Effective Bulk Modulus in Low-Pressure Pump-Controlled Hydraulic Cylinders

Abstract

1. Introduction

2. Materials and Methods

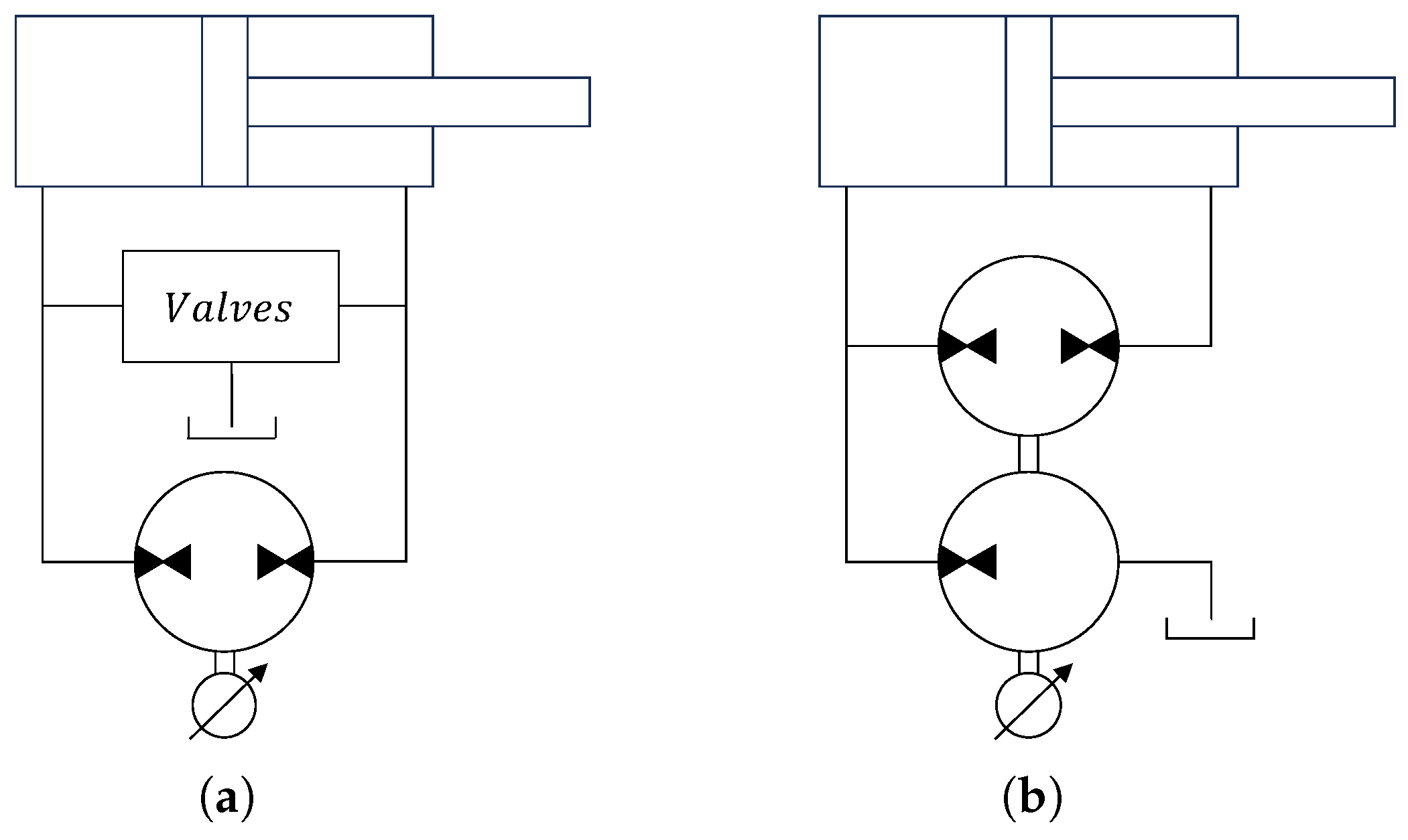

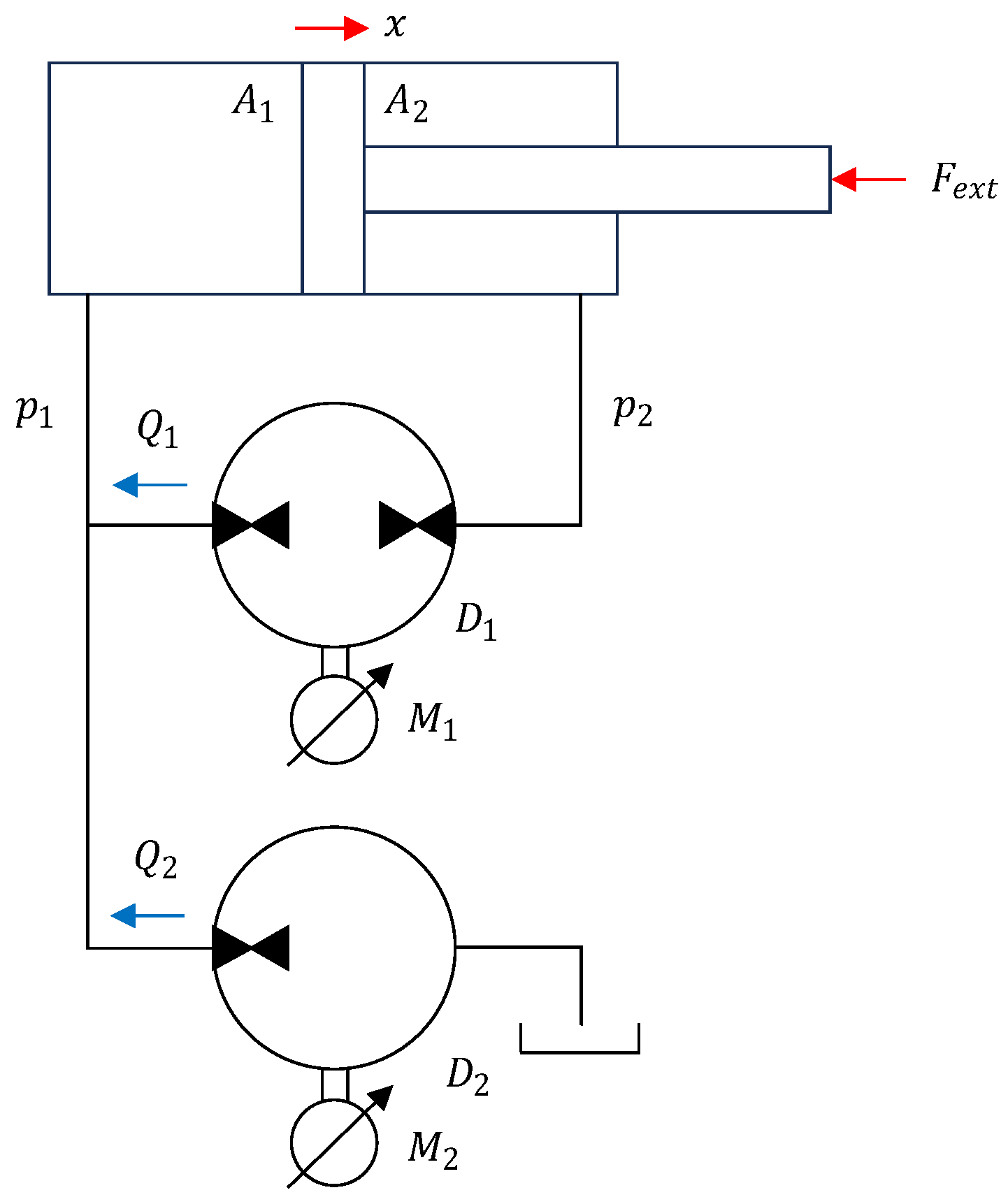

2.1. Experimental Test-Rig

2.2. Methodology

- Establish an LTI model of the system.

- Record the system’s response to a small-stroke (low-amplitude) step signal with the minimum external force acting on the cylinder.

- Perform parameter identification for this operating point (bulk modulus, pump leakage, and viscous friction).

- Assume this operating point is the worst-case with respect to stability (i.e., the lowest occurring leakage).

- Design a feedback controller with low stability margins (e.g., a phase margin of less than 40 degrees) for this operating point.

