Abstract

The simultaneous sintering of chips with different specifications generates differential auxiliary sintering pressures, which create eccentric loads on the substrate. These loads disrupt the horizontal alignment of the chip-loading mold and adversely affect sintering quality. To overcome the challenge, an electro-hydraulic servo leveling system featuring active moment compensation is developed, incorporating high-precision pressure control to counteract the influence of eccentric loading. The system design is guided by static analysis to identify the eccentric load distribution, resulting in an optimized mechanical configuration. A feedforward-based Nussbaum gain backstepping adaptive controller is proposed to compensate for multiple nonlinear disturbances, including time-varying hydraulic parameters and external loads, while a feedforward strategy is integrated to improve the dynamic response of the pressure control loop. The effectiveness of the moment compensation leveling system and control algorithm has been validated through simulations and physical experiments on silver sintering equipment. The results show that the baseline deviation of the lower mold platform is reduced by 95%, achieving micron-level precision (≤5 μm). The proposed control algorithm reduces the dynamic tracking error by 42.4% and the steady-state fluctuation error by 50.6%. The introduction of the moment compensation leveling system to the existing silver sintering equipment addresses the issue of chip fracture caused by eccentric loading. The shear strength of the sintered layer is increased by 40.6%, and the thickness uniformity is improved by 65.8%. This study contributes to improved packaging quality and efficiency for power semiconductors, providing a theoretical basis for the development of advanced sintering equipment.

1. Introduction

With the rapid evolution of high-voltage and high-current applications in fields such as new energy vehicles and rail transportation, there is an accelerated demand for the development of third-generation semiconductor technologies represented by SiC [1]. As a critical step in the preparation of power semiconductor devices, packaging technology directly influences their final application performance and plays a decisive role in achieving high integration and multifunctionality [2]. Given the high-power density and elevated service temperatures required by third-generation power semiconductors, these devices must possess excellent heat dissipation capability and high-temperature resistance [3], imposing stringent requirements on both packaging materials and equipment performance [4].

Nano-silver sintering packaging has emerged as a promising solution for high-temperature and high-power applications due to its superior thermal conductivity and high melting point [5]. Silver sintering is categorized into pressureless and pressure-assisted techniques. The application of pressure during sintering significantly enhances densification and reduces porosity in the silver layer [6]. Experimental results show that increasing the sintering pressure from 5 MPa to 30 MPa decreases porosity from 1.39% to 1.14%. This improved densification leads to a 66% increase in shear strength [7]. The resulting low porosity and high shear strength collectively enhance the performance of power semiconductor modules: the dense structure improves thermal conductivity, while the robust mechanical properties extend thermal cycling lifetime and overall reliability [8]. Silver sintering packaging equipment enhances the bonding strength and reduces the void fraction of nano-silver sintered layers by providing precise auxiliary sintering pressure and temperature during the process [9]. However, the simultaneous sintering of power semiconductors with different specifications necessitates the application of varying pressures, which can generate eccentric loads on the substrate. These loads disrupt the horizontal alignment of the chip-loading mold, impair sintering quality, and in severe cases, may lead to chip fracture [10].

Current pressure sintering systems commonly employ pneumatic or hydraulic mechanisms to supply auxiliary pressure [11,12,13]. Considerable research has been conducted to achieve high-precision pressure control in silver sintering equipment. In the field of pneumatic control, Yang L. developed a nonlinear model accounting for fluid pressure drop, oil-gas nonlinearity, and damper effects, and introduced a two-stage hierarchical model predictive control (MPC) strategy for output force regulation [14]. Gaheen, O.A. investigated the influence of pulsating airflow on pneumatic cylinder control and devised a frequency-based pressure regulation method [15]. Chen, B. presented an adaptive MPC approach with a switching unscented Kalman filter to improve the accuracy and stability of electro-hydraulic brake pressure control under temperature variations [16]. In hydraulic control, Yan, G. proposed a dynamic load torque compensation active disturbance rejection strategy for an electro-hydraulic servo pump control system, which enhanced output force stability by addressing system nonlinearities [17]. To enhance the real-time tracking performance of an electro-hydraulic servo valve force control system, a method combining an offline-designed feedback controller and an online adaptive compensator was proposed, resulting in significantly improved force tracking performance [18]. A combined feed-forward force controller, including a modified force inverse model compensator and a velocity feed-forward compensator with internal model control, was proposed to compensate surplus force disturbance caused by active motion of an electro-hydraulic shaking table and yield a high-fidelity force loading tracking performance [19]. Although high-precision control of auxiliary sintering pressure has seen technological advances, it still cannot fully mitigate the adverse effects of eccentric loading on the substrate on the quality of sintered products. To address this, current silver sintering processes often employ cushioning materials (such as Teflon tape or silicone rubber) placed between the chips and the loading head to compensate for height variations among multiple chips, improve pressure distribution uniformity, and thereby enhancing sintering quality [20]. However, this approach represents a passive compensation mechanism with limited adjustment capability. Therefore, it is necessary to introduce an active leveling system to fundamentally correct horizontal reference deviations caused by eccentric loading, ensuring high shear strength of the silver sintered layer while effectively preventing chip fracture.

High-performance control of the leveling system is critical to equipment performance [21], numerous studies have addressed leveling system design and control. Wang, R. developed a hydraulically interconnected omnidirectional leveling system for crawler machinery, improving leveling accuracy [22]. Xu, F. designed a model predictive-based synchronous leveling strategy with variable load constraints for cranes, enabling synchronized leveling and optimal load distribution [23]. Liu, K. implemented an electro-hydraulic leveling system with independent adjustment capability and applied human-simulated intelligent control (HSIC) for precise platform angle and cylinder force regulation [24]. Dai, J. proposed a robust control method utilizing deep reinforcement learning within a maximum entropy framework, significantly enhancing leveling control accuracy and system robustness in multi-cylinder hydraulic presses [25]. Geranmehr, B. developed a hybrid robust control strategy that integrated feedback from cylinder position sensors, pressure sensors, and platform roll/pitch angle sensors, effectively mitigating coupling effects in multi-cylinder systems [26]. To meet development needs for large stroke, strong anti-eccentric load capability, and high leveling torque in hydraulic press leveling systems, Sun, C. proposed a four-axis average synchronization control strategy that effectively minimizes synchronization errors among the axes [27]. However, the micron-level flatness required in third-generation power semiconductor silver sintering—where positional deviations are difficult to detect—demands further research into optimized leveling system design and advanced control strategies.

