Abstract

Given the fact that belt drives are used to transmit power to a fairly large extent, it is natural to devote scientific attention to their transmission with an effort to contribute to the constant technical and technological progress in the field of belt production and use. For testing and monitoring belt drives, a measuring system was designed and manufactured, which allowed the installation of various types of belt drives and, under a controlled load, to monitor selected parameters and the behavior of individual transmission elements. The presented contribution presents both the measuring system itself and experimental measurements on three V-belts of the same size manufactured by three different manufacturers. During the experimental measurements, parameters such as belt tension were changed by changing the axial distances of the pulley axes; by connecting electric motors through frequency converters, it was possible to control the change in the input speed of the transmission and, at the same time, the load on the output pulley. On the proposed specific design solution for testing belt drives, the actual speed of the input and output pulleys was measured by sensors to determine the belt slip, and the belt’s floating in one plane was monitored using high-precision distance measurement sensors. The analysis of the belt drives also included an assessment of their impact on other parts of the machine or equipment (for example, when transmitting large forces, this can have a negative impact on bearings and gearbox components) on which they are installed; therefore, vibration measurements were also performed. The results of the experimental measurements can contribute to designers choosing a belt drive, for example, even under boundary load parameters and extreme conditions.

1. Introduction

Due to the important role of belt transmissions in various structural solutions of industrial sectors, it was necessary to focus on the development of a new test device. In response to this need, the design of a test device for belt transmissions under controlled load was created. Based on the initial concepts, a 3D model was created, which subsequently materialized into a real device and integrated into a complex measuring system. The test stand consists of three main parts: measuring, controlling, and monitoring. This new test facility was built within the faculty laboratory for testing and monitoring technical systems. It is used for belt transmission research and at the same time as an educational aid for students [1].

A key factor in analyzing belt drives is proper installation and maintenance. At the same time, belt drives can wear out or be damaged due to inappropriate tension, excessive load, and other factors. The regular inspection and maintenance of belt drives is therefore essential. When selecting the appropriate type of belt drive, the specific requirements of the application must be considered, as there are many types of belts designed for different purposes. For the optimal functionality and durability of belt transmissions, the correct tension of the belt is also key, as is the exact placement of the pulleys [2].

Several Key Factors Must Be Taken into Account When Assembling Belt Drives

Choosing the right belts: Choosing the right type and size of belts is equally essential to achieving optimal performance. The belt must be of adequate width and properly tensioned to effectively transfer energy and movement.

Correct belt tension: The correct belt tension is essential for their trouble-free operation. A belt that is too loose can cause slipping, while too much tension can lead to premature wear, e.g., bearings or broken pulleys. Optimum tension should be according to the manufacturer’s recommendations, and it is usually recommended that the belt be compressed about 1/4 inch.

Proper belt placement: It is also essential to ensure proper belt fit on the shafts and pulleys to prevent slipping or excessive wear. The position of the belt can be affected by the alignment and level of the shafts, so it is important to carefully check that they are correctly adjusted.

Regular maintenance: As with any machine, belt drives require regular maintenance to prevent wear and tear. Gears must be regularly checked for wear, correct tension, and possible damage. If any fault or damage to the belt appears, it must be repaired or replaced immediately [3].

Tension force and belt tension are critical factors affecting performance. Correct tension ensures reliable operation and minimizes the risk of malfunctions. The calculation of the tension force depends on the dimensions, material, and application of the belt. A higher clamping force can increase the efficiency of power transmission, but excessive force leads to overloading and premature wear [4]. There are several methods for determining proper belt tension, including measuring elasticity. Gauges and other tools are used to check tension. When adjusting the tension, it is important to follow the manufacturer’s specifications for the belt type and application.

When using belt transmissions, it is necessary to distinguish between belt slippage and belt slippage. Slippage occurs when the belt is insufficiently tensioned and can be eliminated by adjusting it properly. Belt slip, also known as gauge slip, occurs even with proper tension and increases with increasing tension [5]. Since slippage cannot be completely ruled out, it became the subject of my measurements.

As part of the study of the professional literature review of the issue of belt transmissions, there are relatively few research publications compared to other transmissions. The authors Shandook, Ogaili, and Al-Haddad discussed the diagnosis of belt drives using Taguchi expert systems in their article. In their study, they addressed the monitoring of a belt drive with speeds from 500 to 2000 RPM at a belt tension of 70 and 150 N [6]. In 2020, the authors Yordanov and Gyurov published the results of their study, where they investigated failures of belt drives driven by induction motors, while diagnostics were performed using stator current spectral analysis (MSCA) and drive belt loosening [7]. The monitoring of rotor systems driven by electric motors is discussed in a 2019 article by Huang et al. [8]. In 2021, a study by Pollak et al. was published in the field of anomaly detection based on vibrations obtained from the operation of a belt drive. Continuous fault diagnosis for anomalies is a fundamental step in estimating the remaining life of a component and subsequently obtaining a reliable predictive maintenance system that reduces production costs [9]. Since belts are made of various materials, they have received great attention in the scientific research community, as evidenced by the research results published in 2024 by the authors Ryba and colleagues. This article presents tests of the strength of the rubber belt material and its damage under load. In the experiment, various configurations of longitudinal and transverse damage were verified, and statistical methods were used to analyze the results [10]. The authors Skoczylas and colleagues, in 2021, published the results of experimental measurements and the detection of conveyor roller faults based on acoustic signals. The analyzed data were collected using the ANYmal autonomous robot from a specific plant [11]. In 2019, Homisin, Grega, Kassay, Fedorko, and Molnar published the results of their scientific research in the field of monitoring vibrations of a conveyor belt with the aim of accurately determining and predicting the cause and location of drive wear [12]. Kuric and colleagues focused on diagnosing drives of technologically robotized workplaces using various monitoring sensors, and their study was published in an article in 2021. Intelligent diagnostic models have been developed based on sensory systems to diagnose drive models of technological robotized workplaces [13]. Bortnowski, Gladysiewicz, and Ozdoba published an article in 2020 presenting measurements of linear belt speed using various sensors and measuring devices, which is essential to know to identify slip-on friction surfaces [14]. Kozłowski and colleagues focused on diagnosing joints on belt belts, and they also presented the results of their research. In this paper, the authors propose an automated procedure applied to real measurement data and final results [15].

