Abstract

Tile delamination on the façades of tall buildings poses significant concerns for public safety worldwide. This study investigates the underlying causes of tile delamination and their linkages with other prevalent façade defects in order to develop a risk assessment for preventing future tile delamination in tall buildings. Drawing on Singapore’s experience, data were gathered from case studies through field inspections and expert interviews. The results have been supported by data findings and past laboratory testing conducted in the Singaporean context. The findings indicate that the main causes of tile delamination in Singapore’s tall buildings are linked to design, workmanship, materials, and environmental conditions. Notably, cracks and water penetration often indicate a high risk of tile delamination, highlighting a strong connection between delamination’s root causes and their frequent occurrence on tile façades. Finally, this study gives recommendations for designers, constructors, and maintenance teams to mitigate and eliminate risks associated with tile delamination, aiming to enhance the safety and durability of building façades.

1. Introduction

Selecting a façade type for a high-rise building involves consideration of several key factors, including structural integrity, durability, cost efficiency, sustainability, and occupant comfort [1]. In the wide range of façade options, the use of tiles as a cladding material for the external walls of tall buildings is still popular in many countries due to their hard-wearing properties, low cost, pleasing aesthetic qualities, and perceived maintenance-free properties [2,3].

Tile delamination is one of the most frequently encountered falling hazards worldwide. According to Ma et al. [4], ceramic tiles account for 36% of falling objects from high-rise buildings in Shanghai, making them the second most common. Typically, these tile falls occur due to various factors, including improper adhesive application, thermal expansion and contraction, structural movement, and a range of other issues stemming from technical or environmental influences [5]. With more incidents of falling objects from heights globally, more countries have enacted legislation on Periodic Façade Inspection (PFI) to tackle this serious public safety issue [6].

A tiling system is like a laminate system, comprising the tile, bedding adhesive, plaster, and substrate. Its performance therefore depends on each layer, their compatibility, and the grouting system. A good understanding of the mode of debonding failure is essential for the whole delivery process of tiling the façade of a tall building, especially when exposed to harsh environmental conditions. Factors to be considered include the selection of tiles and bedding adhesives, design and construction of movement joints, and adequate workmanship in installing the plaster, bedding adhesive, and tiles [7]. There has been a precedent established in landmark litigation cases that designers have a duty to ensure proper design and supervision of construction projects of tall buildings with tiled façades.

Although there are several methods for fixing façade tiles, such as mechanical (dry) fixing and the traditional wet method using cement mortar, the adhesive method is the most popular for tiling the façades of tall buildings in Singapore. This approach was introduced to the country around the 1970s, beginning with mosaic tiles and later expanding to ceramic tiles and marble. Figure 1 shows a few examples of mosaic and marble-tiled fades that were tiled using the adhesive method.

Figure 1.

Mosaic and marble-tiled façades.

Since the early 1990s, numerous cases of fallen tiles from tall buildings in Singapore have appeared in media headlines, drawing significant public attention and concern. These incidents have underscored a critical public safety issue, especially in areas where falling tile debris poses serious risks to pedestrians and property. These delaminations not only pose severe risks to operational safety but also degrade the lifespan of buildings, allowing water infiltration, reducing thermal insulation, compromising structural integrity, and diminishing aesthetic appeal [8].

Façade tile delamination is not a defect that appears first; rather, it occurs after the appearance of various other defects such as tile cracks, budging, water leakages, and so on [9,10]. Therefore, it is critical to reduce and eliminate tile delamination risks by implementing early defect detection procedures. Several studies have been conducted to investigate tile façade flaws and associated mitigations, with a focus on important factors such as weather, tile design, proactive maintenance measures such as laser scanning, and thermographic defect diagnosis [11,12,13]. Furthermore, studies such as Wetzel et al. [14] have investigated the progression of tile delamination from early tile cracking to crack propagation and crack enlargement, which leads to full tile detachment, and offered appropriate mitigation techniques. Even though all of these studies focus on tile delamination, there is a significant lack of scientific evidence that informs building/facilities managers about the risk of façade tile delamination while focusing on the availability of façade defects which provoke the root causes of tile delamination.

Given the knowledge gap mentioned above, the aim of this study is to conduct a thorough analysis of the root causes of tile delamination and their relationships with other prevalent tile façade anomalies in order to quantify the vulnerability of future tile delamination. Furthermore, by focusing on Singapore’s experiences, this research will improve global awareness and provide actionable insights into best practices for improving the safety, longevity, and maintainability of tiled façades. The results of the study could guide building professionals in maintaining tile façades, enabling safer, more robust buildings capable of withstanding a variety of situations impacting tile performance.

2. Materials and Methods

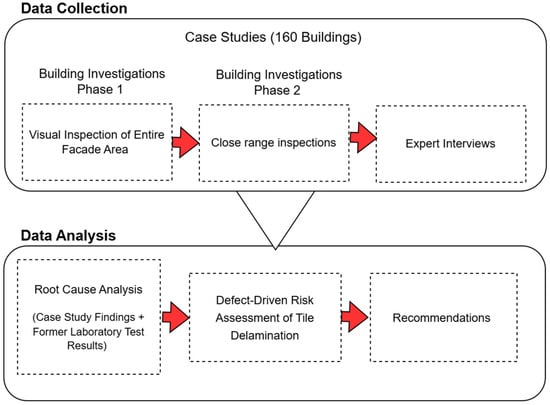

In order to accomplish the goal of the study, a mixed-method approach comprising both qualitative and quantitative analysis was used. The significant public safety concern of façade tiles falling from tall buildings in Singapore encouraged the study, and a knowledge gap was discovered through works from the literature. The data collection and analysis phases of the study were designed as shown in Figure 2 below.

Figure 2.

Phases of data collection and analysis.

2.1. Data Collection

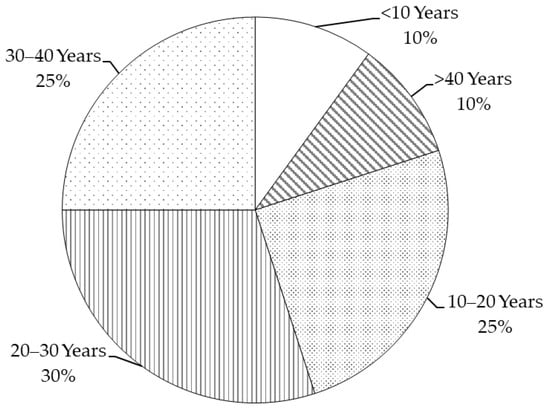

The case study approach was selected as the primary data collection method, and 160 tall Singapore buildings with tile delamination were studied over a three-year period. These 160 buildings were chosen based on a range of factors, including location, function, environmental exposure, and, most importantly, building age. However, all buildings were comparable in terms of height and build. Accordingly, these buildings included a variety of facilities such as HDB residential complexes, shopping malls, and office buildings, all of which were located within 10 km of the southern coastline area and had experienced tile delamination issues. When considering the ages of the buildings, four age categories were taken into account, as shown in Figure 3.

