Thermomechanical Performance of Ambient-Cured Fly Ash Geopolymers Under Fire Exposure: Role of Activator Type and Mix Design

Abstract

1. Introduction

- -

- Investigate the influence of alkaline activator type (sodium vs. potassium) on the thermomechanical performance, dimensional and mass stability of ambient-cured fly ash geopolymers under identical ISO 834 fire exposure conditions for both 1 h and 2 h heating durations.

- -

- Conduct a comparative assessment of fundamental mix proportioning parameters and their isolated effects on thermal performance and residual mechanical properties of ambient-cured fly ash geopolymers following fire exposure.

- -

- Evaluate the effects of thermal shock, induced by water quenching immediately after fire-rate heating, on residual strength, densification mechanisms, and overall structural integrity.

2. Materials and Methods

2.1. Raw Materials

2.2. Material Characterisation

2.2.1. X-Ray Fluorescence (XRF)

2.2.2. X-Ray Diffraction (XRD)

2.2.3. Scanning Electron Microscopy (SEM)

2.2.4. Particle Size Analysis (PSA)

2.2.5. Gas Pycnometry

2.3. Synthesis of FA Geopolymer

2.4. Mixing and Sample Preparations

2.5. Test Programme Details

3. Results and Discussion

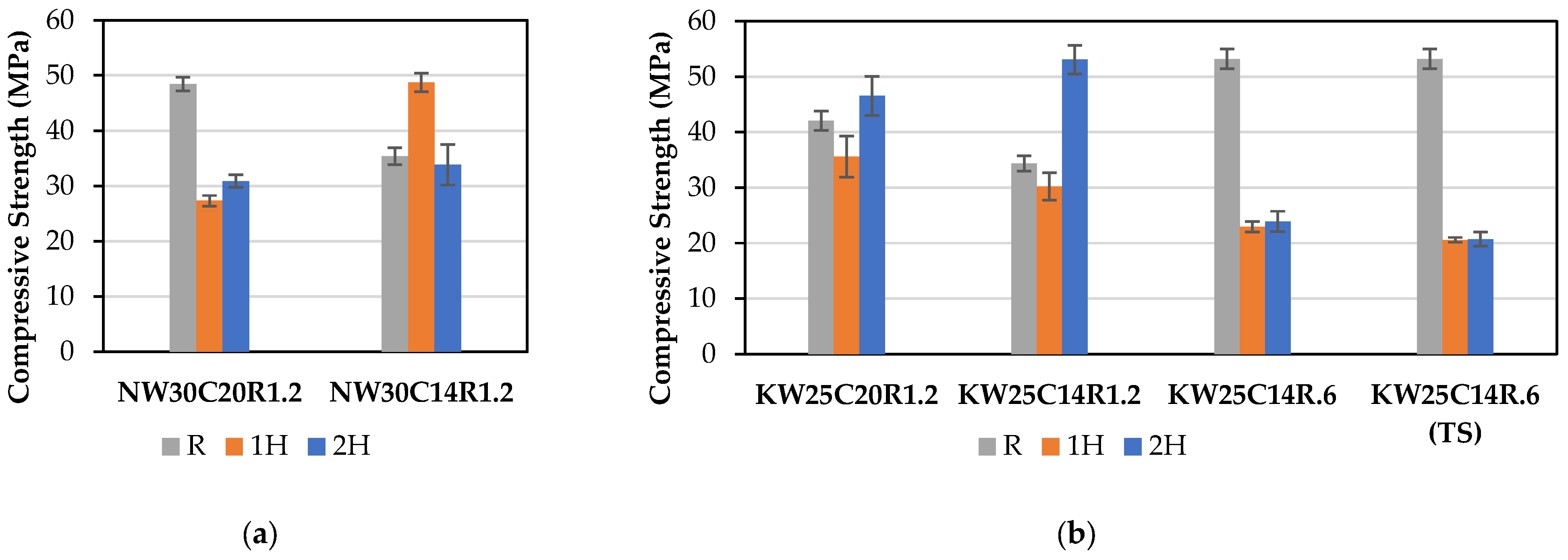

3.1. Compressive Strength

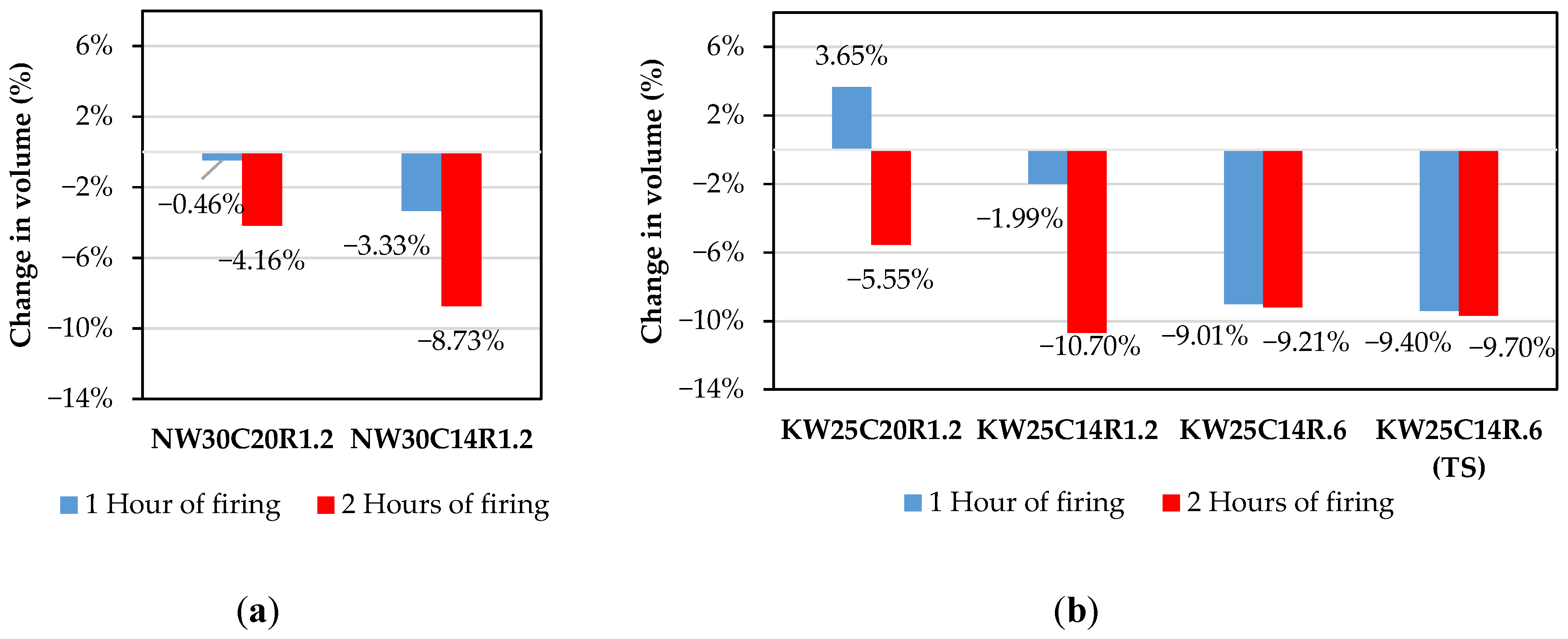

3.2. Volumetric Change

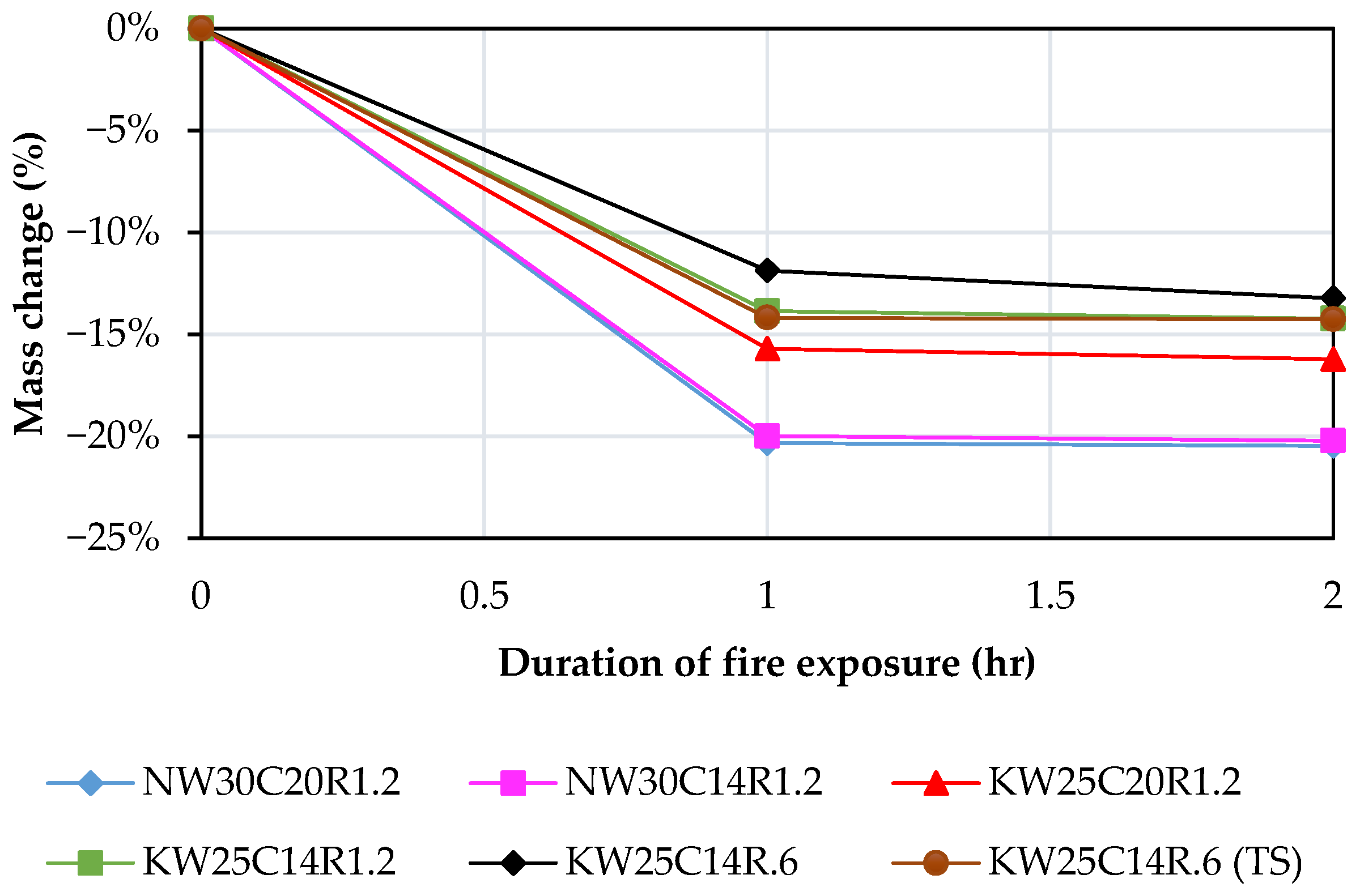

3.3. Mass Loss

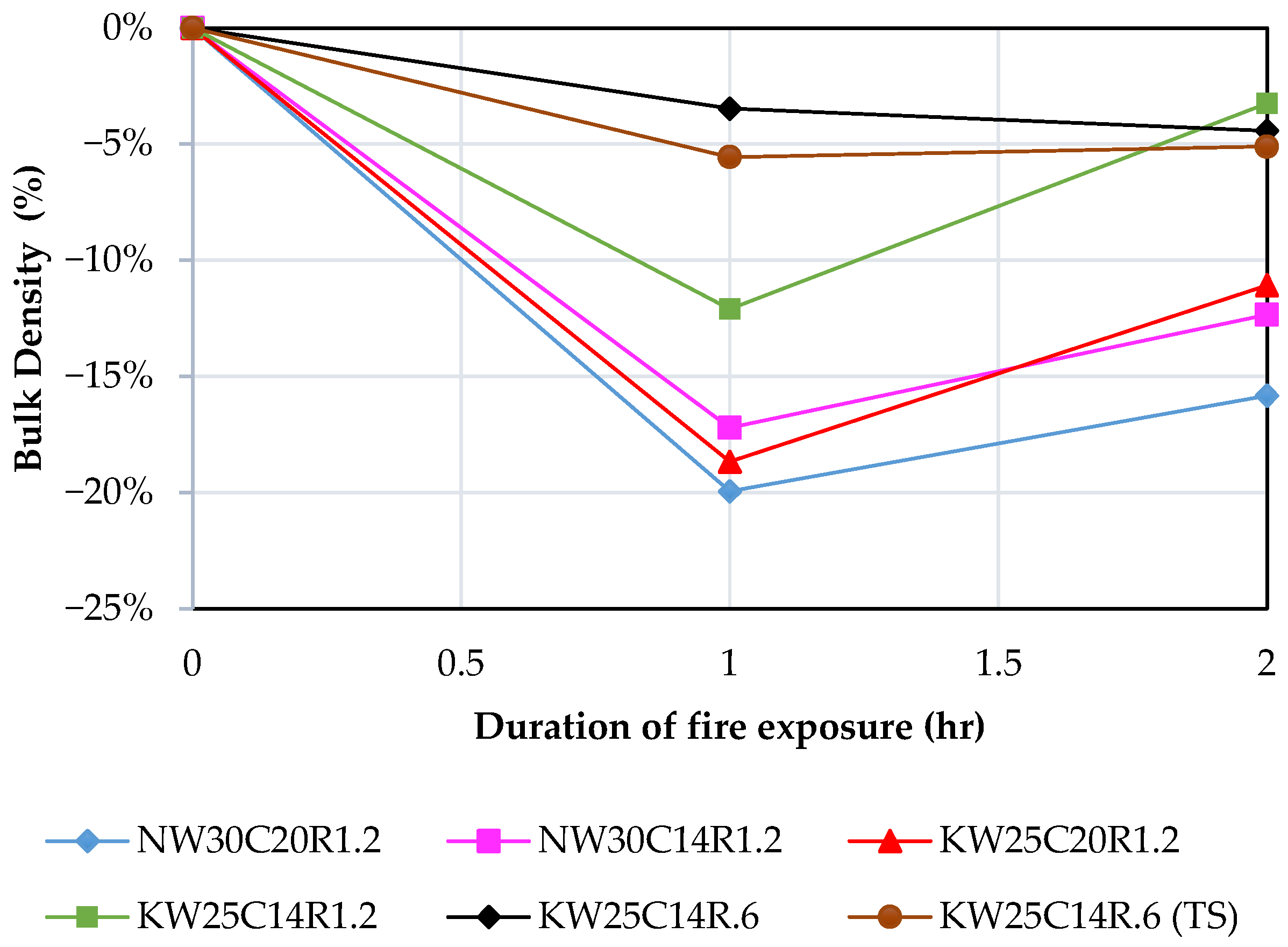

3.4. Density Change

3.5. Effect of Thermal Shock

3.6. Compressive Strength—Density Relationship

3.7. Microstructural Characterisation

