methodological framework and the results related to the design and implementation of the proposed platform (

Section 2). This includes the development of the robotic system architecture, the platform components, and the programming and control interface that together fulfill our primary objective. Furthermore, in the same section, we describe the parameters used to evaluate the system’s effectiveness and the results of its performance assessment, addressing our secondary objective. Finally, we conclude with a summary of the contributions and final considerations (

Section 3).

2. Platform Development: Methods and Results

2.1. Robotic Platform

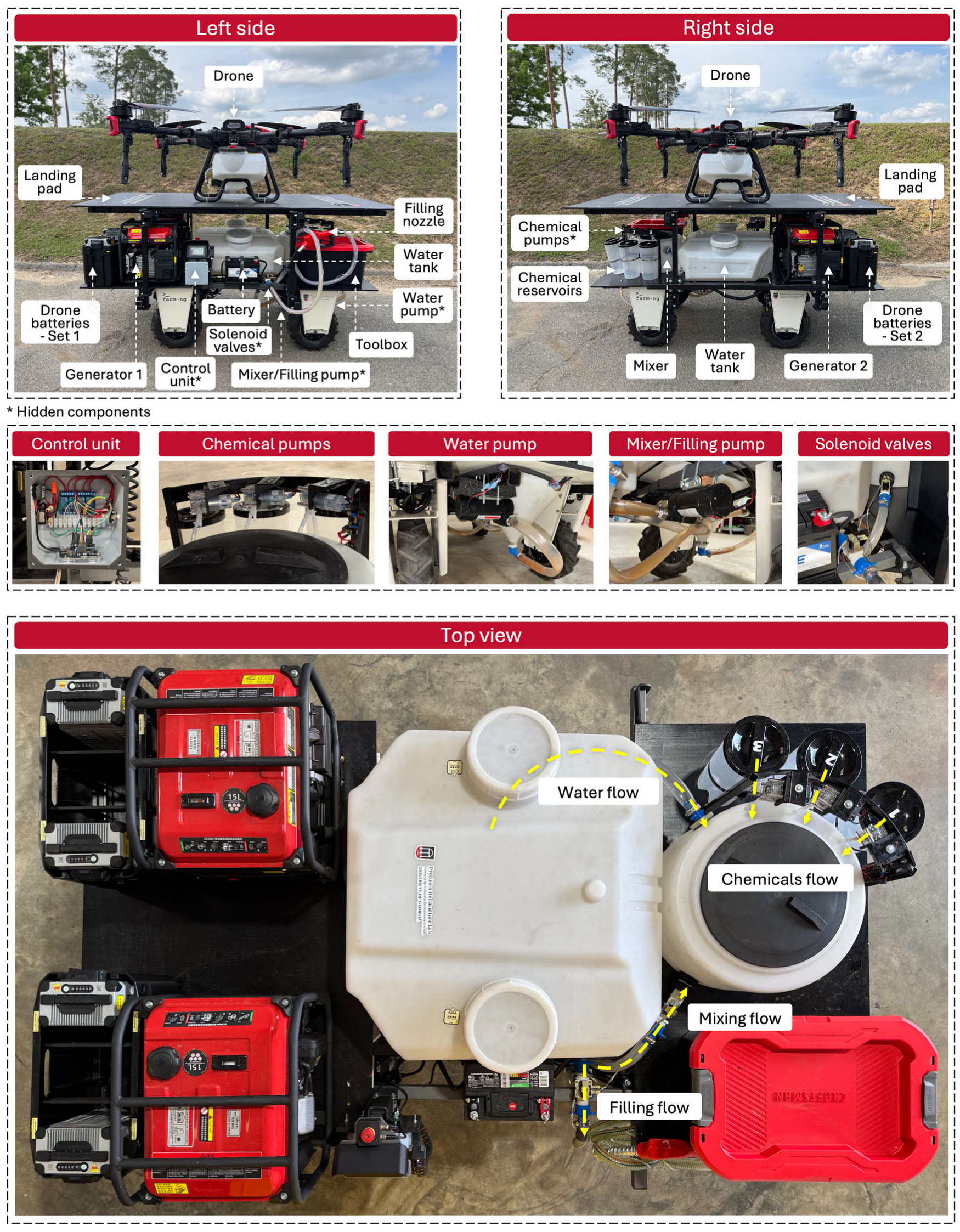

A ground robot (Farm-ng Amiga, Watsonville, CA, USA) was the platform deployed for this study (