This work presents a comprehensive investigation into third-generation power semiconductor silver sintering packaging systems. To address the challenges associated with simultaneous sintering of multi-specification chips and achieve high-precision substrate leveling, an electro-hydraulic servo moment compensation leveling system (MCLS) integrated with an adaptive pressure control strategy is developed. The research methodology encompasses three main aspects: First, static analysis is employed to characterize the force distribution across the substrate plane during concurrent chip sintering, providing the theoretical foundation for MCLS design. Second, a feedforward-based Nussbaum gain backstepping adaptive controller (FB-NG-BAC) is formulated to compensate for uncertainties in hydraulic parameters and enhance the leveling system’s dynamic response characteristics. The control strategy’s efficacy is quantitatively assessed through comparative analysis of output pressure tracking performance against conventional methods. Furthermore, system validation is conducted under maintained auxiliary sintering pressure conditions, with sintering quality evaluated through shear strength testing and thickness uniformity measurements. The experimental results conclusively demonstrate the effectiveness of both the proposed leveling system architecture and its associated high-precision pressure control framework.

2. Principle of MCLS

2.1. Structural Principle of MCLS

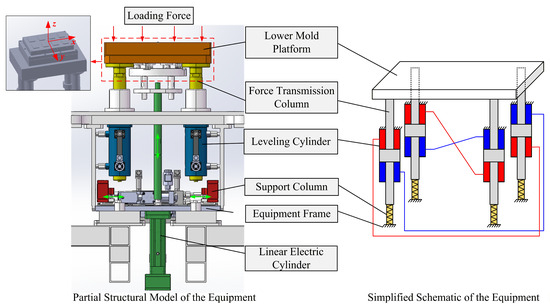

The silver sintering packaging equipment comprises several core components: the frame, lower mold platform, linear electric cylinder, support columns, and leveling cylinders, as depicted in Figure 1. Specifically, the left portion displays a partial structural model of the equipment, while the right portion provides a simplified schematic representation. The linear electric cylinders drive vertical positioning of the lower mold platform, while the horizontally movable support columns bear both the platform weight and the total sintering load. Power semiconductor chips distributed across eight sintering zones on the lower mold platform can be simultaneously subjected to different predetermined sintering pressures. During packaging operations, uneven load distribution among these zones induces eccentric loading on the four support columns and force transmission columns. This eccentric loading generates differential z-axis displacements in the lower mold platform, causing horizontal reference deviations that significantly degrade sintering quality. To mitigate these effects, a moment compensation leveling system is implemented, applying compensatory moments to the lower mold through four leveling cylinders to counteract eccentric load influences. The force transmission columns additionally function as hydraulic cylinder piston rods, with their corresponding barrels fixed to the frame, collectively constituting four symmetric hydraulic cylinders.

Figure 1.

Structural diagram of the MCLS for silver sintering equipment.

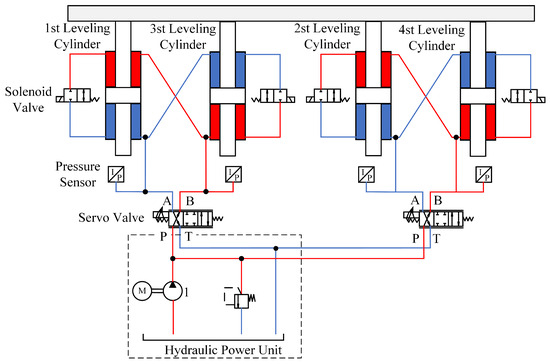

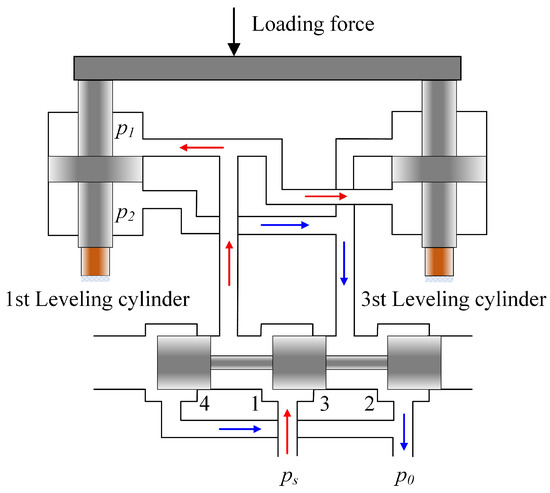

The hydraulic schematic of the MCLS is shown in Figure 2. The core components include a hydraulic power unit (HPU), two servo valves, four double-acting symmetrical leveling cylinders, four solenoid valves, and four pressure sensors. The HPU serves as the system pressure source. The four leveling cylinders are divided into two groups, each consisting of two diagonally opposed cylinders. Within each group, the upper and lower chambers are cross-connected—specifically, the upper chamber of cylinder 1 is connected to the lower chamber of cylinder 3, and vice versa. Each set of interconnected chambers is linked to port A and port B of a dedicated servo valve. By adjusting the servo valves, both the magnitude and direction of the hydraulic moment compensation can be precisely controlled for each cylinder group. The four solenoid valves are normally open during platform movement to allow piston rod following, and close during moment compensation to isolate the cylinder chambers.

Figure 2.

Hydraulic schematic of the MCLS.

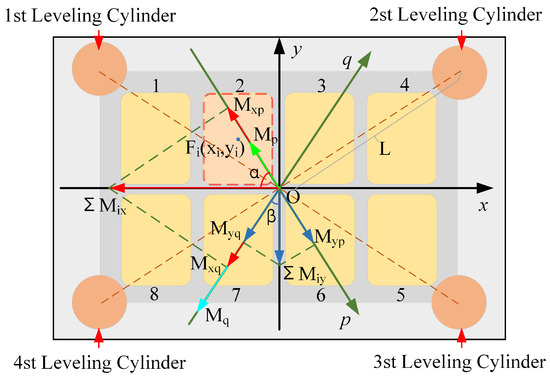

Multiple chips within a single sintering zone are uniformly distributed. According to the force translation theorem, the loading forces within each sintering zone are equivalently concentrated as resultant force at the zone centroid. To facilitate moment compensation algorithm design, a dual-coordinate system ( and axes) is established with its origin at the lower mold centroid, as illustrated in Figure 3. The -axis and -axis are mutually orthogonal, while the -axis and -axis are, respectively, perpendicular to the centroidal connection lines of the two diagonally distributed leveling cylinder groups.