4. Conclusions

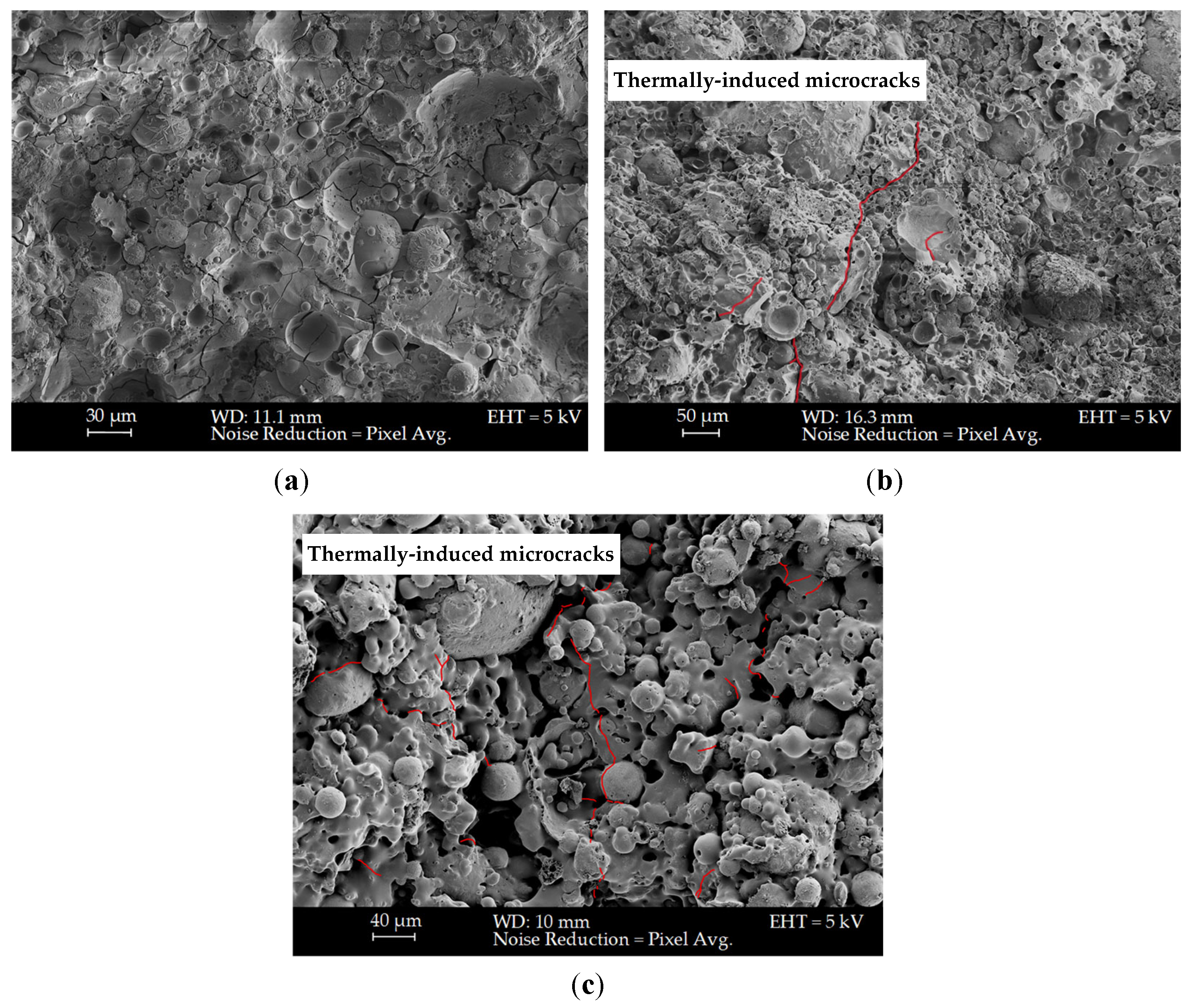

- Across all formulations, irrespective of activator type, exposure to the ISO 834 nominal fire curve revealed a progressive viscous sintering mechanism. During the first initial one-hour heating phase, scanning electron microscopy analysis revealed early-stage melting phenomena and modest consumption of unreacted fly ash particles, indicating incipient sintering activity accompanied by a maximum thermal shrinkage of 9.4%. During the subsequent one-hour heating phase, viscous sintering intensified, resulting in accelerated consumption of unreacted fly ash and enhanced production of additional geopolymer gel. This process facilitated pronounced microstructural densification, manifested by increased thermal shrinkage of 10.7%.