Figure 1). It is a 4 × 4 all-electric skid-steer vehicle powered by a 1.32 kWh dual battery pack. The system can run up to 8 h with a single battery charge, depending on the load conditions, based on the manufacturer’s specifications [

26]. The robot is capable of carrying a payload of up to 450 kg, hauling up to 430 kg, towing up to 900 kg, lifting up to 360 kg (with a 3-point lift kit), and reaching speeds of up to 8 km/h. Additionally, it is composed of crossbars and truckbars that are fully adjustable to the desired wheel track width. For this specific study, the robot was configured to a width of 0.80 m and a length of 1.13 m. It served as the base vehicle, with all components subsequently installed on it. The robot is operated via a pendant controller, and the settings are accessed via a touchscreen dashboard display.

2.2. Components and Development of the System

The platform was developed to transport the drone and all of its supporting components to the field, including the chemical reservoirs, mixer, and charging system. The main components included a 150 L water tank, three 3.5 L chemical reservoirs, a 60 L mixing tank, two generators for drone battery charging, and a top takeoff and landing pad (

Table 1). The overall layout and physical configuration of these components are illustrated in

Figure 2. Independent pumps were designated to deliver water and chemicals to the mixing tank. Considering the low-volume application, low pressure, and repeatable chemical dispensing, we used peristaltic pumps for dispensing the chemicals, ensuring precision and accuracy. The chemical pumps achieve a nominal flow of approximately 500 mL/min. Conversely, the pumps for the water supply and the mixer/filling process need to operate at higher volumes to ensure a faster process. Therefore, for the water supply, we used higher-pressure pumps with a nominal flow of approximately 50 L/min. The pump designated for the mixer tank was implemented to extract the application mixture through suction and recirculate it back into the mixer tank via a tank agitator device installed in the mixing tank. This system was also integrated into the drone filling process using a solenoid valve system. When the agitation is running, a solenoid valve is normally open, allowing the application mixture to recirculate to the mixing tank. A momentary push button was installed in the filling nozzle trigger. When the trigger is pressed, the solenoid valve system closes the solenoid of the mixing process and opens another solenoid valve, delivering the application mixture to the drone’s tank through the hose. To start the mixer/filling process, we installed a toggle button for customized and rapid action according to the user’s needs.

The integration method involved mounting all components onto the robotic platform using modular brackets and fasteners. Pumps were connected to tanks via flexible PVC tubing, and solenoid valves were placed at key junctions to control flow direction. All pumps and valves were powered by a 12 V electrical battery and further controlled using a microcontroller, which communicated wirelessly with a mobile app.

During operation (i.e., during the mixing, refilling, and drone launching processes), the platform functions as a stationary base. After the drone takes off, the robot does not move or dynamically reposition itself during the spraying cycle. As a result, there is no battery consumption during this phase, with the power primarily used during initial positioning and setup.

2.3. Programming and Control Interface

The water and chemical pumps were automatically controlled using a microcontroller (Arduino UNO R4 WIFI). In addition to the microcontroller, a cloud programming interface (

https://app.arduino.cc, last accessed on 22 July 2025) was used, which allowed for dashboard creation and full control through a mobile app (IoT Remote). Initially, we developed a programming code to perform all of the desired steps (

Figure 3, left). This code determines all of the input and output signals that the microcontroller needs to handle. Subsequently, we created a mobile app to transform the process into a user-friendly platform (

Figure 3, right). Through the app, the user only needs to fill in the boxes with information such as “Area (acre),” “Rate (Gallons Per Acre—GPA),” and up to three chemicals (“Chemical 1”, “Chemical 2”, and “Chemical 3”). Additionally, we implemented a list of illustrative examples of pre-saved chemicals to facilitate further suggested chemical doses. As a result, this system automatically calculates the “Total number of tanks” needed to execute the spraying task in the specific field, and the “Total Chemicals” needed for each active ingredient in the field. To initiate the application mixture preparation, the user only needs to press the “ON/OFF” button to turn the system on. Similarly, when needed, the user can also interrupt the operation by clicking the button again to turn it off. As the application progresses, the mobile app continuously updates the user on the “Number of remaining tanks.” The mobile app also contains a “Reset” button to restart the system and clear previous input information. To complement the description and better illustrate the system in operation, a Supplementary Video is provided (

Video S1).

