Abstract

Hydraulic excavators operate in harsh environments where direct measurement of actuator chamber pressures and boom displacement is often unreliable or infeasible. This study presents a novel control strategy that estimates actuator chamber pressures from work port pressures using differential equations, eliminating the need for direct pressure or position sensors. A fuzzy logic-based proportional–derivative (PD) controller is developed to mitigate boom oscillations, particularly under high-inertia load conditions and variable operator inputs. The controller dynamically adjusts gains through fuzzy logic-based gain scheduling, enhancing adaptability across a wide range of operating conditions. The proposed method addresses the limitations of classical PID controllers, which struggle with the nonlinearities, parameter uncertainties, and instability introduced by counterbalance valves and pressure-compensated proportional valves. Experimental data is used to design fuzzy rules and membership functions, ensuring robust performance. Simulation and full-scale experimental validation demonstrate that the fuzzy PD controller significantly reduces pressure overshoot (by 23% during extension and 32% during retraction) and decreases settling time (by 31.23% and 28%, respectively) compared to conventional systems. Frequency-domain stability analysis confirms exponential stability and improved damping characteristics. The proposed control scheme enhances system reliability and safety, making it ideal for excavators operating in remote or rugged terrains where conventional sensor-based systems may fail. This approach is generalizable and does not require modifications to the existing hydraulic circuit, offering a practical and scalable solution for modern hydraulic machinery.

1. Introduction

Mobile hydraulic machines, particularly hydraulic excavators, represent critical equipment in construction, mining, and agricultural industries, where they must operate reliably under extreme environmental conditions including high temperatures, vibrations, dust, and moisture exposure [1]. The harsh operating environments pose significant challenges for conventional sensor-based measurement systems, particularly when attempting to monitor actuator chamber pressures through direct sensor placement within hydraulic cylinders [2]. Traditional approaches requiring direct pressure measurement at actuator chambers often fail due to sensor vulnerability to environmental factors, leading to unreliable system performance and potential safety hazards [3,4,5].

The fundamental challenge in controlling mobile hydraulic machines lies in accurately estimating actuator chamber pressures without relying on sensors placed directly within the actuators themselves. Direct pressure measurement approaches are inherently problematic in mobile applications due to the exposure of sensors to harsh operating conditions, including extreme temperatures, shock loads, and contamination from hydraulic fluids [6,7]. The reliability issues associated with direct measurement systems necessitate alternative approaches that can maintain system performance while ensuring robust operation under adverse conditions [8].

Mobile hydraulic systems are characterized by complex nonlinear dynamics [9], time-varying parameters, and significant coupling between actuator motions [10,11,12]. These systems must handle varying load conditions while maintaining precise control, particularly for applications requiring high positioning accuracy such as excavator boom control [13]. The energy-storing capability of hydraulic fluids, combined with high inertia loads and discontinuous operator inputs, creates a propensity for system oscillations that can compromise both performance and stability [14].

Recent research has demonstrated significant advances in hydraulic system control through various methodologies. Conventional control approaches have traditionally relied on proportional–integral–derivative (PID) controllers, which, while robust and widely implemented, often struggle with the inherent nonlinearities and parameter uncertainties characteristic of hydraulic systems [15,16,17]. Sometimes, PID controllers are combined with mode-based controllers in a cascade control approach to enhance system stability [18]. The limitations of classical control techniques have motivated researchers to explore advanced control strategies that can better accommodate system complexities.

Fuzzy logic is a an approach to computing based on degree of truth [19]. Unlike traditional Boolean systems, fuzzy logic is similar to human thinking and reasoning. With the developments in control theory, fuzzy logic is employed in control systems [20,21,22] and the tuning of PID controllers [23,24,25]. The design processes of such PID controllers are discussed in [26]. Mohan and Sinha [27] discusses the stability analysis of such controllers. A Lyapunov-based stability analysis of fuzzy systems was carried out by Precup et al. [28].

With the introduction of powerful microprocessors, fuzzy control systems are employed for real-time control of electrohydraulic systems. Chen et al. [29] employed fuzzy control to improve the ride comfort of an automobile using a hydraulic actuator. Sivakumar et al. [30] also employed a fuzzy logic control for real-time control of hydraulically actuated active suspension and experimentally demonstrated the results. Position control of a hydraulic actuator was performed using a fuzzy logic controller, with fuzzification parameters optimized with the particle swarm technique in [31].

In this study, the chamber pressures of a hydraulic actuator are estimated indirectly from the work port pressures, which can be measured more reliably due to the robustness of hydraulic control valves under harsh operating conditions. These estimated pressures are then used in a set of differential equations to model the actuator dynamics. Undesired oscillatory behavior is filtered using a frequency-based approach and subsequently controlled with a fuzzy PD controller. Hydraulic machines operating under high-inertia loads are particularly susceptible to oscillations due to the compressibility of hydraulic fluids, variable load conditions, and discrete operator inputs. The presence of components like over-center valves (CBVs) and pressure-compensated proportional valves further adds to system instability. Conventional control methods are often inadequate due to the nonlinear and uncertain nature of such systems. To address these challenges, a nonlinear fuzzy logic-based PD controller with gain scheduling is proposed, which does not require modifications to the hydraulic circuit and is generalizable to similar machines. The approach avoids direct measurement of actuator pressures and positions, enhancing reliability. Experimental results are compared against a conventional control system, showing improved dynamic stability and reduced cost function values. This validates the effectiveness of the proposed control strategy in damping boom oscillations in hydraulic machines.