One of the dangerous effects on the life of belts is also incorrect belt guidance, and this is precisely what the authors Dabek et al. in the publication [16] focused on, where they monitored lateral deviations of the belt, vibrations in selected locations of the assembly and changes in force components. The authors Ilankovic et al. published in the article [17] the results of research into the effect of fatigue loading on the fatigue life of the belt, for the implementation of which a specially designed and manufactured test device was used, which enabled the precise control and monitoring of the load, as well as the number of load cycles until the belt broke. Experiments have shown that at a load of less than 70% of the breaking strength, the belt life is very long. By developing an analytical model of a typical belt feeder and determining its stability and forces on the supports, the authors Krauze and colleagues in the article [18] contributed to new knowledge in the field of belt mechanisms. At the same time, it enabled the development of an application for testing the stability of a belt feeder already at the design stage or when introducing design changes. Continuous monitoring, data collection, and data processing were addressed in relation to a conveyor belt in the article [19] by Bzinkowski et al. They presented a new measurement system based on linear strain gauges located in the rear pulley assembly. The monitoring of the device was in real time. An interesting study was carried out by Blatnicky et al., who, in their article [20], described and used the proposed chain tensioning mechanism. By combining this proposed mechanism and the measurement system from the previous article, a specific tensioning mechanism with online monitoring could be created.

The motivation for conducting experimental measurements in the field of belt transmissions and the related design of a new measuring system was to contribute new scientific research knowledge to manufacturers of various types of belts as well as designers who plan to incorporate the transmission into the assembly. The measuring system, as a modular assembly with the possibility of controlling the transmission load, belt tension, input speed, and output torque load, contains various monitoring points from which it is possible to obtain parameters directly affecting the functionality and service life of the transmission. The introductory part of this article is devoted to the basic overviews and knowledge necessary for designing new design solutions, as well as a literary review concerning the results of scientific research activities in the field of designing and monitoring belt transmissions. The following part is devoted to a more detailed description of the designed system, which was used in individual measurements. Chapter 3 describes experimental measurements of slip, belt swimming, and vibrations at a selected location. An analysis of individual measurements of the belt drive is presented in Chapter 4. The overall evaluation of experimental measurements and the influence of individual parameters on the functionality of the drive is summarized in the conclusion.

Since belt drives are an integral part of many industrial and mechanical devices, and their functionality can be compromised by various types of damage, regular diagnostics of belt damage are necessary. This is crucial to prevent serious problems and ensure the efficient operation of machines. Workers performing a belt drive inspection should have enough information to determine the condition and functionality of the drive, which was one of the motivations for designing and performing these experiments. Any new information, such as the results of our experimental measurements, can help in practice to determine the condition of the belt drive more easily, faster, and more accurately.

2. Assembly of the Measuring System for Testing Belt Transmissions

Various techniques and tools are used to diagnose the damage and condition of belts, which allow for the accurate detection of the problem of failure without the need to disassemble the entire mechanism. The proposed measuring device also offers solutions for monitoring and diagnosing belt drives, which allow for increasing the efficiency and reliability of the device and was designed with an emphasis on versatility and flexibility, which makes it an easily modifiable device. Investment in diagnostic tools and regular maintenance can significantly reduce the costs associated with replacing and repairing damaged parts, which also motivated the researchers to design such a measuring system. Proper diagnostics and the timely maintenance of belt drives are key to extending the life of machines and reducing unplanned downtime. This design solution allows the easy replacement and adaptation of individual components according to the current needs of the research or experiment. The device is designed so that basic elements such as drive and driven pulleys or the belt itself can be changed quickly and efficiently, and these changes have a fundamental impact on the functioning of the entire system.

The possibility to change driving and driven pulleys is one of the main advantages of this system. In this way, the gear ratio between input and output can be easily adjusted, which is an important parameter when testing different types of belt drives. Changing the gear ratio can affect the speed and load of the entire system, which, in turn, affects the behavior of the belt, for example, its floating or vibrations. This flexibility is especially crucial in belt drive research and innovation, where different combinations of components and settings are often tried out to achieve optimal results.

Another advantage of this measuring system is the possibility to change input and output parameters as needed. This makes it possible to simulate different operating conditions; for example, changing the speed of the drive pulley or the load on the driven pulley is necessary for complex experiments. The flexibility of the system allows researchers to precisely set various parameters and then observe how these changes affect the behavior of the belt drive [21].

In research and innovation projects, where emphasis is placed on testing and optimizing belt transmissions, such a measuring system is an irreplaceable tool. It allows not only experimentation with different types of belts and pulleys but also the accurate measurement of their performance parameters. Thanks to its modularity and the possibility of the quick replacement of components, this system contributes to the more effective research and development of new technologies in the field of mechanical transmissions [22].

During the development and construction-design phase, 3D modeling and simulation software Autodesk Inventor 2024 was used, which allowed us to design and analyze the entire assembly before its production. The inventor offers the advantages of digital prototyping and integration of 2D drawings from the Autodesk AutoCAD program with a 3D model, thus enabling the merging of both types of data into a single entity.