2.4. System’s Control Flow

Figure 4 presents the control flow diagram of the automated liquid dispensing system designed to control water and chemical delivery. The system is managed through a mobile app, where the user inputs the required parameters, including the volume of water and up to three chemical active ingredient solutions. Based on these inputs, the total required volume and pump activation timings are calculated automatically, as follows:

Initially, the number of remaining tanks is set as:

where:

This value represents the total number of application tanks needed to cover the specified field area at the given rate. Each time the mixture preparation process is completed (i.e., when the ON button is activated and the mixture is dispensed), is subtracted by one.

To compute the effective water delivery time per tank, the algorithm compensates for the volume of chemical inputs to be allocated to the mixture. This ensures that the total mixture volume (water + chemicals) remains consistent with the target application rate. The water delivery time is calculated using the following equation:

where:

(ms).

.

.

.

.

.

To compute the dispensing time for each chemical, the algorithm considers both the desired dosage and the effective area to be treated. The logic dynamically adjusts based on the total area and the number of tanks remaining, ensuring that chemical inputs align with the prescribed application rate. When the remaining area requires less than one full tank, the algorithm proportionally adjusts each chemical’s dispensing time to avoid overdosing. Conversely, for full tank preparations, the system uses predefined flow rate coefficients for each chemical to determine the dispensing time. Initially, the number of remaining areas is set as:

where:

.

.

.

.

Based on the value of

, the system then determines the dispensing duration for each chemical. When the system identifies that the remaining field area corresponds to at least one full tank (

), the chemical dispensing times are computed assuming one full tank at a time. In this case, the area is not used in the calculations because the algorithm is designed to prepare and dispense one tank per cycle, rather than calculate the dosage based on the total area. The chemical timers are computed as follows:

where:

.

.

.

Once the ON/OFF command is triggered through the mobile interface, the system initiates a sequence beginning with the activation of the water pump (W1), followed by the chemical pumps (C1, C2, C3).

These pumps operate on a specific sequential logic following the application technology principles for tank mixtures, as follows:

- (i)

The water pump (W1) is initially activated to deliver half of the required water volume into the mixer tank;

- (ii)

After this initial water delivery, the chemical pumps (C1, C2, and C3) are simultaneously activated to dispense the pre-set amounts of each chemical into the mixer;

- (iii)

Once chemical dispensing is complete, the water pump (W1) resumes operation to deliver the remaining half of the water volume, completing the mixing process.

The mixer is equipped with an agitator to ensure homogeneous blending of water and chemicals. The mixed solution is then directed to either the drone tank or the filling/refilling reservoir, depending on the status of solenoid valves S1 and S2.

The solenoid valves operate automatically based on feedback from the nozzle trigger mechanism, as follows:

- (i)

By default, S1 is open and S2 is closed, allowing the mixture to recirculate within the mixing tank during agitation.

- (ii)

When the nozzle is pressed, an electric signal is sent to the solenoids, causing S1 to close and S2 to open. This redirects the flow of the mixture from the tank to the drone. When the nozzle is released, the system returns to its default state, resuming recirculation.

Once the full dispensing cycle is complete, based on the defined timing, the system powers down automatically.

The control system was developed and structured to execute sequential operations based on user input. Pump actuation is triggered once all input parameters (field area, application rate, and chemical dosages) are confirmed. The volume thresholds are calculated in real time within the mobile app, and the corresponding pump runtimes are computed using calibration coefficients (

Section 2.5). Safety checks include cut-offs based on both virtual buttons (ON/OFF and Reset) on the mobile app and physical buttons on the platform, followed by indicator LEDs.

2.5. Analysis of the System’s Effectiveness

Before evaluating the system’s effectiveness, we meticulously calibrated the pumps by conducting detailed measurements of the time required to deliver varying amounts of both water and chemicals. For safety and consistency in this initial study, only water was used in the chemical reservoirs. As a result, the pumps for the water supply and the mixer/filling process exhibited a real flow rate of 27 L/min, while the chemical pumps operated at 420 mL/min. Following calibration, we employed evaluation metrics to assess both the precision and accuracy of the robotic system. Precision was quantified using the standard deviation (SD) and the coefficient of determination (R2), while accuracy was evaluated through the mean absolute error (MAE) for water and chemical dosages. These metrics enabled us to quantify the system’s consistency and reliability in delivering the target application rates. To perform this evaluation, we programmed six different application rates and chemical dosages into the mobile app for delivery into the mixer tank. The water and mixer/filling pumps were tested with volumes of 10, 20, 30, 40, 50, and 60 L. These volumes reflect the typical tank capacities of commercial spraying drones. The chemical pumps were tested with dosages of 100, 200, 300, 400, 500, and 600 mL to represent the variability found in common recommendations of agricultural pesticide labels. Each application rate and dosage was replicated five times to ensure statistical robustness.