Figure 3.

Age profile of case study buildings.

In the case studies, data were collected through façade inspections and expert interviews. The façade inspections followed Singapore’s PFI (Periodic Façade Inspection) requirements, which involve a two-stage investigation process. First, drone cameras were used to conduct visual inspections, assessing tile delamination and other defects in building façades. The drone images were then reviewed to identify problem areas and potential falling tiles, guiding close-range examinations. To assess the extent of the issues, hands-on close-up inspections were conducted. These included tactile assessments, localized tile removal, and visual tests for signs of deterioration.

Following the façade inspection, semi-structured interviews were conducted with maintenance professionals in the inspected building, including facility managers and maintenance supervisors, with a maximum of three specialists per building. The interviews focused on the causes of tile delamination and other defects, as well as prevention techniques for tile detachment.

2.2. Data Analysis

The data acquired from façade investigations and expert interviews were analysed using manual content analysis to determine the main causes of tile delamination in tall buildings in Singapore. This analysis method is well-known for its capacity to capture nuanced meanings, high accuracy, flexibility, rich qualitative insight, and its application in cases where subjective interpretations are necessary [15,16]. Furthermore, this root cause analysis was supported by the results of several laboratory tests conducted specifically to investigate tile façades in the context of Singapore.

Moreover, this study used a defect-driven risk assessment to determine the vulnerability to tile delamination based on the presence of various façade defects, which are linked to the root causes of tile delamination to varying degrees. This defect-based risk assessment method has been used in many studies across multiple disciplines, including research in the built environment (Table 1).

Table 1.

Real-world examples of defect-based risk assessments.

In adopting the risk assessment process, the number of cases of each defect reported in the investigated buildings was considered as the probability (P) value for the occurrence of a specific failure. Subsequently, the linkages between each defect and the root causes of tile delamination were mapped based on expert opinions regarding defects and established knowledge in the field. The overall significance of a defect linkage to the root causes was considered as an impact factor, determined by the number of linkages between the defect and the root causes of tile delamination. It was calculated using the following mathematical model developed.

Defects identified (Ai), where i is the unique identifier for a defect.

Root cause categories of tile delamination (Cj), where j is the category number.

Root cause under each category (Rjk), where k is the number of root causes under each category.

If a linkage is present between a root cause and a defect (X): Xijk = 1; if not Xijk = 0

Linkage Significance () per root cause category.

where n is the number of available root causes for the root cause category considered.

Normalized:

Overall Linkage Significance () for a defect:

where m is the number of root cause categories of tile delamination.

Using the values of OLS and defect probabilities (P), the typical formula for risk estimation can be adapted to calculate the Delamination Risk Index (DRI) using the following equation.

Following risk assessment, recommendations for addressing the root causes of tile delamination were made based on the results of the study and a review of the state of the art in façade tile delamination.

3. Results and Discussion

3.1. Tiling System

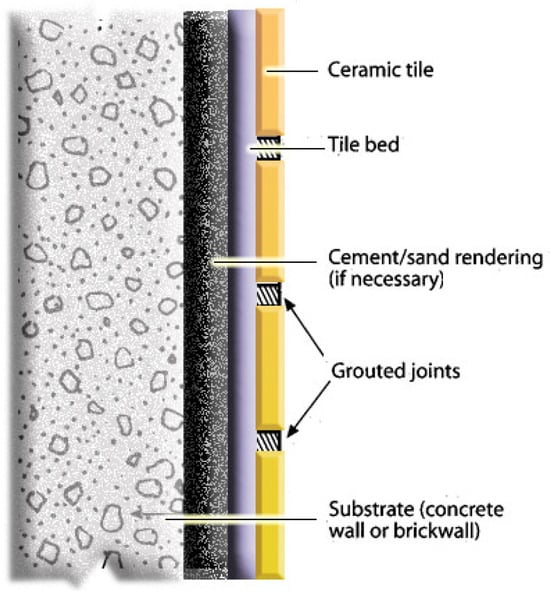

Tile claddings in tall buildings in Singapore comprise several layers (Figure 4) applied onto the external wall (substrate), which include the following:

Figure 4.

Sectional view of a tiling system.

- -

- Cement/Sand Rendering: This layer is applied over the substrate to provide a smooth, level surface for the tile bed. It also serves as a levelling base to address irregularities on the substrate surface, ensuring that the tiles are laid consistently. Additionally, this layer helps distribute stress from the substrate, reducing direct impact on the tile bed.

- -

- Tile Bed (Bedding Adhesive): This is the layer that bonds the ceramic tile to the cement/sand rendering layer. It is often made of adhesive mortar, ensuring that the tiles are securely fastened and able to withstand environmental stressors such as wind loads and temperature-induced expansion and contraction.

- -

- Ceramic Tiles: The visible, outermost layer provides an aesthetic finish to the building. It protects the underlying layers while withstanding environmental stresses such as wind loads and temperature-induced expansions and contractions. Additionally, it provides protection to the structure against impact from objects.

- -

- Grouted Joints: Grout fills the gaps between individual tiles, creating a seal that protects the edges of the tiles from water penetration and allows for slight movements. Grout also enhances the visual appearance by forming clean lines between tiles.

- -

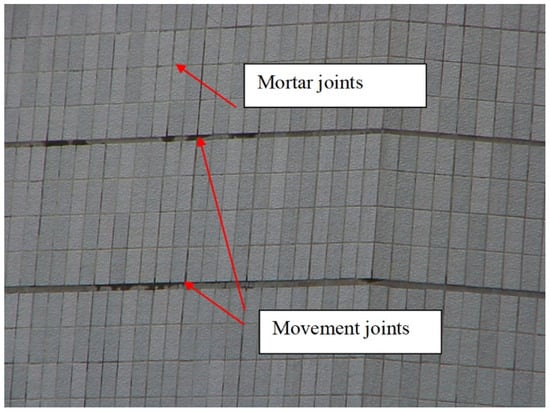

- Movement Joints: These joints are designed to accommodate the expansion and contraction of materials caused by temperature changes, moisture variations, and structural movements. They are typically filled with flexible materials, such as sealants, which allow for elastic movement without cracking or causing stress on the tiles (Figure 5).

Figure 5. Front elevation of tiles, mortar joints, and movement joints.

Figure 5. Front elevation of tiles, mortar joints, and movement joints.