Figure 3.

Schematic diagram of sintering zones on the lower mold.

The moment generated by loading forces in each sintering zone about the lower mold centroid can be decomposed along the -axis and -axis. The resultant moments and about these axes are calculated as follows:

where denotes the loading force of the -th indenter, represents the moment arm of about the -axis, and represent the moment arm about the -axis.

Subsequently, and are further decomposed along the -axis and -axis to obtain the resultant moments and :

where is the angle between the -axis and -axis, and is the angle between the -axis and -axis.

The output forces of the four leveling cylinders are calculated as

where is the leveling forces of diagonally distributed cylinders 1 and 3, is the leveling forces of cylinders 2 and 4, and is the denote effective moment arm for respective cylinder groups.

2.2. Simulation Verification of MCLS

A static analysis is performed using SolidWorks Simulation (2022). To simplify calculations and highlight key mechanical behaviors, the model retains only the core structural components of the moment compensation leveling system. The material parameters for each component are strictly set according to the actual equipment, with specific values provided in Table 1. The model is meshed using tetrahedral elements.

Table 1.

Material parameters of components in the MCLS.

The boundary conditions are set as follows: the frame is defined as a rigid body with fixed constraints, while all other contact surfaces are treated as “Bonded,” with friction between components ignored.

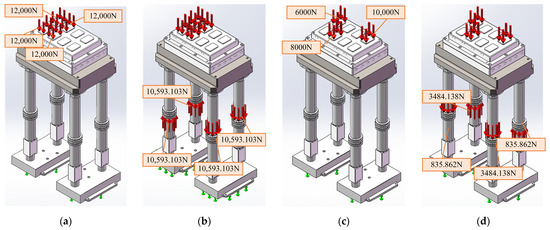

To validate the effectiveness of the moment compensation leveling system design, two sintering loading conditions are analyzed. The load setting is based on an effective sintering area of 400 mm2 per substrate. Condition 1 applies a pressure of 30 MPa to sintering areas 1, 2, 7, and 8 (equivalent to a load of 12,000 N per sintering area), simulating an extreme unilateral eccentric loading condition. Condition 2 applies sintering pressures of 15 MPa, 25 MPa, and 20 MPa to sintering areas 1, 4, and 7, respectively, simulating non-uniform loading under different process parameters. The displacement of the lower mold platform surface before and after leveling is analyzed.

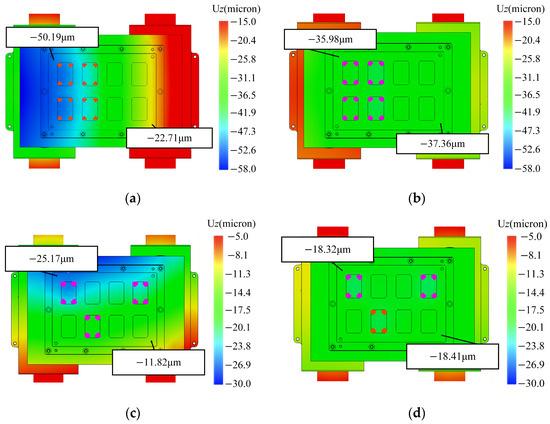

Based on Equation (3), the force distribution of leveling cylinders 1, 3 and 2, 4 under the two conditions are calculated. The leveling load is applied to the effective piston area of the leveling cylinders. Figure 4 compares the load configurations with and without moment compensation for the two conditions.

Figure 4.

Simulation load configurations for two loading conditions. (a) Condition 1 without moment compensation; (b) Condition 1 with moment compensation; (c) Condition 2 without moment compensation; (d) Condition 2 with moment compensation.

The z-displacements of the sintering platform under two loading conditions, before and after compensation by the MCLS, are shown in Figure 5. From Table 2, the proposed MCLS achieves significant reductions in z-displacement across the lower mold sintering surface. Under Scenario 1, the displacement is reduced by 26.10 μm, while Scenario 2 showed a reduction of 13.32 μm. The final compensated displacements reached 1.39 μm and 0.03 μm for the two scenarios, respectively—both well below the 5 μm flatness specification for silver sintering processes. These results conclusively demonstrate the effectiveness of the moment compensation leveling principle.

Figure 5.

Comparison of z-displacement for the lower mold under two working conditions. (a) Condition 1, pre-leveling; (b) Condition 1, post-leveling; (c) Condition 2, pre-leveling; (d) Condition 2, post-leveling.

Table 2.

Simulation results of lower mold z-displacement.

3. Mathematical Model of MCLS

The actuation unit of the moment compensation leveling system in silver sintering equipment employs a valve-controlled symmetric cylinder configuration for pressure control. Given the structural symmetry of the two leveling cylinder groups under different working conditions, the modeling in this study focuses on a single set of leveling cylinders. The schematic diagram of the pressure control system is provided in Figure 6, and the corresponding system parameters are listed in Table 3.

Figure 6.

Schematic diagram of the pressure control system.

Table 3.

Model parameters of the pressure control system.

- Hydraulic Servo Valve Model

The linearized flow equation governing the servo valve is expressed as

- 2.

- Proportional Amplifier Model

Given the proportional amplifier’s inherent frequency substantially exceeds that of the valve-controlled cylinder system, its dynamics are negligible and thus modeled as a proportional gain:

- 3.

- Flow Continuity Equation for Leveling Cylinders

With the leveling cylinders operating at mid-stroke positions, their upper and lower chamber volumes and piston displacements are equal, while internal leakage coefficients remain identical. Consequently, the interconnected chambers of cylinder 1 and cylinder 3 are equivalenced as a single volume, yielding the following flow continuity equation:

- 4.

- Load Kinematics Equation

The load is equivalenced as a spring–damper system, neglecting nonlinearities such as Coulomb friction. Per Newton’s second law, the force balance equation for the leveling cylinder is derived:

The output equation of the leveling pressure control system is transformed to the frequency domain:

The system represents a third-order dynamic system, with the input voltage to the servo valve designated as the control input and the load pressure of the leveling cylinder established as the control output. Defining the load pressure, its first derivative, and its second derivative of the leveling cylinder as the system state variables, i.e., , , , the new state-space equation is obtained as

where , , , , .