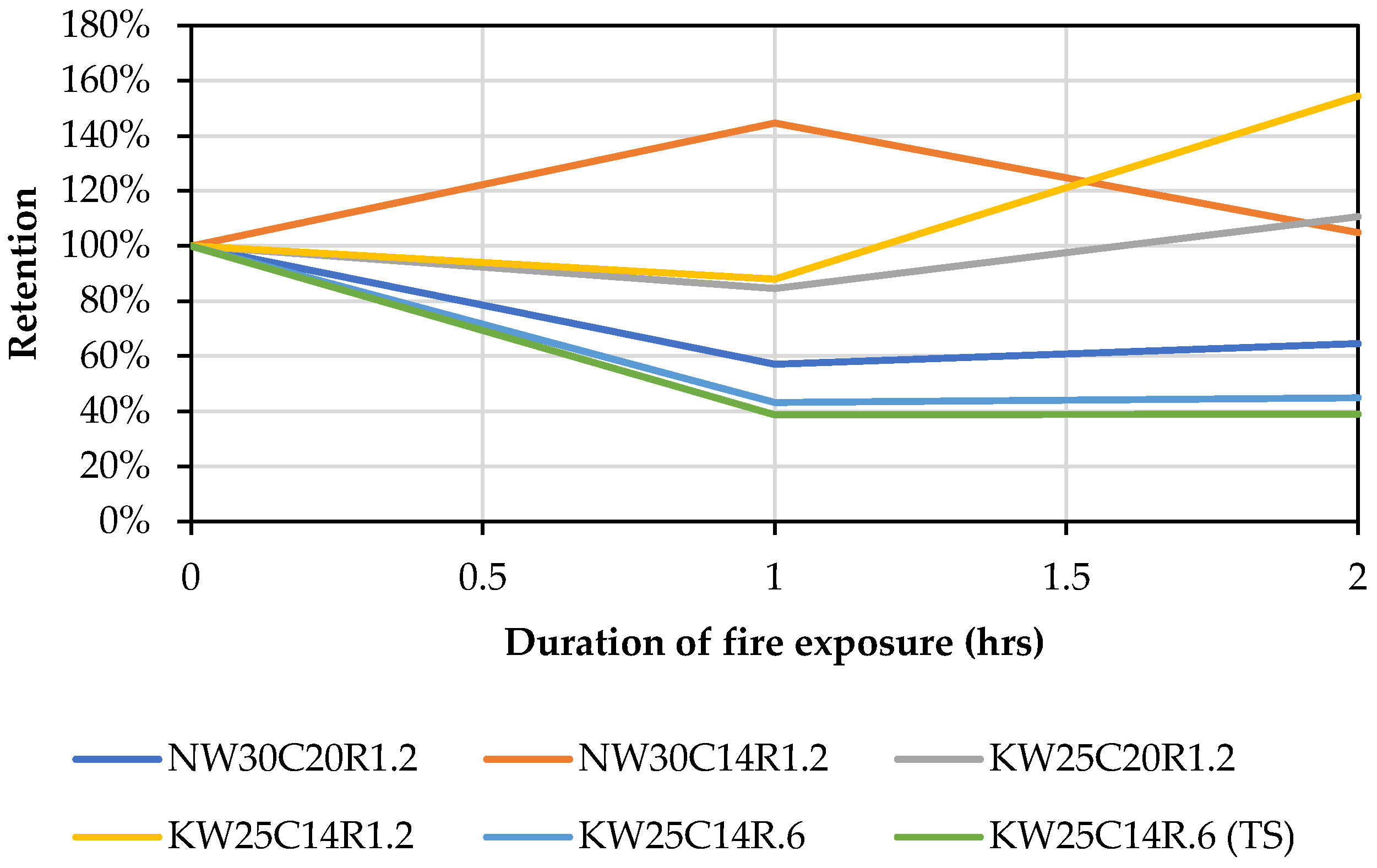

- Potassium-activated geopolymers exhibited approximately 5% lower mass loss compared to their sodium-activated counterparts, which can be attributed to the superior thermal stability and lower mobility of potassium cations. The delayed densification observed in potassium systems resulted in reduced shrinkage during the first hour of firing and the highest retained strength after the second hour (154%). This behaviour is linked to slower geopolymerisation kinetics and the higher melting temperature of potassium. In contrast, sodium-activated mixes demonstrated maximum retained strength at the first hour (145%) and lower shrinkage at the second hour, due to earlier densification and more rapid dehydroxylation.

- The oxide ratio had a greater influence over the total oxide content when reducing the oxide ratio of the activator from 1.2 to 0.6, while maintaining a fixed total alkaline activator content had the greatest impact on compressive strength at ambient temperature, increasing it by 55%. This reduction enhanced both compressive strength and mass stability by promoting improved gel formation and densification, supported by SEM. However, it significantly compromised strength retention at elevated temperatures, likely due to the initially compact microstructure which is more susceptible to thermal degradation. Conversely, increasing the oxide ratio, corresponding to higher silica content, led to a remarkable reduction in thermal shrinkage by approximately 5% (even offsetting to expansion) likely resulting from the swelling of the increased unreacted silica content.

- The rapid heating rates characteristic of ISO 834 fire conditions accelerated moisture release during initial heating to significantly higher rates than those in the literature employing slow heating protocols. This moisture loss resulted in high porosity with large, interconnected voids, reducing density and compressive strength.

- Exposure to thermal shock, induced by rapid water quenching immediately following ISO 834 fire heating, resulted in additional compressive strength reductions of 10% and 13% for potassium-activated fly ash geopolymers at 1 and 2 h of heating exposure, respectively. This thermal shock-induced degradation was accompanied by supplementary volumetric contraction of 0.5% and mass loss of 2%, attributed to differential thermal strains, microstructural microcracking evident in scanning electron microscopy analysis, and likely abrupt phase transformations within the geopolymer binding matrix precipitated by the rapid temperature decline.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| FA | Fly Ash |

| AA | Alkaline Activator |

| XRF | X-ray Fluorescence Spectroscopy |

| XRD | X-ray Diffraction |

| SEM | Scanning Electron Microscopy |

| PSA | Particle Size Analysis |

References

- Davidovits, J. Properties of geopolymer cements. In Proceedings of the First International Conference on Alkaline Cements and Concretes, Kiev, Ukraine, 11–14 October 1994; pp. 131–149. [Google Scholar]

- Omar, S.; Messan, A.; Prud’homme, E.; Escadeillas, G.; Tsobnang, F. Comparative Study on Geopolymer Binders Based on Two Alkaline Solutions (NaOH and KOH). J. Miner. Mater. Charact. Eng. 2020, 8, 407–420. [Google Scholar] [CrossRef]

- Phair, J.W.; Van Deventer, J.S.J. Effect of the silicate activator pH on the microstructural characteristics of waste-based geopolymers. Int. J. Miner. Process. 2002, 66, 121–143. [Google Scholar] [CrossRef]

- Panias, D.; Giannopoulou, I.P.; Perraki, T. Effect of synthesis parameters on the mechanical properties of fly ash-based geopolymers. Colloids Surf. A Physicochem. Eng. Asp. 2007, 301, 246–254. [Google Scholar] [CrossRef]

- Nongnuang, T.; Jitsangiam, P.; Rattanasak, U.; Chindaprasirt, P. Novel electromagnetic induction heat curing process of fly ash geopolymer using waste iron powder as a conductive material. Sci. Rep. 2022, 12, 9530. [Google Scholar] [CrossRef] [PubMed]

- Hager, I.; Sitarz, M.; Mróz, K. Fly-ash based geopolymer mortar for high-temperature application—Effect of slag addition. J. Clean. Prod. 2021, 316, 128168. [Google Scholar] [CrossRef]

- Pan, Z.; Sanjayan, J.G. Factors influencing softening temperature and hot-strength of geopolymers. Cem. Concr. Compos. 2012, 34, 261–264. [Google Scholar] [CrossRef]

- Hosan, M.A.; Haque, S.; Shaikh, F. Comparative study of sodium and potassium based fly ash geopolymer at elevated temperatures. In Proceedings of the International Conference on Performance-Based and Life-Cycle Structural Engineering, Brisbane, Australia, 9–11 December 2015. [Google Scholar]

- Sitarz, M.; Castro-Gomes, J.; Hager, I. Strength and Microstructure Characteristics of Blended Fly Ash and Ground Granulated Blast Furnace Slag Geopolymer Mortars with Na and K Silicate Solution. Materials 2021, 15, 211. [Google Scholar] [CrossRef]

- Fernández-Jiménez, A.; Palomo, A.; Criado, M. Alkali activated fly ash binders. A comparative study between sodium and potassium activators. Mater. Constr. 2006, 56, 51–65. [Google Scholar] [CrossRef]