3.2. Defects in Tile Façades

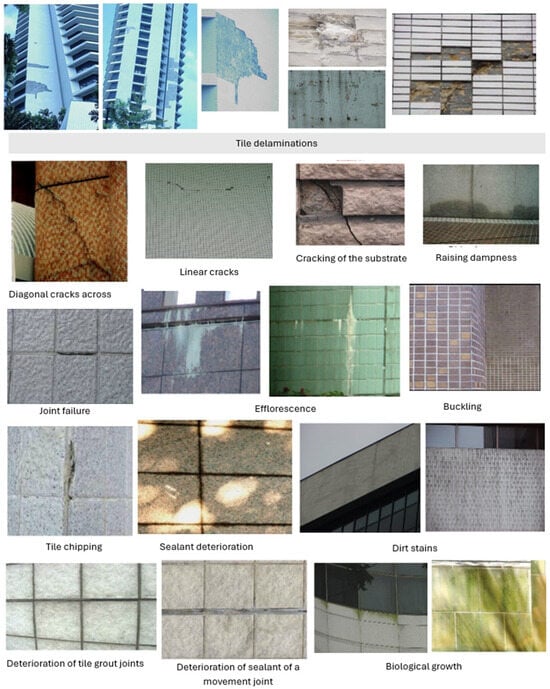

A large number of tile façade issues were discovered during the two-stage investigation into tile cladding in 160 buildings with tile delamination, and a few of them are depicted in Figure 6. The kinds of anomalies detected varied greatly in terms of their extent and root causes. For example, some cracks were horizontal whereas some others were diagonal (as illustrated in Figure 6), implying that the root causes of these cracks are indeed different. Further, delaminations had occurred due to the failure of various part of the tiling system of façades, such as substrates and adhesive layers.

Figure 6.

Anomalies identified in tall buildings’ tile façades.

Among the identified anomalies, the seven most common defects were highlighted, and the number of buildings exhibiting each defect was recorded according to their respective age categories. To obtain the probabilities of defects, these frequencies were also expressed as percentages of the total number of buildings within each age category, as shown in Table 2.

Table 2.

Defects in tile façades.

The data indicate that cracking and water penetration are the most common defects in tall buildings that have already experienced tile delamination. Moreover, water penetration issues tend to increase with the building’s age. These results support the findings of Silvestre et al. [22], which explain that cracks are one of the major tile façade anomaly categories and the second most critical defect after tile delamination. Although it was initially challenging to identify water penetration through drone images, hands-on inspections at the locations suggested by the first-stage observations revealed that water penetration was associated with most of the other defects. Failures in movement joints and grouted joints, as well as varying degrees of staining, were also commonly observed as other defects. It is also fair to conclude that chemical attacks are the least common defect, as tiles are composed of dense, non-porous, and chemically stable materials that do not easily react with alkalis, acids, or salts under tropical environmental conditions.

3.3. Root Cause Analysis

3.3.1. Type and Extent of Problems

Failures of tiled façades are not limited to tile debonding alone. Other distress symptoms, such as cracking, water penetration, efflorescence, and sealant joint failures, may contribute to the eventual debonding of tiles. Based on observations of these failures, the patterns and distribution of debonding can be broadly categorized as follows:

- -

- Localized and Isolated: The form of failure is limited to specific regions of the façade rather than affecting entire sections. They may appear as isolated areas where tiles have deboned or broken;

- -

- Widespread and Random: These failures occur in a scattered, irregular pattern across the façade, often without a predictable pattern;

- -

- Regular and Consistent: In this type, failures occur in a predictable, uniform pattern across similar locations on a building.

As realized in the close-range investigations, it can be very difficult to determine the extent of a building where the failure appeared to be localized and isolated or widespread and random. It is as unpredictable as the workmanship itself. Regular and consistent failure patterns on the other hand are largely predictable and usually related to design or building layout. Examples include failure along corners of the building, within the vicinity of movement joints, and around embedded steel. Given the multiple layers in a tiled wall, the failure mechanism can and has been shown to occur in several modes. The more common mechanisms of failure are the following:

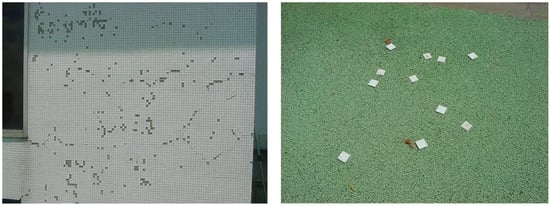

Cohesion failure within the plaster and bedding adhesive (internal failure within materials), as well as movement and corrosion of embedded metals, were also observed. For mosaic tiles, the common problem is the debonding of the mosaic from the bedding adhesive. This is understandably due to the inherent difficulty in bonding to the glass mosaic. The hazard of such failure may appear low for individual mosaic debonding (Figure 9), but can be serious if the debonding is in the form of a patch (Figure 10).

Figure 9.

Random debonding of individual mosaic.

Figure 10.

Debonding of mosaic in a patch.

3.3.2. Causation Factors

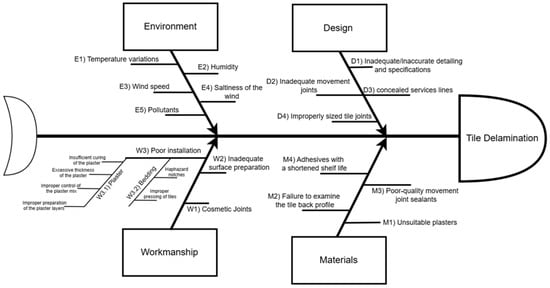

Based on the findings from field observations, expert interviews, and the support of previous laboratory tests, the causes of façade tile delamination have been thoroughly explained in this section, and they mainly include the following:

- Design, including specifications, for instance, lack of provision for movement joint;

- Workmanship, such as poor installation and surface preparation;

- Materials, such as unsuitable adhesive and plaster;

- Environment.

Being a laminated system of different layers, failures of any of the layers due to the above causes can result in disastrous tiling failures.

Design Considerations

The errors identified in the design through close-range investigations and expert interviews include incorrect or insufficient detailing and specifications of design elements, such as dimensions, material types, and the integration of façade elements, as well as performance requirements, and standards. One of the common errors in design is inadequate movement joints at the expense of aesthetics. Also, as Castro et al. [23] state, a lack of and inadequately sized movement joints lead to reduced mechanical strength and ability to absorb structural deformations effectively. Movement joints are perceived as compromising the outlook of the building and hence provided at too far a distance or not at all. Where movement joints were provided, they had often been wrongly positioned in the investigated cases. If proper movement joints are not allowed for, the overall deformation of the concrete frame under loading, creep and concrete shrinkage, and the progressive moisture expansion of the tile leads to a build-up in stress and likely interface failure. To determine the size of movement joint to be provided, the amount of movement that could be experienced from the structure must first be understood. This requires knowledge of the behaviour of structural concrete under dead and live loads over time. Such awareness is seldom exhibited in the design and provision of movement joints, to the point that it was accepted practice not to include movement joints in the wall tile designs of buildings constructed in the 1970s and 1980s. Additionally, the width of tile joints or tile-to-tile joints is another point to consider in the cases observed. A wider width is usually required in areas where large movements of the tiled system are anticipated.