4. The Pressure Control Algorithm Research

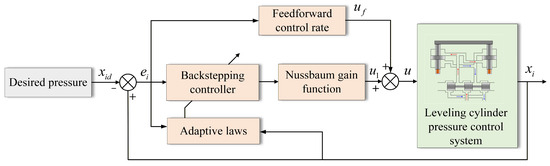

The MCLS serves as a critical actuation unit in silver sintering packaging equipment, with its core objective being to ensure the output pressure of the leveling cylinders accurately tracks dynamic compensation pressure commands. This requirement places stringent demands on the control system’s dynamic response speed and disturbance rejection capability. However, control accuracy is often compromised by parametric uncertainties, time-varying dynamics, and external disturbances. While existing adaptive control methods primarily rely on feedback mechanisms to compensate for slowly varying parameters, they exhibit limitations in handling fast dynamic processes and multi-source disturbances [28,29,30]. To address these challenges in achieving both rapid response and strong disturbance rejection, this paper proposes a FB-NG-BAC, with the control structure depicted in Figure 7.

Figure 7.

Schematic of FB-NG-BAC.

The proposed controller integrates three key functional components into a cohesive architecture. A command feedforward unit enhances dynamic response by establishing a nonlinear mapping between control input and pressure output, calculating feedforward signals in real time based on desired pressure commands. The backstepping adaptive controller, grounded in Lyapunov stability theory, ensures global system stability through progressive construction of virtual control variables while employing adaptive laws to estimate and compensate for parametric uncertainties online. Furthermore, a Nussbaum function module enhances robustness under complex operating conditions by automatically adjusting the controller’s equivalent gain to accommodate unmodeled dynamics and sudden disturbances. This control architecture effectively combines feedforward and feedback actions, providing a comprehensive solution for MCLS in silver sintering equipment. It significantly improves the dynamic performance of pressure control while maintaining guaranteed system stability.

- Feedforward Control Law

The feedforward control law is defined based on the servo valve pressure gain:

where denotes the feedforward command input, represents the servo valve pressure gain coefficient, and denotes the desired pressure value of the leveling force control system.

The feedforward command is obtained by polynomial fitting of the measured servo valve pressure gain curve under actual system pressure:

where are polynomial coefficients and is the hydraulic supply pressure.

- 2.

- Backstepping Adaptive Control Law

The control objective of this study is to design a control law such that the system state tracks the desired state . The system tracking errors are defined as follows:

where represents the first derivative of the desired pressure and indicates the second derivative of the desired pressure.

The Lyapunov function for the first subsystem is selected as

Differentiating yields

The virtual control input is designed as

The Lyapunov function for the second subsystem is selected as

Differentiating yields

The virtual control input is designed as

The Lyapunov function for the third subsystem is selected as

Differentiating yields

To address parameter uncertainty in the control term, the Nussbaum gain method is employed with the following function:

The actual control law is designed as

Thus, the actual control term is decomposed into two components, as the control gain compensation term and as the auxiliary control term, where denotes the estimated values of system parameters.

The adaptive laws are given by [28]:

From Equations (11) and (22), the final control law consists of the feedforward control term and the backstepping control term :

The stability proof of the FB-NG-BAC is provided in Appendix A.

5. Simulation and Experimental Research

5.1. Analysis of Simulation Results

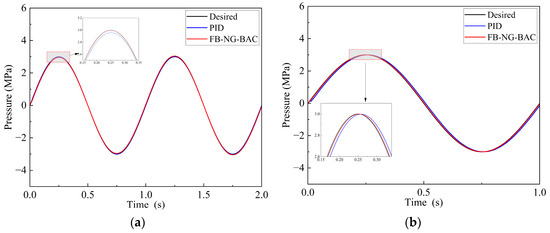

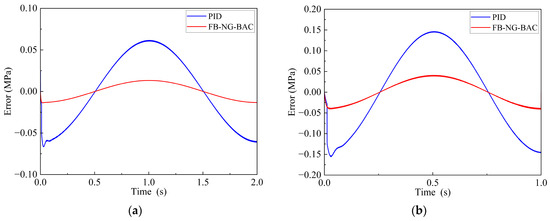

To evaluate the dynamic performance of the leveling force control system, sinusoidal signals with amplitudes of 3 MPa and frequencies of 1 Hz and 2 Hz are applied as reference commands, selected according to the system’s typical operating pressure range. The sign variations in these pressure commands correspond to directional changes in the compensation moment. The corresponding simulation response curves and tracking error profiles are presented in Figure 8 and Figure 9, respectively.

Figure 8.

Simulation pressure curves of sinusoidal signals tracking control. (a) 1 Hz condition; (b) 2 Hz condition.

Figure 9.

Simulation error curves of sinusoidal signals tracking control. (a) 1 Hz condition; (b) 2 Hz condition.

The maximum absolute error is adopted as the evaluation metric. As evidenced by the data in Table 4, the proposed FB-NG-BAC demonstrates superior control performance under sinusoidal excitation at different frequencies. Notably, at the 2 Hz condition, the maximum absolute error achieves a 74.3% reduction compared to conventional PID control.

Table 4.

Analysis of simulation results for sinusoidal signal tracking control.

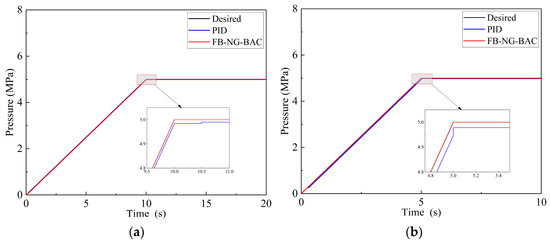

Furthermore, to address the ramp-like pressure profiles characteristic of actual chip sintering processes, additional validation is conducted using ramp command signals. These signals are configured with a peak amplitude of 5 MPa and slope rates of 0.5 MPa/s and 1 MPa/s. The resulting pressure tracking performance is presented in Figure 10.

Figure 10.

Simulation pressure curves of ramp signals tracking control. (a) 0.5 MPa/s condition; (b) 1 MPa/s condition.