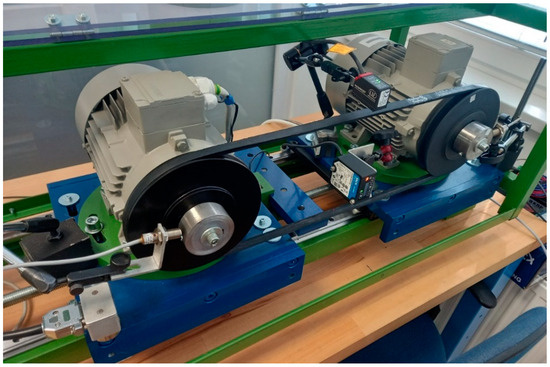

The new test system consists of a basic frame on which the driving and driven electric motors are located, with the driven motor performing the function of the braking system. The shafts of both electric motors are equipped with pulleys and connected by a V-belt, creating a belt transmission. Siemens asynchronous electric motors (type 1LA7090-2AA10ZA11, 1.5 kW, 2900 min−1, 400 V, Y, 50 Hz, IMB3, PTC thermistor) are mounted on a frame with the possibility of displacement, which allows the V-belt tension to be adjusted by changing the axis distances pulleys. The control panel is shown in the following Figure 1.

Figure 1.

Control panel of the new measuring system.

The control panel of the measuring system consists of a frequency converter FM1 (I) for controlling and monitoring the input electric motor as the driving element of the assembly, and a frequency converter FM2 (II) is used for monitoring and controlling the output electric motor with its main function as a loading element of the assembly. The regulators (III) can be used to switch the load on the output pulley either by changing the torque or, if necessary, by changing the speed. The panel (IV) can be used to turn the entire system on/off and, at the same time, regulate the input speed of the driving electric motor. The complete electrical circuit is connected via circuit breakers, residual current devices (V), and the main power supply switch (VI).

The driven electric motor, controlled by means of a frequency converter, functions as a brake, and its braking effect can be regulated as needed. This creates corresponding forces in the belt in the loaded and unloaded branches, which leads to a measurable slip of the pulley. The set includes a monitoring and evaluation unit with a computer and relevant software (SoMove, Motor, and others) [16].

Belt tension is often given as a tension range or tension force value. The tension range determines the minimum and maximum values that the belt can withstand.

Various Methods Can Be Used to Determine the Correct Belt Tension, Including the Following

Belt movement method: This procedure consists of loosening the belt and manually turning it 90 degrees. When properly tensioned, the belt should be able to rotate 30 to 45 degrees.

The use of the tensioning device: The tensioning devices are designed to accurately determine the correct tension of the belt. These devices are attached to the belt and serve to regulate its tension until it reaches the value recommended by the manufacturer using the touch method.

In our experimental measurements, we used two different methods to monitor belt tension. The first was a non-contact method where we used an SKF measuring device. This device enables accurate measurement without direct contact with the belt, which is especially advantageous for minimizing interventions in the measured assembly and ensuring higher measurement accuracy.

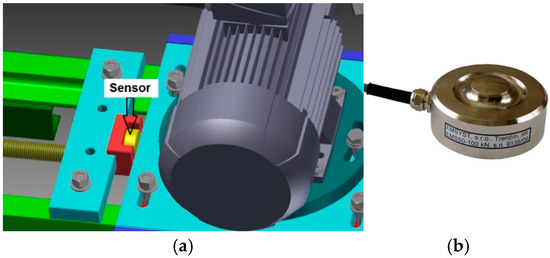

The second method was an integrated tensometric pressure sensor EMSYST EMS50, which was directly placed in the measuring assembly. This membrane sensor uses a bridge connection and allows the measurement of force in the direction of pressure in a wide range, from 0.1 to 100 kN. Thanks to these properties, it is suitable for various applications not only in the industry but also in a laboratory environment where high accuracy and reliability are required. This combination of the two methods allowed us to obtain detailed data on the tension of the belt, which was crucial for analyzing its behavior during the tests.

Figure 2a shows the specific installation of the EMSYST sensor and its location within the assembly. Figure 2b shows a photo of the Emsyst EMS50-100 kN sensor in use. Before the experiments were carried out, the sensor was calibrated after being mounted in the assembly using the calibration parameters supplied by the manufacturer Emsyst, exactly according to the sensor serial number. Since the sensor is not located in the plane of the belt, it is necessary to count on the necessary calculation of the exact value of the belt tension, which can be compared with the actual value of the belt tension. The actual value of the belt was measured by the aforementioned non-contact method using the SKF measuring device.

Figure 2.

Monitoring the tension of the belt (a) using a tensometric sensor (b) that detects the compressive (tensioning) force.

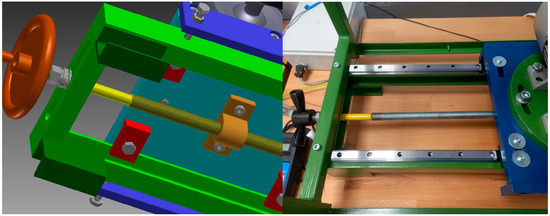

The tensioning of the belt from the belt transmission is carried out using a threaded rod, which is located on the bottom of the device (Figure 3). By turning the crank, one of the electric motors is moved, which tightens the belt to the desired value. This equipment is designed to allow new types of belts to be tested while changing pulleys and belts is very easy. Testing belts in extreme conditions can be achieved through simple adjustments to the desired belt setting. In this way, we can adjust the pulleys to have a certain angular and axial misalignment, ensuring accurate testing under extreme conditions.

Figure 3.

Mechanism used to tension the belt in the mechanism.

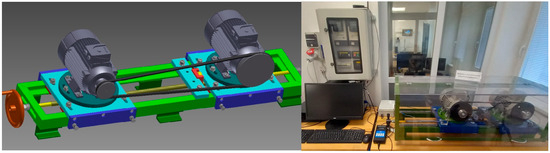

The quantities needed to calculate the slip are recorded using speed sensors of the drive and driven electric motor axes and are then processed by a computer. Belt tension values are evaluated in real time. Figure 4 shows a 3D model and a physically produced system intended for monitoring belt slip on belt drives and testing various other types of belts.

Figure 4.

Three-dimensional model and real measuring and monitoring equipment.