Often, in attempts to mitigate failure, significant emphasis has been placed on the specification, selection, and installation of the tiles, while neglecting the plaster. There are rarely any adequately prepared specifications regarding how the plaster should be applied, including proper surface preparation, application, and mix composition. Detailing for plastering at the interfaces of different substrates is usually not provided, and these areas are frequent sources of tiling failures. This observation is also supported by Pereira et al. [24], who explained that inadequate plastering techniques, such as lack of experience or poor material selection, can lead to higher defect rates in tile façades.

Concealed services or features have been observed to have caused tile bulging and delamination. In one of the cases investigated, concealed lightning conductors in the plaster behind the tiles had led to tile debonding. Water had leaked into the render along the lightning conductor, causing corrosion and the plaster to fail. Additionally, defects in concealed service lines beneath the façade accelerated the deterioration of tile façades, such as through water leakage and the penetration of moisture into the underlying layers.

Workmanship Issues

Problems with workmanship in the investigated cases started from surface preparations of the substrate to receive the plaster. Debonding plaster from brick walls was rare, as most of the plaster failures were on concrete substrates such as beams, columns, and walls. This was due predominantly to inadequate surface preparation such as roughening or hacking. The use of precast concrete exacerbated the problems. Mold oil that is not cleaned off inhibits good adhesion of the plaster. The increased grade of the concrete also means that adhesion of the plaster becomes more difficult due to the increased surface density of the concrete.

The application of plaster needs attention. Recommended practice is that concrete walls should receive a spatterdash coat on striking formwork, and a cement render backing (1:3 cement/sand or weaker) to level the surface before beating tiles into a full bed of mortar. The sequence of work is important, especially during hot days; cement applied directly under the sun will not have time to hydrate, which will affect bond strength. Due to the increasing speed of construction, there is often insufficient time for the plaster to cure and subsequent shrinkage can cause tiling failure. Application in excessive thickness increases the shrinkage, which can also lead to failure of the plaster. This is common where the wall is misaligned and plaster is used to compensate for it. Application of subsequent layers that are richer than the earlier layers also increases shrinkage and risk of debonding of the plaster. Improper control of the plaster mix on site and a lack of preparation of the preceding plaster layer before application of the next may lead to plaster failure.

There were many cases in observed buildings where the bedding was poorly applied. Notched marks were seen on the bedding after debonding. In some severe cases, the tiles appeared not to have been adequately pressed onto the notched adhesive, giving little contact between the tiles and the notched adhesives. Notching has also been noted to have been carried out haphazardly in all directions, resulting in inconsistent coverage of the adhesive. There was also evidence of poor and inadequate coverage or adhesive being applied too thinly in some incidences.

Not using an appropriate trowel was identified as another workmanship-related issue. Different methods of application of adhesives such as trowelling with notching and buttering are available and specified in codes, but there is a lack of appreciation for which method is optimum for a specific application. In terms of the trowel itself, there are different sizes and types, such as square and dog-tooth. In many cases, installers had not paid attention to which type of trowel to use, which depends on numerous parameters such as tile size, adhesive type, tiling site, and tile back key design. As a result, the proper thickness of the adhesive mortar layer or tile bed was not maintained. Nonetheless, workers should be aware that increasing thickness does not always increase adhesion and can in fact diminish it due to stress concentration.

In some cases, movement joints were thought to have been provided, but these were not true joints but rather cosmetic joints. The joints were not carried through the structure, and some were even filled with mortar instead of resilient sealant with backer rods. Some sealants had been poorly applied, resulting in a layer that was too thin or under-cured.

Another possible cause for observed tile failures due to unstable tile bedding would be poor workmanship during the construction of cement–sand rendering. Most construction workers follow the stipulated component ratio standards when mixing cement mortars; however, a few increase the sand content, which reduces the bed’s ability to withstand compression.

Material Properties

During the study, numerous material-related causes of tile delamination were discovered. The observed characteristics of movement joint sealants, such as sticky or excessive softness, and small cracks and fractures on the surface, suggest that the materials used in movement joint sealants are of poor quality. These were easily identifiable even in buildings under the age of ten. Failures in movement joint sealants allow pollutants, water ingress, and chemicals to penetrate the layers beneath the tiles, weakening them and causing tile delamination. As a result, it was observed that choosing materials capable of withstanding the designed stresses of the tiling system is essential, because outdoor circumstances, including heating and cooling, wetting and drying, pollution, and wind, combine to produce effects like thermal shock, which are extremely harmful to materials in tropical climates.

Another important consideration in material selection is examining the back profile of tiles, as poor back profiles increase the risk of failure. Tiles with enough surface roughness, including prominent peaks and valleys, enable adhesive mortar to grasp more effectively through mechanical interlocking. However, when using high-quality adhesive, mortar can still form a strong bond with tiles which have smoother back profiles. These adhesive mortars should support both mechanical interlocking and chemical bonding, while also providing wetting resistance and minimizing shrinkage.

Furthermore, selecting adhesives with the best shear life while being compliant with the building’s climatic conditions is also a challenge. The open time, i.e., the period before skinning of the bedding adhesive sets in after spreading and trowelling onto the wall, as stated in most product literature, is calculated under laboratory circumstances. This normally lasts 20 to 40 min. On site, however, the adhesive’s shelf life might be drastically reduced due to exposure factors such as wind and temperature. In other situations, the shelf life was lowered to a little more than 5 min. Therefore, applying such adhesives ultimately led to tile detachments.

Environment

The tropical climate in Singapore, characterized by harsh weather conditions, poses significant challenges to the durability of tile façades on tall buildings. These adverse conditions affect not only the performance of tile façades during their operational phase but also affect the bonding strength of adhesives during construction. As evidenced by laboratory tests (Table 3), the frequent temperature fluctuations (high-frequency thermal cycles) and moisture variations (high-frequency moisture cycles) typical of tropical climates have a detrimental effect on the adhesive strength of tiles. Although non-tropical countries, such as those with temperate temperatures, experience large temperature fluctuations throughout the year, the rate of change is less than in the tropics. This reduces the frequency of thermal stress in tile systems, resulting in a slower adhesive expansion and contraction cycle. As a result, the risk of tile delamination is lower than in tropical regions [10,25]. Furthermore, the slower curing rate in temperate areas diminishes adhesive bonding strength, resulting in a weakened connection between the tiles and the underlying layers.

Table 3.

Laboratory tests on tile façades [10,26,27].