The simulation results for ramp command tracking control in Table 5 demonstrate the superior control performance of the proposed FB-NG-BAC algorithm: under 0.5 MPa/s conditions, dynamic tracking error (0.0007 MPa) and steady-state fluctuation error (0.0005 MPa) are reduced by 95.8% and 95.2%, respectively, compared to the PID algorithm; at 1 MPa/s ramp rate, its dynamic tracking error (0.0014 MPa) shows a 97.4% reduction versus the PID algorithm (0.0539 MPa), while steady-state fluctuation error (0.0011 MPa) decreases by 94.8% compared to PID (0.0215 MPa). This validates that the feedforward compensation mechanism effectively eliminates system inertia lag through real-time inverse solution of nonlinear gain models, combined with the strong robustness of Nussbaum gain and backstepping adaptive strategies against parameter perturbations.

Table 5.

Analysis of simulation results for ramp command tracking control.

5.2. Experimental Results Analysis

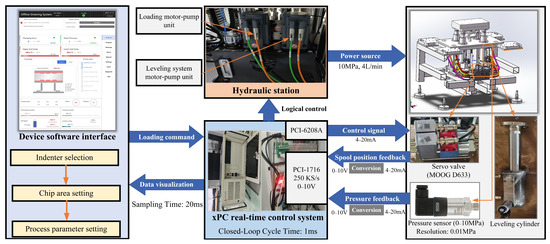

5.2.1. Experimental Platform Introduction

The experimental platform of the moment compensation leveling system control system based on xPC Target is shown in Figure 11. It primarily consists of a hydraulic power unit subsystem, a moment compensation leveling subsystem, an xPC real-time control system, and a device software interface. The parameter configurations of key components are listed in Table 6.

Figure 11.

MCLS experimental platform.

Table 6.

The parameter configurations of key components.

The device software interface allows for the setting of product parameters and sintering process parameters, while also displaying and recording equipment process data. The hydraulic power unit subsystem comprises two motor-pump units, which provide hydraulic power sources for the loading system and the moment compensation leveling system, respectively. Serving as the control center, the xPC real-time control system generates real-time loading commands and leveling system pressure commands based on sintering process parameters. It implements start–stop logic control for the hydraulic station, acquires real-time signals from pressure sensors and servo valve spool position feedback in the moment leveling compensation system, and outputs control commands calculated by the control software to the servo valves in the moment compensation leveling system, thereby achieving dynamic pressure control of the leveling cylinders.

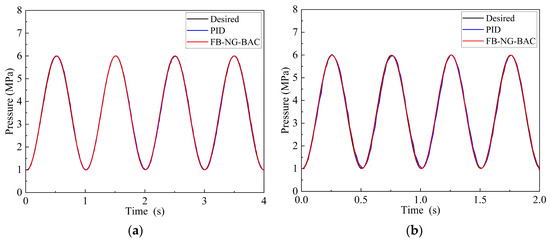

5.2.2. Pressure Control Results Analysis

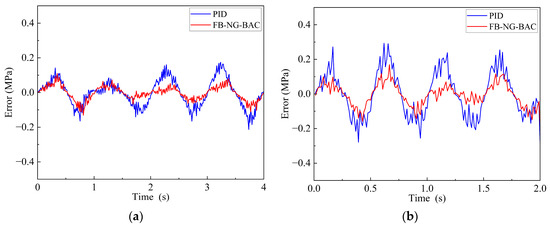

To evaluate the dynamic control performance of the FB-NG-BAC algorithm in the physical leveling system, experimental validation is conducted through sinusoidal pressure tracking tests at frequencies of 1 Hz and 2 Hz. The pressure command amplitude ranged from 1 to 6 MPa, covering the system’s typical operational range. The experimental pressure responses and corresponding tracking errors are presented in Figure 12 and Figure 13, respectively. Comparative analysis confirms the superior tracking accuracy of the proposed FB-NG-BAC over the conventional PID controller. Quantitative results in Figure 13 and Table 7 show that the FB-NG-BAC achieves maximum absolute errors of 0.131 MPa at 1 Hz and 0.170 MPa at 2 Hz, demonstrating 39.10% and 41.97% improvements, respectively, compared to PID control. Minor discrepancies between experimental and simulation results are observed, potentially attributable to practical factors including pressure sensor noise and signal conversion delays in the physical implementation.

Figure 12.

Experimental pressure curves of sinusoidal signals tracking control. (a) 1 Hz condition; (b) 2 Hz condition.

Figure 13.

Experimental error curves of sinusoidal signals tracking control. (a) 1 Hz condition; (b) 2 Hz condition.

Table 7.

Analysis of experimental results for sinusoidal signal tracking control.

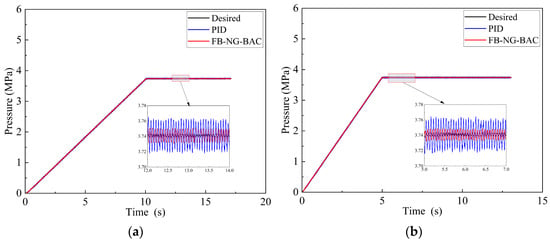

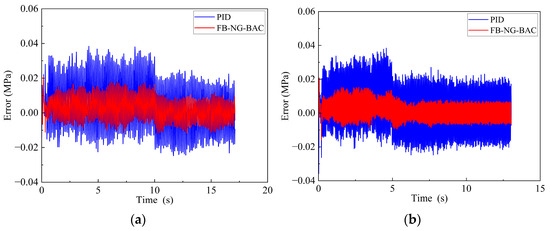

Furthermore, ramp signals—characteristic of actual pressure profiles in chip sintering processes—are employed as reference commands. During experimentation, loading forces are applied to sintering zones 1, 2, 7, and 8, with the ramp signals configured to reach a maximum pressure of 20 MPa at slopes of 2 MPa/s and 4 MPa/s. The moment compensation leveling controller subsequently converted the real-time loading force measurements from each sintering zone into pressure control commands for the leveling cylinders, with a maximum target pressure of 3.74 MPa for these conditions. The resulting pressure control performance and corresponding tracking errors for leveling cylinders 1 and 3 are presented in Figure 14 and Figure 15, respectively. To quantitatively assess controller performance, the dynamic maximum tracking error and steady-state maximum error of the leveling cylinder pressure are adopted as evaluation metrics, with the experimental results systematically summarized in Table 8. The experimental results confirm the superior performance of the FB-NG-BAC controller over the conventional PID approach in both dynamic response and steady-state accuracy. In dynamic performance tests under 2 MPa/s ramp conditions, the FB-NG-BAC achieves a maximum absolute error of 0.0221 MPa, representing a 42.4% improvement over the PID controller (0.0384 MPa). At the higher 4 MPa/s ramp rate, the dynamic error is further reduced to 0.0207 MPa—a 46.1% enhancement compared to PID—effectively suppressing system lag and overshoot. Regarding steady-state performance, the FB-NG-BAC demonstrates error reductions of 50.6% and 65.2% at 2 MPa/s and 4 MPa/s conditions, respectively, compared to PID control. These findings validate the effectiveness of the FB-NG-BAC in compensating for parameter variations and external disturbances, significantly improving system robustness. The advanced control capability provided by FB-NG-BAC offers crucial technical support for enhancing sintering quality in power semiconductor manufacturing.