The proposed 3D model was created during the design and construction of the measuring device, from which technical documentation for the production of individual components was subsequently created. Due to the robustness and rigidity of the structure and the relatively low load, verification using strength analyses has not yet been performed. During the planned experimental measurements under extreme loads, it will be necessary to perform simulation studies that exclude damage to the transmission or other elements of the assembly.

The frequency converters, which are used to control the electric motors, are connected in the assembly based on the previously designed schemes. The output electric motor is carefully adjusted and regulated to optimize speed and torque. In this way, it acts as a burdening element on the entire system [23]. The integration of frequency converters into the system also allows the easy setting and monitoring of the performance of the electric motors through the specialized SoMove software, which simplifies the management and monitoring of their activity.

3. Experimental Measurements and Analysis of Results

Belt tension monitoring was carried out with a manual belt tension gauge from SKF. After the correct installation of the driving and driven pulley so that both pulley axes were parallel and the pulleys were built in one plane, the entire system was tested with initial measurements at different settings of the influencing parameters. The following Figure 5 shows the construction solution of the designed device for testing belt transmissions. Measurements were made on three V-belts, A1450Lw 13 × 1420Li, from different manufacturers (Optibelt, Rubena, and Gufero).

Figure 5.

Transmission part of the device intended for testing belt transmissions.

In order to achieve the most accurate experimental measurement results, combinations of different measuring devices were used for the calibration of measurements. For example, to determine the friction coefficient, it was necessary to know the actual input and output speeds, which were monitored by static sensors, but to verify the correctness of the values, they were also measured by a manual laser meter DT-2234C. When measuring the belt float, the correct measurement results were verified by repeated measurements and using two different distance sensors (SICK OD2000 and Micro Epsilon optoNCDT). During each preparatory phase of the newly set belt drive load parameters, preparatory repeated measurements were performed for calibration. During the system loading, the vibrations of the designed structure were also monitored secondarily using a contact sensor with a CMMS Checker measuring unit. To verify the correctness of the measured parameters, vibration measurements were also performed by a non-contact method using the Polytec PDV 100 measuring device.

3.1. Measurement of Belt Slip of Belt Transmission

In order to monitor and determine the values of the slip coefficient of the belt transmission, input parameters such as the speed of the electric motor, the theoretical transmission ratio indicated on the label, the tension of the belt, and the torque were taken into account. It is precisely for the monitoring of these parameters that a system with two sensors was designed to measure the actual speed on the input and output shafts of the pulleys. Monitored values were obtained through sensors placed directly on the device in pre-selected locations [24]. The measured parameters, such as the real revolutions of the driving pulley of the electric motor (n1s) and the driven pulley (brake) (n2s), were transferred to the software using an analog-to-digital converter. The “Motor” software was designed for the belt slip measurement system, which then processed these data and calculated the necessary values, which are used to determine the final belt drive slip.

The parameters of the belt slip measurement are as follows:

- n1t—table revolutions of the electric motor driving machine;

- n1s—the actual speed of the motor under the load of the driven part under the given conditions of the tension force F;

- n2—speed without slip on the drive machine;

- it—the theoretical transmission ratio;

- n2s—measured (actual) speed of the driven machine with slip;

- Δn2—slip speed;Δn2 = n2 − n2s

- T—the measured (real) time of the slip revolution [s];

- ξ—specific slip;

- ψ—coefficient of elastic slip;ψ = 1 − ξ

- i—gear ratio in belt transmission;

The “Motor” software was used to determine the value of the belt slip and is designed for direct integration with the equipment’s monitoring system, while input parameters such as input and output revolutions and the gear ratio must be entered before starting the measurement.

The measurement itself can be implemented in two different ways

- Measurement at constant speed of the electric motor and brake load: In this case, the constant speed of the electric motor and the same torque are maintained using the brake. During the measurement, the values of ψ and ξ are obtained at a minimum of five different levels of tensioning force, both during the loading and unloading of the transmission. Based on these values, it is possible to create graphs that show the dependence of the elastic slip coefficient on the tension force value. These data are then processed and entered into the results table.

- Measurement at constant input speed and tension force: In this scenario, constant values of electric motor input speed and tension force are maintained. The measurement focuses on the elastic slip coefficient ψ at different torques of the electric motor. At least five different values of the torque are obtained from the measured input power of the electric motor according to the established procedure, which enables the precise determination of the coefficient ψ.

Electric motor performance Pe:

Here, Pke—power measured by wattmeter,

ηe—the efficiency of the electric motor stated in the technical specifications.

The torque on the pulley can then be calculated as follows:

Here, n1s—real revolutions of the driven pulley obtained from the program “Motor“.

Measurements were taken while loading and unloading the gear. The results of these measurements were presented as the dependence of the quantity ψ on the torque at various additional parameters. All obtained dependencies were recorded and are displayed in the tables. Instead of power measurement, it was also possible to use the measurement of electrical quantities such as voltage and current or measure the electrical power directly on the driving and driven devices. The aim of these measurements was to show how slips affect the efficiency of the belt transmission. The efficiency of the transmission itself was calculated using a well-known formula, while the measurements served to confirm the theoretical assumptions and demonstrate the practical effects of slippage on the efficiency of the transmission.

Subsequently, the efficiency with slip acceptance was expressed by the following mathematical relationship:

For the laboratory determination of power based on electrical quantities, it was necessary to complete the physical connection of the measuring devices and to extend the monitoring software with functions for power measurement. At the same time, it was necessary to determine the accuracy of the power measurement, which will allow the exact calculation of the observed efficiency of the belt’s transmission according to the established formulas. Experimental monitoring of type A belts involved changing the belt’s tension force [25]. This force was selected and adjusted based on the recommended values of optimal tension for a given type of belt, with the value set at 254 N. These measurements made it possible to observe the behavior of the belt at different levels of tension and to analyze its effect on the efficiency of the belt transmission.