Pollutants trapped in joints and layers were often noticed during case studies. The high pollutant levels in tropical climes which are caused by heightened temperatures, wind, and rain cycles, have left a substantial impact on tile façade longevity. These conditions also have promoted vegetation in tile gaps. Salt crystallization on façades was also noted as a grave problem. The wind, which brings high humidity and frequent showers, aids in the transportation of salt to the façades. As the temperature rises during the day, moisture evaporates from the façade, leaving salt deposits behind. The crystallization process causes the salt to expand, creating pressure between the façade’s adhesive and substrate layers, eventually resulting in tile delamination.

Based on the causes discussed in each category, a Fishbone (Ishikawa) diagram can be used to illustrate the root causes of tile delamination (see Figure 11). To provide ease of future reference, each root cause is allocated its own code.

Figure 11.

Fishbone diagram on the root cause analysis of façade tile delamination.

3.4. Defect-Driven Risk Assessment

Tall buildings with tile delamination often exhibit a range of other defects, as discussed in the previous sections. Notably, tile delamination can be reduced or eliminated by addressing other anomalies that typically foreshadow it. A clear identification and understanding of how each defect is linked to tile delamination make it easier to implement proactive measures. To support this, the relationships between the defects identified in the case study buildings and their direct linkages to the root causes of tile delamination were mapped in Table 4. This mapping was based on expert insights gathered through interviews, field observations, and established knowledge of building defects.

Table 4.

Defect–root cause map.

Tile cracks and water penetration issues were identified as the major defects showing a significant link to the root causes of tile delamination. In contrast, chemical attacks exhibited the least direct link to tile delamination, given their minimal impact on the functionality of façade elements. Even though this matrix does not provide any indication of the impact of defects on each other, it does not affect the goal of this risk assessment. This is because most of these defects do not act individually in contributing to the vulnerability of tile delamination but rather function as risk contributors to varying extents.

The linkage significance, which represents the quantified strength of the connection between a defect and a root cause category, was determined based on the number of linkages in Table 5. The overall significance of these linkages was calculated using the mathematical model developed in Section 2.

Table 5.

Calculation of overall linkage significance.

Defects (Ai), i = 1, 2, 3, …, 7.

Root Cause Category (C j), j = 1, 2, 3, 4.

Root Causes (R jk), k = 1, 2, 3, 4 for C1, C2, C3 and k = 5 for C4.

Linkage Significance () per root cause category

Normalized:

Overall Linkage Significance () for a defect:

Once OLS is obtained, the final step is to determine the delamination risk indices. These can be obtained by multiplying the OLS by the likelihood of defects in tile façades (Table 6).

Table 6.

Delamination risk indices.

Cracking and water penetration exhibited the highest delamination risk indices, given that both their defect likelihood and their relationship with the root causes of tile delamination were stronger than those of other defects. This implies that the presence of cracks and/or water penetration on tile façades significantly increases their vulnerability to future tile delamination. This result can also be confirmed by the findings of several studies. Castro et al. [23] identify cracking as a major anomaly that greatly contributes to the degradation of tile façades. Their study further explains that water penetration compromises the overall condition of tile cladding, reducing its durability and service lifespan. Similarly, Silvestre et al. [22] highlight that cracking is a frequent and severe anomaly that can directly cause or lead to tile detachment. Furthermore, this study emphasized that water penetration into the adhesive was the primary cause of more than 30% of the 281 defects observed.

In real-world contexts, it is rare to identify the discussed façade defects individually, as they are interconnected through complex relationships. However, the provided risk implications for each defect create a sense of independence among them, offering guidance on maintenance work by indicating which defects should be prioritized based on their criticality in order to prevent façade tile delamination.

4. Recommendations

4.1. Design

In the design of tiling works, a greater understanding of the environment and tile properties is needed to select tiles suitable for external use. The characteristics of the project such as the environment the tile will be exposed to, the structural behaviour of the building, and the geometry of the building must be analysed and assessed. The selection of materials used in the tiling system requires a good understanding of project characteristics, including their compatibility and suitability for the intended environment. For example, the use of non-textured surface tiles is recommended to reduce the accumulation of dirt and improve the maintainability of the façades. Additionally, identifying the composition of the adhesive mortar is important when suggesting materials for construction. Understanding the chemical phenomena that affect mortar over time can help diagnose potential issues, and the mortar to be used should be determined with these factors in mind. Designers can draw on studies, laboratory tests, experiences from similar cases, and careful consultations with product manufacturers to make informed decisions [25,28].

Currently, researchers and industry professionals are exploring more sustainable and safer tile façade materials. One promising approach is the use of low-thickness ceramic tile cladding with fiberglass net reinforcement, which demonstrated exceptional improvements in mechanical performance and safety when checked through extensive artificial aging tests conducted in the study by Bazzocchi et al. [29]. In this study, tests were conducted to simulate harsh weather conditions on low-thickness tile cladding. The results showed that the fiberglass net improved the tiles’ ductility. After breakage, the tiles did not collapse immediately but kept the fragments in place, reducing the risk of falling debris. This finding is immensely valuable for high-rise buildings, where falling tiles pose a serious safety risk.

For effective tile façade design, the Code of Practice for the Design and Installation of Ceramic Tiles, Part 2: Wall Tiling (BS 5385-2:2015), along with SS 509-2 and BS 8221-2, should be used as references for tile façade design, providing essential guidelines for recommended surface treatments and protection. It is crucial to ensure proper detailing at critical junctions, such as window and door openings, as well as abutment points, where water seepage can occur and potentially lead to delamination of the tiles. Implementing these practices will enhance the durability and performance of tile façades. Design movement joints are recommended on the structural concrete in accordance with BS 6093 or equivalent.

4.2. Materials

Tiles—Tiles perform differently under varying exposures. Under tropical conditions, cyclical expansion and contraction affect tiles differently depending on their thermal and moisture expansion coefficients. The former is dictated by the tile’s colour, while the latter depends on the makeup and the manufacturing process of the tile. Heavier tiles require high adhesion bond strength and are more commonly associated with failures. Thin ceramic glazed tiles are relatively lightweight, while clinker tiles are heavy in comparison. Such characteristics should be understood thoroughly before tile selection and use. Test reports (such as SS 483) provide a good indication of the tile’s future performance.

Tile bed—Cement mortar used for the plaster layer may be modified with polymer or latex additive to increase its adhesion, cohesion, and water resistance. The render used should be of a high grade capable of withstanding external conditions.

Tile adhesive—A poor bond between the tile and the tile bed is a common cause of tile failure. As revealed by the root cause analysis, weathering agents attack and deteriorate adhesives. As a solution, epoxy adhesives are recommended for their high resistance to chemical attacks from acid rain. Adhesives with an excessively short pot life should be avoided, particularly in hot and dry environments. In addition to that, the application of geopolymer adhesives has been scientifically confirmed to enhance the conservation and restoration of tile façades. The study by Moutinho et al. [30] tested the performance of two different geopolymers, evaluating their water absorption, compressive strength, and resistance to salt formation. Overall, the results showed that one type exhibited higher workability, lower water absorption, moderate adhesion, and better resistance to salt formation, indicating its suitability for conservation purposes. The other type demonstrated higher compressive strength and stronger adhesive properties, making it more effective for restoration work.

