Timber-Reinforced Concrete and Its Application in Portugal

Abstract

1. Introduction

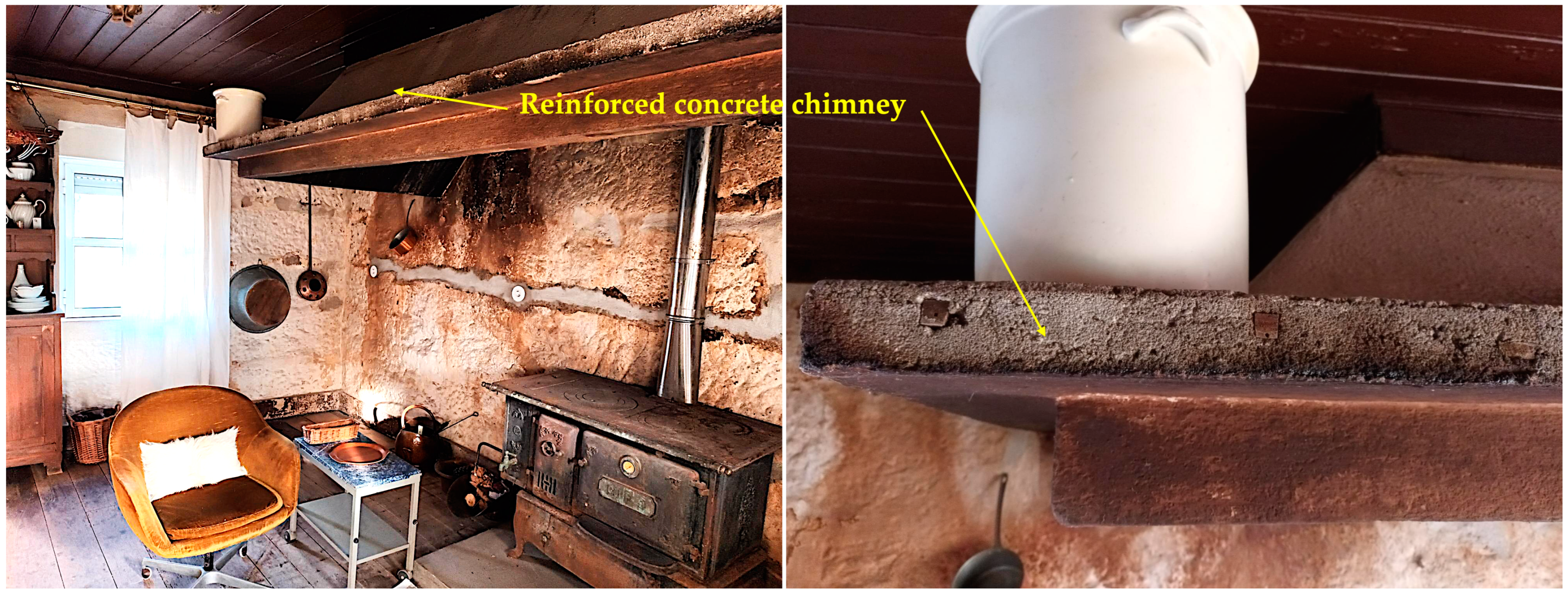

2. Examples of Traditional Portuguese Structural Timber Solutions

3. Examples of Traditional Portuguese Timber Reinforced Concrete Solutions