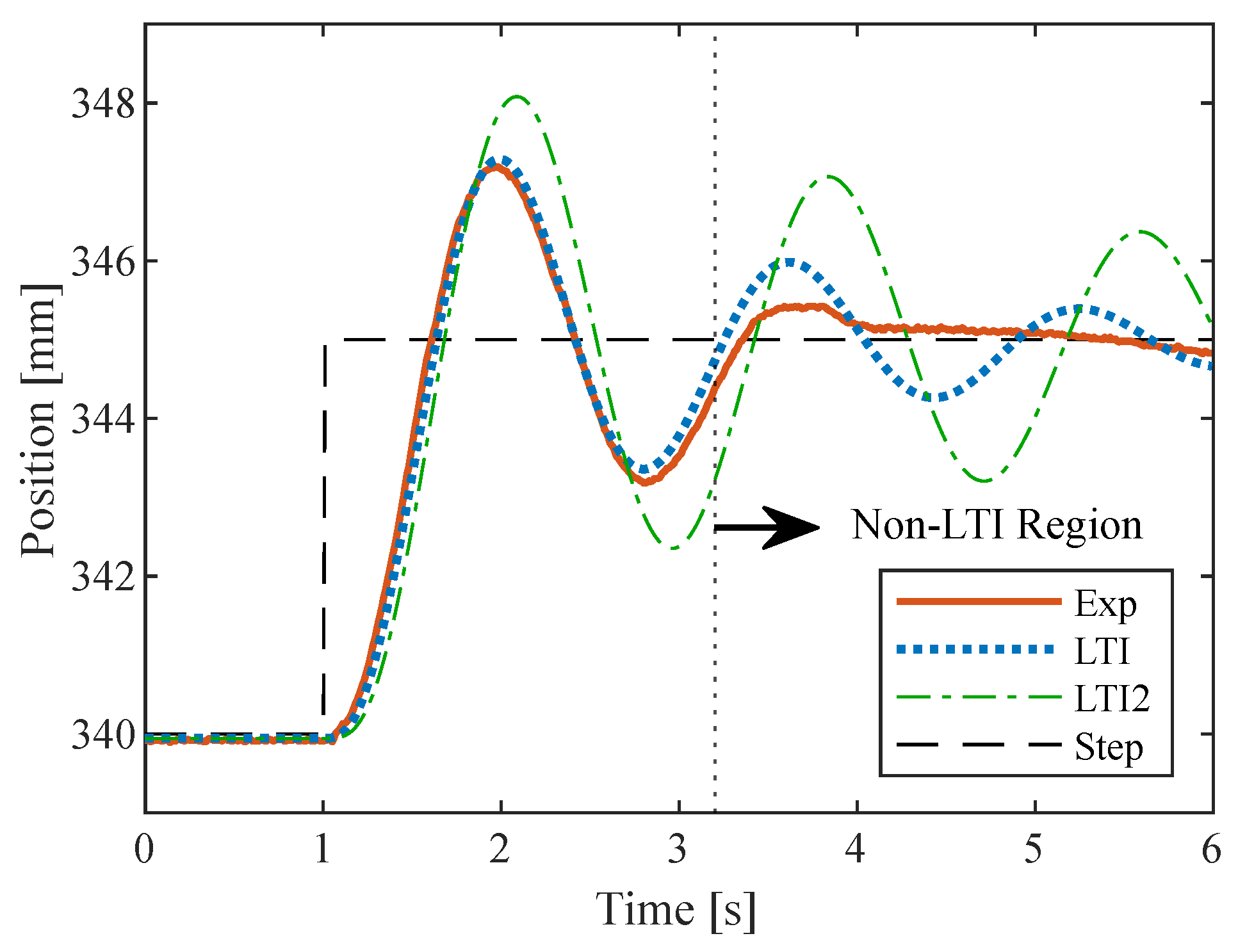

- Investigate if the system remains stable for large-stroke signals.

- A step signal is designed according to the aforementioned guidelines.

- A proportional controller sufficiently large to produce a pronounced overshoot of the system is implemented.

- The step response of the system is recorded, referred to henceforth as the identification set.

- A parameter optimization routine is utilized to determine the value of the effective bulk modulus (and possibly other uncertain parameters) by comparing the experimental response with that of the LTI model.

2.3. Modeling

2.3.1. Linear Time-Invariant Model

2.3.2. Leakage Model

2.3.3. Block Diagram and Transfer Function

- For SISO LTI analysis in the frequency domain, a numerical transfer function is obtained by using the block diagram of Figure 4 after entering numerical values for each parameter utilizing MATLAB R2021b ’s linmod command. For open-loop frequency responses, the lowest feedback branch in Figure 4 is removed.

- For time-domain simulation (step responses), the block diagram of Figure 4 is utilized with the addition of the sum pressure control loop. The simulations are executed in Simulink, and the results are exported to MATLAB’s workspace for post-processing.

2.3.4. Parameters

2.4. Parameter Identification

2.4.1. Electric Drive

2.4.2. Identification and Validation Data

2.4.3. Leakage Identification

2.4.4. Grid Search Optimization

- A lower and upper bound are defined for each unknown parameter, resulting in a continuous range.

- The continuous range is then discretized for each parameter.

- Using the discretized range for each parameter, all possible combinations of the parameters (referred to as the grid) are then simulated, and the results are recorded and compared to the experimental data.