Grout for tile joint—Polymer- or geopolymer-modified grouts are recommended for their superior adhesion, flexibility, and water resistance. The study by Assaad [31] highlights the advantages of using polymer-modified compounds in tile grouts and adhesives by testing polymer-modified mortar against unmodified mortar. The results show that the polymer-modified mortar offers higher flexural and compressive strength, as well as improved adhesive strength, helping to prevent damage caused by water penetration.

Material for movement joints—Polymeric backer-rod or compressible filler board should be used to fill movement joints. The sealant used to seal movement joints should also be compatible with the backer rod material. If not, a bond breaker strip should be provided between them.

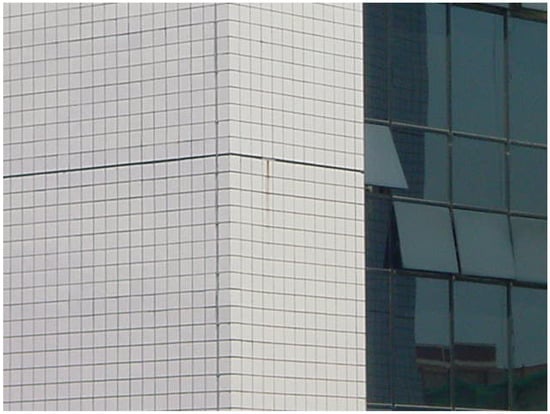

Joint Design—The design of movement and grout joints is important for tiling works to accommodate cyclical expansion and contraction of the tiling systems. In addition, these joints must be installed over substrate movement joints to compensate for movement caused by substrate shrinkages and movements [32]. Where movement joints cannot be provided at all required locations, stainless steel mesh should be used to traverse areas of expected movement. Generally, movement joints of 6–10 mm width (Figure 12) are recommended for the following:

Figure 12.

Movement joints of 6–10 mm width.

- -

- Every 3 to 4.5 m in horizontal and vertical directions;

- -

- At storey heights;

- -

- Where the tiling changes directions or angle;

- -

- Where tiles abut other surfaces and along existing movement joints in the structure;

- -

- Filled with a stable sealant such as polyurethane

4.3. Workmanship

Sufficiently remove the curing agent (used for early stripping of formwork) to ensure proper adhesion on the substrate and ensure proper substrate preparation (cleaning) prior to application of plaster/tile finishing. Perform quality workmanship on the façade through the correct handling and angle of application to prevent delamination and debonding in accordance with BS 8000-0 or equivalent. Lay adhesive and tiles in the sequence according to the manufacturer’s instructions.

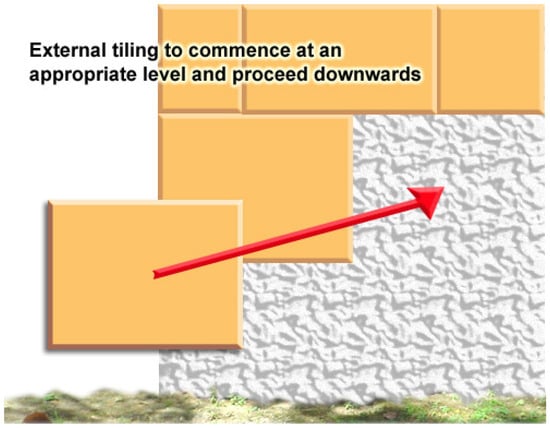

External tiling work should commence at an appropriate level and proceed downwards. This will prevent contamination of completed tiling at lower levels from the works above. It also allows for quicker dismantling of scaffolding once tiling works at the upper levels are completed (Figure 13).

Figure 13.

Sequence of tiling (red arrow indicating where the next tile needs to be installed).

For multi-story construction, some form of deflection of the building may occur at lower levels due to increased loading with height. Hence, by selecting an appropriate level at which to commence tiling, movement due to deflection at the lower levels can be accommodated before tiling work begins. The substrate should be well-cleaned and free from dust, ready to receive the tile bed. When applied in hot and dry environments, the concrete substrate should be dampened and cooled with a wet sponge. The surface should also be surface saturated-dry. Too wet a surface will result in poor bonding. The substrate should also be adequately roughened so that the adhesive will bond. If this cannot be achieved, then a stainless-steel mesh should be mechanically secured to the substrate and the tile bed applied over it.

During the tiling process, tiles selected at random should be removed from time to time to ensure that proper adhesion is achieved. The adhesive mix proportion should be in accordance with the manufacturer’s specifications. Too rich a mix causes excessive shrinkage and stress between layers. Plaster mix, if too rich, may result in excessive shrinkage. When excessively fine aggregates are used, the water content of the mix must then be increased to obtain workability, and an increased water/cement ratio increases shrinkage. The back of the tile should be covered with adequate adhesive and, once installed, the tile must be firmly pressed into place to eliminate voids.

Potential points of water ingress should be identified and protection provided over these areas so that water is not given a chance to seep beneath the tile. Metal cappings and flashings can run over tile heads, tile edges, windows, doors, or similar abutments so that all such openings are protected. Horizontally tiled surfaces should also be avoided. Preventing water ingress from concealed systems, such as water supply and drainage, into façade layers is essential for durable tile installations. This can be achieved by using high-quality, water-resistant sealants or adhesive compounds and ensuring their proper application. Additionally, it is vital to perform all necessary system checks, including pressure testing, before enclosing the systems. Applying waterproofing membranes correctly in vulnerable areas further enhances protection. Together, these measures contribute to improved workmanship and durability in tile façade construction [33].

4.4. Maintenance

Enhancing maintenance programs is an essential solution to prevent tile delamination. Based on the nature of the examined tile failures, most of them could have been mitigated and eliminated through a proper maintenance program. According to Prieto [34], issues within the key defects of tile cladding, which are cracking, water penetration, joint defects, and many more, could be effectively addressed through well-developed maintenance programs aligned with relevant maintenance standards. Repair of spalled surfaces should be carried out by removing loose and flaking material down to the base and replacing it with new bricks or blocks, or with layers of mortar. Consolidate weathered masonry (to stabilize the degradation) in accordance with SS 509-2, BS 8221-2, or equivalent. Maintenance and repair of renders should be carried out in reference to BS EN 13914-1, ASTM C926-20, or equivalent. Attend to cracks on the façade surface promptly to control moisture ingress in order to avoid delamination. Re-tile deboned tiles or over-clad existing the façade to remedy delamination.