2. System Description

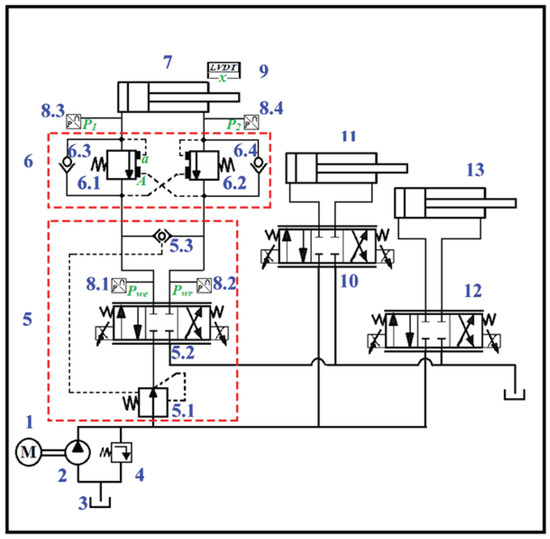

The hydraulic circuit of the system is illustrated in Figure 1. The fixed displacement hydraulic pump (2) is powered by an electric motor (1). The pump draws hydraulic fluid from the reservoir (3). The pressure relief valve (4) prevents over-pressurization of the circuit. A pressure-compensated proportional flow control valve (5) regulates the fluid flow to the boom actuator. The valve assembly includes a solenoid-actuated proportional flow control valve (5.2), a pressure compensator (5.1), and a shuttle valve (5.3).

Figure 1.

Hydraulic circuit of system.

The pressure at the extension work port of the flow control valve is denoted by , and the pressure at the retraction work port is denoted by . Dynamic pressures at both work ports are measured by pressure sensors (8.1) and (8.2). The proportional flow control valve is a solenoid-actuated, closed-center, electrical position feedback type, connected to a computer running LabVIEW. A cRIO controller is used to transmit the control signals generated by the computer to the servo valve.

The dual-acting counterbalance valve (6), which includes counterbalance valves (6.1) and (6.2), prevents load overrunning during negative loading conditions and ensures leak-tight holding of the load. The pilot area ratios of (6.3) and (6.4) correspond to one-way valves that permit unidirectional fluid flow only. Pressure sensors (8.3) and (8.4) are installed in both chambers of the hydraulic cylinder (7) for measuring and logging the dynamic pressures, denoted by and , respectively.

A Linear Variable Differential Transformer (LVDT) (9) is used to measure the position of the actuator. The linear actuators (11) and (13) are controlled by proportional flow control valves (10) and (12), respectively. Details of the components used in the experimental setup are listed in Table 1, and the system parameters are provided in Table 2. The hydraulic system used for experimentation is shown in Figure 2.

Table 1.

Components of hydraulic system.

Table 2.

System parameters.

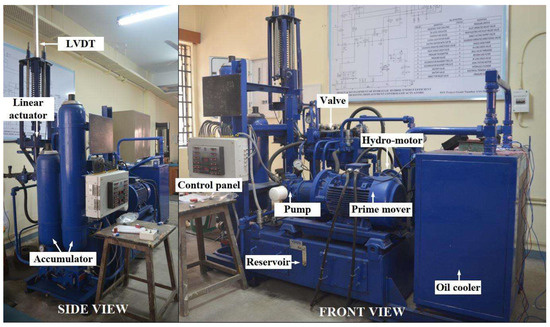

Figure 2.

Experimental setup.

3. Mathematical Modeling

The following assumptions are considered for developing the mathematical model of the system:

- Change in system parameters with temperature variation is not considered.

- Fluid inertia is not considered.

- Friction present in the proportional valve spool is neglected.

- Internal leakage in the proportional valve spool is neglected.

- The dynamics of the check valve and shuttle valve are neglected.

- The dynamics of the pressure compensator are neglected.

- There are no external leakages in the system.

For applications where a constant flow rate is required for a given control signal despite drastic pressure fluctuations, a pressure compensator is introduced to maintain a constant pressure drop across the orifice. The pressure drop across the proportional valve is determined by the pressure compensator setting

where is the pressure setting of the spring attached to the pressure compensator. The flow across the valve is given by

Here, is the density of the fluid and is proportional to , the input signal to the flow control valve solenoid, which is determined by the input current. The spool of the flow control valve is modeled as a second-order system, with spool displacement in the frequency domain expressed as

where and are the natural frequency and damping ratio of the valve, obtained from the manufacturer’s datasheet, and is the command signal.

3.1. Counterbalance Valve

The boom actuator includes two counterbalance valves (CBVs), one on the piston side and one on the rod side. CBVs prevent load overrunning during lowering and ensure leak-tight load holding in the event of hose failure. The flow from the valve side to the actuator side goes through a check valve; its dynamics are neglected.