- 1·1·

- 1·1·

- ··

- ·

- ·

- ·

3. Results

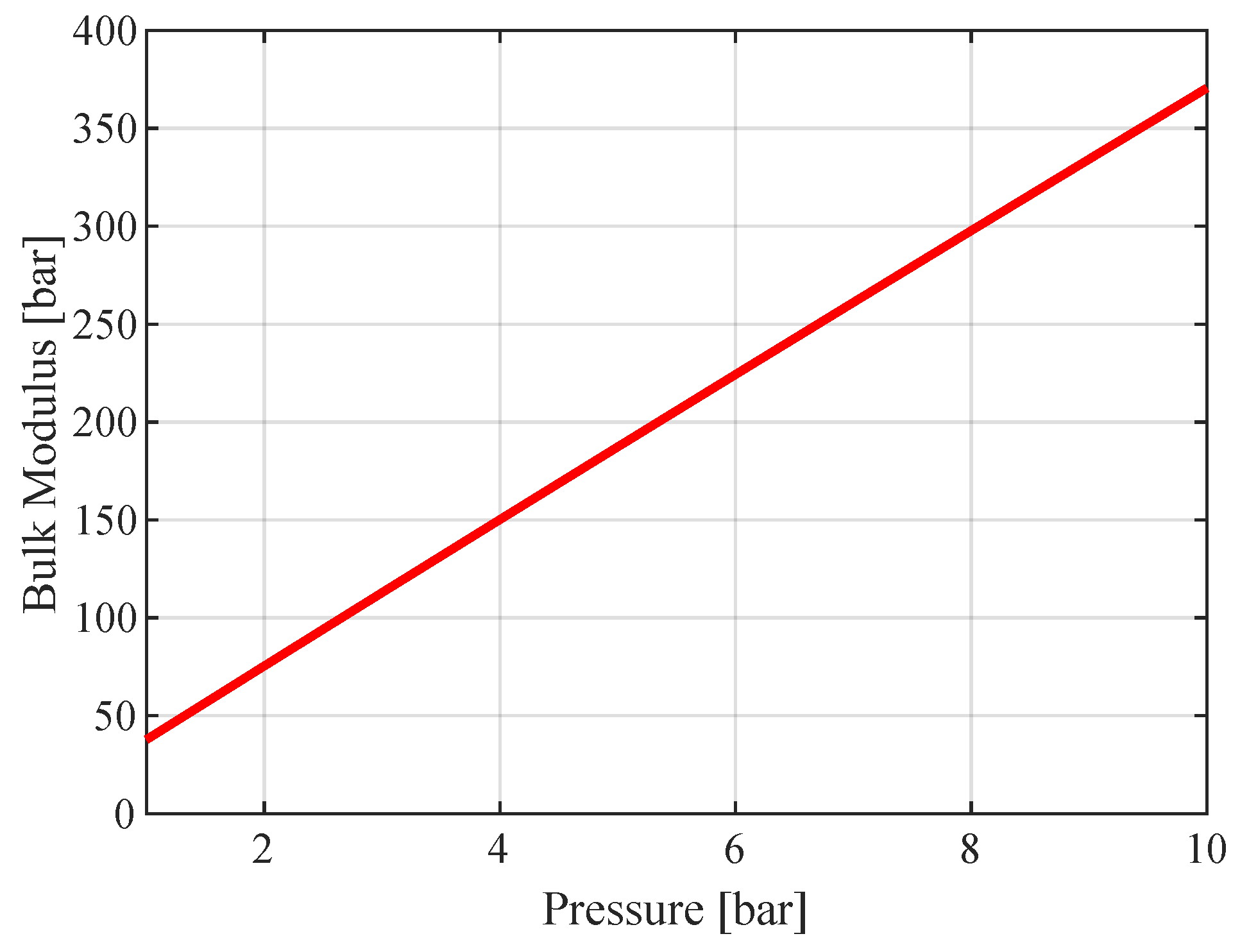

3.1. Bulk Modulus

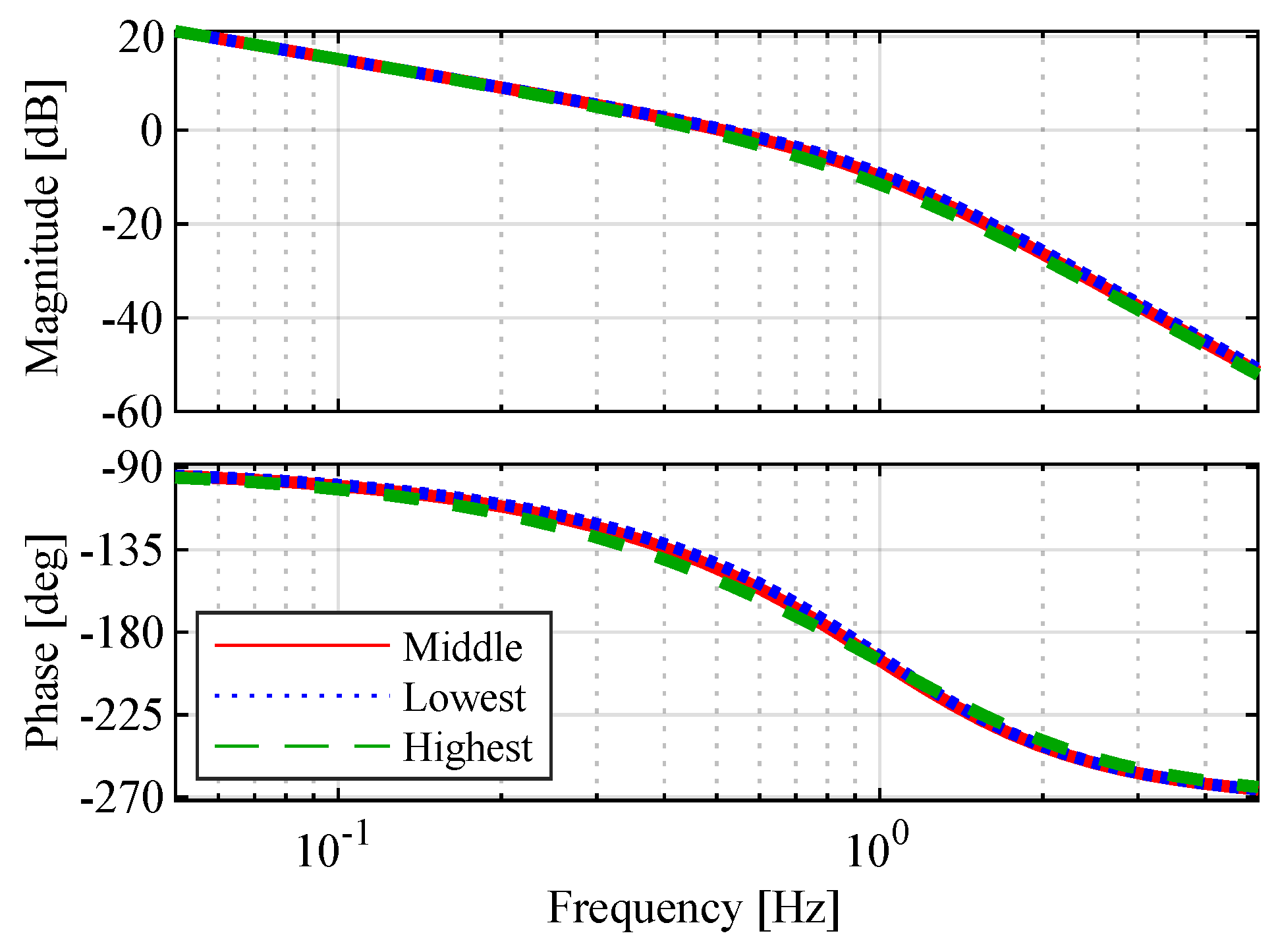

3.2. Resonance and System Damping

3.3. Feedback Control Design

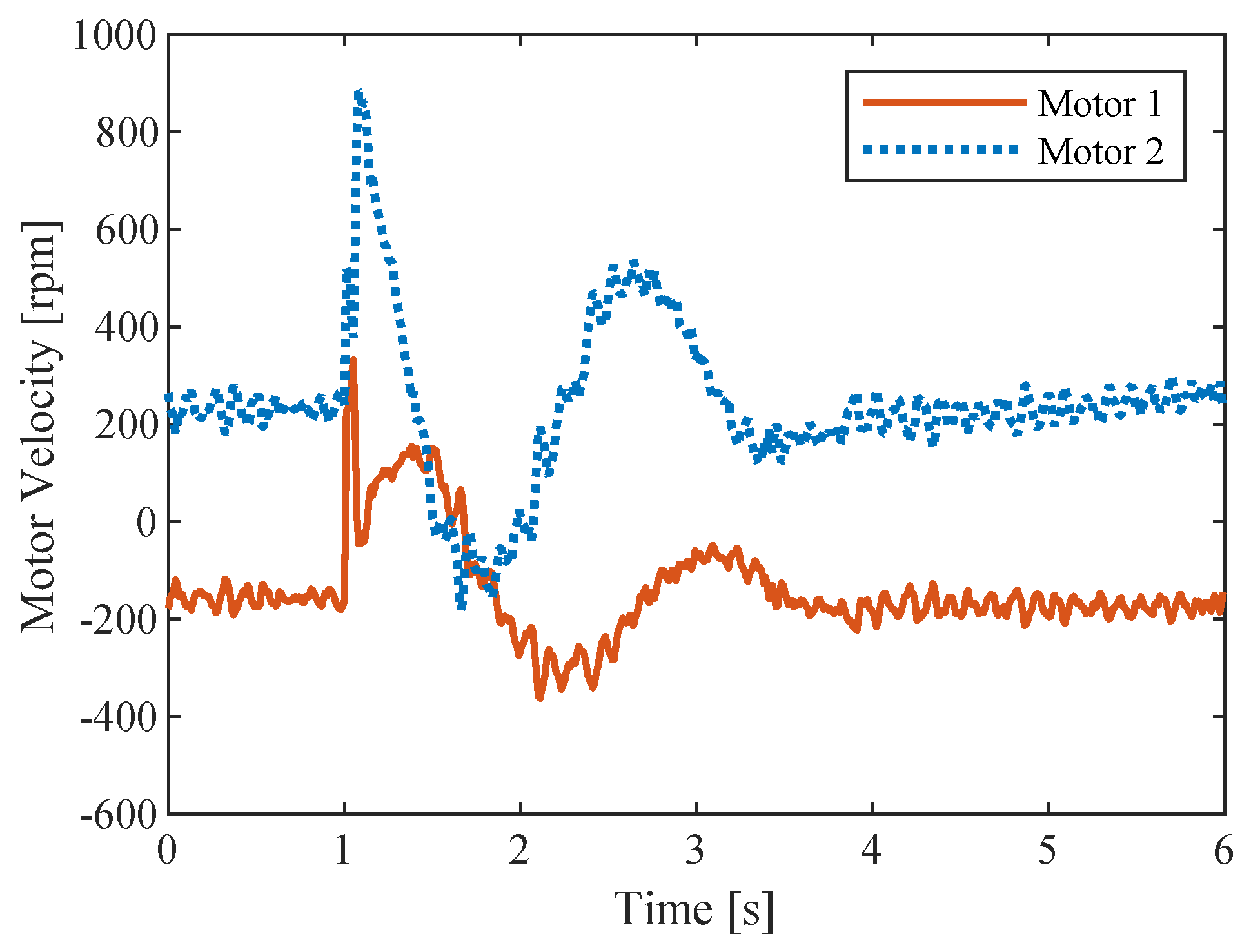

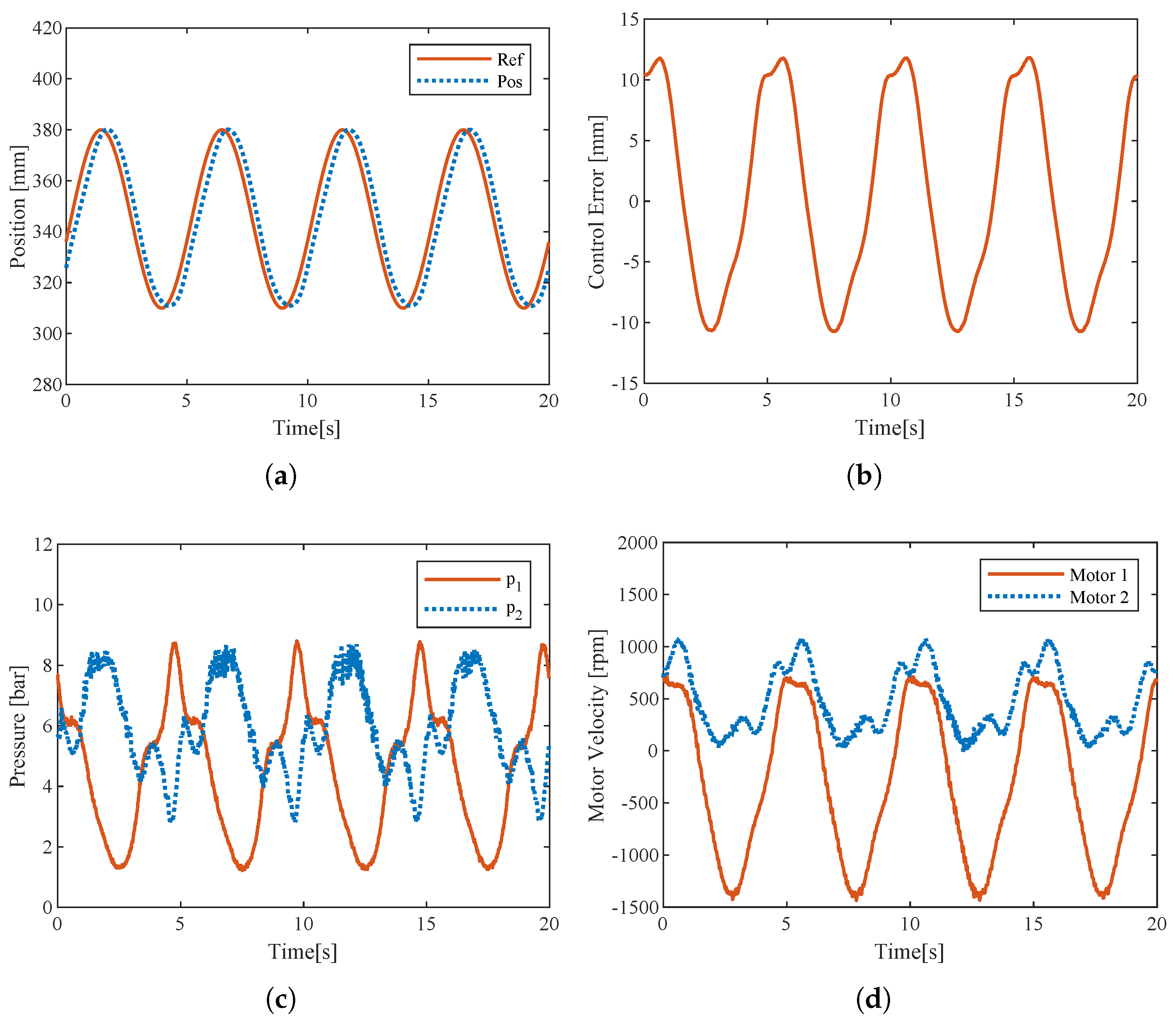

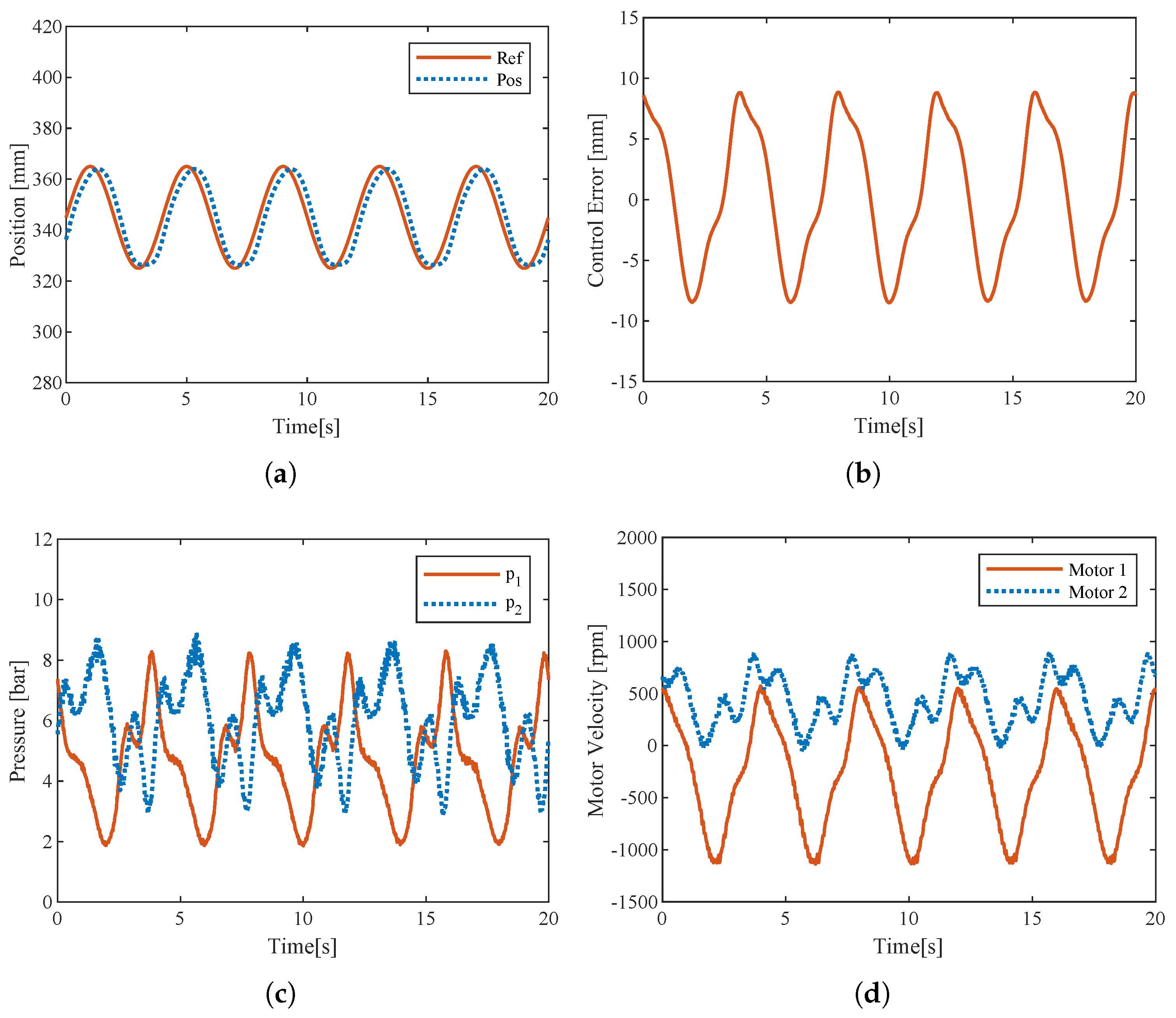

3.4. Performance Under Feedback Control

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| DPM | Dual Prime Mover |

| LTI | Linear Time-Invariant |

| MIMO | Multiple-Input Multiple-Output |

| SISO | Single-Input Single-Output |

References