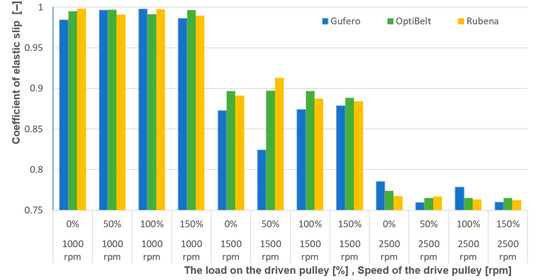

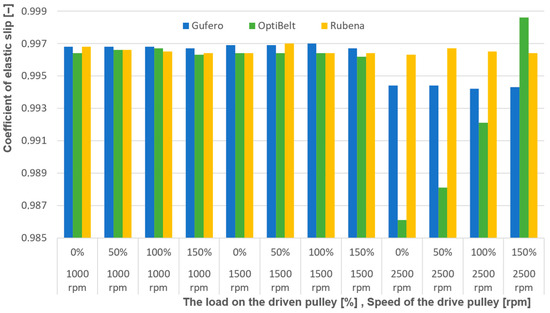

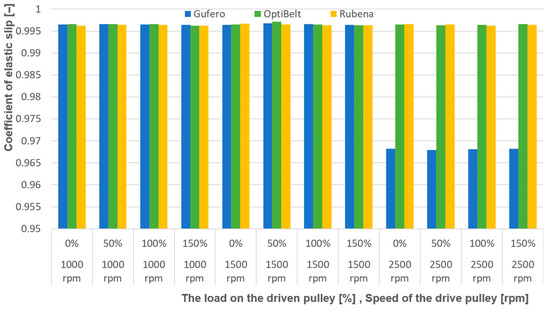

Based on the optimal value of the belt tension, which, according to the manufacturer, is given in Table 1, the belt tension values of 50 N, 250 N, and 450 N were chosen for the experiment. Figure 6 shows how the resulting values of the coefficient of elastic slip change depended on the difference in the speed values on the input drive pulley and the load on the output drive pulley, while the load was changed by changing the torque when the belt was tensioned to 50 N. The change in the output load was set through the FM2 frequency converter, which was connected to the output electric motor. The coefficient of elastic slip was measured using the “Motor” software, which simultaneously monitored the actual revolutions of the driving and driven pulleys. The optimal value of the belt tension was set at 254 N, which was taken into account during the measurements. The results of this measurement are shown in Figure 7, while the overload above the optimum value, namely when the belt was tensioned at 450 N, is shown in Figure 8.

Table 1.

Table of specific weights and recommended belt tension values [26].

Figure 6.

Dependence of the coefficient of elastic slip on the input speed and the load at the output of the belt transmission when the belt was tensioned at 50 N.

Figure 7.

Dependence of the coefficient of the elastic slip on the input speed and the load at the output of the belt transmission with a belt tension of 250 N.

Figure 8.

Dependence of the coefficient of elastic slip on the input speed and the load at the output of the belt transmission when the belt was tensioned at 450 N.

3.2. Determining the Float Value of the Belt Drive Belt

The manufactured test stand was designed to enable the precise adjustment of the belt transmission so that it could work under both optimal and extreme conditions. The basic prerequisite for minimizing belt floating was the correct fitting of the pulleys and subsequent tensioning of the belt to the value recommended by the manufacturer, which was determined according to the tables. If the belt was properly tensioned to the optimum value, which in this case was 250 N, it was expected that the floating, i.e., unwanted movements of the belt during its operation, would be minimal. The device was designed with this very goal in mind to monitor how the setting of various parameters affects the swimming of the belt.

For the accurate measurement of float values, high-precision distance sensors were installed near the loaded and unloaded branches of the belt. These provided data on how the belt behaves in different phases of the transmission. Although one of the options for measuring swimming is the use of a high-speed camera, for economic reasons, a measurement method based on distance sensors was chosen. This method was reliable and less expensive.

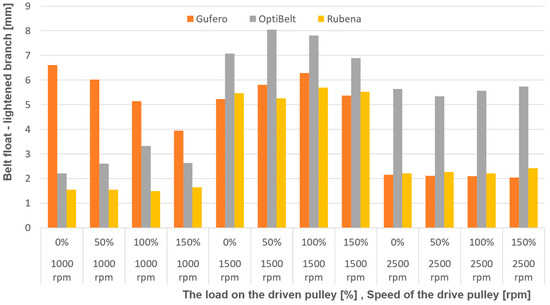

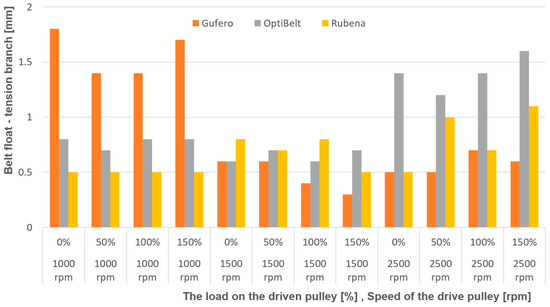

Figure 9 shows the results of experiments that show the dependence of the belt float in the lightened branch at optimal tension and different conditions. As part of the experiment, the input speed of the drive pulley and the output load were varied [27]. Tests were performed with three A-type V-belts from different manufacturers. As can be seen from the results, the differences in the belt float are clearly visible, both depending on the load change and when the belt manufacturer was changed, indicating the influence of material quality and processing on the operational behavior of the belt.

Figure 9.

Dependence of the belt floating in the lightened branch on the input speed and the load at the output of the belt transmission when the belt was tensioned at 250 N.

The following Figure 10 shows the dependence of the belt float in the upper traction branch depending on the change in the input speed of the drive pulley and the output load on the driven pulley. The output load is affected by the torque, which is regulated through the FM2 frequency converter. This converter allows precise control over the torque and, thus, the load, which is important when investigating the behavior of the belt under different operating conditions.

Figure 10.

Dependence of the belt float in the traction branch on the input speed and the load at the output of the belt transmission when the belt was tensioned at 250 N.