For retraction, the force balance on the CBV (3.1) gives

Defining the area ratio , we have

where is the spring pressure of the CBV. The cracking pressure required to start valve opening is , and the pressure for full valve opening is . The CBV behavior is defined as

When and , the CBV acts like a relief valve. The cracking pressure is set higher than the allowable load pressure. Due to system stability concerns, CBVs are not ideal relief valves.

Flow through the CBV (from the actuator to valve side) is given by

where is the dimensionless valve opening

3.2. Linear Hydraulic Actuator

The force balance on the cylinder yields

where is the equivalent inertia of the boom and load, and is the total friction force.

The piston side flow equation is

Leakage flow is the sum of internal and external leakages:

For the rod side,

where

External leakage is neglected in this analysis. Internal leakage is not typically apparent until severe piston seal damage occurs, but it can be quantified experimentally.

Since the proportional valve uses a pressure compensator, the flow is load-independent and given by

Neglecting the pressure drop across the check valve during extension,

The pressure in the rod side is

The change in the volume of the chamber is calculated by differentiating the actuator position signal. Low-pass filtering is applied to reduce sensor noise.

4. Estimation of Actuator Dynamics from Work Port Pressures

In the experimental setup, the actuator chamber pressures were directly measured using pressure transducers installed near the actuator. However, in practical applications, such as hydraulic load-handling equipment operating in harsh environments, installing sensors on the boom actuator is often unreliable. Therefore, this section presents a method to estimate actuator chamber pressures from work port pressures and , and subsequently compute actuator dynamics using the estimated pressures.

4.1. Estimation of Actuator Chamber Pressures from Work Port Pressure Measurements

4.1.1. Case 1: Actuator Extension/Retraction

When the actuator is extending (), the pressure is related to as

Once the flow through the proportional valve is calculated using Equations (1) and (2), Equation (19) becomes

Here, is the flow resistance offered by the one-way valve, and is the hydraulic resistance offered by the extension-side transmission lines. Both values are determined experimentally.

During extension, the rod-side chamber pressure is estimated using the pressure build-up equation:

where

- is the initial rod-side pressure at the beginning of extension;

- is the effective bulk modulus of fluid in the rod-side chamber.

During retraction (), the rod-side chamber pressure is given by

where is the one-way valve resistance and is the transmission line resistance on the retraction side.

The piston-side pressure is then estimated using

4.1.2. Case 2: Stopping After Extension/Retraction ()

When the actuator stops after an extension, its inertia may continue extending the cylinder momentarily. The fluid in the extension-side transmission lines continues to flow into the piston-side chamber, causing pressure build-up. With zero input flow, the piston-side pressure is

During this phase, the CBV on the retraction side remains fully open due to high pilot and chamber pressures, and the rod-side pressure is

Similarly, when the actuator stops after retraction, the inertia and gravitational forces promote continued retraction, pressurizing both chambers. Both CBVs open fully, and pressures can be approximated as

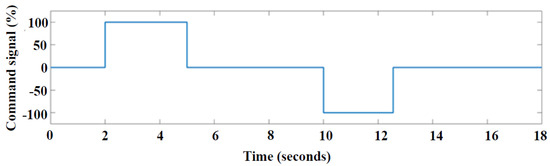

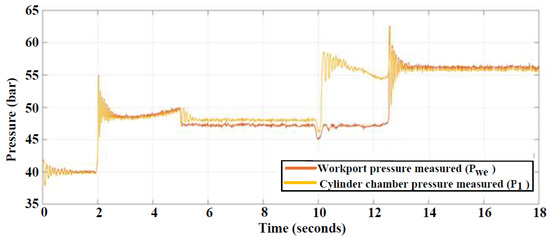

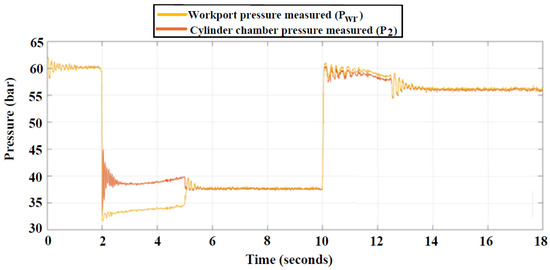

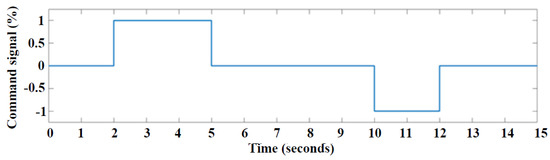

The extension work port pressure and piston side pressure for the command signal in Figure 3 are shown in Figure 4. The retraction work port pressure and rod side chamber pressure are illustrated in Figure 5.

Figure 3.

Command signal.

Figure 4.

and pressure graphs.

Figure 5.

and pressure graphs.