2.6. Performance of Water and Chemical Measurement and Dosing

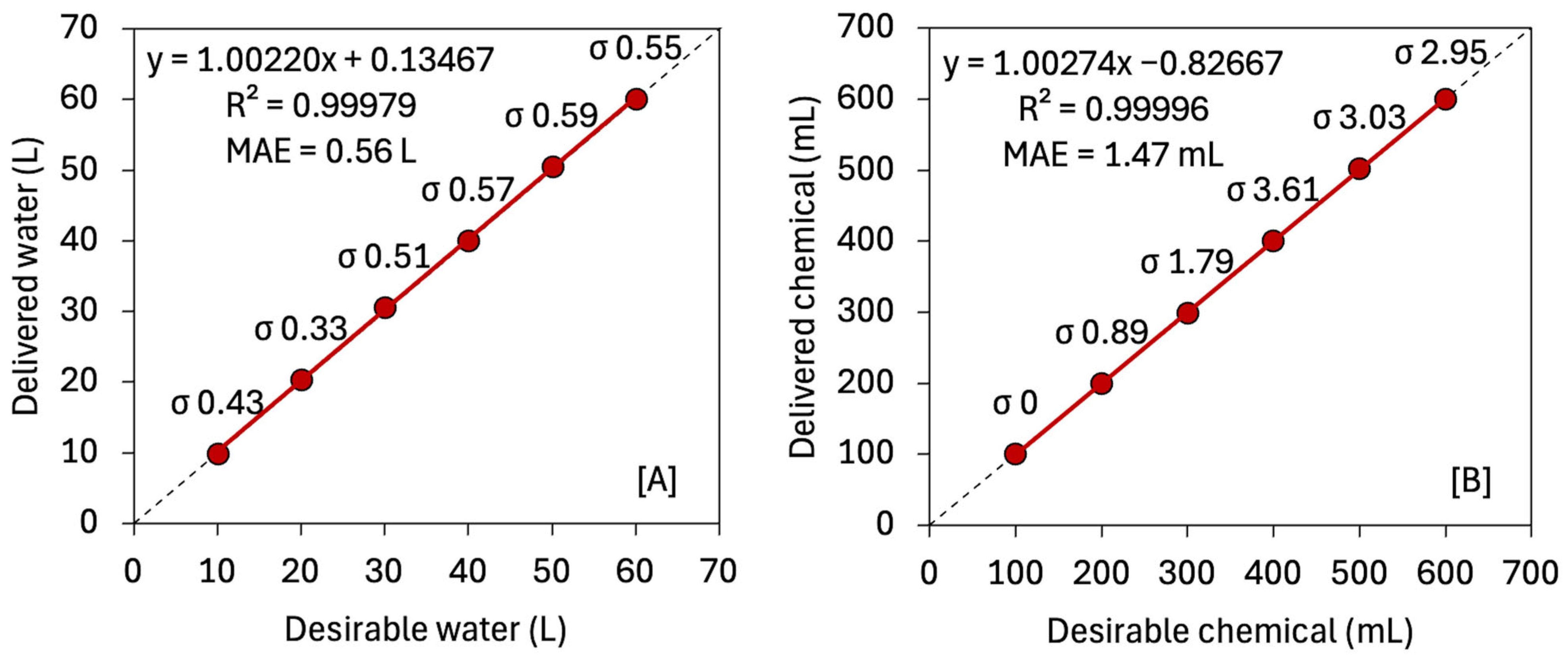

The results of the robotic system demonstrated high performance in delivering the desired amount of water and chemicals into the mixing tank (

Figure 5). When delivering water, the system proved to be both precise (R

2 > 0.99; SD = 0.33–0.59 L) and accurate (MAE = 0.21 L) (

Figure 5A). Overall, water delivery was consistent across all of the application rates. The same type of pump was used for both mixing and filling operations. Based on the pump’s real flow rate of 27 L/min, the times required to deliver 10, 20, 30, 40, 50, and 60 L were approximately 22 s, 44 s, 1 min 7 s, 1 min 29 s, 1 min 51 s, and 2 min 13 s, respectively. Conversely, when delivering the chemicals, the system also showed high effectiveness, with R