- Zhang, Q.; Chen, H.; Wu, T.; Jin, T.; Pan, Z.; Zheng, J.; Gao, Y.; Zhuang, W. The opposite effects of sodium and potassium cations on water dynamics. Chem. Sci. 2017, 8, 1429–1435. [Google Scholar] [CrossRef]

- Bakharev, T. Thermal behaviour of geopolymers prepared using class F fly ash and elevated temperature curing. Cem. Concr. Res. 2006, 36, 1134–1147. [Google Scholar] [CrossRef]

- Bignozzi, M.C.; Manzi, S.; Natali, M.E.; Rickard, W.D.A.; van Riessen, A. Room temperature alkali activation of fly ash: The effect of Na2O/SiO2 ratio. Constr. Build. Mater. 2014, 69, 262–270. [Google Scholar] [CrossRef]

- Rickard, W.D.A.; Williams, R.; Temuujin, J.; van Riessen, A. Assessing the suitability of three Australian fly ashes as an aluminosilicate source for geopolymers in high temperature applications. Mater. Sci. Eng. A 2011, 528, 3390–3397. [Google Scholar] [CrossRef]

- Provis, J.L.; Palomo, A.; Shi, C. Advances in Understanding Alkali-Activated Materials. Cem. Concr. Res. 2015, 78, 110–125. [Google Scholar] [CrossRef]

- Hang, Y.-J.; Heah, C.-Y.; Al Bakri Abdullah, M.M.; Lee, Y.-S.; Ong, S.-W.; Ooi, W.-E.; Lim, J.-N.; Tee, H.-W. Effect of Water-to-Binder Ratio on Density, Compressive Strength and Morphology of Fly Ash/Ladle Furnace Slag Blended One-Part Geopolymer. Arch. Metall. Mater. 2024, 69, 1381–1384. [Google Scholar] [CrossRef]

- Xie, J.; Kayali, O. Effect of initial water content and curing moisture conditions on the development of fly ash-based geopolymers in heat and ambient temperature. Constr. Build. Mater. 2014, 67, 20–28. [Google Scholar] [CrossRef]

- Dai, X.; Aydin, S.; Yardimci, M.Y.; Lesage, K.; de Schutter, G. Influence of water to binder ratio on the rheology and structural Build-up of Alkali-Activated Slag/Fly ash mixtures. Constr. Build. Mater. 2020, 264, 120253. [Google Scholar] [CrossRef]

- Provis, J.L.; van Deventer, J.S.J. Geopolymers: Structure, Processing, Properties and Industrial Applications; Woodhead Publishing: Cambridge, UK, 2009. [Google Scholar]

- Srinivasa, A.S.; Swaminathan, K.; Yaragal, S.C. Effect of Water to Geopolymer Solids Ratio on Properties of Fly Ash and Slag-Based One-Part Geopolymer Binders. Res. Transcr. Mater. 2024, 2, 81–92. [Google Scholar] [CrossRef]

- Rickard, W.D.A.; Temuujin, J.; van Riessen, A. Thermal analysis of geopolymer pastes synthesised from five fly ashes of variable composition. J. Non-Cryst. Solids 2012, 358, 1830–1839. [Google Scholar] [CrossRef]

- Zhang, H.; Li, L.; Yuan, C.; Wang, Q.; Sarker, P.K.; Shi, X. Deterioration of ambient-cured and heat-cured fly ash geopolymer concrete by high temperature exposure and prediction of its residual compressive strength. Constr. Build. Mater. 2020, 262, 120924. [Google Scholar] [CrossRef]

- Xiang, S.; Zhou, Y.; Huang, Z.; Guo, M.; Riaz, M.H. Thermal performance of MK/FA geopolymers: Unveiling the role of FA, equivalent Na2O and modulus. Case Stud. Constr. Mater. 2024, 21, e03531. [Google Scholar] [CrossRef]

- Vickers, L.; Rickard, W.D.A.; van Riessen, A. Strategies to control the high temperature shrinkage of fly ash based geopolymers. Thermochim. Acta 2014, 580, 20–27. [Google Scholar] [CrossRef]

- Vickers, L.; Pan, Z.; Tao, Z.; Van Riessen, A. In Situ Elevated Temperature Testing of Fly Ash Based Geopolymer Composites. Materials 2016, 9, 445. [Google Scholar] [CrossRef] [PubMed]

- Klima, K.M.; Schollbach, K.; Brouwers, H.J.H.; Yu, Q. Enhancing the thermal performance of Class F fly ash-based geopolymer by sodalite. Constr. Build. Mater. 2022, 314, 125574. [Google Scholar] [CrossRef]

- Sarker, P.K.; Kelly, S.; Yao, Z. Effect of fire exposure on cracking, spalling and residual strength of fly ash geopolymer concrete. Mater. Des. 2014, 63, 584–592. [Google Scholar] [CrossRef]

- Kong, D.L.Y.; Sanjayan, J.G.; Sagoe-Crentsil, K. Comparative performance of geopolymers made with metakaolin and fly ash after exposure to elevated temperatures. Cem. Concr. Res. 2007, 37, 1583–1589. [Google Scholar] [CrossRef]

- Alehyen, S.; Zerzouri, M.; el Alouani, M.; el Achouri, M.; Taibi, M.H. Porosity and fire resistance of fly ash based geopolymer. J. Mater. Environ. Sci. 2017, 8, 3676–3689. [Google Scholar]

- Duxson, P.; Lukey, G.C.; van Deventer, J.S.J. Thermal evolution of metakaolin geopolymers: Part 1—Physical evolution. J. Non-Cryst. Solids 2006, 352, 5541–5555. [Google Scholar] [CrossRef]

- Duxson, P.; Lukey, G.C.; van Deventer, J.S.J. The thermal evolution of metakaolin geopolymers: Part 2—Phase stability and structural development. J. Non-Cryst. Solids 2007, 353, 2186–2200. [Google Scholar] [CrossRef]

- Kong, D.L.Y.; Sanjayan, J.G.; Sagoe-Crentsil, K. Factors affecting the performance of metakaolin geopolymers exposed to elevated temperatures. J. Mater. Sci. 2008, 43, 824–831. [Google Scholar] [CrossRef]

- Shaikh, F.U.A.; Hosan, A. Mechanical properties of steel fibre reinforced geopolymer concretes at elevated temperatures. Constr. Build. Mater. 2016, 114, 15–28. [Google Scholar] [CrossRef]

- Shaikh, F.; Haque, S. Effect of nano silica and fine silica sand on compressive strength of sodium and potassium activators synthesised fly ash geopolymer at elevated temperatures. Fire Mater. 2018, 42, 324–335. [Google Scholar] [CrossRef]

- Hosan, A.; Haque, S.; Shaikh, F. Compressive behaviour of sodium and potassium activators synthetized fly ash geopolymer at elevated temperatures: A comparative study. J. Build. Eng. 2016, 8, 123–130. [Google Scholar] [CrossRef]

- Lahoti, M.; Wong, K.K.; Tan, K.H.; Yang, E.-H. Effect of alkali cation type on strength endurance of fly ash geopolymers subject to high temperature exposure. Mater. Des. 2018, 154, 8–19. [Google Scholar] [CrossRef]