4. Study of Slender Timber-Reinforced Concrete Columns

4.1. Slender Concrete Columns

4.2. Timber Reinforced Concrete Slender Columns

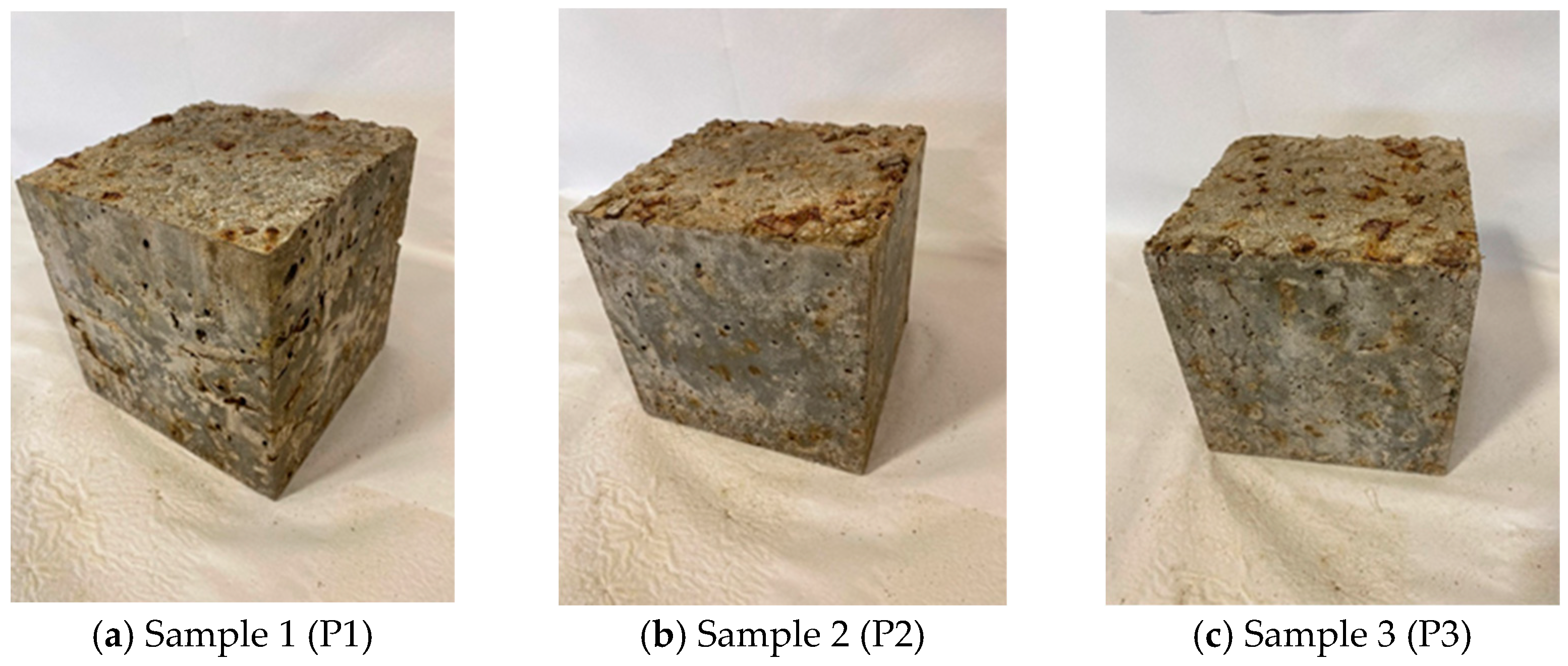

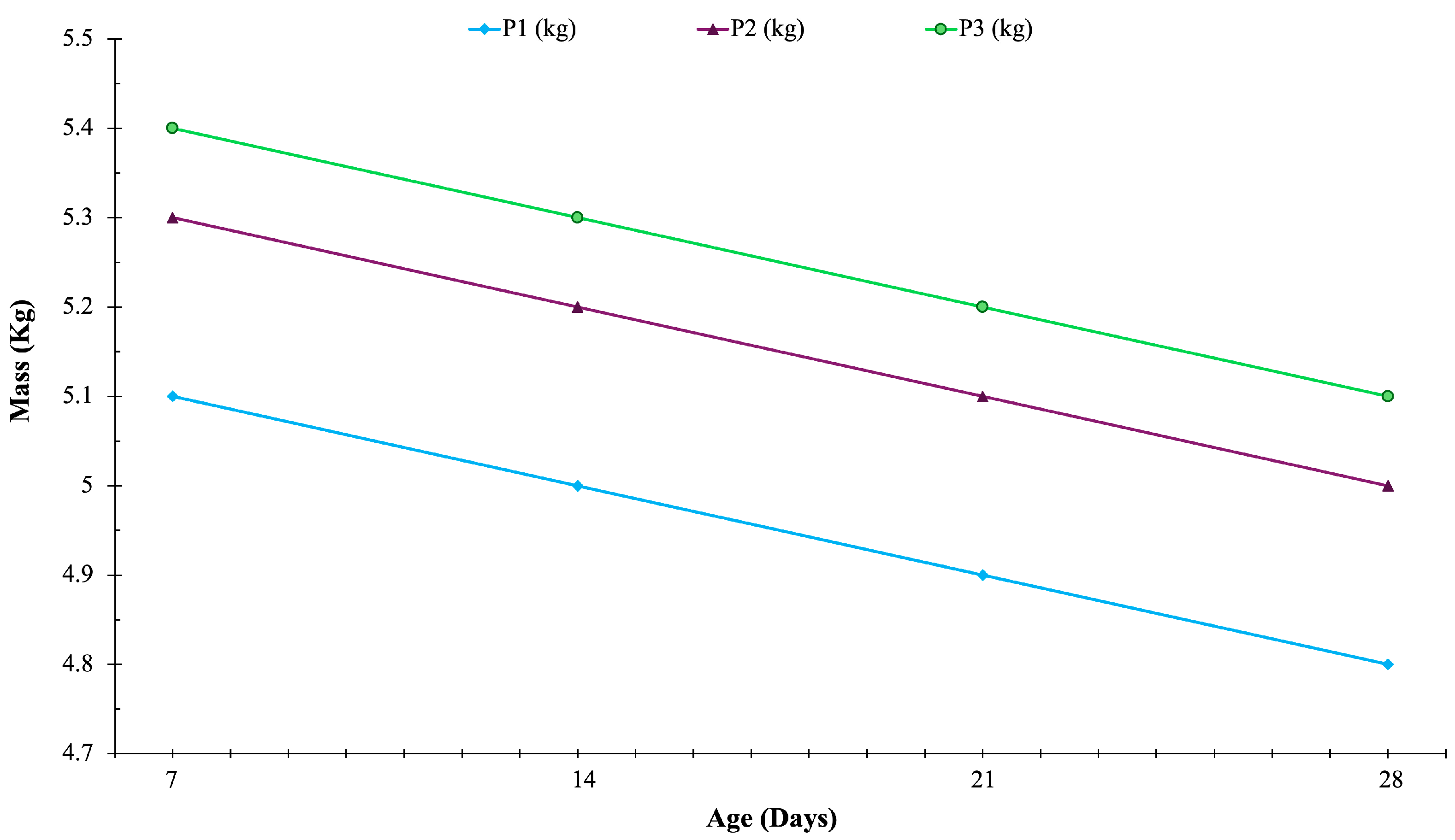

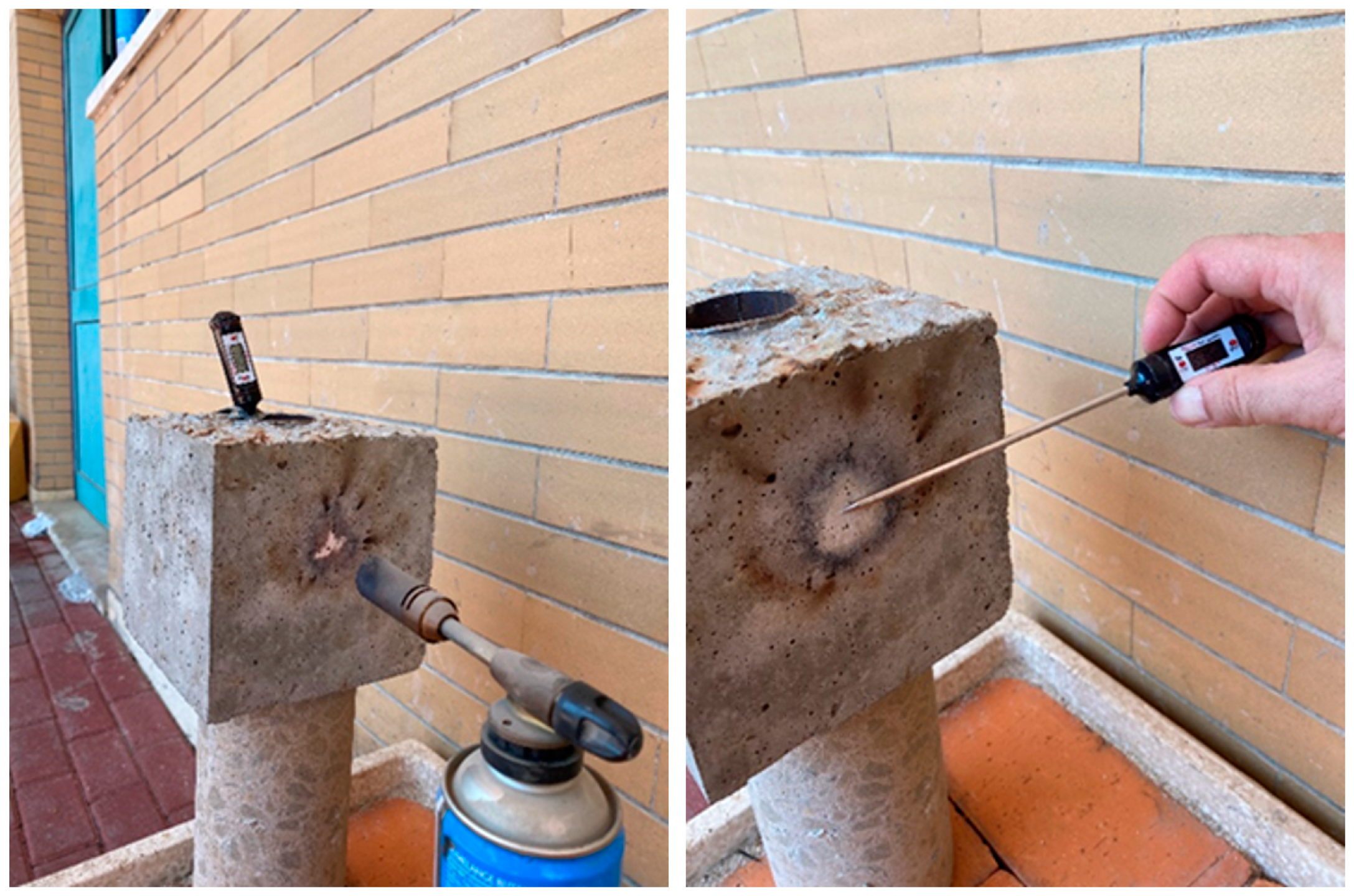

4.2.1. Proposal of a Timber-Based Concrete

- (a)

- The production of concrete that is expected to be used in construction activities where very little compressive strength is needed. These activities include but are not limited to non-load-bearing elements or areas with low suspected seismic activity.

- (b)

- More environmentally sustainable concrete made with a new natural and renewable material as a substitute to minimise the carbon emissions associated with ordinary concrete use and production.