2 > 0.99, SD < 3.61, and MAE = 0.93 mL (

Figure 5B). The chemical pumps exhibited a trend of increasing variability at higher dosage levels. At higher volumes, these pumps can suffer elasticity and fatigue of the silicone tubing and micro-slippage between the rollers, which can lead to subtle inconsistencies in the conversion of rotation into flow. However, the increased variation remained below 1%.

In addition to dosage analysis, we conducted a comparative study on time efficiency, focusing on the following two key processes:

- (i)

Chemical rate calculation using the conventional manual method versus the robotic system via the mobile app.

- (ii)

Chemical dosing using traditional tools (e.g., graduated cylinder) compared to the automated robotic system. To ensure consistency and reduce bias, five independent and experienced individuals were assigned to perform the manual calculations and measurements.

Regarding the time required to calculate and measure chemical dosages between the proposed platform and hand-performed operations, the robotic system was, on average, 9.3 times faster than manual calculation (

Figure 6A). For example, manually calculating the chemical dosage for a specific field took an average of 3 min. In contrast, using the mobile app, the results were generated instantly, with the only time required being the user’s input, which averaged only 20 s. Additionally, the robotic system also outperformed the manual methods in measuring and delivering chemical dosages (

Figure 6B). In a test involving the measurement of 420 mL using the chemical pumps, the robotic system completed the task twice as fast as manual measurement.

3. System Insights and Final Considerations

3.1. Proposed System

In this study, we proposed to design and implement an automatic mixing and refilling platform mounted on a ground-based robotic system to support spraying drone applications. The system integrates hardware and software components to automate critical steps in the drone spraying process. Such steps involve transporting the drone along with all necessary spraying components, preparing the application mixture, and serving as a platform for drone takeoff and landing directly on it. Additionally, we validated the system’s effectiveness by comparing its results against traditional manual methods. This approach demonstrated how ground-based robotic platforms can extend the functionality and operational efficiency of aerial spraying drones, a step toward collaborative robotics for these specific operations. To the best of our knowledge, this represents a novel approach and a pioneering solution aimed at supporting small farms and experimental research fields, for whom large-scale commercial field systems are often financially and logistically inaccessible. By offering a functional, low-cost, and adaptable alternative, the proposed platform addresses real-world challenges in drone-based spraying operations, including reduced manual labor, improved accuracy in chemical preparation, and enhanced operational efficiency.

3.2. Contribution to Small Farms and Precision Agriculture

Small farms represent a substantial portion of global food producers, yet they frequently lack access to advanced agricultural technologies [

1,

27]. By combining mobility, automation, and user-friendly control via a mobile app, our system supports small farm owners to improve productivity and safety, while contributing to broader goals of food security, economic resilience, and sustainable land management. Mobile-app-based solutions are increasingly being developed and recommended as effective tools to facilitate technology adoption among farmers [

28,

29,

30]. In our study, for instance, the mobile app serves as an in-pocket solution that allows users to easily configure spraying parameters. Overall, our system supports field-level precision agriculture without demanding extensive technical expertise from the operator. Moreover, this development introduces these technologies within a co-robotic concept. It serves as a valuable asset for agricultural tasks and has been highlighted as a direction to facilitate robot adoption, primarily by significantly reducing labor [

7] and improving overall efficiency [

15,

17].

3.3. Evaluation of System Performance and Impact

Our results have demonstrated that the robotic system accurately and precisely delivered the desired amount of water and chemicals into the mixing tank, eliminating the need for human intervention and minimizing subjectivity. Furthermore, the system outperformed traditional manual methods in terms of speed. More importantly, the system presents potential social, environmental, and economic impacts.

Socially, it can reduce human exposure to hazardous chemicals, particularly during the automatic measurement and mixing processes, steps identified as primary sources of chemical exposure [

31].

Environmentally, it minimizes chemical waste and contamination, supports cleaner disposal practices, and contributes to sustainable chemical use.

Economically, it potentially lowers costs from chemical overuse and waste, increases operational efficiency and precision, and reduces expenses related to health and environmental impacts.