- Ptáček, P.; Křečková, M.; Šoukal, F.; Opravil, T.; Havlica, J.; Brandštetr, J. The kinetics and mechanism of kaolin powder sintering I. The dilatometric CRH study of sinter-crystallization of mullite and cristobalite. Powder Technol. 2012, 232, 24–30. [Google Scholar] [CrossRef]

- Huang, J.; Li, J.; Shao, R.; Wu, C. Effect of high temperature and cooling method on compression and fracture properties of geopolymer-based ultra-high performance concrete. J. Build. Eng. 2025, 105, 112433. [Google Scholar] [CrossRef]

- Poloju, K.; Srinivasu, K. Method of Determining Characteristics of Geopolymer Concrete under Elevated Temperatures. NeuroQuantology 2022, 20, 11063–11071. [Google Scholar]

- Sundberg, C. An Investigation of Geopolymers for Use in High Temperature Applications. Master’s Thesis, Michigan Technological University, Houghton, MI, USA, 2018. [Google Scholar]

- Peng, G.-F.; Bian, S.-H.; Guo, Z.-Q.; Zhao, J.; Peng, X.-L.; Jiang, Y.-C. Effect of thermal shock due to rapid cooling on residual mechanical properties of fiber concrete exposed to high temperatures. Constr. Build. Mater. 2008, 22, 948–955. [Google Scholar] [CrossRef]

- Luo, Y.; Klima, K.M.; Melzer, S.; Brouwers, H.J.H.; Yu, Q. Uncover the thermal behavior of geopolymer: Insights from in-situ high temperature exposure. Cem. Concr. Compos. 2025, 164, 106282. [Google Scholar] [CrossRef]

- Tu, W.; Zhang, M. Behaviour of alkali-activated concrete at elevated temperatures: A critical review. Cem. Concr. Compos. 2023, 138, 104961. [Google Scholar] [CrossRef]

- Sarker, P.K.; McBeath, S. Fire endurance of steel reinforced fly ash geopolymer concrete elements. Constr. Build. Mater. 2015, 90, 91–98. [Google Scholar] [CrossRef]

- Abdulkareem, O.A.; Mustafa Al Bakri, A.M.; Kamarudin, H.; Khairul Nizar, I.; Saif, A.A. Effects of elevated temperatures on the thermal behavior and mechanical performance of fly ash geopolymer paste, mortar and lightweight concrete. Constr. Build. Mater. 2014, 50, 377–387. [Google Scholar] [CrossRef]

- Ng, Y.-S.; Liew, Y.-M.; Heah, C.-Y.; Al Bakri Abdullah, M.M.; Pakawanit, P.; Vizureanu, P.; Khalid, M.S.; Ng, H.-T.; Hang, Y.-J.; Nabiałek, M.; et al. Improvements of Flexural Properties and Thermal Performance in Thin Geopolymer Based on Fly Ash and Ladle Furnace Slag Using Borax Decahydrates. Materials 2022, 15, 4178. [Google Scholar] [CrossRef] [PubMed]

- Xiang, S.; Guo, M.; Zhou, Y.; Huang, Z. Tailoring thermal performance of geopolymer via metakaolin/fly ash ratio and activator variation. J. Build. Eng. 2025, 103, 111856. [Google Scholar] [CrossRef]

- Prashant, G.S.; Amol, P.; Anant, L.; Harshal, G.M. Compressive Strength of Ambient- and Heat-Cured Fly Ash Geopolymer Concrete after High-Temperature Exposure. J. Comput. Anal. Appl. 2024, 33, 743–748. [Google Scholar]

- Lahoti, M.; Wijaya, S.F.; Tan, K.H.; Yang, E.-H. Tailoring sodium-based fly ash geopolymers with variegated thermal performance. Cem. Concr. Compos. 2020, 107, 103507. [Google Scholar] [CrossRef]

- Lahoti, M.; Wong, K.K.; Yang, E.-H.; Tan, K.H. Effects of Si/Al molar ratio on strength endurance and volume stability of metakaolin geopolymers subject to elevated temperature. Ceram. Int. 2018, 44, 5726–5734. [Google Scholar] [CrossRef]

- Zhang, H.Y.; Kodur, V.; Wu, B.; Yan, J.; Yuan, Z.S. Effect of temperature on bond characteristics of geopolymer concrete. Constr. Build. Mater. 2018, 163, 277–285. [Google Scholar] [CrossRef]

- Ishak, S.; Lee, H.-S.; Singh, J.K.; Ariffin, M.A.M.; Lim, N.H.A.S.; Yang, H.-M. Performance of Fly Ash Geopolymer Concrete Incorporating Bamboo Ash at Elevated Temperature. Materials 2019, 12, 3404. [Google Scholar] [CrossRef]

- Topal, Ö.; Karakoç, M.B.; Özcan, A. Effects of elevated temperatures on the properties of ground granulated blast furnace slag (GGBFS) based geopolymer concretes containing recycled concrete aggregate. Eur. J. Environ. Civ. Eng. 2022, 26, 4847–4862. [Google Scholar] [CrossRef]

- Derinpinar, A.N.; Karakoç, M.B.; Özcan, A. Performance of glass powder substituted slag based geopolymer concretes under high temperature. Constr. Build. Mater. 2022, 331, 127318. [Google Scholar] [CrossRef]

- Ren, W.; Xu, J.; Bai, E. Strength and Ultrasonic Characteristics of Alkali-Activated Fly Ash-Slag Geopolymer Concrete after Exposure to Elevated Temperatures. J. Mater. Civ. Eng. 2016, 28, 04015124. [Google Scholar] [CrossRef]

- Vásquez-Molina, D.; Mejía-Arcila, J.M.; de Gutiérrez, R.M. Mechanical and thermal performance of a geopolymeric and hybrid material based on fly ash. DYNA 2016, 83, 216–223. [Google Scholar] [CrossRef]

- ASTM C618-12a; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM International: West Conshohocken, PA, USA, 2012.

- Kaplan, G.; Öz, A.; Bayrak, B.; Görkem Alcan, H.; Çelebi, O.; Cüneyt Aydın, A. Effect of quartz powder on mid-strength fly ash geopolymers at short curing time and low curing temperature. Constr. Build. Mater. 2022, 329, 127153. [Google Scholar] [CrossRef]

- Ambikakumari Sanalkumar, K.U.; Lahoti, M.; Yang, E.-H. Investigating the potential reactivity of fly ash for geopolymerization. Constr. Build. Mater. 2019, 225, 283–291. [Google Scholar] [CrossRef]

- Nath, S.K.; Kumar, S. Role of particle fineness on engineering properties and microstructure of fly ash derived geopolymer. Constr. Build. Mater. 2020, 233, 117294. [Google Scholar] [CrossRef]

- Hadi, M.; Al-Azzawi, M.; Yu, T. Effects of fly ash characteristics and alkaline activator components on compressive strength of fly ash-based geopolymer mortar. Constr. Build. Mater. 2018, 175, 41–54. [Google Scholar] [CrossRef]