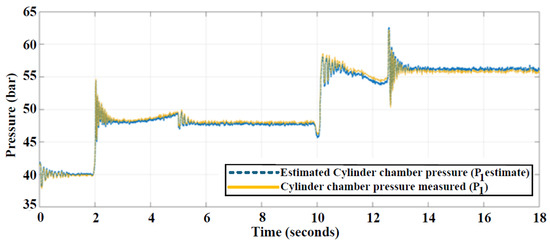

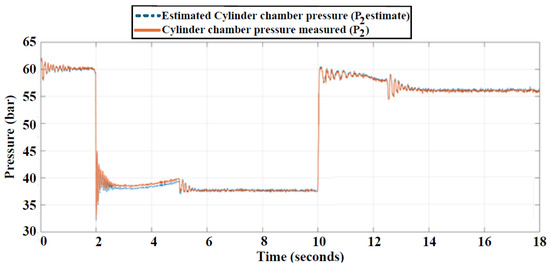

The estimated and measured piston-side and rod-side chamber pressures are shown in Figure 6 and Figure 7.

Figure 6.

and pressure graphs.

Figure 7.

and pressure graphs.

4.2. Estimation of Actuator Dynamics from Chamber Pressure Measurements

The general form of the pressure build-up equations for the actuator chambers can be written as

The chamber volumes are given by

Substituting Equations (30) and (31) into the pressure rate equations yields the following differential equations with chamber pressure and actuator position

The actuator position can be estimated by solving either of these equations depending on which chamber pressure estimate is more accurate. The initial condition is taken as , which is valid for machines like excavators where actuators are fully retracted before shutdown as a safety measure. The estimated actuator position is denoted as .

The actuator velocity considering fluid compressibility is given by

4.3. Estimation of Undesired Actuator Oscillations

The ideal position of the actuator in the absence of oscillations can be written as a function of the input command and the maximum flow rate:

where

Undesired actuator oscillations are represented by the difference between the ideal and estimated actuator positions:

The objective of the controller is to minimize this error.

5. Controller Design

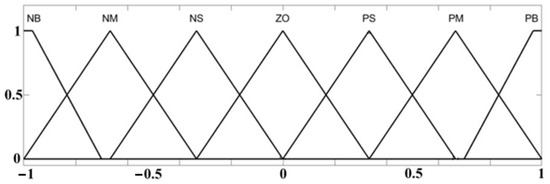

In this work, a novel fuzzy gain-scheduled PD controller is used where the PD parameters are tuned online using a fuzzy rule base. The rules are derived from the data collected from experiments. The inputs for the fuzzy controller are the position error and its time derivative , and the outputs are the P and D gain values.

The proposed control system is designed to improve dynamic stability by reducing boom oscillations, ensure fast response to inputs, and maintain robustness against disturbances like variable loads and operator actions. It also aims to minimize cost function balancing tracking errors and control effort.

In this particular experiment, the I gain of the controller is set to zero because we are not concerned with steady-state error.

The dynamic ranges of and are determined by operating the actuator at different input signals, actuator positions, and under maximum load conditions. The ranges of

are normalized to a scale of . The normalized values are denoted by and , respectively.

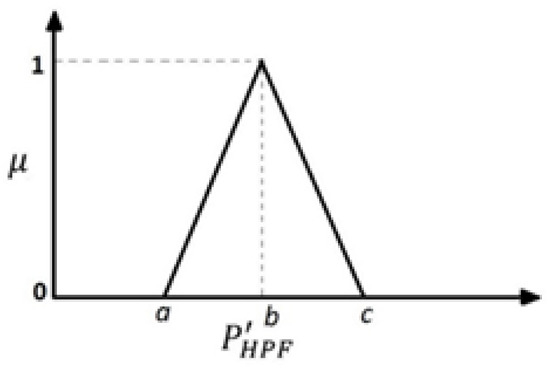

Let be the fuzzy set for and be the fuzzy set for . The membership functions of these fuzzy sets are shown in Figure 8. Triangular and logarithmic membership functions are used for the fuzzy input and output, respectively.

Figure 8.

Graph of membership functions and .

- : High-pass-filtered position error;

- : Time derivative of the error;

- : Normalized position error, ;

- : Normalized derivative of error, .

Fuzzy Linguistic Variables:

- NB: Negative Big;

- NM: Negative Medium;

- NS: Negative Small;

- ZO: Zero;

- PS: Positive Small;

- PM: Positive Medium;

- PB: Positive Big.

The fuzzy set for is defined as

where represents the membership level of in the set .

Similarly, the fuzzy set for is defined as

For a triangular membership function as shown in Figure 9, the membership value is given by

Figure 9.

Triangular membership function.

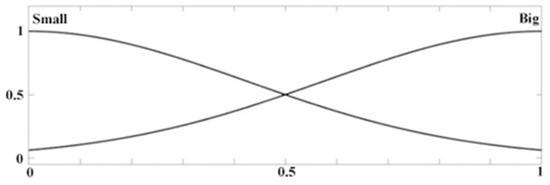

The fuzzy sets for and are denoted by and , where and are the normalized values of and , respectively. They are given by

and are characterized by the membership functions shown in Figure 10, and their membership values can be written mathematically as

Figure 10.

Membership function of and .

The values of and are obtained by calculating the values of and from fuzzy rules, as shown in Table 3 and Table 4, respectively.

Table 3.

Fuzzy rules for .

Table 4.

Fuzzy rules for .

If is and is , then is and is , where .