Figure 14.

Experimental pressure curves of ramp signals tracking control. (a) 2 MPa/s condition; (b) 4 MPa/s condition.

Figure 15.

Experimental error curves of ramp signals tracking control. (a) 2 MPa/s condition; (b) 4 MPa/s condition.

Table 8.

Analysis of experimental results for ramp command tracking control.

5.2.3. Sintering Quality Evaluation

The core function of the moment compensation leveling control system lies in compensating for the uneven load borne by the lower mold platform, ensuring its baseline accuracy, thereby enhancing the sintering quality of power semiconductor chips. Therefore, evaluating the effectiveness of the designed moment compensation leveling system and its control algorithm ultimately needs to be grounded in the inspection of chip sintering quality. Typically, chip sintering quality assessment covers two key indicators: sintering strength and sintered layer thickness uniformity [31].

The working surfaces of both upper and lower sintering molds demonstrate a flatness of less than 5 μm with surface roughness satisfying the Ra 1.6 requirement. The substrates used for sintering are 63 × 54.3 mm AMB (Active Metal Brazed) ceramic substrates with flatness below 30 μm. Sixteen silicon carbide chips, each measuring 4.46 × 5.375 mm with individual flatness under 2 μm, are sintered on a single substrate. The silver paste employed is Heraeus F1510 (particle size: ≤20 μm, silver content: 73%), with the sintering process conducted at 250 ± 3 °C.

Based on the premise that the original auxiliary sintering pressure meets the requirements, the sintering quality of the four products processed by the pressure heads 1, 2, 7, and 8 in the ramp signal loading experiment described in Section 5.2.2 is tested. One chip from each product is selected for push–pull force testing (Chips 1–4), and an additional chip from each product is selected for sintered layer thickness measurement (Chips 5–8).

- 1.

- Chip sintering strength detection

Based on the shear strength test of the sintered silver layer in the packaged chips conducted using a bond tester (MFM1200L, TRY-PRECISION, Shenzhen, China), the experimental results of the shear strength are presented in Table 9. The bond tester exhibits an accuracy error of ±5 N, corresponding to a shear strength error of ±0.21 MPa. The shear strength of the sintered layer for chips packaged at different positions all exceeds 40 MPa, meeting the mechanical performance requirements for power semiconductor packaging. This level of shear strength demonstrates relatively reliable mechanical fatigue life of the sintered layers [20].

Table 9.

Shear strength results of sintered silver layer.

- 2.

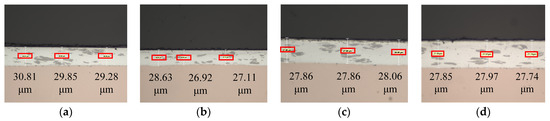

- Sintered layer thickness uniformity detection

During the sintering process, organic additives within the silver paste continuously undergo pyrolytic volatilization, forming a sintered silver layer with a microporous structure [32]. However, partial loading forces during the loading process can lead to uneven thickness distribution in the sintered silver layer. The uniformity of the sintered silver layer is both a key technical indicator for evaluating chip sintering quality and directly verifies the effectiveness of the leveling system designed in this paper in suppressing partial loading. The cross-sections of the sintered layers of chips 5–8 are examined using a scanning electron microscope (SEM). The thickness of the sintered layer is measured at three different locations on each chip, and the maximum thickness variation for each chip is presented in Table 10. The measurement error is ±0.5 μm.

Table 10.

Uniformity test results of sintered silver layer.

From Figure 16 and Table 10, building upon the original auxiliary sintering pressure and incorporating the proposed moment compensation leveling system with its pressure control method, the maximum thickness variation within individual chips ranges from 0.20 to 1.71 μm, while the maximum thickness difference across different chips is 3.89 μm. Compared to the industrial specification requiring silver layer thickness uniformity of ≤5 μm, this system improves single-chip thickness uniformity by 65.8% and cross-chip consistency by 22.2%. These results further validate that the real-time moment compensation mechanism effectively suppresses eccentric load effects and significantly enhances the process consistency of silver sintering packaging.

Figure 16.

Uniformity test results of sintered silver layer. (a) Chip 5; (b) Chip 6; (c) Chip 7; (d) Chip 8.

6. Conclusions

This paper addresses the issues of chip breakage and sintering quality defects caused by load imbalance in the silver sintering equipment. A moment compensation leveling system is designed, and a strategy for rapid and precise adjustment of leveling forces is proposed, enhancing the process quality of chip sintering. The main conclusions are as follows:

- An electro-hydraulic servo dynamic moment compensation leveling control system is designed. Based on system static analysis, a dynamic MCLS is established. Numerical simulations demonstrate that this system can reduce the baseline deviation of the lower mold platform by 95%, achieving micron-level (≤5 μm) horizontal baseline control.

- To address the parameter uncertainty and time-varying nature of the leveling hydraulic pressure control system, a FB-NG-BAC is proposed. This achieves dynamic and precise control of the leveling cylinder pressure. Experimental verification shows a 42.4% reduction in dynamic tracking error and a 50.6% decrease in steady-state fluctuation error.

- The system’s effectiveness is evaluated using dual indicators: sintering strength and sintered layer uniformity. Shear strength test values all met the requirement of ≥40 MPa (reaching a maximum of 56.25 MPa, exceeding the standard by 40.6%). Sintered layer thickness uniformity met the ≤5 μm requirement, with single-chip thickness uniformity improved by 65.8% and cross-chip consistency improved by 22.2%.