The industry is increasingly adopting innovative solutions for protecting tile cladding on tall buildings. One method is to use geopolymer compounds, such as GM1000, for preventive maintenance, focusing on areas where cracks and separations are common in tile façades [35]. The rectification process must begin with removing degraded mortar or fillers with a proper scraping instrument, then wiping the surface with a moist cloth to remove dust and dirt. The GM1000 paste should then be applied using an appropriate applicator, such as a spatula, pressed firmly into the gaps to establish a solid bond, and allowed to cure for at least 24 h at a temperature of 20–30 °C and 50% relative humidity (RH). Unlike standard cementitious mortars, geopolymer treatments result in smaller shrinkage ranges in tile façades, preventing the emergence of new fractures.

Predictive maintenance techniques, such as infrared thermography inspections and drone inspections, can be effectively applied to prevent tile delamination by identifying symptoms early. Infrared thermography tests can identify temperature variations across the tile surface, helping to pinpoint areas where delamination may be occurring due to moisture intrusion, voids, or bond failure. Once images are taken, anomalies should be identified by considering the cooler and irregular thermal spots in the thermal images, as tiles are at risk of delamination and those with underlying voids often show temperature variations. Moisture or air gaps can change the thermal conductivity of façade layers.

The reliability of these inspections can be further enhanced using active thermography tests, which employ a controlled external heat source applied to the surface to improve temperature contrast. In Garrido et al. [36], the active thermography tests effectively distinguished areas of tile façades with trapped air, water, and regions of delamination. In order to perform these inspections, thermal contrast of at least 1.5 °C is needed, and, when there is a higher contrast of up to 4.0 °C, the clarity of the images is improved. Furthermore, to assist with these inspections, drones can be utilized and novel technologies such as machine learning can also be leveraged to prevent façade tile falls. The study by Cao [37] used a specially trained machine learning model called YOLOM to detect tile peeling on building façades. This model scanned images which were captured by drones for patterns that suggest peeling, such as irregular edges or texture differences in tiles. It then created clear outlines around the images of damaged tiles, making it easier to assess them. Additionally, digital replicas also facilitate advance façade monitoring, allowing for regular inspections of façade conditions and the optimization of maintenance work. A real-world application of this approach is discussed in the study by Barbosa et al. [38], which involved creating a virtual prototype of an educational facility using a computational tool to develop strategies for preventing façade moisture damage through thermography evaluations. Accordingly, the captured images of the façade were overlaid onto the virtual model, and then the exact location, size, and shape of the moisture-affected areas due to the moisture were mapped. Using this method, the study identified five types of moisture-related issues in the inspected façade.

5. Conclusions

The problem of tile delamination on the façades of tall buildings in Singapore highlights the urgent need for advancements in the design, construction, operation, and maintenance of buildings. The root cause analysis conducted in this study identified four main categories of root causes contributing to tile delamination, which are linked to other common façade defects to varying extents. Moreover, a novel approach was adopted to predict the risk of future tile delamination through a risk assessment based on existing façade defects. The results indicate that defects such as cracks, water penetration, and joint failures significantly increase vulnerability to tile delamination. These findings emphasize the importance of proactive maintenance management, where actions should be taken based on identified façade anomalies and their respective delamination risk indices. Furthermore, the study provides recommendations on tile façade design, workmanship, materials, and maintenance, offering valuable guidance for construction professionals and facilities managers involved in any phase of a building project to mitigate and eliminate tile delamination risks.

Beyond tile delamination, the proposed approach is adaptable for addressing other issues in the built environment that share similar characteristics. Specifically, this method could be extended to assess the problems in other various types of façade as well. Additionally, further research could focus on evaluating the complex interactions between various types of defect in buildings and developing a methodology to address the root causes of those defects in a holistic manner. Such an expansion would contribute to a more comprehensive understanding of façade deterioration and provide a structured framework for improving long-term building performance.

Author Contributions

Conceptualization, M.Y.L.C. and A.S.A.; methodology, M.Y.L.C.; validation, W.K.U.R.M.K.P.K.S. and A.S.A.; formal analysis, M.Y.L.C.; investigation, W.K.U.R.M.K.P.K.S.; data curation, M.Y.L.C.; writing—original draft preparation, M.Y.L.C., W.K.U.R.M.K.P.K.S. and A.S.A.; writing—review and editing, W.K.U.R.M.K.P.K.S.; visualization, M.Y.L.C. and W.K.U.R.M.K.P.K.S.; project administration, A.S.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The original data presented in the study are available on https://maintainability.com.sg/, accessed on 1 February 2025.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Holm, E. Facades: More than a Wall: Investigating How to Reach Architectural Qualities Using Different Facade Design Principles. Master’s Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2022. [Google Scholar]

- Zanatta, T.; Santa, R.A.A.B.; Padoin, N.; Soares, C.; Riella, H.G. Eco-friendly ceramic tiles: Development based on technical and market demands. J. Mater. Res. Technol. 2021, 11, 121–134. [Google Scholar] [CrossRef]

- Hershcovich, C.; van Hout, R.; Rinsky, V.; Laufer, M.; Grobman, Y.J. Thermal performance of sculptured tiles for building envelopes. Build. Environ. 2021, 197, 107809. [Google Scholar] [CrossRef]

- Ma, F.; Zhang, D.; Wang, Z.; Chen, X.; Jiang, L. Risk Assessment of Falling Objects from Façades of Existing Buildings. Buildings 2023, 13, 190. [Google Scholar] [CrossRef]

- Shih, P.H.; Chi, K.H. A Deep Learning Application for Detecting Facade Tile Degradation. Adv. Intell. Syst. Comput. 2020, 1026, 26–32. [Google Scholar] [CrossRef]

- Chew, M.Y.L. Façade inspection for falling objects from tall buildings in Singapore. Int. J. Build. Pathol. Adapt. 2021, 41, 162–183. [Google Scholar] [CrossRef]

- Feldfogel, S.; Rabinovitch, O. Evolution and stability of tile detachment—Experiments and modeling. Int. J. Solids Struct. 2021, 210–211, 145–161. [Google Scholar] [CrossRef]

- Niedostatkiewicz, M. Emergency Condition of the Ceramic Facade of A Residential Building. Inżynieria Bezpieczeństwa Obiektów Antropog. 2022, 2, 32–38. [Google Scholar] [CrossRef]

- Sioma, A. Automated Control of Surface Defects on Ceramic Tiles Using 3D Image Analysis. Materials 2020, 13, 1250. [Google Scholar] [CrossRef]

- Chew, M.Y.L. The study of adhesion failure of wall tiles. Build. Environ. 1992, 27, 493–499. [Google Scholar] [CrossRef]

- Chew, M.Y.L.; Gan, V.J.L. Long-Standing Themes and Future Prospects for the Inspection and Maintenance of Façade Falling Objects from Tall Buildings. Sensors 2022, 22, 6070. [Google Scholar] [CrossRef]