The truth value of the th rule is obtained by the product of the membership function values as

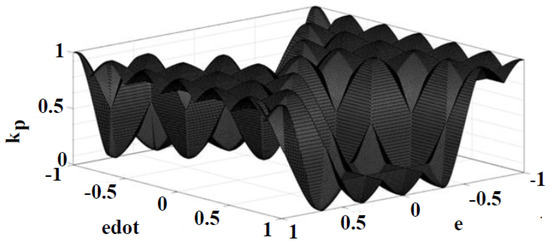

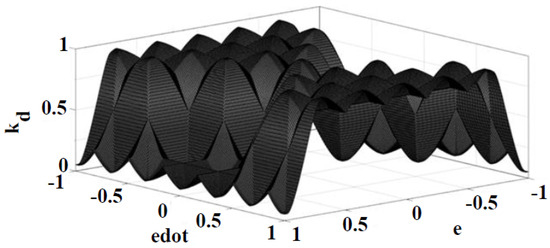

Using the above rules, the fuzzy surfaces for and are shown in Figure 11 and Figure 12, respectively.

Figure 11.

Relationship between inputs error (e) and rate of change of error (edot) for fuzzy controller.

Figure 12.

Relationship between inputs error (e) and rate of change of error (edot) for fuzzy controller.

6. System Stability

In hydraulic systems, especially in load-handling machines where humans operate in close proximity, the stability of the control system for the hydraulic actuator is critically important from a safety perspective. The controller must be capable of generating the necessary flow to counteract pressure fluctuations promptly and with minimal fluctuations in boom velocity.

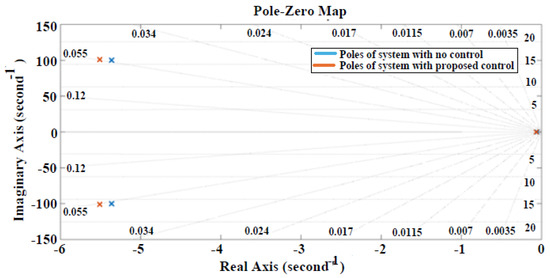

Here, the pole-zero locations of the conventional system are compared with the system using active damping control when the actuator is brought to a stop after motion. And the method demonstrates that the introduction of closed-loop control does not lead to any stability concerns and improves machine dynamics, as evidenced by the shift in pole locations.

To analyze the stability of the fuzzy gain-scheduled PD controller at a particular operating point using frequency-domain methods, the system is linearized. The pole-zero plot of the conventional system and the system with the proposed method, with a command signal step input, is shown in Figure 13. Here, is the system input and boom velocity is the output.

Figure 13.

Pole-zero plot of system with and without proposed control.

All poles lie in the left half of the S-plane, and there are no repeated zeros at the origin. Furthermore, with the implementation of the proposed control, the system dynamics have improved, as explained in Table 5. Using the proposed method, it can be shown that the system remains stable across all combinations of variables.

Table 5.

Comparison of dominant poles of the system with and without control.

The stability analysis demonstrates that the fuzzy gain-scheduled PD controller not only ensures system stability but also actively enhances dynamic performance in safety-critical hydraulic machinery. Furthermore, the controller achieves a significant enhancement in the real-pole decay rate, which is proportional to the real part of the pole. This enables faster suppression of pressure fluctuations and smoother actuator transitions, thereby reducing mechanical jerking. Crucially, the controller maintains system bandwidth, illustrating its ability to improve damping without compromising high-frequency stability, thus resolving the classic trade-off between fast response and robustness. Stability is further evidenced by deeper left-half plane (LHP) pole placement, offering an increase in the stability margin and ensuring consistent stability across all operational conditions, including varying load profiles.

7. Results and Discussions

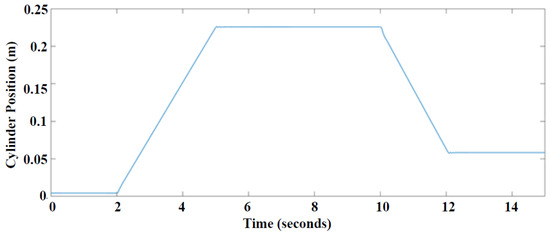

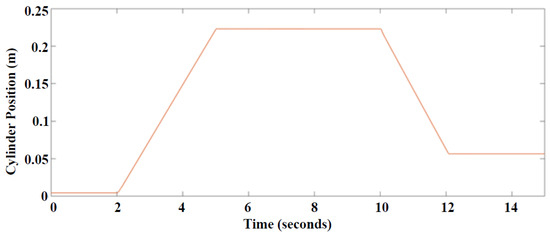

The actuator was loaded with an external cylinder and a command signal, as shown in Figure 14, was applied. The actuator was extended from 2 s to 5 s with a 100% step signal, and then suddenly stopped at 5 s. Retraction occurred from 10 s to 12 s with a −100% step signal and was stopped again at s. The experiment was conducted on both a conventional hydraulic system and the system with the proposed control strategy applied. Actuator chamber pressures were estimated as described in the previous sections for control purposes. The measured actuator chamber pressures and positions were only used to enable performance comparison.

Figure 14.

Command signal for the actuator.