The MCLS is designed to provide practical advantages for silver sintering packaging. Its function of actively compensating for platform tilt from large offset loads is aimed at improving sintering quality. A key practical benefit lies in its potential to eliminate corrective cushion materials, which would streamline the process and lower costs. However, the current research primarily focuses on solving the problems of chip breakage and poor sintering quality caused by load imbalance in silver sintering equipment. Future research will comprehensively consider the force matching control problem between the auxiliary pressure sintering loading system and the moment compensation leveling system, exploring the system’s compensation capability limits under superimposed multi-source unbalanced moment and their comprehensive effects on sintering quality.

Author Contributions

Conceptualization, J.C. and W.G.; methodology, L.C.; validation, J.C. and Y.X.; resources, H.C.; writing—review and editing, J.C.; visualization, H.L.; supervision, C.A. All authors have read and agreed to the published version of the manuscript.

Funding

This work was funded by the National Natural Science Foundation of China (grant nos. 52205060, 52275069 and U22A20178) and the Open Fund of the National Key Laboratory (GZKF-202423).

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

The authors would like to express their sincere appreciation to Li Yang from Chenglian Kaida Technology Co., Ltd. for providing experimental equipment and testing materials during the course of this research.

Conflicts of Interest

Author Huimeng Cui was employed by the company Chenglian Kaida Technology Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Appendix A

The global Lyapunov function of FB-NG-BAC is defined as

where , , .

Differentiating yields

Substituting the adaptive law yields

By the properties of the Nussbaum function, there exists a constant such that

Thus

Since , it follows that

Moreover, , is uniformly continuous. By Barbalat’s lemma [33],

Therefore, the tracking error converges asymptotically to zero, proving the stability of FB-NG-BAC.

References

- Ravindran, R.; Massoud, A.M. An Overview of Wide and Ultra Wide Bandgap Semiconductors for Next-Generation Power Electronics Applications. Microelectron. Eng. 2025, 299, 112348. [Google Scholar] [CrossRef]

- Soomro, H.A.; Khir, M.H.B.M.; Zulkifli, S.A.B.M.; Abro, G.E.M.; Abualnaeem, M.M. Applications of Wide Bandgap Semiconductors in Electric Traction Drives: Current Trends and Future Perspectives. Results Eng. 2025, 26, 104679. [Google Scholar] [CrossRef]

- Alves, L.F.S.; Gomes, R.C.M.; Lefranc, P.; Pegado, R.D.A.; Jeannin, P.-O.; Luciano, B.A.; Rocha, F.V. SIC Power Devices in Power Electronics: An Overview. In Proceedings of the 2017 Brazilian Power Electronics Conference (COBEP), Juiz de Fora, Brazil, 19–22 November 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 1–8. [Google Scholar]

- Stegmann, T.; Durst, K.; Bruder, E.; Gunst, S.; Schwöbel, A. Enhancing Silver Sintering—Effect of Copper Substrate Microstructure on Silver Adhesion and Bond Strength. Surf. Interfaces 2025, 67, 106585. [Google Scholar] [CrossRef]

- Li, D.; Xu, W.; Liu, T.; Zhang, B.; Liu, Y.; Mei, Y. Influence of Sintering Process on High Temperature Cyclic Deformation Behavior and Fatigue Creep Damage Mechanism of Sintered Silver. Int. J. Fatigue 2025, 194, 108839. [Google Scholar] [CrossRef]

- Yang, G.; Lee, E.L.; Yang, K.; Wu, F.; Zhou, L.; Ding, L.; Li, K.; Li, X. Pressure Sintering of Micro-Silver Joints in SiC Power Devices: Optimization of Processing Parameters and FEM Analysis. J. Electron. Mater. 2024, 53, 1313–1332. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, H.; Wang, L.; Fan, X.; Zhang, G.; Sun, F. Effect of Sintering Pressure on the Porosity and the Shear Strength of the Pressure-Assisted Silver Sintering Bonding. IEEE Trans. Device Mater. Reliab. 2018, 18, 240–246. [Google Scholar] [CrossRef]

- Chang, G.; An, D.; Deng, E.; Li, X.; Luo, H.; Huang, Y. Research on the Key Processes of Large-Area Silver Sintering for SiC Power Modules. IEEE Trans. Compon. Packag. Manuf. Technol. 2025, 15, 410–420. [Google Scholar] [CrossRef]

- Gharaibeh, M.A.; Strahringer, D.; Fischer, F.; Ganzenmueller, G.C.; Hiermaier, S. Experiments on the Effect of Sintering Pressure on the Creep Response of Sintered Silver Material. Solder. Surf. Mt. Technol. 2025, 37, 353–363. [Google Scholar] [CrossRef]

- Zhao, K.; Zhao, J. Mechanical Properties and Microstructure of Large-Area Diamond/Silicon Bonds Formed by Pressure-Assisted Silver Sintering for Thermal Management. Mater. Today Commun. 2023, 34, 105230. [Google Scholar] [CrossRef]

- Wang, W.; Liu, J.; Jia, Y.; Yin, J.; Zhang, L.; Zhou, X.; Li, J.; Wang, J.; Yang, G.; Zhang, W. Synergistic Surface Modification of Silver Powder: Mechanisms for Tapped Density Enhancement and Low-Temperature Sintering. Powder Technol. 2026, 468, 121641. [Google Scholar] [CrossRef]

- Du, L.; Schaffar, G.; Jiao, W.; Liu, K.; Poelma, R.H.; Maier-Kiener, V.; Fan, J.; Kiener, D.; van Driel, W.D.; Fan, X.; et al. Tailoring Microstructure and Mechanical Properties of Sintered Cu Nanoparticles. Acta Mater. 2025, 300, 121501. [Google Scholar] [CrossRef]

- National Center for Biotechnology Information. Press Sintering Process Product Carrier, Press Sintering Apparatus and Press Sintering Process. PubChem Patent Summary for US-2021354198-A1, 7 May 2024. Available online: https://patents.glgoo.top/patent/US20210354198A1/en?q=(US-2021354198-A1) (accessed on 15 October 2025).