4.2.2. Proposal of Timber-Based Reinforcement

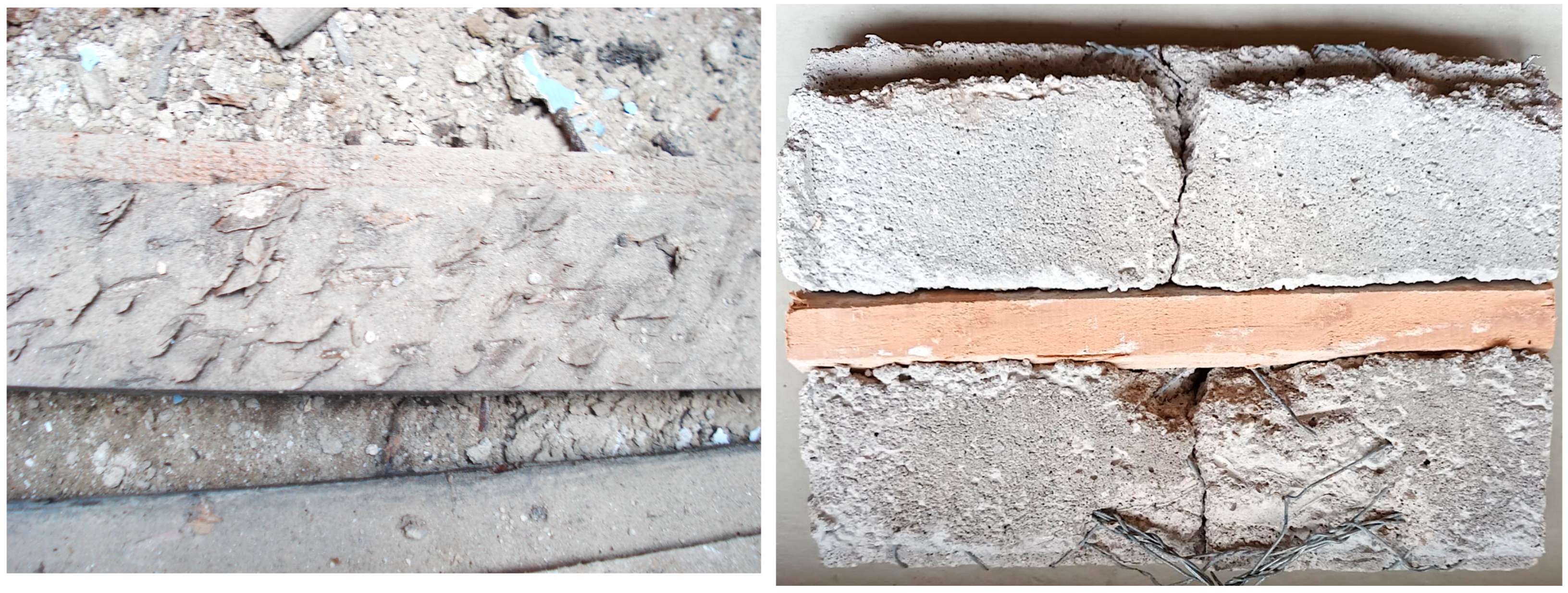

5. Examples of Traditional Solutions to Increase the Connection Between Timber and Concrete

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Furtado, A.; Rodrigues, H.; Arêde, A.; Varum, H. Mechanical properties characterization of different types of masonry infill walls. Front. Struct. Civ. Eng. 2020, 14, 411–434. [Google Scholar] [CrossRef]

- Barroso, C.E.; Oliveira, D.V.; Ramos, L.F. Physical and mechanical characterization of vernacular dry stone heritage materials: Schist and granite from Northwest Portugal. Constr. Build. Mater. 2020, 259, 119705. [Google Scholar] [CrossRef]

- Pinto, J.; Gülay, G.; Vieira, J.; Meltem, V.; Varum, H.; Bal, İ.E.; Costa, A. Save the Tabique construction. In Structural Rehabilitation of Old Buildings. Building Pathology and Rehabilitation; Costa, A., Guedes, J.M., Varum, H., Eds.; Springer: Berlin/Heidelberg, Germany, 2014; Volume 2, pp. 157–185. ISBN 978-3-642-39685-4 (Print)/978-3-642-39686-1 (Online). [Google Scholar]

- Padrão, J.; Arêde, A.; Guedes, J.M.; Pinto, J. Experimental characterization of mechanical behaviour of existing Tabique walls under compressive and shear loading. In Structural Analysis of Historical Constructions; RILEM Bookseries; Springer: Cham, Switzerland, 2019; Volume 18, pp. 568–576. [Google Scholar] [CrossRef]

- Ortega, J.; Vasconcelos, G.; Rodrigues, H.; Correia, M. Local seismic cultures: The use of timber frame structures in the south of Portugal. In Historical Earthquake-Resistant Timber Framing in the Mediterranean Area; Lecture Notes in Civil; Springer: Cham, Switzerland, 2016; Volume 1, pp. 101–111. [Google Scholar] [CrossRef]

- Poletti, E.; Vasconcelos, G.; Lourenco, P. Timber frames as an earthquake resisting system in Portugal. In Seismic Retrofitting: Learning from Vernacular Architecture; CRC Press: Boca Raton, FL, USA, 2015; Volume 161. [Google Scholar] [CrossRef]

- Cardoso, R.; Lopes, M.; Bento, R. Earthquake resistant structures of Portuguese old “Pombalino” buildings. In Proceedings of the 13th World Conference on Earthquake Engineering, Vancouver, BC, Canada, 1–6 August 2004. [Google Scholar]