Comparing Figure 9 and Figure 10, the differences in belt float between the upper tension branch and the lower relief branch are clearly visible. In the upper tension branch, which is subjected to a greater load, the different behaviors of the belt are manifested compared to the lower, lighter branch. These differences are significant because they show how different operating conditions, such as rotational speed and load, affect the belt float. In the lower branch, where the load is lower, swimming manifests itself differently than in the upper, loaded part of the belt.

In addition, the graph shows differences even when using belts from different manufacturers. These differences point to the influence of the quality and properties of the materials used in the production of belts on their behavior during operation. A belt from one manufacturer may show a more significant float than a belt from another manufacturer, indicating the importance of choosing a quality manufacturer for optimal results.

This analysis points out that the designed belt float monitoring system in a belt drive plays a vital role in preventing potential breakdowns and failures in the drive. Experimental measurements have proven the effectiveness of this system in detecting belt floating, which indicates its possible application in real operating conditions. In the future, it might be possible to improve this system with the function of the automatic regulation of the belt tension based on the analyzed data, which would increase its reliability and efficiency. At the same time, the author’s new idea is to develop a universal tensioning mechanism that would include a pressure roller and allow the monitoring of the belt’s movement in two planes. The measurement results of this article present the lateral movement of the belt in only one plane on the unloaded and loaded branches of the transmission.

The proposed system for monitoring belt float in belt transmission offers considerable potential in the field of machine and equipment operation. It enables operators to prevent serious breakdowns, thereby increasing the overall efficiency and safety of the operation. Belt oscillation in a belt drive is one of the key factors that lead to wear on the belt and other drive components. Therefore, it is important to have a reliable and accurate system for monitoring this parameter to ensure the long-term and efficient operation of the equipment. As part of the research, measurements were also taken of the belt’s float and of the traction and unloaded branches when the belt was tensioned to a value of 50 N and 450 N.

3.3. Measurement of Vibrations of the Measuring System from the Belt Transmission

Belt drive equipment is often subject to vibrations that result in an undesirable phenomenon known as belt “floating” [28]. It is necessary to study this phenomenon in detail because it can have a negative effect on the life of the entire system and lead to premature wear of its components, especially the bearing of the shafts. On the newly designed test equipment, it is possible to change the belt tension in a controlled manner by adjusting the axial distance between the pulleys. This function makes it possible to analyze the behavior of vibrations in different places of the system and under different operating conditions.

Vibrations arising during the belt’s operation have the potential to disrupt the functionality of the system and can significantly reduce its service life. Therefore, it is necessary to analyze the influence of various parameters, such as the revolutions of the drive pulley and the load of the driven pulley, on the intensity of vibration. The goal is to find out how these factors affect vibrations and then provide suggestions for minimizing them.

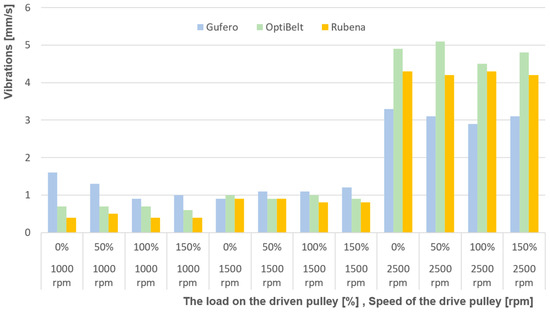

Figure 11 shows the small differences in vibration when using an “A” belt from different manufacturers. At higher speeds, which in the experiment reached a value of up to 2500 revolutions per minute (rpm), these differences become more pronounced. At lower speeds, namely 1000 and 1500 rpm, the differences in vibrations were less significant. This fact indicates that higher revolutions lead to an increase in vibration, and the differences between belts from different manufacturers are manifested primarily under these conditions [29].

Figure 11.

Dependence of vibrations on the input speed and the load at the output of the belt transmission when the belt is tensioned at 250 N.

Experiments were performed at three different values of belt tension: 50 N, 250 N, and 450 N. It was found that at the optimal belt tension of 250 N, the vibrations were the most stable and lowest. This condition is also documented in Figure 11. The results show that not only the revolutions but also the correct setting of the belt tension have a significant influence on the behavior of the system.

Based on these experimental findings, recommendations can be made for users of belt systems [30]. This is mainly about reducing vibrations when the belt is properly tensioned and when the revolutions are maintained at optimal values, which can significantly extend the life of the entire device and minimize the risk of premature wear.

After analyzing the measured vibration values at the selected location of the stand, we can conclude that at input speeds of 1000 and 1500 rpm, the vibrations are relatively low, without significant differences between different types of belts. However, when the speed increases to 2500 rpm, there is a significant increase in vibration. This increase is significant regardless of the type of belt used, which indicates that higher revolutions have a major impact on the generation of vibrations in the system.

4. Analysis of Individual Belt Transmission Measurements

The main goal of research in the field of testing belt transmissions on newly designed equipment is to formulate recommendations that will help reduce the occurrence of failures in belt transmissions. During the operation of belt transmissions, various problems often appear, which can lead to a decrease in the efficiency and service life of these systems. The most common problems include the rapid wear of the belt, a decrease in the speed of the driven pulley, overheating of the belt caused by external influences, and transverse and longitudinal cracks on the belt. The purpose of testing specific belts is to provide recommendations to minimize these problems. The results of such experiments motivated the authors to develop this system with further possibilities, which can help to expand our knowledge of belt wear in practice. During the initial designs of the measuring system and planning of the experiments, the problems of production, assembly, and functionality were consulted with the belt manufacturer Rubena (Nachod, Czech Republic). The primary goal of the experiments was to contribute to the extension of the service life of the transmission belt and, at the same time, limit the critical load setting, which also affects the entire mechanism of the belt transmission.

One of the main aspects of the design of the measuring device was to determine the limit during extreme loads and to identify the point of destruction of the belt. The construction of the test equipment was based on technical and construction knowledge that was obtained from the professional literature, available materials, and consultations with experienced experts in the field. Before choosing the final solution, several alternative concepts were considered, which were elaborated in the form of a virtual 3D model [31].