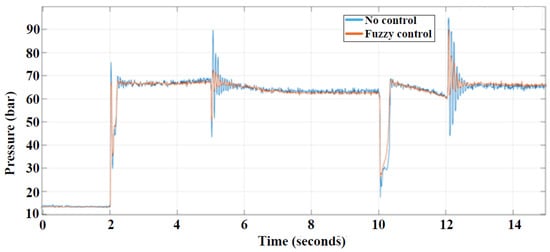

The measured actuator chamber pressure is shown in Figure 15. It can be observed that in the system with the proposed control (red curve), pressure oscillations are significantly damped in comparison with the conventional system (blue curve). Details regarding the overshoot and settling time of the pressure signals for both systems are provided in Table 6.

Figure 15.

Comparison of pressure graphs of conventional system and system with proposed control.

Table 6.

Comparison of pressure overshoot and settling time.

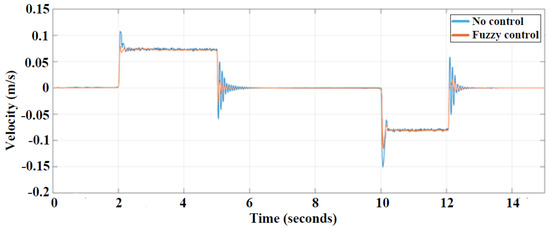

Figure 16 shows the actuator velocity. The blue curve represents the conventional system and the red curve represents the system with the proposed control strategy. It is evident from the plot that velocity oscillations are significantly damped when the proposed controller is applied.

Figure 16.

Comparison of actuator velocity of conventional system and system with proposed control.

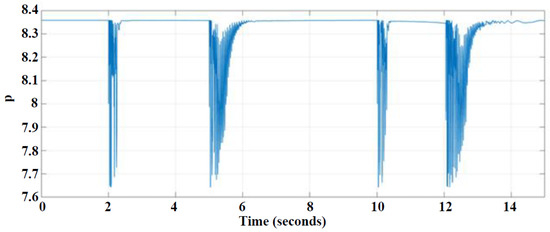

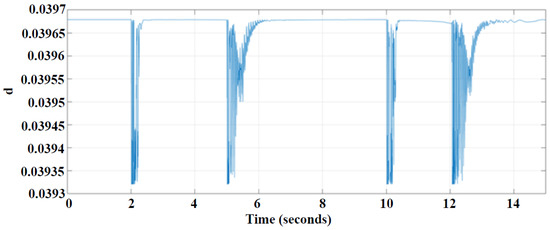

The variations in the PD parameters P and D over time are shown in Figure 17 and Figure 18, respectively. Figure 19 and Figure 20 show the actuator position with and without control, respectively. From the figures, we can conclude that the actuator position did not vary much after the implementation of the proposed controller.

Figure 17.

Variation in control parameter p.

Figure 18.

Variation in control parameter d.

Figure 19.

Actuator position (no control).

Figure 20.

Actuator position (no control).

8. Conclusions

This study presents a control strategy aimed at damping boom oscillations in the hydraulic actuator of an excavator, particularly in environments where direct measurement of actuator chamber pressures and boom displacement is impractical. To overcome this challenge, actuator chamber pressures are estimated from work port pressure signals using a set of differential equations, while undesired oscillations are identified through actuator flow equations, thus eliminating the need for additional sensors such as accelerometers or displacement transducers.

To address the limitations of conventional PID controllers under variable and nonlinear operating conditions, a fuzzy logic-based proportional–derivative (fuzzy PD) controller is developed. This controller dynamically adjusts its gains using fuzzy inference, providing enhanced adaptability and effective damping performance. Evaluation of the controller demonstrates significant performance improvements: pressure overshoot is reduced by 23% during maximum velocity extension and 32% during retraction, while settling time is reduced by 31.23% and 28%, respectively. The reduction in pressure overshoot greatly exceeds typical industrial benchmarks, leading to smoother operation, reduced mechanical stress, and enhanced safety—especially important for human-coexisting machinery. Similarly, the decrease in settling time improves system responsiveness and productivity, while reducing vibration risks. These improvements, supported by pole-zero and frequency-domain analyses, confirm enhanced damping and stability. The results demonstrate that the proposed controller offers not only localized performance gains but also broader implications for safer, more efficient, and more durable hydraulic systems across various applications. Pole-zero and frequency-domain analyses confirm the improved damping characteristics and system stability.

To further improve the robustness and applicability of the proposed strategy, future research may focus on integrating machine learning techniques for adaptive tuning of fuzzy parameters, extending the approach to multi-degree-of-freedom systems, and implementing the controller on embedded real-time platforms. Incorporating fault detection and isolation (FDI) capabilities, optimizing energy efficiency, and conducting long-term field trials will provide deeper insights into system performance, scalability, and reliability in real-world operating conditions.

Author Contributions

Conceptualization, J.T.J., G.W. and J.D.; Methodology, S.K.M., G.W., P.R., J.T.J. and J.D.; Investigation, J.T.J., G.W. and J.D.; Visualization, G.W. and J.T.J.; Writing—Review and Editing, S.K.M., G.W., P.R. and J.T.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The dataset is available on request from the authors.

Acknowledgments

This work was carried out during the course of doctoral studies.