- Mascarenhas, J.; Belgas, L.; Branco, F.G.; Vieira, E. The Pombaline Cage (“Gaiola Pombalina”): An European anti-seismic system based on enlightenment era of experimentation. In Structural Analysis of Historical Constructions; RILEM Bookseries; Springer: Cham, Switzerland, 2024; Volume 47, pp. 56–67. [Google Scholar] [CrossRef]

- Correia, M.; Carlos, G. Cultura Sísmica Local em Portugal Local Seismic Culture in Portugal. Argumentum. 2015. Available online: https://esg.pt/seismic-v/assets/uploads/2015/10/seismic_v_cultura_sismica_local.pdf (accessed on 23 January 2025).

- Correia, M.; Carlos, G.D.; Viana, D.; Gomes, F. Seismic-V: Vernacular seismic culture in Portugal. In Vernacular Architecture: Towards a Sustainable Future; Taylor & Francis: London, UK, 2014; pp. 217–223. [Google Scholar] [CrossRef]

- Icimoto, F.H.; De Souza, A.M.; Fernandes, C.V.; Ferro, F.S.; Júnior, C.C. Properties of strength and elasticity of structural elements of round timber of AMARU for use in civil construction. In Proceedings of the WCTE 2014—World Conference on Timber Engineering: Renaissance of Timber Construction, Quebec City, QC, Canada, 10–14 August 2014; Available online: https://www.scopus.com/inward/record.uri?eid=2-s2.0-85067757114&partnerID=40&md5=20238c241ac2bd9815ea7add4500b800 (accessed on 5 January 2025).

- Martins, C.; Ferreira, C.; Negrão, J.; Dias, A.M.P.G. Poplar as an alternative species for load bearing structures. In Sustainable and Digital Building; Springer: Cham, Switzerland, 2023. [Google Scholar] [CrossRef]

- Pinto, J.; Varum, H.; Cruz, D.; Sousa, D.; Morais, P.; Tavares, P.; Lousada, J.; Silva, P.; Vieira, J. Characterization of traditional tabique constructions in Douro North Valley region. J. WSEAS Trans. Environ. Dev. 2010, 6, 105–114. [Google Scholar]

- Murta, A.; Varum, H.; Pinto, J. Advantages of using raw materials in ancient and recent buildings. Smart Innov. Syst. Technol. 2011, 7, 35–44. [Google Scholar] [CrossRef]

- Branco-Teixeira, M.; Oliveira, D.V.; Pereira, E.; Matos, J.C.e.; Azenha, M.; Couto, J.P.; Silva, R.; Tinoco, J.; Granja, J.; Oliveira, A.S. Manual de Inovação e Sustentabilidade: Os Desafios e as Soluções na Reabilitação Urbana 4.0—Materiais, Tecnologias, Recursos Humanos e Segurança; Grupo Editorial Vida Económica, Ed.; Universidade Fernando Pessoa e Associação dos Industriais da Construção Civil e Obras Públicas: Porto, Portugal, 2023; p. 337. ISBN 9789897689949. [Google Scholar]

- Monteiro, S.R.S.; Dias, A.M.P.G.; Lopes, S.M.R. Transverse distribution of concentrated loads in timber–concrete floors: Parametric study. Proc. Inst. Civ. Eng.-Struct. Build. 2020, 173, 340–351. [Google Scholar] [CrossRef]

- Viroc—Investwood. Available online: https://www.investwood.pt/en/viroc/ (accessed on 5 January 2025).

- Almeida, G.P.; Duarte Cardoso, R.V.; Freire, J. Historiography of wood construction in Portugal. In Proceedings of the 4th International Civil Engineering and Architecture Conference, Seoul, Republic of Korea, 14–17 March 2025; pp. 271–283. [Google Scholar] [CrossRef]

- Feio, A.O.; Félix, D.; Cunha, V.M.; Machado, J.S. Selected solutions for rehabilitation of wooden structures: Some portuguese case studies. Adv. Mater. Res. 2013, 778, 731–738. [Google Scholar] [CrossRef]

- Alalbashi, A.; Reis, C.; Pinto, J.; Pimenta, F.; Oliveira, N.; Bento, N. Two modular architectural solution of MICADO. Alex. Eng. J. 2023, 78, 576–583. [Google Scholar] [CrossRef]

- NP EN 206-1 Betão. Parte 1: Especificação, Desempenho, Produção e Conformidade. 2007. Available online: https://www.scribd.com/document/746155739/Documents-NP-en-206-1-2007 (accessed on 5 January 2025).