- Michel, S.; Weber, J. Electrohydraulic Compact-drives for Low Power Applications considering Energy-efficiency and High Inertial Loads. In Proceedings of the 7th FPNI PhD Symposium on Fluid Power, Reggio Emilia, Italy, 27–30 June 2012; pp. 1–18. [Google Scholar]

- Michel, S.; Weber, J. Energy-efficient electrohydraulic compact drives for low power applications. In Proceedings of the ASME/BATH, Bath, UK, 12–14 September 2012; pp. 12–14. [Google Scholar]

- Merritt, H.E. Hydraulic Control Systems; John Wiley and Sons: New York, NY, USA, 1967. [Google Scholar]

- Manring, N.D.; Fales, R.C. Hydraulic Control Systems; John Wiley and Sons: New York, NY, USA, 2019. [Google Scholar]

- Long, Q.; Neubert, T.; Helduser, S. Principle to closed loop control differential cylinder with double speed variable pumps and single loop control signal. In Proceedings of the Fourth International Symposium on Fluid Power Transmission and Control (ISPP’ 2003), Wuhan, China, 28 August 2003. [Google Scholar]

- Padovani, D.; Ketelsen, S.; Hagen, D.; Schmidt, L. A self-contained electro-hydraulic cylinder with passive load-holding capability. Energies 2019, 12, 292. [Google Scholar] [CrossRef]

- Jarf, A.; Minav, T.; Pietola, M. Nonsymmetrical flow compensation using hydraulic accumulator in direct driven differential cylinder application. In Proceedings of the 9th FPNI PhD Symposium on Fluid Power, Florianópolis, Brazil, 26–28 October 2016; Volume 50473. [Google Scholar]

- Goytil, P.H.; Padovani, D. Motion control of large inertia loads using electrohydrostatic actuation. In Proceedings of the 2020 IEEE 16th International Workshop on Advanced Motion Control (AMC), Kristiansand, Norway, 14–16 September 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 73–78. [Google Scholar]