Conflicts of Interest

Author Joseph T. Jose was employed by the company NLC India Limited. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| CBV | Counterbalance valve |

| SVM | Support vector machine |

| MPC | Model predictive control |

| PID | Proportional integral derivative |

| DCV | Directional control valve |

| ANN | Artificial neural network |

| PSO | Particle swarm optimization |

| BPSO | Binary particle swarm optimization |

| EKF | Extended Kalman filter |

| UKF | Unscented Kalman filter |

| AI | Artificial intelligence |

| RMS | Root mean square |

| CWT | Continuous wavelet transform |

| DWT | Discrete wavelet transform |

| PC | Personal computer |

| Piston-side chamber pressure (Pa) | |

| Rod-side chamber pressure (Pa) | |

| Extension-side work port pressure (Pa) | |

| Retraction-side work port pressure (Pa) | |

| Estimated piston-side chamber pressure (Pa) | |

| Estimated rod-side chamber pressure (Pa) | |

| Piston-side area (m2) | |

| Rod-side area (m2) | |

| Piston-side volume (m3) | |

| Rod-side volume (m3) | |

| a | Area of pilot port of CBV (m2) |

| A | Area of pilot port of CBV (actuator side) (m2) |

| Spring setting of CBV (N) | |

| Cracking pressure of CBV (Pa) | |

| Maximum operating pressure of CBV (Pa) | |

| Flow across CBV () | |

| x | Actuator displacement (m) |

| Actuator velocity () | |

| Estimated actuator displacement (m) | |

| m | Mass of load () |

| Flow to the piston side chamber () | |

| Flow to rod side chamber () | |

| Pressure compensator setting () | |

| Density of fluid used () | |

| Flow across DCV () | |

| Valve spool displacement (m) | |

| Natural frequency of DCV () | |

| Bulk modulus of fluid () | |

| Effective bulk modulus of fluid in piston side () | |

| Effective bulk modulus of fluid in rod side () | |

| Capacitance of piston side () | |

| Capacitance of rod side () | |

| Effective capacitance () | |

| Stribeck velocity () | |

| P | Prediction horizon of MPC controller (s) |

| M | Control horizon of MPC controller (s) |

| Error in position (m) | |

| Cost function of MPC controller | |

| Q | Weighing parameters for state target |

| R | Weighing parameters for control signal |

| Proportional gain | |

| Derivative gain | |

| Damping ratio of DCV | |

| Control valve command signal | |

| Pilot area ratio of CBV |

References

- Liu, J.; Yuan, C.; Matias, L.; Bowen, C.; Dhokia, V.; Pan, M.; Roscow, J. Sensor technologies for hydraulic valve and system performance monitoring: Challenges and perspectives. Adv. Sens. Res. 2024, 3, 2300130. [Google Scholar] [CrossRef]

- Kim, S.; Park, J.; Kang, S.; Kim, P.Y.; Kim, H.J. A robust control approach for hydraulic excavators using μ-synthesis. Int. J. Control. Autom. Syst. 2018, 16, 1615–1628. [Google Scholar] [CrossRef]

- Ha, Q.; Nguyen, Q.; Rye, D.; Durrant-Whyte, H. Impedance control of a hydraulically actuated robotic excavator. Autom. Constr. 2000, 9, 421–435. [Google Scholar] [CrossRef]

- Ma, W.; Tan, L.; Feng, H.; Ma, S.; Cao, D.; Yin, C. A Data-Driven LSTM Soft Sensor Model Based on Bayesian Optimization for Hydraulic Pressure Measurement of Excavator. IEEE Sens. J. 2023, 23, 25749–25759. [Google Scholar] [CrossRef]

- Wrat, G.; Ranjan, P.; Mishra, S.K.; Jose, J.T.; Das, J. Neural network-enhanced internal leakage analysis for efficient fault detection in heavy machinery hydraulic actuator cylinders. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2025, 239, 1021–1031. [Google Scholar] [CrossRef]

- Van, T.N.; Tran, H.Q.; Ha, V.X.; Ha, C.; Minh, P.H. Fuzzy Feedback Control for Electro-Hydraulic Actuators. Intell. Autom. Soft Comput. 2023, 36, 2441–2456. [Google Scholar]

- Tang, H.H.; Ahmad, N.S. Fuzzy logic approach for controlling uncertain and nonlinear systems: A comprehensive review of applications and advances. Syst. Sci. Control Eng. 2024, 12, 2394429. [Google Scholar] [CrossRef]

- Cheng, W.B.; Di, Y.Y.; Zhang, E.M.; Moser, M.A.; Kanagaratnam, S.; Korman, L.Y.; Sarvazyan, N.; Zhang, W.J. Modeling and in vitro experimental validation for kinetics of the colonoscope in colonoscopy. Ann. Biomed. Eng. 2013, 41, 1084–1093. [Google Scholar] [CrossRef]

- Song, K.Y.; Behzadfar, M.; Zhang, W.J. A dynamic pole motion approach for control of nonlinear hybrid soft legs: A preliminary study. Machines 2022, 10, 875. [Google Scholar] [CrossRef]

- Liu, R.; Alleyne, A. Nonlinear force/pressure tracking of an electro-hydraulic actuator. J. Dyn. Sys. Meas. Control 2000, 122, 232–236. [Google Scholar] [CrossRef]