- Mahmud, H.M.I.; Mandal, A.; Nag, S.; Moinuddin, K.A.M. Performance of fire protective coatings on structural steel member exposed to high temperature. J. Struct. Fire Eng. 2021, 12, 193–211. [Google Scholar] [CrossRef]

- Lublóy, É.; Biró, A.; Hlavička, V.; Németh, Z.; Csanaky, J. Effect of bulk density on flame resistance of rockwool in combined fire-resistant facings. J. Therm. Anal. Calorim. 2022, 147, 11693–11704. [Google Scholar] [CrossRef]

- Iwankiw, N. Structural fire resistant design basics for concrete, masonry, and wood. Pract. Period. Struct. Des. Constr. 2007, 12, 3–8. [Google Scholar] [CrossRef]

- Al-Jamaily, N.M.S.; Atiea, H.M.; Jabal, Q.A.; Mahdi, W.H.; Alasadi, L.A. Concrete’s fire resistance improvement with waste glass and ceramic aggregates. Pollack Period 2024, 19, 95–99. [Google Scholar] [CrossRef]

- Zheng, W.; Hou, X.; Wang, Y. Progress and prospect of fire resistance of reinforced concrete and prestressed concrete structures. Harbin Gongye Daxue Xuebao/J. Harbin Inst. Technol. 2016, 48, 1–18. [Google Scholar] [CrossRef]

- Branco, J.M. Portuguese traditional timber structures: Survey, analysis and strengthening. In Proceedings of the International Conference on Protection of Historical Buildings, Rome, Italy, 21–24 June 2009; pp. 261–266. [Google Scholar]

- Branco, J.M.; Varum, H.; Piazza, M. Portuguese Traditional Timbers Trusses: Static and Dynamic Behaviour; Departamento de Engenharia Civil, Universidade do Minho: Guimarães, Portugal, 2005. [Google Scholar]

- Parisi, M.; Piazza, M. Seismic strengthening and seismic improvement of timber structures. Constr. Build. Mater. 2015, 97, 55–66. [Google Scholar] [CrossRef]

| Parameter | P1 | P2 | P3 |

|---|---|---|---|

| Mixing Date | 06/17/2022 | 06/17/2022 | 06/17/2022 |

| Test Date | 07/15/2022 | 07/15/2022 | 07/15/2022 |

| Age of Specimen (days) | 28 | 28 | 28 |

| Storage Conditions | Room temperature | Room temperature | Room temperature |

| Dimensions of Specimen (cm) | 15 × 15 × 15 | 15 × 15 × 15 | 15 × 15 × 15 |

| Mode of Failure | Normal | Normal | Normal |

| Weight of Specimen (kg) | 4.823 | 5.032 | 5.093 |

| Failure Load (kN) | 77.7 | 98.6 | 94.3 |

| Failure Stress (MPa) | 3.5 | 4.4 | 4.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Reis, C.; Pereira, S.; Sedira, N.; Paiva, A.; Pinto, J. Timber-Reinforced Concrete and Its Application in Portugal. Buildings 2025, 15, 1532. https://doi.org/10.3390/buildings15091532

Reis C, Pereira S, Sedira N, Paiva A, Pinto J. Timber-Reinforced Concrete and Its Application in Portugal. Buildings. 2025; 15(9):1532. https://doi.org/10.3390/buildings15091532

Chicago/Turabian StyleReis, Cristina, Sandra Pereira, Naim Sedira, Anabela Paiva, and Jorge Pinto. 2025. "Timber-Reinforced Concrete and Its Application in Portugal" Buildings 15, no. 9: 1532. https://doi.org/10.3390/buildings15091532

APA StyleReis, C., Pereira, S., Sedira, N., Paiva, A., & Pinto, J. (2025). Timber-Reinforced Concrete and Its Application in Portugal. Buildings, 15(9), 1532. https://doi.org/10.3390/buildings15091532