All of these impacts are aligned with the United Nations (UN) Sustainable Development Goals (SDGs) and the Environmental Protection Agency (EPA) Endangered Species Act and Pollinator Protection Actions.

3.4. Levels of Collaboration: Robot–Drone–Human

This study demonstrates two distinct forms of collaboration, as follows:

Robot–drone collaboration: The ground robotic platform autonomously prepares the application mixture and facilitates safe takeoff and landing for the drone.

Robot–human collaboration: A human operator interacts with the system through a mobile app, inputting parameters such as field area, application rate, and chemical dosages. The robotic system then executes the mixing and refilling tasks without manual intervention.

Although the drone operates independently during spraying, the interaction cycle between the drone and robot, through landing, refilling, and takeoff, demonstrates a practical form of asynchronous robotic collaboration.

3.5. Technical and Operational Advantages over Existing Systems

Most existing drone spraying operations rely heavily on manual processes for chemical mixing, dosage measurement, and refilling, often requiring skilled labor and increasing operator exposure to hazardous substances. While recent studies have explored systems for automating the mixing and preparation of application mixtures [

32,

33], our work advances the field by delivering a fully integrated platform that extends beyond mixture preparation. The proposed system demonstrates strong practical applicability by automating multiple stages of the spraying workflow, including transportation, chemical preparation, and drone support within a user-friendly interface. This combination of operational robustness and ease of use highlights the system’s potential for real-world deployment, particularly in small-scale and research-based agricultural settings. Although the platform was purposefully developed to support drone-based spraying applications, its modular and flexible design allows it to be easily adapted for use with conventional field sprayers, autonomous ground sprayers, and other similar systems. Furthermore, many commercial support platforms are either highly costly, not portable, or lack flexibility for use in small-scale or research farms, and do not account for smart control systems. Furthermore, our results have demonstrated that the system accurately and precisely prepares the application mixtures as intended. Since the platform is stationary and not required to navigate field terrain during the spraying task, its performance is robust across both controlled and real-world environments, unaffected by ground conditions, crop type, or field layout. In short, our system provides the following:

Automated chemical preparation: Reducing human error and exposure by automating water and chemical measurement.

Mobile app integration: Offering a user-friendly interface that simplifies operation without the need for advanced technical training.

Modular, low-cost design: Making advanced automation more accessible to smallholder farmers and research environments.

3.6. Limitations of the Current System

We acknowledge the following limitations of the current implementation:

Manual drone refilling: Although the ground robot automates the mixture preparation and delivers it to a static tank, the actual transfer of the mixture into the drone is not yet automated. This step still requires human intervention and limits full autonomy.

Real-time communication between agents: The current system operates asynchronously, meaning that the ground robot and drone do not exchange data during the spraying mission.

Stationary operation: The robot currently operates in a fixed location and cannot navigate autonomously in the field while the drone is operating. This restricts the system’s operational range and adaptability.

Arduino-based programming architecture: There are limits to scalability, processing capacity, and integration with more advanced sensors or communication protocols.

User interruption or power failure: The system does not support error recovery for hardware faults. In case of user interruption or power failure, the system defaults to a safe state (all pumps off), and operations must be reinitiated.

3.7. Future Research

To further enhance automation, future studies will incorporate a robotic arm to automate the drone filling and refilling process. This addition will complete the automation loop and also eliminate the need for human involvement in these tasks, thereby increasing safety and operational efficiency. Additionally, a built-in display on the platform will provide an alternative interface to the mobile app, increasing accessibility for users in the field. Furthermore, for broader deployment in commercial or research environments, a more robust operational system will be implemented. Moreover, future versions will implement non-volatile memory logging and improved fault detection. Ultimately, the system is envisioned to become fully autonomous, capable of navigating the field and coordinating directly with the drone to optimize mission planning and battery management. Certainly, this step will require further communication and coordination between the collaboration robot and the drone [

34].

3.8. Conclusions

This study represents a substantial contribution to the advancement of agricultural robotics by demonstrating a practical, low-cost option and a step toward collaborative robotics. The main finding of this work lies in the development, integration, and operational feasibility of the proposed platform, highlighting its value as a functional and adaptable solution for real-world spraying applications. It opens new possibilities for efficient and safe spraying operations, particularly in small-scale and research farming environments, and lays the groundwork for future developments in co-robotic systems designed to meet the evolving challenges of precision agriculture.