- Yan, J.; Li, B.; Guo, G.; Zeng, Y.; Zhang, M. Nonlinear modeling and identification of the electro-hydraulic control system of an excavator arm using BONL model. Chin. J. Mech. Eng. 2013, 26, 1212–1221. [Google Scholar] [CrossRef]

- Cristofori, D.; Vacca, A. Modeling hydraulic actuator mechanical dynamics from pressure measured at control valve ports. Proc. Inst. Mech. Eng. Part I J. Syst. Control Eng. 2015, 229, 541–558. [Google Scholar] [CrossRef]

- Wrat, G.; Bhola, M.; Ranjan, P.; Mishra, S.K.; Das, J. Energy saving and Fuzzy-PID position control of electro-hydraulic system by leakage compensation through proportional flow control valve. ISA Trans. 2020, 101, 269–280. [Google Scholar] [CrossRef] [PubMed]

- Durfee, W.; Sun, Z.; Van de Ven, J. Fluid Power System Dynamics; Center for Compact and Efficient Fluid Power: Minneapolis, MD, USA, 2009. [Google Scholar]

- Nimawat, D.; Nagar, N. Self-tuning fuzzy PID controllers application on industrial hydraulic actuator using unique system identification approach. J. Commun. Technol. Electron. Comput. Sci. 2019, 22, 1–6. [Google Scholar]

- Rahmat, M.F. Application of self-tuning fuzzy PID controller on industrial hydraulic actuator using system identification approach. Int. J. Smart Sens. Intell. Syst. 2009, 2, 246. [Google Scholar]

- Rozali, S.M.; Rahmat, M.; Wahab, N.A.; Ghazali, R. PID controller design for an industrial hydraulic actuator with servo system. In Proceedings of the 2010 IEEE Student Conference on Research and Development (SCOReD), Kuala Lumpur, Malaysia, 13–14 December 2010; pp. 218–223. [Google Scholar]

- Wen, J.; Wang, F. Stable levitation of single-point levitation systems for maglev trains by improved cascade control. Sci. Technol. 2024, 27, 348–361. [Google Scholar] [CrossRef]

- Hentout, A.; Maoudj, A.; Kouider, A. Shortest path planning and efficient fuzzy logic control of mobile robots in indoor static and dynamic environments. Sci. Technol. 2024, 27, 21–36. [Google Scholar] [CrossRef]

- Lee, C.C. Fuzzy logic in control systems: Fuzzy logic controller. I. IEEE Trans. Syst. Man. Cybern. 1990, 20, 404–418. [Google Scholar] [CrossRef]

- Tanaka, K.; Sugeno, M. Stability analysis and design of fuzzy control systems. Fuzzy Sets Syst. 1992, 45, 135–156. [Google Scholar] [CrossRef]

- Mohammadzadeh, A.; Taghavifar, H.; Zhang, Y.; Zhang, W. A Fast Nonsingleton Type-3 Fuzzy Predictive Controller for Nonholonomic Robots Under Sensor and Actuator Faults and Measurement Errors. IEEE Trans. Syst. Man Cybern. Syst. 2024, 54, 4175–4187. [Google Scholar] [CrossRef]

- Niewiara, Ł.; Zawirski, K. Auto-tuning of PID controller based on fuzzy logic. Comput. Appl. Electr. Eng. 2013, 11, 230–240. [Google Scholar]

- Tayeb, E.B.M.; Ali, A.T. Comparison of some classical PID and fuzzy logic controllers. Int. J. Sci. Eng. Res. 2012. [Google Scholar]

- Wrat, G.; Ranjan, P.; Bhola, M.; Mishra, S.K.; Das, J. Position control and performance analysis of hydraulic system using two pump-controlling strategies. Proc. Inst. Mech. Eng. Part I J. Syst. Control Eng. 2019, 233, 1093–1105. [Google Scholar] [CrossRef]

- Zhao, Z.Y.; Tomizuka, M.; Isaka, S. Fuzzy gain scheduling of PID controllers. IEEE Trans. Syst. Man, Cybern. 1993, 23, 1392–1398. [Google Scholar] [CrossRef]

- Mohan, B.; Sinha, A. A simplest fuzzy PID controller: Analytical structure and stability analysis. In Proceedings of the IEEE INDICON 2004. First India Annual Conference, Kharagpur, India, 20–22 December 2004; pp. 288–293. [Google Scholar]

- Precup, R.E.; Tomescu, M.L. Fuzzy logic control system stability analysis based on Lyapunov’s direct method. Int. J. Comput. Commun. Control 2009, 4, 415–426. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, Z.L.; Qiu, J.; Huang, H.Z. Hybrid fuzzy skyhook surface control using multi-objective microgenetic algorithm for semi-active vehicle suspension system ride comfort stability analysis. J. Dyn. Sys. Meas. Control 2012, 134, 041003. [Google Scholar] [CrossRef]

- Sivakumar, K. Fuzzy Logic Control of Hydraulic Actuated Active Suspension System. Int. J. Mech. Mechatronics Eng. IJMME-IJENS 2016, 16. [Google Scholar]

- Wonohadidjojo, D.M.; Kothapalli, G.; Hassan, M.Y. Position control of electro-hydraulic actuator system using fuzzy logic controller optimized by particle swarm optimization. Int. J. Autom. Comput. 2013, 10, 181–193. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).