- Hagen, D.; Padovani, D.; Choux, M. A Comparison Study of a Novel Self-Contained Electro-Hydraulic Cylinder Versus a Conventional Valve-Controlled Actuator—Part 1: Motion Control. Actuators 2019, 8, 79. [Google Scholar] [CrossRef]

- Long, Q.; Neubert, T.; Helduser, S. Differential cylinder servo system based on speed variable pump and sum pressure control principle. In Proceedings of the Fifth International Conference on Fluid Power Transmission and Control, Hangzhou, China, 3–5 April 2001; pp. 69–73. [Google Scholar]

- Gholizadeh, H.; Burton, R.; Schoenau, G. Fluid bulk modulus: Comparison of low pressure models. Int. J. Fluid Power 2012, 13, 7–16. [Google Scholar] [CrossRef]

- Goytil, P.H.; Padovani, D.; Hansen, M.R. A novel solution for the elimination of mode switching in pump-controlled single-rod cylinders. Actuators 2020, 9, 20. [Google Scholar] [CrossRef]

- Mommers, R.; Achten, P.; Achten, J.; Potma, J. Benchmarking the performance of hydrostatic pumps. In Proceedings of the 17th Scandinavian International Conference on Fluid Power, Linköping, Sweden, 1–2 June 2021; pp. 322–331. [Google Scholar]

- Ellis, G. Control System Design Guide: Using Your Computer to Understand and Diagnose Feedback Controllers; Butterworth-Heinemann: Oxford, UK, 2012. [Google Scholar]

- Goytil, P.H.; Padovani, D.; Hansen, M.R. On the energy efficiency of dual prime mover pump-controlled hydraulic cylinders. In Proceedings of the ASME/BATH 2019 Symposium on Fluid Power and Motion Control, Longboat Key, FL, USA, 7–9 October 2019; Volume 59339. [Google Scholar]

- Ketelsen, S.; Andersen, T.O.; Ebbesen, M.K.; Schmidt, L. A self-contained cylinder drive with indirectly controlled hydraulic lock. Model. Identif. Control 2020, 41, 185–205. [Google Scholar] [CrossRef]

- Caliskan, H.; Balkan, T.; Platin, B.E. Hydraulic position control system with variable speed pump. In Proceedings of the ASME 2009 Dynamic Systems and Control Conference, Hollywood, CA, USA, 12–14 October 2009; Volume 48920, pp. 275–282. [Google Scholar]

- Boes, C.; Helbig, A. Electro hydrostatic actuators for industrial applications. In Proceedings of the 9th International Fluid Power Conference, Aachen, Germany, 24–26 March 2014; pp. 134–142. [Google Scholar]

- Hagen, D.; Padovani, D.; Ebbesen, M.K. Study of a self-contained electro-hydraulic cylinder drive. In Proceedings of the 2018 Global Fluid Power Society PhD Symposium (GFPS), Samara, Russia, 8–20 July 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1–7. [Google Scholar]

- Zhao, W.; Bhola, M.; Ebbesen, M.K.; Andersen, T.O. A Novel Control Design for Realizing Passive Load-Holding Function on a Two-Motor-Two-Pump Motor-Controlled Hydraulic Cylinder. Model. Identif. Control 2023, 44, 125–139. [Google Scholar] [CrossRef]

- Costa, G.; Sepehri, N. Hydrostatic Transmissions and Actuators: Operation, Modelling and Applications; John Wiley and Sons: New York, NY, USA, 2015. [Google Scholar]

- Goytil, P.H.; Padovani, D.; Hansen, M.R. Linear Time-Invariant Modelling of Electrohydraulic Cylinders. In Proceedings of the 2022 International Conference on Electrical, Computer, Communications and Mechatronics Engineering (ICECCME), Maldives, 16–18 November 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 1–6. [Google Scholar]

| Parameter | Value | Unit |

|---|---|---|

| 63 | mm | |

| 36 | mm | |

| 0.1272 | dm3 | |

| 500 | mm | |

| 1600 | kgmm2 | |

| 600 | kgmm2 | |

| 34 | kgmm2 | |

| 1256.6 | 1/s | |

| 0.0012 | 1/s | |

| 314.1593 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gøytil, P.; Hansen, M.R.; Tvilde, H. Effective Bulk Modulus in Low-Pressure Pump-Controlled Hydraulic Cylinders. Actuators 2025, 14, 366. https://doi.org/10.3390/act14080366

Gøytil P, Hansen MR, Tvilde H. Effective Bulk Modulus in Low-Pressure Pump-Controlled Hydraulic Cylinders. Actuators. 2025; 14(8):366. https://doi.org/10.3390/act14080366

Chicago/Turabian StyleGøytil, Petter, Michael Rygaard Hansen, and Håkon Tvilde. 2025. "Effective Bulk Modulus in Low-Pressure Pump-Controlled Hydraulic Cylinders" Actuators 14, no. 8: 366. https://doi.org/10.3390/act14080366

APA StyleGøytil, P., Hansen, M. R., & Tvilde, H. (2025). Effective Bulk Modulus in Low-Pressure Pump-Controlled Hydraulic Cylinders. Actuators, 14(8), 366. https://doi.org/10.3390/act14080366