It is possible to measure the actual revolutions of both pulleys on the device, which are important parameters for determining the slippage of the belt transmission. Placing the device on shock-absorbing rubber pads also enables the measurement of transmission vibrations and belt floating. The results of these measurements can significantly contribute to knowledge in this field of research and the development of new types of belts and belt transmissions. In this way, we aim to increase the reliability and efficiency of belt transmissions in practice.

5. Conclusions

This article presents a unique design solution that serves as an alternative for the effective monitoring, determination, and verification of key parameters affecting the operation and service life of belt-driven equipment. When designing such solutions, economic costs are primarily influenced by the design and development phase, not by production itself. The construction plays a fundamental role in the functionality and reliability of the final product. The functional states of the individual nodes of the designed measuring system were verified by experimental measurements, and at the same time, by changing the load and tension of the belt, extreme transmission conditions were also performed.

The presented solution is modular and has found its application in various fields, including the development of laboratories, the professional training of students as part of the educational process, as well as in the creation of final theses, and solving tasks associated with the design, control, and testing of belt transmissions. This design solution is useful not only from an academic point of view, but also from a practical point of view as it can inspire further research in this area.

Experimental measurements showed that the highest values of the belt elastic slip coefficient were at the lowest set speeds, but when the speeds were increased, the tension was increased, and these values reached an optimal state. The monitoring of the belt slip was carried out on the loaded and unloaded belt branch, with higher slip values measured on the unloaded branch, which has a more significant impact on the overall vibrations of the entire system. From the perspective of belt life, the values on the loaded branch were more significant, and the measurements showed that the belt tension and speed have a significant impact on this parameter. The range of medium values of the set tension and speed parameters can be considered optimal. From these findings, it can be deduced that tensioning above a certain level no longer brings benefits in the form of reducing slip but can have a negative impact on the life of the belt or other components, such as bearings. From the perspective of vibration, increasing the speed logically has the highest impact, while the belt tension has only a minimal impact on the measured values. To eliminate vibrations, it would be appropriate to incorporate damping elements into the assembly so that they do not negatively affect other drive elements.

If the results presented in this article stimulate further research and deeper analysis of the issue, we can conclude that the new measurement system and its measurements have a real and practical benefit. This benefit lies in the ability to more effectively test and analyze belt transmissions, which has significant application not only in research but also in practice. The overall results of this study support long-term research in this area while being consistent with previous theoretical assumptions and experimental experience. In the future, we plan to expand the measurement system for belt transmissions with additional functions that will enable even more accurate and complex measurements. Among these extensions is the monitoring of the deviation of the movement of the belt in the two axes, which would bring new knowledge about its dynamic behavior. Another planned innovation is the tracking of temperature changes in belt transmission components using thermal imaging. This measurement would make it possible to analyze temperature changes that can have a significant impact on the performance and life of the belts, especially when various operating parameters are changed.

Author Contributions

Conceptualization, J.M. and T.C.; methodology, J.M. and T.C.; software, T.C.; formal analysis, J.M. and T.C.; resources, T.C.; data curation, J.M. and T.C.; writing—original draft preparation, T.C.; writing—review and editing, J.M.; visualization, T.C.; project administration and funding acquisition, J.M. All authors have read and agreed to the published version of the manuscript.

Funding

This work was funded by the Slovak Research and Development Agency under contract No. APVV-21-0228, and VEGA 1/0509/23 were granted by the Ministry of Education, Science, Research and Sport of the Slovak Republic. The article is the result of the Project implementation: Development of Excellent Research Capacities in the Field of Additive Technologies for the Industry of the 21st Century, ITMS: 313011BWN5, supported by the Operational Program Integrated Infrastructure funded by the ERDF.

Data Availability Statement

Data are contained within the article.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Kawalec, W.; Suchorab, N.; Konieczna-Fuławka, M.; Król, R. Specific energy consumption of a belt conveyor system in a continuous surface mine. Energies 2020, 13, 5214. [Google Scholar] [CrossRef]

- Alharbi, F.; Luo, S.; Zhang, H.; Shaukat, K.; Yang, G.; Wheeler, C.A.; Chen, Z. A brief review of acoustic and vibration signal-based fault detection for belt conveyor idlers using machine learning models. Sensors 2023, 23, 1902. [Google Scholar] [CrossRef] [PubMed]

- Bajda, M.; Hardygora, M.; Marasova, D. Energy efficiency of conveyor belts in raw materials industry. Energies 2022, 15, 3080. [Google Scholar] [CrossRef]

- Mascenik, J.; Vojtko, I. Experimental monitoring and diagnostics of belt gears in testing device. MM Sci. J. 2016, 2016, 964–968, ISSN 1803-1269. [Google Scholar] [CrossRef]

- Wu, X.; Wang, C.; Tian, Z.; Huang, X.; Wang, Q. Research on Belt Deviation Fault Detection Technology of Belt Conveyors Based on Machine Vision. Machines 2023, 11, 1039. [Google Scholar] [CrossRef]

- Shandookh, A.A.; Ogaili, A.A.F.; Al-Haddad, L.A. Failure analysis in predictive maintenance: Belt drive diagnostics with expert systems and Taguchi method for unconventional vibration features. Heliyon 2024, 10, e34202. [Google Scholar] [CrossRef]

- Yordanov, Y.; Gyurov, V. Experimental Study of Methods for Diagnostics of Electrical Equipment with Belt Drive Mechanisms. In Proceedings of the 2020 IEEE 12th Electrical Engineering Faculty Conference (BulEF), Varna, Bulgaria, 9–12 September 2020; pp. 1–5. [Google Scholar] [CrossRef]

- Huang, B.; Feng, G.; Tang, X.; Gu, J.X.; Xu, G.; Cattley, R.; Gu, F.; Ball, A.D. A performance evaluation of two bispectrum analysis methods applied to electrical current signals for monitoring induction motor-driven systems. Energies 2019, 12, 1438. [Google Scholar] [CrossRef]