- Provis, J.L.; Yong, C.Z.; Duxson, P.; van Deventer, J.S.J. Correlating mechanical and thermal properties of sodium silicate-fly ash geopolymers. Colloids Surf. A Physicochem. Eng. Asp. 2009, 336, 57–63. [Google Scholar] [CrossRef]

- Carabba, L.; Moricone, R.; Scarponi, G.E.; Tugnoli, A.; Bignozzi, M.C. Alkali activated lightweight mortars for passive fire protection: A preliminary study. Constr. Build. Mater. 2019, 195, 75–84. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, X.; Zhang, W.; Li, Z.; Zhang, Y.; Li, Y.; Ren, Y. Effects of Si/Al ratio on the efflorescence and properties of fly ash based geopolymer. J. Clean. Prod. 2020, 244, 118852. [Google Scholar] [CrossRef]

- Qaidi, S.; Najm, H.M.; Abed, S.M.; Ahmed, H.U.; Al Dughaishi, H.; Al Lawati, J.; Sabri, M.M.; Alkhatib, F.; Milad, A. Fly Ash-Based Geopolymer Composites: A Review of the Compressive Strength and Microstructure Analysis. Materials 2022, 15, 7098. [Google Scholar] [CrossRef]

- Ma, J.; Wang, D.; Zhao, S.; Duan, P.; Yang, S. Influence of Particle Morphology of Ground Fly Ash on the Fluidity and Strength of Cement Paste. Materials 2021, 14, 283. [Google Scholar] [CrossRef]

- Rodríguez, E.D.; Bernal, S.A.; Provis, J.L.; Paya, J.; Monzo, J.M.; Borrachero, M.V. Effect of nanosilica-based activators on the performance of an alkali-activated fly ash binder. Cem. Concr. Compos. 2013, 35, 1–11. [Google Scholar] [CrossRef]

- Leong, H.Y.; Ong, D.E.L.; Sanjayan, J.G.; Nazari, A. The effect of different Na2O and K2O ratios of alkali activator on compressive strength of fly ash based-geopolymer. Constr. Build. Mater. 2016, 106, 500–511. [Google Scholar] [CrossRef]

- Rashad, A.M. Influence of different additives on the properties of sodium sulfate activated slag. Constr. Build. Mater. 2015, 79, 379–389. [Google Scholar] [CrossRef]

- An, E.-M.; Cho, Y.-H.; Chon, C.-M.; Lee, D.-G.; Lee, S. Synthesizing and Assessing Fire-Resistant Geopolymer from Rejected Fly Ash. J. Korean Ceram. Soc. 2015, 52, 253–263. [Google Scholar] [CrossRef][Green Version]

- Park, S.M.; Jang, J.G.; Lee, N.K.; Lee, H.K. Physicochemical properties of binder gel in alkali-activated fly ash/slag exposed to high temperatures. Cem. Concr. Res. 2016, 89, 72–79. [Google Scholar] [CrossRef]

- ASTM C109; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars. ASTM International: West Conshohocken, PA, USA, 2008.

- ISO 834-1:2025; Fire-Resistance Tests—Elements of Building Construction—Part 1: General Requirements. International Organization for Standardization (ISO): Geneva, Switzerland, 2025.

- Rashad, A.M.; Zeedan, S.R. The effect of activator concentration on the residual strength of alkali-activated fly ash pastes subjected to thermal load. Constr. Build. Mater. 2011, 25, 3098–3107. [Google Scholar] [CrossRef]

- Cheng, T.W.; Chiu, J.P. Fire-resistant geopolymer produced by granulated blast furnace slag. Miner. Eng. 2003, 16, 205–210. [Google Scholar] [CrossRef]

- Hardjito, D.; Tsen, M. Strength and Thermal Stability of Fly Ash Based Geopolymer Mortar. In Proceedings of the 3rd International Conference-ACF/VCA 2008, Ho Chi Minh City, Vietnam, 11–12 November 2008. [Google Scholar]

- Duxson, P.; Provis, J.; Lukey, G.; Mallicoat, S.; Kriven, W.; Van Deventer, J. Understanding the Relationship Between Geopolymer Composition Microstructure and Mechanical Properties. Colloids Surf. A Physicochem. Eng. Asp. 2005, 269, 47–58. [Google Scholar] [CrossRef]

- Duxson, P.; Mallicoat, S.W.; Lukey, G.C.; Kriven, W.M.; van Deventer, J.S.J. The effect of alkali and Si/Al ratio on the development of mechanical properties of metakaolin-based geopolymers. Colloids Surf. A Physicochem. Eng. Asp. 2007, 292, 8–20. [Google Scholar] [CrossRef]

- Xu, H.; Van Deventer, J.S.J. The geopolymerisation of alumino-silicate minerals. Int. J. Miner. Process. 2000, 59, 247–266. [Google Scholar] [CrossRef]

- Lin, C.-Y.; Chen, T.-A. Effects of Composition Type and Activator on Fly Ash-Based Alkali Activated Materials. Polymers 2022, 14, 63. [Google Scholar] [CrossRef]

- Tran, T.T.; Kwon, H.M. Influence of Activator Na2O Concentration on Residual Strengths of Alkali-Activated Slag Mortar upon Exposure to Elevated Temperatures. Materials 2018, 11, 1296. [Google Scholar] [CrossRef] [PubMed]

- Bocullo, V.; Vitola, L.; Vaiciukyniene, D.; Kantautas, A.; Bajare, D. The influence of the SiO2/Na2O ratio on the low calcium alkali activated binder based on fly ash. Mater. Chem. Phys. 2021, 258, 123846. [Google Scholar] [CrossRef]

- Leko, V.K.; Mazurin, O.V. Analysis of Regularities in Composition Dependence of the Viscosity for Glass-Forming Oxide Melts: II. Viscosity of Ternary Alkali Aluminosilicate Melts. Glass Phys. Chem. 2003, 29, 16–27. [Google Scholar] [CrossRef]

- Luo, Y.; Li, S.H.; Klima, K.M.; Brouwers, H.J.H.; Yu, Q. Degradation mechanism of hybrid fly ash/slag based geopolymers exposed to elevated temperatures. Cem. Concr. Res. 2022, 151, 106649. [Google Scholar] [CrossRef]

- Rovnaník, P.; Bayer, P.; Rovnaníková, P. Characterization of alkali activated slag paste after exposure to high temperatures. Constr. Build. Mater. 2013, 47, 1479–1487. [Google Scholar] [CrossRef]

- Hwang, E.; Kim, G.; Choe, G.; Yoon, M.; Son, M.; Suh, D.; Eu, H.; Nam, J. Explosive Spalling Behavior of Single-Sided Heated Concrete According to Compressive Strength and Heating Rate. Materials 2021, 14, 6023. [Google Scholar] [CrossRef]

- Fernandes, B.; Gil, A.; Bolina, F.; Tutikian, B. Thermal damage evaluation of full scale concrete columns exposed to high temperatures using scanning electron microscopy and X-ray diffraction. DYNA 2018, 85, 123–128. [Google Scholar] [CrossRef]

- Cao, B.; Li, Y.; Li, P. Synergistic Effect of Blended Precursors and Silica Fume on Strength and High Temperature Resistance of Geopolymer. Materials 2024, 17, 2975. [Google Scholar] [CrossRef]