- Edis, E.; Flores-Colen, I.; De Brito, J. Building Thermography: Detection of Delamination of Adhered Ceramic Claddings Using the Passive Approach. J. Nondestr. Eval. 2015, 34, 1–13. [Google Scholar] [CrossRef]

- Güler, S. Production and Characterization of Wall Tile Ceramics with the Addition of Amorphous Boron. Mugla J. Sci. Technol. 2024, 10, 98–105. [Google Scholar] [CrossRef]

- Wetzel, A.; Zurbriggen, R.; Herwegh, M.; Greminger, A.; Kaufmann, J. Long-term study on failure mechanisms of exterior applied tilings. Constr. Build. Mater. 2012, 37, 335–348. [Google Scholar] [CrossRef]

- Vourvachis, P.; Woodward, T. Content analysis in social and environmental reporting research: Trends and challenges. J. Appl. Account. Res. 2015, 16, 166–195. [Google Scholar] [CrossRef]

- Victar, H.C.; Waidyasekara, K.G.A.S. Circular economy strategies for waste management in Sri Lanka: A focus on demolitions and repurpose and material recovery and production stages. Waste Manag. Res. J. A Sustain. Circ. Econ. 2023, 42, 953–976. [Google Scholar] [CrossRef] [PubMed]

- Elmasry, M.; Hawari, A.; Zayed, T. Defect based risk assessment model for prioritizing inspection of sewer pipelines. In Pipelines 2018; American Society of Civil Engineers Reston: Reston, VA, USA, 2018; pp. 1–9. [Google Scholar]

- Asmone, A.S.; Senarathne, H.N.Y.; Chew, M.Y.L. Risk-Informed, Reliability-Driven Decision Support for Building Basement Systems. Buildings 2023, 13, 2737. [Google Scholar] [CrossRef]

- Lee, S.; Lee, S.; Kim, J. Evaluating the Impact of Defect Risks in Residential Buildings at the Occupancy Phase. Sustainability 2018, 10, 4466. [Google Scholar] [CrossRef]

- Fan, C.-L. Defect Risk Assessment Using a Hybrid Machine Learning Method. J. Constr. Eng. Manag. 2020, 146, 04020102. [Google Scholar] [CrossRef]

- Jamshidi, A.; Roohi, S.F.; Núñez, A.; Babuska, R.; De Schutter, B.; Dollevoet, R.; Li, Z. Probabilistic Defect-Based Risk Assessment Approach for Rail Failures in Railway Infrastructure. IFAC-PapersOnLine 2016, 49, 73–77. [Google Scholar] [CrossRef]

- Silvestre, J.D.; De Brito, J. Ceramic tiling in building façades: Inspection and pathological characterization using an expert system. Constr. Build. Mater. 2011, 25, 1560–1571. [Google Scholar] [CrossRef]

- Castro, W.; Souza, J.; Gaspar, P.; Silva, A. Mapping the Risk of Occurrence of Defects in Façades with Ceramic Claddings. Buildings 2023, 13, 1209. [Google Scholar] [CrossRef]

- Pereira, C.; Silva, A.; De Brito, J.; Silva, A. Contribution of cracking and spalling to the degradation of façade claddings in current buildings. In Proceedings of the CIB World Building Congress 2019, Hong Kong SAR, China, 17–21 June 2019. [Google Scholar]

- de Freitas, V.P.; Corvacho, H.; Quintela, M.; Delgado, J.M.P.Q. Durability Assessment of Adhesive Systems for Bonding Ceramic Tiles on Façades: The Research and the Practice; Springer: Berlin/Heidelberg, Germany, 2013; pp. 173–205. [Google Scholar] [CrossRef]

- Chew, M.Y.L. Factors affecting ceramic tile adhesion for external cladding. Constr. Build. Mater. 1999, 13, 293–296. [Google Scholar] [CrossRef]

- Chew, M.Y.L. Evaluation of the Curing of High Performance Sealants. Archit. Sci. Rev. 2000, 43, 25–30. [Google Scholar] [CrossRef]

- Oliveira, F.; Bonfim, V. Façades of an Iconic Building in Sao Paulo, Brazil: Assessment for Restoration Design. In Rilem Bookseries; Springer: Dordrecht, The Netherlands, 2019; Volume 18, pp. 696–705. [Google Scholar] [CrossRef]

- Bazzocchi, F.; Bertagni, S.; Ciacci, C.; Colonna, E.; Di Naso, V. Mechanical characterisation of a low-thickness ceramic tile cladding subject to ageing phenomena. J. Build. Eng. 2020, 29, 101105. [Google Scholar] [CrossRef]

- Moutinho, S.; Costa, C.; Cerqueira, Â.; Rocha, F.; Velosa, A. Geopolymers and polymers in the conservation of tile facades. Constr. Build. Mater. 2019, 197, 175–184. [Google Scholar] [CrossRef]

- Assaad, J.J. Development and use of polymer-modified cement for adhesive and repair applications. Constr. Build. Mater. 2018, 163, 139–148. [Google Scholar] [CrossRef]

- Chew, M.Y.L.; Ping, T.P. Staining of Facades; World Scientific Publishing: Singapore, 2003; pp. 1–161. [Google Scholar]

- Pereira, C.; de Brito, J.; Silvestre, J.D. Contribution of humidity to the degradation of façade claddings in current buildings. Eng. Fail. Anal. 2018, 90, 103–115. [Google Scholar] [CrossRef]

- Prieto, A.J.; Silva, A.; de Brito, J.; Macias-Bernal, J.M. Serviceability of facade claddings. Build. Res. Inf. 2018, 46, 179–190. [Google Scholar] [CrossRef]

- Moutinho, S.; Costa, C.; Andrejkovičová, S.; Mariz, L.; Sequeira, C.; Terroso, D.; Rocha, F.; Velosa, A. Assessment of properties of metakaolin-based geopolymers applied in the conservation of tile facades. Constr. Build. Mater. 2020, 259, 119759. [Google Scholar] [CrossRef]

- Garrido, I.; Barreira, E.; Almeida, R.M.S.F.; Lagüela, S. Introduction of active thermography and automatic defect segmentation in the thermographic inspection of specimens of ceramic tiling for building façades. Infrared Phys. Technol. 2022, 121, 104012. [Google Scholar] [CrossRef]

- Cao, M.T. Drone-assisted segmentation of tile peeling on building façades using a deep learning model. J. Build. Eng. 2023, 80, 108063. [Google Scholar] [CrossRef]

- Barbosa, M.T.G.; Rosse, V.J.; Laurindo, N.G. Thermography evaluation strategy proposal due moisture damage on building facades. J. Build. Eng. 2021, 43, 102555. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).