- Pollak, A.; Temich, S.; Ptasiński, W.; Kucharczyk, J.; Gąsiorek, D. Prediction of belt drive faults in case of predictive maintenance in industry 4.0 platform. Appl. Sci. 2021, 11, 10307. [Google Scholar] [CrossRef]

- Ryba, T.; Bzinkowski, D.; Siemiątkowski, Z.; Rucki, M.; Stawarz, S.; Caban, J.; Samociuk, W. Monitoring of Rubber Belt Material Performance and Damage. Materials 2024, 17, 765. [Google Scholar] [CrossRef]

- Skoczylas, A.; Stefaniak, P.; Anufriiev, S.; Jachnik, B. Belt conveyors rollers diagnostics based on acoustic signal collected using autonomous legged inspection robot. Appl. Sci. 2021, 11, 2299. [Google Scholar] [CrossRef]

- Homisin, J.; Grega, R.; Kassay, P.; Fedorko, G.; Molnar, V. Removal of systematic failure of belt conveyor drive by reducing vibrations. Eng. Fail. Anal. 2019, 99, 192–202. [Google Scholar] [CrossRef]

- Kuric, I.; Klackova, I.; Nikitin, Y.R.; Zajacko, I.; Cisar, M.; Tucki, K. Analysis of diagnostic methods and energy of production systems drives. Processes 2021, 9, 843. [Google Scholar] [CrossRef]

- Bortnowski, P.; Gladysiewicz, L.; Krol, R.; Ozdoba, M. Tests of belt linear speed for identification of frictional contact phenomena. Sensors 2020, 20, 5816. [Google Scholar] [CrossRef]

- Kozłowski, T.; Wodecki, J.; Zimroz, R.; Błażej, R.; Hardygóra, M. A diagnostics of conveyor belt splices. Appl. Sci. 2020, 10, 6259. [Google Scholar] [CrossRef]

- Dąbek, P.; Wroblewski, A.; Wodecki, J.; Bortnowski, P.; Ozdoba, M.; Król, R.; Zimroz, R. Application of the methods of monitoring and detecting the belt mistracking in laboratory conditions. Appl. Sci. 2023, 13, 2111. [Google Scholar] [CrossRef]

- Ilankovic, N.; Zivanic, D.; Zuber, N. The influence of fatigue loading on the durability of the conveyor belt. Appl. Sci. 2023, 13, 3277. [Google Scholar] [CrossRef]

- Krauze, K.; Wydro, T.; Klempka, R.; Mucha, K. Application of an Analytical Model of a Belt Feeder for Assessing the Load and Stability of Its Structure. Energies 2023, 16, 8111. [Google Scholar] [CrossRef]

- Bzinkowski, D.; Rucki, M.; Chalko, L.; Kilikevicius, A.; Matijosius, J.; Cepova, L.; Ryba, T. Application of Machine Learning Algorithms in Real-Time Monitoring of Conveyor Belt Damage. Appl. Sci. 2024, 14, 10464. [Google Scholar] [CrossRef]

- Blatnicky, M.; Dizo, J.; Bruna, M.; Matejka, M. A Case Study on the Possibility of Extending the Service Life of the Demining Machine Belt. Materials 2024, 17, 5206. [Google Scholar] [CrossRef]

- Svoboda, P.; Brandejs, J. Fundamentals of Construction; Academic Publishing House CERM: Brno, Czech Republic, 2019; ISBN 9788076230095. [Google Scholar]

- Kulinowski, P.; Kasza, P.; Zarzycki, J. Influence of design parameters of idler bearing units on the energy consumption of a belt conveyor. Sustainability 2021, 13, 437. [Google Scholar] [CrossRef]

- Pavlenko, S.; Halko, J.; Mascenik, J. Parts and Mechanisms of Machines; Kosice TU: Kosice, Slovakia, 2017; p. 249. ISBN 978-80-553-2844-7. [Google Scholar]

- Gelman, L.; Abdullahi, A.O.; Moshrefzadeh, A.; Ball, A.; Conaghan, G.; Kluis, W. Innovative Conveyor Belt Monitoring via Current Signals. Electronics 2023, 12, 1804. [Google Scholar] [CrossRef]

- Mascenik, J.; Pavlenko, S. Alternative learning of slippage of belt drives. Automot. Ind. Mag. 2015, 8, 64–65, ISSN 1337-7612. [Google Scholar]

- Řemenové Převody. Available online: https://strojirenstvi.studentske.cz/2010/11/14-remenove-prevody.html (accessed on 22 June 2024).

- Romaniuk, V.; Mascenik, J.; Krenicky, T.; Panda, A.; Zaborowski, T.E. Design of a concept for online monitoring of beam deflection under controlled loading. In Mechanical and Physical Properties of Materials in Different Constellations Monograph; Polish Academy of Sciences, Institute of Research and Scientific Expertise: Poznan, Poland, 2023; pp. 86–92. ISBN 978-83-66246-66-9. [Google Scholar]

- Bortnowski, P.; Gładysiewicz, L.; Król, R.; Ozdoba, M. Models of transverse vibration in conveyor belt—Investigation and analysis. Energies 2021, 14, 4153. [Google Scholar] [CrossRef]

- Raad, H.A.; Mohsen, K.A. Diagnostic of pulley-belt system faults using vibration analysis technique. J. Univ. Babylon Eng. Sci. 2018, 26, 167–180. [Google Scholar]

- Bajda, M.; Hardygora, M. Analysis of the Influence of the Type of Belt on the Energy Consumption of Transport Processes in a Belt Conveyor. Energies 2021, 14, 6180. [Google Scholar] [CrossRef]

- Hrabovsky, L.; Nenicka, P.; Fries, J. Laboratory machine verification of force transmission provided by friction acting on the drive drum of a conveyor belt. Machines 2023, 11, 544. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).