- Nikolov, A.; Karamanov, A. Thermal Properties of Geopolymer Based on Fayalite Waste from Copper Production and Metakaolin. Materials 2022, 15, 2666. [Google Scholar] [CrossRef]

- Mallikarjuna Rao, G.; Gunneswara Rao, T.D.; Siva Nagi Reddy, M.; Rama Seshu, D. A Study on the Strength and Performance of Geopolymer Concrete Subjected to Elevated Temperatures. In Recent Advances in Structural Engineering; Springer: Singapore, 2019; Volume 1, pp. 869–889. [Google Scholar]

- Hussain, S.; Amritphale, S.; Matthews, J.; Paul, N.; Matthews, E.; Edwards, R. Advanced Solid Geopolymer Formulations for Refractory Applications. Materials 2024, 17, 1386. [Google Scholar] [CrossRef]

- Al Bakri Abdullah, M.M.; Jamaludin, L.; Hussin, K.; Bnhussain, M.; Ghazali, C.M.R.; Ahmad, M.I. Fly ash porous material using geopolymerization process for high temperature exposure. Int. J. Mol. Sci. 2012, 13, 4388–4395. [Google Scholar] [CrossRef]

- Moutaoukil, G.; Alehyen, S.; Sobrados, I.; el Mahdi Safhi, A. Effects of Elevated Temperature and Activation Solution Content on Microstructural and Mechanical Properties of Fly Ash-based Geopolymer. KSCE J. Civ. Eng. 2023, 27, 2372–2384. [Google Scholar] [CrossRef]

- Jamil, N.H.; Al Bakri Abdullah, M.M.; Che Pa, F.; Mohamad, H.; Ibrahim, W.M.A.W.; Chaiprapa, J. Influences of SiO2, Al2O3, CaO and MgO in phase transformation of sintered kaolin-ground granulated blast furnace slag geopolymer. J. Mater. Res. Technol. 2020, 9, 14922–14932. [Google Scholar] [CrossRef]

- Zulkifli, N.N.I.; Al Bakri Abdullah, M.M.; Przybył, A.; Pietrusiewicz, P.; Salleh, M.; Aziz, I.H.; Kwiatkowski, D.; Gacek, M.; Gucwa, M.; Chaiprapa, J. Influence of Sintering Temperature of Kaolin, Slag, and Fly Ash Geopolymers on the Microstructure, Phase Analysis, and Electrical Conductivity. Materials 2021, 14, 2213. [Google Scholar] [CrossRef] [PubMed]

- Heah, C.-Y.; Liew, Y.-M.; Al Bakri Abdullah, M.M.; Hussin, K. Thermal Resistance Variations of Fly Ash Geopolymers: Foaming Responses. Sci. Rep. 2017, 7, 45355. [Google Scholar] [CrossRef]

- Luo, X.; Sun, W.; Chan, S.Y.N. Effect of heating and cooling regimes on residual strength and microstructure of normal strength and high-performance concrete. Cem. Concr. Res. 2000, 30, 379–383. [Google Scholar] [CrossRef]

| Material | SiO2 | Al2O3 | Fe2O3 | CaO | TiO2 | K2O | MgO |

|---|---|---|---|---|---|---|---|

| FA | 55.6 | 26 | 5.6 | 4.1 | 1.8 | 2.8 | 1.9 |

| Slag | 33.2 | 12.6 | 0.3 | 43.3 | - | - | 5.9 |

| Mineralogical Phase | Weight (%) |

|---|---|

| Quartz (SiO2) | 20.9 |

| Mullite (Al2.28O4.86Si0.72) | 26.03 |

| Amorphous | 53.07 |

| Description | Moles of Si (per 100 g Fly Ash) | Moles of Al (per 100 g Fly Ash) | Si/Al Molar Ratio |

|---|---|---|---|

| Total content (XRF) | 0.93 | 0.51 | 1.81 |

| Crystalline content (XRD) | 0.47 | 0.37 | 1.25 |

| Amorphous content | 0.46 | 0.14 | 3.33 |

| Mix I.D | FA (g) | Slag (g) | Tot. Water (g) | W/B | * MOH Solids (g) | * M2SiO3 Solids (g) | (* Oxides) /B | * SiO2 /M2O | ** Si/Al | ** Si/M |

|---|---|---|---|---|---|---|---|---|---|---|

| NW30C20R1.2 | 1710 | 90 | 540 | 30% | 84.48 | 294.55 | 0.20 | 1.20 | 4.72 | 2.10 |

| NW30C14R1.2 | 1710 | 90 | 540 | 30% | 59.14 | 206.18 | 0.14 | 1.20 | 4.3 | 2.7 |

| KW25C20R1.2 | 1710 | 90 | 450 | 25% | 78.40 | 294.18 | 0.20 | 1.20 | 4.72 | 3.20 |

| KW25C14R1.2 | 1710 | 90 | 450 | 25% | 54.88 | 205.92 | 0.14 | 1.20 | 4.3 | 4.17 |

| KW25C14R0.6 | 1710 | 90 | 450 | 25% | 131.53 | 212.36 | 0.14 | 0.60 | 4 | 2.82 |

| Mix I.D. | Bulk Density (kg/m3) | Compressive Strength (MPa) | Relative Compressive Strength (%) | |||

|---|---|---|---|---|---|---|

| R | 1H | 2H | 1H | 2H | ||

| NW30C20R1.2 | 1800 | 48 | 27 | 31 | 57% | 65% |

| NW30C14R1.2 | 1755 | 34 | 49 | 35 | 145% | 105% |

| KW25C20R1.2 | 1780 | 42 | 36 | 47 | 85% | 111% |

| KW25C14R1.2 | 1738 | 34 | 30 | 53 | 88% | 154% |

| KW25C14R0.6 | 1714 | 53 | 23 | 24 | 43% | 45% |

| KW25C14R0.6 (TS) | 1714 | 53 | 21 | 21 | 39% | 39% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Shdeifat, H.; Kalfat, R.; Al-Mahaidi, R. Thermomechanical Performance of Ambient-Cured Fly Ash Geopolymers Under Fire Exposure: Role of Activator Type and Mix Design. Buildings 2026, 16, 327. https://doi.org/10.3390/buildings16020327

Shdeifat H, Kalfat R, Al-Mahaidi R. Thermomechanical Performance of Ambient-Cured Fly Ash Geopolymers Under Fire Exposure: Role of Activator Type and Mix Design. Buildings. 2026; 16(2):327. https://doi.org/10.3390/buildings16020327

Chicago/Turabian StyleShdeifat, Hamzeh, Robin Kalfat, and Riadh Al-Mahaidi. 2026. "Thermomechanical Performance of Ambient-Cured Fly Ash Geopolymers Under Fire Exposure: Role of Activator Type and Mix Design" Buildings 16, no. 2: 327. https://doi.org/10.3390/buildings16020327

APA StyleShdeifat, H., Kalfat, R., & Al-Mahaidi, R. (2026). Thermomechanical Performance of Ambient-Cured Fly Ash Geopolymers Under Fire Exposure: Role of Activator Type and Mix Design. Buildings, 16(2), 327. https://doi.org/10.3390/buildings16020327