- Yang, L.; Wang, R.; Ding, R.; Liu, W.; Zhu, Z. Investigation on the Dynamic Performance of a New Semi-Active Hydro-Pneumatic Inerter-Based Suspension System with MPC Control Strategy. Mech. Syst. Signal Process. 2021, 154, 107569. [Google Scholar] [CrossRef]

- Gaheen, O.A.; Benini, E.; Khalifa, M.A.; Aziz, M.A. Pneumatic Cylinder Speed and Force Control Using Controlled Pulsating Flow. Eng. Sci. Technol. Int. J. 2022, 35, 101213. [Google Scholar] [CrossRef]

- Chen, B.; Zhang, R.; Huang, H.; Gao, K.; Yang, Y.; Du, R. Online Parameter Identification Based Predictive Pressure Control for Train Electro-Pneumatic Braking Systems with Thermal Effect. ISA Trans. 2024, 152, 427–438. [Google Scholar] [CrossRef]

- Yan, G.; Zhang, T.; Liu, X.; Yao, C.; Ai, C. The ADRC Strategy Research of Electro-Hydraulic Servo Pump Control System Based on Dynamic Load Torque Compensation for High-Performance Force Control. Int. J. Electr. Power Energy Syst. 2025, 171, 110991. [Google Scholar] [CrossRef]

- Shen, G.; Zhu, Z.; Zhao, J.; Zhu, W.; Tang, Y.; Li, X. Real-Time Tracking Control of Electro-Hydraulic Force Servo Systems Using Offline Feedback Control and Adaptive Control. ISA Trans. 2017, 67, 356–370. [Google Scholar] [CrossRef]

- Shen, G.; Zhu, Z.; Li, X.; Tang, Y.; Hou, D.; Teng, W. Real-Time Electro-Hydraulic Hybrid System for Structural Testing Subjected to Vibration and Force Loading. Mechatronics 2016, 33, 49–70. [Google Scholar] [CrossRef]

- Yan, H.; Liang, P.; Mei, Y.; Feng, Z. Brief Review of Silver Sinter-Bonding Processing for Packaging High-Temperature Power Devices. Chin. J. Electr. Eng. 2020, 6, 25–34. [Google Scholar] [CrossRef]

- Li, L.; Chen, H.; Jin, R.; Xu, Y.; Liu, Q.; Li, G.; Huang, H. Independent Metering-Based Leveling System with Multi-Actuator for Energy Saving: Modeling, Control, and Application on Large-Size Forming Equipment. Energy Convers. Manag. 2024, 302, 118119. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, K.; Ding, R.; Jiang, Y.; Jiang, Y. A Novel Hydraulic Interconnection Design and Sliding Mode Synchronization Control of Leveling System for Crawler Work Machine. Agriculture 2025, 15, 137. [Google Scholar] [CrossRef]

- Xu, F.; Hu, H.; Feng, S.; Zhou, C. Synchronous Leveling Control Method of Crane Vehicle Platform Based on Position–Force Coordination. Actuators 2025, 14, 441. [Google Scholar] [CrossRef]

- Liu, K.; Kang, S.; Cao, Z.; Liu, R.; Ding, Z. Angle and Force Hybrid Control Method for Electrohydraulic Leveling System with Independent Metering. Math. Probl. Eng. 2021, 2021, 6642597. [Google Scholar] [CrossRef]

- Dai, J.; Zhang, H.; Li, W.; Guo, R.; Zhao, J. Research on Leveling Strategy of Suspension System of Roadway Heavy-Load Transport Vehicle. In Proceedings of the 8th International Conference on Advances in Construction Machinery and Vehicle Engineering, Shanghai, China, 14–15 October 2023; Halgamuge, S.K., Zhang, H., Zhao, D., Bian, Y., Eds.; Lecture Notes in Mechanical Engineering. Springer: Singapore, 2024; pp. 1181–1190, ISBN 978-981-97-1875-7. [Google Scholar]

- Geranmehr, B.; Vafaee, K.; Sadeqi, A. High Precision Electro-Hydraulic Self Leveling Platform System. In Proceedings of the 2014 Second RSI/ISM International Conference on Robotics and Mechatronics (ICRoM), Tehran, Iran, 15–17 October 2014; IEEE: Piscataway, NJ, USA, 2014; pp. 029–034. [Google Scholar]

- Sun, C.; Wei, J.; Fang, J.; Huang, C.; Li, M. Co-Simulation ADAMS-Simulink for Analysis of Passive Four-Point Leveling System of the Hydraulic Press. In Proceedings of the BATH/ASME 2016 Symposium on Fluid Power and Motion Control, Bath, UK, 7–9 September 2016; American Society of Mechanical Engineers Digital Collection: New York, NY, USA, 2016. [Google Scholar]

- Zang, W.; Zhang, Q.; Shen, G.; Fu, Y. Extended Sliding Mode Observer Based Robust Adaptive Backstepping Controller for Electro-Hydraulic Servo System: Theory and Experiment. Mechatronics 2022, 85, 102841. [Google Scholar] [CrossRef]

- Wang, F.; Chen, G.; Liu, H.; Yan, G.; Zhang, T.; Liu, K.; Liu, Y.; Ai, C. Research on Position Control of an Electro–Hydraulic Servo Closed Pump Control System. Processes 2022, 10, 1674. [Google Scholar] [CrossRef]

- Ji, X.; Wang, C.; Zhang, Z.; Chen, S.; Guo, X. Nonlinear Adaptive Position Control of Hydraulic Servo System Based on Sliding Mode Back-Stepping Design Method. Proc. Inst. Mech. Eng. Part J. Syst. Control Eng. 2021, 235, 474–485. [Google Scholar] [CrossRef]

- Chua, S.T.; Siow, K.S. Microstructural Studies and Bonding Strength of Pressureless Sintered Nano-Silver Joints on Silver, Direct Bond Copper (DBC) and Copper Substrates Aged at 300 °C. J. Alloys Compd. 2016, 687, 486–498. [Google Scholar] [CrossRef]

- Ordonez-Miranda, J.; Hermens, M.; Nikitin, I.; Kouznetsova, V.G.; van der Sluis, O.; Ras, M.A.; Reparaz, J.S.; Wagner, M.R.; Sledzinska, M.; Gomis-Bresco, J.; et al. Measurement and Modeling of the Effective Thermal Conductivity of Sintered Silver Pastes. Int. J. Therm. Sci. 2016, 108, 185–194. [Google Scholar] [CrossRef]

- Wang, C.; Wen, C.; Guo, L. Multivariable Adaptive Control with Unknown Signs of the High-Frequency Gain Matrix Using Novel Nussbaum Functions. Automatica 2020, 111, 108618. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).